Always Up for a Challenge

Mastering 3,500 acres: How the McAllisters leverage technology and precision farming for premium malt barley production

Farmers and ranchers can get an

Mastering 3,500 acres: How the McAllisters leverage technology and precision farming for premium malt barley production

Farmers and ranchers can get an

on

See our o ers for farmers and ranchers.

See our current promo o ers.

©2024 Bombardier Recreational Products Inc. (BRP). All rights reserved. ®, TM and the BRP logo are trademarks of BRP or its a liates. O ers valid in Canada only between August 20, 2024 to June 30, 2025. The conditions may vary depending on your location and this o er is subject to termination or change at any time without notice. This o er is not refundable, exchangeable or transferable (including from dealership to another), cannot be redeemed for cash, credit or other products of equivalent value. Null where prohibited by law. Until supplies last. Eligible units are all new and unused 2024-2025 Can-Am Defender, Commander and Outlander models, excluding X mr packages. † Quali ed agricultural and commercial consumers get an additional year of coverage on select models: The buyer of an eligible model will receive 12 months of B.E.S.T. coverage. Subject to the exclusions, limitations of liabilities, and all other terms and conditions of BRP’s standard limited warranty contract, including without limitation the exclusions of damages caused by abuse, abnormal use or neglect. B.E.S.T. service contract is subject to a $50 deductible on each repair. For complete details, please see the BRP limited warranty and the B.E.S.T. contract. See your BRP dealer for details. BRP recommends that all ATV-SSV drivers take a training course. See your dealer or call the ATV Safety Institute at 1-800-887-2887 (USA) or the Canadian Safety Council at 1-613-739-1535 (Canada). ATV and SSV can be hazardous to operate. Never exceed the ATV-SSV’s passenger capacity. All adult model ATV are meant to be used by drivers of age 16 and older. Carefully read the vehicle’s operator’s guide. Follow all instructional and safety material and observe applicable laws and regulations. ATV and SSV are for o -road use only; never ride on paved surfaces or public roads. For your safety, the operator and passenger(s) must wear a helmet, eye protection and applicable protective clothing. Always remember that riding and alcohol/drugs don’t mix. Never engage in stunt driving. Avoid excessive speed and be particularly careful on di cult terrain. Always ride responsibly and safely. See your authorized BRP dealer for details and visit www.can-am.brp.com.

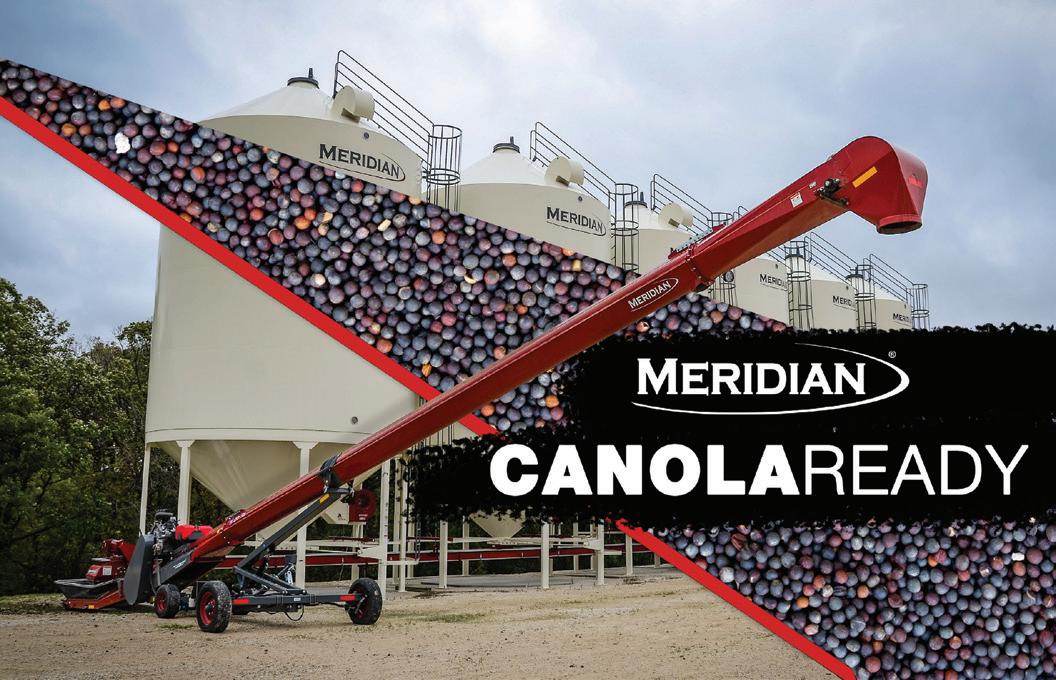

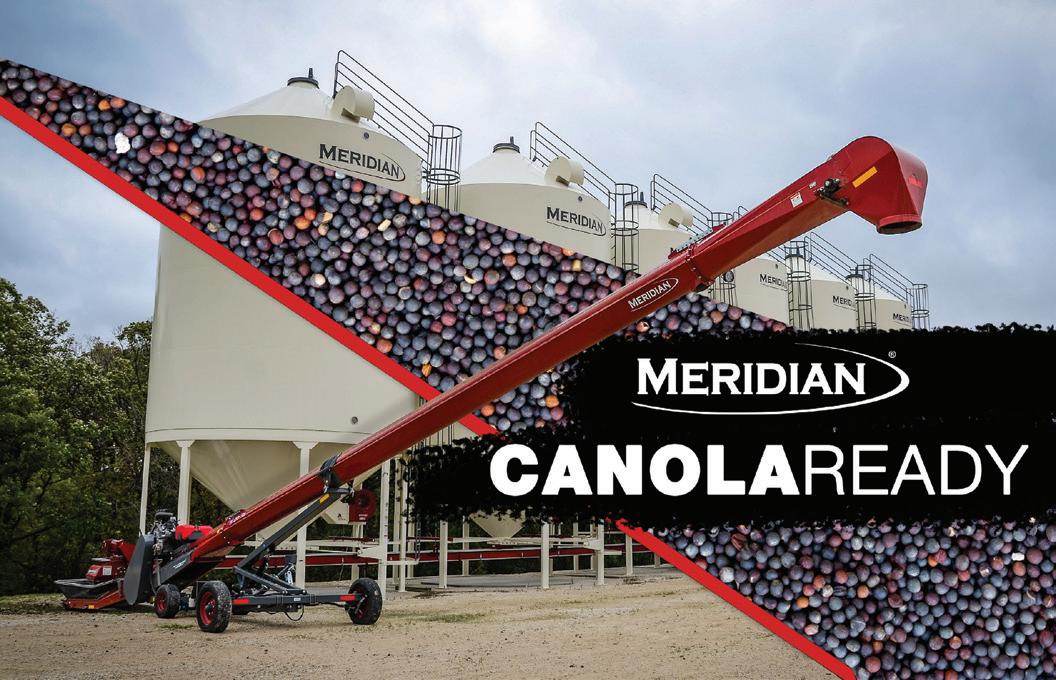

Can save 30 minutes each time you fill your drill. With 5 fills per day, that can add up to an extra 2.5 hours a day of seeding. On a 76’ drill with a rate of 34 acres/hour, that can add an extra 85 acres PER DAY. That

A Farmer’s Viewpoint

Solving the Key Person Dilemma by Kevin Hursh 12

Grain Market Analysis

Late Fall Rally Should Help with Crop Pricing by Scott Shiels

13

Farming Your Money Can We Have Win-Win Deals? by Paul Kuntz 33

20

Farm Buildings Steel or Wood? by Lisa Kopochinski

Company Profile SMS Manufacturing Celebrates Two Decades of Keeping Customers Happy by Angela Lovell 24

Agricultural Innovation

WGRF: Research for Farmers by Farmers by Braden Hursh

36

Spraying 101 The Rate of Change by Tom Wolf

40 Those Wily Weeds Herbicide Failure or Weed Success? by Tammy Jones

42 Livestock Managing Stressful Transition for Healthier Cattle by Jaclyn De Candio

Take charge of your future with the FREE University of Guelph Foundations in Agricultural Management Course. Get started with eight self-paced lessons in ag business strategy, farm management, succession planning and financial fundamentals. Sign up today at guelphagriculturalmanagement.com

Publishers

Pat Ottmann & Tim Ottmann

Editor

Lisa Johnston

Design

Cole Ottmann

Regular Contributors

Kevin Hursh

Tammy Jones

Paul Kuntz

Copy Editor

Scott Shiels

Tom Wolf

Nerissa McNaughton

Sales

Pat Ottmann

pat@farmingfortomorrow.ca 587-774-7619

Nancy Bielecki nancy@farmingfortomorrow.ca 587-774-7618

/farming4tomorrow

/FFTMagazine

/farming-for-tomorrow

/farmingfortomorrow

WWW.FARMINGFORTOMORROW.CA

Farming For Tomorrow is delivered to 90,720 farm and agribusiness addresses every second month. The areas of distribution include Manitoba, Saskatchewan, Alberta and the Peace region of B.C.

The publisher does not assume any responsibility for the content of any advertisement, and all representations of warranties made in such advertisements are those of the advertiser and not of the publisher. No portion of this publication may be reproduced, in all or in part, without the written permission of the publisher. Canadian Publications mail sales product agreement no. 41126516.

Kevin Hursh, P.Ag.

Kevin Hursh is one of the country’s leading agricultural commentators. He is an agrologist, journalist and farmer. Kevin and his wife Marlene run Hursh Consulting & Communications based in Saskatoon. They also own and operate a farm near Cabri in southwest Saskatchewan growing a wide variety of crops. Kevin writes for a number of agricultural publications and serves as executive director for the Canary Seed Development Commission of Saskatchewan and the Inland Terminal Association of Canada (ITAC).

Twitter: @KevinHursh1

For many years, a longtime friend and colleague has helped my wife and me with seeding and harvest. This year, he was not able to come because his wife was very ill. As a result, the farm ended up with a total of six employees. That’s in addition to my wife and me, owner of the farm corporation.

Having six employees sounds like a big operation. We are not. Time per employee ranged from one extended weekend for the shortest stay up to a couple weeks for the longest.

Our three boys each live in the city, a three-hour drive from the farm, and they have their own careers and family obligations. Our youngest son is a school teacher and doesn’t have any kids, so he has the ability to do a bit more farming.

A retired mechanic friend was a big help this season with seeding activities and some equipment maintenance after seeding. Another friend with limited farm experience was eager to learn and ran a combine for a while. Our nephew, a professional welder who lives less than an hour from the farm, came to help after his workdays and on a couple of weekends. He was a great asset for keeping equipment going.

It’s great to have the help, but everyone has different aptitudes and a different level of experience. Two of our sons are comfortable running the seeding outfit once everything is set up. Everyone can run the land roller, although not all are comfortable putting it in and out of transport.

Everyone can operate the older combine, but only one son ran the newer one before the hydraulic drive pump on the header went down and the manufacturer was unable to come up with a replacement. Some can handle the old 13-gear tandem grain trucks. Others haven’t mastered that skill.

With so many different levels of knowledge and experience, things can go wrong. Pressed for time, I gave my nephew a crash course on the old combine. He’s good with equipment and ran a combine a number of years ago. I combined up the field, explaining controls and how everything

works. He jumped in the seat and combined on the way back. He seemed to be doing fine, so I jumped out and left him on his own.

I never told him about the rotor speed control on the console. If it gets bumped or you inadvertently turn it rather than the reel speed control, the rotor speed won’t be correct. With so many things to watch and think about, he paid little attention to the grain going in the tank. We ended up with a few hundred bushels of maple peas with a lot of splits due to the rotor speed being too high.

He felt bad, but it was the instructor at fault and of all the things that can go wrong, this was pretty minor.

A friend from the city moved an old tandem truck across the field. This didn’t involve much gear shifting and I’d told him about the operation of air brakes, but he was baffled when he turned the key off and the engine wouldn’t die. I hadn’t told him about the fuel shutoff.

I haven’t tried to train anyone else on the sprayer. There’s a lot of stuff to know and it’s important to get it right.

Like many farms, ours has a key person issue. This goes well beyond running all the equipment. Crop selection, variety choice, agronomy, marketing, finances, crop insurance. Our boys discuss these things with me, but there’s a lot to know. Without me, the key person, it would be difficult to carry on.

My wife worries about what to do with the farm should I suddenly be sidelined by disability or death. She takes care of all the bookkeeping and understands that aspect better than me, but she would have trouble managing all the other parts.

We’ve had discussions about how to go about renting out the land or perhaps forming a joint venture with a neighbour when I am no longer able to continue. The boys all have some affinity for the farm, but none of them want to make it their life’s work at this point.

When I show someone new how to run a combine, I usually tell them it isn’t a case of “if something will go wrong” with the machine, it’s only a case of “when.” The same is true for the key person.

I have farming neighbours younger than me trying to figure out when to schedule hip replacement surgery. I have neighbours older than me still going strong. Some are successfully transitioning to the next generation and they aren’t the key person anymore. Sometimes a relatively young key person is sidelined by injury.

Who is your key person or persons? What’s the plan should they suddenly not be able to continue?

HELP SHAPE THE FUTURE OF CANOLA IN ALBERTA!

November 21 - Lethbridge

November 26 - Lacombe

November 28 - Camrose

Join us for a day of conversations on how your grower dollars are making an impact. Learn what Alberta Canola is doing to support your long-term success through research, advocacy, and consumer education. Connect with fellow farmers, regional directors, and staff to discuss the current challenges and opportunities facing canola growers and the Alberta Canola Producers Commission. REGISTER EARLY for a chance to win a Milwaukee M18 Grease Gun! Must be in attendance to win!

December 11 - Grand Prairie December 18 - Online Broadcast

Scott Shiels grew up in Killarney, Man. and has been in the grain industry for 30 years. He has worked with Grain Millers Canada for 10 years and manages procurement for both conventional and organic oats for their Canadian operation.

Scott is an elected board member for Farm and Food Care Saskatchewan and sits on several other committees on both the organic and conventional sides of the oat industry. Scott and his wife Jenn live on an acreage near Yorkton, Sask. Find out more at www. grainmillers.com.

What an interesting year it has been so far in the grain marketing world! From extremely short rail strikes and Chinese tariffs on canola at harvest to a crop that was subpar quality wise, we have had – and will continue to have – a very challenging year in the markets.

As we rolled into harvest, quality of the crop became quite the concern on the Prairies as a hot and dry July took some bushels, but more importantly, it took test weight out of a lot of crops that just needed a rain to finish filling. Once again, we bore witness to the fact that it’s not always about the amount of rain we get, it’s the timing that’s most critical to our crops. As we pushed through the first quarter of harvest and neared the middle, quality began to improve, giving producers and buyers some confidence that all was not lost.

Futures markets were under pressure throughout August and September, with very little bullish information coming from anywhere in North America. Corn, wheat and soybean production forecasts from south of the border continue to put a bearish spin on things, so we will have to see what actually comes off after harvest is complete.

On our side of the border, throughout much of the harvest season, markets remained soft as the trade based a lot of what they were doing on the potential this crop had earlier in the summer. The reality of the damage done by the heat in July really was not apparent until the combines rolled and, by then, most commodities had lost a considerable percentage of the cash prices. By midSeptember, most of the bids locally had started to recover some of the losses, but we still have a long road ahead to get back to the numbers that were available just six months ago on this crop.

One thing this late fall rally should do is help with new crop pricing for the coming year. With a smaller crop in the bin, causing tighter supplies across the board, prices will need to be aggressive, and compete, to drive acres into the ground to replenish supplies in the new year. I believe the most competition will be in the cereal acres, with wheat, barley and oats all looking to increase acreage for the coming year, and I believe there is a good chance some of these acres will come at the expense of canola acreage on the Prairies. With the big carryout and large acreage this year, even a smaller canola yield average is going to leave that market with an over-abundance of product to crush. If the Chinese remove their tariff on Canadian canola, it could help the market considerably, but if it remains in place, we could see a significant reduction in canola acreage in 2025. With the cost of production on canola not coming down any time soon, today’s prices don’t pencil out very well on the bottom line. Hopefully, all of these factors straighten themselves out over the coming months, but I’m not holding my breath.

Until next time…

Paul Kuntz

Paul Kuntz is the owner of Wheatland Financial. He offers financial consulting and debt broker services. Paul is also an advisor with Global Ag Risk Solutions. He can be reached through wheatlandfinancial.ca.

I would like to take the view that there is always a way to have a win-win situation in a business deal. The opposite is the idea that the only way to be successful is for the other entity to lose. This type of thinking does exist. There are times when we feel like we must have lost because it appears the other side won.

In the business world, products and services must be sold at a price to return the company an amount that allows them to pay their bills and have some left over for growth and contingencies. As a purchaser of these products, we understand that if the product or service is continually sold at a price below the cost of production, the business will eventually fail.

Where the matter gets confusing is when we discuss how much extra is needed to sustain the business. If a product costs $10 to make, can the company sell it for $11? Or does the company have to sell it for $20? If the market will bear $20, some businesses will charge the $20 until they cannot anymore.

I recently had an experience with my internet service provider. A competitor called me to ask for my business. I wasn’t interested. This competitor kept calling and was insistent their service would be as good as what I currently had at half the cost of what I was paying. Eventually I said I’d try this new service.

After I got the equipment hooked up, it appeared that perhaps this competitor had a decent service. I called my existing internet service provider to ask what the cancellation process entailed. They assured me it was a simple process, but asked why I wanted to cancel. I explained a competitor had offered service for half the cost. The customer service representative immediately said a new program was available that would cut my bill in half. My first thought was, “really?” As soon as a competitor offers the service for half the price, a program becomes available for me to receive my existing service for half the cost? That seemed odd to me.

To add insult to injury, a few days later, my existing internet company called to say that although they wanted to just “flip a switch” and increase my speed, they would need to come out to install brand-new equipment, for free, to increase my speed. I asked about the special promotion to cut my bill in half and they assured me it was still going to happen.

This company, that I have dealt with for over 10 years, had the ability to increase my speed and reduce my cost, but yet they did nothing until a competitor came along. This frustrated me. My initial reaction was to punish my existing company and reward the new company, but as it turned out, the competitor was not able to match the service I was receiving. The internet service was very slow. I would have never cancelled my existing internet service, but I will now receive faster service at half the cost I was paying before.

Why does that have to happen? Why do businesses offer an inflated deal but if you balk, then they cave to a much better deal? Why not offer the best deal up front?

In my world of being a residential mortgage broker, we pride ourselves on always offering the best deal up front. It is part of our licensing requirement through the Department of Justice that we always act in the client’s best financial interest. It is the law that we offer the best deal all the time.

Financial institutions will often offer their best rates on a mortgage, be it for farmland or a house, when you first get the deal done. All lenders are eager to provide great rates and service. Where the wheels start to fall off the wagon is at

We can have a meaningful discussion about a problem, or a disagreement in pricing, but still be honest and respectful. The key is that we, as the consumer, must feel valued and the business representative must seem sincere.

renewal time. If a lender has a five-year special for 4.5 per cent, they will not offer it to existing customers. They will have a higher rate for renewals. The reasoning: they think it is too much hassle to move your mortgage for a small difference in rates. They have your business, so they don’t need to earn your business. Instead, they’ll offer a better rate to a stranger rather than a loyal customer. This, in my opinion, is wrong, but it happens every day, all the time.

Optimum® GLY is the highest yielding glyphosate-tolerant trait on the market, created to unlock agronomic excellence.

Pioneer® brand canola hybrids with the Optimum GLY trait allow you to make the herbicide applications you need without impacting the yield potential of the hybrids you love.

Learn more at Pioneer.com/ca

When you get a mortgage renewal, call your lender and ask for a better rate than you were offered. You will almost always get a better deal. The question I have for those lenders is why do you make your existing loyal customer beg for a better deal when you would give that reduced rate to an unproven new client?

In the agriculture world, there are many similar examples. Machinery dealers argue warranty claims to get out of paying the repair bills when the item in question is clearly under warranty. Chemical prices magically become lower when you threaten to buy somewhere else.

Grain buyers can be another group that seem one-sided. I deliver grain to a company that has buyers who are always looking out for me. They always do their best to help me out. Another company down the road has grain buyers who will use every excuse possible to downgrade or increase dockage. I understand both have a job to do, but you can still perform your duties and have the farmer’s best interest in mind.

There must be a win-win attitude on both sides in order to accomplish a utopian world. Perception is very important through this transaction. As the consumer, we cannot be talked down to by the business or service provider. There cannot be any condescension. We must feel valued. My preference would be full transparency. When I call out a business for having a fee that is too high, I would like that business to admit they were

trying to get as much profit as possible, but now that they are being challenged, they will lower the cost. Do not insult my intelligence by telling me that a program just became available right at this moment that will allow me to get a better price.

We can have a meaningful discussion about a problem, or a disagreement in pricing, but still be honest and respectful. The key is that we, as the consumer, must feel valued and the business representative must seem sincere.

As producers of commodities that are priced outside of our hands, the cost of the supplies we purchase can be cause for concern and even anger. We are told that supply chains have been compromised, there are shortages of components, shipping costs have increased and a myriad of other excuses as to why the cost of what we need has risen. We are not offered the same courtesy when we sell our products. We have to take what the market provides. This is where we, as agriculture producers, have to be the bigger person in our transactions.

As you go through your day-to-day interactions with suppliers and buyers, take a moment to see the win-win attitude among the people you deal with. You will begin to notice who has it and who does not. We do not always have choices as to where we can do business, but I would suggest doing as much business as you can with people who believe both sides can win and there does not have to be a loser.

Farming & Ranching is a never-ending job.

And running out of fuel is never an option. With convenient bulk fuel delivery, and our exclusive Dieselex Gold fuel, you’ll be good to go. And, with a range of premium Shell Rotella lubricants, UFA has everything you need to keep things moving with no down time.

WHEN YOU’RE ON THE GO, WE’VE GOT YOU COVERED.

28,874

This is Danny, with three of his four kids, Ivy, Max and Thomas. If the kids look a little excited, it’s because they’re thrilled about the $28,874 profit shares cash payout Danny got from Vision Credit Union last year. You see, Danny is using his share of the profits to put in a swimming pool. Getting a share of the profits is nice, says Danny, but getting ‘best dad’ votes from the kids –that’s what it’s all about. What’s your share ?

Real people. Real results.

by Nerissa McNaughton

ATB Financial has always been an institution committed to Alberta and understanding its key industries.

The focus on Alberta and what drives its economy is where ATB dedicates its team’s expertise. For Albertans in the agriculture sector, throughout the value chain, this is where ATB stands out – and who better to reach our local farmers and ranchers than a real cowboy?

Lee Irvine, Beef Segment Specialist, Agriculture & Agribusiness at ATB, is a second generation cattle producer with a degree in animal science. He has worked as a cowboy in Canada, the United States and Australia. He has also worked in veterinary pharmaceuticals so he could help grow and innovate in the industry.

“While my background wasn’t in banking, when the opportunity came to work with ATB in this role, my firsthand experience in cattle production was invaluable,” he says. “ATB’s commitment to understanding the agribusiness space by hiring specialists like myself is truly unique, as is their dedication to developing products and services that support the industry.”

In this position, Irvine has a very well rounded view of the issues facing the industry and how ATB can help.

“It is important to understand,” he says, “that adversity is not new to agriculture. Farmers and ranchers have always had to deal with grasshoppers, droughts, floods and fires. Over the last few years, we have seen producers shifting their mindset from a year-to-year strategy to multi-year strategies to deal with these events.”

It’s no secret that the cattle industry is feeling economic pressure. Consumers feel it at the till as they buy beef for their summer barbeques, but Irvine says that the producers feel the pinch just as much – if not more.

“We have seen costs double, if not triple,” Irvine points out. “Diesel to run tractors, for example, has gone up significantly, as has the cost of trucks and farming equipment. It’s a struggle for the entire industry, but there’s still a need to keep producing if we want to keep feeding the world.”

He shares something that many consumers do not know.

“Cattle producers are not the ones setting the prices. Producers get paid through price discovery – what buyers are willing to pay at auction. In other industries, such as car dealerships, they can set the price and wait for someone to buy the product. Cattle doesn’t work that way. When it is time to move the animal, the animal must move. It cannot stay on the grass; producers have to take the price the buyers set.”

Why not just hold out?

“There are limits due to land and forage. Producers set aside forage and animal costs a year ahead of time, so in order to properly feed the animal there needs to be a plan in advance. If the producer is planning to carry the animal over, that takes years to set it up and do it correctly.”

This ties back into what Irvine said earlier about the mindset shift. As the conditions continue to change, producers are looking at longer-term strategies. However, the changes do not – and cannot – happen overnight.

“Another thing to consider,” says Irvine, “is that producers buy inputs based on the global market but sell on the local market. A recent example of this is corn in the United States.

ABOVE: LEE IRVINE, BEEF SEGMENT SPECIALIST, AGRICULTURE & AGRIBUSINESS AT ATB.

It looks like it will be a significant crop there this year, which means producers are able to buy it at a lower price. Sometimes the global markets play to the industry’s benefit; other times, when there is high demand, input costs go up.”

Make no mistake, however. Those in the agribusiness are not just going where the wind blows. They are planning and making changes, levering technology and innovation and doing everything they can for the industry and consumers. Seeing the results simply takes time.

Industries that support agribusiness are also invested and responding in kind.

“We are seeing a lot more risk management tools in the market, such as different forms of insurance. As for producers, we’re seeing them take on more complex strategies to mitigate risks.”

It is, as Irvine says, a “complicated beast.”

“Due to the drought, we’ve seen many producers either exit the cattle industry or decrease their herd size to maintain financial sustainability. Low cattle inventory impacts supply and demand, and strong prices may persist as we head into the fall. In the U.S., producers are rebuilding their herds since their numbers are at their lowest since the 1960s. Fewer animals are in feedlots, which increases demand and, consequently, prices. Should beef demand drop, we’ll see prices fall as well but right now, we are seeing continued demand for beef both domestically and internationally.”

Is it hopeless? Far from it! As Irvine points out, adversity in agribusiness is simply another day on the farm. From before the time of technology and tractors, farms and ranches were affected by weather, wars, and everything in between. Agriculture is, at its heart, incredibly resilient and as much as global and local factors are affecting supply and demand, those same factors are driving the innovations that are revolutionizing it.

Irvine says, “We have an aging demographic in the cattle industry. Given the current conditions, some see it as a good time to retire. But we’re not seeing the next generation step in due to higher costs. As an industry, we are actively working to attract young producers back. The Alberta government has programs in place to support this effort and ATB is also exploring initiatives to help. Stay tuned!”

The result? A new generation of farmers powered by innovation with the ability to leverage decades of agronomy and global market data to face new challenges and revolutionize farming.

Let’s not overlook the incredible progress that has already been made, and that continues to drive the industry forward.

“Today, we produce the same amount of beef on 25 per cent less land than we did in 1981 and with 15 per cent fewer

emissions. This achievement is due to advanced production research and improved environmental practices. The beef industry is also a significant source of employment. Each job in the sector creates an additional 1.8 jobs in other areas of the economy, resulting in an employment multiplier of 2.8 person-years. Overall, the beef sector is directly and indirectly responsible for 81,000 person-years of employment.”

Another benefit? Long-term sustainability. An excellent example is the Canadian Cattle Association’s documentary called Reduce, Reuse and Ruminate, showing how industry is using food by-products and food waste as cattle feed.

Beef is central to the economy in many ways.

“The Canadian beef industry contributes $22 billion to the country’s GDP and $55 billion in overall sales. In Alberta, the cattle sector contributed $5.8 billion to the provincial GDP annually (2021-2023 average). Check-off dollars are used to fund research through various organizations. For example, beef producers pay a check-off that funds research through the Beef Cattle Research Council and Alberta Beef Producers that looks at how we can produce beef more efficiently.”

When the price of a steak is high and the cost to barbeque it is equally painful, don’t forget to look at the big picture. With a wealth of supportive programs and products on the rise and with innovations in the agribusiness sector, Alberta’s farmers are changing the game. The short-term pain is influencing longterm gains.

As the people driving the business go from horses to tractors, from weeding to automated sprayers, ATB keeps pace with changing needs, demands and technology, bringing in bootson-the-ground talent like Irvine and creating niche programs to support Alberta’s farmers and agribusiness entrepreneurs.

A financial institution can’t control the weather. It can’t influence growing or herding conditions in foreign markets. It can’t stop a grasshopper plague. But it can leverage years of data, listen to its clients and hire talent that can make a difference. As those in agribusiness continue to adapt, ATB continues to support Albertans and the many diverse roles they play in helping the province grow and thrive.

ATB is pleased to present a 2024 profile series on the businesses and people who are facing challenges head-on to build a strong Alberta.

By Lisa Kopochinski

When it comes to constructing one farm building or several, careful planning is imperative with many factors to take into consideration.

Based in Thamesville, Ont., WeCover Structures designs and manufactures a wide variety of farm structures, including barns, riding arenas, storage buildings and more.

“There are many factors to consider such as building codes (snow loads, wind loads, frost depth, etc.) which can vary and impact costs heavily,” says company representative Jake Warren. “For example, how much work needs to be done to prepare the site for the building and lay a foundation? Ventilation systems should also be considered.”

Warren stresses the importance of vetting one’s options in order to find a trusted partner that will deliver on time and complete a job without surprise costs. “Budgeting for the unexpected is wise and loan rates from the banks need to be considered.”

Brian Perrier, operations manager at Prairie Steel Products Ltd. in Clavet, Sask., agrees and says farm building prices differ based on use and the location of the building.

“It would be wise to get a solid understanding of the

purpose of your building and the size requirements before reaching out for quotes. Most builders will be able to tell you what you’ll need to be able to meet code for that building for the particular location that you’re building it.”

Budgets can vary greatly depending on how much groundwork is required for the site and how far away services like electrical or gas need to be developed for the building.

When making such a decision, the importance of seeking information and guidance from an advisor cannot be understated.

“The farmer needs a trusted advisor to work through the many variables involved with how a new building can be profitable for the farm,” says Warren. “It involves discussing the logistical flow on the farm (cattle handling, equipment, commodity movement), floor layout, and how those needs might change in 10 years, just to name a few factors.”

Essentially, finding the balance between a building that meets the farmer’s needs at the right price point is crucial. “The process of discussion is invaluable,” he says. “It’s

You work hard to fill your bins with the highest quality grain. GrainVue makes it easy to get the most out of them. Monitor moisture, temperature and inventory 24/7. Dry, cool, rehydrate or maintain with the touch of a button. All for less than you think. Contact your dealer today.

about finding the best performance for the farmer – not what is easiest for the builder to do.”

According to Perrier, working with a particular builder can be advantageous to ensure building codes are met. “If the farmer has worked with the same builder for a few projects, that builder should be familiar with what the farmer is looking to achieve and can help make recommendations based on familiarity.”

Deciding whether to have a steel-frame structure versus a wood-frame building often depends on the size of the structure. For example, smaller buildings often benefit from wood due to less span or height requirements.

“The most common form of wood farm building is the pole shed, where in place of a foundation, the wood poles that make up the walls are simply embedded into the ground,” explains Perrier.

Conversely, steel is more commonly used for larger buildings with span widths greater than 70 or 80 feet. Also, steel buildings can be made as tall as needed with no compromise to the durability of the structure.

Warren adds that all farm buildings can be built with steel or wood framing. Farm buildings are not inherently incompatible with one option or the other, but other factors would determine choice.

“For example, steel thrives with larger buildings as it is simply stronger and able to handle wider spans and heavier loads. Wood will often be more economical in smaller buildings. Steel buildings can be relocated, which is an asset to some. Fire risk favours steel building options (building codes may be much more easily obliged). Longevity also favours steel buildings. Steel framing allows for a fabric roof option which allows natural light in a building and can improve animal production and health in livestock or dairy housing.”

Perrier adds, “A wood-framed structure will have a steep pitch to accommodate snow load. If you’re in an area that has heavy snow, a steel building will offer greater snow load capacity and won’t require as great of pitch.”

He says steel buildings are always deployed on some form of deep foundation system that will complement the long life of steel. Just a few examples include heavy-duty mechanic shops, dairy barns and facilities, and potato storage/sorting buildings.

“A steel building is going to last two or three times as long as a wood structure.

Essentially, any building larger than 70 or 80 feet would

“The farmer needs a trusted advisor to work through the many variables involved with how a new building can be profitable for the farm.”

- Jake Warren

benefit from being built with steel. This is because steel can better accommodate a large building and when you’re investing in a building that size, you’re going to want it to be of high quality.”

Steel is more long lasting and durable. It can support big doors, cranes and large mezzanines, or any additional complexities required such as plenums, wash bays, or future plans for building expansion.

With respect to what should be discussed about electrical systems and doors, Perrier says such details need to be planned and coordinated during the pre-engineering phase prior to quoting a project.

“Our team will include walk-in doors and bifold doors with our packages. Other doors, such as overhead doors, would be planned with us for the door opening during preengineering. However, the building owner would deal with their favourite local overhead door supplier/installer who can install the door once the erecting crew is finished. We don’t deal with electrical, as this is something the farmer would need to outsource.”

Warren says where and how much power the building will require is key. The size of equipment should be considered for door placement and floor plan, including how future equipment might fit. For example, will the combine headers be upgraded in five years?

“You need to think through as much variables as possible, especially the flow of livestock and supplies, and how you can maximize the efficiency of your chores or work with the new building. A project that has been properly considered this way should help pay for itself in efficiencies gained.”

To sum up, he adds, “You can find the right balance between a building that meets the farmer’s needs and the price point. The process of discussion is invaluable. It’s about finding the best performance for the farmer and not what is easiest for the builder.”

By Braden Hursh

As a constantly evolving industry, agriculture in Western Canada needs to be growing, improving and adapting to meet new challenges. From technology to biology, economics to efficiencies, agriculture, as an industry, has countless moving parts. So, when someone asks the question, “What do western Canadian farmers need to be successful?” The best people to answer are western Canadian farmers.

In 1981, the Western Grains Research Foundation (WGRF) was formed and was granted $9 million from a discontinued federal emergency program under the Prairie Farm Assistance Act. Since inception, WGRF has invested over $240 million to agricultural research across Western Canada in a wide variety of areas that directly impact farmers. WGRF is now the largest producer-led funder of crop research in Canada.

WGRF is a farmer-funded and farmer-directed non-profit organization that invests directly into agricultural research that benefits western Canadian producers. Today, the WGRF board of directors comprises 14 producers from 14 different western Canadian organizations such as

Agricultural Producers Association of Saskatchewan, Alberta Grains, BC Grain Producers Association and Manitoba Crop Alliance. To date, over 140 farmers have served on the WGRF board.

Wayne Thompson, executive director of WGRF, states, “We are made up of organizations that are collecting checkoffs from farmers to fund research plus also policy organizations. So, we have a well-rounded board that has direct insights into what farmers are looking for in regards to research. It is valuable to have directors from across Western Canada from the member organizations, as it provides a lot of valuable perspectives into what farmers are seeking when it comes to research. It’s also very representative because we have people all across the Prairie provinces and they all have a say.”

Instead of sending out its own call for research proposals, WGRF relies on its partnerships from across Western Canada to bring forward proposals intended to benefit producers. WGRF works with the partners to review proposals sent to them and then the board discusses and collaborates on the best ways for this research to

positively impact producers across the different regions. Research priority areas are variety development and production. Proposals can include single-crop research involving barley, canary seed, canola, chickpea, corn, faba bean, flax, lentil, mustard, oats, pea, soybean, sunflower, wheat and winter cereals or research that includes several of the crops listed.

Thompson explains, “The WGRF research committee is made up of some directors currently on the WGRF board, who can bring the farmer perspective to the research recommendations, and also external scientists.” Between the farmers and the scientists, the proposals are reviewed, discussed and then recommendations are brought to the WGRF board for final funding approval.

Each proposal is measured by three parameters:

1) Impact on farmers. Is this something the research committee suspects farmers will see value in? Example: a new agronomy practice to control disease would have a more significant impact and be ranked higher.

2) Is it good science? When the research committee examines the proposal, they look at the process and method. Example: if a proposal to control kochia is put forward, WGRF would want to see that the study is done in different locations to have well-supported research results.

3) Is it likely to succeed? Based on the knowledge of the research committee, will the result be achievable in the way proposed in the research? Example: will a new or improved agronomic practice use farm equipment that is widely in use or require different equipment to be adopted on the farm?

WGRF has funded more than 700 research projects across Western Canada with a major emphasis on applicable research that is consistent and accessible to as many farmers as possible.

Thompson points to a couple of specific examples of this applicable research that is now at the fingertips of all farmers and agronomists across Western Canada. Several websites available to all farmers include:

1) Prairie Crop Disease Monitoring Network (prairiecropdisease.com)

2) Prairie Weed Monitoring Network (prairieweeds.com)

3) Prairie Pest Monitoring Network (prairiepest.ca)

4) Field Heroes – beneficial insects (fieldheroes.ca)

The websites provide farmers with a combination of interactive maps, research, forecasts and regular updates to help them plan their year and also adapt mid-season to potential changes. Thompson says, “We have been working with Agriculture and Agri-Food Canada (AAFC), the provincial researchers, extension specialists and scientists at the universities. The value of these sites has grown over time because the farmers have access to information about what insects, diseases or weeds to watch out for at different parts of the growing season. This helps them to work with their agronomist when scouting fields for pests.”

For a full list of past and ongoing projects, visit WGRF.ca.

Along with funding research for today, WGRF also looks ahead to the future of agricultural research. WGRF is currently funding graduate scholarships at the University of Manitoba, University of Saskatchewan, University of Alberta, University of Lethbridge and University of British Columbia. Thompson says, “We’ve had these in place for a few years and they are meant to help graduate students continue their studies and provide them with experience in agriculture. We also supported research chairs at several universities, and the purpose behind those is to increase the capacity to do the research that is of interest to farmers. One of the drivers for the funding has been to fill gaps for agronomy research.”

Along with funding researchers, WGRF has also put an emphasis on funding research infrastructure. The WGRF Accelerating Capacity initiative has helped put the people, tools and infrastructure in place to accelerate agricultural research capacity across Western Canada. This has involved the purchasing of equipment and the construction of buildings to increase the capacity to perform high-level research at various research farms across the Prairies, multiple AAFC research stations and several universities. Research can often be limited by the tools available to the researchers. “Say they had an older small plot seeder,” says Thompson. “It is probably time to get a model with GPS or better designs to collect reliable data. Sometimes you can be limited by the equipment at your disposal. It helps to have similar, if not the same, equipment at different locations to improve collaboration between researchers and provide results and information that may be used by farmers in a wider region of the Prairies.”

The emphasis on applicable research directly benefiting farmers of Western Canada has always been a benchmark of the Western Grains Research Foundation and will continue the drive to seek and fund the ideas of tomorrow.

By Angela Lovell

Photography by Nicole Hopaluk Photography

People have often asked Wade and Scott McAllister how they farm 3,500 grain acres with just four people and one combine. Their answer: by using technology, improving efficiency, keeping meticulous records, challenging accepted ways of doing things and not being afraid to try something new.

The McAllister brothers own and operate Antler Valley Farm with their parents, Wayne and Sherri, near Red Deer, Alberta. Proud to be one of many top malt producers in Canada, they grow three different varieties of malt barley, as well as specialty malts including oat, rye and soft white wheat under contract with Canada Malting. They also grow CPS wheat, peas and canola.

Besides the McAllisters, there is only one full-time employee, Jim Leslie, who has worked with the family for 40 years; 30 years on Wade’s father-in-law’s seed farm and the past 10 at Antler Valley Farm.

When the brothers completed high school, the farm wasn’t big enough for them to stay and work, so Wayne – an agricultural engineer – encouraged his sons to experience off-farm careers.

“I always felt it was important to gain different skills in different areas, and before you become your own boss, to work for somebody else,” Wayne says. “Then you understand, once you have employees, how to treat them.”

Wade moved to Kelowna to train as a helicopter pilot and spent four years flying, fighting fires, monitoring pipelines or moving drills to the Northwest Territories. He quickly gained skills and a reputation rare for someone 20 years old. He still actively flies and for the past six years has chiselled out two to three weeks each summer to fight fires with Alberta Forestry.

Younger brother Scott attended Red Deer College to train as a millwright and competed in the Skills Canada challenge, winning a gold medal in Alberta, and a silver medal in the national competition. He then worked at Collicutt Energy Services to obtain his journeyman status.

All the while, both brothers were still helping on the farm when they could during busy times, and although they enjoyed and excelled at their off-farm careers, by 2011 they were both missing farm life. After talking things over with their dad, they decided it made sense for them both to move back and farm together, with the reassurance that they had

alternative careers to fall back on should things not pan out as expected.

But the farm still wasn’t big enough to support additional family, so the brothers bought a couple of Super-B grain trailers and ran an additional grain hauling business as they slowly expanded to where they could start farming full time, approximately 10 years ago.

Using technology to make them more efficient has been central to their operation and the impetus behind their purchase, four years ago, of a 60-foot SeedMaster ultra single rank seed drill, with an integrated 750-bushel tank and 15-inch seed spacing, that has saved them money on operating costs.

“The SeedMaster drill only requires 400 horsepower to pull it, whereas a competitor’s drill that size would need over 550 horsepower, so we can do what we used to do with our old drill but far cheaper,” Wade says. “Other technology on the

drill includes turn compensation, sectional control, full scales and variable rate technology by section.”

The farm has been under zero tillage management since 2002 and going from six-inch seed spacing to 15 inches has helped provide many benefits, including less disease and less soil disturbance, in turn improving soil health by increasing organic matter and reducing nitrogen fertilizer use.

“Everything we do from start to finish, proper seeding rates, proper field preparation, the SeedMaster drill and our fungicide applications, all adds up,” Wade says. “We have had excellent results so far, even in years like this when we have had only four to five inches of rain since seeding.”

Their off-farm training and experiences have brought many benefits to the farm operation – some obvious like Scott’s and Wayne’s mechanical skills, but others less so, like Wade’s meticulous attention to maintenance and record keeping, which is crucial for a pilot.

Our industry stands ready to meet the challenges and opportunities of the future. With innovation and drive, we will find new approaches, develop new techniques and grow agriculture in Alberta.

As malt barley growers, the McAllisters are used to keeping detailed records about every aspect of their operation, from seeding and spraying to harvest and weather during the season, because these are things their buyers want to know and will pay a premium for.

“I can tell you what I sprayed every year since we started on the farm down to dates and the weather,” Scott says. “Then at harvest, every single load that comes into the yard is sampled, moisture and temperature tested. Brewers want to know where this grain came from and what happened to it; what field, what the ground tested, everything.”

They have also gained a lot of knowledge custom hauling grain from farmers’ yards that has helped them decide exactly how they wanted to build a new bin yard on their farm.

“Custom hauling was a good experience because we saw things we liked and things we didn’t,” Scott says. “We have had a goal for the last 10 years to have all the storage in the main yard with no field bins, no secondary sites, and this year we’ve achieved that goal. We have just over 300,000 bushels of air storage capacity in our yard.”

The other thing that has been crucial to the efficiency of their operation is their grain drying capacity, which they have significantly increased over the past five years, going to a large dryer with three fans, three burners and multiple zones that allows them to dry malt without affecting the germ to maintain a high-quality product.

“We dry a lot of grain, and that’s basically like us having a second combine,” Scott says. “We are not scared to dry grain. I had 22,000 bushels of barley this week and dried every bushel of it. We can pull off enough grain in a day and the dryer can keep up, so we can dry day after day and not have wet grain storage in the yard backed up.”

Having the dryer has saved them the cost of another combine and header, but also the related costs of another operator and grain truck for hauling.

“It’s a lot of acres to do with one combine, but if we can go at nine o’clock in the morning and the first two loads have to go in the dryer, we just go,” Wade says.

A couple of years ago the farm worked with Olds College to run an autonomous seeder trial on some of its acres, which the McAllisters say was an interesting experience.

“The autonomous seeder has the same seeding platform as our drill, and we linked up with the robot to seed a field of

canola, and our mapping systems talked to each other,” Wade says. “It opened up the field and did three or four outside rounds while we used our big drill, seeding back and forth, and neither would seed where the other had seeded, so it cut the seeding time by about half.”

While it was an interesting experiment, and there were definite efficiencies to be had, the McAllisters don’t plan on giving up their driver seats to a robot any time soon.

“We enjoy running the equipment,” Wade says. “That’s what farming is all about, being out there on the land. Driving through your quarter twice a year, doing herbicide and fungicide applications, you get a good grasp on how everything is looking, so you can address any problems that you see. If it looks like it’s going to be a bumper crop, that could open up more marketing opportunities. It’s always good to be able to keep an eye on the crops as they grow.”

The McAllisters are definitely thinking about the future, as the sixth generation grows up on the farm which was founded by their great-great-grandfather Ephriam in 1890. Wade and his wife Sabrina have two daughters, Mia (10) and Macy (7), and Scott and his wife Brittany have two sons, Dane (3) and Boyd (1). They will continue to grow, be as sustainable as they can, and explore new opportunities as they come along, but they don’t plan to stray far from what is working well for them today.

“We don’t have any major goals other than just to keep doing what we’re doing at the moment,” Scott says. “Change

doesn’t happen overnight, and we have got to keep doing a good job so that we can take opportunities as they come.”

The McAllisters are always open to new ideas and believe it’s important to be involved in the industry. A good example is Wade’s 10 years on the Agri-Trade show board, following in the footsteps of his father-in-law who was the chair for many years.

Agri-Trade is celebrating its 40th year, and Wade believes it’s important for farmers to give input. “It is good to have some farmer voices to give the show some direction on where the industry is going for farmers,” he says, adding that the technology side of the show has grown significantly over the past four to five years. “There is now a full section of the show strictly showcasing the technology.”

The family tradition of attending Agri-Trade lives on as Wade and Scott are now taking their children to the show.

“It’s a big toy box for kids and they love to go and climb on every piece of equipment,” Wade says. “It’s good to get the kids involved and interested in agriculture because they are the future of farming.”

But it’s not just a toy box for the kids, Wade admits. “The show is incredible, and it’s a great time to have the show at the end of harvest,” he says. “The farmers are done, they know what they have for a crop, and how much money they can maybe spend and it’s great to go out and network with other farmers.”

More so than any type of business, a family business embodies the core values of its owners, and for SMS Manufacturing that means providing exemplary customer service.

“Whether we are dealing with our suppliers or our customers, we strive to make them happy,” says SMS founder Scott Macknak. “It’s important to our customers that they are dealing with the person who makes the product as it gives them confidence. I always make sure they are buying the machine that best meets their needs.”

SMS Manufacturing – a family-owned company that specializes in mobile grain cleaning equipment – is celebrating 20 years of serving farmers across Western Canada and the United States.

A focus on customer service and the family’s hands-on approach has made SMS synonymous with mobile grain cleaning. Because they sell direct from the factory to farmers, they can provide a personalized service that prioritizes building long-term relationships and meeting their customers’ exact requirements. Repeat customers are common, coming back to trade

their grain cleaners for newer or larger ones as they expand their operations. “We have built four or five machines for some customers over the years,” Macknak says.

In fact, it was feedback from customers that provided the early impetus for SMS to develop new products to better met specific needs. “We started out installing stationary grain cleaners, and customers began asking if we could put them on a trailer so they could move them around,” says Macknak. “I figured out how to mount these units to make them mobile, and the business evolved from there.”

By 2012, the company had moved to a larger manufacturing facility in Dysart, Saskatchewan and begun to build its own line of mobile grain cleaners and air screen machines. Today, SMS employs six people – one of whom has been with them for eight years – and offers several models in a variety of sizes from 400 to 1,200 bushels per hour capacity. Offering many different options, they can custom design a system for any size of

“We can incorporate whatever machine is needed to suit the needs of the customer such as screen machines, indents, gravity tables and colour sorters. These units are unique as they are portable and fully self-contained with their own generator for power, and the cost is much less than a stationary plant.” - Scott Macknak

operation and provide comprehensive after sales service and replacement parts. SMS also sells digital auger scales and is the sole Canadian distributor for U.K.-based Crown Gravity Separators.

“We have supplied units to commercial seed growers along with custom grain cleaning companies,” Macknak says. “We can incorporate whatever machine is needed to suit the needs of the customer such as screen machines, indents, gravity tables and colour sorters. These units are unique as they are portable and fully self-contained with their own generator for power, and the cost is much less than a stationary plant.”

SMS is still listening to its customers by continually evolving, developing new products and improving on existing ones. Currently, the team is developing a larger capacity grain cleaner that is going through the on-farm testing stage before launching, hopefully later in the year.

Also, because customers were constantly calling about where they could get replacement parts, SMS decided to convert a portion of its shop into a parts service counter two years ago and hired a full-time parts person.

As a small, rural business, SMS is committed to its community, supporting many projects and using local contractors as much as possible – like their electrician and a local construction company that builds the offices attached to their grain cleaner trailers.

It’s also important to the family that they provide opportunities for young people to get a taste of what it’s like to work in an agricultural manufacturing business. This year they hosted a Grade 12 student to learn welding at their facility as part of a work experience school credit program. Macknak’s daughter, Jazmin, spent the summer of her Grade 12 year helping to set up social media for the new parts side of the business, and

developed a number of manuals for the grain cleaners. That experience sparked her interest in agricultural management, which she is now studying at Olds College.

Building a legacy

Macknak is proud of the reputation SMS has built in the industry for quality products and service. “I am confident that I can provide my customer list and contact names for anybody interested in our products to talk to and they won’t get any negative feedback,” he says.

Building the business to where it is today has taken a lot of hard work, determination and some sacrifices along the way, and it could not have been done without the support of the whole family. Macknak’s wife Shannon, mother Brenda, and son Carson (a journeyman welder) all work in the business, ensuring that the SMS legacy will continue for another 20 years.

“My hope is that there will be many more years ahead for us to provide service to our existing customers and to new ones,” Macknak says.

But they have also never lost sight of the things that matter the most, like taking family time away at their cabin at Echo Lake during the summer, and watching Carson and their eldest son Kody (who is a teacher) play hockey at various local rinks through the winter.

Your North American Partner for all your hydraulic, bearing and power transmission, design and service solutions. We achieve superior performance by adding value and working with you to achieve success now and into the future.

Tom Wolf, PhD, P.Ag. Tom Wolf grew up on a grain farm in southern Manitoba. He obtained his BSA and M.Sc. (Plant Science) at the University of Manitoba and his PhD (Agronomy) at Ohio State University. Tom was a research scientist with Agriculture & Agri-Food Canada for 17 years before forming AgriMetrix, an agricultural research company that he now operates in Saskatoon. He specializes in spray drift, pesticide efficacy and sprayer tank cleanout, and conducts research and training on these topics throughout Canada. Tom sits on the Board of the Saskatchewan Soil Conservation Association, is an active member of the American Society of Agricultural and Biological Engineers and is a member and past president of the Canadian Weed Science Society.

A wise professor once asked his class what they thought was the most powerful force in the universe. The students produced a lot of answers. “Gravity,” said one. “TNT,” said another. “Nuclear fission,” bested a third. The professor shook his head. “Incremental change. That is the answer,” he said. The students looked at each other. What on earth did he mean?

When charting a course for change, we are inclined to pin our hopes on big things. The breakthroughs. The game-changers. Like a new mode of action to address herbicide resistance. Or a new crop that is easy to grow and offers tremendous returns. And although these do happen from time to time, the majority of change in our lives is stealthier. It comes in small increments, so small that many are hard to even detect. But over time, their impact is impossible to ignore, and even harder to reverse. An example from the banking sector is compound interest. In agriculture, it could be plant breeding. And in spraying, it could well be precision.

Precision application continued to elude spraying when site specific fertility was already well established. The reason was the inability to map weed populations easily. Spot sprays put an end to that. Suddenly, we can treat just the weeds, and that presents a lot of savings. And it has the potential to be a game-changer. But spot sprays are a large investment, something that may not be right for everyone. And it has risks, such as misses, or gaps in algorithms, where certain crops or weeds are not yet recognized. Is there something more intermediate – more incremental – that leads to the same outcome? Something less flamboyant than spot sprays?

There are several examples that come to mind, and I’d like to highlight two of these.

The first is the technology provided by Croptimistic of Naicam, Sask. (swatmaps.com). Long known for mapping the electrical conductivity (EC) of soils and layering this with elevation maps to produce 10 “SWAT” cropping zones, they’ve upped their offering with weed and crop establishment information. By mounting two cameras on a sprayer (SWAT CAM), one on each boom, they snap photos that capture images of the growing crop. With some artificial intelligence, these images confer information on crop and weed establishment. For crops, information such as plant spacing can teach about the frequency of planter skips and validate the target plant density. It can also teach about the uniformity of plant establishment. Adjustments to seeding, or fertilizer rate, can then be made on a zone by zone basis if justified.

Knowledge of the weed distribution across a field is fundamental. We’ve waited a long time for weed density maps so that we can initiate a precision response. Higher weed densities point to the need for more crop competition, more diligent weed control, or both. The traditional way of measuring plant biomass using NDVI (Normalized Difference Vegetation Index) doesn’t discriminate between crop and weed plants. The AI employed on the images does. This information isn’t meant to trigger individual nozzles. Instead, it strengthens the fundamentals of elevation and soil characteristics and applies them to crop and weed growth.

If weed establishment can be tracked, sprayer settings can be managed. This would be done on a whole boom basis, with changes in dose implemented via spray pressure or travel speed. For some sprayers equipped with direct injection, it may be possible to adjust herbicide rates or tank mixes. Of course, the recurring appearance of high weed densities in some zones justifies a change of strategy that goes beyond herbicide application.

Fungicide application can also be matched to SWAT zones that represent high or reduced yield potential based on crop images. Yes, SWAT CAM is another layer of information that has to be managed. But it’s a step towards greater precision, accuracy and product stewardship.

A second Canadian venture is Geco Strategic Weed Management (geco-ag.com). The company was founded to help manage weed populations by attempting to predict where they will emerge. Instead of using boom mounted cameras, Geco uses historic satellite images to identify field areas with recurring weed patches. It requires a cropping history dating back five years, herbicide history dating back two years, cropping intention, as well as soil type information from the grower. Although satellite imagery is much coarser than close-up photography, it has the advantage of making dozens of images per year available, allowing crop progress to be tracked. Its algorithms can separate crops from weeds in a temporal way.

A subscriber receives three pieces of information. First, a historical trend of the weedy patches in their fields. Second, an indication of patches with potential resistance. And finally, a prescription for where Geco estimates the weeds will occur the next season.

The Geco system is meant to be complementary to other, more finely resolved approaches. For example, their prescriptions could be used to apply residual products. During the growing season, this would help reduce the pressure on a post-emergent spray or allow a spot spray to produce greater savings. Or it could inform seeding rates.

When it comes to change, the size of the step isn’t nearly as important as the direction.

Three prescription maps are produced for the customer, with three levels of conservatism represented by projected hit rates from 85 to 95 per cent. The higher hit rate map covers more area to be treated, hitting more of the weed patch and using more herbicide. The 85 per cent hit rate would save more product and emphasize just the hot spots. The individual user would decide where their comfort zone is.

As with all plant sensing technologies, there will be some uncertainty. And that’s where Geco has identified a matrix of scenarios that can help users. It’s the classic 2x2 matrix. On the x-axis we have two weed situations: weedy or weed free. One the y are two responses: sprayed or unsprayed.

The four scenarios are then populated with outcomes. If no weeds are present and the region is unsprayed, it’s a true negative and there is no cost. If weeds are present and they are sprayed, it’s a true positive, and the cost is the treatment, but the benefit is the yield protection. If there are no weeds and the area is sprayed, that’s a false positive. An example would be having a small patch but spraying a large area; the perimeter would be treated with little prospect for a benefit and could represent waste. And the final scenario is where there are weeds, but the region is unsprayed. That’s a false negative, and it’s costly.

A user would evaluate their comfort zone for each scenario and choose the level of conservatism that matches their temperament.

Geco says their clients don’t need any special equipment. They submit a request and the required information and get a report and shape files for their fields.

Both of these examples represent an intermediate size step to greater precision and accuracy. They also add something that spot spraying isn’t yet doing widely – incorporating the findings into longer term agronomic strategies and monitoring the results.

When it comes to change, the size of the step isn’t nearly as important as the direction. And although we always want beneficial change to happen quickly, biological systems tend to respond best to small, but strategic change over time. For those reasons, it’s worth looking at these incremental technologies.

60’ x 220’ & 60’ x 280’ Backgrounding Barns 750 head capacity Dugald, MB

Fit 450 feeder cattle, or 150 cow-calf pairs in this flexible use 106’ x 240’ barn design. Features like outside feeding, manure storage, a center alley, can all be customized for your needs. Call our Design Specialists today.

The X-Treme® grain carts feature a patented front-folding design that angles the auger upward, outward and forward for the easiest unloading and greater visibility of the downspout. This direct line of sight to the downspout from the side window of the tractor cab eliminates the need to twist around during unloading, reducing fatigue and increasing unloading accuracy. Models are available in capacities from 1,500 to 1,000 bushels and include a standard four-way directional downspout, a 21" sump auger that unloads grain up to 650 bushels per minute, and your choice of highflotation single tires or tracked undercarriage.

Tammy Jones B.Sc., P.Ag

Tammy Jones completed her B.Sc. in crop protection at the University of Manitoba. She has more than 15 years of experience in the crops industry in Manitoba and Alberta, with a focus on agronomy. Tammy lives near Carman, Man., and spends her time scouting for weeds and working with cattle at the family farm in Napinka.

I’ve heard Dr. Peter Sikkema speak about weed control many times, and the various factors that impact on herbicide efficacy. During a War Against Weeds podcast (March 12, 2024), he made the statement “…it’s irresponsible for herbicide manufacturers, ag retailers and agronomists to guarantee acceptable weed control with herbicides. And also, I think it’s unreasonable for farmers to expect perfect weed control with herbicides in every field in every year.”

A number of factors impact on herbicide activity, ranging from the uncontrollable aspects of weather (including rainfall, temperature and relative humidity) to the controllable decisions on herbicide selection and application timing. The argument can be made that based on the extensive testing of herbicides, the labelled rate of a herbicide should be guaranteed to control weeds, as long as they haven’t developed resistance.

Dr. Sikkema pointed to the tank mix application of dicamba, a synthetic auxin primarily used for broadleaf control, antagonizing any accompanying Group 1 herbicides that provide grass weed control. After much research, the antagonism was found to be due to the dicamba upregulating enzymes that metabolize the Group 1 herbicides. Oddly enough, more antagonism occurs when dicamba was co-applied with quizalofop-p-ethyl than clethodim, even though they are both Group 1 herbicides.

Studies have also shown that glyphosate and dicamba combined will be less effective than when applied separately. In this case, the antagonism is due to a reduction in translocation of the glyphosate as the dicamba quickly impacts on the plant to limit the movement of the glyphosate. While unfortunate, the examples of antagonism are somewhat frequent and the typical method of overcoming this is to adjust the rates of the herbicide in formulated products to achieve consistent control. But there are many instances where a herbicide application involving a single herbicide (therefore no antagonism) has failed to obtain the expected level of control. The weed population is not resistant based on subsequent testing and the agronomist or herbicide manufacturer is struggling to provide an explanation.

A paper from Kansas State University (KSU) is a fascinating example of how challenging it is to understand the mechanisms that allow a weed to survive normally lethal doses of herbicide. It’s an understatement to say “it’s complicated.” The study published in 2015 by Dr. Mithila Jugulam’s lab in the KSU department of agronomy investigated the impact temperature can have on herbicide activity. The research team confirmed that Palmer amaranth sprayed with mesotrione was much more likely to survive under elevated temperatures (approximately 85 F to 95 F or 29 C to 35 C) than under cool conditions (less than 80 F or 27 C). For two main reasons, it seemed

counterintuitive (to me) that hot temperatures would favour the survival of Palmer amaranth after mesotrione application.

1. Mesotrione is a Group 27 “HPPD-inhibitor” herbicide, which kills plants by blocking the HPPD (4-hydroxyphenylpyruvate dioxygenase) enzyme. Without this enzyme, a sensitive plant will begin to turn white, as the chlorophyll in plants is destroyed by sunlight, which is why the Group 27 herbicides are sometimes referred to as “bleachers.” In my mind, warmer temperatures would equate to sunshine and the Group 27 herbicide should be impacting the plant more, not less.

2. Palmer amaranth is a C4 plant, native to southwest U.S. and northern Mexico, which also led me to believe that the elevated temperatures referenced in the study would be normal and not a stress to the plant.

In order to determine how the Palmer amaranth plants were surviving in warmer temperatures, the KSU team allowed the plants to grow between eight to 12 inches (20-30 centimetres) under three different temperature regimes. Mesotrione was applied to the plants and then tracked. The weed scientists determined there were two separate processes that allowed

the weeds to survive the herbicide:

1. At higher temperatures, Palmer amaranth was able to metabolize more mesotrione within the plant before it could cause significant injury, conversely cooler temperatures slowed metabolism.

2. At higher temperatures, HPPD enzyme activity in the Palmer amaranth was increased, making it harder for the HPPD-inhibitor herbicide to block all the activity of the HPPD enzymes in the weed.

The practical implication of this study is that by timing mesotrione application for earlier in the growing season or earlier in the morning versus afternoon, when temperatures are cooler, Palmer amaranth control is more consistent.

Bringing that back to Western Canada, where mesotrione and thankfully Palmer amaranth are not frequently encountered, it makes sense that farmers, with limited time to apply spray, may see differences in the efficacy of herbicides based on the timing of application. This is not due to herbicide resistance or the perceived failure of the herbicide, but rather the diabolical ability of a weed to survive.

By Jaclyn De Candio

Today’s commercial beef cattle tend to be quite robust thanks to genetics and careful selection for health traits. But there is one inevitable Achilles’ heel that can wreak havoc on the healthiest of animals – transitional stress.

Hauling up the road, weaning calves or bringing back a trailer load of new purchases from the sale barn are stressful events contributing to immunosuppression. While it is impossible to eliminate all stressful events, there are ways they can be managed to reduce impact on animal health.

Stress is inevitable in cattle production, but it’s the ability to reduce the intensity and duration that makes the difference for animal health. Proper management practices can significantly lessen how much stress animals experience, particularly during key transition periods.

Cattle owners and stockers can face challenges when it comes to moving cattle from “stage to stage,” such as transition stress syndrome, which can compound existing problems.

Before we look into remedies, we should clearly define what stress is in livestock.

“It’s the inability of an animal to cope with stress that affects its ability to maintain a homeostatic state,” explains Dr. Karen Schwartzkopf-Genswein, principal research scientist of Beef Cattle Physiology and Welfare at Agriculture and Agri-Food Canada. “These changes in the environment can range from minor to major, and there’s a gradient in how well they can adapt.”

Stress is a multifaceted issue caused by a variety of factors. It can happen during transitional phases in a cow’s life cycle such as changes in the animal’s environment, handling, social dynamics or nutrition. Schwartzkopf-Genswein notes that stress is an adaptive response, but chronic or overwhelming stress can impair an animal’s ability to cope.

“One common stress response is secretion of glucocorticoids (cortisol),” she says. “Cortisol can increase morbidity and mortality in cattle by reducing immune function. The greater amount of cortisol and the longer the period of time it’s elevated in the blood, the greater effect it has on reducing immune function.”

The suppression of immune function due to prolonged cortisol elevation makes cattle more vulnerable to infections, particularly during stressful transition periods. This is especially evident in calves moving through the production system.

“Calves are transitioning from one sector of the industry to another, usually from the cow-calf to the feedlot sector,” explains Dr. John Campbell, a veterinarian at the University of Saskatchewan. “During that time period, there’s a lot of different stressors that hit those calves and as a result, they end up being exposed to the more common diseases, such as bovine respiratory disease (BRD).”

Stress isn’t just a concern for cow-calf operations or the feedlot sector, it affects everyone who handles the cattle. According to Campbell, stressors like commingling – when animals are brought together during sales or transport – are

astic containers and DEF containers, d air clean and safe.

ts and over 30 registered collectors ng networks in the country let's use it! drop count cling. Reusing

JANUARY 28 - 29, 2025

EARLY BIRD TICKETS ON SALE UNTIL DECEMBER 31, 2024

Opening night reception on January 27

Keynote addresses from Michele Payn, Bill Wirtz & Drew Lerner

Forward thinking sessions for today's farmer

Valuable networking opportunities to foster fresh ideas & meaningful connections

major contributors. Not only are animals exposed to unfamiliar peers, but they’re also encountering new viruses and bacteria.

“Probably the number one stress is weaning,” Campbell notes. “If calves are weaned, sold and then transported immediately, stacking those stressors significantly increases the risk of illness.”