Great product developments and a brand new aluminium collection!

Read all about it on page 60

Great product developments and a brand new aluminium collection!

Read all about it on page 60

Over recent months, new market opportunities have unfolded due to significant shifts among leading national stakeholders in the fenestration industry.

At Insight Data, we are dedicated to the pivotal role that streamlined lead generation plays in the pursuit of new opportunities. Over the years, we've worked with hundreds of businesses who have used Insight Data to help deliver instant lead generation results with a fast return on investment. Through our comprehensive prospect data, market intelligence and direct marketing support, we empower businesses to identify costsaving opportunities, target lucrative prospects, and win new business at a fraction of the cost of other providers.

Here’s how we do it: Targeted Marketing Campaigns

In today’s market, targeted marketing is essential for success. It’s not just about reaching a broad audience; it’s about reaching the right audience with the right message at exactly the right time. Insight Data provides businesses with the market intelligence they need to execute precisely targeted marketing campaigns. By utilising a database that

allows for easy segmentation of prospects based on criteria such as industry, location, and purchasing behaviour, businesses can optimise their marketing efforts for maximum impact. This targeted approach not only increases the efficiency of marketing campaigns but also reduces costs by minimising wasted resources on reaching uninterested or irrelevant prospects.

Efficient Lead Generation Efficient lead generation is the cornerstone of a successful business strategy. Insight Data's extensive databases offer access to over 80,000 direct contacts to senior decisionmakers across the trade and commercial market, enabling precise targeting of key stakeholders or influencers. By leveraging comprehensive databases containing detailed information on potential clients, businesses in the fenestration, construction, and wider building-product industries can streamline and personalise their lead generation process, saving time and increasing conversion rates.

Streamlined Operations Time is money, and inefficiencies in business operations can lead to significant cost implications. Insight Data enables businesses to streamline their operations by providing access to real-time information and analytics instantly. From tracking financial performance to monitoring market dynamics, businesses can gain valuable insights that help them operate with efficiency. Insight’s

integrated sales and marketing platform also offers automated reminders and overdue notifications to help delegate tasks, as well as a calendar feature that connects directly to Outlook, Google Calendar, iCal, and more. Increased productivity and operations mean only one thing: an enhanced bottom line for all businesses.

Competitive Advantage With the industry experiencing difficulties throughout recent months, gaining a competitive advantage is more important than ever. Insight Data gives businesses the edge they need to outperform the competition by providing access to timely, accurate, and actionable information. Whether it’s identifying untapped market opportunities, understanding customer needs, or staying ahead of industry trends, businesses can leverage market intelligence to stay one step ahead of the competition. By making data-driven decisions and executing targeted strategies, businesses can carve out a distinct competitive position and drive growth.

Ready to tap into the potential of Insight Data?

Schedule a free demo today to explore how Insight Data can help your business reduce costs, optimise time management, and boost profit margins.

Contact Insight Data on 01934 808 293 to find out more or email hello@insightdata.co.uk.

Reason

Reason

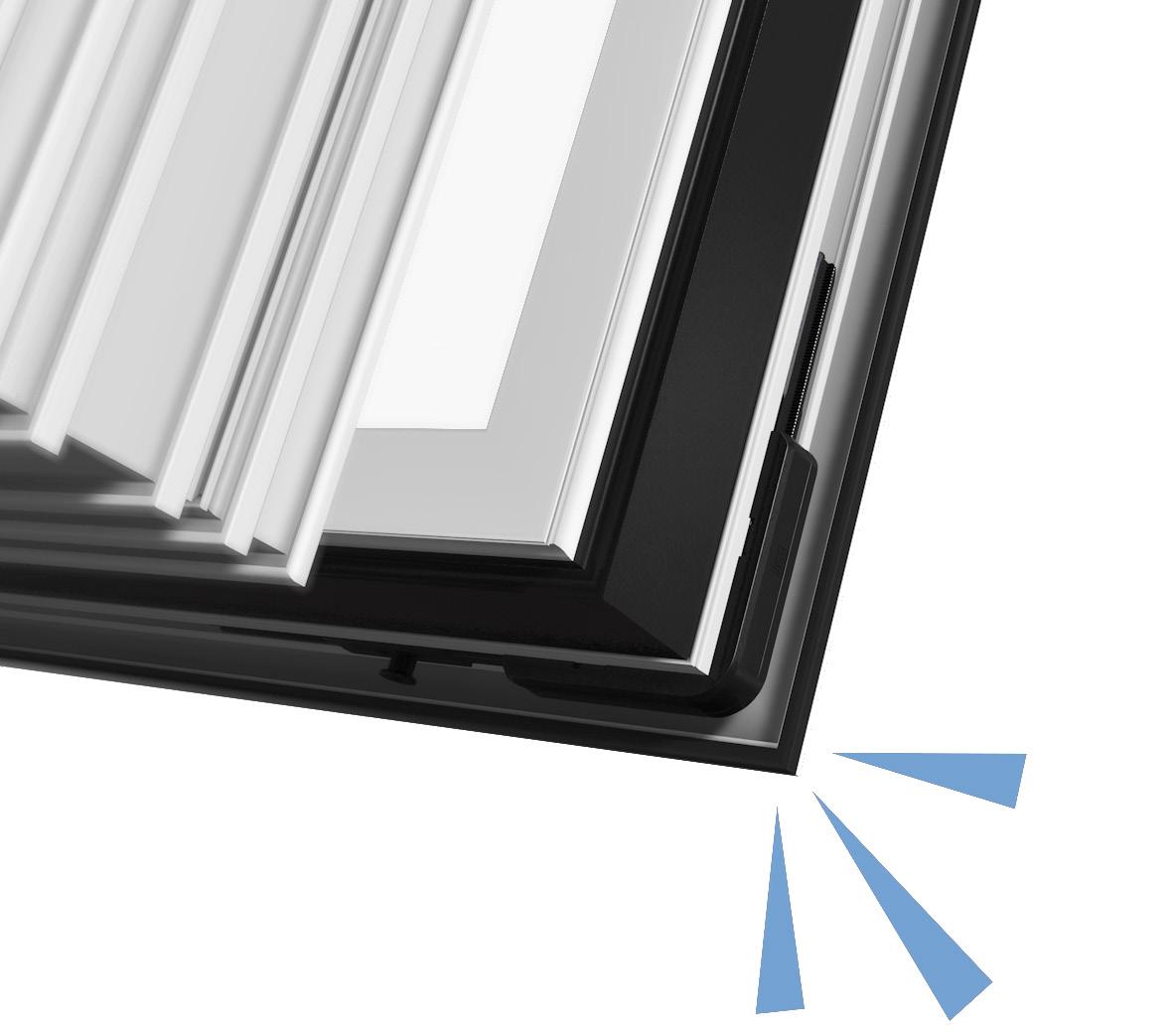

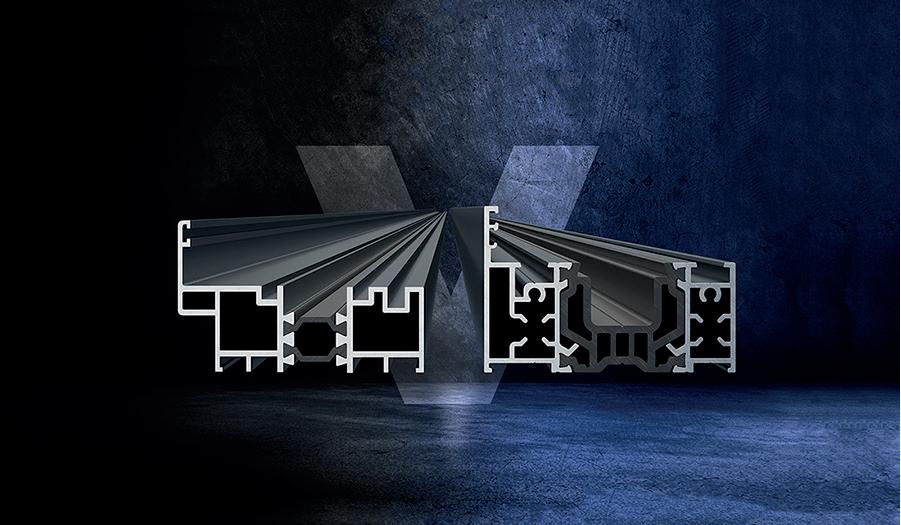

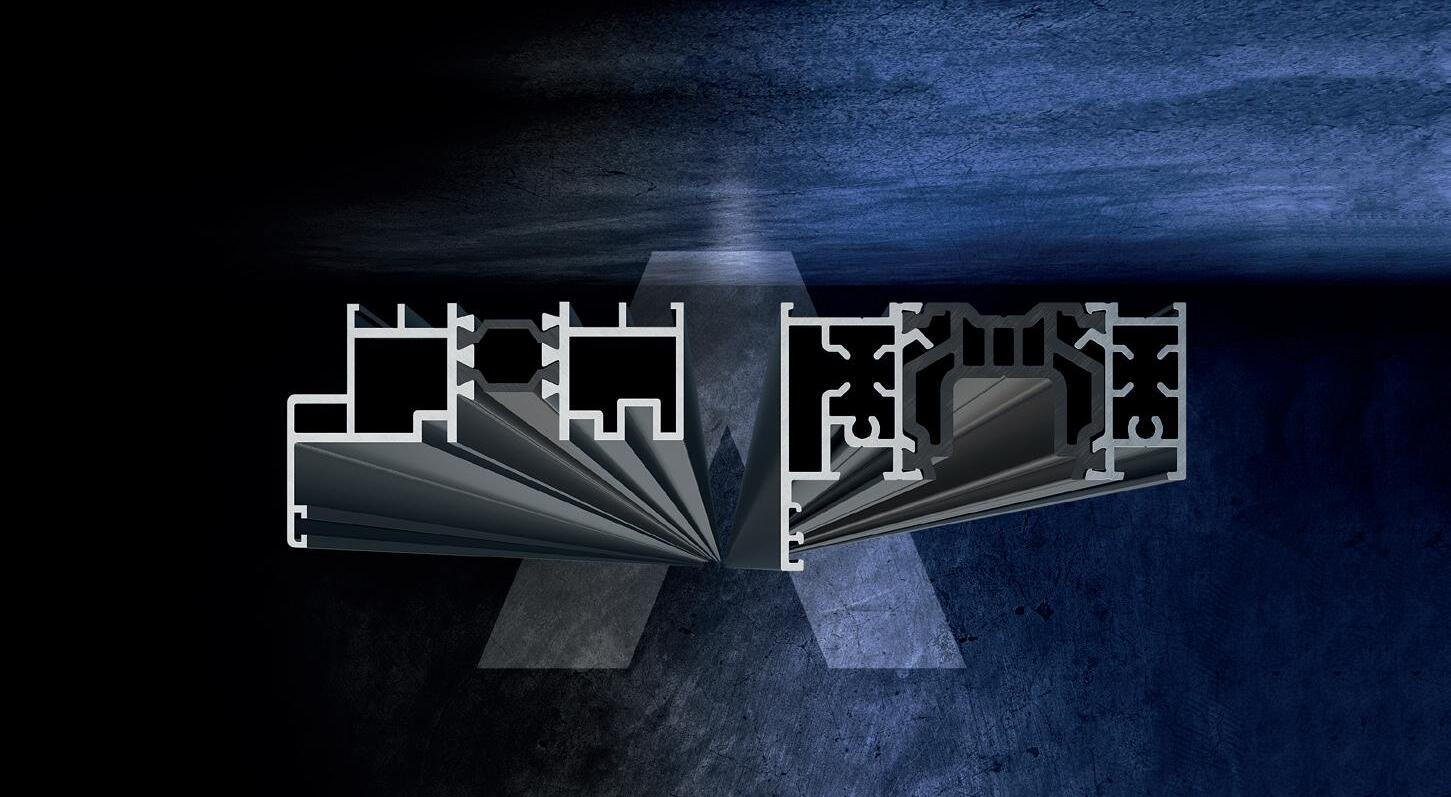

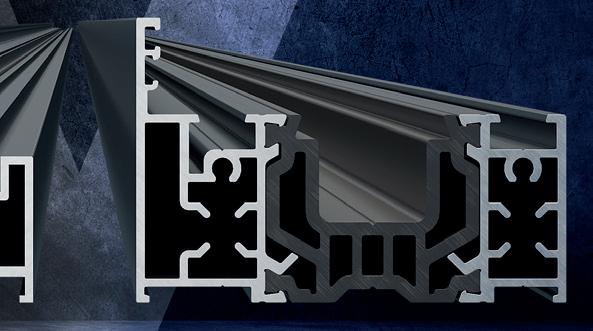

Reasons 8, 23 and 72: Excellent weather performance, the highest industry thermal values, and enhanced security are just three of them. OMNIA. Innovation through detail. 100 reasons. 1 ch ice.

Maybe it’s not surprising that our industry is viewed with some suspicion. After all the odd bad apple in the barrel is what can ruin the whole crop. The days of the foot in the door salesman may, largely, be a thing of the past but the days of the dodgy ‘phone calls is very much with us.

At Champion Towers we seem to have a whole tribe of energy assessors and advisors solely focused on us! The ‘phone calls are incessant and all of them claiming to be the energy advisor for my area or postcode….I’m not sure that a) we could have so many personal advisors and b) that they are all blissfully unaware that they are just one of many! Now, none of this is a problem as it is sorted by simply putting the ‘phone down but the latest call intrigued me. This time I was informed that the company had been asked by Planitherm to research the glass in the windows in our road, they would test it and if it didn’t pass there was a whole raft of grants and incentives from the government that would be made available to bring us up to standard. Well, this was certainly news to me, and I asked the lady if they worked with Saint-Gobain? “No,” she said, “I don’t know about them, it’s Planitherm who have asked us to do this survey.”

I know I’m pretty gullible, and a trusting sort of bloke, but even I could smell a scam here! A bit of delving and it transpired that the mob contacting me were from Accrington in Lancashire…not exactly on my doorstep. So, when they pushed for an appointment to test our glass, I thought it might be interesting. Another lady ‘phoned me back a couple of days later to confirm that they would be coming round to measure up. Naively, I asked why they would do that as I thought Planitherm just wanted to test the glass? She then asked about the property, age of the windows and all those good things, stating that as we had 1937 Crittall windows they would not pass the glass test and they would measure up to quote for new windows. And what about the grants and incentives that are available to me? She didn’t know about those, but I could ask the guy when he turned up. “Are you a window installation company.” I asked. “Well, yes, we can fit windows.” Said she.

I guess I should have followed through with the appointment just to see what happened but me and Mrs C were uncomfortable letting a bunch of con artists into our home. I have a sneaking suspicion it would have meant appearing on someone else’s list and we would have been inundated with solar panel companies, kitchen fitters, roofers or whatever! A bit of a search indicated

that a company of the same name, from a town only a stone’s throw from Accrington, had been fined £130,000 for making nuisance calls to TPS and CTPS ‘do not call’ registered telephone numbers - not just a few, but over 500,000 direct marketing calls!

I’m guessing that it is virtually ‘de rigueur’ to mention the general election this month although by the time our July edition of Glass News hits your desks it will be all over bar the shouting. When I say ‘all over’ I really meaning just beginning! Will things get better? Can things get any worse? I’m afraid I’m one of those that having voted for one side for many decades now wish there was a box to tick that said, “None of the above”. Mind you I would add some qualifying words to describe my thoughts and feelings about politicians and why I chose that option. In all seriousness, the changes we are likely to experience will undoubtedly affect our industry not least being the uncertainty in the markets and a reluctance on the part of the homeowner to expend disposable income or to take on new financial commitments. The world is not exactly in a great position currently and it is certainly not just the UK that is going through political turmoil. Let’s hope for a more settled future.

Meanwhile, as an industry we keep moving forward and there are plenty of success stories out there although it’s clear that it’s the survival of the fittest and those with the foresight and commitment to investment, both in plant and marketing, who will come out on top. On a personal note, I’m enjoying meeting new people and watching companies grow and it always amazes me how our industry innovates with new and more efficient processes and products to go with them.

The Glass Conference scheduled for Wednesday 16th and Thursday 17th October at the Telford International Centre will, I believe, be an important event for our industry. An opportunity for us all to get together and discuss where our industry is going. Mind you, getting a bit of summer before then would be very welcome….. the current weather isn’t what I expected from ‘global warming’!

Chris

‘TIME

Sudoku:

Cliff Thompsett, Abbeyglass & Windows, Chippenham

Eye Spy: Gillian Shields, Leeds

Spot the Difference: Keane Grantham, Roseview Windows, Milton Keynes Crossword:

Mrs S Turner, Rugby, Warwickshire

Congratulations to all our winners! Good luck in this months Time Out pages!

4

Christina Lazenby

Managing Director / Advertising Enquiries

M: 07805 051322

E: christina@glassnews.co.uk

Emma Champion

Advertising Manager

M: 07508 263262

E: emma@glassnews.co.uk

Justin Lazenby

62

68

76

80

82

Finance Director / Press Release Enquiries

M: 07711 828710

E: justin@glassnews.co.uk

Chris Champion

Editor / Editorial Enquiries

M: 07850 267223

E: chris@glassnews.co.uk

Kate Carnall

Graphic Design

E: kate@glassnews.co.uk

Deadline for copy: 16th of each month

GOT SOMETHING TO SAY?

Email Chris

Your education and the subject or activity in which you excelled?

I went into further education and completed my A-Levels in Sociology, Design & Technology, Psychology, English Literature, and English Language. English Language and Literature will forever captivate me, as I have a deep passion for both. Meanwhile, my studies in Psychology and Sociology have provided invaluable insights that greatly assist me in working effectively in customer-facing roles.

Your favourite sports or interests?

In my household, sports allegiances run deep. My husband is a true Newcastle United fanatic, while my daughter is a Liverpool fan. As you can imagine, I’ve developed quite the peacemaking skills to navigate their spirited arguments. Personally, I am a passionate follower of Formula 1, with Mercedes being my team of choice. The controversial Max Verstappen win in 2021 still resonates with me deeply, fueling my support for Mercedes even more. I also drive a bright yellow Mercedes AMG, which sometimes makes me forget that I’m not actually an F1 driver.

Someone or Something that inspires you.

My Grandad is my biggest inspiration. I have never known anyone else like him, and I believe I never will. The belief he instilled in me will stay with me forever. My mum has also been a tremendous influence, gifting me with her work ethic and resilience. Sadly, we lost my Grandad suddenly almost a year ago. It is now my life’s mission to continue his legacy, look after our family, and make them all proud.

When and how did you join this industry?

I joined Virtuoso Doors five years ago as a front-of-house receptionist on a shortterm contract. After moving to the area upon meeting my now-husband, I wanted a complete career change from the care industry I knew and loved. Since then, I have held several positions at Virtuoso, including Customer Support Advisor, Sales Support, and within the Contract Services Department. My dedication to customer support has always remained, and I continually strive to go above and beyond for our customers. I have now progressed to the role of Customer Support Manager, where I lead a team of four.

THIS MONTH: Corrine Thynne Customer Services Manager, Virtuoso Doors

Corrine started working in Virtuoso doors 5 years ago and now looks after all customer services support.

Your greatest achievement?

Becoming the Customer Support Manager has been a vision of mine since I first joined Virtuoso Doors. I put everything into earning this role and am enjoying everything it has to offer—even the stress!

What would you like to do if you weren’t in this industry?

If I weren’t in this industry, I’d likely look towards the trades to help improve customer service in the community. That being said, there’s something about the fenestration industry that truly grips you, motivating you to do better each day. The job is incredibly rewarding when you get it right.

A particular ambition?

It is my ambition to lead a team with as much passion and dedication as I demonstrate, if not more. I aim to support and guide them, ensuring Virtuoso customer service becomes the best in the industry. Working in the North East is one of the best places to empathise with our customers, providing them with quick, accurate information and corrective actions, all delivered with a bit of banter and personality. While emails have

become a way of life, my priority is to ensure that people can pick up the phone, have a friendly chat, and come away feeling secure that their issue is resolved and that Virtuoso Doors are easy to deal with.

The way you want to be remembered. I’d love to be remembered as someone who strived for each and every customer, someone who truly cared about them as well as the end user who benefits from having a Virtuoso Door in their home. Most of all, I’d like to be remembered as someone who went above and beyond for colleagues, peers, and customers alike.

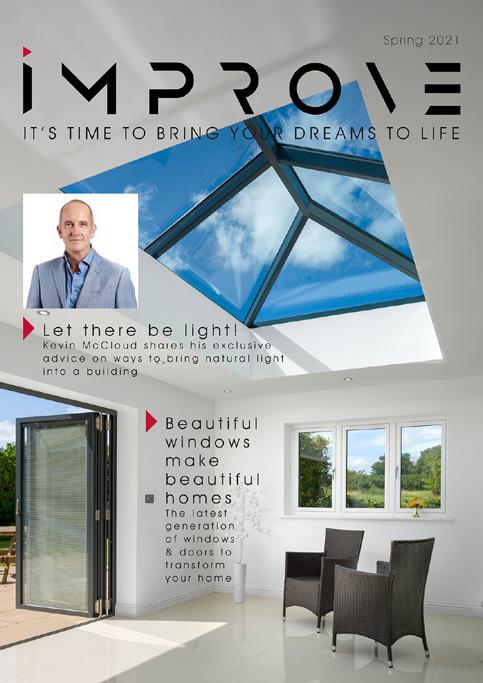

JACK SCULLION, VEKA PLC – PRODUCT & INNOVATION MANAGER

Consumers have never had so much choice when it comes to the style and finish of their windows. While coloured PVCu products have been circulating in the market for years, appetite for them continues to increase. As such, manufacturers are expanding their ranges to provide a wider palette of colours than ever before, across more of their window styles.

Jack Scullion, VEKA plc Product & Innovation Manager

At VEKA plc, we constantly monitor colour trends across the industry to get an in-depth understanding of consumer preferences when it comes to coloured PVCu. The research shows us that demand certainly isn’t going to decrease any time soon.

According to the Renolit Quarter 1 Sales Colour trend report, colours consumers are most likely to seek out in their windows are dark greys (37%), black or black brown (24%), or darker wood effects (12%). A lighter grey comes in at just 4%, as do lighter wood effects (4%).

Demand for solid colours (83%) is higher than for printed effects (17%), while the colours that have seen the biggest sales growth (2023 to 2024) are all shades of grey, such as slate grey (34%) and agate grey (31%).

As a market-leading manufacturer VEKA offers an extensive colour offering across its portfolio, with many product ranges offering a choice of up to 31 different colourways. Most popular colours are continually stocked at our Burnley facility (in May 2024 97% of orders were fulfilled

“We

expect VEKA’s new system, OMNIA to take coloured windows and doors to the next level.”

from stock and delivered within three days), while others are made bespoke to order with a lead time of just six weeks.

It’s clear that coloured PVCu products are becoming increasingly driven by trends. For example, in Europe, homeowners don’t tend to change their windows for around 30 years. However, in the UK, time frames are now closer to just 10 years. Those who can afford to change their windows more frequently, are doing so, as they know that coloured windows can be updated in line with latest trends within a relatively short period of time. So, just as with any type of fashion, we can expect coloured PVCu trends to become cyclical, with fluctuations in demand for different colours based on these shorter time spans.

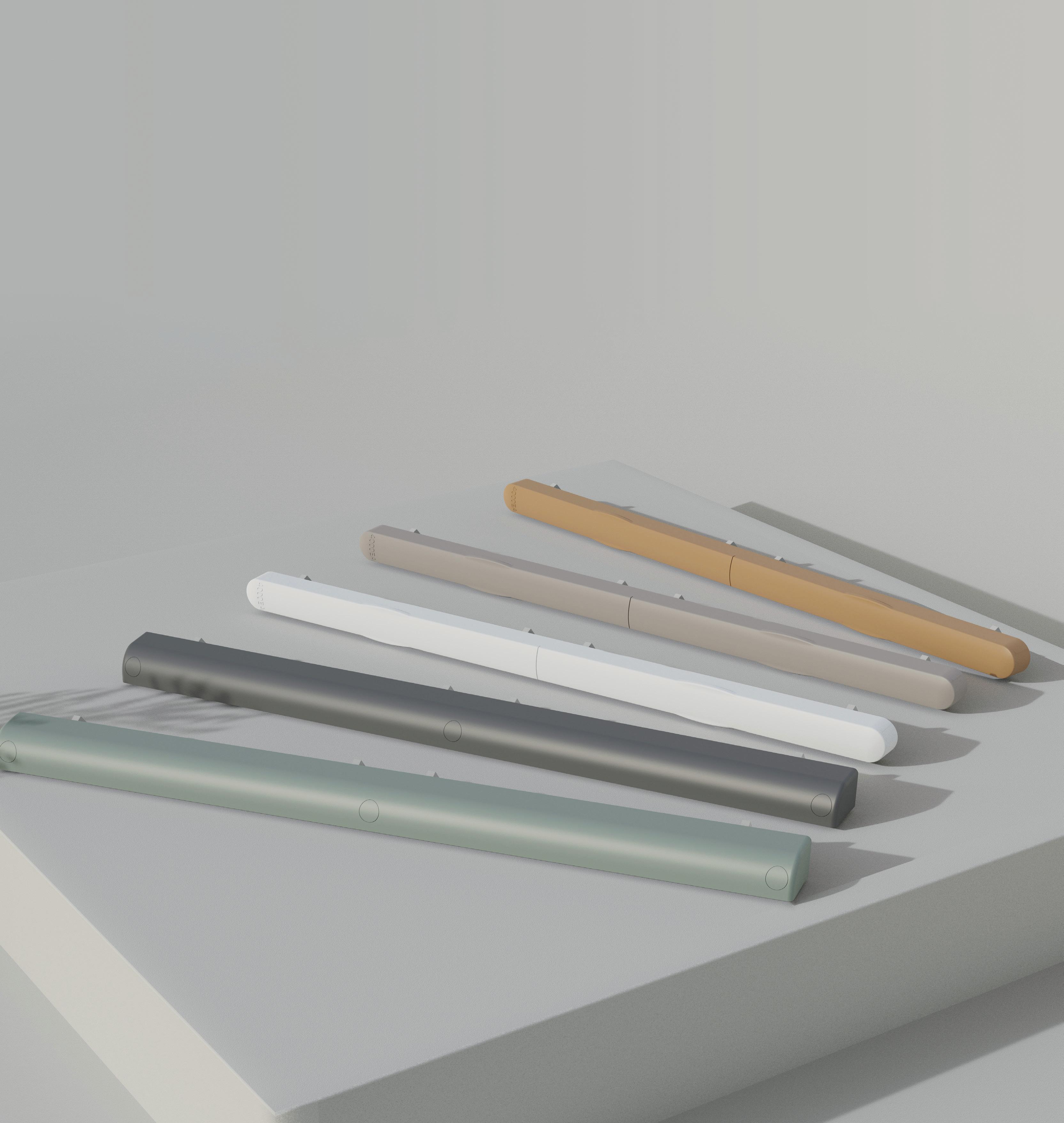

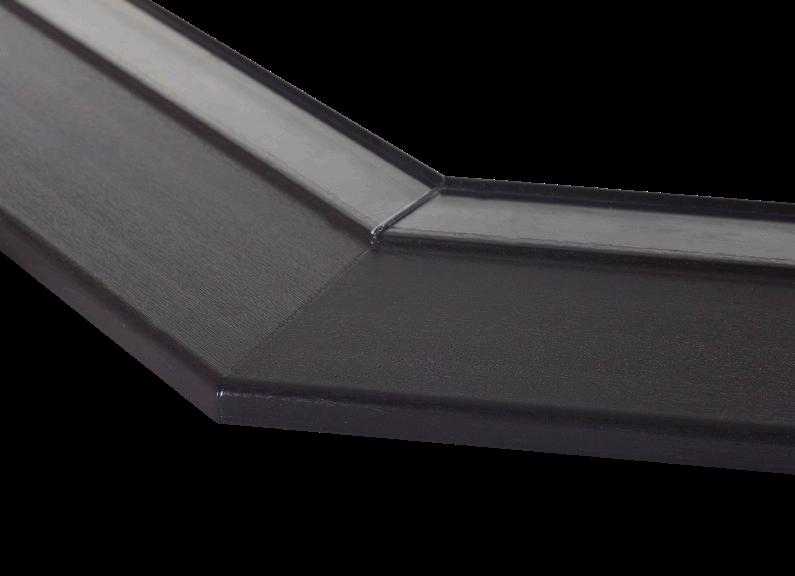

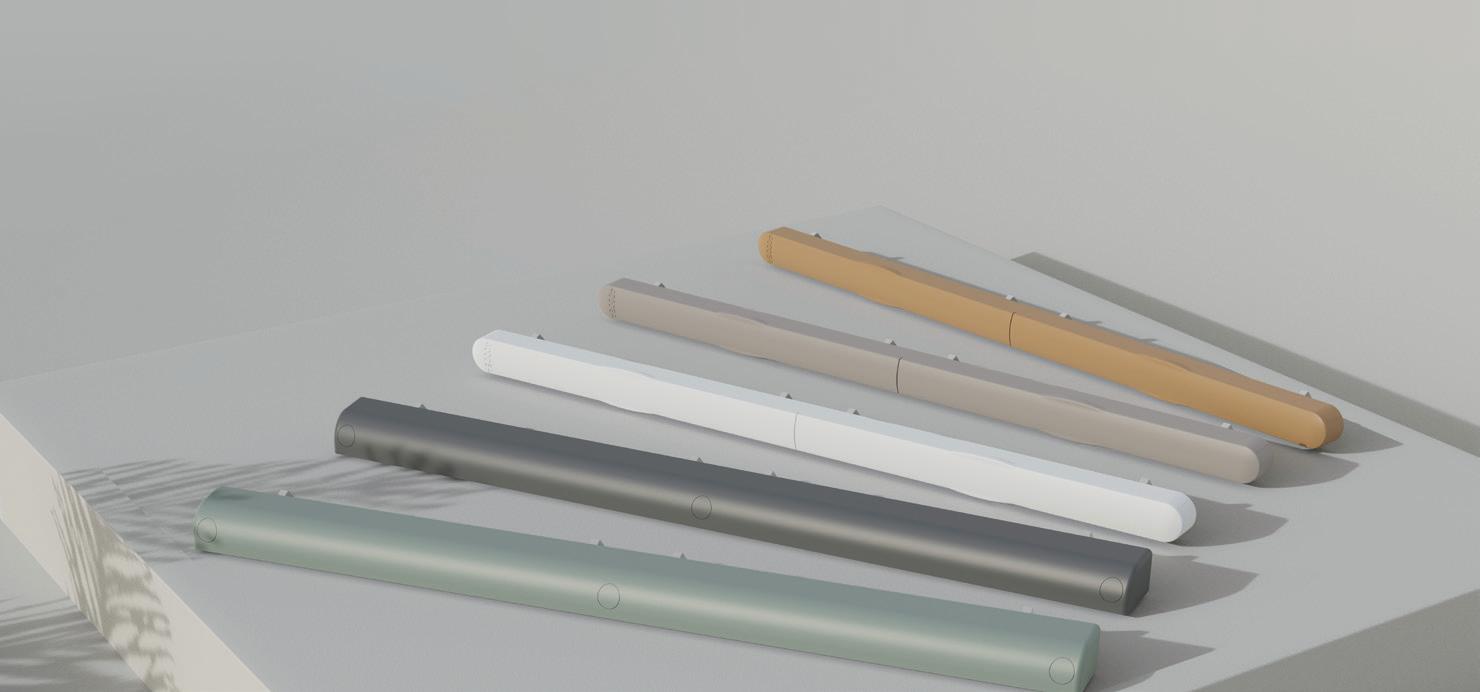

Flush Sash systems are growing in popularity, with the vast majority of sales being foiled. We expect VEKA’s new system, OMNIA to take coloured windows and doors to the next level.

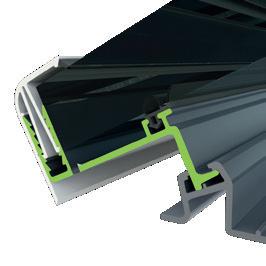

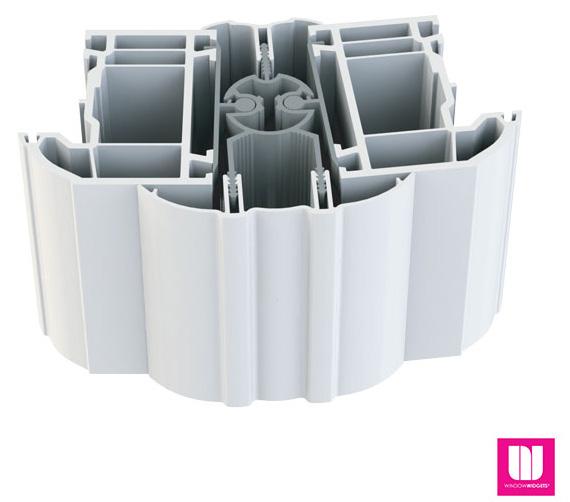

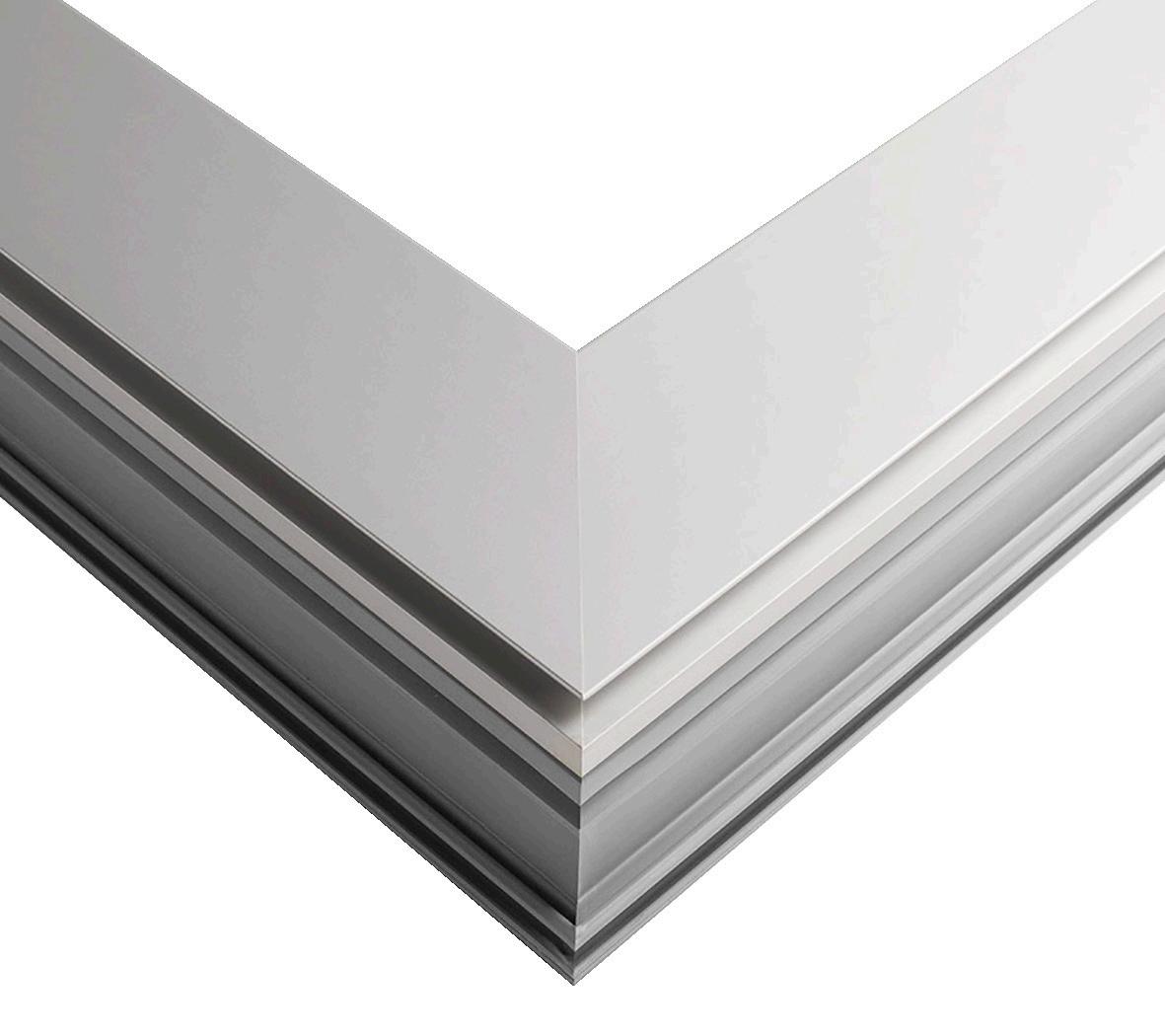

Developed to offer a trailblazing solution that’s fit for the future and easy to produce and install, OMNIA is the result of a three-year-long period of research and development to create the UK’s first

double-rebated, double-flush system for every application. It offers a complete suite of design opportunities for casement windows, tilt and turn windows, residential and French doors, using just nine different profiles.

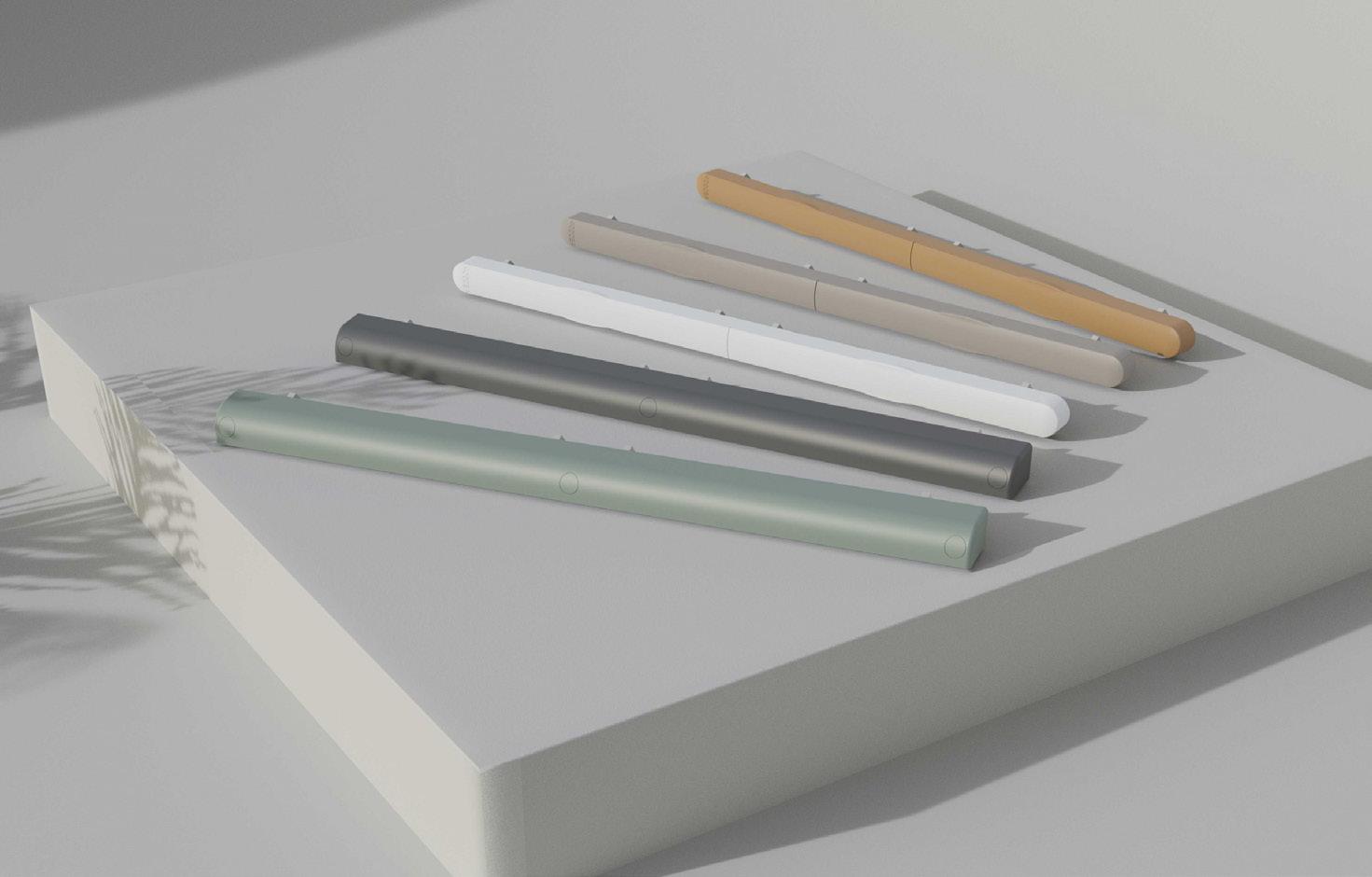

OMNIA’s coloured window offering – which includes four brand-new colours - is split across three core segments. ‘Light and earthy’ combines neutral tones, such as greys, creams, and greens with a nod to clay and stone shades. Our ‘dark and stormy’ range covers blacks, browns and dark greys including anthracite. The ‘true timber’ range taps into the demand for printed effects and covers a range of different wood grains in both light and dark shades.

This next generation product is set to be one of VEKA’s fastest growing, and with 81% of VEKA’s current flush sash being foiled, it’s likely to generate a higher percentage of sales in colour finishes than any other product range. Sleek, minimalistic window design is at the forefront of consumers’ minds, and knowing that they can add a distinctive touch by selecting from a vast swatch of shades, is clearly appealing too.

Innovation and quality are two of VEKA’s key focuses – they’re part of our DNA –and that’s apparent in the ways in which we approach colour. We’re dedicated to revolutionising the PVCu sector through our approach to design, using customer insights to help shape our next steps. Our colour range is designed to appeal to every taste and enhance every style of masonry. But more than that, the colour ranges we’ve developed give fabricators the choice to sell into any market they’d like to, and installers the opportunity to meet a vast range of customer preferences, meaning we play a huge part in growing their business. It’s a win for all.

Colour is one way how we as people express ourselves. So, at VEKA we are dedicated to ensuring our colour options help homeowners to do just that – by offering a wide and innovative range of colours for all trends and tastes.

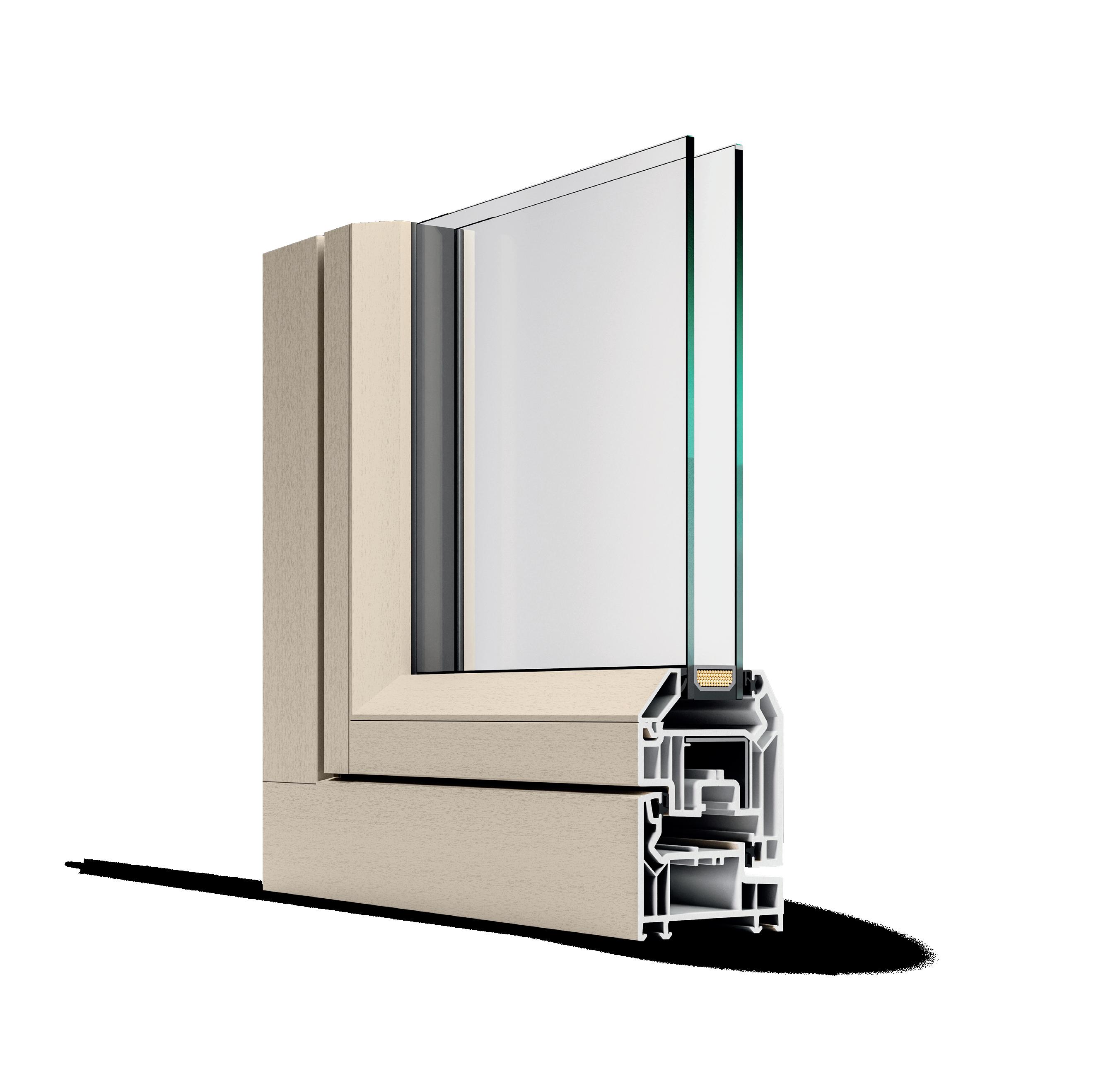

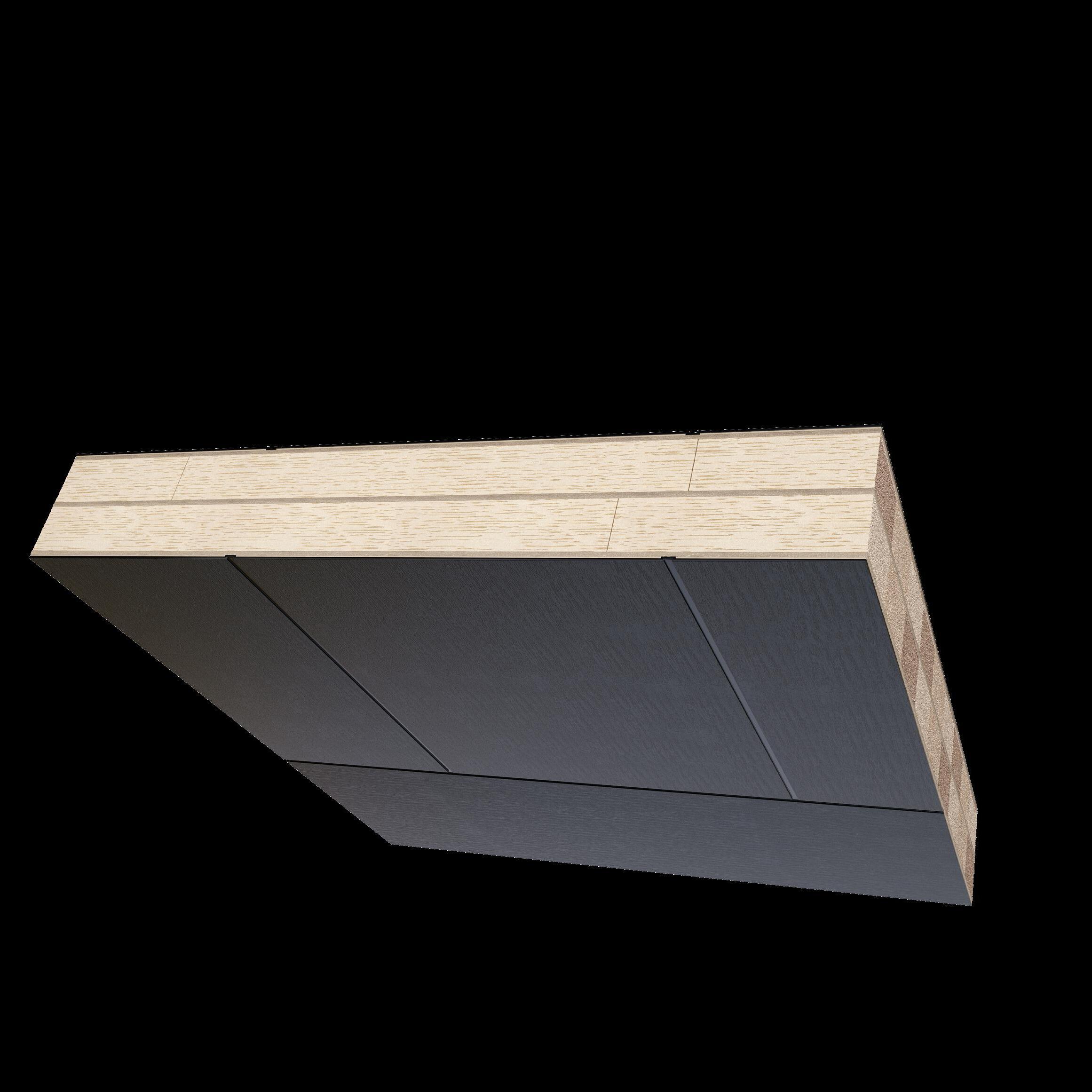

A window and door system designed to authentically replicate 19th Century timber designs.

It can accommodate 28mm and 44mm glazing to create highly efficient glazed units that offer outstanding thermal and acoustic performance, with a WER rating of A++ and U-values as low as 0.74 w/m2K. Contact your local fabricator today.

A window and door system designed to authentically replicate 19th Century timber designs.

It can accommodate 28mm and 44mm glazing to create highly efficient glazed units that offer outstanding thermal and acoustic performance, with a WER rating of A++ and U-values as low as 0.74 w/m2K. Contact your local fabricator today.

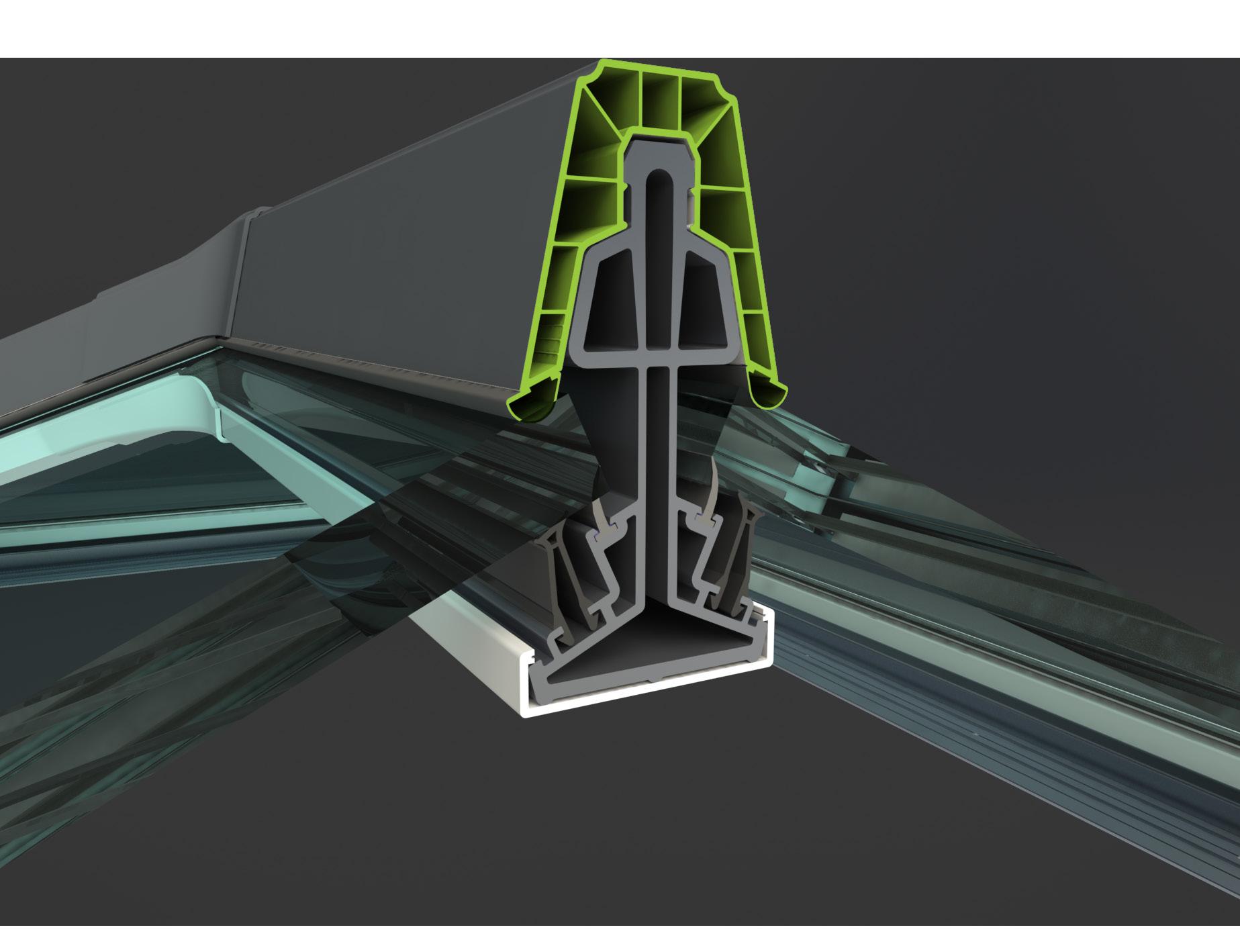

Sheerline has named Titan Aluminium as one of the top suppliers of its award-winning S1 Roof Lantern. With over 30-years’ experience, the Hampshire-based company specialises in the manufacture of rooflights.

Titan wanted a roof lantern that would complement their existing range while also ensuring it offered comparable benefits in terms of the overall look and style, thermal efficiency, security, and quality, which is why they selected the S1 system, rather than the other options available.

Part of the appeal of Sheerline’s roof lantern is the fact the in-house design team developed the product from the ground up. They knew the weaknesses that existing roof lanterns had, including the areas prone to leaks and poor thermal efficiency, and set about changing this.

Applying Sheerline’s vision and contemporary style to the S1, the company took a traditional roof lantern design and transformed it, making it slimmer and sleeker. With unique inline corner and rafter caps.

The key benefits of this, from the perspective of Titan Aluminium is a combination of factors; the aesthetics, the ‘fit and forget’ confidence of the product they supply and the ease of installation. Resulting in happy customers and repeat business.

Besides the S1, Titan also supplies SheerVent® – Sheerline’s revolutionary approach to roof vents, which was revealed on the company’s stand at FIT Show 2023. It’s another unique selling point as it overcomes the historic issues of leaky, unreliable ventilation options.

John Jones, Managing Director of Titan Aluminium, said: “If you’re thinking about stocking the S1, but you’re unsure, it’s an evolution of all the good roofs you’ve known, but it’s been innovated and updated – it’s the warmest, slimmest and most stylish lantern. Your fitters will love it because it’s easy to install and your customers will love the look.”

“We had been looking for a roof lantern for years, but I hadn’t found one I felt I could put my name to, until this one. The product is second to none, and working with Sheerline is brilliant – I’ve had nothing but a great experience,” he added.

Tony Basile, Sheerline’s Sales Director, said: “We’ve been working with Titan Aluminium for a number of years now, so it’s no surprise that they’re one of our top S1 suppliers. The relationship our companies have is based on a shared ethos where the customer comes first because we create quality products that are innovative, work, and look good at the same time.”

To find out more about Sheerline’s S1 and SheerVent®, visit the website: www.sheerline.com/product/s1-roof-lanterntrade/ . Alternatively, contact the team directly on 01332 978000 or email: info@sheerline.com.

View Titan’s range here: www.titanaluminium.co.uk. To speak to the team directly, they can be reached on 01256 760070 or email sales@titanaluminium.com.

In the contemporary design landscape, glass has become a favoured material for its ability to zone areas, control crowds, and partition spaces without obstructing views.

This is particularly evident in commercial and public settings where maintaining an open and airy ambience is crucial. Golf clubs, with their expansive greens and scenic surroundings, benefit immensely from the use of glass balustrades. These installations not only offer unobstructed views but also effectively delineate hospitality areas.

Golf clubs are unique environments where aesthetics and functionality must harmonise. The seamless integration of glass balustrades allows members and guests to enjoy panoramic views of the golf course while ensuring safety and structure within the club’s facilities. Whether used internally or externally, these glass partitions offer a modern and sophisticated touch that enhances the overall experience for visitors.

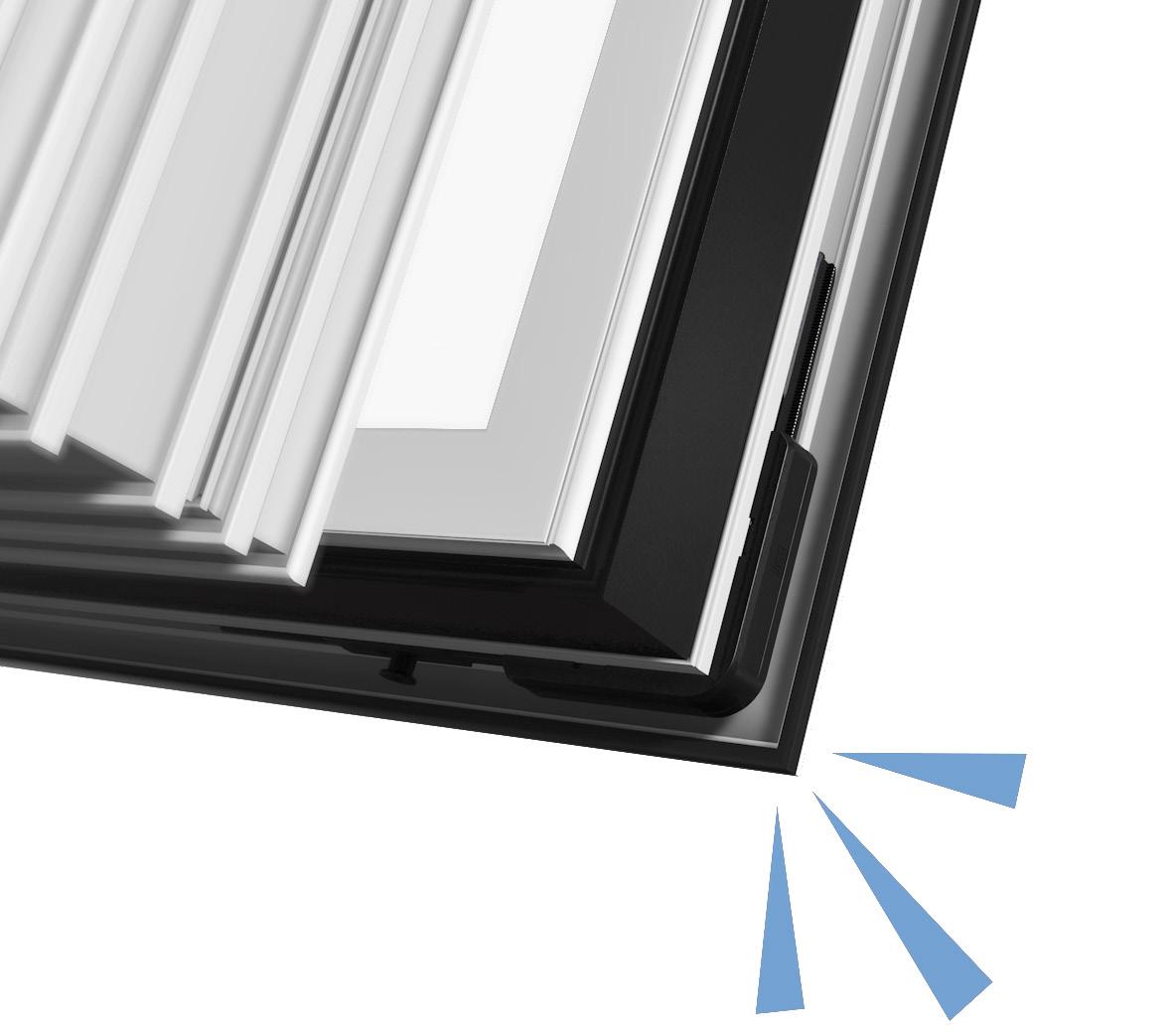

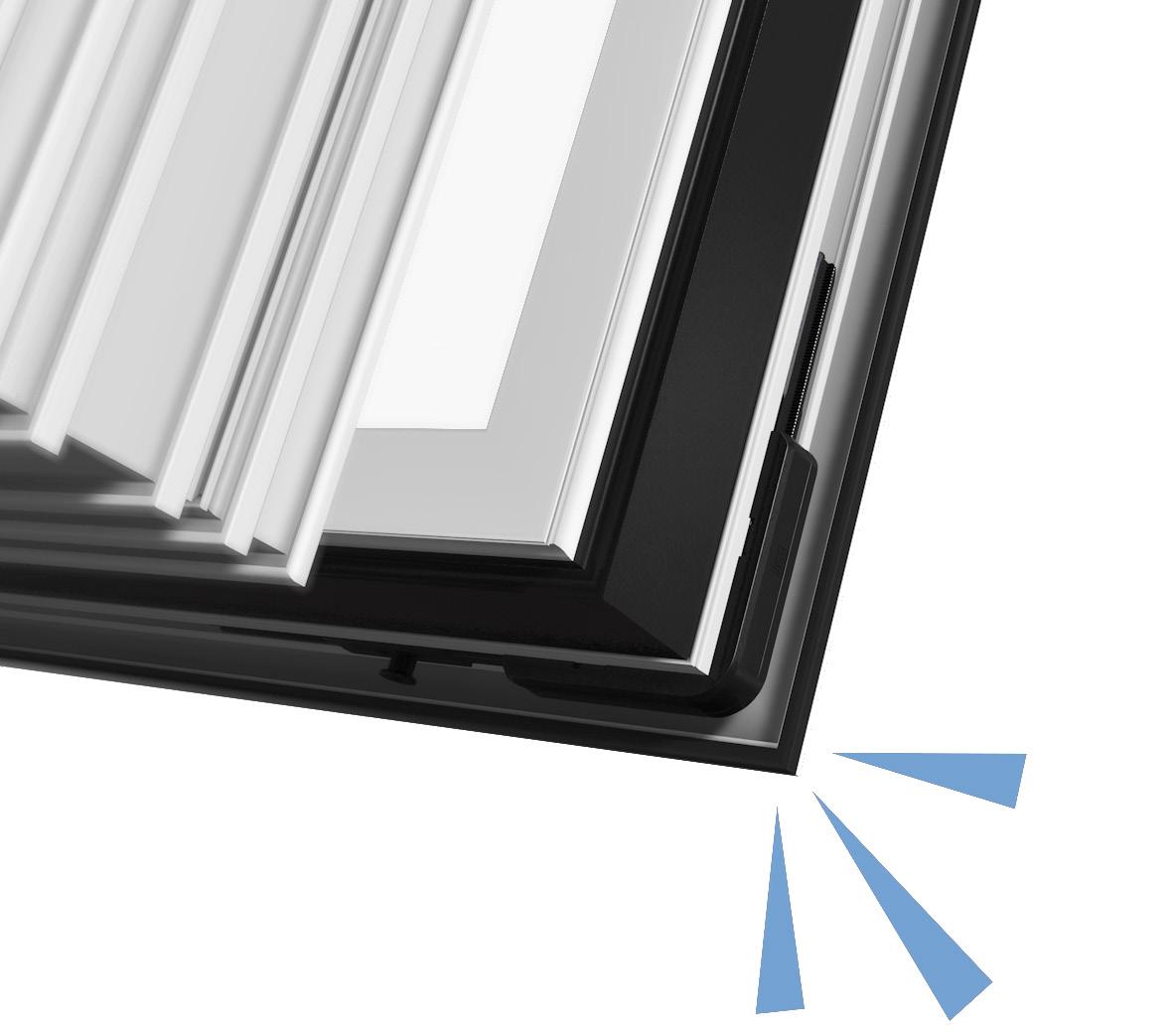

One of the critical aspects of using glass in such settings is ensuring straightforward and secure installation. The latest innovations in screw-clamp technology have revolutionised the way glass panels are installed and adjusted. This technology involves using clamps that securely lock the glass panels in place, providing stability and safety without the need for bulky frames or intrusive fixtures.

St Helens and Bolton are just two of the UK’s golf clubs that have recently showcased the CRL Posiglaze system as a practical and stylish glass balustrade solution.

Using the CRL Posiglaze screw-clamp technology, the installers on these projects were able to securely anchor the glass panels without compromising on the aesthetic appeal. Posiglaze is designed to provide the greatest possible adjustment opportunities, enabling each panel to be perfectly aligned during, or even after, installation. This innovative patented and market leading screw-clamp technology locks glass panels into position effortlessly, with four immobilising fasteners per metre of channel.

This solution preserved the breathtaking views of the greens for the golf club patrons. The result on both projects is a seamless, uninterrupted view of the lush greens, enhancing the club’s appeal to its members and visitors.

The use of glass balustrades in golf clubs epitomises the blend of functionality and aesthetic appeal. Innovations like screw-clamp technology have made it easier and safer to install these systems, offering a practical solution that meets the high standards of modern design. With successful implementations at clubs like St Helens and Bolton, it’s clear that glass balustrades are not just a trend but a significant improvement in creating beautiful, unobstructed, and safe environments for all.

For further information call 01706 863600, email crl@crlaurence.co.uk, or visit www.crlaurence.co.uk.

With the emphasis on achieving a luxurious finish, glass proved pivotal in the construction of the newly established Eindhoven-Best Hotel, in The Netherlands. To achieve the aesthetic design brief and stringent safety standards, Pyroguard Protect fire safety glass was specified as the optimal solution.

Part of the Van der Valk chain’s Exclusive collection, the 15-storey hotel boasts 200 rooms, each dressed in a vintage seventies style, offering a blend of nostalgia and modernity. Its amenities include a contemporary à la carte and dynamic

live cooking restaurant, sky bar, wellness centre, and swimming pool. Notably, the hotel was constructed and certified to the prestigious BREEAM label 'Outstanding,' solidifying its status as one of the most sustainable hotels in The Netherlands.

The emphasis on achieving a luxurious and high-quality finish was present throughout both the interior and exterior of the hotel, with glass serving as a fundamental element in the architectural design. Featuring beautifully glazed partitions and elegant timber doorways throughout every floor, it was important to maximise the hotel’s natural light and create inviting interior spaces where guests could relax and enjoy.

As a result, Pyroguard Protect (EW30 13-1) was chosen for the project and supplied by Buys Glas B.V., where it was expertly installed within the hotel's fire doors and restaurant entrance, combining functionality with visual appeal.

Stefan van Gerven, Benelux Sales Director at Pyroguard, commented: “Pyroguard Protect was the perfect solution for this project. Certified for use in a range of profiles (including timber), it’s renowned for its high performing acoustic properties, excellent UV stability and 1B1 impact rating. Pyroguard Protect not only enhanced the building safety but also seamlessly complemented the surrounding aesthetics too.”

For more information, please visit: www.pyroguard.eu.

The latest Builders Merchant Building Index (BMBI) report, published in June, shows builders’ merchants’ value sales were up +3.9% in April compared to the same month a year ago. Volume sales increased +4.7% and prices eased -0.8%. However, with three additional trading days this year, like-for-like value sales were down -11.0%.

Eight of the twelve categories outperformed Total Merchants year-on-year, with Workwear & Safetywear (+28.9%), Miscellaneous (+15.0%), Decorating (+14.1%) and Plumbing Heating & Electrical (+13.2%) in the lead. The three largest categories – Heavy Building Materials (+1.4%), Timber & Joinery Products (+1.4%) and Landscaping (+3.2%) – all grew more slowly.

Total sales in the three months February to April 2024 were -5.0% lower than the same three-month period a year ago. Volume sales were down -5.9% and prices edged up (+0.9%). With one more trading day this year, like-for-like sales were -6.6% lower. Half of the twelve categories sold more with Workwear & Safetywear (+14.3%) growing the most. Renewables & Water Saving (-23.9%) was the weakest performing category.

April total value sales were +5.0% higher than the previous month. Volume sales increased +7.4% and prices were down -2.3% compared to March. With one more trading day in April, like-for-like value sales were flat (+0.0%). Ten of the twelve categories sold more, with seasonal category Landscaping (+15.4%) well up. But the two largest, Heavy Building Materials (+4.8%)

and Timber & Joinery Products (+3.6%) recorded more moderate growth. Plumbing Heating & Electrical (-1.4%) and Workwear & Safetywear (-4.6%) were the weakest performing categories.

Total merchant sales in the 12 months from May 2023 to April 2024 were -4.7% lower than the same period the year before (May 2022 to April 2023). Volume sales slumped -9.6% and prices rose +5.4%. With four extra trading days in the most recent 12-month period, like-for-like sales were down -6.3%. Nine categories sold more

with Workwear & Safetywear (+8.3%), Decorating (+7.5%) and Miscellaneous (+5.3%) doing best, but the three largest categories - Heavy Building Materials (-5.0%), Landscaping (-5.7%) and Timber & Joinery Products (-11.3%) - all sold less.

For the full report, including comments from the BMBI’s panel of leading industry Experts, please visit www.bmbi.co.uk.

Complete your toolbox with the AdminBase Service app

Capture information on work done and parts required

Inform service engineers of balances to collect

Collect signatures to sign off on service calls

Service calls are automatically updated in AdminBase

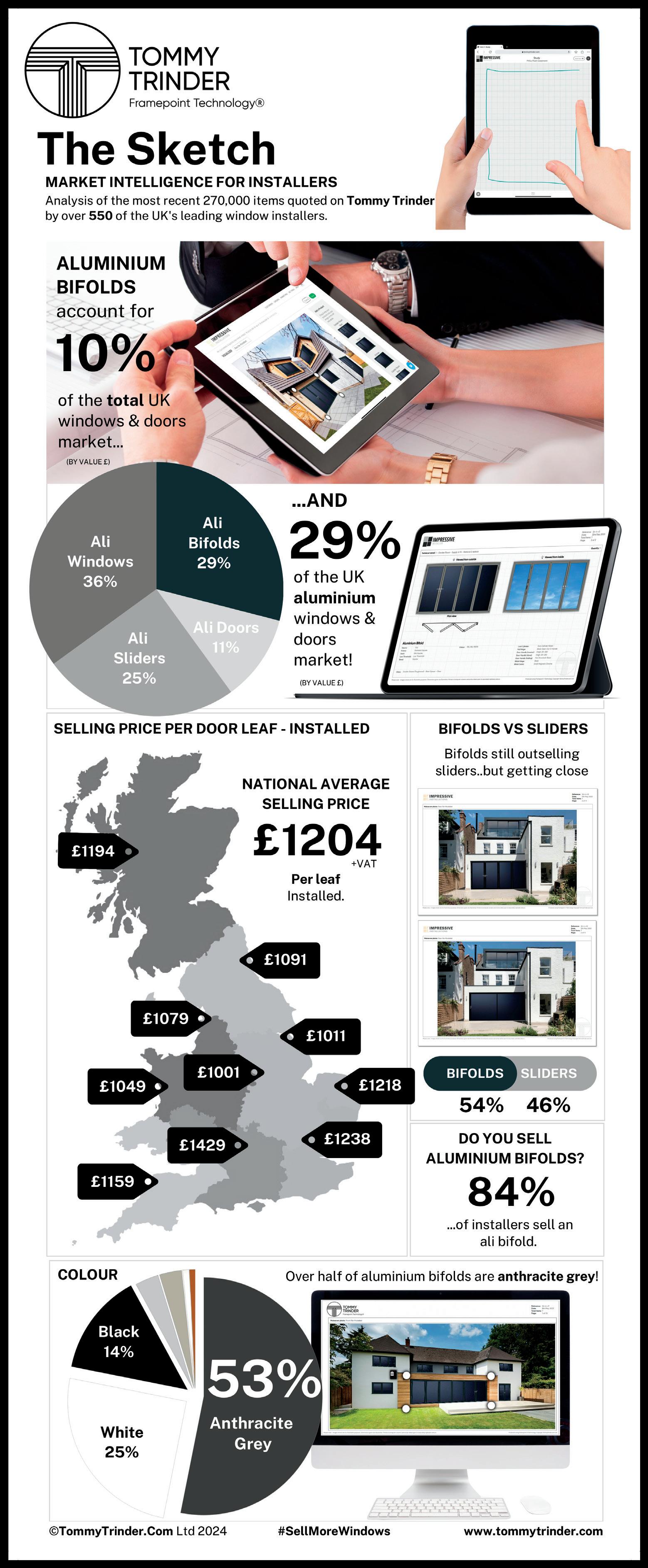

Software pioneers Tommy Trinder are celebrating another milestone as the total number of window companies using the sales platform passes 550.

“We are on a mission to put the fun back into selling windows,” says founder and CEO, Chris Brunsdon, “getting to 550 subscribers is a sign we’re making progress!”

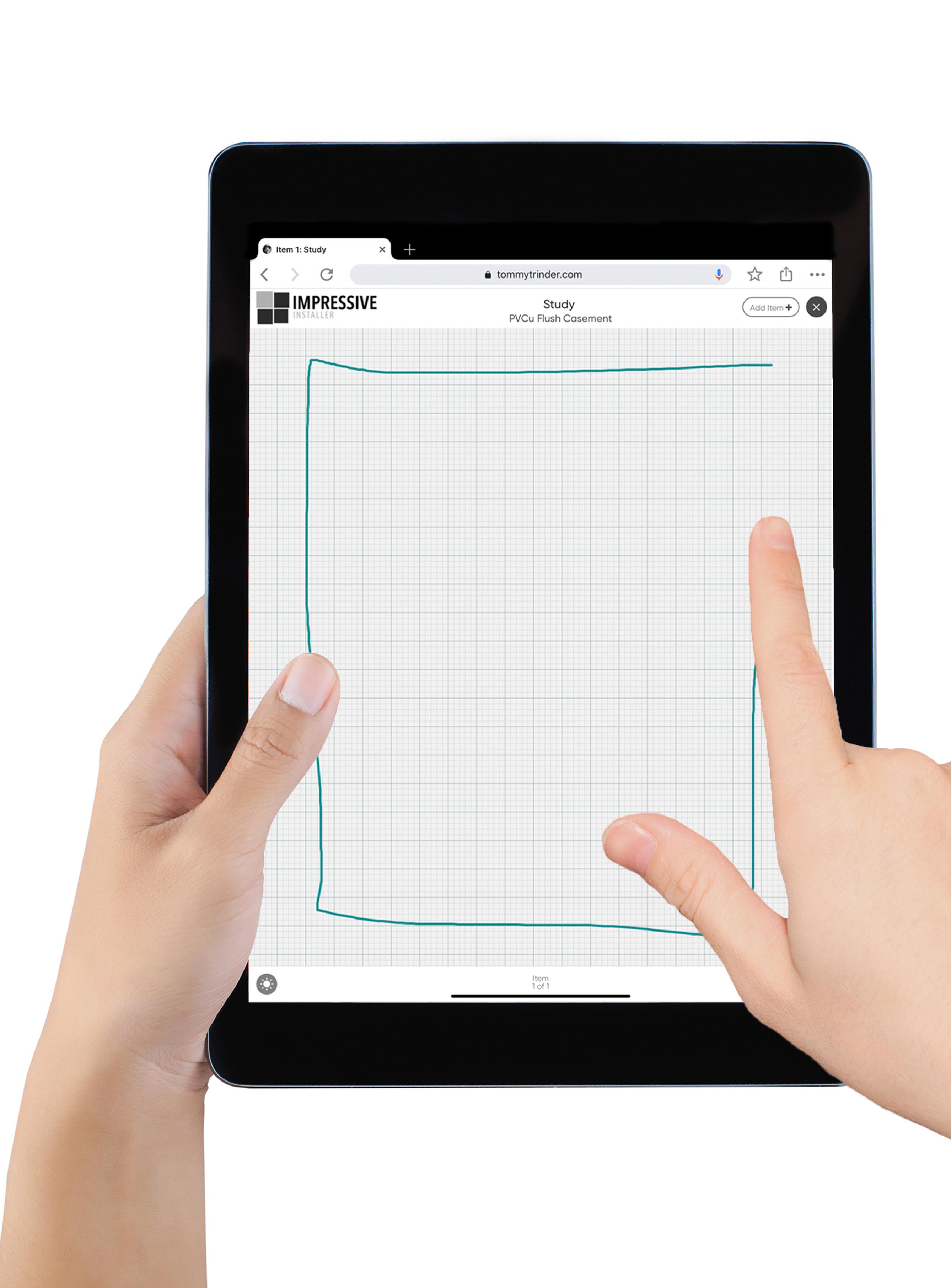

From one-man bands to nationals and from the highlands to the Channel Islands, Tommy Trinder has established itself as go to app for installers looking to add zip to their sales process. The firm’s patented Framepoint Technology® allows users to free draw PVCu, aluminium and timber windows and doors with your finger or mouse, just like sketching on a pad. It’s easy to chop-and-change ironmongery, colour, and bar options until the homeowner is happy and the price is right.

And in a tap installers can show clients how their new windows and doors will look in situ. Says Chris: “Tommy makes it super simple to wow customers, even if you’re a dinosaur with computers. And in a demanding market it’s ever more important to have an edge, something to impress clients and keep those conversion rates up.”

The value of work quoted by installers on Tommy Trinder is on the rise too. Every month an eye-watering £200 million pounds worth of work is quoted to homeowners via the platform. High average quote values are also a feature with quote values climbing towards £7400 over the last six months, says Chris;

“We are seeing premium materials making significant market gains; aluminium and timber combined now account for around half of everything quoted by installers. And when it comes to PVCu, Tommy subscribers are managing to get a bit more on every job by routinely showing off value-added features such as foils, dual colours, dummy vents, mechanical joints, flush casements, dummy peg-stays and surface mounted bars in a visual and compelling way.”

The firm reports that more than 12,000 homeowners receive a quote generated by Tommy Trinder every month and, notably, around half of them are provided with visualisations to accompany their quote;

“Homeowners are expecting a more complete buying experience and the makeover tool, where installers provide a mockup to the homeowner of their new windows in situ, is becoming a standard part of the quoting process,” says Chris.

“Homeowners expect more. They want to see exactly what they are getting; they want to try before they buy. And Tommy Trinder is proving to be the tool for the job.”

Installers can find out more about Tommy Trinder and book a free demo at www.tommytrinder.com.

Epwin Window Systems has introduced an exciting new sales and marketing tool: an immersive 360º showroom tour that showcases its comprehensive product range.

Gerald Allen, Head of Marketing at Epwin Window Systems, said: “By leveraging the power of 3D technology, we now offer an immersive experience that allows our customers and prospects to explore everything our products have to offer.”

The innovative tour is accessible on the Epwin Window Systems website and its online digital portal, Connect. It’s a 3D digital twin of the company’s new showroom at its headquarters in Telford, Shropshire. The platform provides users with a 360 degree capture of the showroom, with the ability to click on each product and view detailed specifications. Users can also book an in-person tour that includes the showroom, extrusion and finishing plants, warehouse and distribution centre.

Gerald explains: “We know that businesses prefer to conduct thorough online research before reaching out to a prospective supplier. Our virtual showroom simplifies this process, allowing them to see the

aesthetics and technical excellence of all our products in detail, anytime and anywhere. And when they’re ready to take the next step and visit in person, we’ve made that as easy as possible too.”

Besides benefitting prospective fabricators and installers, Gerald highlights how the immersive 3D tour will be useful for existing customers’ sales processes. He added: “The tour will be an invaluable sales tool for showing architects, specifiers and consumers how good Epwin Window Systems’ products look in situ.”

He continued. “Whilst nothing beats visiting our showroom in person, our virtual experience is the next best thing. It also extends the shelf life of any customer or prospect visit as they can go back and re-immerse themselves in the detail at a later date.”

Epwin Window Systems is renowned for its intelligent, value-added customer support. For example, its award-winning Connect platform has set industry standards by offering a 24/7/365 bespoke digital platform that provides comprehensive access to the wide range of benefits available to Epwin Window Systems customers. The 360º showroom tour is the latest testament to the systems company’s innovative approach to customer success.

Tel: 0845 340 3968

www.epwinwindowsystems.co.uk

Rhonda Ridge of Ab Initio, creator of AdminBase, discusses the importance of assimilating remote teams into the core of an installation business, and explains how an all-encompassing installer management system can help.

Admin can be a bugbear in any department, in any business, but individuals working in practical jobs like fitters and service engineers, can find it particularly intrusive. Depending on the system in place, admin might feel over the top and like you have to fill out a lengthy form for every move you make, or it might be lacking, and feel like the left hand doesn’t know what the right hand is doing. That’s not to say admin isn’t important. In fact, I would argue that having a robust admin system that streamlines internal processes, improves productivity, allows for easier reporting and measuring, encourages better communication with colleagues and customers, and improves the connectivity between all individuals in a business, is a critical strategic investment. Why? Because from personal experience, the effect of either good or poor admin on a business can be immense.

BRING YOUR TEAMS TOGETHER

As long as the system is easy to use, a good CRM will bring everyone in the installation business together. Whether an individual is working in the office, on an installation, or servicing a project after the fact, they will feel like part of the team if they are informed and know what is happening on the project they are involved with, and if

“Remote working and the systems that make it possible have become a lot more prevalent since the pandemic but managing information and communication between office-based staff and remote teams, is something window installation and servicing teams have been dealing with for decades.”

they can update everyone else when they have completed their related tasks.

This is precisely why AdminBase was developed over 20 years ago, and why the central system and accompanying apps are in such high demand among installation businesses today. We have specifically seen a lot of interest in the AdminBase Service app recently, which works seamlessly with the main CRM to make service engineers’ lives easier.

The Service app allows installation businesses to send pertinent details of an appointment, directly to a service engineer’s device. The accounts team could even let them know of an outstanding balance

that needs to be collected. Once at the installation, the engineer can access relevant information sent from AdminBase about the project, as well as capture data about the work they complete that day, or any additional parts that are required to finish the work, and upload that back into the system.

If the project requires the engineer to return another day to finish the work when parts have arrived for example, they can note this for the service call administrator within the app. And once the job is complete the engineer can collect a signature to sign off the service call. All of the details that are captured during the service calls can also automatically be e-mailed to the customer on completion, so they have a record of the work that has been done.

Similarly, fitters out in the field can use the AdminBase Fitting app to view all relevant information from an installation project, including contracts and surveys. This saves printing reams of documents to give to fitters when they collect products

for an installation. When the installation is complete, fitters can collect photos, conduct a customer questionnaire, and obtain an electronic signature in the app for sign off, which again is uploaded and live straight away for all relevant users to see in AdminBase. The whole process is smoother and easier to manage.

Remote working and the systems that make it possible have become a lot more prevalent since the pandemic but managing information and communication between office-based staff and remote teams, is something window installation and servicing teams have been dealing with for decades. It has traditionally had its problems, but for more than 20 years, AdminBase has been able to offer a solution to bring teams together and improve efficiencies and productivity within an installation business. So, if you’re looking for the next strategic investment with big impact, look no further.

and installers, manufacturing standard square window and door frames is tried-and-tested routine.

But when it comes to complex arched, angled or entirely bespoke designs, many shy away due to the specialised machinery, expertise and headaches involved.

This often means turning down lucrative projects featuring architecturally challenging fenestration.

However, there is a solution that allows companies to capitalise on this profitable market segment without the major investment – partnering with a trusted arched frame specialist like Premier Arches.

The UK’s leading manufacturer of arched and angled frames takes the complexity out of non-standard designs, transforming them into simple, hassle-free profit generators.

“Arched windows and angled frames require a level of skill and equipment that most PVC fabricators and installers simply aren’t equipped for,” said Sean Greenall, Managing Director at Premier Arches.

“My brothers and I started this company after seeing a gap in the market for a reliable, quality supplier focused solely on arched framed manufacturing. Our goal is to make these once daunting projects straightforward for our customers.”

Based in St Helens, Premier Arches specialises in manufacturing arched, angled, gabled, circular and entirely bespoke window and door frames across a wide range of different systems, including popular profiles like Residence 9.

This specialised capability opens up new revenue streams for trade partners who previously had to walk away from jobs featuring non-standard designs.

“We've seen demand for our arched frame offerings grow significantly since our launch in 2015, as more companies recognise the benefits of outsourcing this complicated process to experts,” said Sean. “It allows them to focus on the high-volume square frames their operations are optimised for, while still being able to fulfill special orders and keep customers happy.”

In addition to arched frames, Premier Arches has expanded its services to include manufacturing complete products – fabricating both curved sashes and outer frames rather than just the latter. This comprehensive offering provides fabricators and installers a seamless, single-source solution for uniquely-shaped fenestration.

“Fabricators used to make the square sash themselves and outsource just the arched outer frame to us,” Sean explains. “But more are shifting to having us manufacture the entire product. It simplifies their operations while ensuring a perfect matched solution every time.”

Beyond its expanding capabilities, Premier Arches distinguishes itself through its relentless focus on customer service and efficiency. The company’s 20-strong production team prides itself on delivering exceptionally crafted frames with rapid turnarounds and reliable, hassle-free service.

This customer-centric approach extends to Premier Arches’ self-developed online pricing, ordering and job tracking platform. The system provides an easy, paperless experience by enabling customers to generate instant

quotes, place orders with a few clicks, and monitor status updates in real-time.

“We know fabricators and installers are extremely busy, so we strive to make working with Premier Arches as seamless as possible,” Sean said. “From getting an upfront price quickly, to receiving quality finished products on a timeframe that meets their schedules, our goal is to be an extension of their operations, not a hindrance.”

As demand for distinctive designs continues growing, Premier Arches stands ready to help more companies tap into this profitable opportunity without the headaches. The company’s specialised expertise in uPVC profile bending simplifies even the most complex arched window and angled frame projects.

Sean concludes: “Our comprehensive services and systems take the hassle out of complicated orders, empowering fabricators and installers to win more of that lucrative business. For companies looking to generate new revenue streams by expanding their arched frame capabilities, we’re ready to seamlessly fill that gap as a trusted, quality-driven arched frame partner.”

www.premierarches.co.uk

May marked Mental Health Month in DoorCo’s bustling 2024 wellbeing calendar, and the composite door market leaders dedicated themselves to promoting healthy minds, raising awareness, and fundraising.

Ellie Pool, marketing manager tells us more: “From the very beginning of the month, we embraced the ‘Make a Moment for Movement’ theme of Mental Health Awareness Week with enthusiasm. To support our colleagues, Mark Towers and Lucy Daniels, who are set to climb Kilimanjaro for Kelly’s Heroes, the whole DoorCo team undertook the challenge of walking 100,000 steps each over the month.

“Weekly updates on the steps leader board kept everyone motivated, and the challengers quickly smashed through their targets, with one team member achieving 100,000 steps within the first five days! Collectively, we amassed an impressive 6.5 million steps throughout May, equivalent to scaling Kilimanjaro 65 times.”

“The team’s dedication and commitment to the 100,000-step challenge has been a real inspiration to see,” commented Head of HR, Dek Wright. “It’s been great to see everyone

going out for walks on their lunch breaks and taking time to get moving to help their mental and physical health.”

Ellie continues: “In true DoorCo spirit, the efforts didn’t stop at the step challenge. On 16th May, we all donned our best green

attire for Wear It Green Day in support of Mental Health Awareness. The standout prize went to Freya from customer services, who was adorned in green from head to toe.

“To wrap up a successful month, we hosted a Friday Fundraiser on 31st May to support

Mark and Lucy’s cause. Everyone made donations to enjoy a pick and mix treat, wrote messages of encouragement for Mark and Lucy to read during their trek, and spread positivity by writing uplifting mental health messages on a pink door in DoorCo’s reception window.

“During the day, the step challenge was also concluded with prizes awarded to the top three steppers and the individual who logged the most steps on the final day. The event raised a commendable £306.50 towards the Kilimanjaro goal for Kelly’s Heroes, while also significantly enhancing participants’ physical and mental well-being.”

A year on from its debut at FIT Show 2023, the Sheerline x Coastal Group partnership is going from strength to strength as it offers consumers even greater choice in terms of the hardware options available to leverage their quality aluminium windows and doors.

This includes the Classic Heritage Door, which the companies first collaborated on and was revealed at Sheerline’s stand during the key industry event last year. Based in Cornwall, the Coastal Group manufactures architectural ironmongery using 316 grade marine steel. They’re committed to keeping things simple for consumers with the perfect fit guaranteed, superior standards, and the ultimate in lasting performance. Like Sheerline, the company offers a range of different finishes that keep pace with contemporary trends.

For example, while black is one of the most popular colours at present (and works well with the Heritage door), brass is up and coming. The wide choice of hardware available for both windows and doors means the partnership has broad appeal for Sheerline’s customers.

As both are British-based manufacturers that pride themselves on providing innovative yet stylish products for discerning customers, there was a clear synergy between the two brands. This has forged the way for a productive partnership that benefits the customers of each.

In addition, Sheerline supplied a window for Coastal’s showroom to help customers better visualise how the two products work together from a practical perspective and how they elevate and complement each other from a purely aesthetic point of view.

Brooklyn Jenner, responsible for Business Development at Coastal Group, said: “We’re delighted to add one of Sheerline’s premium windows to our brand centre. This latest addition to the showroom gives customers the opportunity to feel the quality and finish for themselves, experiencing Sheerline’s stunning aluminium products alongside Coastal Group’s high quality solid stainless-steel hardware.”

Sheerline’s Head of Marketing, Dave Wigley, commented: “This partnership highlights the value that can be added for customers when two quality brands come together and collaborate. This partnership speaks volumes to the discerning customer that wants to achieve a high-end aesthetic and elevate their beautiful Sheerline windows and doors, and why shouldn’t they?”

Find out more about collaborating with Sheerline, call the team directly on 01332 978000, email: info@sheerline.com or visit the website to view the full range of products: http://www.sheerline.com.

For more information about the Coastal Group, visit: https://www.coastal-group.com or call: 01726 871 025 to speak to the team directly.

Freefoam Building Products, a leading manufacturer in the PVC extrusion sector, is delighted to announce the launch of its newest line of PVC window accessories. This investment will significantly enhance our Window Trim offering and give Freefoam customers a comprehensive suite of trims to service the window installation market.

The new range comprises a new 12mm quadrant, a new 25mm Square trim and a new 28mm Fillet, all offering the perfect solution for a neat and professional finish to any window or door installation.

Designed with meticulous attention to detail and crafted from high-quality materials, our new range of PVC window accessories is the perfect complement to any residential or commercial project.

Freefoam recognise the strength and popularity of colour in the Window and Door sector. The new range is available in a wide range of colour options designed to match and complement and is suitable in a variety of situations, both traditional and contemporary homes.

Freefoam have always been at the heart of the roofline sector offering an outstanding market leading range of fascia, soffit and gutter products. These new additions to the existing Window Trim range re-position Freefoam as a leading manufacturer, and opens up new opportunities for PVC suppliers.

Key features of our new PVC window accessories include:

• Versatility: Our accessories are designed to fit a wide range of PVC window profiles, ensuring compatibility and ease of installation.

• Durability: Built to withstand the elements, our accessories are engineered for long-lasting performance, providing years of reliable service.

• Aesthetic Appeal: With stylish designs and colour options, our accessories add a touch of elegance and sophistication to any window installation.

“We are thrilled to introduce our new range of PVC window accessories to the market,” said Colin St John, Commercial Director “With these new additions to our Window Trim range, we aim to provide our customers with a comprehensive choice of high quality products, allowing them to meet the needs of Home Improvement, Window and Door installation companies.”

www.freefoam.com

Deceuninck has installed 2,200 solar panels onto the roof of its Calne manufacturing facility, generating a total of 895,762 kWh of clean energy.

The renewable energy source not only reduces Deceuninck’s reliance upon fossil fuels for its operations, but also significantly reduces CO2 emissions by 498,507kg a year.

Darren Woodcock, Operations Director, Deceuninck, said: “The solar panels went live on 15th March. We only experienced around four hours of operations downtime whilst the inverters were connected. It was a seamless installation.

“We have every aspect of the roof that could be covered in panels, covered. The solar energy will help us offset rising energy costs, but will also generate huge environmental savings, further reducing our CO2 emissions, and allowing fabricators to benefit from the saving.”

Deceuninck has established a lead on sustainability based on its’ commitment to the Science Based Targets (SBTi) programme, with a headline pledge to cut the CO2 emissions from its own operations (Scope 1&2) by 60% by 2030 from a 2021 baseline.

Research by Deceuninck shows that while fabricators and installers want to lower their carbon footprint, many struggled to know where to start and were put off by the complexity involved in the process.

As a result of Deceuninck’s new renewable energy usage, fabricators can now increase their own sustainability simply by purchasing Deceuninck products and benefitting from the work done upstream in the supply chain.

In addition to allowing window companies to measure their carbon footprint through its innovative Carbon Calculator, Deceuninck has also provided guidance on how companies can lower their own CO2 emissions – and how a more sustainable approach can help them win more business.

This includes a Sustainability Marketing Toolkit, with headline positional statements drawing on Deceuninck’s commitments under Science Based Targets; own-brandedprintable sustainability brochures; plug-and-play website content; e-shots; social media assets; presenter decks; and video content; door-drop leaflets; sustainability logos; showroom pull-up banners, wall decals; and flyers.

“We are going to be able to display the number of trees that we have saved every day by cutting our CO2 emissions through using clean energy in our reception area”, said Darren.

“This is a clear, tangible way of communicating our savings to our customers, in the same way that our customers can benefit from the free, substantial messaging and resources available within our Marketing Toolkit.”

For more information about Deceuninck, call 01249 816 969, email deceuninck.ltd@deceuninck.com or visit www.deceuninck.co.uk.

True authenticity comes from a blend of heritage styling and modern performance.

Single features may grab attention, but a true heritage sash window is designed to ensure the seamless integration of all its parts.

Everything has to work together: slim overlapping putty-line profiles, a 35mm midrail, heritage chalk finishes, seamless ornate sash horns, true mechanical joints, deep cills and innovative balance chamber covers, to name but a few.

Add to that a 1.2 W/m2k u-value without specialist glass, and you have a true conservation-grade sash window with outstanding modern performance.

Only Roseview’s Ultimate Rose sash window delivers all this. Because it’s more than a sum of its parts.

Outlet, one of the UK’s leading manufacturers of home improvement products, is celebrating the continued success of its apprenticeship programme.

After investing a six-figure sum into developing the skills of young professionals in West Yorkshire last year, the firm has seen the number of apprenticeships and those undertaking official training within the company grow by 25%.

The firm has also recently created two brand-new positions for two young graduates, Sam Allen (Finance Assistant) and Ben Bradbury (Order Processor) who have recently passed their AAT Level 2 and Business Admin Level 3 courses respectively.

Karen Starkey, Head of HR at Conservatory Outlet, commented: “As one of Wakefield’s largest employers, we believe it is critical to offer new opportunities

Karen Starkey, Conservatory Outlet’s Head of HR

and development pathways for our staff and the local community.

“As we continue to grow and evolve as a business, we look to the future.

Apprentices are the best way of doing this and we actively promote our apprenticeship programme to existing staff, school leavers and new starters alike.”

The Wakefield-based firm, which employs nearly 200 staff at its Thornes Lane Wharf factory, has won plaudits for its approach to vocational learning and

“As part of our plan to achieve Investors in People Silver status and cement Conservatory Outlet as an employer of choice, we’re investing in our people and futureproofing their skills. A company is only as good as its people and we want to make sure that our team remains the best in the sector.”

professional development.

The company’s approach isn’t solely focussed on young people and school leavers as they also provide ongoing training for staff keen to progress and learn new skills.

Such examples include Maintenance Engineer Joe Davies, who has

completed several courses with the full backing of Conservatory Outlet and is now studying towards a degree-level qualification, and Marketing Coordinator Missy Mortimer, who has recently started a specialised marketing course to help further support the firm’s wider marketing strategy.

Additionally, over 15 team leaders and senior leaders across transport, manufacturing, operations and customer service departments have enrolled on strategic vocational management courses in the past year.

And more are expected to follow.

Karen adds: “As part of our plan to achieve Investors in People Silver status and cement Conservatory Outlet as an employer of choice, we’re investing in our people and futureproofing their skills. A company is only as good as its people and we want to make sure that our team remains the best in the sector.”

Conservatory Outlet is one of Yorkshire’s fastestgrowing manufacturers, supplying an exclusive range of windows, doors and living space products – all manufactured at its headquarters in Wakefield.

The firm supports its Premium Retail Network, a collection of nearly 30 independent home improvement businesses in the UK, and continues to grow year-on-year.

Quickslide, a leading manufacturer and supplier of PVC-U sash windows, has signed a five-year contract with Epwin Window Systems to continue manufacturing its market-leading Vertical Sliding Sash Window. The agreement further extends the relationship between the two businesses, which started in 2019.

Ben Weber, Managing Director of Quickslide, commented: “We are very selective about our choice of supply partner because we know we can only be as good as the suppliers we work with. Our relationship with Epwin Window Systems has gone from strength to strength since 2019, and we look forward to deepening our ties even further.”

Katrina Earl, Sales Director at Epwin Window Systems, said: “We are delighted to extend our relationship with Quickslide for a further five years. The company is a great example of how a fabricator can leverage

maximum benefit from a partnership with us and make full use of the resources and personnel we have available within our business.”

Ben notes that the credentials of the Epwin Window Systems Vertical Sliding Sash

Window were key to choosing the systems company as its supply partner. However, he says the true value lies in the strength of the relationship, which has significantly benefited Quickslide’s business.

He said: “We’ve seen great value from the closeness of our relationship with Epwin Window Systems. Everyone is very personable, open to market discussions and proactive – we’ve been impressed by the emphasis they place on listening to customers and working with them for mutual benefit.”

He continued: “We’ve been involved in numerous forums and had open dialogues with the senior management team to discuss continuous product developments and building regulation changes, which have helped us remain ahead of the curve for our customers. For example, the new slimline meeting rail was developed as a direct result of customer feedback.”

Deceuninck has added to its ISO (International Organization for Standardisation) accreditations with the addition of ISO 45001, recognising excellence in operational Health and Safety. Demonstrating a solid framework for the health, safety, productivity and wellbeing of its employees, ISO 45001 accompanies ISO 9001, recognising Deceuninck’s quality in its extrusion and products, and ISO 14001, recognising its environmental pledges, in Deceuninck’s list of ISO achievements.

Darren Woodcock, Operations Director, Deceuninck, said: “We have had the ISO 0001 and ISO 14001 for a while, but we have been putting a lot of hard work into our health and safety on site – it’s one of the most important aspects at Deceuninck, that we vigorously ensure our employees’ safety.

“So we went and attempted to achieve the ISO 45001, and we got it at the first attempt, which was fantastic news. We plan to run the three accreditations for the next three years, and then roll them into one accreditation during a week-long audit in 2027.”

Deceuninck’s health and safety achievements are mirrored by their recent environmental achievements; a G22 Sustainability Initiative of the Year Award was followed up by a G23 Marketing Initiative of the Year Award, for its Sustainability Marketing Toolkit.

It has also already lowered the carbon footprint of its operations by 21% compared to its 2021 baseline, in line with its commitment to the Science Based Targets (SBTi) programme, with a headline pledge to cut its operational CO2 emissions (Scope 1&2) by 60%.

Stellar aluminium windows and doors have been installed in a 285 year old windmill near Llanerchymedd as part of a transformative upgrade. Melin Gallt-y-Benddu has been an iconic part of Anglesey’s landscape for nearly three centuries. However, in recent years, the windmill, which was completed in 1738, was in danger of becoming a ruin. Its third-generation owner and his wife wanted to restore the building and to achieve this, the couple enlisted the help of local architectural technologist Adrian Williamson of WM Design & Architecture and P&C Building Contractors Ltd. The system specified for the project was Stellar Aluminium and the windows and doors were manufactured by longstanding Epwin Window Systems’ fabricator, Heritage Trade Frames Ltd. Richard Moore, Area Sales Manager at Heritage Trade Frames, said: “We’d manufactured Stellar products for several of Adrian and WM Design & Architecture’s previous projects, so he knew the quality Heritage Trade Frames brings. He also understood all the benefits of Stellar Aluminium, including its QUALICOATapproved marine-grade paint finish, which is perfect for Anglesey’s coastal environment, as well as its slim sightlines and contemporary flush styling.”

Richard continued: “The original specification was for casement windows, but a site visit with P&C resulted in a change to tilt and turn windows. Looking at the five-storey building, it was clear that tilt and turn windows would be the better option because they would be easier to clean from the inside.”

To secure the agreement of the local planning department, Heritage Trade Frames supplied a sample window alongside a detailed specification. The planning officer agreed the Stellar Flush Tilt & Turn Window had all the credentials required and permission was granted.

The 22 Stellar Tilt & Turn Windows, Stellar Flush Casement Window and Stellar French door, were installed by P&C Building Contractors over a five month period.

To achieve an exceptional visual finish, the colour of the window and door units was critical. The exterior of the building uses the Baumit render system in Chalk, skilfully applied by M.W. Plastering Ltd. Against this understated colour, Anthracite Grey (RAL 7016) gave a beautiful contrast. Internally, the frames were white to match and brighten the décor.

He concluded: “A close-knit relationship and mutual respect is in everyone’s best interests in a supplier-customer partnership. With Epwin Window Systems, we have these benefits in abundance.”

Quickslide is based in Brighouse, West Yorkshire and prides itself on the product quality it offers. It has been recognised for its excellence and has won many regional and national awards including Fabricator of the Year, Business of the Year and Training Initiative of the year at the prestigious G Awards.

Epwin Window Systems is one of the UK’s largest and most proactive systems houses. As Ben’s comments make clear, one of the reasons for its status is its understanding of its customers and its consistent ability to help them stay one step ahead.

Tel: 0845 340 3968

www.epwinwindowsystems.co.uk

For more information about Deceuninck, call 01249 816 969, email deceuninck.ltd@deceuninck.com or visit www.deceuninck.co.uk.

Thermal efficiency was a critical requirement of the project to protect the building’s inhabitants from the sometimes fierce coastal weather but also to minimise the carbon footprint. Units were double-glazed using PLANITHERM® ONE T on the inner pane and PLANITHERM® Clear on the outer pane, giving an overall u-value of 1.45 W/m²K.

The building’s most startling new addition is a fully glazed viewing platform that gives 360-degree views of the surrounding landscape. To prevent too much solar gain in this room, the window units use SGG COOL-LITE® SKN 176 solar control glass.

The finished result is a beautiful building that retains all its iconic charm but has been updated for future generations.

Tel: 0845 300 9356 – www.stellaraluminium.co.uk

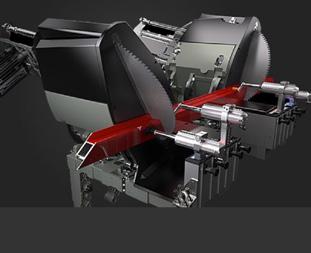

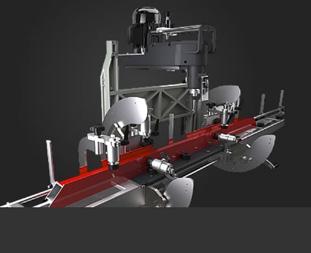

Epwin Window Systems is renowned for its commitment to sustainability. This commitment is in clear evidence in its recent investments in using recycled material in its manufacturing processes.

Phil Parry, Technical Director at Epwin Window Systems, commented: “Forecasts suggest that demand for PVC in Western Europe will increase at a rate higher than GDP between 2024 and 2028. This will put pressure on raw materials and we are taking the lead on being prepared for that shift. Our latest investments enable us to produce class-leading, sustainably manufactured systems efficiently while also building our capacity for future growth.”

The company has installed numerous Krauss Mafai co-extruders and multiple twin strand Greiner Red Line tools and downstreams. These investments

"This year, the company will introduce multiple new Optima mainframe tools that will incorporate a recycled core that won’t be visible when manufactured. On average, each section will contain 45% recycled content."

have allowed the company to introduce additional co-extruded profiles that use post-consumer recycled PVC-U into its product offer. The material is all reprocessed in the UK from recycled window profiles with a demonstratable chain of custody, something that means Epwin Window Systems is already aligned with proposed future legislation.

This year, the company will introduce multiple new Optima mainframe tools that will incorporate a recycled core that won’t be visible when manufactured. On average, each section will contain 45% recycled content.

These latest investments build on a long track record of using recycled content.

As part of its manufacturing process, Epwin Window Systems recycles waste bar length into RCM (recycled composite material). These RCMs are made up of 100% recycled PVC-U and provide the perfect blend of product performance and sustainability.

These investments and innovations are all part of a wider programme of initiatives designed to put sustainability front and centre of all business practices.

Phil concluded: “As an industry, we have a lot to celebrate when it comes to sustainability. Since 2000, through the VinylPlus® initiative, our industry has recycled 8.1 million tonnes of PVC. In the process, we’ve saved 6.2 million tonnes of CO2 and created over 1,600 direct jobs in recycling plants. As our latest investments show, here at Epwin Window Systems we’re committed to continuing this progress, leading the way and doing everything we can to make sustainable business practices the new norm.”

Tel: 0808 101 4143

www.epwinwindowsystems.co.uk

They’ve done it. 13 participants from the Conservatory Outlet Network have successfully completed the 24 Peak Challenge, raising over £13,000 for charity in doing so.

The 24 Peak Challenge is a gruelling endurance event that tests entrants’ physical and mental endurance. From the start point in Keswick, participants had to scale 24 of the Lake District’s highest and most difficult peaks in just 24 hours.

The group completed the challenge in 22 hours, two hours under the target time.

By the time the team made it to the finish line in Dockray after scaling the likes of Hellvelyn, Great Gable and Great Dodd, the group had walked over 35 miles and tackled over 4,000 metres of elevation across the route.

And then there was the weather, which can only be described as ‘typically British’.

Despite many of the country enjoying sunshine, clear blue skies and temperatures in the high teens, the Lake District was buffeted with 50mph winds, rain and hail. It was only towards the end of the second leg of the challenge that the clouds cleared, temperatures picked up and the sun appeared.

That break in the clouds gave the team a second wind. Able to marvel at the views across the Lake District and see several RAF training flights pass close by, the group on to marched on and made great time whilst covering the final half of the challenge.

“We wanted to build on our success last year in completing the National Three Peaks. This year, we wanted to do something bigger and so the 24 Peak Challenge was born,”

Greg Kane, CEO of Conservatory Outlet explains.

“This pushed us further than we’ve gone before, forcing us to walk greater distances and tackle some of the most difficult hiking routes in the country. I’m incredibly proud of every member of the team. We completed this challenge together and we had to dig deep and work hard to make it to the finish line as a group.

“I always say that the Conservatory Outlet Network is something special and this showcases what a talented

and resourceful collective we are. I’m incredibly proud of everyone involved.

“Most importantly, we’ve raised a phenomenal sum of money for charity. On behalf of the team and the entire Conservatory Outlet Network, I’d like to thank all our friends, family, customers and commercial partners for supporting both ourselves and our chosen charity for 2024, Mind.”

Mind is a leading mental health charity operating in England and Wales. For over 70 years, Mind has been leading the way in ensuring that everyone experiencing mental health problems can get the support they need

Matt Grafton, Managing Director of West Yorkshire Windows, adds: “To have been involved in this year’s Network charity challenge has been one of the toughest yet most rewarding things I’ve done.

“Since joining West Yorkshire Windows and by extension the Conservatory Outlet Network several years ago, I’m constantly blown away by the unity of the group. One of the best things about being associated with Conservatory Outlet and other Premium Retailers is that we faces challenges together and we overcome them together; whether that’s in business or through this fantastic fundraising adventure.”

Endurance® Doors is building on its already impressive commitment to sustainability.

As part of its robust environmental policies, the manufacturer of solid, secure, and stylish composite doors has used carbon offsetting since 2022 to compensate for any unpreventable carbon emissions caused by its operations.

The business has now entered into a new partnership with Carbon Neutral Britainô that will enable it to continue this important activity.

Formed in 2020, Carbon Neutral Britainô is one of the UK’s largest carbon offsetting organisations. It is supported by both individuals and organisations who are looking to play a positive and proactive role in combating climate change.

By investing in different carbon capture or reduction projects around the world, Carbon Neutral Britainô enables its partners to balance out their carbon footprint. To date, it has backed projects that have seen additional trees planted in UK woodland, in the Amazon rainforest, and in African mangrove forests. It has also been instrumental in the construction of new wind and solar energy farms.

Endurance® Doors ultimately plans to work with Carbon Neutral Britain™ to become a fully and independently verified carbon neutral organisation certified to the highest global standards.

Carbon offsetting is just one of the many ways in which Endurance Doors is working to minimise its environmental impact. The business also utilises energy

“We recognise the urgent need for

all individuals

and organisations

to do more to combat the environmental issues facing our planet."

from renewable sources, including solar panels on its factory roof, and makes widespread use of electric vehicles.

In addition, it sends zero waste to landfill, employs recycled materials wherever possible, and uses timber to produce its doors from trees grown in sustainably managed, PEFC and FSC certified North European forests.

Commenting on the manufacturer’s new partnership with Carbon Neutral Britainô, Andrew Speakman, commercial director at Endurance® Doors, said: “Endurance® Doors is proud to be at the forefront of developing more sustainable solutions for the fenestration market.

“We recognise the urgent need for all individuals and organisations to do more to combat the environmental issues facing our planet. We also know that many homeowners are looking to do their part by making more environmentally responsible product choices.

“To address both requirements, we never stop looking for ways to reduce our carbon footprint, to control our resource consumption and to minimise our waste contribution.

“Our new partnership with Carbon Neutral Britainô reflects that commitment to ever higher standards of environmental performance.”

unique, patent-pending lock stile allows easy adjustment during

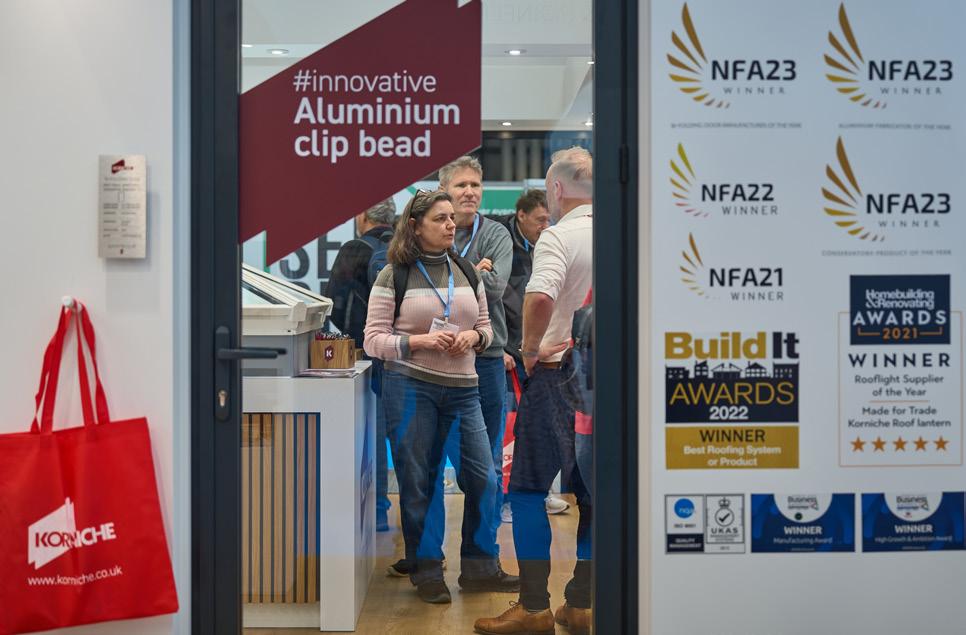

This autumn, experience Korniche’s innovative, industryleading roof lanterns, bi-folding doors, and Flat Glass rooflight tailored for trade success.

After an impressive performance at the Birmingham NEC, Korniche is geared up to boost the business prospects of our trade partners at the upcoming Homebuilding & Renovating Shows in September and November 2024. Industry professionals from across the country can attend shows in both Harrogate and London to experience our cutting-edge products.

The shows are the perfect platform for trading experts to experience the multiaward-winning Korniche products for themselves and gain that competitive edge with the market-leading innovative products for their customers.

Thousands of building enthusiasts and homeowners have already experienced the transformative impact of our esteemed products, positioning Korniche at the forefront of consumer minds. Already a sought-after brand, the autumn shows are meticulously designed with industry

professionals in mind, allowing you to engage directly with the products and network with potential future customers.

Mark Millar, a recognised tradesman and Korniche brand ambassador with firsthand knowledge of the products will return to the London show to share his insights. From client satisfaction to installation ease, Mark will help you understand the benefits that Korniche’s products can bring to your business. His presence on the ‘MasterClass’ Stages will provide you with the knowledge needed to utilise the products further and shed light on their unique selling points.

At ExCeL London, you can expect a display that will be more dynamic than ever before. The full Korniche range will be showcased,

allowing you to interact directly with all the products in a hands-on experience. The range will include our Flat Glass Rooflight, renowned for its exceptional thermal properties and sleek aesthetics, making it ideal for all-year-round usage and superb client appeal.

Our transformational Roof Lanterns and elegantly engineered Bi-Fold Doors will also be featured at the shows. This will allow you to understand the craftsmanship and impressive quality behind the products and see why Korniche products are the preferred choice for enhancing your clients’ living spaces. These displays are designed with your needs in mind. With the highly rated appeal of the Korniche products on consumers’ minds, your projects will be informative and bespoke to your client proposals, giving you that competitive advantage.

WHY CHOOSE MADE FOR TRADE AND KORNICHE PRODUCTS?

For any business looking for a reliable aluminium fabricator, the Korniche products, designed and crafted with precision, offer an array of benefits. Their award-winning design and functionality and collection of industry accolades offer customers reassurance in their quality. Korniche is also a brand that homeowners know and trust. By aligning your business with Korniche products for those renovation and building projects, you can boost your business appeal.

EXPLORE. ENGAGE. EXPAND.

Are you planning a distinctive project and hoping to elevate your business? Visit our stand, and we can provide detailed information on our products and exclusive offers. By aligning your project with our Korniche products, you can raise your business profile, and with our partnership guidance, we can help your business thrive in a competitive landscape.

HOW CAN YOU CONNECT WITH KORNICHE BEFORE THE SHOW?

If you want a head start and simply cannot wait until September, you can visit the Korniche and Made for Trade websites or engage with our social media platforms. Look at our market-leading products and consider how you might integrate these into your business strategy from today.

Trade aluminium fabricator Fentrade has reported a 20% increase in sales compared to the same period last year. Chris Reeks, Managing Director of Fentrade, said: “The growing strength of the aluminium market is reflected in our sales and we’re seeing a significant uptake in commercial projects across the board.”

Chris notes that Fentrade’s commercial order book encompasses projects of all sizes and in all sectors.

In the education sector, the company has been involved in two major projects involving complete window and full façade replacements. It’s a trend that is already set to continue, with future projects booked in for the summer holiday months.

Smaller scale projects are also increasing in number. Commercial entrance doors and emergency access products are particularly popular, with installers working with local authorities, retailers and main contractors.

Looking forward, Fentrade are quoting for a high volume of individual projects including for care homes and the MoD.

Chris commented: “Our strong sales pipeline reflects a buoyant commercial sector and we’re delighted to be playing our part in helping our customers to secure and deliver these contracts.”

Fentrade is an intelligent choice of aluminium fabrication partner because its wide range of systems means it can meet all customers’ needs.

The fabricator manufactures Kestrel and Jack Aluminium for its commercial products, with the AluK SL52 curtain walling and the GT55 ground floor treatment range also proving popular.

Alongside the appealing product range, Fentrade customers also benefit from the company’s depth of experience. Chris commented: “Our team has over 30 year’s fenestration experience, so we understand what customers need. We always communicate fully with every customer from quote to delivery.”

As Fentrade’s sales growth shows, the aluminium market is buoyant at the moment. As increasing numbers of customers are finding, Fentrade offers an exceptional way to capitalise on the opportunities.

Tel: 01633 547787

www.fentradealuminium.co.uk

Hardware manufacturer UAP Ltd has been announced across eight categories in this year’s National Fenestration Awards. The winners with the most votes for each title will be awarded at an October ceremony at Doncaster Racecourse.

You can vote for UAP and its individual prize nominees in the following categories, between now and September:

• Director/Managing Director of the Year

– Nicola John (FDM)

• Office Manager of the Year – Tasha Doyle

• Social Networker of the Year – Barry Halpin