3 minute read

M.Koch Terahertz filter gratings

Terahertz filter-gratings

Fatima Taleb1, Enrique Castro-Camus2 , and Martin Koch1

Advertisement

1 Physics department and material science center, Philipps-Universität Marburg, 35032 Marburg, Germany. 2 Centro de Investigaciones en Optica A.C. Leon GTO. 37150, Mexico.

Abstract — We explore the possibility of combining a terahertz grating and a THz mesh filter in a one layer device. The structures could be produced in aluminum by laser cutting.

I.INTRODUCTION

Amature THz technology requires not only emitters and receivers but also a variety of optical components. This includes simple lenses, reflectors, waveguides, filters and gratings. One class of established, well known filters are mesh filters, which were first reported in 1967. The standard fabrication procedure for these structures is photolithography which is somewhat cumbersome. Recently, it was shown that such filters can be produced by laser cutting of an regular aluminum foil [1]. Also THz gratings produced by this method were recently demonstrated [2]. If one would like to combine the function of both structures one would need two structured aluminum layers and position them one after the other. Here, we explore the possibility to combine the functionality of both structures in a one-layer device.

We simulated a diffraction grating formed by 327.5µm stripes of metal alternating with void stripes forming a total period of 1310µm. In addition, we simulated a combined structure in which we replaced the air stripes with a frequency selective metamaterial made out of void crosses on the metal plate. The crosses are formed by two orthogonal slots of 170µm length and 40µm width (3 cross rows fit in each space period originally void in the conventional diffraction grating). Such a structures could be produced by laser cutting e.g. with a frequency-doubled Nd:YAG laser. Details of such a cutting system can be found in [3].

To determine the performance of such a structure the simulations mentioned earlier were carried out using the finite element time-domain solver CST MICROWAVE STUDIO. The material parameters of aluminum were taken from the CST database.

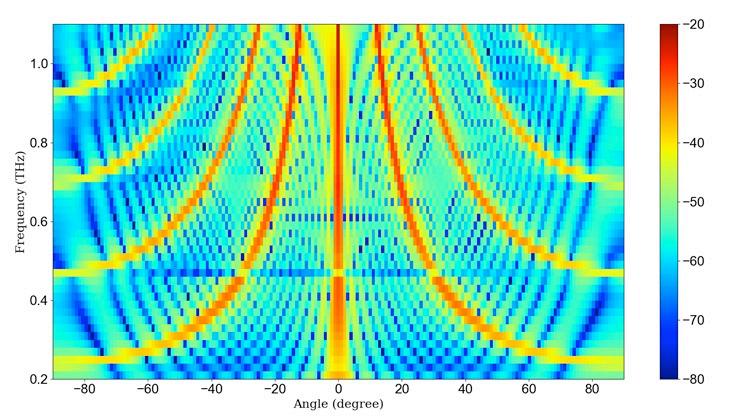

While Fig.1 shows the typical pattern of a diffraction grating, the combined structure does show a more complex behavior in Fig.2. “Hotspots” are shown at the intersection of the diffraction arms with the ~800GHz band, which is consistent with the resonance frequency of the cross-metarmaterial filter. In addition, the fourth diffraction order is intensity-enhanced with respect to the other orders. This can be explained by the additional periodicity introduced by the metamaterial, which has a period of ¼ of the original diffraction grating.

Additional simulations (not shown) were performed changing a variety of geometrical parameters such as the grating period and the cross dimensions. By doing this we could control the position of the diffraction orders and the hotspots independently, demonstrating the possibility of engineering application-specific devices for telecommunications among other applications.

Fig. 1. Relative intensity (in dB) of the diffracted radiation as function of the angle and frequency for the conventional diffraction grating obtained from full electromagnetic simulation. The results are consistent with the analytically expected behavior.

Fig. 2. Relative intensity (in dB) of the filter-grating structure.

REFERENCES

[1] H. Alaboz, M.Schneider, J. Ornik, E. Stübling, D. Jahn, and M. Koch, "A laser cut THz metal mesh bandpass filter with high transmission", EOS Topical Meeting on Terahertz Science & Technology, Berlin (2018). [2] J. Ornik, Y. Zhang, M. Schneider, M. Taherkhani, H. Alaboz, and M. Koch, "THz gratings produced by laser cutting" 44th International Conference on Infrared, Millimeter, and Terahertz Waves, Paris (2019). [3] N. Born, R. Gente, I. Al-Naib, and M. Koch, "Laser beam machined freestanding terahertz metamaterials," Electron. Lett. 51(13), 1012–1014 (2015).