60 minute read

News

Seafood exporters call for action on post-Brexit delays

Above: Donna Fordyce

THE leaders of Scotland’s main seafood and food trade bodies have called on the UK Government to help resolve the delays to EU exports which are causing signifi cant problems for the sector.

Scotland Food and Drink, the Scottish Salmon Producers Organisation (SSPO) and Seafood Scotland have made a joint appeal for a “lighter touch” approach to help exports get through to the main European markets more smoothly.

Dozens of lorry loads of fi sh have failed to leave Scotland on time since the end of the Brexit transition period on 31 December. Confusion over paperwork, the extra documentation needed and IT problems have all contributed to delays and hold-ups. There has also been a backlog of traffi c to deal with as a result of France’s temporary travel ban introduced to slow the spread of a new Covid-19 variant.

Many of the problems have been encountered at inland locations in Scotland rather than at port entry points, but there have also been a number of issues around Dunkirk on the other side of the Channel. Some drivers have been forced to wait for more than 24 hours while lengthy checks are carried out.

The trade bodies had warned that a last-minute arrangement would create problems if there was no “grace period” to implement it. They now say the UK-EU trade deal, which was agreed on Christmas Eve – just one week before the new regulations came into effect – gave businesses no time to prepare for the huge changes necessary to get produce to the continent.

Tavish Scott, Chief Executive of the SSPO, said: “Had a deal been concluded even a couple of months ago, that would have given our producers and hauliers the time to test out the new systems, trial the paperwork and get everything in place.

“As it is, we have had lorry loads of salmon stuck in Scotland, waiting for the right paperwork, we have seen delays in France because of IT problems in bringing in whole new systems and confusion everywhere.

“Our members are resourceful and have been trying everything they can to get fi sh to customers in Europe, including new routes, but every delay forces the price of our product down and hands the initiative to our international competitors.”

Donna Fordyce, Chief Executive of Seafood Scotland, said: “All our producers have been working incredibly hard to work through all the extra red tape which has been put in place since 1 January but it is an almost impossible task given the lack of preparation time.

“The UK Government has to realise the enormous diffi culties that have been placed in the way of exporters simply because there wasn’t a workable system in place by the end of Brexit transition, despite numerous warnings that there would be issues.”

James Withers, Chief Executive of Scotland Food and Drink, said: “For the last few months, we have been appealing to the UK Government to agree a grace period with the EU. We wanted to see the gradual implementation of the new Brexit trade rules, a sixmonth bedding-in period which would have allowed exporters and the EU to adjust to the new demands.

“Instead, we have had to cope with a cliff edge with everything changing on 1 January. We warned this would lead to problems but our appeals for the grace period were ignored.”

Scotland’s Rural Economy Secretary Fergus Ewing said he understood that this was a time consuming and costly time for Scottish businesses.

He said: “We have been working with logistics companies to provide an EHC (export health certifi cate) service at a number of central Scotland logistics hubs, thereby reducing the burden on local authorities.

“We are all learning – including businesses – how to manage the considerable burden of this new bureaucracy on exporting food products.

“We warned the UK Government that we needed much more clarity much sooner than we got on what the export process would involve after the transition period ended and that its plans to leave the single market would create barriers like this.”

MSPs slate lack of progress in marine planning

REGIONAL Marine Plans in Scotland are stalling due to a lack of political leadership and funding, according to a critical report from a committee of the Scottish Parliament.

In a report published in December, Holyrood’s Environment, Climate Change and Land Reform Committee (ECCLRC) finds that, 10 years on from the Marine (Scotland) Act 2010, there has been slow progress in establishing Marine Planning Partnerships (MPPs) and developing Regional Marine Plans (RMPs). Of the anticipated 11 MPPs, only three have been established.

MPPs have been left to figure out how to develop complex plans with little advice on best practice, the report says, and the MSPs say there is a need for clearer

guidance from the Scottish Government on the roles and responsibilities of MPPs Above: Gillian Martin

and the process for developing RMPs from the outset.

In gathering evidence, the committee also heard that there has been a lack of clarity in decision making processes which has led to “a breakdown in trust” between stakeholders and has had a detrimental impact on collaborative working.

The report calls on the government to demonstrate its continued commitment to regional marine planning by publishing a renewed vision statement, including details of work to secure long-term finance and indicative timescales for establishing future MPPs. ECCLRC Convener Gillian Martin MSP said: “Successful marine planning outcomes in places such as Norway and New Zealand have largely been driven by strong local and national leadership. We believe that stronger leadership in Scotland, by both the Scottish Government and Marine Scotland, would enable our success too.” She added: “We believe marine planning partnerships lack the necessary funding to perform their statutory functions and Scotland’s allocated funding is ‘significantly below’ that of international examples. The Scottish Government must ensure adequate investment is allocated for the duration of the three-year marine planning statutory review cycle.” The report stresses that more needs to be done to communicate the benefits of regional marine planning, given the importance of the marine economy to jobs and growth in Scotland.

Specific recommendations include the publication of national guidance for regional marine planning; improving the expertise available for RMPs; training for members of newly created MPPs; clear socioeconomic and environmental objectives for coastal regions; and investigating opportunities to involve community representation in RMPs.

Environmental award for waste recycling project

SCOTTISH Sea Farms has won an environmental award for its work in recycling hatchery waste into nutrient-rich agricultural fertiliser.

The company was presented with a VIBES Scottish Environment Business Award in December, as part of an initiative that recognises work by Scottish-based businesses to adapt their way of working, products or services as a consequence of Covid-19 or have continued to progress low carbon opportunities despite the pandemic.

Scottish Sea Farms was praised by the award organisers for its work to capture fish waste from its new salmon hatchery at Barcaldine, near Oban, and recycle it as fertiliser to enrich farmland.

The project is part of the company’s drive to set a new benchmark for sustainability in the sector and contribute to the Scottish Government’s ambition to be net zero by 2045.

As part of the hatchery’s recirculating aquaculture system (RAS), any waste material, such as fish faeces or uneaten feed, is removed and captured for recycling.

Lead Engineer for Barcaldine RAS Hatchery, Ewen Leslie, explained: “Using technology by Norwegian engineering company Scanship AS, we first aerate the waste to prevent any unwanted bacteria from germinating, then we bind it together into larger particles via the addition of a cationic polymer.

“That done, the waste is filtered to separate the solids from the water. These solids, which are now of a sludgelike consistency, are then collected in a storage tank.”

Invergordon-based waste management company Rock Highland, part of the Avanti Environmental Group, then ensures the sludge is both safe and suitable for agricultural land. Rock Highland

Above: The first fish to be hatched at Scottish Sea Farms’ RAS hatchery at Barcaldine were harvested late last year

started out finding uses for waste from whisky distilleries and is now applying the same technique to fish farming.

Scottish Sea Farms’ freshwater team are now developing phase two of their fish waste recycling plans, with the goal of removing the remaining water content and converting the sludge into dry pellets.

“The benefit to the environment of moving from wet to dry form longer-term would be a reduction in the volume of waste material, thereby reducing the number of tankers and road miles required to transport it from hatchery to farmland,” said Ewen Leslie.

“For land farmers, dry form would provide an even more nutritional and valuable natural fertiliser alternative that’s easy to handle.”

Scottish Government orders weekly sea lice reporting

Above: Sea lice

MANDATORY reporting of sea lice numbers has moved to a weekly basis for Scottish fish farmers.

An Order was laid in the Scottish Parliament in December, introducing what the Scottish Government call a “step change” in sea lice reporting. It requires average weekly female sea lice numbers per fish to be reported one week in arrears, in place of current arrangements which require reporting only where specific levels are met or exceeded.

The policy was flagged up earlier in December by Cabinet Secretary for Rural Economy and Tourism, Fergus Ewing, while giving evidence to the Scottish Parliament’s Rural Economy and Connectivity Committee.

The additional information is intended to help the Fish Health Inspectorate to monitor and enforce policy on sea lice management. The data will be published to promote transparency.

As well as making the reporting of average sea lice numbers mandatory, the Order will require a reason for no count to be given and will refer to the penalties for not doing so.

The policy was developed through the Farmed Fish Health Working Group and a six week consultation on the new Order was held with relevant parties including the farmed fish sector, regulators, wild salmon interests, environmental interests and professional veterinarians.

As previously, the Fish Health Inspectorate sea lice reports will be available in spreadsheet format via the Scottish Government website.

Scottish food and drink exports hit by Covid-19

SCOTTISH food and drink export sales were down £1.1bn on the same period in 2019, figures published by the Scottish government in December have revealed. In percentage terms, Scottish exports were down by 22.4% year on year.

The contraction

in Scottish food Above James Withers

exports was seen in all categories except animal feed and live animals, with exports of fish and seafood seeing large decreases (down £112m) compared to Q1-Q3 2019.

James Withers, Chief Executive at Scotland Food & Drink, reacted to the figures, saying: “We have never seen a drop in export sales like this before and it emphasises how horrendous 2020 has been for food and drink exporters in Scotland.” Speaking ahead of the post-Brexit trade deal agreed in late December, he warned that the food and drink sector was “fragile” as a result of the Covid-19 pandemic and stressed that that food businesses, hauliers and border inspection systems were not ready for 1 January and the end of the Brexit transition period, deal or no deal.

Scottish Salmon Company harvest up for Q4 2020

THE Scottish Salmon Company delivered an increased harvest during the final quarter of 2020, its owner, the Bakkafrost group, has disclosed in a Q4 trading update.

The Faroe Islands salmon company completed the purchase of SSC at the beginning of October 2019 and is currently in the process of integrating the business into the wider group.

So far it looks to be living up to expectations, given the negative impact of Covid-19 on all salmon farming and seafood enterprises.

SSC produced a heads on gutted harvest of 9,300 tonnes in the 2020 October to December period, compared with 7,900 tonnes for the same period in 2019.

Its Faroe Islands based business produced a total harvest of 16,000 tonnes against 17,900 tonnes a year ago. However the Faroe figure is somewhat higher than the 12,200 tonnes delivered during Q4 2018.

Feed sales in Q4 2020 were 30.9 thousand tonnes, up from the 2019 Q4 figure of almost 28,400 tonnes.

The full final quarter 2020 report, which will include details of turnover, profit or loss, along with the financial effects of Covid, is scheduled to be released on 23 February.

Meanwhile, Bakkafrost is moving ahead with its vision to become one of the most sustainable salmon farming companies in the world. It recently announced that the total production of green energy from biological waste at its Strond hatchery on the Faroe islands will produce enough electricity to fuel more than 225 homes.

Hatchery operations manager Rógvi Jacobsen said the development was a huge step forward in utilising all the material from its salmon production. He added: “We are privileged to be among the first movers in the Faroe Islands to use biological waste to produce green energy.”

Scottish Sea Farms provides lifeline grant for charities

COMMUNITY groups and good causes facing uncertainty or hardship because of the coronavirus shared in a Christmas gift of £18,280 from Scottish Sea Farms. This brings the total donated by the salmon farmer to £1.3m since 2011.

In total, 43 local causes across the company’s farming regions of main-

land Scotland, Orkney and the Above: Rainbow Child Care, Dunstaffnage was given a grant for weatherproof clothing

Shetland Isles are to £10,000, each of our efi ted before the year was set to benefi t from grants of farm managers is given a out, each farm manager was up to £500 from the compa- £500 community allowance asked to nominate projects ny’s Heart of the Communi- annually to support the local in their communities where ty Trust. cause or causes of their the funds might make a real

The funds were allocated choosing. It’s a great way and positive difference to from Scottish Sea Farms’ of ensuring that the money those struggling because of Heart of the Community goes where it’s needed the coronavirus.’ fund, using cash which had most. The initiatives chosen range not been distributed during “This year however, with from food banks, mental the year because of the Cov- the coronavirus taking health charities and befriendid-19 pandemic. up everyone’s focus from ing schemes, to community

Heart of the Communi- March onwards, only a small hospitals, nursery groups (inty Coordinator Georgie number of farm managers cluding Rainbow Child Care, MacKenzie said: “In addi- had been able to allocate Dunstaffnage near Oban, tion to the main Heart of their awards, with the result where the fund supplied the Community fund which that there was still £18,280 weatherproof clothing for gives out grants of anything remaining in the fund. staff and children - pictured) from a few hundred pounds ‘To ensure local causes ben- and aid for refugee families in Scotland.

The Oban offi ces of the

Royal National Lifeboat

Institute and the

Samaritans also stand to benefi t, as do several local schools.

Alan Tangny, Farm

Manager for Spelve on the Isle of Mull, chose to support the library at

Salen Primary School, where four of his fi ve children are pupils, with a gift of £500.

As a father of fi ve, he has four children currently at the school. and his eldest was also a pupil there. He said:

“They are having to quarantine books that are taken home so having extra books will be a big help.”

The company’s Northern Isles Regional Manager, Richard Darbyshire, picked Fernvalley Wildlife Centre for his allocation. He said; “As with so many local organisations, it’s been a tough year fi nancially for the Centre after being forced to close for months. £500 won’t fi x all of the problems that come with that but if it helps the Fernvalley team to continue looking after the animals then it’s money well spent.”

PatoGen set to build lab in Oban

Above: The laboratory

FISH health company PatoGen Ltd is to set up a laboratory for preventive and diagnostic services in Oban, Scotland. The move by the Norwegian company is part of its expansion into the UK, which started in 2014. PatoGen established its offi ce at the SAMS campus in Oban in August 2018.

The company says: “Since PatoGen entered the Scottish market we have collaborated well with the farming companies with steady increase in activity. The farming companies in Scotland have embraced our services and developed the use even further and made it a part of the industry’s daily routines.”

Dr. Teresa Garzon, PatoGen’s key account manager for the UK, said: “It is the excellent collaboration, and the proactive farmers focus on maintaining good fi sh health and welfare that allows us to commit to the next step in PatoGen’s establishment in the UK.”

The laboratory in Oban is planned to be operational during this coming summer.

SAIC membership passes 150 mark

SHELLFISH producer Isle of Skye Mussel Company and marine engineering specialist Malin Group have become members of the Scottish Aquaculture Innovation Centre’s consortium, taking the SAIC’s membership beyond 150.

The consortium acts as a connecting point for different parts of the aquaculture sector, including seafood producers, supply chain companies, regulators, and the public sector. Beyond aquaculture, sectors represented include biotechnology, subsea companies, equipment suppliers, logistics firms and retailers.

Consortium membership particularly grew in 2020, increasing by around 25% from February. Earlier in the year, the innovation centre launched its ongoing rapid-response funding programme to support investment in innovation at a highly challenging time.

Dr Judith Brown, Director of Isle of Skye Mussel Company, said: “Joining the consortium during our start-up phase has enabled us to build relationships within a range of fields from research to industry, and the positivity of the SAIC staff has been fantastic during a difficult time to start a new business. The SAIC network encourages a spirit of knowledge-sharing and collaboration that has been invaluable to us… it has opened the doors to an entire community of aquaculture experts that are willing to work together.”

More than half of SAIC’s membership (57%) is made up of SMEs, while another 31% is large organisations. Around half (48%) of the consortium is based in Scotland, while 28% are located in other parts of the UK and 9% overseas, reflecting the growing diversity of organisations with an interest in Scottish aquaculture and its R&D projects.

Heather Jones, CEO of SAIC, said: “The growth of SAIC’s consortium reflects the increasing commitment from aquaculture – as well as the many industries that support it – to innovation and collaboration. It also highlights the growing diversity of the sector, not only in terms of geography, but also in the types of businesses involved, their size, and areas of focus.”

Chris Dunn, Principal Naval Architect for Malin Group, said: “Aquaculture is growing at pace, and it is encouraging to see so many businesses harnessing new and innovative technology. Joining SAIC’s consortium has been a great development for the Malin Group, providing a forum to learn more about aquaculture, as well as develop our activity in this important sector.

In December, SAIC announced funding worth £2.2m for eight new innovation projects aimed at supporting the sustainable development of the aquaculture sector in Scotland and beyond.

Projects selected for the funding round will explore new methods for sea lice control, managing gill health and environmental impact modelling, among other areas, SAIC says. Research will concentrate on a variety of species to reflect the diverse make-up of the sector, including salmon, trout, and wrasse, and at least one of the projects will support shellfish production – one of SAIC’s priority innovation areas.

The projects represent a total combined investment of more than £2.2m from industry, academia and SAIC, including a package of more than £900,000 from the innovation centre itself.

The new projects are expected to commence this year and will last between five months and three years. Proposals were assessed by SAIC’s Independent Scientific Panel (SISP) against a range of criteria, including their long-term commercial impacts and opportunities for sharing knowledge and applying outcomes across the entire sector.

Heather Jones said: “The aquaculture sector is well placed to help meet the growing demand for high-quality protein, and innovation continues to play a crucial role in expanding the sector’s capacity and unlocking new opportunities. Scotland can be at the forefront of new initiatives and developments in technology that will help the sector to grow sustainably.

“The results from our previous collaborative research projects – including the development of new tools, new jobs, and even new businesses – are great examples of what can be achieved when industry and academia work together. Finding answers to some of the sector’s most pressing challenges has seldom been more important, particularly in the wake of Covid-19.

“Our consortium represents the entire aquaculture sector supply chain which is reflected in the variety and scope of these latest projects. They have the potential to deliver valuable outcomes that could make a real difference to the future of the sector.”

SAIC said innovation will play a key part in realising the ambition of Scotland’s aquaculture sector to sustainably double its economic contribution from £1.8bn in 2016 to £3.6bn by 2030.

Grants Oak Smoked reports ‘successful’ year

ONE of the UK’s leading traditional smoked salmon companies says it has managed to adapt well, despite the Covid-19 pandemic, building on revenue which grow by more than a third in 2019.

Like many seafood businesses, Grants Oak Smoked Ltd – based in Maryport, Cumbria – found markets both at home and abroad either closed or locked down.

Despite these challenges, founder and director Jonathan Brown said the company has managed to weather the storm.

He was commenting after last week’s publication of the company’s latest accounts which showed a substantial increase in sales in the (pre-Covid) financial year to 31 December 2019.

Reporting on a “very successful year financially”, he said turnover surged by 35 per cent from £17.4m the previous year to £23.56m in 2019, of which exports accounted for more than half. This, he added, was due to Grants gaining new markets both at home and abroad.

The financial year ended with Grants adding two gold medals to an already impressive list of prizes, at the Italian based International Food Taste Awards which recognises the finest foods from across the world. All entries are blind tasted by independent judges.

Established in 1983, the company supplies smoked salmon to UK and overseas hotels, restaurants, retailers and food companies, all markets which have been severely hit by the coronavirus pandemic.

The report says that in the face of such obstacles, Grants has managed to maintain tight control of expenditure and ensure a reliable source of raw materials and ingredients.

At the 2019 year end, operating level profits rose by 130 per cent to £1.525m which it described as a “significant achievement”.

Grants says it is working closely with customers to ensure supply, adding that the 2020 year end position remained strong with a secure financial base and an adequate cash flow to support future operations.

Scottish start-up helps alternative protein research

SALMOSIM, a salmon simula- in the world able to produce protor start-up, has secured its first tein from gas at scale. Its Calyscommercial contract with Cali- seo 50/50 joint venture with Adisfornia-based Calysta, supporting seo is building the world’s first trials for a sustainable alternative commercial FeedKind production protein source that could be rolled facility in Chongqing, China, with out across the global aquaculture 20,000 tonnes of capacity coming industry. online in 2022.

Using a gut simulator that mimics The SalmoSim gut simulator the digestive tract of Atlantic salm- was first developed as part of a on, SalmoSim will conduct a trial of collaborative research project Calysta’s single-cell feed ingredient that began in 2016, funded in part

FeedKind protein, which is made by fermenting natural gas. FeedKind has been developed to meet the Above: L-R Martin Llewellyn, Raminta Kazlauskaite and Joey Humble of SalmoSim by the Scottish Aquaculture Innovation Centre (SAIC). The consortium, led by the University of

growing global demand for protein cost up to £150,000 each time. Glasgow, included Nofima, Alltech and is designed to be a sustainable sub- Dr Martin Llewellyn, founder of Salmo- and Mowi, with the Marine Institute and stitute for proteins such as fishmeal and Sim and senior lecturer at the Universi- University College Cork both involved soy, which are currently widely used in ty of Glasgow, said: “Our gut simulation in a linked project. seafood production. system provides a powerful tool for As well as supporting trials for alter-

The SalmoSim team will use the gut carrying out basic and applied research native feed sources, SalmoSim could simulator equipment to support Calys- into fish digestion and we’re pleased to be used to tackle a range of significant ta’s product quality program while also be supporting Calysta with the devel- challenges in the aquaculture sector, testing a number of variables in support opment of its alternative protein… including trialling novel approaches to of new product development. Results SalmoSim can help feed manufacturers limit the impact of sea lice. The comfrom the simulation, taking place at with an important pre-screening phase, pany is also exploring the potential for the University of Glasgow, will provide allowing them to eliminate unviable building additional simulators for other Calysta with valuable data on digestibil- options without the time and expense fish species. ity comparing FeedKind in SalmoSim associated with full-scale tests.” to existing in vivo data. In vivo trials can Calysta is currently the only company See Feed feature, page 52.

Netwax E4 Greenline

Netwax E4 Greenline offers excellent protection against fouling on pen nets

► Powerful waterbased antifouling that offers excellent protection against fouling ► Protects against UV radiation ► Keeps nets soft and pliable ► Controlled leaking of the active ingredient, which is approved by Ecocert (Institute for Marketechology) and listed by OMRI (Organic Materials Review Institute)

Slalåmveien 1, NO-1410 Kolbotn, Norway Ph.: +47 66 80 82 15 - post@netkem.no

NEWS...

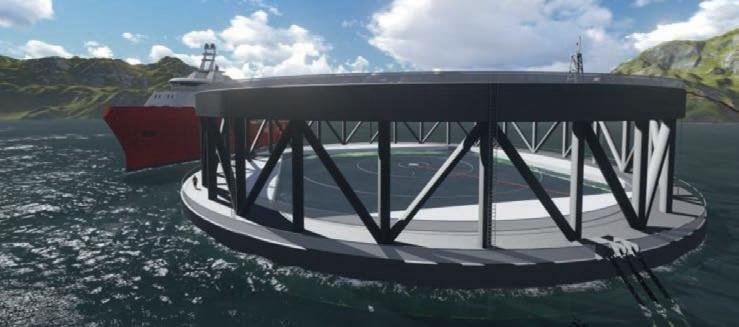

Aker Solutions signs up to Arctic Offshore Farming project

Above: Arctic Offshore Farming AKER Solutions has signed a contract with Arctic Offshore Farming, a subsidiary of Norway Royal Salmon, to help deliver an ambitious ocean-based fi sh farm project.

The contract is worth NOK 40m (£3.4m). Aker Solutions says it has identifi ed fi sh farming as a market with several interesting prospects and, together with NRS, it has developed the design for Arctic Offshore Farming’s harsh environment installation.

This deal means that the company will now also make its fi rst delivery of such facilities.

Karl-Petter Løken, executive vice president, renewables at Aker Solutions said: “We will leverage our expertise and capabilities from the oil and gas industry also in other markets. Our ambition is to grow our renewable projects and low-carbon solutions to count for one third of the revenues by 2025, and two thirds by 2030. We are currently pursuing prospects within offshore wind power, carbon capture, fi sh farming and several other solutions.”

He added: “The new contract shows that we can be a relevant and competitive contractor for such markets.”

Arctic Offshore Farming’s facilities are currently being prefabricated as four separate sections at the Fosen Yard in Emden, Germany. During the fi rst quarter 2021, the modules will be transported on a barge to Aker Solutions’ specialized yard in Verdal where the four sections will be assembled to make two circular fi sh farming units.

Knut Engene, senior vice president, projects, at Norway Royal Salmon explained: “Arctic Offshore Farming is a development project 12

by Norway Royal Salmon and is an important project for further growth and to maintain NRS as one of the world’s leading producers of farmed salmon.

“It is a project that will bring us into the future for facilitating environmentally sustainable salmon farming further out at more open sea. “

Aker Solutions’ scope includes preparatory activities for the fabrication, receipt of components, assembly, services to Arctic Offshore Farming and their suppliers, as well as preparation for sea transport. Each of the two fi sh farming units weighs about 3,800 metric tonnes, has a diameter of 80 metres and a height of 22 metres.

Preparations for the project start in early 2021. The activity will be at its highest in April and May when around 50 employees will be working on the project. The fi sh farming units will be installed at the Arctic Offshore Farming location outside Tromsø in Northern Norway.

Meanwhile, Norway Royal Salmon is to receive NOK 800m (£68m) in state guarantees from towards the construction of its futuristic offshore submersible fi sh farm and hatchery, Arctic Offshore Farming.

The loan assurance has come from the Guarantee Institute for Export Credit, commonly known in Norway as Giek, an organisation which reduces the risk for businesses and their banks.

Giek says lower risk gives parties the incentive to sign contracts and increase exporter competitiveness. Already this year it has supplied almost NOK 4.8bn (£410m) to the country’s seafood industry.

Benchmark appoints digital chief

BENCHMARK Genetics has appointed Bara Gunnlaugsdottir as head of digital technologies, with a brief to develop the company’s strategy and innovation.

In her new role, she will be driving the digital strategy and innovation programs of the business area, including the responsibility for all strategic management systems within production, quality and environment. As head of digital technologies, Benchmark says, she will lead the development, implementation and maintenance of application systems and ensure that Benchmark Genetics is well prepared for the future.

Bara Gunnlaugsdottir joined the company’s Icelandic operation, StofnFiskur in 2004 as production manager. Before being appointed to the new position, she has been heading the division’s Strategic Business Systems, a job she has held since 2018.

Bara’s educational background is a Diploma in Aquaculture from the University of Holar, Iceland, a BSc in Business Management from the University of Akureyri, Iceland and an MBA degree from the University of Reykjavík, Iceland. Recently, she completed a program in Digital Transformation from MIT professional education, and she will bring this additional knowledge to her new role in the business area.

Gunnlaugsdottir said: “Our most advanced customers are already utilizing technologies such as blockchain and AI, and I am convinced that these technologies will play an important role in aquatic breeding looking forward.”

Norway records strong export numbers

NORWAY’S seafood industry enjoyed the second best year in its history during 2020 with exports again smashing through the all-important NOK 100bn barrier, despite the challenges presented by Covid-19.

This country of 5.3 million people exported 2.7 million tonnes of fish last year worth NOK 105.7bn (£9.2bn) last year with farmed salmon again leading the way. The figure is just short of the all-time record, NOK 107bn, achieved in 2019.

Renate Larsen, CEO of the Norwegian Seafood Council, said: “Even though 2020 was a different year, large parts of the seafood export have managed to defy the biggest challenges in the wake of the corona pandemic.

“We have really seen how strong Norwegian seafood is globally and can be proud of our seafood industry, its ability to adapt quickly here at home and the strong position we have with consumers worldwide.”

The year started well for the industry as prices nudged NOK 80 a kilo, with little hint of the crisis that was to come. But by March much of the world was shutting down as Covid-19 spread its tentacles.

Larsen explained: “Norwegian seafood exports lost a very important sales channel, namely the restaurant and hotel segment. There were challenges in logistics, and sales of seafood were largely moved to grocery chains, online shopping and take-away services.”

Seafood and Fisheries Minister Odd Emil Ingebrigtsen said: “I am happy that seafood exports once again cross the milestone of NOK 100 billion in export value.

“The first time we managed this was in 2019, and that this is repeated in the coronavirus year 2020, is fantastic.”

The salmon sector was by far the largest single species measured in both volume and value with exports totalling 1.1 million tonnes and worth NOK 70.1bn (almost £6.1bn) even though prices were sluggish for much of the year. This represents a volume increase of 2% on 2019, but a drop in value of 3%.

Seafood Council analyst Paul T Aandahl said: “The pandemic has led to increased demand for processed products for sale in the retail trade. An increasing proportion of salmon is further processed in Norway. The export value for salmon in 2020 is the second highest that has been registered, and in terms of volume it is a record.”

He added: “At the same time, there has been a shift in the flow of goods towards countries such as Poland, Denmark and the Netherlands, which to a large extent processes salmon for resale to other markets, primarily in the EU.

“Some markets have received lower salmon volumes from Norway in 2020. The largest decline has been in the export value to Italy, China, Lithuania and the Hong Kong SAR (special administrative region).” It was an even better year for farmed trout with export volumes hitting 71,800 tonnes, a rise of 21 per cent on 2019 and the value reaching NOK 3.9bn (£339m), up by 5%. Cod exports totalled 172,000 tonnes (down by four per cent) with a value of NOK 9.6bn (£835m), compared with NOK 10.1bn 12 months ago. The loss of the restaurant segment is blamed for the drop. Of other species mackerel export volumes increased by 26% to 300,000 tonnes and this sector was worth five billion kroner, a value rise of 16%.

Herring also performed strongly with the value up by 18 per cent to NOK 3.8bn even though volumes were down by 11 per cent to 316,000 tonnes.

It was not such good news for the shrimp (prawn) sector, where the UK is the second largest market, with volumes 25% lower at 12,000 tonnes and the value 16% lower at NOK 909m. Again, the loss of the restaurant trade was mainly to blame.

Aquaculture accounted for 70% of seafood exports, by value, and 44.9% by volume out of the total for 2020.

Norway exported 1.2 million tonnes of fish from aquaculture which was worth NOK 74.2bn. Volume was up 3% but value was down by 3%

The total seafood export figure of NOK 105.7bn represents almost NOK 20,000 (£1,660) for every man, woman and child in the country – or 25,000 meals for each minute of last year.

Novel virus may explain fry mortality in Ballan wrasse

A novel virus in Ballan wrasse hatchlings could be the cause of unexplained high mortality for hatchlings, according to fish health research business Patogen.

The Norwegian-based company has named the virus Ballan wrasse birnavirus (BWDV).

Patogen worked with a fish farmer to investigate diseased fish for relevant pathogens and histology, and performed a full genome sequencing in which researchers found the

genome of the novel birnavirus. Downstream PCR studies detected large amounts of virus Above: Ballan wrasse

in fish larvae from groups with increased mortality. PatoGen believes that biosecurity measures against BWDV will reduce the mortality in this critical phase of the ballan wrasse production.

The mortality for wrasse occurs after a short period of loss of appetite and peak mortality typically occurs between day 17 and 25 post hatching (DPH). Samples from fish at the farm were collected weekly from hatching and were examined with PCR for relevant pathogens and histology. The genome sequencing analysis revealed high amounts of gene sequences of a novel virus grouped within the virus family Birnaviridae. The gene sequences of the novel Ballan wrasse virus were genetically different from other known birnaviruses and aquabirnaviruses. The best known birnavirus in Norwegian aquaculture is Infectious pancreatic necrosis virus (IPNV), an aquabirnavirus known to cause fry mortality in Atlantic salmon. Other birnaviruses are associated with early fry mortality on other marine fish species.

The investigation showed that the virus infection is maintained in the population for a long time after the peak mortality and at high levels.

PatoGen is now offering fish growers a PCR analysis for the Ballan wrasse birnavirus.

Academics to review Norway’s ‘traffic light’ zoning

TWO Scottish university professors are among an elite introduced at the beginning of the year, was designed to group of academics who have been chosen to evaluate part ensure predictable and sustainable growth in the aquaculof Norway’s controversial “traffic light” scheme for regulat- ture sector and was based on scientific advice. The sector ing salmon farming. is constantly evolving, the Council added, which is why a

The Norwegian Research Council has been commissioned broad based expert group had been brought in to conduct to examine the scientific basis of the scheme, with empha- an evaluation. sis on how it controls lice. The Norwegian coastline has been divided into three

Fisheries and Seafood Minister Odd Emil Ingebrigtsen said colour-coded zones: green, where growth is free to take it was important to have a professional assessment on the place; amber, which allows for limited expansion; and red, situation in order to make it even better. where there can be no expansion and where existing pro-

The seven strong evaluation team will be chaired by duction must be reduced. Crawford Revie, professor of Data Analytics at the Univer- However, the scheme has not gone down well with some sity of Strathclyde’s department of computer and informa- sections of the industry. Up to 25 salmon and trout compation sciences. nies who have found themselves in the red zone said they

Two years ago he returned to the UK after spending a plan to sue the Norwegian government, claiming they are decade at the University of Prince Edward Island’s Atlantic being robbed of part of their livelihood. Veterinary College. Before moving to Canada Professor Re- The other members of the team are: Deputy Director / vie worked on projects involving fish health and sustainable Professor Anders Koed, DTU Aqua, Denmark salmon aquaculture. Top Jimmy Turnbull • Professor Andre Visser at DTU Aqua, Denmark

He will be joined on the team by Jimmy Turnbull, Pro- Above Odd Emil • Dr Dave Jackson at Marine Institute Ireland fessor of Aquatic Population Health and Welfare at the Ingebrigtsen • Associate Professor Heather Swanson at University of University of Stirling’s Institute of Aquaculture. His work has taken him Aarhus, Denmark to several countries. • Assistant Professor Jarno Vanhatalo at University of Helsinki, Finland

The Research Council said it looked for candidates with high • Head of department Kirstin Eliasen at Fiskaaling, Faroe Islands. scientific competence, but at the same time avoiding strong ties to They will submit their final report to the Research Council by the the Norwegian environments. It pointed out that traffic light system, end of November this year.

Labour shortage fears for Norway’s seafood sector

EMPLOYERS in Norway’s fishing and seafood sector are worried about being able to get enough workers through the country’s long winter months.

Businesses are hoping that the 195,000 Norwegians currently on the unemployment register or looking for work can help to fill the gap, as well as reduce the risk of Covid infected people coming in from abroad.

Labour and Social affairs minister Henrik Asheim, Fisheries and Seafood Minister Odd Emil Ingebrigtsen and Hans Christian Holte, director of NAV which looks after employment issues, have just met with industry leaders in a bid to solve the problem.

They included representatives from the employers’ organisation, Seafood Norway, and Leroy Seafood, which is not only one of the country’s main fish farming companies, but also operates a large trawler fleet.

A statement issued after the meeting said: “It is extremely important that we now use Norwegian labour as far as possible.”

Labour Minister Asheim added: “The use of domestic labour instead of foreign workers will

Above Sxxxx

also reduce the risk of import infection.”

They said it was very important that people seeking work take advantage of the opportunities and help on offer, which could include travel and relocation expenses.

Concern was also expressed about the risk of infections brought in by foreigners looking for work.

The government has decided to introduce a travel registration system. This means that those who want to cross the Norwegian border must register information about – among other things – name, contact information, quarantine location and employer if relevant.

Police also plan to tighten controls at borders in the north of the country.

The statement added: “Those who come to Norway to work will be allowed to come in, but the police want to check that those who come meet the entry conditions, and have plans for how to implement the quarantine.”

AKVA upgrades its Sandstad service centre

AQUACULTURE technology group AKVA is expanding its service station at Sandstad, Norway. Work is set to start in the first half of this year and the project is due to be completed in 2022.

Sandstad is located in the Kalvøya industrial area in Hitra municipality

AKVA group is making a major commitment at Sandstad, , with an upgrade to its service station including an assembly facility for pens, a deep-water dock, a modern workshop and office buildings. The initial building phase will commence in the first half of 2021. “This demonstrates our commitment and our confidence in Sandstad and the surrounding region. The area is centrally located for aquaculture operations in Mid-Norway and will now be significantly upgraded,” said Odd Jan Håland, AKVA group Nordic’s Service Manager.

In time the service station will provide enough repair capacity to serve the entire Scandinavian market.

The initial building phase will commence in the first half of 2021 and the new service station is expected to be completed in 2022. Normal operations will be maintained during the construction period, with the existing buildings eventually being converted to a simple storage facility and additional workshop.

Industrial fabric producers join FiiZK Group

Heavy Duty and COMFORTABLE

NEW ISOMAX

ISOMAX

NEW COLOUR CONDITIONSEXTREME Manufacturing in France since 1964

NEW COLOUR CHINOOK

www.eggedosis.no

www.guycotten.com

Above: FiiZK semi closed cage in Norway

NORWEGIAN Weather Protection (NWP), which makes industrial seams for aquaculture, agriculture and other sectors is to become part of the FiiZK Group.

FiiZK, a major supplier to the fish farming sector ranging from closed cages to software, announced the NWP will become its wholly owned subsidiary as from 1 January 2021. In a statement, FiiZK said: “The collaboration between NWP and FiiZK provides increased flexibility and expertise between our factories. As a result, our partners will benefit from increased production capacity as well as rapid and innovative product development.”

NWP’s factory at Frekhaug, outside Bergen, will continue to operate, as part of FiiZK’s production setup, while functions within sales and administration will be coordinated from FiiZK’s head office in Trondheim.

FiiZK’s product range includes lice skirts, treatment tarps, land-based fish farming systems and a digital feeding solution that integrates pellet detection with activity monitoring and multilocation management.

A Global Supplier and Partner for Maritime Aqua Services

Local presence, global reach.

SERVICE VESSELS HARVEST VESSELS LIVE FISH CARRIERS

FEED CARRIERS

Above Salmon smolt

A court ruling in Oslo has led to a war of words between feed giant Biomar and nutrient specialist STIM over a smolt feed patent.

The argument concerns Biomar’s smoltifi cation feed Intro Tuning, which STIM maintains infringes the patent of its own SuperSmolt FeedOnly. Both are specialist products to control smoltifi cation, reducing the number of immature fi sh transferred to sites in the sea too early and also preventing smolts from maturing too early.

In July, STIM AS submitted a request to the Norwegian courts, stating that BioMar should be prohibited from the sale of their smoltifi cation feed, Intro Tuning. According to STIM, the feed violated a new European patent that STIM has recently been granted.

The Oslo County Court held hearings in the case the fi rst week in November. A decision was handed down by the court on 8 December concluding that BioMar’s feed Intro Tuning should not be the subject of an injunction. Biomar hailed the decision as vindication of its position. Håvard Jørgensen, Managing Director of BioMar Norway, said: “We are very happy with the outcome of this case. The decision from the court is in accordance with the European Patent Offi ce’s (EPO) understanding of STIM’s patent, and thus as expected. This decision means that fi sh farmers can continue to choose feed from our product portfolio that promotes growth and health during smoltifi cation and transfer to seawater.” STIM, however, expressed a very different interpretation of the ruling. Its CEO, Jim-Roger Nordly, said: “Jørgensen has no basis for making such a claim. In reality, Biomar succeeded with nothing more than legal fi libuster and a reasoning that fl ies directly in the face of the work that EPO does to protect important innovations against unlawful exploitation.”

STIM maintains that Biomar’s substitution of alternative amino acids for SuperSmolt’s key ingredient, L-Tryptophane, does not absolve the larger company from the charge of patent infringement.

The decision by the Oslo County Court can be appealed, but an expiration deadline was set for the second half of January.

The smoltifi cation feed is aimed at enabling optimal smolt growing in full light, rather than restricting light and ensuring that immature fi sh are not transferred too early into seawater.

The decision by the Oslo County Court can be appealed, but an expiration deadline was set for the second half of January.

Cermaq commissions new wellboat

CERMAQ Norway has entered into a deal to build a new advanced technology wellboat with a larger than usual capacity of 6,000 cubic metres.

The charter agreement with Norsk Fisketransport AS (NFT) is for fi ve years, but there is an option for up to a further four years in two year stages.

NFT’s General Manager Oddleif Wigdahl said: “We have had good collaboration with Cermaq Norway for several years now, so we are pleased and grateful that the company has shown renewed confi dence in us through this agreement.

“Using the skills of Cermaq and that of our own employees, we will be taking new steps in the development of tomorrow’s wellboat technology.”

The vessel will be ready for operation in the fi rst half of 2023 and will have circular tanks for optimal fi sh welfare.

Norsk Fisketransport, part of the aquaculture services giant NTS’ subsidiary Frøygruppen, has three wellboats of 3,200 cubic meters under construction at its Norway-based Havyard Ship Technology. They are expected to be ready for delivery by 2021. Norsk’s subsidiary, Havyard Design & Solution, has been chosen to carry out the design. A construction contract has yet to be signed.

Havyard said: “The different parties will work closely together to optimise the design for the most effi cient operation possible.”

NFT already operates two wellboats on a contract basis for Cermaq with a capacity of 3,200 and 1,500 cubic metres.

Cermaq Norway regional director Snorre Jonassen said the new vessel will cover the company’s capacity needs in terms of harvesting, smolt transport and delicing.

Tank bursts at Havlandet RAS site

A 500 cubic metre tank has burst at an experimental new pilot land-based salmon farm in Norway just a few days before the facility was due to take its first fish.

According to the newspaper Bergens Tindene, initial estimates of the cost of the damage to the tank – also known as a bioreactor - is thought to be around three million kroner, or £250,000. It was filled with water at the time.

The incident took place at the Havlandet RAS pilot which is part of the INC Group. At first it was reported there had been an explosion, but this has since been ruled out.

The INC group said it was carrying out a full investigation into the cause of the rupture which was still unknown, but a crack in the tank has been discovered. The company stressed there is no risk of pollution.

The plant was due to have received around 200 tonnes of fish the following week. The first harvest is scheduled for next autumn.

Havlandet, which has more than 17 years’ experience of land-based farming with other fish species, began construction work on the site in January this year, close to the city of Florø in western Norway.

The company currently has a licence for 10,000 tonnes of salmon onshore, but plans are to build a larger facility based on the experience of the pilot.

It believes that a capacity of more than 30,000 tonnes of salmon can be produced within the available area, in addition to a significant amount of farmed cod.

Depending on how much work is eventually carried out, the entire cost of the project is estimated at between NOK 40m and 60m million (£3.4m - £5m).

Mowi offloads its stake in DESS Aquaculture

MOWI has sold its 50 per cent stake in the aquaculture vessel support company DESS Aquaculture Shipping for around €115m (NOK 1.2bn).

The sale will provide the global salmon giant with a useful boost to its cash reserves during a diffi cult time for the fi sh farming sector.

The buyer is Antin Infrastructure Partners, a leading private equity fi rm focused on infrastructure investments. It has bases in London, Paris and New York.

Based in Grimstad, Norway Dess (Deep Sea Supply) operates a modern fl eet of live fi sh carriers, well boats and other support vessels.

An announcement said that Mowi had invested €60m in DESS and , with its share of the proceeds at €115m it would give the company a gain of approximately €55m.

It added: “The company’s primary interest is fi sh farming, primarily salmon, the operations of which are focused on Norway, Scotland, Canada, the Faroe Islands, Ireland and Chile.

“The group has a share of 25 to 30 per cent of the global salmon and trout market, making it the world’s largest company in the sector.”

Founded just four years ago as a joint venture between Deep Sea Supply and Mowi, the company has developed vessels and its operation based on a combination of DESS’s experience as an Offshore Supply Vessel (OSV) owner and MOWI’s seafood production expertise.

They said at the time that the aim was to build DESS into one of the world’s largest aquaculture shipping companies, offering vessels of high welfare standards and innovative design.

DESS is currently building two new wellboats for Mowi. All the latest industry news from Europe Samherji expands in Iceland ICELAND’S largest fi shing company is working to further expand its plans to establish a large fi sh farming operation near the fi shing town of Grindavik on the southern peninsula of Iceland.

Samherji Fiskeldi ehf has prepared an environmental assessment plan to produce up 12,000 tonnes of Arctic char and salmon, a fourfold increase on what is allowed under the current licence, at a location called Staður. Locals have until the end of the year to comment on the proposal.

There has been a fi sh farm at the Staður site since 1984, when the industry was in its early stages in Iceland.

Samherji Fiskeldi began a modest expansion of the site about three years ago when it applied for an operating licence to increase char production from 1,600 to 3,000 tonnes.

The company said in its planning application that it was looking to harvest sought-after, quality products on a sustainable basis, adding that the site was blessed with a large amount of geothermal heat and water for the production process.

It also pointed out that other companies are already farming char, salmon and trout in the area.

The parent company, Samherji hf, is best known as Iceland’s largest trawler and fi sh processing operator, with interests in the UK and Europe. It has now embarked on a serious expansion of its fi sh farming business. A couple of months ago Samherji announced its intention to buy a former aluminium smelting plant, also near Grindavik, and convert the site into a salmon farm.

Samherji is the world’s largest producer of Arctic char, a fi sh closely related to salmon but with milder fl avour.

Above Arctic char

SalMar reports increased harvest volumes

NORWEGIAN Salmon farming giant SalMar has reported a 3,000 tonne plus increase in its harvest figures for the final quarter of 2020.

The total figure is 43,600 tonnes for the three months between October and December, compared with 40,300 tonnes for the same period in 2019.

SalMar’s farming operations in Central Norway produced a harvest volume of 20,900 tonnes while Farming North Norway had a harvest volume of 19,100 tonnes and Icelandic Salmon (formerly known as Arnarlax) had a harvest volume of 3,600 tonnes.

SalMar also has a 50 per cent stake in Scottish Sea Farms, which it shares with the Lerøy Seafood Group. But because it is classed as an associate company, the SSF harvest figures are not usually included in trading update figures.

In its third quarter report in November SalMar said that Scottish Sea Farms had turned the corner from the biological problems which had beset the business in earlier years.

A more detailed indicator of the Scottish performance should become known on 25 February when the full Q4 report, which will also include financial results, is scheduled to be published.

SalMar was one of the few major salmon farming companies to deliver exceptionally strong 2020 third quarter results, defying the impact of coronavirus.

It included an increased operating profit or EBIT of NOK 646.8m (£54m) which CEO Gustav Witzøe attributed to a clear operational focus and a strong biological performance. It was also one of the few salmon companies to have paid a dividend for the quarter.

NEWS...

Vancouver Island mayors protest salmon shutdown

Above: Bernade� e Jordan LOCAL government leaders and representatives of the salmon farming industry have written an open letter to Canada’s Fisheries Minister to protest her decision to phase out 19 salmon farms in British Columbia.

The decision to phase out all open-net fi sh farming in the Discovery islands region over the next 18 months was announced by Bernadette Jordan, Minister for Fisheries, Oceans and the Canadian Coast Guard, earlier this month.

The letter, published yesterday, states: “Salmon farming is deeply integrated into the fabric of local lives and, as one of the most signifi cant local employers, your decision has the potential to unravel the viability of North Island Indigenous and non-Indigenous communities. Yet you made this decision without even speaking to the industry nor locally-elected offi cials who deeply understand BC’s salmon farming communities and have a direct interest in your action.”

The letter says the decision puts at risk 1,500 jobs supported by the farms, and indirectly threatens the viability of the industry throughout British Columbia.

It goes on: “Like all Canadians and residents of our communities during the pandemic, workers in the salmon farming industry, and local business owners are under severe emotional strain. Now they face the prospect of losing their jobs and their businesses going under.”

And it asks Bernadette Jordan: “What is your plan now to help our communities recover from your decision? What is your government willing to commit at this stage, and beyond, to help us pick up the pieces for the people who live, work and take care of their families here on our coast?”

Announcing the shutdown, the Canadian government said that it had consulted with First Nations representatives in the region, who blame fi sh farmers for the decline in wild salmon.

UNESCO highlights lack of funding for ocean research

LACK of funding is hampering the development and implementation of marine research and its valuable applications, according to a report published by United Nations agency UNESCO.

The Second Global Ocean Science Report, published by UNESCO’s Intergovernmental Oceanographic Commission (IOC), finds that on average, states devote only 1.7% of their research budgets to sciences of the ocean (0.03% to 11.8%, depending on the country). This is much less than other fields of scientific research, which is “incomprehensible”, the report says, considering the fundamental role of the ocean in regulating the climate and its rich biodiversity.

The report’s publication comes ahead of the United Nations Decade of Ocean Sciences for Sustainable Development 2021-2030.

“Our knowledge of the oceans is a key element for the future of humanity,” said UNESCO Director-General Audrey Azoulay. “The Global Ocean Science Report 2020 underlines the essential role of ocean research and international cooperation for all key issues of the 21st century.”

The number of ocean science publications is increasing in Asia and, to a lesser extent, in North America and Europe. The most advanced countries are China, Japan and the Republic of Korea. Budgets for ocean science vary considerably from country to country and over time. For example, between 2013 and 2017, 14 countries increased their average budget, with the Russian Federation recording the highest annual growth (over 10%), followed by the UK and Bulgaria. Meanwhile nine countries reduced expenditure, in some cases significantly, including Japan, Ecuador, Turkey, Brazil and Italy.

Moreover, while the international community committed to controlling the exploitation of ocean resources by 2030 in line with Sustainable Development Goal 14 of Agenda 2030, few have defined strategies to achieve this, the report points out.

The report highlights an increase in international collaboration among oceanographers and calls for the strengthening of South-South and NorthSouth partnerships. Innovation, complemented by technology transfer, must play a fundamental role in helping developing states achieve sustainable marine and fisheries resource exploitation.

The report also highlights the crucial need for training in the various areas of ocean management. It notes the under-representation of women, who account for 39% of all oceanographers, an increase compared to the previous report, and six points higher than the percentage of women in the natural sciences overall.

The report also calls for more data sharing in the field of oceanography.

Krill industry joins forces to protect penguins in Antarctica

THE fi shing industry and a coalition of non-governmental organisations (NGOs) have agreed to stop krill harvesting in an area of the Antarctic Ocean, to protect the penguin population. Krill, which is used as a component in fi shmeal for feed as well as pet food and nutritional supplements for humans, is a key part of the penguins’ diet.

The closure is year-round and permanent, affecting a 4 500km2 area of ocean around Hope Bay in the northern Antarctic Peninsula. The move is supported by the Association of Responsible Krill Above: Adélie penguinsharvesting companies (ARK) and an NGO coalition of Greenpeace, Pew, WWF and Oceanites.

The move expands voluntary restricted zones that came into effect in 2018. It is intended to secure the year-round protection of the largest Adélie penguin colony in the region, and sends a strong statement of intent in support of a marine protected area in the Antarctic Peninsula from industry to the Commission for the Conservation of Antarctic Marine Living Resources (CCAMLR) and the entire Antarctic community.

The companies making the commitment represent 85% of the krill fi shing industry in the Antarctic and are all members of the Association of Responsible Krill harvesting companies (ARK). They are: Aker BioMarine, CNFC, Jeong IL Co., Dongwon Ind. Co., PescaChile, Rimfrost, Fujian Zhengguan Fisheries Development Corporation, Liaoning Pelagic Fisheries corporation.

Pål Skogrand, Director of Antarctic Affairs with krill harvesting company Aker BioMarine, said: “Nature is changing fast in Antarctica, faster than policy and regulation is able to understand and keep up with. When the krill industry moves to an all-year closure ahead of its time, this is a necessary precautionary action that we take because we can. To get things right in Antarctica we need to move outside of our comfort zones and develop ‘shared ownership’ of crucial conservation concepts across industry, Governments and NGOs”. Aker BioMarine said studies have shown a strong population decline among the Adélie penguins within the time span they have been monitored. By closing this area, the company argued, the krill industry reinforces its precautionary approach, upholding important ecosystem values and facilitating a better scientifi c understanding of penguin performance. The move will also help answer the question of why some colonies are in decline and others are not.

Will McCallum of Greenpeace’s Protect the Oceans campaign, said: “This is a major step towards seeing permanent protection in the Antarctic Peninsula and we are pleased to see the fi shing industry listening to the movement of individuals, scientists and politicians across the world calling for ocean protection… we urge governments to step up and commit to creating ocean sanctuaries in the Antarctic, free from harmful human activities. At this year’s major UN conference on Biodiversity they need to agree an ambitious target to protect at least 30% of the world’s oceans by 2030.”

China set to build giant fi sh farming ships

CHINA is embarking on plans to build a powerful Dong Shaoguang, deputy general manager of the fl eet of giant fi sh farming vessels. Construction on Conson group. the fi rst of these 100,000 gross tonnage vessels The company also believes the project will bring began just before Christmas at Qingdao in the major environmental benefi ts in that the breeding eastern Shandong province. cycle will be shortened, allowing the production of

It is the fi rst of 50 such ships and should be quality seafood such as yellow fi sh. delivered in little over 18 months. They will be able They are expected to operate in the South to deliver large volumes of farmed fi sh both inside China Sea, the East China Sea and the Yellow and beyond China’s territorial waters. Together, Sea where China has been increasing maritime their output could be worth up to US $2bn. activities, much to the concern of nearby countries

They will also be equipped with some of the such as Vietnam, the Philippines, Japan and South most advanced aquaculture equipment including Korea. underwater cameras and automated feeding It is not just in aquaculture where China has facilities and able to withstand rough weather. been fl exing its muscles. Part of its huge fi shing

The Qingdao Conson Development Group fl eet has been spreading its nets across the Pacifi c Company plans to invest in the construction of Ocean. an aquaculture fl eet consisting of 50 such ships In the last couple of weeks the Chilean with a gross tonnage of 100,000 tons each, which government has ordered its navy to track the are expected to annually produce about 200,000 activities of several trawlers operating close to tons of seawater fi sh with an annual output value its exclusive economic zone (EEZ). Neighbours exceeding US$1.68bn. Peru and Ecuador are also closely monitoring the

The state-owned group primarily operates situation. as an investment company, focusing on ocean development projects. But it is also involved in non-marine businesses such as hotels and property.

Almost 250 metres long, each vessel will be fi tted with 15 tanks that can provide 80,000 cubic metres of aquaculture water which can be refreshed or exchanged without interruption, said Huon blames net tear for December escape

TASMANIAN fish farmer Huon has blamed a “net tear” caused by net cleaning for the mass escape of salmon from one of its pens in December.

An estimated 120,000 to 130,000 young salmon escaped from Huon’s Yellow Bluff site.

“Following extensive internal investigations including multiple discussions with on-water crew, analysis of vessel movements and assessment of works plans, the recent net tear at one of our pens in Storm Bay was most likely caused during net cleaning operations,” Huon said.

The company added that initial uncertainty around the cause was due to inconsistent GPS data about the location of vessels near the lease.

Huon’s statement went on: “Net cleaning is a complex task, with crew working with multiple pieces of equipment including generators, electrical and mechanical pressure pump systems, high and low voltage motors and associated parts,” stated Huon.

“We have implemented a range of actions to strengthen our operational processes including the installation of ROV (remotely operated vehicle) cameras on every net cleaning vessel and additional equipment training.

Shortly before the net tear incident, a fire on one of Huon’s other sites caused the escape of around 50,000 salmon.

TOUGHER new Covid-related health regulations have been announced for seafood companies exporting to China.

The Chinese authorities have said that much tougher requirements are justifi ed in response to the way the pandemic is spreading in certain parts of the world. They add that all seafood exporting countries must comply.

Businesses can continue to use existing health certifi cates until details of a new certifi cate have been agreed, but Beijing is demanding that companies list their entire seafood production chain. This means that many companies will have to register before the new certifi cates can be issued.

Those who were already listed were required to re-register if they want to continue doing business with China and the deadline for that was quite short – Friday, 8 January.

In addition, production volumes and other export details of seafood sent to China during the past 12 months will have to be stated.

The new requirements for health certifi cates demand that the entire production chain must be stated on the certifi cate and that includes names of fi sh farms or trawlers, freezer and reefer vessels, processing sites and storage sites.

Packaging and methods of transport (trucks, ships aircraft etc) must be thoroughly disinfected to prevent the spread of Covid-19. Packaging should also be able to withstand disinfectant treatments.

There are also further regulations about fi sh farmed or landed in one country and then exported on ships from another.

This is at least the third time since the outbreak of coronavirus that China has toughened the rules for seafood exporters.

Xelect and FirstWave in tilapia breeding partnership

AQUACULTURE genetics specialist Xelect has signed a partnership agreement with FirstWave Group, Africa’s largest tilapia fi sh producer.

The deal will create a breeding programme aimed at developing local, high-performance Nile tilapia breeds in east Africa, working with FirstWave’s operating companies Yalelo Zambia and Yalelo Uganda.

This strategic partnership, the companies say, will enable FirstWave to bring a data-driven solution to its breeding management.

FirstWave is Africa’s leading aquaculture fi rm, operating a vertically integrated group of companies across the production, distribution, and retail of aquafeed and fi sh in southern and eastern Africa.

Tembwe Mutungu, FirstWave Group Co-CEO said: “Success in leading innovation within African aquaculture requires the best ecosystem partners in addition to the best people. We are excited to partner with Xelect as they apply their global expertise and cutting-edge, data-driven tools to our local husbandry practices in Zambia and Uganda. This will allow us to breed tilapia pedigrees adapted to our local production environments, while avoiding the use of foreign genetics that present a risk to ecological balance.”

Xelect’s CEO, Prof Ian Johnston, added: “We’re delighted to be working with FirstWave as they are clearly one of the biggest names in African aquaculture. We share their passion for creating a sustainable, local source of protein, and were immediately struck by their high standards of professionalism. We’re seeing more and more producers realise the value of harnessing natural genetic variation to create the best possible fi sh for local conditions and believe this will become a fl agship example of best practice.”

Xelect is confi dent that a data-driven breeding program will lay the foundation for precision aquaculture farming at FirstWave, enabling locally developed tilapia to achieve superior performance in growth. quality, and health. Above: Tilapia

Benchmark Genetics wins Ningbo contract

BENCHMARK Genetics has been awarded a fi ve-year contract to supply eggs to Nordic Aqua Partners’ massive land-based salmon farm in Ningbo, China.

Construction on the Nordic Aqua Partners’ (NAP) site at Ningbo begins next month. Using RAS (recirculating aquaculture system) technology, the farm will have an initial capacity of 8,000 tonnes annually, but it is planned to increase this to 16,000 and then 40,000 tonnes. It will be the fi rst fully integrated and commercially viable RAS facility in China.

Ningbo is a coastal city, strategically close to Shanghai and with a population of 7.6 million in the city and surrounding area. The port of Ningbo-Zhoushan is one of the busiest in the world.

Benchmark has committed to provide 9.5 million ova, from its site in Iceland. NAP says biosecurity is a key issue for the Chinese government, and Benchmark’s biosecure facilities combined with a comprehensive screening system make the company confi dent that the eggs from Benchmark have the best starting conditions when entering into their RAS system.

Ragnar Joensen, Chairman of the board of NAP, said: “Benchmark Genetics has a proven record of their ability to supply live eggs all-year-round to destinations worldwide, and security of supply is of key importance to optimise the production planning at our facility. Their R&D capabilities and product offering, adapted for land-based RAS production add to the benefi ts of signing long term agreement with this provider.”

Geir Olav Melingen, Commercial Director at Benchmark Genetics, said he was excited about signing another contract with a landbased project, adding: “We aim to be the leading supplier of genetics to land-based farming, wherever located around the globe.

“We have already supplied eggs to China since 2002 and have established a logistic system that so far has worked successfully, even during the challenging times of Covid-19.”