4 minute read

HIGH PROFILE – UFR

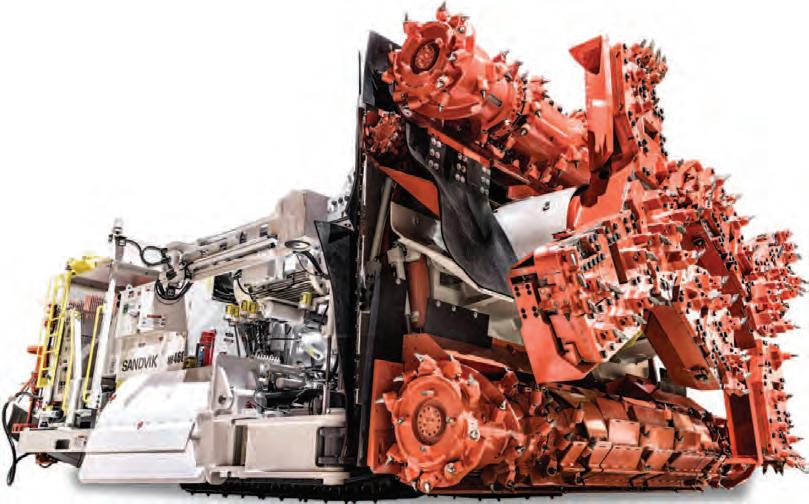

More robots for better mining

Universal Field Robots Managing Director, Jeff Sterling, outlines how the greater use of robotic technology can at the time make operations safer and more efficient

Advertisement

With a mantra of more robots for safer mining, Universal Field Robots (UFR) sees a future involving swarms of small robots inhabiting the space between bigger mining equipment and activities. The pandemic is still impacting mining, with skills shortages and many critical tasks delaying production. UFR is working towards having the largest robot fleet on the planet and has enrolled robots to manufacture these robots. Robot manufacturing provides high quality and speed, with lower cost a valuable byproduct.

In collaboration with IMDEX Limited, UFR is building BLAST DOG™ robots in increasing numbers, with a presence on multiple mine sites across the globe. BLAST DOG™ is an autonomous system to optimise blasting based on highresolution three-dimensional material models built from the sensor data the robots collect from blastholes. UFR is advancing the BLAST DOG™ automation application and each new release brings improvements in operating performance and new capabilities.

Supporting swarms of robotic machines around the world is a new challenge, which is supported by technology. Working robots record what they see and feel and UFR has built infrastructure to capture these moments. Robot memories can be teleported to the cloud allowing robotics engineers to replay an event to find the cause of a performance decline or operations glitch. This allows us to reimagine the future, adjust some computer code or settings and squeeze even higher levels of performance from our robot team. Shaving a few seconds off an action mightn’t sound like much but repeated 200 times a day 24/7 it quickly results in higher levels of performance and profitability. The repeatability of robotics can’t be beaten for tasks like working on thousands of blastholes that appear almost identical from the surface.

While robots are delivering efficiency, they are also paving the way for safer operations via zero entry mining. One example is voids in hazardous mining areas that can have tragic consequences. Natural and historical mining voids can cause a collapse of ground with no warning. Robots can drive over ground of unknown competency, map voids, reduce delays and improve productivity, while eliminating operator risk. UFR’s development roadmap features safe robotic solutions commencing with all blasting activities.

In collaboration with multiple mining clients and METS Ignited, UFR is developing a new robotic application for zero entry work on underground production blastholes. The robots first capabilities are cleaning and surveying –some of the remaining dirty, dangerous, and diabolical underground mining tasks. This requires work at heights in a basket to push a hose ~30 m up a blast hole, resulting in rock and water showers along with damaging highpressure air noise.

The new robot drives to a ring and uses perception to find/align the specially designed attachment that pushes a hose into the blastholes. Training has been completed at our test mine in Brisbane and trials have commenced on minesites in Queensland and Western Australia. The development team has found some blastholes can require 3-4 cleaning cycles, but as it’s an automated process, the robot doesn’t work up a sweat. Operators are happier being far from the showering gravel and noise and can make coffee while checking on the robots via the remote-control station. Our collaboration partners recognise the importance of eliminating hazardous activity with significant health and safety improvements.

To simplify setting up remote control at a safe distance, UFR has also released a containerised remote-control station that can be quickly deployed with mesh radio. The containerised RCS is insulated and air conditioned with a desk incorporating two operating locations for a variety of scenarios with ample room for a coffee machine.

New user interface enhancements continue, some via operating partner suggestions. New work applications are demonstrating LIDAR perception value with its detailed and accurate capture of surroundings. Complex tasks are assisted with camera views, LiDAR images and cartoon reimaginations from gamified angles. One South African mining partner has requested the user interface show drone captured changes in the mine environment to enhance operators’ situational awareness.

Robot capabilities built for one application can also quickly be adapted to benefit others. This platform approach also works across sectors with cross pollination of ideas accelerating capability roll out. Enhanced movement control and better AI vision developed for a defence project can be shared to boost performance of other applications.

It’s early days and what we can do now is almost certainly a fraction of what is possible. Robotics that allows people to avoid hazards is available and is the only way for operators to truly be safe. What are we waiting for? IM