8 minute read

Advances in Machine Control

On the jobsite, safety, efficiency and uptime are key to success in a market that’s facing tighter margins, a smaller labor pool and the need to do more with less. As contractors and crews face increasing demands for productivity, advancements in machine control capabilities are enabling operators to have more intuitive control over their work trucks.

From the ability to remotely customize cab settings and control attachments to improved diagnostic capabilities and troubleshooting, the benefits of control systems are revolutionizing the construction industry by taking the guesswork out of operations.

The best machine control systems combine strong, reliable hardware with flexible, intuitive software that leverages large amounts of data to help equipment operators more accurately position and operate attachments, such as electric, hydraulic and articulating cranes, and provides them with real-time load and safety information.

Often, a system’s technology allows decisions to be made based on data, in addition to relying on the skill and experience of the operator. As the construction industry faces ongoing challenges with labor shortages, datadriven control capabilities will become even more critical.

The construction industry averaged more than 390,000 job openings per month in 2022, the highest level on record, according to data from Associated Builders and Contractors.

A proprietary workforce shortage model developed by Associated Builders and Contractors found that the construction industry will need to attract an estimated 546,000 additional workers on top of the normal pace of hiring in 2023 to meet the demand for labor.

In 2024, the industry will need to bring in more than 342,000 new workers on top of normal hiring to meet industry demand.

As the industry works to get operators onboarded and trained quickly, safely and efficiently, advanced control systems can help minimize the downtime needed for training while also helping to increase operators’ performance and accuracy as new hires learn the ins-and-outs of operating a work truck.

Continued technological advancements and optimized functionalities with control systems are enabling operators to have control over their productivity, reliability and safety in the palm of their hand.

Improved Safety, Efficiency

One of the biggest benefits of control systems is the focus it brings to safety and efficiency. Some safety features enabled by control systems include the ability to run stabilizers from a wireless remote control so that operators have a clear view of what’s around them when deploying the stabilizers. This allows the operator to deploy stabilizers and observe the unit position for leveling from an improved vantage point. Data collected by the system also provides operators with information about the load and safety checks and warnings from the remote alert operators when they are reaching crane load capacity.

When it comes to efficiency, control systems help eliminate downtime between tasks by allowing the operator to not have to walk back to their truck every time they want to turn something on or turn something off.

For example, operators are able to turn on a compressor or engage a PTO right from the remote to prevent them from having to climb off the piece of equipment they’re operating, saving time and resources on the job.

Customization Capabilities

Machine control systems also allow for the customizable programming of work truck operations. Control systems can be easily adjusted from their default settings allowing work trucks, which are designed to take on many different applications, the ability to operate in different jobsite environments.

With control systems operators can individualize multiple operations, including things like flood lights, compartment lights, and more. Being able to easily program different lighting setups is a valuable feature that helps to ensure operators are able to accommodate every environment they work in.

Upgraded Diagnostics

In addition to the safety features and customization options, control systems enable improved diagnostic capabilities that help operators to be more productive. Operators have the ability to see inputs, outputs, crane fault codes and more, which empowers them to quickly and efficiently diagnose issues to maintain optimal uptime.

In the advent of electrification, greater operational precision and increased data collection will help to make machine control systems even more adept and efficient.

Electrification improves data capture opportunities because battery powered equipment generates more data than traditional diesel-powered equipment and provides deeper connectivity, leading to improved equipment insights and diagnostics.

With advanced load management capabilities, improved crane diagnostics, customizable cab operations and more, advancements to control systems are helping to keep operators well-equipped for any job at hand.

Generac LINKTower Light Tower

The LINKTower portable, linkable, zeroemission LED light tower includes 235-W LED fixtures for long-lasting and efficient illumination.

• Impact-resistant LED light fixtures provide 39% more lumen output and have 32% more coverage

• Powered supplied by a standard 120-V outlet, providing silent, emission-free operation

• Ergonomic folding handles and an added caster wheel allow for one-person maneuverability

• Smaller size fits through a standard door opening and a single person can set it up

• Can be used individually or as many as five units can be linked to illuminate large areas

Lind Beacon LED Towers

Lind Equipment says its Beacon LED Lind Equipment’s LE980LEDV-T4 light Tower delivers as much light as a traditional light head with four 1,000-W metal-halide lights but in a completely unexpected package. The Beacon LED Tower uses direct-drive, high-efficiency LED lights and runs whisper-quiet on user-supplied generators or when attached to an external power source.

Compact and weighing just over 300 lbs., the Beacon LED Tower is manportable. Two can be transported in a standard pickup-truck bed. Although Beacon towers don’t come with their own power source, they can have a supplemental fuel tank built in with the capacity to run the tower using a 2,000-W generator for up to 45 hours between refueling. With acquisition costs at half that of traditional light towers, operating costs can be as low as $ 0.10 per hour. Both models are available with two or four light heads.

• Lind LED heads match Lind’s light-level tests show the Beacon LED Tower putting more light onto the work area than traditional metal halide light towers at median light output metal-halide output at 80% less power

• Lind lights warrantied for 3 years, rated for 50,000 hours

• Two towers can run on a 15-A circuit

Larson Electronics WAL-TP2X50E-1224 LED Light

The WAL-TP-2X50E-1224 tripod mounted LED light for work areas comes with two LEDP10W-50E LED spotlights that each produce 4,300 lumens of light while drawing 4.17 amps from a 12-V electrical system. This portable LED work light features five 10-watt LEDs that each produce 860 lumens that are paired with high purity optics to produce a 20-degree spot beam that is 525 feet long by 75 feet wide. The light features LED light bars that are waterproof up to 3 m and sealed to prevent dust and dirt from getting inside. The LEDs on this unit can operate on voltages ranging from 9 V to 46 VDC without the need for modifications. This LED light can withstand rapid temperature changes of -40˚C to 85˚C and features LEDs that offer 50,000 hours of lamp life.

National Signal Sunray LTS

This tower is designed to meet the rigors of heavy-use areas such as construction, mining, utility and security. Its silent nature provides quiet operation. The LTS mast is built extra heavy to provide a solid foundation for almost any use. On top of the mast are four heavyduty LED light fixtures with ultra-high intensity, state-of-the-art LED’s with remarkable brightness. LED light fixtures boast brightness levels of 40 W, 85 W, and 160 W.

Allmand GR-Series Light Tower

The Night-Lite GR-Series light tower has an air-cooled Yanmar diesel engine that provides lightweight, low-maintenance power and can handle temperatures of -6°F to 104°F.

• Four fuel-efficient LED fixtures with 195,592 total lumens provide a 300-hour run time

• 40-gal. fuel tank

• 20 units can be shipped on a 48-ft. truck

• Simpler, lighter, lower cost GR-Series Chain model designed to be easy to deploy and maneuver, works with any 15-amp or 20-amp power source and features daisychain capabilities

Thermal Intelligence Basecamp

The Basecamp green-certified heater, light tower and generator delivers efficiency as a flameless heater plus provides a 360-degree LED lighting package and 27 kW of available power.

• SmartTalk IoT technology monitors and controls the heater 24/7 and alerts via SMS or email before there’s a problem

• Light package produces 192,000 lumens 5K color

• Minimum run time of 48 hours with 27 kW of continuous power

• Kubota 2.4-liter, electronic Tier 4 Final engine

• 119-gal. fuel tank capacity

Ignite Attachments

Fit-Finder

Ignite Attachments offers Fit-Finder for construction businesses looking to compare attachment products for their work vehicles. The Fit-Finder tool compares the specs of the carrier and the attachment to determine compatibility. The interface of the Fit-Finder delivers a simple experience and eliminates the need for holds or callbacks with the entire process accessible from its mobile-friendly site.

Ritelite Systems K65

Ritelite Systems’ new quad pod

K65 mobile lighting towers gathers the maximum light emitted from the LEDs (measured in lumens) and enables users to optimize the light projected onto the work site (measured in lux) to suit their specific application. Specially designed optics enable the LED modules to be aligned almost parallel to the ground instead of pointing directly into the worker’s line of sight. This helps prevent accidents on the construction site due to distraction from light glare. The beam control LED light heads are driven by remote and dimmable LED drivers mounted at the base of the light mast. The Ritelite beam control system, delivers the following output levels: 180-degree directional illumination = 20 lux average over 6,868 m.

B2W Software Alert and Notification Features

B2W Software added new alerts and notifications capabilities in the current release of its B2W Platform. The new features let contractors communicate automatically and in real time across the office, field and shop to support resource scheduling, field performance tracking and equipment maintenance workflows. More than two dozen actions taken in the B2W Schedule, B2W Track and B2W Maintain applications can now trigger messages delivered to selected recipients by text message or email. These actions range from creation of resource assignments and maintenance requests to submission, approval or rejection of field logs and mechanic timecards.

Trimble X9 3D Laser Scanner

Trimble announced the launch of the X9 3D laser scanning system, a new reality capture solution for surveying, construction and engineering professionals. The X9 is built on Trimble’s laser scanning technologies, engineered for performance in various environments using Trimble X-Drive technology for automatic instrument calibration, survey-grade self-leveling and laser pointer for georeferencing.

A new center unit design supports signal transmission for scan quality. With reality capture capabilities, the X9 broadens potential applications for customers in surveying, building construction, oil and gas, rail, forensics, monitoring, tunneling, mining and others.

HCSS ADPlus Dashcam

Heavy construction companies can use the HCSS Dashcams on their fleet vehicles to not only protect drivers but to avoid accidents. HCSS Dashcams integrate with the HCSS Telematics system. The HCSS ADPlus Fleet Dashcam is a plug-n-play dash camera with a built-in Al processor to detect driving events like forward collision and improper driver behavior, such as using mobile phone usage and distracted driving. HCSS Dashcams will alert the driver in real-time of potentially unsafe behaviors and upload events to HCSS Telematics to be reviewed by a fleet manager.

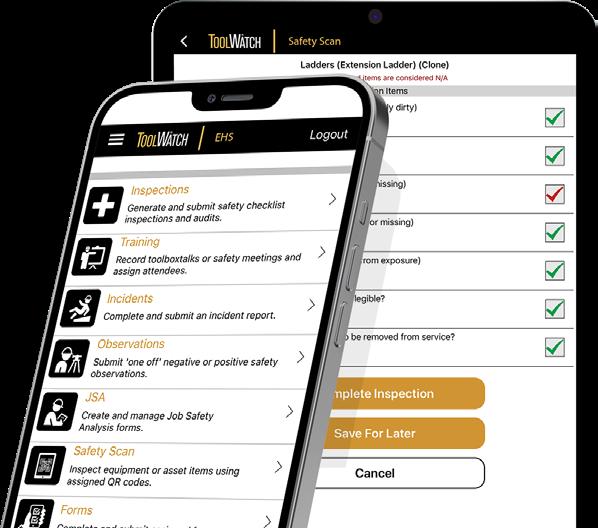

ToolWatch Construction EHS Management Solution

ToolWatch EHS is an environmental health and safety product offering that helps general and specialty contractors manage their safety programs. The addition of EHS expands the ToolWatch construction operations platform to integrate safety and compliance with other jobsite workflows and data. ToolWatch EHS offers a suite of safety management tools, enabling construction organizations to manage safety and compliance on a single platform. These capabilities include inspections, compliance reporting, training, observations, incidents, job safety analyses, custom safety forms and a dashboard for administration, data analysis and reporting.