Experience, Expand, Evolve with

ZeeWeed* 500

Proven success in Florida municipalities - the next generation of superior MBR technology for large municipal MBR applications.

• Meet high growth demands

• Meet strict nutrient reduction regulations

• Reduce membrane tank footprint by up to 50%

• Lower energy usage

• Longer membrane life

Learn more and hear customer testimonials

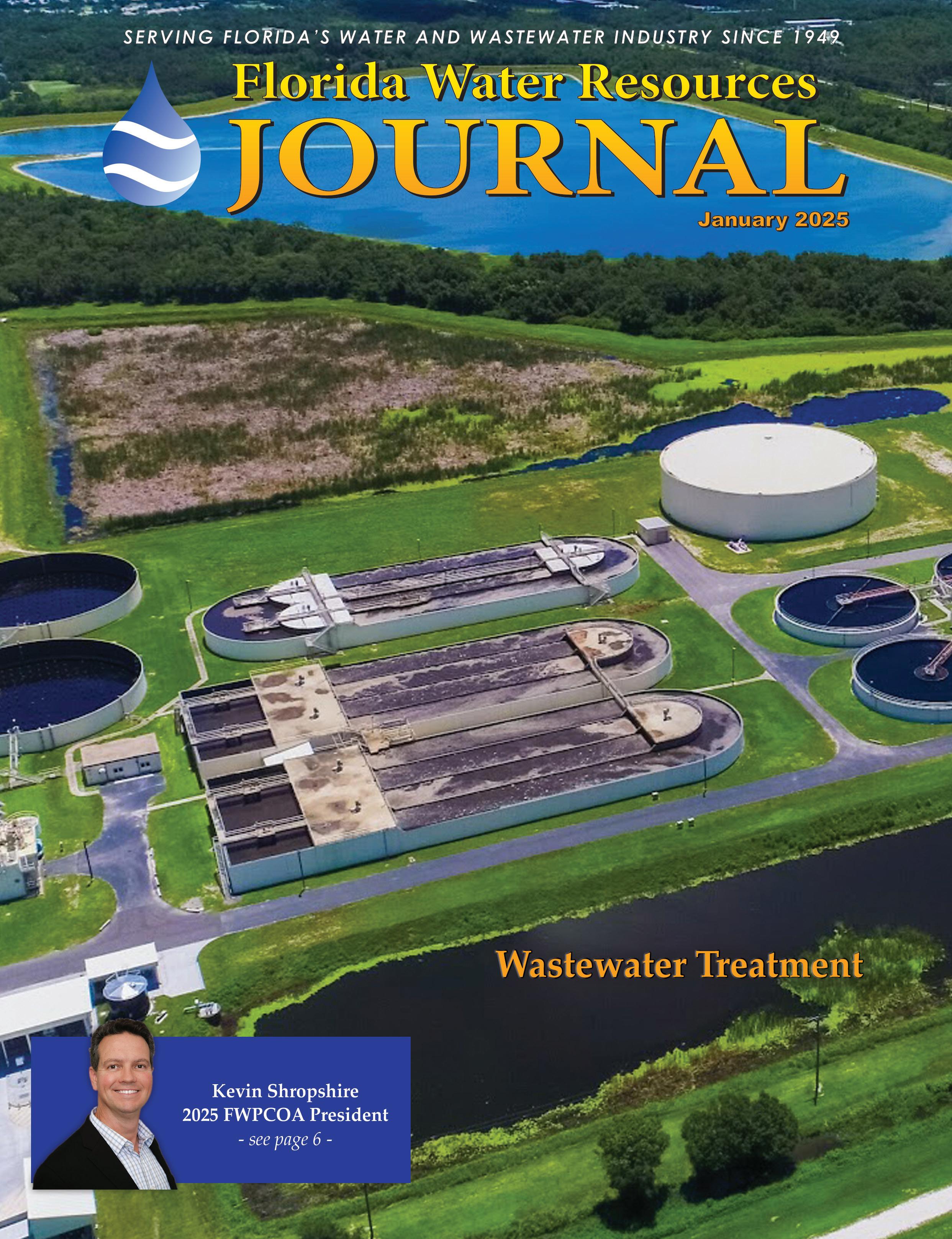

Crest Avenue WWTF

7.5 MGD (2025)

Latest installation of MBR technology

Babcock Ranch WRF

Phase 1 - 0.75 MGD (2020)

Phase 2B – 1.5 MGD (2023)

Bonita Springs East WRF

4.1 MGD (2007)

Fort Drum Service Center

0.1 MGD (2013)

Glades County WWTP

0.36 MGD (2005)

Island WWTP 5.0 MGD (2006)

Rotonda WWTP 2.0 MGD (2008)

Donax WRF

2.0 MGD (2021)

Marco

Sanibel

Editor’s Office and Advertiser Information:

Florida Water Resources Journal

1402 Emerald Lakes Drive

Clermont, FL 34711

Phone: 352-241-6006

Editorial, editor@fwrj.com

Display and Classified Advertising, ads@fwrj.com

Business Office: 1402 Emerald Lakes Drive, Clermont, FL 34711

Web: www.fwrj.com

General Manager: Michael Delaney

Editor: Rick Harmon

Graphic Design Manager: Patrick Delaney

Mailing Coordinator: Buena Vista Publishing

Published by BUENA VISTA PUBLISHING for Florida Water Resources Journal Inc.

President: Richard Anderson (FSAWWA) Peace River Manasota Regional Water Supply Authority

Vice President: Joe Paterniti (FWEA) Clay County Utility Authority

Treasurer: Rim Bishop (FWPCOA) Seacoast Utility Authority

Secretary: Mish Clark Mish Agency

Moving?

The Post Office will not forward your magazine. Do not count on getting the Journal unless you notify us directly of address changes by the 15th of the month preceding the month of issue. Please do not telephone address changes. Email changes to changes@fwrj.com or mail to Florida Water Resources Journal, 1402 Emerald Lakes Drive, Clermont, FL 34711

Membership Questions

FSAWWA: Casey Cumiskey – 407-979-4806 or fsawwa.casey@gmail.com

FWEA: Laura Cooley, 407-574-3318, admin@fwea.org

FWPCOA: Darin Bishop – 561-840-0340

Training Questions

FSAWWA: Donna Metherall – 407-979-4805 or fsawwa.donna@gmail.com

FWPCOA: Shirley Reaves – 321-383-9690

For Other Information

FDEP Operator Certification: Ron McCulley – 850-245-7500

FSAWWA: Peggy Guingona – 407-979-4820

Florida Water Resources Conference: 407-363-7751

FWPCOA Operators Helping Operators: John Lang – 772-559-0722, oho@fwpcoa.org

FWEA: Laura Cooley, 407-574-3318, admin@fwea.org

Websites

Florida Water Resources Journal: www.fwrj.com

FWPCOA: www.fwpcoa.org

FSAWWA: www.fsawwa.org

FWEA: www.fwea.org and www.fweauc.org

Florida Water Resources Conference: www.fwrc.org

News and Features

4 WEF Represents Water Sector at White House Roundtable on Water Security and Climate Resilience

6 Kevin G. Shropshire Elected as FWPCOA President for 2025

8 Contractors Roundup: STOP THE STCKY: Innovative Safety Program Focuses on Stopping Construction Fatalities

14 The Story of Water: How JEA’s H2.O Purification Center Will Immerse Visitors in the Water Experience—Geoff Thatcher, Ryan Popko, Shea Dunifon, and Jo Ann Jackson

24 2024-2025 FSAWWA Board of Governors

32 Get Ready for the 2025 Florida Water Resources Conference—Mish Clark

34 Good News From WEFTEC 2024: Contest Win, Committee Chair Recognition

49 News Beat

53 Water System Upgrades Could Require More Than $1 Trillion Over Next 20 Years

56 Technology Spotlight: Algae Control and Reducing Chlorine Loss

58 Research Finds Switching to Green Wastewater Infrastructure Could Reduce Emissions, Prove Huge Savings

59 FWEA Safety Committee Welcomes New Chair

Technical Articles

18 Advanced Phosphorus Recovery in Reclaimed Wastewater: A History of Pilot Studies of an Innovative Phosphorus Recovery Media— Domenic Contrino, Benjamin Pepper, Sebastian Sayavedra, Leverto Jean Charles, Stephen Suau, and Regina Rodriguez

45 Using Your Nose to Protect Your Assets: Wastewater Odor and Corrosion Control— Vaughan Harshman, Nickolas Wagner, Erik Gibson, and David Hunniford

Education and Training

Columns

Speaking Out—Lisa Wilson-Davis

Let’s Talk Safety: Be Kind to Your Body and Stretch Before

FWEA Focus—Joe Paterniti

Yourself—Charles Lee Martin Jr.

Departments

WEF Represents Water Sector at White House Roundtable on Water Security and Climate Resilience

The Water Environment Federation (WEF) joined other national leaders at a White House roundtable on water security and climate resilience that was held on October 31. As a water sector representative, WEF had the unique opportunity to highlight its commitment to building a more sustainable and resilient water future.

Ralph Exton, WEF executive director, stressed the importance of moving toward a circular water economy—an approach that

makes the most of every drop by reusing water, reducing waste, and turning byproducts into valuable resources. This shift is essential to ensure that America’s homes, agriculture, and industries have a dependable water supply, especially in the face of intensifying climate pressures.

Exton also emphasized WEF’s ongoing commitment to promoting innovative conservation technologies, as well as the importance of redefining the economics of water to drive conservation and resilience. In

particular, WEF advocated for policy changes to provide targeted incentives for water conservation technologies, including grants, low-interest loans, and tax incentives.

“Innovative funding approaches are essential. The estimated $1.25 trillion investment needed over the next 20 years calls for a sustainable economic model to support the future of our water infrastructure,” said Exton. “By advocating for better funding mechanisms, economic incentives, and supportive policies, the industry is helping create a path for meaningful conservation and innovation across the sector. It was a powerful moment of collaboration, and I’m proud of how our work positions WEF as a leader in this crucial conversation.”

At the roundtable, attention was also focused on the need to build a skilled and diverse water workforce to tackle future challenges by attracting workers with varied talents and experiences, investing in skills training, and establishing standardized career pathways for the sector. Through expanded workforce training and data-driven management practices, WEF seeks to empower communities and industries, enhancing water efficiency and resilience.

“The participation of WEF in this roundtable reflects our dedication to addressing water security through collaboration, innovation, and community engagement,” said Exton. “By prioritizing a circular water economy and workforce development we can help secure our nation’s water future for generations to come.” S

Ralph Exton at the roundtable.

Kevin G. Shropshire Elected as FWPCOA President for 2025

Kevin G. Shropshire was elected president of FWPCOA at the organization’s October 2024 board of directors meeting.

Kevin has been the pretreatment coordinator for the City of Rockledge since 2017. He has spent more than 20 years as an environmental regulatory professional at the municipal level within the state of Florida, working for the cities of Oldsmar, West Palm Beach, Orlando, and now, Rockledge. He specializes in industrial pretreatment, stormwater, and wastewater, and the enforcement, regulation, and public education that accompanies those topics.

Kevin has been involved as an active member of FWPCOA for 20 years as well, between Region IV and Region III, with most of that time actively involved with the board of directors at many levels. Over those years, he has earned his Pretreatment C and B; Stormwater C, B, and A; and Wastewater Collections C licenses through the organization. He also chairs the Industrial Pretreatment Committee, which is within the Education Committee.

He has also been an active member of the Florida Industrial Pretreatment Association for

20 years, earning his Pretreatment A license, and now serves as president of that organization.

He has lived in Florida since 1997, splitting time between Hillsborough County and Brevard County. He spent several years volunteering time with environmental programs around the Tampa Bay area, including the Tampa Bay Estuary Program, as well as representing the City of Oldsmar at the Tampa Bay Nitrogen Management Consortium. Since 2017, he has represented the City of Rockledge on the Indian River Lagoon National Estuary Program within the Management Council, as well as a member of the Small Communities Advisory Subcommittee to the U.S. Environmental Protection Agency.

He enjoys amateur nature photography, learning and sharing new environmental experiences and knowledge, volunteering at local environmental events, and especially spending time with his young family. He also serves on the local Special District Advisory Committee (local zoning), School Advisory Council for his children’s school, and has been a youth soccer coach with Port St. John United Soccer Club for over seven years.

His wonderful wife, Debra, keeps his “honey do” list short and a few people appreciate his witty, yet dry, sense of humor. This leaves him time to focus on his true passion, which is to realistically protect and improve the natural environment for his children’s future. His boys, Devin and Julian, are his “mini-mes” known around the FWPCOA boardroom, and are soccer stars, academically talented, respectful, and gifted, with their mother’s sensitivity and heart and their father’s wit.

As the next president of FWPCOA, one of his priorities is to increase involvement of the membership—not just showing up to meetings and events, but accepting and carrying the torch of leadership to the next generations. He hopes to expand membership in the many current FWPCOA committees and spread the opportunities to volunteer, from the few to the many. S

Grow your septage, FOG, and sludge receiving business with a Raptor Septage Acceptance or Complete Plant.

Trippensee Shaw, Inc. Eustis, Sebring, & Boca Raton, FL T: 407-222-0575 www.TrippenseeShaw.com

Florida Panhandle Only T: 205.424.7570 www.eshelmancompany.com

Raptor Septage Acceptance Plant

Removes debris and inorganic solids from municipal and industrial septage, FOG, and sludge. This heavy-duty machine incorporates the Raptor Fine Screen for screening, dewatering and compaction. Accessories include security access and automated accounting systems.

Raptor Septage Complete Plant

With the addition of aerated grit removal, the Septage Acceptance Plant is offered as the Raptor Septage Complete Plant.

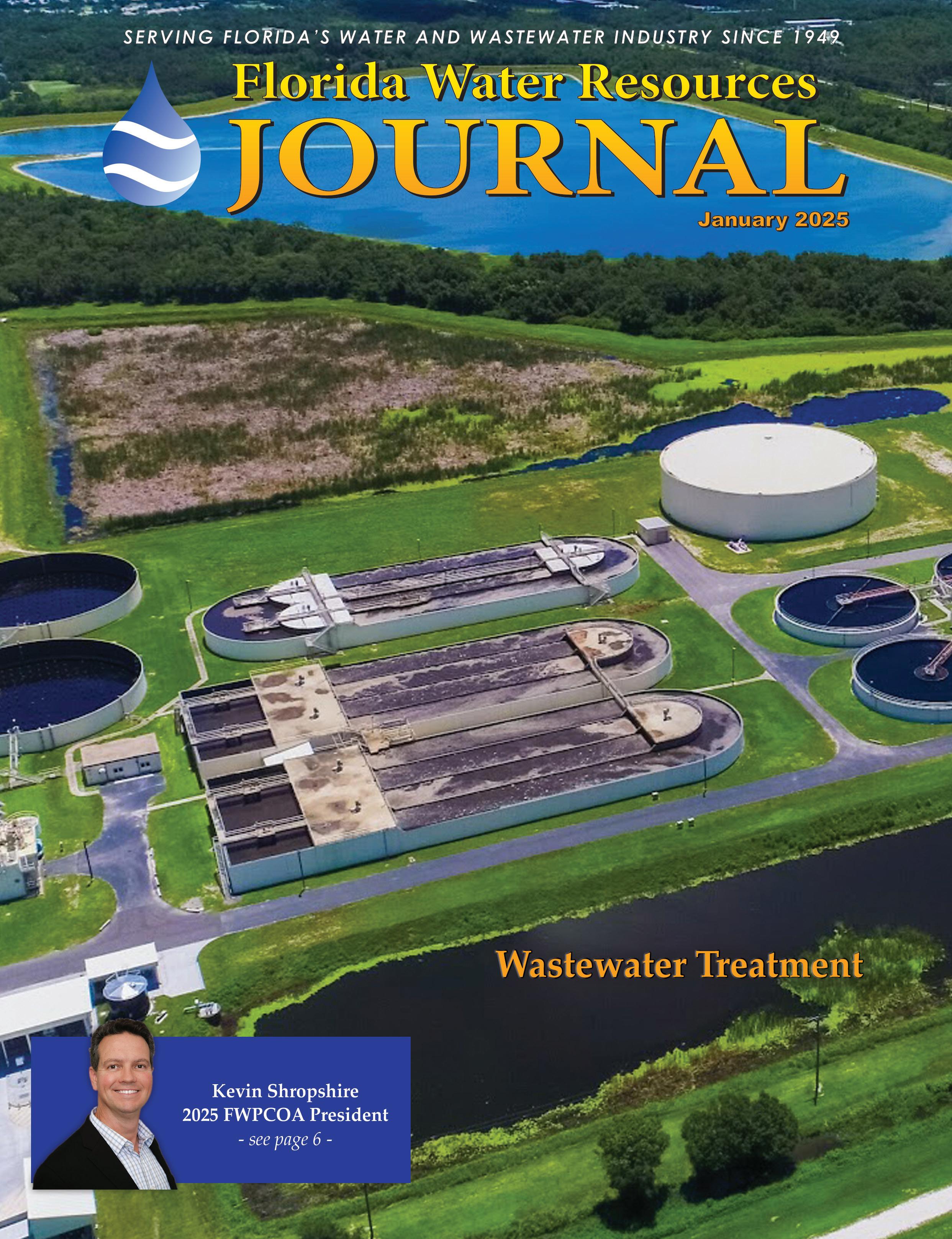

STOP THE STCKY: Innovative Safety Program Focuses on Stopping Construction Fatalities

With an influx of new workers entering the construction workforce, it‘s paramount employers educate and train their employees on safe behaviors that focus on not only keeping these employees safe, but preventing fatalities.

In 2019, Sundt discovered the construction industry’s recordable injury rate has steadily fallen over the last 20 years; however, the rate at which construction workers lose their lives on the jobsite hadn’t declined since 2007, with that number actually plateauing. Indeed, the metrics used in traditional construction worksite safety programs—the recordable injury rate and the experience modification rate—just aren’t cutting it.

Because fatalities in the industry aren’t declining, even the safest contractors could inevitably face a fatality. That’s not an acceptable result. Sundt is looking to close the gap through its innovative safety approach with its STOP THE STCKY® program.

What is the STOP THE STCKY Program?

The acronym STCKY stands for S#*! That Can Kill You—a mindset for all construction companies and their employees to pay attention to. According to Paul Levin,

vice president and corporate director of health, safety, and environment at Sundt Construction, “With STOP THE STCKY, we measure all information related to safety that gives you a whole new view of what success and improvement look like within the construction safety landscape.”

Going beyond recordables, Sundt now tracks and classifies all incidents, starting with all unplanned events. Not all incidents are equal; they are either classified as STCKY (high-energy) or non-STCKY (releases of energy). The STOP THE STCKY program was created and developed to disrupt the plateau and redefine safety in the industry.

The company has also reframed assumptions about risk and safety, and its safety training now includes enhanced techniques for assessing jobsite high-energy STCKY hazards and learning the direct controls and safeguards needed to control the energy that causes injuries. From this process, Sundt has also created and instituted a new four-step casual analysis to more clearly understand how incidents happen, rather than assign blame.

STCKY Wheel, Walks, and Technology

To improve high-energy hazard

recognition, the company created the STCKY Wheel to help in identifying energy sources that most frequently cause severe injuries and fatalities.

To truly make an impact on jobsites, the company instituted daily and weekly STCKY walks at the jobsite by the project team to identify high-energy STCKY hazards and then to remind workers about the proper protections, direct controls, and safeguards to prevent injuries and fatalities. Examples of direct controls include lockout/ tagout, properly protected excavations, and engineered fall protection systems. Safeguards include excavation perimeter protection, controlled access zones, and use of a spotter.

“The way we’re doing these STCKY walks and observations allows us to look at how somebody put themselves at risk when they were performing their work,” said Eric Cylwik, Sundt’s director of innovation. “We review the way a particular safety task or system was designed to determine whether workers even knew there was a STCKY hazard there. Perhaps they didn’t have the materials or equipment they needed to stop that from being a STCKY hazard; or, they did have all those things and they just didn’t utilize them in the best way.”

Continued on page 10

1. POLYMER REDUCTION: P6 PolyMix® Systems reduce polymer consumption by providing complete polymer/sludge mixing in a shear-sensitive manner. This patented mixing process allows long-strand polymer chains to remain intact and unbroken and wastewater floc to remain intact and unsheared. Typical applications result in a 25-50% REDUCTION IN POLYMER CONSUMPTION, thus saving the customer thousands of dollars in polymer expenses. By not breaking up the polymer chains, the dewatering equipment will experience less fouling, providing more reliability and reducing equipment cleaning costs.

2. DRIER CAKE SOLIDS: P6 PolyMix® technology optimizes the polymer and sludge mixing process, allowing INCREASE DEWATERED SOLIDS CONCENTRATION and INCREASED PERCENT SOLIDS CAPTURED. This unique mixing process results in more efficient sludge hauling, allowing customers to transport less water and more dewatered cake off-site.

3. ELIMINATION OF PUMP MAINTENANCE: P6 PolyMix® technology reduces pump parts and maintenance by utilizing the abrasion-resistant Discflo pumping principles of Boundary Layer/Viscous Drag. This principle can save the customer thousands of dollars in parts and maintenance over the lifetime of the equipment. All P6 PolyMix® systems in the municipal market include a 10-YEAR (extendable to 20 years) 100% WET END WEAR WARRANTY, No other pump manufacturer in the industry provides a wear warranty, let alone a 20-year wear warranty!

4. PUMPS & MIXES: P6 PolyMix® technology uses the unique principles of Boundary Layer/Viscous Drag for mixing polymer versus a mixer/check valve; this, paired with its unique InjeX™ polymer injection mixing chamber, is designed for MINIMAL POLYMER DEGRIDATION, allowing for maximum polymer savings. The hydraulic shear forces within the mixing pump provide a complete homogeneous wastewater polymer slurry fed to the dewatering equipment without breaking the long chain polymers or reducing floc size.

5. LOWER OPERATING PRESSURE AND INSTALLED HORESPOWER: P6 PolyMix® technology dramatically reduces the operating pressure by reducing back pressure within the piping system due to eliminating mixer/check valves. In some applications, customers have had a 75% REDUCTION IN PRESSURE Lower pressure allows the feed pump to operate at lower horsepower. HORSEPOWER SAVINGS OF UP TO 50% OR MORE are possible by installing a P6 PolyMix® system. Customers can see substantial long-term energy savings and reduced upfront capital costs associated with lower installed horsepower.

6. HOW IS IT APPLIED: P6 PolyMix® systems entirely replace bulky, expensive, outdated traditional sludge feed pumps. You can now replace thousands of dollars in equipment and regain valuable real estate space by switching to P6 PolyMix® and utilizing its unique compact design, patented process for eliminating mixer/check valves, and ultra-efficient polymer mixing process. Contact us to learn how P6 PolyMix® can revolutionize the efficiency of your BELT FILTER PRESSES, GRAVITY BELT THICKENERS, ROTARY THICKENERS, SCREW PRESSES, AND CRENTIFUGES.

Continued from page 8

Sundt’s safety team then uses the insight gleaned from the STCKY walks and observations to determine what kinds of improvements the company needs to make so workers on the frontline are equipped to make the best possible decisions. The STCKY walkers are empowered to stop the work if they see a safety issue. The “stop work” rate is tracked by project, type, and reasons— all information used to forecast trends. For example, after examining data on multiple projects, the team may determine there is an issue around potential building heights, but workers hadn’t realized there was a potential issue. By taking a few moments to identify how the decision was made to work in a

manner that was unsafe, it helps the company determine whether more education is needed or whether it may need to invest in fall arrest systems with more-clearly-designated labels.

Sundt has also leveraged the right tool to track STCKY situations. The STOP THE STCKY program utilizes an easy-to-use, modern solution that makes sure these new daily activities don’t slow down the construction process. Smart technologies make incident reporting and analysis seamless and convenient from the field to the office. The company’s custom-built incident reporting process enables on-the-spot reporting and classification of all incidents. Its STCKY walk feature enables the field to easily record all high-energy hazards

observed on each walk, and whether the proper direct controls and safeguards are in place.

Sundt’s safety dashboard enables the creation of transparent and intuitive reports that make it easy to track progress on the company’s mission to STOP THE STCKY. Sundt classifies incidents into non-STCKY situations, where significant injury or death would not likely have occurred, and STCKY situations, where significant injury or death could have occurred.

Sundt further classifies STCKY incidents into:

S STCKY success, where no significant injury or death and adequate controls were in place.

S STCKY luck, where no significant injury or death and inadequate controls were in place.

S STCKY injury, where significant injury or death did occur.

These metrics are tracked in real time with easy-to-understand dashboards.

STOP THE STCKY Success

Sundt’s team measures the program’s success by determining whether the company has the right controls and safeguards in place for all unplanned events to make sure that workers remain safe—even in the rare chance a major incident happens. The percentage of controls and safeguards in place is now significantly higher than before the program was implemented.

Over the last five years, STOP THE STCKY has evolved into a way of life at Sundt—a comprehensive framework encompassing innovative practices, safety engagement, and proactive measures constructed to mitigate high-energy STCKY hazards.

“Through ongoing evaluation, radical candor, and feedback, we have refined our approach to safety, integrating industry best practices and leveraging advanced technologies,” Levin reports. “Perhaps the most significant aspect of STOP THE STCKY is the people behind it—the dedicated employees who have embraced its principles, championed its initiatives, and made safety a nonnegotiable aspect of their work ethos.”

The unwavering dedication of the employees, combined with the support of Sundt’s leadership team, has propelled STOP THE STCKY from a concept to a cornerstone of the company’s culture. “As we reflect on our journey thus far,” Levin said, “we remain committed to advancing the cause of safety in the construction industry.”

Sharing the STOP THE STCKY Story

Sundt has developed a dedicated website to spread the word about STOP THE STCKY that’s geared to encourage other construction companies to integrate its concepts into their program. The program can fit into any company, regardless of size, experience, or trade specialty, or whether the company selfperforms work or manages the work of other companies.

“We’re all part of the construction industry safety journey,” Levin said. “This is designed to help any company, at any mile marker of that journey—whether it’s how to complete orientations, safety planning, inspection compliance, or even better STCKY walks and incident management. The program reflects this modern-day view of safety.”

Levin added, “If you ask yourself ‘Is the industry safer?’ how would you answer that? That’s the dilemma we are facing because we’ve all convinced ourselves that success is a lower recordable injury rate or experience modification rate, when there’s other metrics

to be looking at. This program can drive better results for those metrics.”

To learn more about Sundt’s STOP THE STCKY Program, please visit www. STOPTHESTCKY.com and register for the company’s STOP THE STCKY Academy.

Acknowledgments

This article was published originally in the July/August 2024 issue of Constructor. It’s reprinted with permission from AGC of America and edited for content.

Contacts at Sundt

S Paul Levin, vice president and corporate director of health, safety, and environment

S David Rieken, P.E., DBIA, ENV SP, regional vice president S

Wastewater Operations— and the Knowledge Involved

Kevin Shropshire President, FWPCOA

’m not a wastewater operator; I’m a pretreatment coordinator. I regulate the industry’s processes and wastewater before it reaches wastewater treatment facilities. I have, however, worked alongside wastewater operators for almost the entirety of my 20-year career in pretreatment.

For the first several years, my “office” was merely a desk in the wastewater operators’ laboratory. Through the processes of observation, conversation, occasional assistance, and maybe a bit of osmosis, I’ve absorbed a lot of wastewater operations knowledge.

There is a lot of information and knowledge of the treatment types that can be learned and utilized within wastewater operations: biological, chemical,

physical, etc. I can tell you the basic biological process of wastewater treatment, with a hint of chemical and physical processes, and I can give a tour of a treatment plant to less-knowledgeable citizens, but there are many specifics of wastewater treatment of which I have no first-hand knowledge.

What Kind of Operator Are You?

Over the years, I’ve observed different types of wastewater operators. There are those who absorb knowledge like sponges, eager to use and share their information. There are also those who seem to have no interest in new knowledge; they just want to complete their shift, hoping for no change or upset to the routine. There are also many levels in between.

Where Are You as an Operator?

As an operator, which shift do you work? I understand we often don’t control our work shifts (for many reasons), but do you have any knowledge of how the wastewater treatment process differs during the day, night, or overnight shifts, or weekday versus weekend? I’ve observed many different treatment plants, with many differences in day versus night versus weekend flows.

How do the operators handle the changes? How do day, night, and weekend tasks and duties differ? Have you made an effort to change your shift assignment, maybe even temporarily, to learn what another side of the treatment process requires and involves? This is experiential learning.

When a consultant arrives to install a new process, are you hands-on, assisting, asking questions, listening, or more importantly, taking notes, so that you may troubleshoot a situation down the road? Where are those notes stored and are they accessible by others? Or are you sitting in a chair watching, comfortable with the fact that an expert has installed a new process that won’t require troubleshooting and that can be resolved without calling a consultant to fix the situation? How much is that consultant charging for their time? What happens when that consultant moves on?

What specific knowledge of wastewater treatment do you have or lack? Are you actively learning new information from water-related journals, reading the quizzes, obtaining continuing education units from new sources?

Do you attend local FWPCOA meetings, network with other operators, tour other facilities?

Do you attend classes—in person or online—to expand your

knowledge, sometimes even free of charge, courtesy of your employer?

As a supervisor to wastewater operators, which scenario that I’ve described represents your operators, and what are you doing to lead them, educate them, and encourage them to improve, thus advancing your facility operations and treatment?

Improve Yourself, Your Utility, and Your Community

If you’ve read this far, there’s a chance you’re likely interested in improving yourself, and thus, your collective community of wastewater operators. I encourage you all to expand your horizons and absorb new knowledge, whether from a book, online course, journal article, coworker, consultant installing something at your treatment facility, or even another operator at a nearby treatment plant.

Ask to attend a class. Ask “what-if” questions to the consultant. Ask for that shift change. Attend a regional meeting. Visit a nearby facility. Improve yourself.

Get Involved

For anyone interested, the FWPCOA website (www.fwpcoa. org) has a list of all the regions and a calendar of events. Every region of FWPCOA has regional meetings, training events, and/or some type of networking.

How involved are you as an operator? The health of our citizens and the environment depend directly on your involvement and knowledge as a wastewater operator.

Here’s to improving ourselves in 2025—as individuals, coworkers, colleagues, members of FWPCOA, and members of our society. S

The Story of Water: How JEA’s H2.O Purification Center Will Immerse Visitors in the Water Experience

Geoff Thatcher, Ryan Popko, Shea Dunifon, and Jo Ann Jackson

When talking about water, professionals in the water industry usually begin with technical terms and jargon, such as antimicrobial resistance, base flow, or parts per million. Water, however, is more than research, statistics, and a critical sector.

Water is a story. Water moves us. Water is life.

Most people see Florida as a “wet state” with an abundance of water, but growing populations and increasing demands on groundwater are forcing many utilities to think

and sewer utility—known as JEA—delivers its customers more than 120 million gallons per day (mgd) of drinking water and produces over 30 mgd of reclaimed water. Yet, even with water conservation education programs, the demand for potable water continues to grow in Jacksonville, which is the largest city, in terms of square miles, in the continental United States. For JEA, water reuse is the future.

A new visitor center is being built by JEA that will communicate with the public via storytelling. Set to open in 2025, this facility will help JEA share its water story with the community it serves, and perhaps will inspire others in the water sector to follow suit.

Crafting a Story to Engage the Community

The same question must be answered by JEA that other utilities around Florida are facing: How does it explain to the public, government officials, and stakeholders that reuse is not only part of a sustainable future, but also backed by sound science? The answer begins with crafting a story and then translating this story into an experience.

For JEA, the story can be summarized in a few sentences:

“Water is the source of all life on Earth and all living creatures must have water to survive. All water on Earth is reused again and again. Here in Florida, water is all around us—in wetlands, springs, and the aquifer—but the supply of water is not endless. By reusing water, we can keep more water local for humans, as well as for the plants and animals that rely on it.”

As with any good book, there are chapters to this story and JEA identified three important themes.

Water Transforms the World

This theme focuses on the source of water— the Floridan aquifer—and highlights how JEA thinks about the water supply every moment of every day. While this theme touches on the role of the water cycle, it focuses on telling a unique Florida story, beginning and ending by both figuratively and literally stepping into the Floridan aquifer and then coming to the surface to see how water transforms the world.

Water Transforms Lives

“Water is vital to the way we live, the way we work, and the way we play,” according to JEA, which will remind visitors to the new center that everyone is brought together by the miracle of water, connecting plants, animals, and humans with its unique chemical characteristics. This reinforces the importance of protecting this valuable resource and ensuring that future generations will have a reliable source of clean water, while also protecting the environment.

Technology Can Transform Water

This final chapter of the story demonstrates how JEA is diversifying the water supply in Jacksonville through sector-leading technology. One innovative solution is replenishing the aquifer with purified water that exceeds drinking

The proposed entrance of the JEA H2.0 Purification Center, which is scheduled to open this year in Jacksonville. (courtesy: Haskell)

This conceptualized design for the circular Aquifer Theater shows the planned limestone walls designed to resemble the Floridan aquifer. (courtesy: Creative Principles)

water standards. Not only does this purified water increase the available water supply below ground; it also improves the quality of that supply. While visitors will be touring a demonstration facility, the message here is about a sustainable future made possible by technology.

Drawing Inspiration From the Sector

As important as JEA’s water story is, it means nothing unless people can experience it in ways never before possible. As one of the nation’s largest publicly owned utilities, JEA is building the first visitor center of its kind in Florida in the same facility as its purification demonstration center to create and drive a narrative.

The journey to designing this center began with a story and was shaped by studying other water exhibits and attractions, followed by brainstorming with other team partners.

Starting in the U.S., the team visited several leading facilities, such as the Orange County Water District’s Groundwater Replenishment System in California and Hampton Roads Sanitation District’s Sustainable Water Initiative for Tomorrow Research Center in Virginia Beach,Va.

The team also toured the Water Replenishment District’s Albert Robles Center for Water Recycling and Environmental Learning (ARC). Located in Southern California, ARC was built to engage and educate the community about potable reuse and how water recycling provides a sustainable water supply for the region. The ARC offers an immersive, dynamic, and interactive environment for students and teachers to explore a diverse range of water topics. Visitors also can learn more about water careers with varying educational requirements.

Traveling abroad, team members also visited Singapore’s NEWater Visitor Centre, which demonstrates how NEWater—the brand name given to highly treated reclaimed water produced by Singapore’s Public Utilities Board—is produced. Appropriate for all ages, the facility emphasizes fun and enrichment, offering interactive tours and educational workshops. Singapore is a worldwide leader in the application of potable reuse, and the facility has been integral in educating the public about the benefits of recycling water.

Lastly, the team studied the Museum of Water in Saint Petersburg, Russia, which is located in the city’s very first water tower, built in 1860. Today, the former water tower offers a modern exhibition with plenty of hands-on experience for visitors. Museumgoers can see how water was treated, and currently is treated, in Saint Petersburg, and can try out pump operations and plumbing assembly themselves to learn more.

All of this research and brainstorming in a series of workshops kept leading the team back to the same thing—the story.

Bringing the Story to Life

The JEA H2.O™ Purification Center is branded as a nod to the 2.0 version of its water supply and showcases its commitment to not only a sustainable water future in northeast Florida, but also improved water quality.

To guide visitors, JEA partnered with a company that specializes in creating entertainment and educational experiences, Creative Principals, in Savannah, Ga., to design a unique experience that moves visitors through the water cycle, connecting the natural and human-engineered processes, beginning with the source of the local potable water supply.

Step Into the Aquifer

The experience begins in the lobby as guests step inside a circular theater with limestone walls resembling the Floridan aquifer. As guests look up at water rippling into a spring, they will hear a voiceover: “Our planet has a finite amount of water—one water—that has been used and reused since the beginning of time. It’s up to us to protect this precious resource. Like a drop of water in a still pond, the care we take today will spread, and the Floridan aquifer will thrive now and in the future.”

The Water Cycle

As guests exit the Aquifer Theater, they walk past a large wall graphic featuring the water cycle in Jacksonville. This graphic helps explains the role of JEA in this cycle, from wells and treatment facilities to reclaimed water production to the new purification facility. This graphic also explains the basic science of evaporation, condensation, precipitation, and natural replenishment.

Purification Facility and Control Room

Guests will walk up a long ramp as they begin to see the purification facility through windows on their left. Halfway along this ramp, they will stop at a wall of floor-to-ceiling windows that appear opaque white. These windows actually are electrified with “snap glass” and can transform from opaque to transparent in an instant. After a short video discussing JEA’s larger purification program, the windows will reveal both the control room and the purification equipment. The lights in the control room will dim as theatrical lighting, accompanied by a voiceover, shows the path water takes through the technology. To simplify this story for guests, the center will focus on four key points in the water treatment journey:

Continued on page 16

The center will demonstrate the role of JEA in the Jacksonville water cycle, as shown in this water cycle exhibit design concept. (courtesy: Creative Principles)

As envisioned, floor-to-ceiling windows reveal the water purification facility and control room. (courtesy: Creative Principles)

S Membrane filtration

S Reverse osmosis

S Ultraviolet advanced oxidation

S Return to the aquifer

Water Tasting

Following the tour of the control room and purification facility, guests will continue up the ramp to a water tasting area where they can sample the same purified water that replenishes the aquifer. While sipping the water, they can sit on a concrete bench in the shape of the state of Florida, with blue resin epoxy simulating water spilling across the state and onto the floor.

Water Purification Experience

As guests step down and back toward the lobby, they will pass through the purification process as if they were droplets of water. Actual cutaway technology and products will be on display as guests walk through the experience so they get a closer look at what they saw through the windows earlier in the tour.

Interactive Water Table

As they exit the purification experience, guests will find themselves standing around an interactive water table. Here, they can design their own water system with a whimsical network of pipes and tanks. Water will be in constant motion as guests get their hands wet, connecting wells to water treatment plants, and then to homes, revealing the interconnected underground piping network that is typically invisible to JEA consumers.

Message Wall

The final experience in the center will challenge guests to answer the following question: “How does water impact my life?” Visitors can leave their answers in two ways. First, their answers will appear projected onto a screen when they type into their cellphones after scanning a QR code. Second, they can pull small props, such as an orange, coffee cup, football helmet, rubber duck, or even sprinkler head, out of a barrel and place them into open pipes on the message wall. The final image they will see on this wall is the Earth inside a drop of water, which connects

them back to the story introduced in the aquifer theater that water is life.

Challenges Ahead

While a good story can unite the storyteller and the audience, a story made the wrong way— no matter how valid the argument—may lose the audience. It simply is not enough to have the best new idea, new product, or most desirable new feature; storytellers need to get audience members involved in their story so they drop their defenses and become more receptive to the message. To convey information, storytellers first must engage the imagination; then, audience members can project themselves into the desired scenario. This is how stories work.

Water reuse is not a new topic in the water sector, but for Florida, the concept is not as widespread as in many other U.S. states. As mentioned, Florida is a wet state, and water appears abundant—from lakes, rivers, and nearby oceans—so most people do not see any water shortages with their eyes. There also is the challenge of introducing younger generations to the science and technology “beyond the traditional water cycle” they are taught in school. Lastly, there are challenges associated with misinformation. Providing basic information on treatment processes, technology, and examples of sound science allow communities the opportunity to see JEA’s approach to a sustainable water supply firsthand.

The H2.O Purification Center will showcase the exceptional purity of the water, as well as the meticulous quality control of the purification process while engaging the public and stakeholders through compelling, emotional content and fun, captivating, and interactive learning. The visitor education center will be available for community tours, with content to inspire environmental stewardship of this precious resource.

Included here are renderings of the center, which will strive to be a symbol for not only Jacksonville, but all of Florida, as JEA transforms the story of water to include the future — reuse.

This article is reprinted with permission from Water Environment & Technology (Vol. 36, No. 8), August 2024, ©2024, Water Environment Federation, Alexandria, Va. All rights reserved.

Geoff Thatcher is the founder and chief creative officer at Creative Principals in Savannah, Ga. Ryan Popko, P.E., is H2.0 purification program manager for JEA in Jacksonville. Shea Dunifon is chair of the WEF Public Communications and Outreach Committee and a program manager with JEA. Jo Ann Jackson, P.E., is the national practice leader for One Water in the Orlando office of Black & Veatch, which is headquartered in Overland Park, Kan. S

This conceptual design shows the water tasting area, which will feature a bench in the shape of Florida. (courtesy: Creative Principles)

Visitors will get their hands wet and design their own water system, as shown in this design concept for the interactive water table. (courtesy: Creative Principles)

Advanced Phosphorus Recovery in Reclaimed Wastewater: A History of Pilot Studies of an Innovative Phosphorus Recovery Media

Domenic Contrino, Benjamin Pepper, Sebastian Sayavedra, Leverto Jean Charles, Stephen Suau, and Regina Rodriguez

Introduction and Motivations

Increasingly, nutrient enrichment in waterways warrants the development of costeffective technologies. Utilization of treated wastewater effluent (also known as reclaimed water) for irrigation is a beneficial use of water resources, but can contribute to elevated nitrogen and phosphorus enrichment and resulting harmful algae blooms and eutrophication of downstream waterways. The state of Florida issued advanced wastewater treatment (AWT) standards, pursuant to Section 403.086(4)(a)4 of the Florida Statutes, establishing average annual nutrient concentration targets of 3 mg/L total nitrogen (TN) and 1 mg/L total phosphorus (TP) for treated wastewater effluent.

Activated carbon is not typically able to adsorb phosphorus from water. Finn et al. [1] showed that various raw materials of biochar and activated carbon contained different mineral compositions and thus created different affinities for removing ions from the solution. Their work highlighted the effects of inherent magnesium content and its conversion to magnesium oxide (MgO) during biochar formation at a minimum temperature of 840°F. Alternatively, they also

showed that MgO can be directly used to remove phosphorus from solution.

The presence of MgO has several benefits to phosphate adsorption. First, due to the high pHpzc of MgO of 12 [2] at pH values typical for reclaimed water (i.e., near 8) the MgO surface particle will possess a positive charge, which is beneficial for the attraction of negatively charged ions such as PO43-. Furthermore, the MgO directly reacts with phosphate species to create MgPO4 complexes [1, 3]. The presence of MgO as a mineral, or more likely Mg(OH)2 once in contact with water, is the driving mechanism in adsorption. Finn et al. showed the addition of Mg2+ ions to solution (by MgCl2 addition) had no effect on phosphate removal [1].

Through specialized manufacturing and additives, Carbonxt was able to deploy activated carbon pellets capable of removing phosphorus. Hydrestor® is a specially blended activated carbon pellet available in 4-mm pellets to minimize head loss through the media bed and is a product based on a patented process [4]. The company’s team in Gainesville has been studying nutrient impacts in the water systems for years, with a focus on developing, commercializing, and producing unique engineered activated carbons. A renewable

Domenic Contrino is an engineer, Benjamin Pepper is applications engineer, Sebastian Sayavedra is research and development director, Leverto Jean Charles is laboratory manager, and Regina Rodriguez is chief executive officer at Carbonxt Inc. in Gainesville. Stephen Suau is the owner and managing partner of Carbon-Life LLC in Nokomis.

wood-based sorbent is produced that lends itself very well to this application, having a wide distribution of pores for adsorption. The team has industry-leading research and development capabilities and a strong commitment to environmental remediations. This article showcases the work to date, through multiple pilot tests, of the efficacy of engineered activated carbon for the recovery of phosphorus from reclaimed wastewater.

Phase I: Small-Scale Pilot

The first pilot test using this novel adsorption media was conducted with 30-galsized adsorption vessels (Figure 1). This trial showed favorable results over a wide range of influent TP concentrations. It maintained the

Figure 1. 30-gallon bed volume drum setup for Phase 1.

Figure 2. Small-scale trial with

reduction of reclaimed wastewater below the target 1 mg/L TP with an empty bed contact time of 20 minutes (Figure 2). This test was done with a 30-gal bed volume drum filled with media and a gravel base using reclaimed wastewater directly fed to each vessel.

In a second trial, with much lower influent concentrations of TP (average 0.3 mg/L), the Hydrestor media was successful in reducing phosphorus concentrations down to 0.07 mg/L TP, and on average, the percent removal neared 40 percent (Figure 3). These results illustrate that even at already reduced concentrations of TP, the media was able to further reduce and polish phosphorus. These results were achievable as the utility was in a watershed with stringent discharge limits well below AWT standards. The results in Figure 3 were accomplished with extended empty bed contact times of 80 minutes and were also conducted with reclaimed wastewater.

Phase II: Full-Scale Trench System

In 2021, construction was completed for a unique passive reclaimed water treatment system to treat 1 mil gal per day (mgd). The design of this system flows the reclaimed water through pine chips for biological reduction of nitrogen and then through a modified activated carbon for chemical adsorption of phosphorus (Figure 4). The ingenuity of this system was that, aside from pumping to the site and spraying on top of the cells, no pumps were required, thus providing the ability to treat 1 mgd passively (Figure 5).

In this passive system, nitrogen removal was proven successful through the wood chips; however, phosphorus removal was not as effective. This was likely due to biological fouling found on the activated carbon, which had been installed directly downstream of the biologically active wood chip contactors with exceedingly low flow rates. It was found that a biofilm had grown on the carbon and clogged access to the pore network, thus reducing adsorption. Nonetheless, the trial showed this type of system was effective at reducing nitrogen; however, use of an adsorbent for phosphorus, vessels, or traditional contactors may be needed, thus prompting the work presented herein.

Phase III: Modular Pressure Vessel System

In fall 2023, to further test the media and provide the utility with a cost-effective solution to reduce its nutrient loadings in the reclaimed wastewater, a project was proposed to the Florida Department of Environmental Protection (FDEP) Innovative Technologies Grant Program and was awarded. The aim was to test the media

Continued on page 20

Full-scale trench system (during construction) with cells to be filled with wood chips (right), followed by a surrounding trench of Hydrestor media (black media on left). The arrow indicates direction of water flow by gravity.

Total Phosphorus Concentration (mg/L)

Figure 3. Removal efficiencies as a function of influent total phosphorus concentration.

Figure 5. Diagram of the trench system. Orange cells were filled with wood chips for nitrogen removal, and the blue region filled with Hydrestor media for phosphorus removal. In some cells (3 and 4), woodchips were place on top of Hydrestor media.

Figure 4.

in a traditional pressure vessel system across different empty bed contact times to validate the innovative water treatment system designed to remove phosphorus from reclaimed wastewater to below AWT standards (1 mg/L TP). Funding was awarded by the FDEP grant program, and the trial took place in the Lakewood Ranch Stewardship District and was operated through the Braden River Utilities Department.

The trial, the new treatment design, and its effectiveness in phosphorous removal with a modular set up over eight to 10 weeks of pilot testing are presented.

Materials and Methods

Water Quality and Sorbent

Influent reclaimed water was collected from the community’s local water authority. The average influent water characteristics for the duration of the pilot are shown in Table 1.

The activated carbon used in this pilot trial was a commercially available phosphorusreducing sorbent, Carbonxt Hydrestor (Figure 6). The media is manufactured by proprietary processes using wood-based activated carbon agglomerated with specific binders to form a cylindrical pellet. Media specifications are listed in Table 2. Where applicable, industry standard ASTM methods have been used.

Porosity characteristics were analyzed using nitrogen adsorption/desorption via a Quantachrome NOVA 2200e (Boca Raton, Fla.). Each sample was held at 230°F under vacuum for at least three hours prior to analysis to effectively clear out the pores for accurate measurements. Isotherms were conducted with ultrahigh-purity nitrogen gas (Airgas) at a constant temperature of approximately -320°F as is typically done. The surface area of each sample was calculated by the Brunauer–Emmett–Teller (BET) equation at a relative pressure, P/P0, of 0.01 to 0.3. The average pore size is calculated from the pore volume, distributed over various pore sizes as done within the instrument software. The volume of adsorbed nitrogen gas adsorbed by the carbon was plotted against the relative pressure to determine the total pore volume.

Vessel Configuration

A mobile pilot trailer was installed in a previously established pump station near a reclaimed water retention pond. Connection to a municipal reclaimed water main line allowed for the continuous water supply to the vessels and adequate pressure. The pilot trailer (Figure 7) includes four 500-gal vessels, each loaded with virgin media.

The four vessels were configured in two separate lead-lag system trains and operated at a 60- and 90-minute total empty bed contact time, respectively (Figure 8). Sampling locations were on the inlet water line after primary filtration and on the outlet of each vessel. Particle filtration was done with 100-µ bag filters at the inlet of the system.

Operation and Monitoring

Minimal site modifications were required. Shell was added to the ground and compacted where the trailer would be parked to support the weight and allow for proper drainage. A dedicated reclaimed water service supply line capable of supplying 100 gal per minute (gpm) was extended from the existing infrastructure

Table 1. Average Water Quality of Influent Reclaimed Wastewater

Table 2. Hydrestor Media Parameters

Figure 6. Hydrestor media.

Figure 7. Pilot trailer installed in a roughly 20- by 40-foot space within an existing pump station.

and was connected to the pilot trailer inlet. The actual flow throughout the test was 30 gpm. Power was established with an installed transformer and was wired to the control panel to provide power to the automatic flow controls and pump. The pump, however, was not needed as pressure from the reclaimed water distribution system was sufficient. The treated water was discharged to a reclaimed water reservoir.

To provide the necessary empty bed contact time in each adsorption vessel, flow rates were monitored through inline flow meters and cross-referenced with flow totalizers. The average flows leading into Systems 1 and 2 were 18 and 12 gpm, respectively, and were maintained consistently, outside of a few instances where the upstream particle bag filters had clogged and reduced flow (further discussion follows). Some data points have been omitted to reflect these instances and smooth the overall data.

Sampling was conducted over a two-month period from September through November 2023. Influent and effluent water samples were taken in the field on days of sampling and brought to a FDEP-certified laboratory on the same days. Samples were taken in accordance with approved FDEP methods in precleaned high-density polyethylene bottles. Upon sampling, the bottles were immediately preserved with sulfuric acid (if necessary) and placed on wet ice to keep below 39°F. Laboratory analysis was then done for nutrient concentrations included TP, orthophosphorus, TN, nitrate, nitrite, ammonia, and total kjeldahl nitrogen (TKN) in accordance with U.S. Environmental Protection Agency (EPA) methodology as outlined in Table 1. The TP, TN, ammonia nitrogen, and TKN were preserved with sulfuric acid. Orthophosphorus was filtered in the field through a 0.45-µ filter to remove nondissolved species during sampling.

Results

Nutrient Reduction

As expected, longer empty bed contact times were more effective at removing phosphorus. Breakthrough for the purpose of this study is the 1 mg/L of TP as outlined in the AWT standards; however, in real compliance monitoring, it would be a yearly average. An empty bed contact time of 90 minutes showed the longest time to breakthrough at 437 bed volumes. The shortest time to breakthrough was with a 30-minute empty bed contact time and a breakthrough time of 247 bed volumes. In all cases, increased empty bed contact time led to a longer time to breakthrough (Figure 9). Additional time from 30 minutes empty bed contact time to 45 minutes further increased the initial adsorption capacity and time to breakthrough for the lead vessels (Figure 10). Time to breakthrough increased as a function of empty bed contact time, and therefore, the volume of water treated also increased (Table 3). Of note, however, is that there is an apparent diminishing return with increased residence time of vessels placed in series. The configuration of the lead-lag systems shows that the majority of phosphorus uptake is achieved in the first vessel, followed by additional removal and polishing in the second vessel. This is most apparent in System 1 where the addition of a second vessel and doubling of total empty

Continued on page 22

Figure 8. Process layout of the two system treatment trains.

Figure 9. Breakthrough curves of total phosphorus for System 1 (a) and System 2 (b) plotted

bed contact time only adds an additional 20 percent of bed life, whereas System 2 shows an increase of 30 percent. Regardless, it’s apparent that the majority of adsorption occurs in the lead vessels, and there is a possibility to increase removal efficiency and further reduce the effluent TP concentration and extend bed life with the addition of adsorption vessels in series.

While TN was not an intended metric for removal, it was important to track any impacts the treatment may have had; over the course of the trial, TN was largely unaffected. Additional species of nitrogen, such as nitrate, nitrite, TKN, and ammonia, followed similar patterns, fluctuating with variations of the influent TN concentrations, and are omitted for brevity.

Phosphorus Capacity of the Media

Determination of phosphorus capacity was important to compare costs and long-term applicability. The adsorption capacity varied between vessels and averaged 2.3 mg/g in single-

pass vessels (i.e., 2.18 mg/g for 30 and 2.45 mg/g for a 45-minute empty bed contact time) and 1.8 mg/g in double-pass vessels (i.e., 1.94 mg/g for 60 and 1.71 mg/g for 90-minute empty bed contact time). While the media is the same in all vessels, the increased adsorption capacity is attributed to higher influent concentrations of TP into the lead vessel, along with higher rates of removal from the lead vessel. If the test continued until full saturation, it’s expected that the secondary lag vessels adsorption capacities will have increased. This drop in adsorption capacity, which was calculated by dividing the cumulative phosphorus removed over the trial period by the mass of media in each vessel, shows that the majority of adsorption occurred in the first vessel of the lead-lag configuration, with the second vessel acting as a polishing step. These are commonly observed activated carbon uses.

Longer empty bed contact times of 90 minutes showed the best removal efficiency and a maximum bed life of approximately 450 bed volumes before breakthrough above

AWT targets of 1 mg/L of TP. Adsorption capacities showed a maximum of 2.45 mg/g, achieved at 45-minute empty bed contact time. An elemental analysis by inductively coupled plasma atomic emission spectroscopy of the spent media was conducted showing an uptake of only 0.7 mg/g after use. Further work is needed to understand the differences between adsorption capacity as measured by removal and the elemental analysis. Possible leaching of phosphorus (and subsequent adsorption in the lag vessel) may indicate lower true phosphorus loadings while maintaining high removal efficiency.

Conclusions, Cost Analysis, and Engineering Benefits

Over two months, a novel pelletized activated carbon media was pilot-tested in 500-gal vessels with reclaimed wastewater directly from a municipal distribution system. Long-term scalability, including economic and engineering analysis, was also conducted. The cost for a full-scale 1-mgd system rated at a residence time of 60 minutes using a similar vessel configuration and a scalable vessel design was considered. During cost modeling, the influent TP concentrations, media adsorption, and phosphorus removal were assumed to equal those of this pilot system. Upgrading this pilot system to a full-scale system can be facilitated by using six vessels in series, each holding 30,000 lbs of media. For an all-inclusive system operating at 60-minute residence time, capital costs for a new installment are estimated at $650,000, which includes vessel materials, equipment, installations, control panel, and pump station (at the time of this writing). Annual operational costs include power consumption and routine media changeouts. For the 1-mgd system operating with a 60-minute residence time, costs are estimated to be $1.1 million, which translates to an annual unit cost of $393 per lb of TP removed. The largest contributor to the operating costs is replenishment of adsorption media. Operating costs may vary as each water utility will be operated at different TP concentrations and have different background matrices.

This system can be scaled up for small and/ or rural wastewater facilities. The effectiveness can be translated to a full-scale system where influent and target effluent concentrations (presumably at AWT standards) are specified to determine the residence time and media volume required. The modularity of vessels may suit small and/or rural facilities where typical biological processes prove costly or difficult to operate.

Table 3. Performance Metrics of Each System Train

Figure 10. Comparison of lead vessels performance.

Future work is also needed to understand the benefits of reusing spent media as a soil amendment. Biochar, or possibly woodbased activated carbons, have been shown to be effective soil amendments that enhance water retention in soil, foster bacteriological growth, and raise agricultural productivity [5, 12] . Furthermore, similar MgO-amended sorbents have shown promise as a slow-release fertilizer [13]. It’s possible that a beneficial reuse of spent media as a soil amendment could reduce overall operating costs of the utility. Additional work is needed to determine the viability of spent media as a soil amendment.

Acknowledgments

Funding for this project was provided through the Florida Department of Environmental Protection Innovative Technologies Grant Program. Oversight and field operations were directed and performed by Anne Ross, Erik Fields, and Vincent Dodge. Their dedication and support is greatly appreciated. A special thanks goes to additional Carbonxt personnel who helped support this work, including Jack Drwiega, and Kemi

Moores. Additional acknowledgments are made to Waste2Water in Ocala for constructing the mobile trailer to custom specifications.

References

1. Finn, M., et al. Impact of inherent magnesium in biochar for phosphate removal from reclaimed water streams. Journal of Environmental Engineering, 2022. 148(2): p. 04021085.

2. Yao, Y., et al. Removal of phosphate from aqueous solution by biochar derived from anaerobically digested sugar beet tailings. Journal of Hazardous Materials, 2011. 190(13): p. 501-507.

3. Chernyakhovskii, V. Technology of unfired periclase-spinel parts with a phosphate binder. Refractories, 1985. 26(1): p. 41-44.

4. Rodriguez, R., D. Mazyck, and S. Suau. Systems and Methods for Pollutant Removal From Fluids With Pelletized High Strength Carbon Products With Reactive Binders. 2020, Carbonxt Inc.: US.

5. EPA, Method 365.3: Phosphorous, All Forms (Colorimetric, Ascorbic Acid, Two Reagent). 1978.

6. EPA, Method 300.0 Determination Of Inorganic Anions By Ion Chromatography. 1993.

7. EPA. Method 351.2. Revision 2.0: Determination of Total Kjeldahl Nitrogen by Semi-Automated Colorimetry. 1993.

8. EPA. Method 350.1: Nitrogen, Ammonia (Colorimetric, Automated Phenate). 1993.

9. ASTM. Standard Test Method for Particle Size Distribution of Granular Activated Carbon. 2022.

10. ASTM. Standard Test Method for Apparent Density of Activated Carbon. 2019.

11. ASTM. Standard Test Method for Ball-Pan Hardness of Activated Carbon. 2023.

12. Ding, X., et al. Biochar application significantly increases soil organic carbon under conservation tillage: an 11-year field experiment. Biochar, 2023. 5(1): p. 28.

13. Yao, Y., et al. Engineered biochar reclaiming phosphate from aqueous solutions: mechanisms and potential application as a slow-release fertilizer. Environmental Science & Technology, 2013. 47(15): p. 8700-8708. S

2024-2025 FSAWWA BOARD OF GOVERNORS

EXECUTIVE COMMITTEE

Lisa Wilson-Davis Chair

City of Boca Raton, Utility Services Department 1401 Glades Road

Boca Raton, Florida 33431 E: lwilsondavis@myboca.us

Tyler Tedcastle, P.E. Chair-Elect

Carter & VerPlanck, a DXP Company 601 S.E. 10th Avenue

Pompano Beach, Florida 33060 E: TTedcastle@cviwater.com

Terri Holcomb, P.E. Vice Chair

E: terri_holcomb@yahoo.com

Marjorie Craig, P.E. Past Chair

Village of Tequesta 345 Tequesta Drive Tequesta, Florida 33469 E: mcraig@tequesta.org

Shea Dunifon Secretary

JEA Springfield Lab 1002 N. Main Street Jacksonville, Florida 32206 E: dunisn@jea.com

Kevin Carter Treasurer Broward County

2555 W. Copans Road Pompano Beach, Florida 33069 E: kcarter@broward.org

Monica Wallis, P.E. Treasurer-Elect

Destin Water Users Inc. P.O. Box 308

Destin, Florida 32540 E: mwallis@dwuinc.com

Richard Anderson Section Director

Peace River Manasota Regional Water Supply Authority

9415 Town Center Parkway

Lakewood Ranch, Florida 34202

E: randerson@regionalwater.org

William Young

Florida Section

AWWA by Region

General Policy Director Wright-Pierce 8647 Baypine Road

Spring Lake Business Center, Bldg. #1, Suite 103 Jacksonville, Florida 32256

E: william.young@wright-pierce.com

COUNCIL CHAIRS

Adam Corn

Contractors Council Chair

Garney Construction

370 E. Crown Point Road Winter Garden, Florida 34787

E: acorn@garney.com

Patrick Williamson, PMP Manufacturers and Associates Council Chair

Badger Meter

2920 Eunice Avenue

4545 W. Brown Deer Road

E: pwilliamson@badgermeter.com

Larry Miller

Member Engagement and Development Council Chair

St. Johns County Utility Department

1205 State Road 16

St. Augustine, Florida 32084

E: lmiller@sjcfl.us

Duane A. Gilles

Operators and Maintenance Council Chair

A2O Consulting LLC

E: duanegilles@gmail.com

Keelie Carlton

Public Affairs Council Chair

Seminole County

200 W. County Home Road Sanford, Florida 32773

E: kcarlton@seminolecountyfl.gov

Mike Stoup, P.E.

Technical and Education Council Chair McKim & Creed 1365 Hamlet Avenue Clearwater, Florida 33756

E: mstoup@mckimcreed.com

Monica Wallis, P.E. Water Utility Council Chair

Destin Water Users Inc. P.O. Box 308

Destin, Florida 32540

E: mautrey@dwuinc.com

REGION CHAIRS

Felicity Appel, P.E.

Region I Chair (North Central Florida) Kimley-Horn

2619 Centennial Blvd., Suite 200

Tallahassee, Florida 32308

E: felicity.appel@kimley-horn.com

2024-2025 FSAWWA BOARD OF GOVERNORS

Emory Gawlik, P.E.

Region II Chair (Northeast Florida)

CDM Smith

4651 Salisbury Road, Suite 420 Jacksonville, Florida 32256 E: Gawlikea@cdmsmith.com

Andrea Netcher, Ph.D., P.E. Region III Chair (Central Florida) Black & Veatch

201 S. Orange Avenue, Suite 500 Orlando, Florida 32801 E: NetcherA@bv.com

Michael J. Condran, P.E. Region IV Chair (West Central Florida) Brown and Caldwell 4413 W. Paul Avenue Tampa, Florida 33611 E: mcondran@brwncald.com

Reshma Thummadi, P.E.

Region V Chair (Southwest Florida) AECOM

4415 Metro Parkway, Suite 404 Fort Myers, Florida 33916 E: reshma.thummadi@aecom.com

Emeliz Torres, P.E.

Region VI Chair (Southeast Florida) Black & Veatch

4226 N. Dixie Highway, Unit 97 Oakland Park, Florida 33334 E: TorresE@bv.com

Catalina Lopez Velandia, P.E. Region VII Chair (South Florida) Miami-Dade Water and Sewer Department 3071 S.W. 38th Avenue Miami, Florida 33146 E: catalina.lopez-velandia@miamidade.gov

Wesley Oehmig, P.E.

Region VIII Chair (East Central Florida) HDR Engineering Inc. 1475 Centrepark Blvd., #230 West Palm Beach, Florida 33401 E: wesley.oehmig@hdrinc.com

Heath Hardy, P.E.

Region IX Chair (West Florida Panhandle)

HDR Engineering Inc. 25 W. Cedar Street, Suite 200 Pensacola, Florida 32502-5945

E: heath.hardy@hdrinc.com

Heather Ripley, P.E.

Region X Chair (West Central Florida)

Kimley-Horn 1514 Broadway, Suite 301 Fort Myers, Florida 33901

E: heather.ripley@kimley-horn.com

Elayne Nash, EI

Region XI Chair (North Florida)

Jacobs 643 S.W. 4h Avenue

Gainesville, Florida 32608

E: Elayne.Nash@jacobs.com

Jeff Brittain, P.E.

Region XII Chair (Central Florida Panhandle)

Kimley-Horn

120 Richard Jackson Blvd., Suite 230 Panama City Beach, Florida 32407

E: Jeff.Brittain@kimley-horn.com

TRUSTEES

Jay Madigan Trustee

Graham Inc.

E: jmadigan@grahaminc.com

Andrew Greenbaum Trustee

Sarasota County Public Utilities

1001 Sarasota Center Blvd. Sarasota, Florida 34240

E: greenbaumal@bv.com

Bina Nayak, Ph.D. Trustee

Pinellas County Utilities 1620 Ridge Road

Largo, Florida 33778

E: bnayak@pinellascounty.org

Mike George Trustee

R&M Service Solutions 11820 Uradco Place, #103 San Antonio, Florida 33576

E: mgeorge@rmservicesolutions.com

Mark McDowell Trustee

InfraTech Group 2920 Eunice Avenue

Orlando, Florida 32808

E: mark@infratechgroup.com

SECTION STAFF

Kim Kowalski

Executive Director

Florida Section AWWA

1320 Tennessee Avenue

St. Cloud, Florida 34769

P: (407) 979-4814

E: kim@fsawwa.org

Peggy Guingona

Section Administrator

Florida Section AWWA 1320 Tennessee Avenue

St. Cloud, Florida 34769

P: (407) 979-4820

E: peggy@fsawwa.org

Casey Cumiskey

Membership Specialist/Certification Coordinator

Florida Section AWWA 1320 Tennessee Avenue

St. Cloud, Florida 34769

P: (407) 979-4806

E: casey@fsawwa.org

Donna Metherall

Training/Events Coordinator

Florida Section AWWA 1320 Tennessee Avenue

St. Cloud, Florida 34769

P: (407) 979-4805

E: donna@fsawwa.org

Jenny Arguello

Section Coordinator

Florida Section AWWA 1320 Tennessee Avenue

St. Cloud, Florida 34769

P: (407) 979-4804

E: jenny@fsawwa.org

OVolunteers: The Heartbeat of Our Organization

Lisa Wilson-Davis Chair, FSAWWA

ur volunteers are the heartbeat of the Florida Section of the American Water Works Association (FSAWWA). With their energy, passion, and dedication, they breathe life into our mission and drive our achievements. Their unwavering commitment ensures that we make a meaningful impact in the water community every day. We are deeply grateful for the invaluable contributions of these incredible individuals who continually go above and beyond to make a difference.

As chair of FSAWWA, I am excited to shine a spotlight on the amazing volunteers who power our organization. Every other month this year, my column will feature a different group of volunteers—celebrating their accomplishments, highlighting their impact, and showcasing the incredible opportunities available for you to get involved.

Read on to discover the outstanding achievements of our councils, divisions, and committees and learn how you too can join this dedicated group of changemakers.

Do You Know About Section Councils?

The Florida Section has seven councils, with volunteers who work together and provide key resources and training for our members.

Manufactures/Associates Council (MAC)

Chair - Mark McDowell

Vice Chair - Pat Williamson

The MAC provides responsible representation of manufacturers and associates in FSAWWA and develops programs and activities to encourage

membership and participation within the organization. Yearly events include the Fall Conference and the Florida Section luncheon each year at the AWWA Annual Conference and Exposition (ACE), as well as the selection of water distribution award recipients.

The members of MAC are pivotal to the success of our annual Fall Conference. In its early years, this dedicated group of volunteers worked tirelessly to coordinate and execute the logistics and activities that laid the foundation for the conference’s success. Thanks to the incredible efforts of the MAC members, the conference grew so much that we eventually recognized the need for dedicated staff to manage the logistics and administrative functions.

Even today, the MAC members remain the driving force behind some of the conference’s most exciting and cherished activities, including the operator competitions, Poker Night, and the golf tournament. Their passion and commitment continue to be at the heart of our conference’s enduring success.

Water Utility Council (WUC)

Chair - Monica Wallis

Vice-Chair - Tara Lamoreux

The WUC is recognized as the authoritative resource for knowledge, information, and advocacy to improve the quality and supply of drinking water. Its mission is to develop action programs to initiate, evaluate, respond to, and comment on legislative, regulatory, and other matters directly affecting water utilities in Florida.

The members of WUC play a pivotal role in shaping water policy across our state through their work with the legislature and regulatory agencies. During each legislative session, they diligently track bills relevant to the water community, provide expert testimony during committee meetings, and have even been instrumental in drafting legislation that has become law.

One of its most impactful events is the annual Tallahassee Fly-In, where members travel to the state capital to meet with over

50 legislators, advocating for the priorities of Florida’s water community.

You have the chance to join us and make a difference! Mark your calendar for the next Fly-In, happening Jan. 21-23, 2025, in Tallahassee. Together, let’s ensure a brighter future for water in Florida!

Public Affairs Council (PAC)

Chair- Shea Dunifon

Vice Chair- Keeli Carlton

The PAC enhances awareness regarding the water industry and the expertise that we provide in the stewardship of Florida’s water resources. This is accomplished by execution of a marketing/communications plan in coordination with collaborative partnerships with all stakeholders maintaining effective relationships with the public, media outlets, government officials and liaisons, and educational outreach programs.

This council is extremely busy, with two committees and several subcommittees under it.

Youth Education and Outreach Committee

Subcommittees include:

S Drop Savers - A poster contest to raise awareness of water conservation in grades K-12.

S High School Operator Academies - Helps create a workforce pipeline between utilities and students seeking careers upon high school graduation.

S Model Water Tower Competition (MWTC) - Introduces youth to the field of engineering by building a functional water tower.

Utility Public Affairs and Outreach Committee

Subcommittees include:

S Landmark Awards - Recognizes waterrelated structures over 50 years in age.

S Water Monster Tanks - Provides potable drinking stations to promote the safety and consumption of tap water at public events.

S FSAWWA “Best of the Best” Tasting Drinking Water Contest - The 12 FSAWWA regional contest winners come

together at the Fall Conference to vie for the FSAWWA top honor and represent Florida at ACE.

S Industry and Public Advocacy Awards

– These awards honor individuals both within the water industry and outside FSAWWA who work to strengthen public relations, raise awareness about Florida’s water, and advocate for a sustainable water future.

• Industry Advocate Award: This award recognizes water professionals who go above and beyond to represent the utility and water industry in a positive light. These individuals understand the importance of advocacy and are dedicated to making a meaningful difference.

• Public Advocate Award: This award celebrates individuals outside of the immediate water industry—artists, educators, public officials, board members, and leaders of nonprofits— whose efforts align with FSAWWA’s mission. By raising awareness and building public trust, these advocates contribute to the betterment of Florida’s water resources and future.

With all the activities this council is involved in, the opportunity to volunteer is almost limitless!

Technical and Education Council (T&C)

Chair - Bina Nayak

The T&C is the training and educational resource for water quality and resources, information systems, water use efficiency, and water distribution in the state of Florida. There are five divisions and seven committees under this council, which include:

Divisions

Distribution, Information Technology, Training, Water Quality and Resources, and Water Use Efficiency

Committees

Automation, Contaminants, Customer Service, Cybersecurity, Finance and Rates, Geographic Information Systems (GIS)/ Asset Management, and Master Planning and Modeling

The Training Division offers a wide range of opportunities for operators and engineers to earn continuing education units (CEUs) and professional development hours (PDHs) to support their licensure and professional growth. Courses are available in multiple formats, including in-person seminars,

online prerecorded sessions, live webcasts, teleconferences, and hands-on training.

The seven committees meet regularly to provide specialized education through webinars, seminars, and workshops at state conferences. For example, our new Cybersecurity Committee focuses on cybersecurity and offers training materials, as well as sharing information about conferences and other relevant events tailored to the water sector’s cybersecurity needs.

Contractors Council (CC)

Chair - Adam Corn

Vice Chair - Courtney Dantone

The CC fosters collaboration across all facets of the water industry, including owners, engineers, contractors, and suppliers. Its mission is to help manage Florida’s future infrastructure needs while maintaining a careful balance with the state’s natural resources.

The CC is also known for hosting the ever-popular BBQ Challenge, a highlight of the incoming chair’s reception at the Fall Conference.

In addition to this flagship event, the CC organizes two annual workshops: one at the Florida Water Resources Conference (FWRC) in the spring and another at the Fall Conference. The members also contribute regularly to this magazine through the Contractor Roundup column, providing valuable insights and updates for the water community.

Operators

and Maintenance Council (OMC)

Chair- Duane Gilles

The mission of OMC is to increase member services to water plant operators, distribution system operators, and water supply maintenance staff through increased opportunities for association leadership, participation, local networking, and expanded awards and recognition programs. It also provides direction on long-term needs and priorities to the board of governors.

The OMC has two committees.

Top Ops Challenge Committee. This oversees

the Top Ops Challenge, a highlight of the Fall Conference. Known as the “college bowl” of the water industry, the competition showcases teams of one, two, or three water operators or laboratory personnel from FSAWWA regions. At FWRC, teams face off in a fast-paced, question-and-answer tournament featuring technical questions and math problems.

Since 1997, the FSAWWA has consistently sent a team to compete in the national Top Ops competition at ACE. Florida teams have proudly earned eight first-place wins to date, and we’re aiming for our ninth victory at ACE25 in Denver.

Operator Scholarship Committee. This supports operator development by providing scholarships. The OMC also presents awards recognizing excellence in the following categories:

S Outstanding Class A, B, and C Water Treatment Plants

S Outstanding Water Treatment Plant Operator

S Operator’s Meritorious Service

The committee’s efforts are reflected in the sustained growth of our operator membership, demonstrating the importance and impact of its work.

Membership Engagement and Diversity Council (MEDC)