3 minute read

ENERGY EFFICIENCY AND FIRE SAFETY: THE NEW COLLABORATION BETWEEN PYROGUARD AND TECHNOFORM

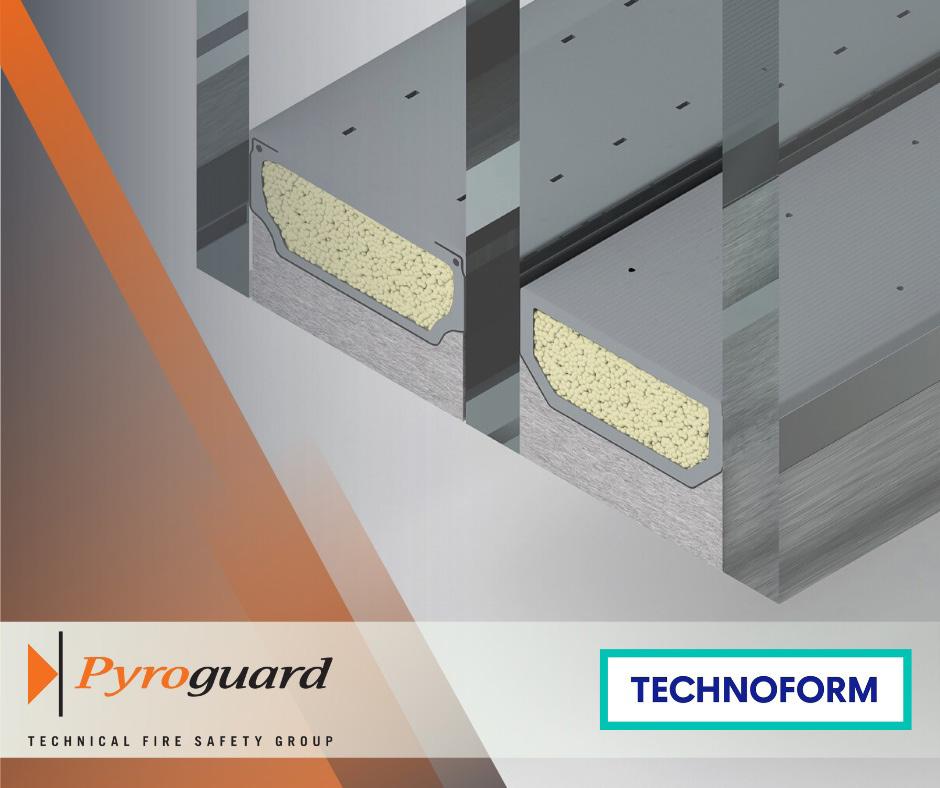

Recognising the increased attention on energy efficiency and sustainability, Pyroguard (part of the Technical Fire Safety Group) and Technoform UK (the profile manufacturer) have successfully collaborated on a test programme and launched a new fire rated solution: the use of high-performance warm edge spacers with Pyroguard fire safety glass.

Available for use in a range of Pyroguard’s fire-rated Insulated Glazed Units (IGUs), this development now enables architects, contractors, façade engineers and fabricators to achieve greater thermal properties and improved unit performance under test conditions.

Spacers - installed as separators between the glass panes - that are certified for use in fire rated IGUs are traditionally manufactured from steel or aluminium, due to the material’s durability in the event of a fire. However, from an energy efficiency point of view, the conductivity of metal can adversely affect the thermal performance of a glazing system.

Working in partnership - and following several full-scale fire tests at Warringtonfire (UK) and Efectis (FR) - Technoform and Pyroguard have developed and qualified this new solution, which complies with BS EN 1364. The warm edge spacers are suitable for use in conjunction with Pyroguard’s fire rated IGUs and are included as standard with many of Pyroguard’s (IGU) constructions. Unlike other warm edge spacer technologies, the Technoform SP14 spacer has a hybrid construction of precision engineered polypropylene and steel. The SP14 delivers improved thermal properties, while the inclusion of steel coextruded into the spacer structure offers structural stability and durability in fire situations.

Speaking about the collaboration, Andy Lake, Sales Director UK & IRE at Pyroguard said: “Sustainability and energy efficiency is becoming an increasingly critical factor for architects and specifiers. Across the glazing industry, we are seeing warm edge spacers being specified with increasing frequency, helping to reduce the thermal bridging of the system. Our partnership with Technoform and our extensive testing programme has enabled us to now bring this improved thermal performance to the fire safety glass sector, combining safety with sustainability.

“We’re very proud to be the first fire safety glass manufacturer to offer this performance upgrade as standard in the market.”

Richard John, Product & Market Manager at Technoform, added: “Specifiers and building owners are constantly looking to improve thermal performance and reduce carbon footprints. Added to this, limited combustibility design is vitally important. Our partnership with Pyroguard now enables us to deliver performance on all these fronts.”

CE and UKCA approved, the new warm edge spacers are compatible with many of Pyroguard’s products. Available in widths from 12 – 22 mm, the spacers are also manufactured in various colours, including black, which is ideal for blending seamlessly with the sealants used in typical IGU constructions.

For more information, please visit: www.pyroguard.eu or www.technoform.com.

One of the best qualities of a steel window or door is its longevity and this is where refurbishment and servicing are vitally important; this is where SWA members can help. Options range from a very basic ease and adjusting, where the windows and doors remain in-situ and are serviced, to a full in-situ overhaul involving significant paint removal and redecoration, where possible.

In a complete refurbishment, all the windows and doors are removed and taken to a factory environment for shot blasting, potentially galvanising, powder coating and servicing; then comes the reinstallation and reglazing. There is also the possibility, especially in heritage situations, of maintaining the original aesthetic of the original window by hand painting and reglazing.

The refurbishment has improved centuries, and, today, clients can expect an upgrade in usability and security as well as both thermal and acoustic performance through glazing and sealant enhancements. In addition, the windows are significantly more aesthetically-pleasing.

For owners of buildings or houses within listed or conservation areas, or those

On-site overhaul is as above but includes removal of visible surface paint; treatment of the visible steel substrate; tightening or replacement of coupled frame intersections and perimeter fixings; replacement of damaged weather seals; potential for upgrading of glass specifications; potential to modernise or refurbish existing ironmongery to include enhanced security; re-introduction of perimeter and window mastic seals; replacement of glazing beads, mastic and putty; and redecoration of painted surfaces.

Full off-site overhaul includes removal of existing frames, and possible temporary protection of apertures, shot blast to bare metal to remove all existing paint and priming material; fully recorded survey of necessary repairs and replacement section, hinges and couplings; full pre-treatment primer and re-painting of the steel sections to required specification; re-installation of frames to apertures, re-glazing with the possibility of thermal / acoustic upgrades; refurbishment and replacement of existing specialist glazing; application of new mastic and primary weather seals; and re-instatement of refurbished or new ironmonger.

For further information on the Steel Window Association, please visit www.steel-window-association.co.uk or call 020 3475 8049.