11 minute read

Three Factors Driving Demand for FULL-SIZE STAND-ON SKID STEERS

transporting equipment can be a daily, yet headache-inducing task for contractors. To help eliminate the downtime associated with this task, it is crucial that you bring machinery onto the jobsite that is designed to be quickly stored at the end of the workday and easily transported from one project to the next. Stand-on skid steers are compact enough to fit on a trailer, yet large enough to make a difference in filling the gap for laborers.

Creative & Versatile Solutions

In addition to added power and workforce support, contractors are reaching for full-size stand-on skid steers for their versatility. Rather than hauling multiple smaller, specialized machines to a jobsite, a larger standon skid steer can be outfitted to complete a wide variety of tasks. Fullsize, stand-on skid steers have the capability to be outfitted with power attachments like a microtrencher for fiber installation projects. A fullsize, stand-on skid steer can go from trenching for a utility installation to hauling gravel in a matter of minutes.

In fact, the versatility has made the tree care industry a major driver larger stand-on skid steer trend. Being able to move bigger logs means tree care professionals are spending less time making cuts before hauling away. Attachments like tree grapples and bucket grapples are being used to help improve efficiency in treecare jobs like debris removal. The compact size—compared to cabbed machines of the same operating capacity—also make it ideal for tree care professionals who need to seamlessly maneuver through yards and residential areas.

With smaller crews and high demand, many contractors are taking on two or three different jobs in a day, so having a machine in the fleet with more power and versatility to stay efficient and cost-effective is key.

Big ROI

With the wide variety of attachments, a stand-on skid steer can be rented year-round for tasks like digging, hauling, grading and snow removal. This versatility means that the machine can be rented to a wide range of customers with different needs, making it a profitable addition to any rental fleet.

Compared to their cabbed counterparts, stand-on skid steers are a simpler, less intimidating option for inexperienced renters working on residential projects. The compact design of a stand-on skid steer allows it to fit navigate around obstacles, making it perfect for use in backyards or other confined jobsites.

Stand-on skid steers are designed to be easy to use, even for novice operators. The simple controls and intuitive design make it easy to get started with the machine, and their reliability gives renters reassurance they’ll be able to complete projects with minimal maintenance. With a stand-on platform, operators receive a 360-degree view. This increase in jobsite visibility and comfort helps operators see what is happening around the machine, boosting jobsite safety.

With so many options on the market, there’s a reason contractors and renters are driving the trend for full-size stand-on skid steers. The powerful, versatile machines are a valuable asset to any rental lot or contractor’s fleet. They’re powerful enough to fill the gap where the workforce is short, yet simple enough for renters to hop on safely and get to work in their backyards. The range of attachments and easy-to-operate design makes full-size, stand-on skid steers a great option for those looking to get the best bang for their buck on the jobsite.

Read more at: https://eqtoday.co/c16gqw

Canycom CMX1402 Ride-On Brush Cutter

The Canycom CMX1402 Ride-on Brush Cutter features four-wheel drive and large tires for added traction on slopes and wet ground.

• Hydrostatic drive system for smooth and seamless operation

• Shaft-driven cutter deck requires no belts or pulleys

• Adjustable cutter deck for trimming from 0 in. to 6 in.

• 389-cc Honda gas engine with a rated output of 14 hp

Ignite Attachments

Grapple LIne

Ignite Attachment’s grapple lineup offers powerful, versatile tools that allow equipment operators to pick up and move heavy objects, such as logs, rocks, roots and debris, without sacrificing heavyduty performance capability. The Ignite grapple attachment is designed to fit a selection of machines and can be used in construction, demolition or landscaping projects. You will be able to find the root, rock and bucket grapples in 82-in., 74-in., 68-in. and 62-in. models. Ignite Attachment’s grapple line is capable of picking up and moving objects of various shapes and sizes. Its powerful jaws can grip objects securely, preventing slips or falls during transport.

Fecon Compact Stumpex

The Compact Stumpex is a slow-speed, high-torque, auger-style stump grinder designed specifically for compact utility loaders.

• Slow auger speed ensures a safer work environment with no flying debris and faster cleanup

• High torque eradicates stumps of any species from 4 in. to 11 in. in diameter in a single plunge

• Powerful, robust drive generates up to 4,000 lbs. of torque

• Features hardened auger cone that ensure positive draw into stump and stepped blades made of 1/2-in.-thick durable AR500 material

• Suited for compact utility loaders with 10 gpm to 20 gpm of hydraulic flow and 2,000 psi to 3,000 psi

Loftness Battle Ax Skid-steer Mulching Attachment

The heavy-duty Battle Ax horizontal drum mulcher is offered in 61-in. and 71-in. cutting widths for skid steers with 50 hydralic hp to 120 hydraulic hp.

• 17-in.-diameter rotor features built-in depth gauges to prevent attachment from engaging too much material at one time

Two-stage cutting chamber allows material to be cut twice by the rotor and helps produce smaller particle sizes

• Primary shear bar adjustable for customizing particle size

• Adjustable skid shoes (0.5 in. to 1.5 in.) enable below-grade mulching

• Fixed-displacement gear or variabledisplacement piston motor

Mastodon Model M60-S and M60-C Mulcher Attachments

The M60-S and M60-C forestry mulchers have a 60-in. cut width and are powered by a 160-cc variable piston hydraulic motor controlled by E-TECH Smartdrive.

• ECU-controlled power management system adapts and controls motor displacement to produce instant torque and optimal mulching performance

• Can be tuned to any machine in seconds using Bluetooth and a smartphone app or with the in-cab monitor

• Direct drivetrain puts all available power to the rotor

• Head on the M60-S produces up 780 ft.-lbs. of torque with a maximum rotor speed of 2,500 rpm

M60-C includes a hydraulically controlled dual-mode cutting chamber that offers fingertip control of mulch size and degree of broadcasting desired

LiuGong 915E FM Excavator

The 915E FM is a professional forestry excavator designed for logging, collecting and transporting wood under harsh working conditions, such as forests, wetlands and more. This machine is equipped with a Cummins engine and a coordinated hydraulic system for output and movement. The 915E FM uses specific protection for forestry and a 960-mm-wide single-grouser track. The minimum ground clearance is up to 600 mm for safety and low grounding pressure for travelling in the forest.

John Deere ME36 and ME50 Mulchers

The ME36 and ME50 are suited for right-of-way maintenance and fire/fuel reduction as well as clearing standing or felled trees and brush along fence rows, roadsides, waterways and other hard to reach places.

• Knife-style cutting teeth on a split ring rotor

• Spiral double helix tool pattern and tool shape allow for efficient cutting of up to 5-in. material

• Controlled and metered cutting depth allows the operator to maintain high rpms and a productive mulching rate

• Teeth may be sharpened and flipped

• Tested and optimized to work with the company’s excavators and compatible with many competitive 5-ton to 10-ton models

Werk-Brau Grubber

The Grubber slices roots and extracts brush in one easy motion and is available in models to fit most excavator sizes and classes including minis.

Constructed with a heavy-duty upper channel, AR400 steel cutting edges and triple pass welds on the high-stress areas

• Available with a replaceable bolt-on edge V-edge or straight edge

• Suited for select extraction of brush and nuisance vegetation

• Minimize ground disturbance, reduce erosion and promote grass growth

Caterpillar D1 Mulcher

Powered by the 104-hp Cat C3.6 Tier 4 Final/Stage V-compliant diesel engine, the D1 Mulcher includes closed-loop hydraulics and upgraded screening that optimize performance while clearing a mix of small- to medium-diameter materials in a 72-in.-wide strip with each pass. The unit is design-matched with the rugged HM518 mulcher, which has a drum speed range of 2,150 to 2,450 rpm and comes with 38 fixed teeth featuring a single-bolt carbide tooth retention design. Its pressurized, heated and air conditioned cab includes mulcher controls mounted on the air suspension seat, a 10-in. color touchscreen monitor with standard reversing camera display and an in-cab drum indicator for monitoring drum speed and direction at a glance.

Fecon 135VRT Mulcher

The 135VRT has a 4,150-lb. rated operating capacity with integrated counterweight or hydraulic winch kit, and is powered by a 132-hp Cummins 3.8L Tier 4 Final engine. A 50-gpm auxiliary attachment flow provides 119 hp to the VM602SS Bull Hog Forestry Mulcher or other attachments; a 16-gpm reserve allows full machine control without loss of attachment performance. A bite-limiting rotor is fitted with 30 carbide or doublesided tools and maintains rotor rpms to easily mulch material up to 8 in. in diameter. An improved loader arm design enhances attachment visibility. The full forestry spec cab includes 1/2-in. polycarbonate side windows, a Level 2 FOPS and a complete guarding package, while the more spacious, comfortable operator station includes an 8-in. color display.

Danuser Stump Auger for Backhoes and Mini Skid Steers

Danuser’s EP Auger System for backhoes, mini skid steers and excavators feature a planetary gear drive that is up to 42% stronger than the competition with greater torque for drilling through hardcompacted surfaces. It is available in a wide array of models, ranging from 6 to 35 gpm and from 1,500 psi to 3,500 psi.

• Accessible check and fill plugs

• Swings from a knuckle to allow left to right, forward to back leveling

Most vehicles with 72-in. or greater hinge pin height may use standard 4-ft. length augers. Hinge pin heights of 71 in. or shorter require 3-ft. length augers maximum

• The output spindle is manufactured as a single piece, allowing Danuser to offer a lifetime warranty covering output spindle pullout

Vermeer HG4000 Horizontal Grinder

Vermeer has introduced a redesigned version of the HG4000 horizontal grinder. This new generation of the HG4000 delivers performance in various wood waste recycling applications and landscaping material production. It’s equipped with a 536-hp (399.7-kW) CAT C13B T4F Stage V diesel engine, a Series III duplex drum, an infeed to accommodate a variety of materials and many performance and durability features. It has a working sound level of 112 decibels. The HG4000 has a feed table capacity of 4.6 cu. yd. (3.5 m3). It features the cutting performance of the Vermeer patented Series III duplex drum with reversible hammers and tips for reliable wear life, compared to singlesided designs, while offering bolt in replacement parts. The hard-faced anvil on the HG4000 delivers cutting action with the drum and a redesigned anvil-mount structure minimizes the hard-faced wear edge replacement process.

Komatsu PC230F-11 Forestry Processor

Purpose-built for processing applications, the 197-hp PC230F-11 has a rugged design, high and wide undercarriage, a powerful swing motor and is designed to withstand high-debris conditions. The wide-fin radiator is covered by heavy-duty forestry screens, and a variable pitch reversing fan helps promote airflow. With a powerful swing system and a large swing circle, trees can be moved with the PC230F-11. Its reach of up to 29.3 ft. (8,951 mm) and maneuverability help support operations. This machine features a Komatsu SAA6D107E-3 Tier 4 Final engine. Operators can adjust to a sudden change in load weight with the Auto Power Max feature. It automatically senses the difference and reacts with an 8.5-second burst of additional horsepower to help pull the trees through during the delimbing process.

SEPPI Mulching Equipment

SEPPI has launched its latest mulching equipment: the MAX 50 le, a mulcher than can be operated by remote control, the MICROFORST cl compact mulcher for skid steers or compact track loaders and the MINISOIL cl that crushes stones and mulches wood. The MAX 50 le can be operated from a safe distance by using a remote control that displays key machine data like fuel, rpm and speed. The MICROFORST cl is a compact mulcher that can attach to any compact track loader or skid steer loader that delivers between 13 gpm and 27 gpm of hydraulic flow. The MINISOIL cl takes the power of a PTO stone crusher and mulcher and brings it down to size for skid steers, compact track loaders and hydraulic tractors that deliver at least 28 gpm to 66 gpm of hydraulic flow.

IronCraft Redesigned Forestry Disc Mulcher

IronCraft redesigned its Forestry Disc Mulcher, which is capable of eradicating 6-in. to 14-in. diameter materials and standing or felled trees. A 60-in. fully machined disc includes 44 beaver teeth located on the top, bottom and perimeter of the disc, with five additional beaver teeth located on the inside of the deck for mulching capacity. An angled throat design guides material into the mulching chamber to support the shredding of brush. This mulcher is available with either 150-cc motor that requires 32 gpm to 44 gpm of hydraulic flow or 200-cc motor that requires 45 gpm to 60 gpm of hydraulic flow. All models feature a 1-in. hinged deflector and 0.375-in. thick deck with reinforced sides.

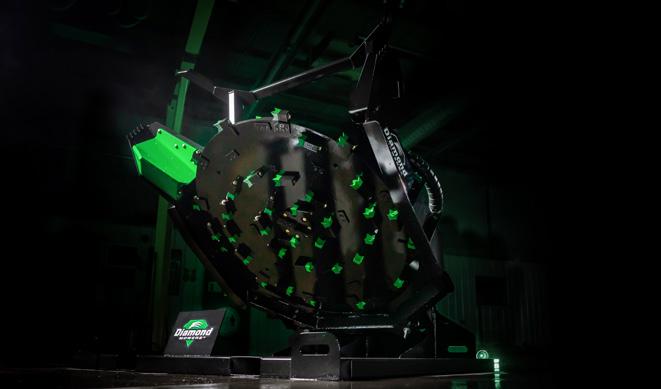

Diamond Mowers Belt Drive Disc Mulcher

Diamond Mowers offers the Belt Drive Disc Mulcher for contractors and mulching professionals. The attachment features reliable torque and promotes low hydraulic temperatures for uptime and carrier life. Forward visibility for contractors minimizes the possibility of hitting obstacles and enables positioning vegetation for performance. Featuring a 60-in. cutting width, this attachment slices through trees and brush up to 14 in. in diameter, shreds material up to 6 in. in diameter and attaches to most skid steers and compact track loaders. While Four-Point Hardened Steel Teeth come standard, users can swap them for Twin Maul Carbide Teeth to absorb impact and apply the right bite for various applications.

Artillian Tractor Mini Skid Steer Quick Attach Frame for Mini Track Loaders

The Mini Skid Steer Quick Attach Frame for Mini Track Loaders includes a Common Industry Interface (CII) loader quick attach, enabling use with a variety of brands of mini loaders, including Bobcat, Boxer, Ditch Witch, Kanga, Ramrod, Toro and more.

• Designed for a maximum load of 3,000 lbs. at an 18-in. load center, depending on fork tine capacity

• Frames can be used with the company’s pallet forks, grapples, stump buckets, hydraulic plow and more

Built using high-strength steel with MIGwelded construction

• Baked-on powder coat augmented by a proprietary graphite coating on the fork rails for easier sliding of forks

• Includes a built-in 2-in. receiver

Mecalac Multifunctional Compact Loader Line

Mecalac’s new product line of compact loaders to the North American market is comprised of six models, including the MCL2, MCL4, MCL4+, MCL6, MCL6+ and MCL8. The series offers performance for industries ranging from agriculture to landscape, forestry, snow removal, utility and construction. The M-Drive and speed control features allow the loader to function as a tool carrier, providing control of rpm by hand throttle and speed via a foot pedal. This enables controlled operation of a wide variety of hydraulic attachments. Each MCL in the series has an option for auxiliary hydraulic lines on the boom and at the rear of the machine, as well as 12-volt three-pole plugs, allowing the ability to use hydraulic attachments on either end of the machine. The MCL series maximizes attachment possibilities with 7.9 gpm flow on the MCL2 and MCL4 models and 15.9-gpm flow on the MCL6 and MCL8 models. Each machine has a 45-degree articulation that keeps the front wheels traveling in the same path as the rear wheels while driving. A 10-degree oscillation allows a stong follow up and maximum traction wherever the machine might travel, including on uneven ground. Each machine in the MCL series offers transportability between jobsites with low transport weight, which ranges between 3,836 lbs. and 6,283 lbs.

Digital solutions, new tread patterns and maintenance improve uptime.

The overall importance of having the right tires on jobsite equipment and maintaining them properly cannot be overstated. Maximizing uptime and increasing efficiency is always top of mind for construction fleets, and both factors are directly impacted by a fleet’s tires, noted Robby Hamby, Bridgestone America’s director of commercial product strategy.

“These tires are asked to navigate challenging surfaces and conditions, making the equipment vital for operations,” Hamby added.