16 minute read

Selection 2020: Village of Wellington Votes for an Anaerobic Selector to Achieve Sludge Volume Index and Phosphorous Control—Shannon

FWRJ Selection 2020: Village of Wellington Votes for an Anaerobic Selector to Achieve Sludge Volume Index and Phosphorous Control

Shannon LaRocque, Bryan Gayoso, Alonso Griborio, Paul Pitt, and Eric Stanley

Advertisement

The Village of Wellington (village) Water Reclamation Facility (WRF) is an oxidation ditch aeration-type activated sludge wastewater treatment plant. The WRF is permitted to operate with a capacity of 6.5 mil gal per day (mgd) on a three-month average daily flow (TMADF) basis. Two important goals were identified in the recently completed WRF master plan and reuse master plan: S Improvement of sludge settleability S Reduction of effluent total phosphorous (TP)

As part of the WRF master plan, it was determined that improvement of the sludge volume index (SVI), a measure of the settleability of solids in secondary clarifiers, is a critical goal to support operation of the WRF within allowable permit constraints as it approaches a rated flow of 6.5-mgd TMADF. Simultaneously, as part of the ongoing reuse master plan, in-plant reduction of phosphorous from the WRF effluent was recommended to be reduced.

Installation of an anaerobic selector tank was identified as the preferred method to improve SVI, and as Phase 1 of a two-phased approach to reduce effluent TP. The return activated sludge (RAS) chlorination was also recommended to provide operators an additional low-cost tool to control occasional sludge-bulking episodes. It was determined that modifying the aerobic digestion process to operate at lower dissolved oxygen (DO) levels and maintain higher pH is anticipated to reduce effluent phosphorous levels. Under future Phase 2, variable frequency drives (VFDs) will be installed on the digester blowers and operational control will be modified to reduce DO or allow for cyclical aeration.

Shannon LaRocque is utilities director and Bryan Gayoso is water reclamation facilities superintendent with Village of Wellington (Fla.) Utilities Department. Paul Pitt is wastewater process design director, Alonso Griborio is senior associate, and Eric Stanley is an associate with Hazen and Sawyer in Boca Raton.

Phases of Operation

Phase 1: Anaerobic Selector to Reduce Sludge Volume Index

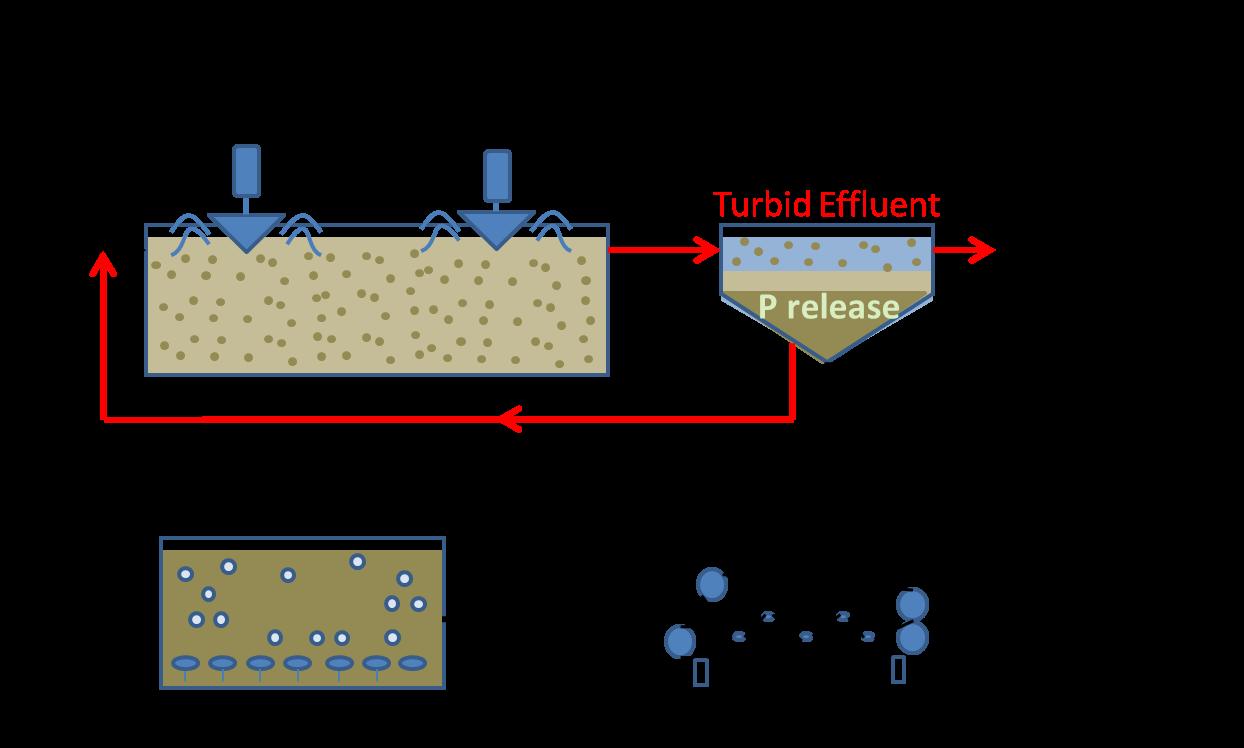

Slow-settling sludge is a chronic issue at the WRF, with an average SVI of 260 milliliters per gram (ml/g), and fifth-percentile SVI of 230 ml/g always in exceedance of the typical maximum recommended value of 200 ml/g. The slow settleability is related to a long solids retention time (SRT), combined with limited oxygen, and utilization of carbon by undesirable filamentous organisms. The primary concern of high SVI is that it increases the risk of permit carbonaceous five-day biochemical oxygen demand (cBOD5) and total suspsended solids (TSS) permit exceedances, and the inability to produce reuse water during process upsets or wet weather events.

A secondary, but important, concern related to slow sludge settleability is that phosphorus release occurs in the clarifier sludge blankets due to the resulting high anaerobic detention time of sludge. Although the immediate concern for high SVI levels and slow settleability may be lessened due to the fact that 100 percent of effluent is filtered, the slow settleability will become more of a concern over time as flow rates to the wastewater plant are expected to increase. Continued on page 6

Continued from page 4

A schematic illustrating the sequence of how the slow sludge settleability affects treatment performance is presented in Figure 1.

Phase 2: Reduction of Effluent Total Phosphorus

The downstream C-51 Canal has a total maximum daily flow (TMDL) requirement for TP of 50 parts per bil (ppb). Although the WRF currently does not have effluent TP or total nitrogen (TN) limits, the village continually endeavors to improve surface water quality discharged to the regional surface water system (C-51 Canal) by implementing stormwater management programs to meet the target; therefore,

Figure 2. Effects of Digester Overaeration and Low pH Inhibition on Treatment Performance stakeholders may be sensitive to increased TP loading that may migrate from reuse water applied to the receiving basin and the canal system, which is why the concurrent reuse master plan investigated reuse water impacts to surface water phosphorous loadings.

During sampling, it was discovered that current elevated effluent phosphorous levels at the WRF appear to be mostly attributed to the low pH inhibition of the aerobic digesters. As air is provided to the aerobic digesters, nitrification occurs (conversion of ammonia [NH3-N] to nitrate nitrogen [NO3-N]), which consumes alkalinity; as alkalinity is consumed, the pH in the process drops. If oxygen continues to be provided after the nitrification process has occurred, acid production continues, resulting in lower pH and destruction of alkalinity to neutralize the acid. This low-pH condition can deactivate or kill biomass, since microorganisms are sensitive to low pH. Because the inactive biomass is not respiring, dissolved oxygen levels further increase. As a result, the filtrate from the belt filter presses following the digesters contains significant levels of TP, which are then returned to the main process and stress the plants ability to uptake phosphorous biologically.

Modifying the aerobic digestion process to operate at lower DO levels or cyclic aeration, and the maintenance of neutral pH, would likely reduce nutrients and oxygen demand recycled back to the aeration basins, and also improve solids capture at the belt filter presses. The biological removal of phosphorous by the anaerobic selector implemented under Phase 1 could then be leveraged for TP removal, as well as SVI reduction.

Figure 2 illustrates the sequence of how overaeration and the low pH inhibition condition affects the treatment performance of the WRF. Figure 3 presents a side-by-side comparison of filtrate from sludge taken from an overaerated low-pH digester to a neutral-pH digester.

Clarifier Capacity Analysis

Prior to recommending measures to improve the SVI, the capacity of the WRF was checked at current SVIs. The WRF clarifiers were checked against typical solids loading rate (SLR) and surface overflow rate (SOR) values, and compliance with U.S. Environmental Protection Agency (EPA) Class I reliability. Table 1 demonstrates that, for the conditions shown, the number of clarifiers online is within typical values, with Continued on page 8

Continued from page 6 one clarifier offline; however, even though the clarifiers meet typical values, the criteria shown in Table 1 do not account for SVI values above 200 ml/g.

Clarifier blanket levels and SVI measurements were collected during the sampling week to evaluate the settleability performance of the mixed liquor suspended solids (MLSS). Eight clarifier blanket readings were taken at each clarifier over the course of five days. The blankets and transition zone were consistently high throughout the sampling event, demonstrating slowsettling solids, as shown in Figure 4. The SVI readings were also performed on the MLSS of Aeration Basin No. 2 and Aeration Basin No. 3 over the course of three days. The SVI values measured were indicative of slowsettling sludge. A picture of one of the SVI tests performed is shown in Figure 5. The slow sludge settling conditions observed during the sampling week were also consistent with available historical data.

State point analysis (SPA) is a method for evaluating secondary clarifier capacity based on the solids flux theory, which does account for SVI. This method uses site-specific SVI data to roughly predict the thickening behavior of secondary clarifiers, and also accounts for RAS underflow rates. Historical SVI values are summarized in Table 2.

The 2015-2017 5th percentile, 95th percentile, and average SVI data (reflecting the best-performing 5 percent of SVI data and the worst 5 percent of clarifier sludge settleability days, respectively) were evaluated to determine clarifier capacity to settle solids and produce satisfactory clarifier effluent. The results of the SPA analysis at the current average daily flow (ADF) flow rate of 3.6 mgd, 75 percent RAS rate, and 3,000 mg/L MLSS are shown in Figure 6.

A clarifier operating within its hydraulic and solids loading capacity should show the intersection of the diagonal lines beneath the flux curve line, and should also show the segments of the diagonal lines that are below the point of intersection, beneath the flux curve line; therefore, Figure 6 demonstrates that, even at the current 3.6-mgd ADF flow rate and average SVI of 260, the plant

Table 1. Clarifier Capacity Analysis Versus Typical Values

Clarifier Design Criteria

Parameter

Surface Overflow Rate @ PHF Solids Loading Rate @ MDF EPA Class I Reliability 10 State Standards

1,000-1,200 WEF MOP 8

1,200

Village of Wellington (Design Flow Rate with 3 clarifiers online) 840

35-50 40-50

27.3 Treat 75% of flow with the largest unit offline

Clarifier Details with Largest Unit Offline

Number (each) Surface Area Total (sf) (1) 90 ft dia, (1) 70 ft dia, (1) 65' dia 13,530 is already critically loaded, and at 95th percentile SVI of 290, the plant is beyond critically loaded. This is consistent with the findings during the November 2019 sampling event of high clarifier blankets, and with the recent plant upset condition in January 2020.

The results of the SPA analysis indicate that the WRF can likely not function much beyond its current capacity and continue to meet permit limits and produce reuse water at currently observed levels of SVI. As plant flow rates increase towards the plants rated capacity of 6.5-mgd TMADF, assuming current high ranges SVI persist, the WRF clarifier performance would be further reduced. Morefrequent plant upset conditions and inability to produce reuse water would result; therefore, it’s critical to implement improvements to reduce SVI at the plant.

A MLSS sample was collected and Continued on page 10

Figure 5. Photograph of Sludge Volume Index Test Results after 30 Minutes of Settling Time

Table 2. 2015-2017 Sludge Volume Index Data

Parameter

Average 5TH Percentile

SVI (ml/g)

260

230

25

20 Solids Flux (lb/sf/day)10 15 5

0 0.0

Intersection of lines outside of curves indciates operation outside of acceptable loading conditions at curent range of SVI values

Solids Overflow Rate

Solids Underflow Rate

Flux Curve - SVI avg

Flux Curve - SVI 95th

1.0 2.0 3.0 4.0 5.0 6.0 7.0

Solids Concentration (x1000 mg/L)

8.0 9.0

Figure 6. Clarifier State Point Analysis at 3.6-mgd Average Daily Flow

10.0

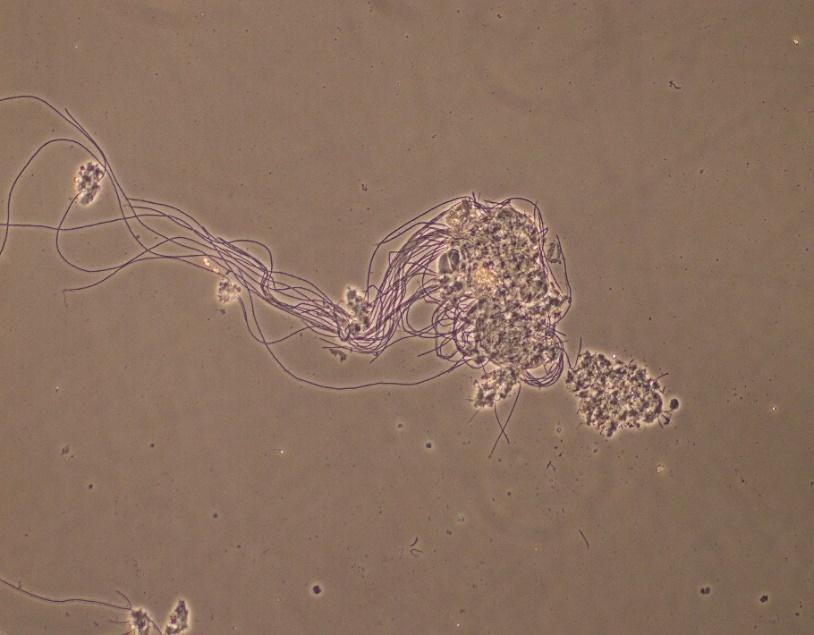

Figure 7. Microscopic Photograph of Large Flocs With Significant Amount of Filaments

30

25

20 Solids Flux (lb/sf/day)10 15 5

Intersection of lines within curves indicates operation inside of acceptable loading conditions at proposed range of SVI values

Solids Overflow Rate

Solids Underflow Rate

Flux Curve - SVI avg

Flux Curve - SVI 95th

0 0.0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 Solids Concentration (x1000 mg/L)

8.0 9.0 10.0 Continued from page 8 analyzed with a microscope. Significant levels of filamentous microorganisms were noted, with significant interfloc bridging and filaments protruding from the flocs. The overall filamentous organism level was “very common-abundant.” At these levels, significant interference with the activated sludge settling properties would be expected. The high SVI values are caused by filamentous organisms associated with simple readily biodegradable material (rbCOD), such as Nostocoida Limicola, and long SRT (type 0041). A picture of the floc, observed with abundant levels of filament, is shown in Figure 7.

Anaerobic Selector Overview

A selector can improve secondary solids settleability by precluding the growth of filamentous bacteria and selecting for bacteria that form tight, dense flocs with good settling properties. Filamentous bacteria can form bridges between flocs, keeping them in suspension and decreasing secondary clarifier performance. Many filamentous bacteria use rbCOD very efficiently, but cannot store or utilize these substances under anoxic or anaerobic conditions.

Anaerobic selectors allow for the rapid uptake of rbCOD under conditions where filamentous organism growth is restricted, limiting their proliferation in the downstream aerobic zone of the secondary treatment process. Implementation of a selector zone can reduce the operation and maintenance costs associated with nuisance organisms, such as those identified in the microscopic samples, as well as increase secondary clarifier performance by improving settleability.

The anaerobic selector allows for the removal of rbCOD by polyphosphateaccumulating organisms (PAOs) under anaerobic conditions, which facilitates biological phosphorous removal and reduction of effluent phosphorous. Filamentous organism growth is restricted in anaerobic conditions, limiting potential proliferation in the secondary treatment process. Anaerobic selector efficacy is dependent on operation at a suitable minimum hydraulic retention time (HRT) of 30 minutes at design flowrates.

Evaluation and Sizing of Anaerobic Selector

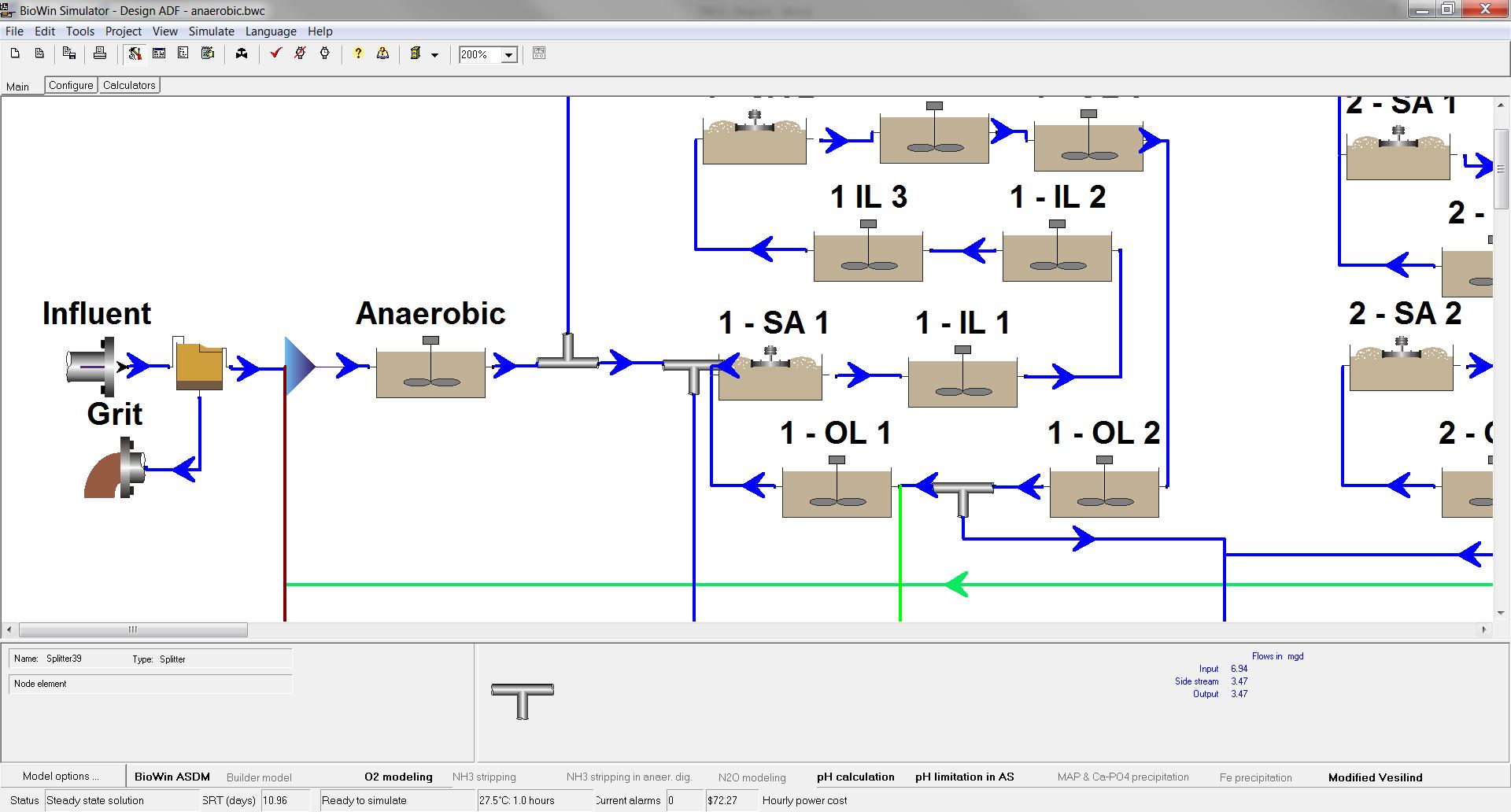

As stated previously, an anaerobic selector HRT of 30 minutes at design flow rate is a typical criterion for anaerobic selector sizing. Additionally, a calibrated BioWin™ model

was used to predict an uptake of rbCOD in the anaerobic zone (thereby preventing rbCOD availability for filamentous bacteria in the downstream aeration basin). A typical target rbCOD uptake in a selector zone is 90 percent of rbCOD.

An anaerobic selector zone was inserted into the process model at design maximum month average day flow (MMADF), as shown as Figure 9. The model predicted that a 200,000-gal tank is adequate to remove rbCOD, promote PAO growth for biological phosphorous removal, and “select” for wellsettling PAO bacteria at design conditions.

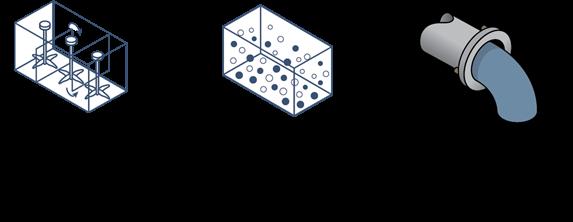

Description of Proposed Anaerobic Selector

An anaerobic selector is proposed as a common tank to receive all plant flow, upstream of the aeration basins. It’s recommended that the anaerobic selector be baffled into at least two separate zones to allow for efficient uptake of rbCOD. Highefficiency vertical mixers are proposed for each zone. Although the anaerobic selector is not anticipated to be a significant source of odors, the zone would be contained with aluminum covers and connected to the odor control system, given the odor sensitivity of surrounding residents. Piping and valves would also allow for bypass of the anaerobic zone. The proposed location and conceptual layout for the anaerobic selector at the WRF is shown in Figure 10.

Conclusion

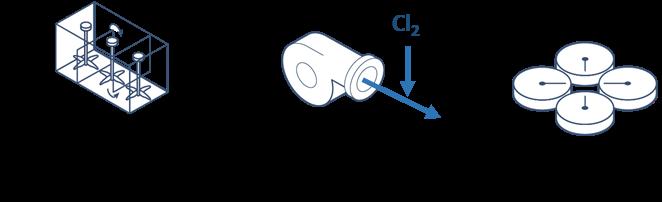

Reducing SVI at the WRF is a critical goal. Reduction of SVI by implementing an anaerobic selector was identified as the preferred alternative. The detailed design of Phase 1 is currently underway at the time of this writing. The RAS chlorination was also recommended to provide operators an additional low-cost tool to control occasional sludge-bulking episodes. Figure 11 illustrates the recommended strategy to reduce SVI.

The concurrent reuse master plan recently concluded that reduction of effluent TP to <1.5 mg/L is sufficient to prevent increased TP loading into surface waterways by reuse water. Figure 12 illustrates the recommended strategy to achieve effluent TP < 1.5 mg/L. S

To Aeration Basins

Figure 9. View of Anaerobic Selector Inserted Into BioWin Model

Figure 10. Plan View of Proposed Anaerobic Selector

Figure 11. Phase 1 Strategy to Reduce Sludge Volume Index

Figure 12. Phase 2 Strategy to Achieve Total Phosphorus Removal < 1.5 mg/L

C FACTOR A New Year, a New Beginning

Kenneth Enlow President, FWPCOA

Year! I am really looking forward to the new year and believe that 2021 will be bright and successful for FWPCOA.

New Board of Directors

I would like to welcome the 2021 board of directors and officers. I know that all of us will do our part to make the year successful and productive.

The officers for 2021 are: Ken Enlow – President Patrick Murphy – Vice-President Rim Bishop – Secretary-Treasurer Athena Tipaldos – Secretary-Treasurer-Elect Mike Darrow – Past-President

If you have any needs, please contact any one of us through our FWPCOA contact email or phone numbers. These can be found on our website at www.fwpcoa.org.

Janet DeBiasio is

Janet DeBiasio was selected as honorary life member of the association by the board of directors at its October 2020 meeting. Janet DeBiasio

Janet’s career includes her employment with the U.S. Environmental Protection Agency (EPA) for 10 years, as well as working for the Florida Department of Environment Protection (FDEP). Janet was a longtime employee with the City of St. Petersburg (March 1993 through May 2017) when she retired. She has been an active member of FWPCOA since shortly after her employment with St. Petersburg and has remained active since here retirement.

She served on the Region IV executive board, as well as representing Region IV as director on the state board of directors. Janet served on the state Education Committee as a member of the Industrial Pretreatment Committee, and served on the state Publicity Committee. She helped organize and instruct at state and regional short schools throughout her years as a member.

Everyone please congratulate Janet on her

Greetings, everyone, and Happy New

Newest Life Member

appointment as an honorary life member.

Rules in Review

Some of the rules of note that are in review by FDEP are related to stormwater discharge, wastewater, and biosolids.

If you are a stormwater, wastewater, wastewater collection, or reclaimed water operator, you will want to do further investigation on these rule changes to see how they may affect your operation and you.

Stormwater Rules

S Environmental Resource Permitting Rules for Stormwater Design and Operation

Regulations (ERP Stormwater)

The FDEP and the water management districts will be initiating rulemaking as directed by Section 5 of Chapter 2020-150, Laws of

Florida, to update the stormwater design and operation regulations for environmental resources. Rulemaking review will begin

Jan. 1, 2020. Check the FDEP website for dates and times for the workshops. S 62-621.300(7), Regulated Phase II MS4s

The FDEP proposes amendments to Chapter 62-621.300(7), F.A.C., to revise and update forms for the existing generic permit for discharge of stormwater from Phase II

Municipal Separate Storm Sewer Systems for consistency with current EPA requirements and to clarify permit language.

Wastewater Rules

S 62-600, Domestic Wastewater Facilities

The FDEP proposes amendments to Chapter 62-600, F.A.C., Domestic Wastewater

Facilities, to update provisions, as well as implement the relevant provisions of

Florida’s Clean Waterways Act (Chapter 2020-150, Laws of Florida). S 62-604, Collection Systems and

Transmission Systems

The FDEP proposes amendments to

Chapter 62-604, F.A.C., Collection Systems and Transmission Facilities, to update provisions, as well as implement the relevant provisions of Florida’s Clean Waterways Act (Chapter 2020-150, Laws of Florida). S 62-610, Reuse of Reclaimed Water and

Land Application Phase 1

The FDEP proposes amendments in Chapter 62-610, F.A.C., to update the chapter to be consistent with other Title 62 chapters, correct regulatory references, clarify current language, and require electronic submittal of annual reuse reports through the business portal. Two separate rulemaking efforts, Phase

I and Phase II, will be undertaken by the department in order to amend this chapter.

Phase I does not include amendments for potable reuse. Phase II will include all the proposed amendments to adopt recommendations of the Potable Reuse Commission’s 2020 report, “Advancing Potable Reuse in Florida:

Framework for the Implementation of

Potable Reuse in Florida,” as required by

Florida’s Clean Waterways Act of 2020.

Phase II will be announced later in 2020. S 62-620.610, General Conditions for All

Permits

The FDEP proposes amendments to Rule 62620.610, F.A.C., General Conditions for All

Permits, to revise the general condition for reporting noncompliance, such as sanitary sewer overflows, spills, and unauthorized discharges, including the incorporation of the public notification of pollution provisions of Section 403.077, Florida

Statutes. S 62-640, Biosolids

The FDEP proposes amendments to

Chapter 62-640, F.A.C., Biosolids, to revise monitoring and permitting criteria for the land application and management of biosolids. The proposed amendments also address biosolids provisions from Chapter 2020-150, Laws of Florida.