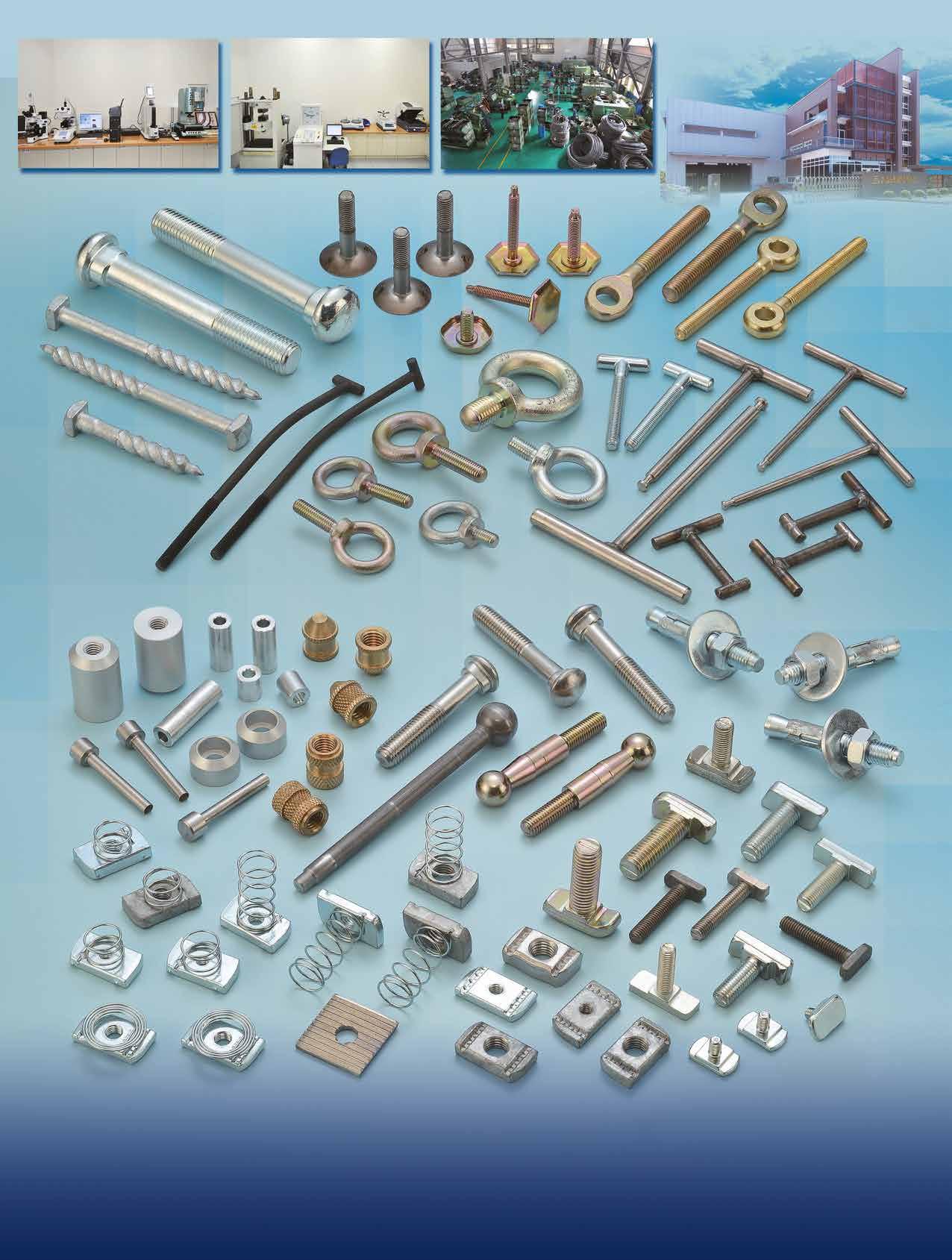

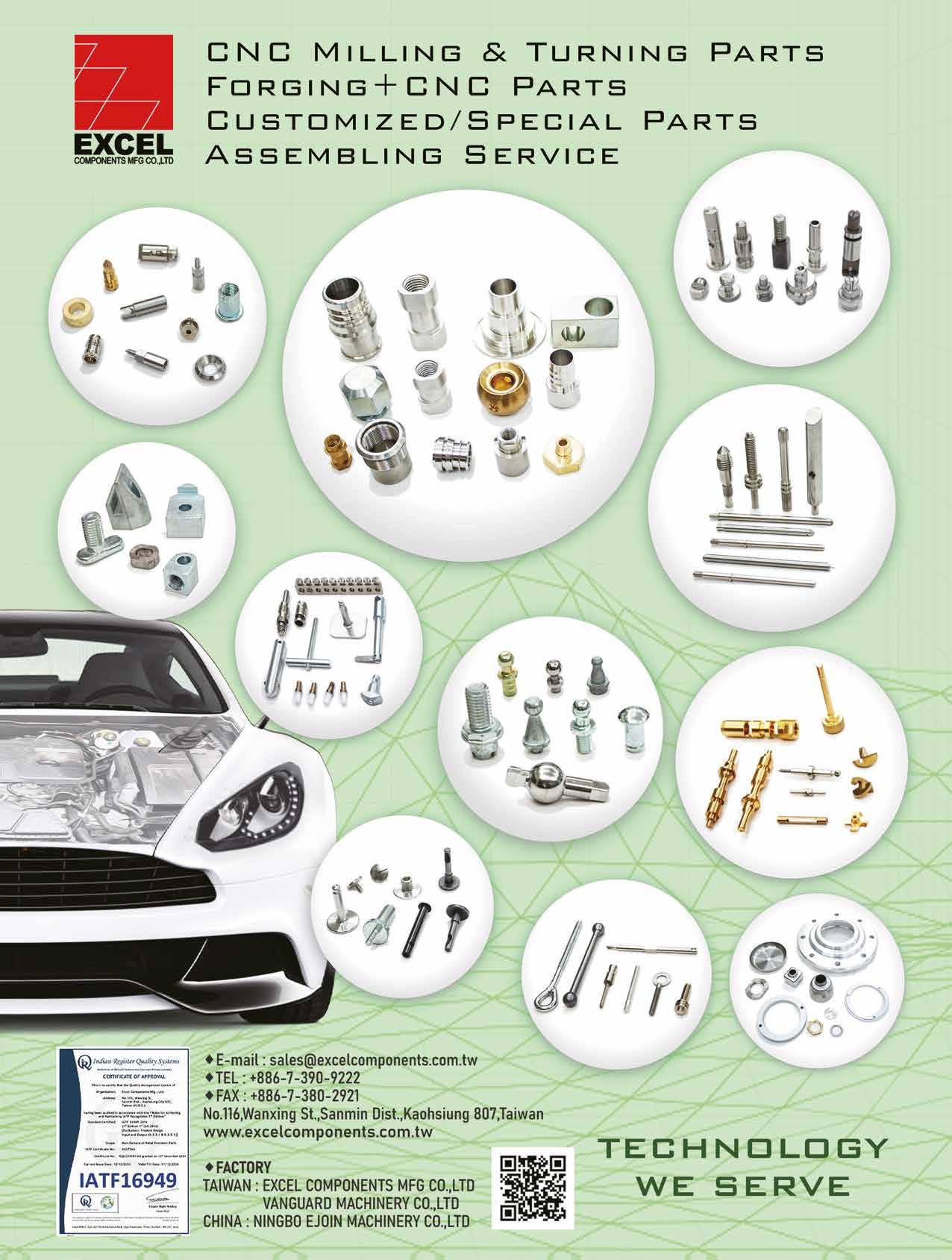

With the ability to design, manufacture, export, implement vertical integration and provide one-stop production, Chinmore Industry secures electronic/automotive communication market shares and gains clients’ trust. It has become a reputable company in the domestic and overseas electronic parts industry as well as a professional in Taiwan specialized in CNC machined precision parts.

In its 25 years of history, the company manufactures and supplies high-frequency antenna components as well as various precision parts made of iron, copper, steel, stainless steel, and PTFE. The company can process parts of diameters ranging from Ø1 to Ø42mm, and lengths from 0.5 to 150mm, within 0.005mm tolerance, offering OEM and ODM service for high-end markets including Taiwan, Europe, the U.S. and Japan. It can supply products in separate batches to help reduce inventory, providing flexible service in accordance with clients’ needs.

“Reputation is backed by quality” is a motto held true by Chinmore that earned CE, RoHS, ISO 9001:2015 and ISO 14001:2015 certifi cates. Chinmore is strict with itself the way like a Japanese craftsman would treat himself. Its manufacturing plant uses composite CNC machine tools from Nomura (Japan) for higher precision and stable quality, better and unified management of parts, stable production, short lead times and high customizability to satisfy clients. It can also cope with rush orders.

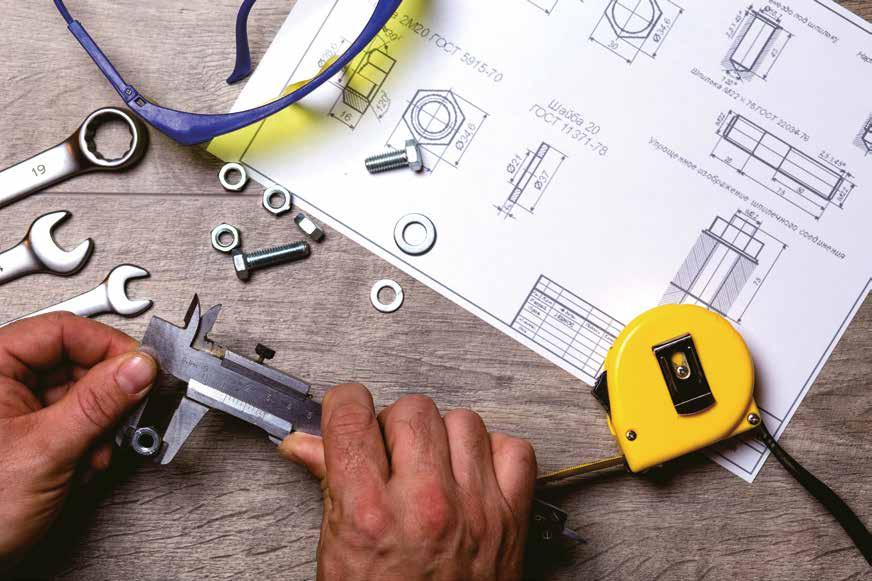

Clients will provide drawings, sizes and requests for special specifications for engineers and technicians to see if the manufacture is possible, and the company will provide suggestions for production. Samples will be provided to clients for confirmation before mass-producing and this fulfills tailored service. Quality inspection on par with clients’ standards will be performed with auto 3D projectors before shipment. “Trust the professionals and place your orders to Chinmore” is the words by many clients rating Chinmore.

Last year Taiwan was in the middle of exploding number of orders from abroad. Overseas demand has boosted the com pany’s sales by 30%. Soon Taiwan will lift border barriers by a larger scale. The company is fully prepared to embrace overseas demand and begin to attend exhibitions abroad this year to develop markets in the U.S. and Europe with 100% efforts.

To cope with precision parts demand from the U.S. and Europe, the company has already purchased 3 manufacturing machines. It will still continue to purchase new equipment to expand capacity. Currently in Europe, Chinmore’s sales have reached Spain, Germany, Czech Republic and other countries. In the future it will continue to develop dies and add industry-leading advanced machines to become the quality benchmark of the industry.

Contact: Mandy Wang Email: mandy@chinmore.com.tw

As the season enters the second half of 2022, the global fastener industry is still struggling to find the best solution to the challenges ahead, while actively creating opportunities for themselves in the face of the epidemic, cost and price pressures, product/technology competition, new market trends and many other challenges, in anticipation of finding the best approach to win in the ever-changing fastener market.

With high demand and good prices, Taiwanese fastener manufacturers have always earned their biggest profit from European and U.S. fastener markets for years, and with excellent technology and competitive quality they’ve also maintained a high market share. According to the data released by U.S. Customs, the U.S. imported more than US$1.4 billion worth of fasteners from Taiwan in the first five months of 2022, with a cumulative growth of 26% from January to May. The U.S. had about 40%

of its fasteners imported from Taiwan, far exceeding the value of imports from China during the same period (only less than US$800 million and representing a market share of about 20% in the U.S.). In addition, EU data also show that Taiwan is among the major fastener import partners of EU countries, such as Germany, France, the Netherlands, Italy, Poland, as well as the UK (which is no longer a member country of the EU), showing that the demand for and the dependence upon Taiwan fasteners in European and U.S. markets remain high.

However, U.S. fastener imports from Japan, Germany, Canada and S. Korea have also increased in the same period, which may be translated into a fact that the increase of U.S. demand for high-end fasteners for automobiles, aerospace and electronics, in addition to low-tomedium end fasteners, has also increased. Taiwanese manufacturers may consider actively working in these directions in terms of product upgrade. It is understood that construction/DIY, automotive, furniture, and aerospace fasteners are all popular items exported to the U.S. market, and the U.S. market has a demand scale of about US$2 billion a year for construction fasteners alone. As a result, Taiwanese fastener manufacturers owning many innovative designs and technical applications in these fields should seize the great opportunity to gain further exposure. At International Fastener Expo (IFE) this year, dozens of Taiwanese manufacturers (such as Fong Yien Industrial Co., Ltd., J.C. Grand Corporation, Fratom Fastech Co., Ltd., Soon Port International Co., Ltd., Mac Precision Hardware Co., etc.) will also showcase their innovative made-in-Taiwan products to demonstrate their strengths.

by Gang Hao Chang, Vice Editor-in-Chief of Fastener World

With the advancement of industrial technology and customers’ increasing emphasis on environmental protection, fastener design and processing must keep pace with the upcoming trend. In recent years, we’ve seen that many manufacturers have started to strengthen their product design capabilities, upgrade their production lines and equipment, eliminate more energy-consuming equipment, and actively invest in the development of new materials/processes/products/equipment/services in response to future market trends, thus getting out of price-cutting competition and creating more efficient and profitable performance. The ideas of ESG, energy saving, net zero carbon emission, lean manufacturing, industry 4.0, digital management, and AI-enabled technology are all very important steps for the fastener industry to move to the next-generation industrial development and enhance its competitiveness on the global stage. Some companies have been also featured in this issue as good examples of how to grasp opportunities to take the lead in the market trends. These companies are: Bi-Mirth (adopting new eco-friendly electroplating solutions and coatings), Abis Innovative Technology (developing new acid free pickling to replace acid pickling), Japanese Art Screw (developing “Motiontite” bolts), and Hwa Hsing Screw Industry (introducing Industry 4.0 production lines and electrostatic smoke-discharging systems).

With the trend of accelerating infrastructure development in emerging countries /regions such as Southeast Asia, the Middle East & North Africa, Turkey, Central & South America to attract more foreign investments as well as the trend of strengthening domestic product upgrade and competitiveness in the market, there has been a significant sign of growing fastener demand in these emerging markets/regions in recent years. For Taiwanese suppliers always focusing on the European and U.S. markets, making efforts to develop emerging markets can also help them avoid the risk of sudden and drastic market changes in the future that may slash their product competitiveness overnight (for example, EU’s anti-dumping measures on Chinese fasteners).

Relevant data show that Thailand, Vietnam, Malaysia, and Indonesia are main fastener demanding countries in Southeast Asia these years. Although Taiwan also ranks among the top three import trading partners of Thailand, it is out of the top 10 of Malaysia. On the contrary, the deployment of China and Japan in the Southeast Asian fastener market continues to grow, so Taiwanese manufacturers still need to do more to catch up with their

pace. Of course, in the ASEAN market there are a few benchmark Taiwanese fastener manufacturers (such as Tycoons, Tong Heer, Chin Well, Homn Reen, Rodex, San Shing, etc.). The first three companies reported over NT$3 billion revenue in 2022 respectively, but they all reported a significant 2-digit decline in revenue compared to the previous year. Is this due to a change in local customers’ demand or the better competitiveness of other competitors’ products and services? This is perhaps a good question for Taiwanese companies to think about.

For promotion and development in emerging markets, Fastener World Inc. will continue to try our best for manufacturers. In H2 2022, we’ll also exhibit at exhibitions in several key emerging markets (incl. Vietnam, Indonesia, Saudi Arabia, and Egypt) to help manufacturers promote and gain exposure. Through close contact with local buyers, we hope to build a solid bridge for interaction and communication between buyers and sellers.

Regarding the issue of significant fluctuations in current market demand and supply, a Taiwanese supplier recently told Fastener World that the order volume Taiwanese suppliers have received over the past 12 months is actually much higher than their total capacity, often resulting in an average lead time of 4-6 months (which was only 2-3 months before). However, his buyers complained to him that they did not have double capital to purchase more and were forced to turn to suppliers in China, Southeast Asia or their parent countries. If we look at the past trend of industrial demand, it is inevitable that there’ll be fluctuations. The current drop in orders may not be a bad thing, as it can sometimes be caused by seasonal adjustments in foreign economies or by customers’ intention to consume existing inventory first. Under the overall market supply and demand cycle, it is expected that the imbalance between supply and demand in the industry will gradually return to normal by the end of this year.

21,424,773

260,847,004

12,563,243 Netherlands 169,348,088

7,266,443 Japan 149,510,874

5,541,891 UK 109,955,298

3,009,690 Canada 107,050,441

2,694,695 China 88,074,895

UK 24,980,984 UK 154,190,272 Philippines 2,570,308 Italy 71,511,493

Turkey 18,765,358 Italy 146,440,438 Switzerland 2,110,473 Sweden 71,109,514

15,773,304

China’s

145,622,009 Sweden 1,740,430 Mexico 70,972,853

Taiwan’s

World 3,280,746,110 World 9,303,405,675 World 206,147,825 World 5,322,552,883

Japan 983,969,032 U.S.A 1,263,573,726 Japan 78,090,806 U.S.A 2,249,900,692

Germany 630,243,449 Russia 544,573,376 U.S.A 35,474,785 Germany 454,994,012

U.S.A 398,160,844 Germany 533,707,080 China 21,189,220 Netherlands 291,941,389

Taiwan 324,224,022 Vietnam 457,539,548 Germany 14,582,412 Japan 246,072,681

Italy 172,577,180 S. Korea 405,583,971 S. Korea 9,414,381 UK 209,199,205

S. Korea 132,572,356 Japan 346,444,260 Philippines 5,401,730 China 191,243,730

France 73,700,211 India 298,269,602 Vietnam 5,375,493 Canada 177,039,530

UK 53,832,105 Italy 277,500,682 Netherlands 5,205,645 Sweden 121,737,174

Turkey 40,893,282 Australia 266,465,334 Switzerland 2,937,108 Mexico 119,553,758

Switzerland 33,779,764 UK 260,145,375 Sweden 2,678,180 Italy 103,873,841

In the first half of 2022, China exported USD 5.14 billion worth of fasteners to the world, which is 1.6 times more than Taiwan’s global export value of USD 3.18 billion in the same period. In the value of fastener import from the world, China was USD 1.47 billion and Taiwan was USD 108 million. Taiwan demanded far less fastener import from the world than China did. China’s top 3 export destinations were the U.S. (USD 850 million), Germany (USD 308 million) and Vietnam (USD 223 million). Taiwan’s top 3 export destinations were the U.S. (USD 1.42 billion), Germany (USD 260 million) and the Netherlands (USD 169 million), and Taiwan exported USD 88.07 million worth of fasteners to China. It shows that the U.S. and Germany were the top 2 fastener export destinations for both China and Taiwan in the first half of 2022. In terms of import, the top 3 sources for China were Japan (USD 430 million), Germany (USD 270 million), and the U.S. (USD 200 million). Additionally, China imported USD 140 million worth of fasteners from Taiwan in the same period. Taiwan mainly imported from Japan (USD 36.17 million) and the U.S. (USD 21.42 million), and it also imported USD 12.56 million worth of fasteners from China. Japan was the largest fastener import source for both China and Taiwan. Germany and the U.S. were respectively the second largest source for China and Taiwan.

0 World 2,786,542,569 World 6,959,807,809 World 157,680,579 World 3,969,360,344

1 Japan 852,790,240 U.S.A 827,330,702 Japan 61,494,765 U.S.A 1,689,801,153

2 Germany 561,700,799 Vietnam 484,775,853 U.S.A 27,844,570 Germany 340,191,792

3 U.S.A 315,945,338 Russia 404,230,744 China 15,143,539 Japan 209,498,781

4 Taiwan 234,702,416 Germany 309,148,054 Germany 10,329,451 Netherlands 195,105,056

5 Italy 141,111,449 Japan 270,056,188 S. Korea 5,660,405 UK 136,840,671

6 S. Korea 130,805,250 S. Korea 249,571,286 Netherlands 4,058,735 China 129,131,272

7 France 62,370,515 UAE 213,085,446 Vietnam 3,719,309 Canada 128,760,834

8 UK 46,517,579 India 203,159,577 Switzerland 2,182,902 Sweden 85,303,928

9 Malaysia 28,608,755 Myanmar 199,601,983 Sweden 2,033,164 Mexico 77,878,026

10 Switzerland 28,247,190 Thailand 196,292,352 UK 2,017,286 Italy 70,888,895

In 2021, China exported USD 9.3 billion worth of fasteners to the world, which is 1.7 times more than Taiwan’s export value of USD 5.32 billion in the same period and it resembles the aforementioned difference of scale in first-half 2022. In the value of fastener import from the world, China was USD 3.28 billion and Taiwan was USD 206 million. China’s top 3 export destinations were the U.S. (USD 1.26 billion), Russia (USD 544 million) and Germany (USD 533 million). Taiwan’s top 3 export destinations were the U.S. (USD 2.24 billion), Germany (USD 454 million) and the Netherlands (USD 291 million), and Taiwan exported USD 191 million worth of fasteners to China. The U.S. was the largest export destination for both China and Taiwan. As for the second largest export destination, it was Russia for China and Germany for Taiwan. In terms of import, the top 3 import sources for China were Japan (USD 983 million), Germany (USD 630 million), and the U.S. (USD 398 million). Additionally, China imported USD 324 million worth of fasteners from Taiwan in the same period. Taiwan mainly imported from Japan (USD 78.09 million) and the U.S. (USD 35.47 million), and it also imported USD 21.18 million worth of fasteners from China. Japan was the largest fastener import source for both China and Taiwan. Germany and the U.S. were respectively the second largest sources for China and Taiwan.

In 2020, China exported USD 6.95 billion worth of fasteners to the world, which is again 1.7 times more than Taiwan’s export value of USD 3.96 billion in the same period. In the value of fastener import from the world, China was USD 2.78 billion and Taiwan was USD 157 million. China’s top 3 export destinations were the U.S. (USD 827 million), Vietnam (USD 484 million) and Russia (USD 404 million). Taiwan’s top 3 export destinations were the U.S. (USD 1.68 billion), Germany (USD 340 million) and Japan (USD 209 million), and Taiwan exported USD 129 million worth of fasteners to China. The U.S. was the largest export destination for both China and Taiwan in 2020. As for the second largest export destination, it was Vietnam for China and Germany for Taiwan. In terms of import, the top 3 import sources for China were Japan (USD 852 million), the U.S. (USD 561 million), and China (USD 315 million). Additionally, China imported USD 234 million worth of fasteners from Taiwan in the same period. Taiwan mainly imported fasteners from Japan (USD 61.49 million), the U.S. (USD 27.84 million) and China (USD 15.14 million). Japan was the largest fastener import source for both China and Taiwan. Germany and the U.S. were respectively the second largest sources for China and Taiwan.

China’s global fastener export grew 33.8% from USD 6.95 billion in 2020 to USD 9.3 billion in 2021, and reached USD 5.14 billion in the first half of 2022, having a potential to grow 7.5% to USD 10 billion for the 12 months of 2022. Despite the virus and city lockdown in the last two years, China’s scale continued to grow, but a big concern is that the growth margin of this year is likely to decrease over 20%.

T aiwan’s global fastener export grew 55.1% from USD 6.95 billion in 2020 to USD 9.3 billion in 2021, and reached USD 5.14 billion in the first half of 2022, having a potential to grow 12.7% to USD 10 billion for the 12 months of 2022. Taiwan gained a large number of orders from overseas last year and expects to grow one fold more than China, but this is far less than the drastic growth last year. For Taiwan, the concern is that the U.S and European clients have yet to clear up their inventory; therefore, they have less purchasing demand for Taiwan.

Caught between the domestic impact (lockdown) and foreign impact (AD tax imposed by EU and 25% tax by the U.S.), China was still able to perform well in fastener export , because the Chinese government provide d subsidies and the Chinese steelmakers offered highly competitive wire prices. Furthermore, China increased fastener export to places other than the U.S. and Europe. This indicates China’s impact mitigation strategy to quickly scatter export and not concentrate on a single market in the face of overseas barriers. In contrast, exporting nearly 90% of fasteners to the U.S. and Europe, Taiwan can reference China’s experience and explore overseas regions other than the U.S. and Europe to be able to cope with future drastic changes. The emerging countries will become a niche market for both China and Taiwan in need of increasing export destinations.

Using the wrong power tool by the assembler can cause many fasteners to fail. There are several new types of nut runners and socket drivers on the market that have a wide range of power and torque output options. Having too much torque can cause unwanted failures.

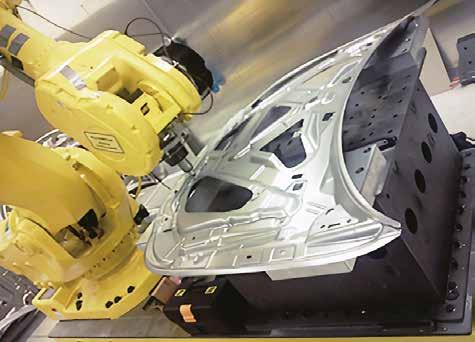

Modern assembly plants use the more sophisticated power tools than those used in maintenance. Most of these tools are digital and will indicate the sequence and pattern to tighten the bolts as well as the torque applied. For example, if #2 bolt is missed in a programmed sequence, the tool will not allow the #3 fastener to be tightened until the #2 fastener is tightened first. This is a well-designed program of sequence tightening for multiple fasteners in a connection.

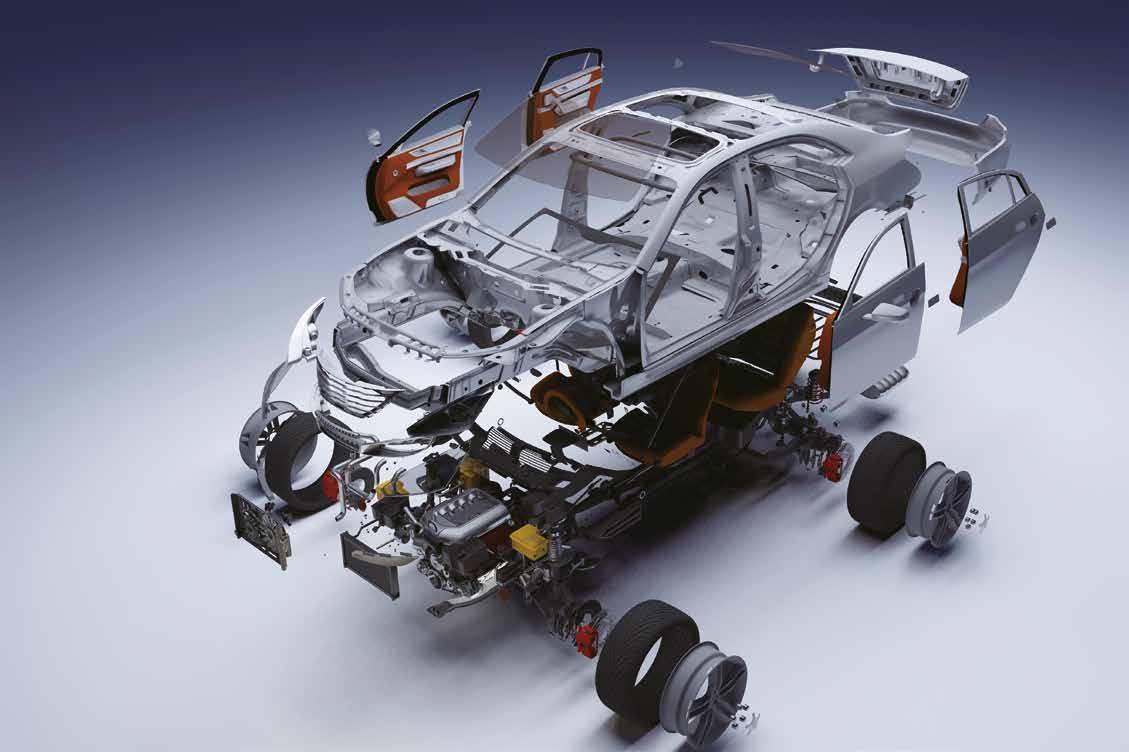

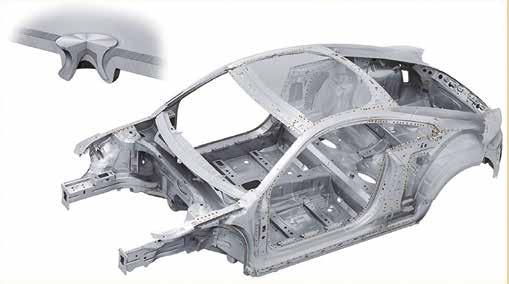

Automotive assembly lines use these types of tools as well as gang nuts or socket runners. This is where several sockets are attached to multiple bolts in the assembly at the same time, such as head bolts on an engine or wheel nuts, then slowly torque all down at the same time. This reduces elastic rebound on critical part assemblies.

Nut runners and powered screw drivers are power assisted tools driven either by pneumatic or electrical energy. The nut runners produce low torque that can be very accurate. These are used to tighten nuts, flanged head screws and small socket head fasteners below ½” or 12 mm on sheet metal parts.

Many earlier nut runners were corded but the DC powered battery tools are more portable and ergonomically easy to use in tight areas.

The more sophisticated DC electric tools are programmable, store multiple torque values, have a data base used for error-proofing and some models will have linear translators for x-y positioning.

The more common and less expensive DC power tools are powered by 20 volt rechargeable Lithium batteries. These tools are mostly used by contractors and maintenance and the majority of which are not adjustable for output speed. If the user is not careful, the heads of small screws can easily become twisted off, such as deck screws and wood screws. If the user is tightening deck screws, etc. with a ½” 20v drill body, there could be many failures.

Comparing the specifications of different well known manufacturers; one ½” drive 20v power tool has an RPM range of 400-1200-1900 and delivers initial impacts of 700-1200 lb-ft of torque, another will deliver 600 lb-ft of torque but only 330 lb-ft initial torque adjustable in pre-set ranges from 0-900-2,000 RPM.

Other models will provide their torque output in inch-pounds, such as 1825 lb-in (152 lb-ft.) or 1400 lb-in (116 lb-ft). There are even ¼” drive 12v models which produce 1300 lb-in (108 lb-ft) that are very adequate to do the job quickly and efficiently for smaller fasteners.

Most pneumatic power tools are commonly known as impact wrenches. These are air driven power tools which produce repeated output blows on an output anvil. The ½” drive models are commonly used in automotive repair shops, truck shops for glider kit (frame) building and tire mounting shops. Some larger models are used to tighten large bolts up to 1 ½” (38 mm).

The advantages of pneumatic power tools are their high torque and high speed. A ½” drive medium duty air driver will produce 600 lb-ft of torque at 7,300 RPM with 1,000 beats per minute (BPM). This is enough torque to destroy any Grade 8 bolt up to 7/8”. The ½” Heavy Duty model will produce 650 lb-ft of torque at 7,500 RPM with 1,100 BPM. There are some older models which produce 450 lb-ft of torque.

A ¾” drive air impact wrench will produce 1,000 lb-ft of torque at 6,200 RPM with 750 BPM. On the smaller side, the 3/8” air ratchet will produce 65 lb-ft of torque.

The disadvantage of pneumatic power wrenches is that there are no torque controls on the more common and less expensive models. The output is inaccurate and can change

while in use. There are more expensive models that can adjust the output torque. The advantage is power and speed for larger fasteners and for removing rusty, old bolts.

The air supply for these power tools comes from a generator which compresses air into a storage tank.

The air is held at a certain pressure, usually around 115-120 pounds-persquare-inch (psi). When the air tool demands power, the compressor tank delivers the air at the stored pressure.

The pressure will naturally drop while being used to a pre-determined amount, usually around 90 psi, at which point the compressor starts up again to regenerate the pressure to 120 psi.

It should be noted that tightening several fasteners at this time will result in unequal assembly torques.

If another air tool or vehicle lift is operated at the same time, the pressure drops more rapidly and the torque disparity is even greater.

Larger shops will probably employ the industrial heavy duty two-stage compressor that will keep more of a constant pressure than the common single stage shop compressor.

Torque wrenches are available in two categories: manual and torque angle. The manual wrench is the most common and is available in many styles: the basic style has a moveable arm against a scale, some have an adjustable spring that is calibrated to dial in a torque value to where the wrench produces a ‘click’ when the value has been reached, some have a dial gauge that measures and marks on and off-torque which can be read after torquing and another type that is electronic which translates data into a control module for error-proofing.

Most are low in cost, portable and can get into tight areas. The accuracy will range from ± 2-20% depending on model and cost. Calibration on the click-type will be lost if dropped; others may be damaged beyond normal repair.

All manual wrenches depend upon the operator and installation variables. The wrench will always ‘see’ 100% of the torque. It does not detect variations of friction. The operator can go fast or slow or vary the speed between bolts. The operator may switch from torquing the nut to torquing the bolt head. All of these have a direct response to accuracy and clamp load.

All torque values are to be used as a guide only. Most are determined of clean and dry threads or ‘as received’. The only accurate use of any manual torque wrench is when the bolt threads are lubricated with a known lubricant.

Torque is a function of friction. Friction can come from debris, burrs, etc. A lubricant will overcome most types of assembly friction encountered and produce consistent clamp loads.

All engine torque values cited in repair manuals are considered ‘wet’ torques, yet the head bolts, connecting rod bolts, etc. do not loosen because the clamp loads are all equal and consistent using the oil as a lubricant. Products like C5A, Moly-Lube, etc. will accomplish the same type of consistency and are very accurate. Just be sure the proper lower torque values are used for the type of lubricant used.

This type of wrench is connected to a data processor which measures the torque applied to the rotational angle that the nut or bolt has turned. This is the most accurate tool used for solid and stiff joints. In most cases the turn will negate friction variables, which is why a pre-torque is first applied to establish a hard base without any further joint compression.

However, in some cases it will not always mean that the preload has been achieved. This depends upon how the data is monitored. If the torque and angle have been achieved within a certain percent window, then the joint is good.

However, if the angle goes significantly beyond the expected tolerance to achieve the proper torque, this means the joint was not solid and there was interference between the joint, such as a burr or even non-conforming part that produced compression or resistance. If the torque becomes high and the angle was not reached, then this could mean debris in the threads, cross threading or something

else that needs to be investigated. If none of these anomalies are noticed and the operator just inputs on torque alone, then there are problems later.

Naturally, if there are complaints of fasteners failing or an assembly failing, check the type of tool used and compressor if it is a pneumatic tool. The bottom line is, when there becomes a rash of failures on a certain product line, without any other complaints, always ask how it was installed and what tools were used. The majority of times it is an operator and equipment error.

Article by Guy Avellon / Copyright owned by Fastener World

Cyun Hong Enterprise Co., Ltd. is a professional industrialuse casters manufacturer in Taiwan. It is headquartered in Taichung City and has two branches in Taoyuan and Kaohsiung. It manufactures casters mainly made from TPR rubber, PU, nylon, or other high-temperature resistant and electricity conductive rubber. The specifications it can currently offer fall within 1.5”-8”. If customers need bespoken service, it is also able to provide necessary service in the R&D of unique spec. products.

As Cyun Hong’s products are comprehensively used in equipment fabrication, conventional machinery, electronics, logistics, and food processing industries, which, compared to others, tend to be more stringent in quality requirements, Cyun Hong already had its products delivered to the third party units for SGS and RoHS tests years ago and has successfully gained the certificates for their loading ability and any relevant parameters that are likely to influence performance of products such as materials, speed, temperature resistance. For certain product categories, if customers need, it can also provide data about durability or service life of products.

“With the approval of certification units along with official reports, our customers can rest assured to use our products, which is also the mission statement of our operation,” Cyun Hong said.

Innovative design has been always one of the main reasons that Cyun Hong wins global customers’ admiration. In order to achieve better high product quality, Cyun Hong introduced CAE software in R&D to modify, analyze, and optimize design on one hand, and dedicated to the collaboration with relevant academic units to get research results obtained from their professional devices on the other hand, continuously optimizing products to respond to market demands and quality standards.

“Through the use of CAE and collaboration with the academia, we are able to stay connected to the development of the ever-changing market and accelerate the release of new products. We also devote ourselves to continuous improvement and innovation and develop patented structural design to enhance the added value of products and make our new product R&D quicker with less effort. For example, the bearings we use allow smoother operation and better loading ability during rolling or turning and the initiating effort resistance can be also reduced, creating a more labor-saving result for users,” said Cyun Hong.

Cyun Hong’s customers are mainly from the semiconductor, automated equipment, traditional machinery, electronics, logistics, as well as food processing, sports utilities, game consoles, aerospace, glass processing, butchery, catering industries, etc. In the future it also plans to develop more overseas customers and establish close collaborative approaches to promote the use of its high quality casters in more international markets.

Cyun Hong contact: Mr. Chien-Hung Chen Email: ch.casters@msa.hinet.net

by Gang Hao Chang, Vice Editor-in-Chief of Fastener World

by Gang Hao Chang, Vice Editor-in-Chief of Fastener World

Global Electric Tool Market Scale to Reach USD 43.2 Billion in 5 Years

Astute Analytica, an analysis company, predicts the global electric tool market scale will reach USD 43.2 billion by 2017 at an annual growth rate of 5.2%. One of the primary contributors is the fact that the global construction industry is increasing the use of cordless electric tools and wrenches.

The electric tool market can be mainly broken down into North America, Asia Pacific, the Middle East, Africa and South Africa. North America has increased industry development and infrastructure and therefore shares 31% of the global market. Asia Pacific has the fastest growth speed at 6.8% driven by rapid automotive industry development, and within this region, the fastest growers are China and India.

China Association of Automobile Man ufacturers’ statistics reveal an uptrend in China’s car export in June 2022. “New Energy Car” has been the highlight of China’s export in recent years. Some of the Chinese automakers have made it into Europe and other regions. In the first half of 2022, China’s new energy car export grew 130%, taking up 16.6% of all China’s car export.

The data released by the Association shows that China manufactured 12.11 million units of vehicles and sold 12.05 million units of vehicles in the first half year of 2022. In terms of export, China set a new record in June in which the Chinese automakers exported 249 thousand units of vehicles, up 57.4%. This includes 198 thousand units of passenger cars that were exported, up 65.6%, and 51 thousand units of commercial cars, up 32.4%. In the first half of 2022, Chinese automakers exported a total of 1.218 million units of cars, up 47.1%. “The Russia-Ukraine war affected part of our export market, but from what we’ve heard from the automakers, they are doing well with oversea orders that don’t appear to reduce in number,” said the vice secretary of the Association.

The drastic growth of Chinese new energy car export was also attributed to Tesla. In 2021, Tesla Giga Shanghai delivered a total of 480 thousand units of vehicles, one third among which were exported to Europe and Asia Pacific. It is worth noting that the number of export, 163 thousand units of vehicles, represent half of all new energy cars exported by China in 2021. In the first 5 months of 2022, Tesla Giga Shanghai exported 96,214 new cars as compared to 36,753 cars exported in the same period last year. Since Tesla Giga Shanghai resumed production, Tesla has outperformed the record in its monthly sales it reached before the pandemic.

The first half of 2022 was a rough time for the European new car market. According to the data by JATO Dynamics, new car registration dipped 14% from the same period last year, landing at 5.54 million registered cars across 27 countries. SUVs and EVs were a main factor preventing a further decrease. SUVs had 4% less registration compared to the last period, taking up nearly 50% of the total registration. EV registration increased from 485 thousand

vehicles to 633 thousand vehicles, up 31%, taking up 11.4% of the whole BEV market share, and up nearly 4 percentage points from a year ago.

The uptrend of BEV demand doesn’t equally benefit all carmakers. Although Tesla still holds a large chunk of EV sales, its growth rate is lower than the market’s average. With issues in new car supply due to the production halt in China as well as the increased number of market competitors, Tesla’s market share dropped from 13.75% in the first half of 2021 to 13.33% in the first half of 2022.

On August 9, 2022, Guatemalan Congress approved Decree 40-2022, which contains the Law on Incentives for Electric Mobility offering tax inducements on the importation, sale, and use of electric vehicles or those that run on hydrogen as well as hybrid cars. Tax benefits include exemption from the Value Added Tax on the purchase and sale of such vehicles, their parts and chargers, and the Value Added Tax on their importation.

According to AMEGUA, in Guatemala there are 2,500 hybrid cars, 145 BEVs, 770 electric scooters and 15 charging stations. The country sold 510 hybrid cars in Q1 2022, up from 92 hybrid cars in 2021.

CEO Musk said Tesla’s production will reach 2 million vehicles this year. He also said he “might be able to announce a new factory construction”. He said that at the end of the day, Tesla will have 10 to 12 megafactories. “Tesla is interested in purchasing companies in the field of technology and AI, and could repurchase stocks in the future depending on cash flow status.

In Taiwan, a company has to trade its shares on the emerging market for at least six months before it can be listed on the main stock exchange or over-the-counter market. Manufacturing industrial adjustable wrenches, pliers, screwdrivers, hexagon socket wrenches, sockets and tool boxes, Proxene began listing its stocks on the emerging market from August 8 at a reference price of NTD 63.5. Its consolidated net profit after tax in the firsthalf 2022 was NTD 83.08 million with an EPS of NTD 5.03, consolidated revenue at NTD 451 million and gross profit margin at 31.17%. In 2021 the company grossed NTD 810 million.

Exporting 80% of its products mostly to the U.S. and Europe, Proxene supplies to global adjustable wrench brands. The company started in 1984 and set up a branch in 2017. It invested NTD 700800 million in a new plant which integrates smart manufacturing.

Uni-axis Auto Screw Fastening Device can be mounted on small vertical multi-joint robots. It weighs lighter and reduces 23% carbon emission. The user can change fastening thrust and set fastening torque and speed. The vacuum suction type FM514VZ model is suited for tight and deep places; the chuck-claw type FM514CZ model is suited for fastening flat surfaces. Screws are fed one by one from the feeder to the fastening unit through air pressure for automatic screw fastening tailored to each product.

General pipe wrenches rely on operators to get a feel for them. The aging of operators could lead to inconsistent quality or insufficient fastening. KTC (Kyoto Tool Co.) worked with Osaka Gas Network and successfully developed a torque wrench for threaded pipes which “clicks” on completion of fastening to ensure consistent operation. Furthermore, the product is strong by design to hold through heavy rain and other severe weather.

The Japanese have to replace large vehicle wheels with the ones for winter before the cold season arrives. The wheel nuts in use for a long time would be rusty from snow melting agent and hard to loosen up. The huge demand for tire replacement in this period would put a lot of loads on impact wrenches. Plus, there are users that claimed impact wrenches are “too heavy, time-consuming due to low torque, easy to act up and costs much for repair.” To that, Vessel has rolled out “SP-390DX” 25.4mm Impact Wrench.

The product’s anvil length shrinks from 8 to 6 inches to reduce torque loss during fastening. The anvil is hollow by design to reduce weight. The diameter of the air duct is increased, and the heat treatment to the air motor and rotor blade is optimized to improve torque via smooth rotation.

The ThreadChecker by Kaman Precision Products is a teachable eddy current inspection tool, widely used for thread detection, plating presence, and absence of heat treatment, as examples. Any physical property difference that relates to material conductivity is readily detected. The ThreadChecker is ideal for use in any automated inspection process in manu facturing.

Consisting of a single electronics module compatible with any probe/material combination, the ThreadChecker can check threads regardless of part cleanliness, reducing the cost of implementation. It features five internal probes, ranging from 2 to 10 millimeters (mm) and two external probes, 6mm and 8mm. Available with a rail mounting option, Thread Checker is CE-compliant and features IP-67 rated probes and electronics.

Martina McIsaac, Region Head and Chief Executive Officer of Hilti North America, has resigned her position effective October 1, 2022. Mike McGowan, currently Senior Vice President and General Manager of the Hilti North America East Market Organization, has been promoted to Region Head and Chief Executive Officer of Hilti North America effective October 1, 2022. In this role he will additionally serve on the Hilti Group Executive Management Team. Mike was chosen after a comprehensive internal search for a candidate with a proven track record of success, deep understanding of the construction business and commitment to company culture.

Mike joined Hilti in 1988 as a Hilti Store Sales Associate and was regularly promoted to positions of increasing responsibility in sales and marketing before taking the top spot for Hilti’s eastern United States business in 2002. Mike’s experience in consistently developing and leading a diverse and inclusive team capable of sustained performance is unmatched.

His market organization consistently ranks in the top five most successful geographies in the Hilti Group.

“For more than 35 years, I have been committed to Hilti, its team members, and its customers. Since the early days of my career, the construction industry has been my passion. I look forward to continuing to build on an already strong foundation of success by working alongside the more than 4,000 team members who have chosen to make Hilti North America their professional home,” said McGowan.

TriMas announced that TriMas Aerospace’s Allfast Fastening Systems business has received a 2021 Supply Chain Performance Achievement Certificate from The Boeing Company for the tenth consecutive year. Boeing issues the award annually to recognize suppliers who have achieved superior performance each year. Allfast Fastening Systems maintained a Silver composite performance rating for each month of the 12-month performance period from January to December 2021.

“This recognition acknowledges our commitment to our customers to consistently provide superior quality, on-time delivery, flexibility and outstanding service,” said John Schaefer, President of TriMas Aerospace. “Our Allfast team tirelessly focuses on operational excellence and customer satisfaction, and we’re grateful for their hard work and dedication. We thank Boeing for this recognition and look forward to continuing to partner on innovative fastener solutions.”

TriMas Aerospace designs, engineers and manufactures engineered ducts and fasteners for the global commercial and military aerospace industry under the following leading brands: RSA Engineered Products, Monogram Aerospace Fasteners™, Allfast Fastening Systems®, Mac Fasteners™, TFI Aerospace and Martinic Engineering™.

flowable pre-applied threadlocker, Loctite DRI 2250-W, is a medium to high strength pre-applied threadlocker that has been created to meet automotive specification requirements.

Loctite DRI 2250-W offers high temperature resistance of over 200ºC and has excellent chemical resistance. Scott Simmons, Business Development Manager, North America, describes how its superior High Temperature Resistance addresses customers’ frustrations with competing products: “Traditional products fail to maintain room temperature (RT) breakloose strength and can typically lose around 50 percent – and in some cases even more –of their strength at 150ºC. By contrast, DRI 2250-W maintains RT strength beyond 150ºC and in most cases can achieve this up to 200ºC.”

Further advantages of Loctite DRI 2250-W include its low coefficient of friction. Tested on multiple plating surfaces, the material maintains a coefficient of friction between 0.10 – 0.16. It also shows superior performance on all plating types, including the newer zinc-flake coating, with added lubricity.

As a pre-applied film, the threadlocker is dry-to-the-touch and remains an inert coating until assembly. During assembly, microcapsules contained within the coating are crushed and release an active ingredient that initiates the anaerobic curing process. When cured, Loctite DRI 2250-W also acts as a thread sealant as well as a threadlocker. It eliminates the need to apply liquid sealants, adhesives, or any other mechanical locking or sealing device to threaded parts during manual or automatic assembly and is flow coatable for higher output speeds.

DRI 2250-W

Henkel has introduced a breakthrough product to its comprehensive range of automotive pre-applied threadlocker coatings that brings the high-speed throughput of a flowable product with the sustainability advan tages of a water-based material. The first ever water-based

Jaime Ramirez, Executive Vice President and President, Tools & Storage, stepped down from his role to pursue opportunities outside of the Company, effective July 22, 2022. Robert Raff, a 20-year Stanley Black & Decker veteran and currently Head of Stanley Outdoor Integration, will be appointed Acting Executive Vice President and President, Tools. Mr. Raff will work closely with Donald Allan, President and CEO of Stanley Black & Decker, to help drive execution of the Company’s strategy focused on the growth of its core businesses.

Robert Raff currently serves as Head of Stanley Outdoor Integration, a role he has held since August 2021. Over the past 20 years, Mr. Raff has served in various leadership roles across Stanley Black & Decker including President, Stanley Security; President, Convergent Security Solutions; President, North America

Commercial Global Tools & Storage; President, Hardware and other roles.

The Company has retained Heidrick & Struggles to conduct an internal and external search for a permanent successor to Mr. Ramirez.

over the 132-member jury, made up of independent experts from all over the world, with its innovative and appealing product design of the buttonless, narrow shape concept.

This makes it much easier for professional users from industry and trade to access narrow and confined spaces during installations. Particularly smooth and parallel jaws also avoid damage to sensitive surfaces. Width adjustment directly on the workpiece makes work more efficient. A ratchet function enables fast screwing without regripping. Pressing & bending tasks take minimum effort thanks to the tenfold increase in manual force. After the German Design Award 2022, this is now the second international award for Wiha product development.

Wiha is a winner of this year’s iF DESIGN AWARD, the world-renowned design prize. The winning product, the Wiha Pliers Wrench Family, won in the discipline “Product”, in the “Industry/Tools”. Each year, the world’s oldest independent design organization, Hannover-based iF International Forum Design GmbH, organizes the iF DESIGN AWARD. The Wiha Pliers Wrench Family won

Klein Tools, for professionals since 1857, introduces the 27in-1 Precision Multi-Bit Screwdriver, which houses all the bits you need for everyday precision driving, plus an integrated 3.5 mm nut driver.

Features:

1. On-board storage of 26 different precision tips and a 3.5 mm nut driver

Barrel contains powerful Rare-Earth magnets for securing

No.

to

Holdings

advanced processes and improve productivity, announced the completion of the previously announced acquisition of Atotech Limited for approximately US$4.4 billion in cash and MKS common stock. Atotech is a global leader in process chemicals, equipment, software and services for printed circuit boards, semiconductor IC packaging, and surface finishing.

Koki Holdings America Ltd., announced a merger of two organizations, Metabo HPT and Metabo Power Tools in North America. Effective December 2022, both brands will operate their headquarters, factory service center and distribution functions from state-of-the-art facility in Braselton, GA, located north of Atlanta. This will support the expansion and continuity of both brands and increase value to our partners.

By integrating operations, both brands will continue to support retailers and end users with world-class power tools for the residential/multifamily construction market and the metal working/industrial markets. This unification will enhance value across the organization, driving new business opportunities for existing Metabo HPT and Metabo customers.

MKS Instruments, Inc., a global provider of technologies that enable

“The acquisition of Atotech positions MKS to accelerate roadmaps for future generations of advanced electronics devices,” said John T.C. Lee, President and CEO of MKS. “By combining leading capabilities in lasers, optics, motion and now process chemistry, MKS is set to be a leader in the next frontier for miniaturization and complexity: Optimizing the InterconnectSM, a significant enabling point of nextgeneration advanced electronics. Atotech’s leadership in functional and decorative surface finishing will also extend MKS’ product offering for industrial applications and grow our market reach. I could not be more excited to welcome the Atotech team to the MKS family.”

MSC Industrial Supply Co., a premier distributor of Metalworking and Maintenance, Repair and Operations supplies to industrial customers throughout North America, announced that it has acquired Tower Fasteners, a Holtsville, New Yorkbased valued-added distributor of Original Equipment Manufacturer (OEM) fasteners and components.

Under the equity purchase agreement, Tower will continue to operate under its current name after becoming an MSC company. Mark Shannon, President of Tower, will continue to lead the business, which has approximately 100 associates. Tower’s revenue in calendar 2021 was approximately US$35 million. MSC’s acquisition of Tower, made through its All Integrated Solutions (AIS) subsidiary, expands the company’s presence in the OEM fastener market, which it entered in 2018 with the acquisition of AIS, a leading value-added distributor of industrial fasteners and components, MRO supplies and assembly tools based in Wisconsin.

Tower’s growing footprint complements AIS’s existing locations concentrated in the Midwest. The company operates eight distribution centers along the East Coast and in the Southwestern regions of the United States, Mexico and Europe. Tower serves manufacturers in the industrial, electronics, medical equipment, aerospace, military, and security, fire and safety sectors. MSC plans to maintain Tower’s operations, providing the company’s customer base access to MSC’s 2 million-plus product portfolio to support their full metalworking and MRO needs. Similarly, MSC will extend Tower’s production fastener solutions to its manufacturing customers. The acquisition is expected to be roughly neutral to MSC’s fiscal 2022 earnings and slightly accretive to fiscal 2023 earnings.

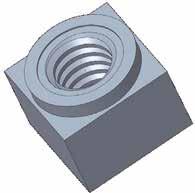

The Murphy screws principle says: “If you are looking for four identical screws, you will definitely find only three.”

In such a case, the question of the interchangeability of the screws and the tightening tools is legitimate. However, as we will see below, not all bolts/nuts and tightening tools are interchangeable. In this article, we will try to specify it in concrete cases.

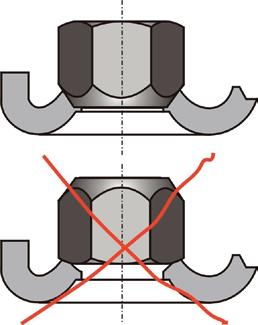

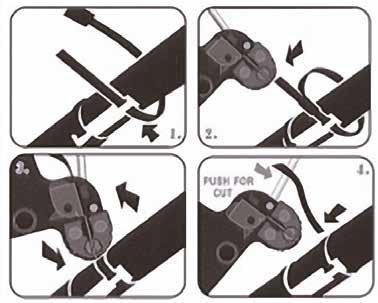

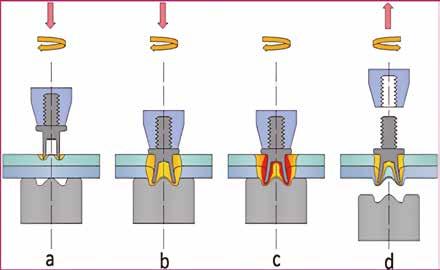

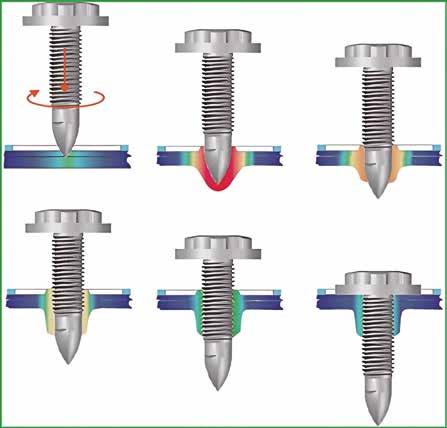

A frequent source of errors is the cross groove on screws. Many people, even professionals, think that there is a universal type of cross slot and they can use with any cross screwdrivers. Despite their similar appearance, these two systems are not interchangeable (Fig. 1). The expert has surely already noticed why. The reason for this is the different shapes of the glossy contact surfaces of the PH (Phillips) and PZ (Pozidrive) systems. Interchanging them could damage not only the bit itself, but also the tightening groove on the screw. And the worst solution would be to use a flat screwdriver for a cross slot. Unfortunately, this also happens in practice.

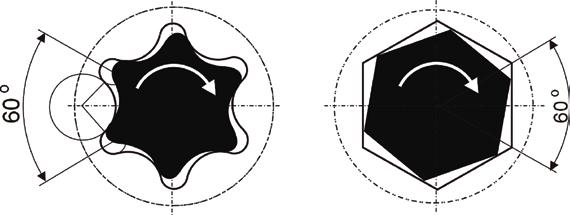

Another example of prohibited interchange is incorrect orientation of fastening nuts of vehicles wheels ( Fig. 4 ). Wrong assembly direction can cause loosening of the wheel during movement. Official statistics do not show the full truth, because there are not many drivers, who will admit that loosening of the wheel was their fault.

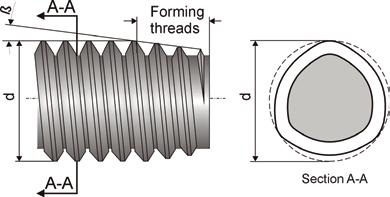

Example of possible interchange is trilobular screw (Fig. 5). Special property of this type of trilobular screw is the ability to make counter

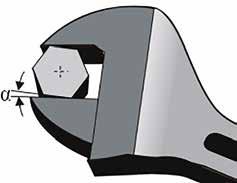

As you can see in Fig. 2, screws are often tightened by popular French keys. It is important to highlight though that it is not advised to use this assembly tool multiple times, because the edges are being damaged quickly (transmission of torque is done only trough the edge). It is nicely demonstrated by Fig. 3a. For this reason, tightening with arc-screw ( Fig. 3b ) is much better (transmission of torque is done through bigger surface).

counter threads during assembly by rolling - without making splinters. It is interchangeable with any other metrical screw of the same diameter. Trilobular screws can in extreme cases be used as a tool to make internal threads.

The Screw with threads dedicated to plastic (Fig. 6) is not interchangeable by any other. In the case where it happens, cracks can emerge in the plastic (Fig. 7).

A s we have seen, there are many ways to use screws and screw drivers wrongly. There are many cases of impossible interchangeability. Not knowing about interchangeability can be damaging to both screws and screw drivers, which can further lead to collapse of construction units. A common example is bad application of fastening screws/nuts of automobile wheels, which can, for the reason of poor application of tightening moment or use of bad strength class, lead to very dangerous loosening of the wheel.

Article by Jozef Dominik and Dominik Makuka / Copyright owned by Fastener World

A:The value of tightening torque changes with the target axial bolt force and the nominal diameter of the threads. Specifically, we can calculate the tightening torque required for fastening by multiplying the product of axial force and nominal diameter by a coefficient called “nut factor”. This expression is the simplified form of an exact equation derived from the balances of the forces and torques on the thread surface and nut bearing surface. The most commonly-used numeric value for the nut factor is 0.2. This value corresponds to a standard value of coefficient of friction, i.e., 0.15, but note that the nut factor greatly changes according to coefficient of friction.

friction. Using the expression and supposing that the coefficients of friction of the thread surface and nut bearing surface are both 0.15 and 0.3, the amounts of nut factor are found to be 0.2 and 0.381. Consequently, when a bolted joint's coefficient of friction changes from 0.15 to 0.3 because of the increase of the surface roughness due to tightening and loosening, only 52% of the target axial force is generated even if you apply the same torque. We can also say that “even if we apply the same torque, the axial force to be generated is almost inversely proportional to coefficient of friction.” This is a noteworthy phenomenon in a bolted joint which is repeatedly fastened and loosened. Contrary to the above case, the coefficient of friction could become smaller than the initial value. In that case, we must pay attention to plastic deformation due to the excessive axial force.

The mechanically exact expression, which shows the relationship between axial bolt force and tightening torque, contains the term pertaining to the friction on the thread surface and nut bearing surface, in addition to the term pertaining to the axial force generated when the male thread climbs up the inclined surface. This is a complex expression involving trigonometric functions, and therefore we usually use the simplified expression (Tightening torque = nut factor x axial force x thread nominal diameter). Consequently, nut factor can be regarded as a coefficient for calculating tightening torque for a given axial bolt force and the size of threads to be used. The value of nut factor K changes because of several reasons, but practically speaking, we can calculate it as the functions of thread surface's COF, μ th, and nut bearing surface's COF, μ nu. This expression is derived by applying a statistical method called least squares method to the exact expression showing the relationship between axial force and torque. The constants in the expression represent the components by which the torque is converted to axial force. It suggests, therefore, that most of the tightening torque is consumed as friction works.

That is right. When fastening threads, the male threads move up the thread surface along the helix, thereby generating axial force. The lead angle, which is the spiral angle of thread surface, is usually from 2 to 3 degrees. On the other hand, the male threads move down along the thread surface when being loosened; therefore, the loosening torque is usually smaller than the tightening torque. The ratio of the two torques can be calculated using an expression derived mechanically. For instance, when the coefficient of friction ranges from 0.1 to around 0.2, we can loosen the threads with a torque which is from 70% to 80% of the tightening torque. The ratio of the two torques decreases with smaller coefficient of friction and smaller nominal diameter. In contrast, the ratio gets quite large in fine threads. If you feel the loosening torque is too large, you should suspect the occurrence of “seizure of threaded fasteners”.

This is because “even if you apply the same tightening torque, the value of axial force changes with coefficient of friction”. As shown in the above expression, the nut factor is expressed as the function of coefficient of

1. Toshimichi Fukuoka, "Threaded Fasteners for Engineers and Design – Solid Mechanics and Numerical Analysis –", pp.76-100, Corona Publishing Co., Ltd. (2015)

Article by Toshimichi Fukuoka Copyright owned by Fastener WorldQ1: Tell me how to determine the value of tightening torque.

Q2: I don’t understand what a nut factor means. How does it affect fastening operation?

Q3: For the purpose of inspection, I fastened the loosened threads again using the same amount of torque in the initial tightening operation, but it turned out the obtained axial force is insufficient. Why is that?

Hardware and Fastening Tools are mostly used in assembly operations in construction, automotive and other industries where versatility in operations is required to the great extent. Moreover, increasing use of bolting and tooling across the electronics and electrical equipment manufacturing has paved the way for fastening tools in the commercial and residential sector.

Fastening tools are generally made from materials including alloy or plastic and fibers which provide extra sturdiness to equipment handling and is most popular among workers for its reliability.

The hardware and fastening tools market is driven by factors such as rising demand for saving time and improving accuracy and efficiency, growing industrial activities, increasing construction and infrastructure activities, rising use of fastening tools in the automotive, DIY, and electrical industries. On the other hand, high costs of advanced hardware and tools and lack of awareness among users is hindering market growth.

One of the major segments, the power tools market, was valued at USD3721.31 million in 2021 in the Middle East and Africa market and it is projected to reach USD5307.17 million by 2029, registering a CAGR of 6.10% from 2022 to 2029. In the same region, drilling and fastening tools account for the largest type segment in the end-use industry owing to their ease of use and because they are cheaper as compared to other power tools. Increasing applica tions of fastening power tools in the aerospace and defense industry, semicon ductors industry and others for maintaining the safety and accuracy of heavy machinery are the major demand drivers for the market.

In Egypt, on the basis of types, the hardware and fastening tools market in Egypt is mainly divided into mechanical, hydraulic, pneumatic, and electric segments. The market for pneumatic tools is expected to grow faster as these tools are durable enough to tolerate in severe (on-site) conditions such as oil & gas, construction and power generation. The hardware in the electric segment continues owing to its features such as density, accuracy, less noise, and quality assurance.

Growth in the E-commerce industry and rising investment in research and development (R&D) is expected to create opportunities for the market in the

future more specifically in the DIY sector. Revenue in the DIY & Hardware Store market amounts to USD16.67 billion in 2022. The market is expected to grow annually by 5.31% (CAGR 2022-2027). In the global comparison, most revenue is generated in China with the value of USD710 billion in 2022.

In value terms, China constituted the largest supplier of hand tools to Egypt, comprising 65% of the total imports. The second position in the ranking was taken by India, with a 6.7% share of the total imports. It was followed by Taiwan, with a 4.7% share. In value terms, Sudan remains the key foreign market for hand tools exports from Egypt, comprising 39% of the total exports. The second position in the ranking was held by the United States, with a 17% share of the total exports. It was followed by the UK, with a 13% share. In 2021, the average hand tools export

price amounted to USD23,838 per ton, with an increase of 195% against the previous year. In 2021, the average hand tools import price amounted to USD2,915 per ton, almost unchanged from the previous year. In 2021, Egypt imported hand-operated spanners and wrenches with the value of USD6.81 million, and USD2.78 million of files, rasps, and pliers. Egypt imported more than USD21 million of tools, interchangeable, for hand tools such as tools for pressing, stamping, punching, tapping, threading, drilling, boring, broaching, milling, turning and screw driving.

The following chart exhibits the value of imports (in thousand US Dollar) to Egypt for major three categories of fastening tools within the last five years:

Increasing adoption of protective equipment for workers at sites and strict regulations for equipment manufacturing are the main factors driving the de mand for the power tools in the market. In addition, increasing developments in tooling technology and the development of hybrid fasteners by prominent players in the market which are used in different sectors for minimal effort and high speed of work are the growth drivers for the market.

High value of fastening power tools and increasing implementation of mechanization across the global industries are the key restraining factors for the market. On the other hand, advancements in the design of the tools and in creasing electrifications made by emerging players in the market are expected to drive the demand for the market in the future.

The left chart shows the value of pneumatic and hydraulic tools exported to Egypt’s market in the last five years. As illustrated in the chart, the top and the only major exporter is China. In 2020, for instance, more than 85% of the total imports to Egypt’s market has been shipped from China.

In terms of the quantity, last year, Egypt im ported more than 1,452 tons of pneumatic and hydraulic hand tools which is about only 5% less than 2020. The value of exports in 2021, was only USD221,000, of which more than 80% was shipped to Tunisia with the value of USD185,000.

Companies operating in the hardware and fastening tools market are extensively investing in research and development to develop new and innovative techniques to manufacture advanced tools and hardware. The prominent players in the market are utilizing strategies such as product launches, mergers & acquisitions, and contracts & collaborations. These strategies are expected to deliver effective goods and high-performance goods, supporting market laws, and better client satisfaction. The hardware and fastening tools market is extremely fragmented with the pres ence of several manufacturers. Furthermore, manufacturers are trying to gain a competitive edge through increased product differentiation. Manufacturers in Egypt are also aiming at pro viding highly efficient and reliable tools having advanced features to make them user friendly, and provide fast, accurate, and safe applications.

in

were ruled by the

is more than 656 million.

and

The main importer of this category was Brazil. It imported 17.9% of the whole tools in this category and its import value was USD 7.648 million in 2021.

Chile was the 2nd biggest importer in Latin America in this sector. The value of its imported tools value in this sector was USD 6.775 million and it bought 15.8% of the whole imported tools in 2021.

Peru as the 3rd biggest importer bought 14.0% of the whole imported tools and its value was USD 5.982 million in 2021.

Argentina as the 4th biggest market for these types of tools bought USD 3.279 million worth of tools and it purchased 7.7% of the whole tools sold in Latin America.

Other countries in this region bought USD 19.067 million of tools and its share was 7.7%.

In this category of tools, 5% of the world’s total imports were sent to Latin America. In 2021, after two years of import decline, the purchase of this type of goods increased by 60.7% in Latin America, and the value of this category was 71.488 million dollars.

5 countries accounted for more than 60% of the imports in this category.

Brazil ranked first with the imports worth USD 8.728 million in total and a share of 19.8% of all imports to Latin America in 2021.

Chile ranked second in this type of tools and its import value was USD 7.891 million, which represented 17.9% of the total import of this category.

Peru ranked third with a 9% share of imports, whose import value was USD 3.984 million in 2021.

Argentina with 7.5% and Ecuador with 6.7% were in the next ranks. Argentina’s import value was equal to USD 3.314 million and Ecuador’s import value was USD 2.969 million in 2021.

Other Latin American countries had an import share of 39%, equivalent to USD 17.215 million in 2021.

The share of Latin American exports in this category was 0.6% and its export value was equivalent to USD 9.791 million in 2021.

Export 2,017

World 1,306,528 1,423,799 1,412,849 1,333,136 1,736,268

Latin America 11,722 9,945 10,191 7,611 9,791

YoY Ratio -15.2% 2.5% -25.3% 28.6%

Brazil was the main market of these type of tools. Its import value was USD 19.105 million and it represented 26.7% of the whole import of tools to Latin America.

Chile with the purchase of USD 12.815 million worth of tools was ranked 2nd and it represented 17.9% of the whole Latin America market.

Peru was ranked 3rd with a 10.5% market share and the value of its imported tools in this sector was USD 7.523 million.

Other countries in this region had 44.8% of the market share and the market value of USD 32.045 million in 2021.

4.4% of the world’s total imports went to Latin America, which means a value equivalent to USD 44.101 million in 2021. After 2 years of fall in import, in 2021 the import of this type of tools grew by nearly 54%, the highest import value since 2017.

Brazil with 60.6% and Argentina with 26.8% were the two main exporters of this category. The export value of each country was as follows:

Brazil: USD 5.937 million

Argentina: USD 2.621 million

In this category, the value of exported fasteners was USD 4.837 million in 2021, representing 0.7% of the world’s total exports in 2021.

Export 2017

World 542,522 592,009 581,274 540,227 672,004

Latin America 7,178 4,704 5,240 3,566 4,837

YoY

Ratio -34.5% 11.4% -31.9% 35.6%

World

Panama had 48.8% of the Latin America’s export share and Argentina had 24.8%. Panama’s export value was USD 2.360 million and Argentina’s export value was 1.2 million in 2021.

Latin America

USD 2.580

in this category in

the

to

Panama and Brazil were two countries that shared 79% of the exported tools in Latin America.

Panama’s export value was USD 1.771 million and Brazil’s export value was USD 1.198 million in 2021.

Brazil had USD 1.648 million in 2021, which was 63.9% of the whole exported tools in this category. Panama was ranked 2nd with USD 1.391 million in value and 15.2% in market share.

share of Latin America in the whole exports of the world and the value of Latin

million in

Latin America could recover its numbers very soon (see the numbers in 2021) which means that it is an agile region. Hence, equipment manufacturers have an opportunity to empower fastener manufacturers through investing in their factories for improving the numbers as the numbers of export are still low.

Mexico, a country with a population of 128.65 million and GDP of USD 2.61 trillion in 2021, is located in North America. Econo mists believe that the Mexican economy is projected to expand by 1.9% in 2022 and 2.1% in 2023. Consumption will be supported by the gradual improvement in the labour market, remittances, and the increasing share of the population vaccinated. Exports will continue to benefit from deep integration in global value chains and a gradual recovery in tourism. Planned public infrastructure projects will benefit investment. Inflation will stand at 6.9% in 2022 and edge down to 4.4% in 2023.

It means that the fastener industry in Mexico has grown in 2022 and will continue in 2023. The following statistics demon strate the situation of the fastener industry in Mexico.

Mexico’s import was USD 49.388 million in this category. Mexican exporters had started a slow growth since 2017, which stopped in 2020 due to the pandemic and even faced a 19%

in the import value. But after the normalization of conditions in 2021, the import growth was 34%, which brought Mexico back to the pre-pandemic growth conditions.

• China was at the 1st place with 32.8% of Mexico’s import market, and its export value was USD 16.177 million in 2021.

• USA was at the 2nd place with 20.4% of Mexico’s market, and its export value was USD 10.077 million in 2021.

• The 3rd place belonged to Taiwan with the export value of USD 9.926 million, and had 20.1% of the Mexican market in 2021.

• India with USD 4.379 million worth of exported tools in this category had 8.9% of Mexico’s market and it was ranked 4th in 2021.

Regarding the value of Mexico’s export, it was USD 14.837 million in 2021. Mexican exporters had challenges under the effects of the pandemic conditions in 2020 and the economic evil of America in 2019, it aborted its exports by 20% in 2019 and 2020.

Mexican exporters experienced a positive growth of 21% in 2021 with the resolution of these problems.

Export from Mexico 2017 2018 2019 2020 2021 World 14,396 15,148 14,144 12,290 14,837

YoY Ratio 5% -7% -13% 21% Unit: Thousand USD

• USA was the main market of Mexican tools in this category. 64.6% of the exported tools from Mexico were bought buy U.S. consumers in 2021. U.S. import volume was USD 9.591 million.

HS CODE 820412:

Mexico’s import was USD 13.708 million in this category. Its 26% growth of exports in 2021 compensated for the decrease in exports in previous years. The export value of Mexico in 2021 was slightly higher than in 2018.

Export to Mexico 2017 2018 2019 2020 2021 World 11,525 13,120 12,503 10,896 13,708

YoY Ratio 14% -5% -13% 26% Unit: Thousand USD

Four countries had more than 94% of the export of this type of tools to Mexico in 2021.

• China had USD 9.125 million export value to Mexico and it got 66.6% of this market.

• USA had USD 1.980 million export value to Mexico in this type of tools and had 14.4% of its market.

• Spain’s export value in this category was USD 1.168 million with 8.5% of Mexico’s market.

• Taiwan’s export value in this category was 0.663 million with 4.8% of Mexico’s market.

The value of Mexico’s export was USD 1.933 million in 2021 in this category. Statistics reveal that Mexico’s exports had been declining since 2018. Mexico’s export value in 2021 was also lower than in 2017.

Export from Mexico 2017 2018 2019 2020 2021 World 2,357 2,718 2,412 2,177 1,933

YoY Ratio 15% -11% -10% -11%

Unit: Thousand USD

Although USA was the biggest buyer of this type of Mexican tools with the import value of USD 0.367 million. There is no exclusive market for this category. Mexico exports its tools to all Central and South American countries in this segment. (Refer to the list below)

Export from Mexico Year 2021 Share

19.0%

17.5%

15.0%

9.2%

7.0%

6.8%

6.5% Dominican Republic 116 6.0% Unit: Thousand USD

This category, which had an import value of USD 30,958 mil lion, had suffered a significant decrease in 2020 due to the pan demic, but the 44% growth in 2021 had compensated well for the 20% decrease in 2020.

Export to Mexico 2017 2018 2019 2020 2021

World 23,463 25,192 26,936 21,548 30,958

YoY Ratio 7% 7% -20%

Unit: Thousand USD

The following three countries had more than 93% of the Mex ican market.

• Taiwan was the leader of suppliers in this category. It sold USD 16.246 million in 2021 which was 52.5% of the Mexican market.

• China was the 2nd biggest supplier with USD 7.876 million export value and 25.4% of the Mexican market.

• USA was the 3rd biggest supplier with USD 4.696 million export value and 15.2% of the Mexican market

The export of this type of tools in Mexico had an explosive increase in 2020, and its export grew by 150% between 2020 and 2021. In 2020, the value of this category increased to more than USD 10, and the main reason for this growth was the American market.

Import from Mexico 2017 2018 2019 2020 2021

World 4,112 4,660 4,390 4,302 10,738

YoY Ratio 13% -6% -2%

Unit: Thousand USD

• By buying 75.5% of this type of tools from Mexico, the Americans were considered exclusive buyers, the value of America’s purchase from Mexico was USD 8.117 million in 2021.

Mexico had import problems in all categories of tools in 2020. In some categories, problems had arisen since 2019. This catego ry had been an export problem since 2019, but in 2021, Mexico was able to make up for the backwardness of 2019 and 2020. The value of this category was USD 20.445 million which was 30% higher than the year of 2020. Its export had been the highest since 2017.

Export to Mexico 2017 2018 2019 2020 2021

World 18,154 20,003 19,008 15,738 20,445

YoY Ratio

10% -5% -17% 30%

Unit: Thousand USD

• China with 68.6% of the Mexican market was the main supplier of this category, and its export value was USD 14.029 million in 2021.

• Taiwan had 11.5% of the Mexican market. It was ranked in the 2nd place with USD 2.357 million USD in 2021.

• USA with USD 1.539 million and 7.5% of the Mexican market and Germany with USD 1.038 million and 5.1% of the Mexican market were ranked in the 3rd and 4th places respectively.

The export of this type of tools from Mexico increased in 2018 and 2019, but it decreased in 2020 and 2021, considering that 29.2% of this product goes to America, the American market has a relatively decisive role in the amount of exports.

Import from Mexico 2,017 2018 2019 2020 2021 World 2,759 3,247 3,619 3,489 3,118

YoY Ratio 17.7% 11.5% -3.6% -10.6%

Unit: Thousand USD

Mexico sent its tools to these countries:

Import from Mexico 2021 Share

Unit: Thousand USD

Mexico is a good market that grew significantly in 2021, and since one of its suppliers is China or Taiwan, there is a great opportunity to invest in the machinery sector, so that Mexican manufacturers can strengthen their exports.

Article by Sharareh Shahidi HamedaniCopyright owned by Fastener World

“International Hardware Fair Cologne” held in Germany every two years opened its gates again to domestic and foreign exhibitors and industrial professionals after the postponement in 2020 due to the pandemic. This Fair opened on September 25 at Kolnmesse. The 2022 Fair opened from 09/25-27 (time: 09:00-18:00) through 09/28 (time: 09:00-17:00). The organizer opened Halls 3, 10, and 11. According to the organizer’s statistics, there were 1,411 German and international companies coming to exhibit this year, which were mainly from the industry sectors of hand tools/power tools, construction & furniture fittings, fasteners & fixings, factory equipment, products for industrial use, DIY & relevant services for industrial purposes, etc. Taiwanese companies and exhibiting groups were also present to demonstrate their latest hand tools, aftermarket tools, gardening tools, relevant industrial tools, sockets & wrenches, and many other hardware products. Fastener World’s staff onsite also observed at the Fair many market trends for future industrial development especially focused by the industry this year, such as energy saving, carbon emission reduction, environmental protection & sustainability, multiple applications, etc. In accordance with buyers’ various sourcing demands in different markets, our staff onsite took a lot of recently released and printed copies to the Fair, which included “Fastener World Magazine, China Fastener World Magazine, Hardware & Fastener Components Magazine, and Emerging Fastener Markets Magazine.” We also talked with several corporate purchasing reps coming to our stand asking for magazines during the Fair and they told us that they were highly interested in purchasing Taiwanese products featuring high performance/price ratios, excellent design, and high quality and collaborating with these suppliers. They hoped that through those printed copies received from Fastener World and our online B2B purchasing platform, they could understand more about superior products from suppliers based in Taiwan and other countries and establish closer collaboration approaches. They also hoped that through the collaboration with Taiwanese and other countries’ suppliers they could build up a more tenacious and integrated post-pandemic global industry supply chain. The next edition will take place on March 3-6, 2024.

Whale Security has a factory and office building of over 13,000 square meters. As a factory specialized in slideway, hardware components and standard component, its main products include brass padlocks, door locks, furniture locks, automotive locks, computer locks, high security cylinders, and various hardware. With powerful strength, Whale’s products are well received in European and American markets.

Yong Song has been dedicated to the power tools industry in Taiwan since 1992. It is now specialized in making Stapler Series, 16 Gauge Series, Coil Nailer Series, Specialties, Powder Actuated Tool Coil Cap Nailer, Stapler Cap Nailer, Corrugated Fastener Tool, Cap, etc. Yong Song continues to research and develop new products and provide better products to satisfy the needs of customers and the demands of the market.

Leading Tools specializes in high-quality artisan tools, including finishing trowels, notched trowels, pointing and gauging trowels, masonry tools, brick and pointing tools, concrete tools, building tools, and flooring trowel.

Young Cycle’s main products include Letter Steel Stamp, Number Steel Stamp, Combination Steel Stamp, Jewelry Stamp, Round-Dotted Steel Stamp Set, Steel Types & Type Holders, Russian Alphabet, Pattern Steel Stamp, Flat Face Steel Stamp, Screw Extractor Set, Automatic Center Punch, etc.

Chen Der launched “Mitools” as its alternative product line. Products include wrenches, pliers, screwdrivers, etc.

Its products include single jack chain, double jack chain, oval chain, machine straight link chain, machine twist link chain, steel sash chain, chain accessories, etc.

by Gang Hao Chang, Vice Editor-in-Chief of Fastener World

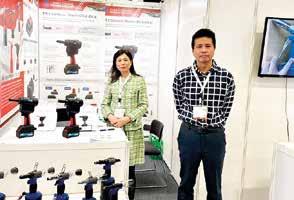

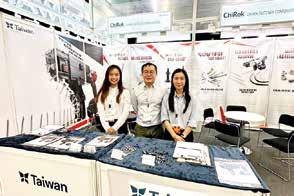

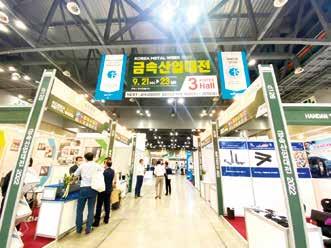

Korea Metal Week has made it across 30 years since it debuted in 1989. Now it has become the top and benchmark metal and industrial parts related fair in South Korea, as well as a stepping stone to tap into the South Korean fastener and industrial parts market. The 2022 edition of this fair was held at Hall 3, Exhibition Center 1, KINTEX in Goyang City, S. Korea from September 21 to 23.

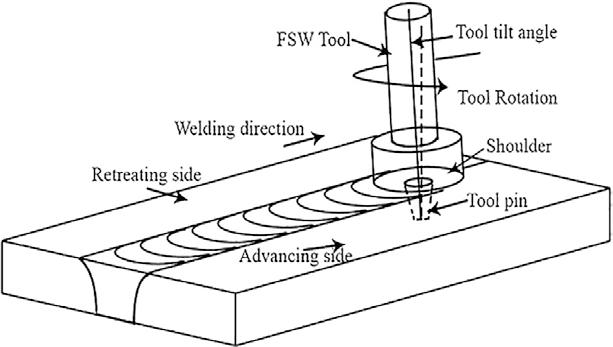

The fair attracted a total of 206 exhibitors. Given the fact that Southeast Asian countries have risen up lately after the pandemic years, the organizer put up a Vietnam Pavilion and India Pavilion at the fair. In addition, the organizer held seminars at the venue focusing on die casting, eco-friendly car parts joining and welding technology, climate change and other automotive industry related issues.