SAFETY WORKS

Workplace inspections

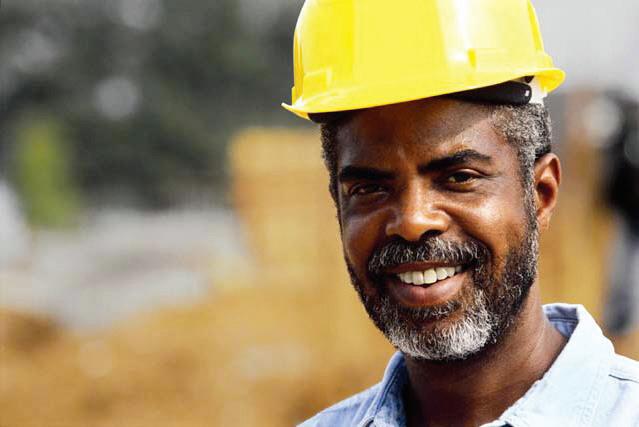

Inspect your way to safer work areas from Snellings Walters' Employee Matters bulletin The ideal workplace inspection isn’t one that follows a safety incident, or a surprise visit from OSHA – it’s the inspection that you arrange yourself !

a great training tool and an effective way of motivating employees to work more safely.

Self-inspection audits offer the most effective way to improve safety management, prevent accidents, and ensure compliance with safety regulations. Work area inspections will: > Evaluate compliance with safety and health policies and procedures > Identify hazards for correction > Determine the need for safety training > Ensure that your work areas get a high grade in the event of an OSHA inspection > Demonstrate your concern for employee safety and health The Occupational Safety and Health Act requires periodic evaluation of workplaces. The timing of self-inspection audits depends on the type of work areas involved. Very hazardous areas might require formal, weekly inspections, while office areas might need only a monthly inspection.

Although management needs to take the lead in work area inspections and is ultimately responsible for making sure action is taken to correct problems, make sure to involve employees. Work area safety inspections provide

> Ask workers to help develop inspection checklists for their work areas. > Appoint individuals — or, even better, a team — to conduct inspections. To get everyone involved, have team members serve on a rotating basis. > Meet with employee inspectors after inspections to discuss safety problems and corrective actions. > Share the results of work area inspections with all employees in weekly safety meetings. Safety is all about awareness and knowledge. Knowledge gives you the power to prevent accidents. One of the best ways to keep informed about ever-changing work area conditions is to perform routine safety inspections. Don’t wait for an accident to find out about a hazard that could have been corrected!

UAC MAGAZINE | SPRING 2021

Supplement scheduled inspections with informal daily walkarounds, targeting areas that have had more than their share of safety problems. Follow up to make sure that previously identified problems have been fixed effectively. Use checklists (preferably written) for every inspection.

Here are a few ideas for getting workers involved in self-inspection audits:

25