10 minute read

Underwater Services

A clearer view

Robotics and imaging technology are transforming the way we work underwater

The underwater environment is intrinsically hazardous, with currents, poor visibility and the perils of decompression just a few of the hazards facing divers. It is important, however, to be able to inspect subsea installations, whether these are deep fish cages, oil and gas pipelines or communications cables.

Fortunately, technology is moving forward to create ever more sophisticated equipment to operate in challenging conditions and provide visibility in the murkiest of waters. Leading marine engineering business Ocean Kinetics, for example, offers a remotely operated vehicle (ROV) service that, the company says, “…is nearly always a much more cost effective operation compared to the use of more expensive manned diving teams.”

One example of an ROV is the Saab Seaeye Falcon. The Falcon, which was launched nearly 20 years ago, is now a multi-functional vehicle that can be fitted with a wide range of tools and sensors. Although just a metre long, it can be packed with different cameras and tools, ranging from rope cutters, cleaning systems and a powerful five function manipulator, along with a variety of cameras.

Matt Bates, Product Director, Saab Seaeye, says: “Aquaculture operators are attracted to the Falcon knowing it can work tirelessly, 24 hours a day for weeks on end, in extremely robust conditions, and at depths to 1000 metres if needed.

“And it can do so much. Nets can be checked and cleaned, moorings examined, ropes cut, repairs made, and items recovered. Also, fish status can be checked, feeding stations monitored and morts removed.

“For working around nets and moorings, the Falcon’s combined power and intelligent control system provides the agility needed to manoeuvre precisely in tight spots and strong currents and stay steady whilst working and filming.”

Marine technology business OTAQ also provides a way to keep tabs on what’s happening underwater with its seabed landers, produced by the company’s offshore division. In October it announced that it had won a contract to supply international marine services provider Unique Group with a number of landers.

Commonly used to record physical, chemical and biological activity, OTAQ Offshore will fit the seabed lander systems with inspection products, such as very high-resolution stills cameras, Eagle IP video cameras, OceanSENSE leak detection system and Dragonfish laser measurement systems. The systems will also be configured to carry other third-party supplied inspection and monitoring equipment.

Two models will be produced for Unique Group: a shallow-water version rated to 300 metres and a deep-water version rated to 4,000 metres, which

Left: Saab diver Right: Deep Trekker REVOLUTION Far right: Tritonia Scientific

will be available to end-users for rental and sale exclusively through Unique Group’s worldwide offi ce network. The two models will allow Unique’s clients to use the landers in a range of applica� ons using their exis� ng cables and winches.

OTAQ Off shore was created following OTAQ’s acquisi� on of Marinesense, which makes the OceanSENSE underwater leak detec� on and Dragonfi sh precision laser measurement systems for the off shore energy industry. It is a good example of the synergy that exists between the off shore energy sector and aquaculture. Technical advances in one sector can o� en help the other.

The big energy players are par� cularly helping to drive progress in developing ROVs and autonomous robots for subsea work. BP, for example, has reportedly commi� ed to a target of 100% of subsea inspec� ons performed via marine autonomous systems (MAS) by 2025.

This presents a huge opportunity for Scotland, which combines cu� ng-edge research into ar� fi cial intelligence (AI) and robo� cs with subsea engineering exper� se, both in energy and aquaculture.

An ar� cle published last year on the Sco� sh Development Interna� onal website www.sdi.co.uk (“New depths: robots in Scotland’s subsea industries”) listed some of the leading players in ROVs, including Aleron Subsea, Innospec� on and AC-CESS and the applica� ons to which they are being put.

The ar� cle also predicted a greater role for fully autonomous devices. While ROVs must be tethered and controlled from a support vessel, robot vehicles incorpora� ng AI (“AIVs”) could be managed from a much greater distance , even from onshore.

The SDI ar� cle says: “Once deployed, the AIV can inspect pipelines, cables and other infi eld infrastructure for the oil and gas industry independently of its support vessel, which can be engaged in other tasks. Its onboard systems use advanced AI and machine learning not only to carry out a pre-programmed mission, but also to recognise and iden� fy poten� al issues on the ground and transmit this data to its human team.

“An autonomous vehicle is more fl exible and effi cient in its approach and can deliver high-quality data even in diffi cult condi� ons.”

Saab Seaeye’s Ma� Bates says: “In a future that sees larger cages, going deeper, I can see advanced robo� c systems growing in importance. A typical key resource will be mul� -tasking robo� cs that can remain in residence at cages, ready to undertake rou� ne inspec� on and interven� on both autonomously and over distant control using the kind of resident robo� c technology adapted from systems we have developed for the off shore energy market. It is an exci� ng � me for robo� cs in aquaculture.”

For AIVs to be truly eff ec� ve, one of the challenges lies in improving communica� ons between robots and humans. Researchers working at the Off shore

EMPOWERING world leader in electric underwater robotics

Robotics for the Certification of Assets (ORCA) project run by Heriot-Watt University and the University of Edinburgh have developed a system that allows humans and machines to interact in natural language.

MIRIAM – Multimodal Intelligent inteRactIon for Autonomous systeMs – permits users to text or speak to a robot and get an answer in plain English, rather than code, just as would be the case with a human diver.

Meanwhile at a more practical level, Canadian robotics company Deep Trekker has developed firmware for its DTG3 and REVOLUTION inspection vehicles to allow users to choose which language they prefer to interact with the devices: English, Spanish or Norwegian. Deep Trekker’s ROVs are powered by long-lasting batteries, so don’t have to be tethered to a cable – making them more manoeuvrable.

It’s not just the vehicles themselves that technology is transforming. Coming up with useful images that can be interpreted accurately is a challenge underwater, particularly where visibility is limited. Tritonia Scientific, an underwater research, diving services and technology company based near Oban on the west coast of Scotland, has developed techniques to deal with the problem (see page 49 for more details). A key part of Tritonia’s technology is “stereophotogrammetry”, that is combining photos or videos to create 3D, highly accurate visual computer models.

Tritonia can combine data from a number of sources, including divers, ROVs, side-scan sonar and aerial drones, and can model objects of any size from sub-millimetre scales to several kilometres across. The process also makes the water “disappear” and the data can be presented in a range of formats, such as visually or in CAD (computer aided design) format, revealing anything from cracks in a pipeline to biofouling by invasive species.

It has often been said that we know more about the surface of the moon than we do about the ocean bed. Increasingly, however, technology is enabling a clearer view of what’s happening down there. FF

Far left: OTAQ Seabed Lander Left: The Falcon DR + skid 145r

Seeing is believing

A vision to advance underwater inspection

Why are accurate and reliable observa� ons of underwater structures and environments vital for the aquaculture industry? Many methods currently exist for obtaining underwater imagery, but most are not of suffi cient quality to support precise measurement or consistent monitoring. Emerging techniques and technologies are now being developed that not only provide visually appealing models but also generate accurate and dependable data, giving confi dence for important management decisions and regulatory repor� ng.

Tritonia Scien� fi c is an underwater research and technology company, located near Oban, which brings together decades of commercial, scien� fi c, and prac� cal marine exper� se to turn informa� on gathered underwater into valuable intelligence for customers’ business needs.

Most of their work uses the technique of stereophotogrammetry that combines photos or videos to create 3D, highly accurate visual computer models. The surveys are planned with clients to meet the specifi c requirements of inspec� ons and Tritonia can integrate data obtained from divers, ROVs, AUVs, side-scan sonar and aerial drones.

Precision and accuracy come from using: • high-end through-water GPS systems for georeferencing; • lasers or delineated markers for scaling and orienta� on; and • salinity-corrected pressure sensors for depth measurement.

Figure 1

Tritonia can model objects over a range of sizes, from several kilometres across down to sub-millimetre scales. These can be presented in a format that is most useful for the client, from CAD models to layered GIS packages.

Tritonia makes the water disappear virtually, producing clear visibility even in turbid or low-light condi� ons. The models visually expose structures or environments that are not possible to see using tradi� onal methods, producing permanent records that can be con� nuously assessed and used for whatever the client needs. Precise changes can be iden� fi ed using comparison so� ware on subsequent models which means that fewer surveys are o� en needed to show what is happening over � me.

Beyond the ini� al survey requirements, Tritonia’s clients have found addi� onal advantages of the models, including exact posi� oning as to where

Figure 3 Figure 2

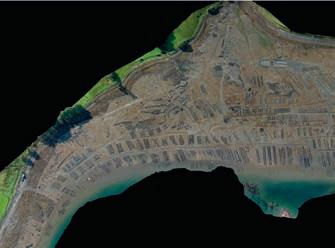

environmental samples, such as seabed cores, are taken or where invasive species have been iden� fi ed during biosecurity surveys. In addi� on, low� de aerial drone surveys can produce photogrammetric maps of broad-scale inter� dal aquaculture resources, such the 47-hectare oyster farm shown in fi g 3. These orthomosaic models display both loca� on and shore eleva� on informa� on.

Whatever the need for wan� ng to know more about what is underwater or close to the water, Tritonia Scien� fi c is dedicated to revealing it all. www.tritoniascien� fi c.co.uk FF

Figure 1: A georeferenced model of a 12x12 m sec� on of seabed produced where in-situ water clarity was 1-2 m. Figure 2: A Model: 136cm rock anchor (medium resolu� on). Used to measure: levels of biofouling, degree of anode sacrifi ce, depth of penetra� on, angle/ direc� on of incline. Figure 3: A 47-hectare oyster farm