Solar panels are a great way for companies to lower their carbon footprint but that means they need to ‘see’ the sun.

Having invested more than six-figures in 2500 solar panels on the roof of its Calne manufacturing facility Deceuninck’s green energy strategy was put under threat from a pesky airborne pest - the Common Gull.

With its large rooftop offering judged a perfect

nesting habitat for the amorous airborne assassins, their guano threatened kilowatt outputs.

Rather than getting into a flap the facilities team turned to their own eco allies, Gerald, Bo Jangles and Nessie, the three Harris Hawks of Talons Out Bird Services.

The natural enemy of nesting sea birds, the three Harris Hawks have been flown regularly over Deceuninck’s facility, to persuade the gulls that solar panels are a less than perfect nesting site.

James Cross, Maintenance Engineer explained: “We installed approaching 2,500

solar panels at the start of this year, but very soon it became clear we had a problem, seagulls – or more accurately their waste, which was starting to coat them.

“The solar panels were installed as part of our sustainability strategy so it’s important that we maximise their outputs which if the seagulls were left unchecked, would have been compromised.

“The Harris Hawks are flown regularly as part of an eco-solution which encourages the gulls to move on and allows us to maximise outputs of renewable energy.”

The new solar panels will generate a total of 895,762 kWh of clean energy per year reducing CO2 emissions from Deceuninck’s Calne site by 498,507kg a year.

Deceuninck has established a lead on sustainability based on its’ commitment to the Science Based Targets (SBTi) programme, with a headline pledge to cut the CO2 emissions from its own operations (Scope 1&2) by 60% by 2030 from a 2021 baseline.

A further six figure investment at the start of this year saw Deceuninck add two new chillers to its operation, delivering a 50% reduction in energy usage.

For more information about Deceuninck’s product and service offer please call 01249 816 969, email deceuninck.ltd@ deceuninck.com or visit www.deceuninck.co.uk.

Getting more and more uptight as the days go by and yet more and more governmental c*** ups come to light, together with plenty of examples of lies and deceit from people we are supposed to be able to trust to guide this country to economic success, I could easily reprint Danny William’s March contribution in the form of Cold Calling. I commend it to the house as essential reading!

Trying to keep politics out of my comments is not easy although, to be fair, if any ruling party could make more of a mess of things than this lot I would be ranting against them in a similar way. Reading a variety of newspaper columns, I was somewhat relieved to find my thoughts, that I have voiced so many times before about politicians needing real world work experience before putting themselves up for selection by the voters, there seems to be more and more commentators agreeing with that very thought. I also wonder how many of our business owners and managing directors in the fenestration industry would stand by the people they’ve employed for senior positions if they found they had lied on their CVs.

Having put a real dampener on this month’s Page 3 you may be surprised to learn that, surprisingly, I am very positive about much of what our industry can achieve. This is driven by listening to the news coming out from so many companies. Businesses that have gone through MBOs that are succeeding in achieving the further investment for future growth. Investment in £ millions for companies such as Jade Engineering, a company that I have had the pleasure to visit this month. Success such as that achieved by Jade is not unusual in our industry and the fact that people are prepared to invest their success back into their businesses, rather than take the cash and sit on a South Seas Island sipping Pina Coladas, is testament to their commitment to what they’ve achieved and to their staff.

Reading through the plethora of press releases that we receive each week can really lift the spirit. OK, there are the odd ‘contrived’ releases, desperately dashed out to complete the quota that has been promised to the client, but generally they do just what is intended: inform about developments within companies whether products, successes achieved, people or anything that enhances the company image. Thinking about that prompted me to look back over what we’ve received this month and re-evaluate the reasons for these releases. According to an AI synopsis (I’m not a complete dinosaur!) “a press release is used to announce newsworthy events, information, or developments to the public, primarily

to attract media attention, raise brand awareness, generate publicity, and control the narrative around a company or event by providing key details to journalists in a structured format.” Funnily enough as I looked through the news that was sent to us one release stuck out above all the rest, and I don’t mean that in a disparaging way to the sundry other releases. It was one from the FIT Show and what made it stand out was the fact that, if you think about it, the show is one big press release all on its own! The industry, gathered together at our biggest networking event and enhanced by stands that display products, new ideas: innovation of every kind.

The Fit Show release from mid-February announced another 14 exhibitors and undoubtedly there’ll be more to come. This prompted me to have a look through the full exhibitor list and as I was doing this the invitations to save times and dates to visit specific stands was growing apace. Why am I getting excited about this year’s show? I really think it’s a mixture of the dates heralding the arrival of some warmer weather…hopefully…. and the indication that our industry is determined to weather the economic storm from which we are all suffering. It isn’t just a matter of turning up to the show. Exhibiting takes planning, financing and commitment and there is that ROI to consider – do we expect a return on investment or is it a pure marketing cost? And if you are a visitor to the show again there are financial considerations, time, effort, and that balance between the possible loss of earnings from that day’s visit or perhaps reaping the benefit from the investment by finding something new, learning, finding a supplier or maintaining contact with those you use now.

There are many reasons to invest in the FIT Show and I like to think it’s an indication of the industry pulling together for the collective good. Times may be hard, exacerbated by incompetent politicians, and not just for those employing staff with issues of minimum wages and hikes in national insurance but the homeowner that represents a large percentage of the fenestration industry’s customers.

Is the FIT Show the answer to all our problems?

Regrettably, no. But it represents our determination to win through, whatever the odds!

Chris

GOT SOMETHING TO SAY?

Email Chris at: chris@glassnews.co.uk

‘TIME OUT’ WINNERS –FEBRUARY!

Sudoku: R McAllister, Edinburgh

Eye Spy: Leah Taylor, Salford, Manchester Spot the Difference: Sharon Cottingham, InsulationServices, Crowborough, East Sussex

Crossword:

Mr M Roberts, Leamington Spa, Warwickshire

Congratulations to all our winners! Good luck in this months Time Out pages!

6

8

Christina Lazenby

Managing Director / Advertising Enquiries

M: 07805 051322

E: christina@glassnews.co.uk

Emma Champion

Advertising Manager

M: 07508 263262

E: emma@glassnews.co.uk

Justin Lazenby

Finance Director / Press Release Enquiries

M: 07711 828710

E: justin@glassnews.co.uk

Chris Champion

Editor / Editorial Enquiries

M: 07850 267223

E: chris@glassnews.co.uk

Kate Carnall Graphic Design

E: kate@glassnews.co.uk Deadline for copy: 16th of each month

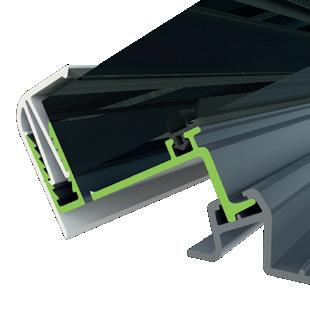

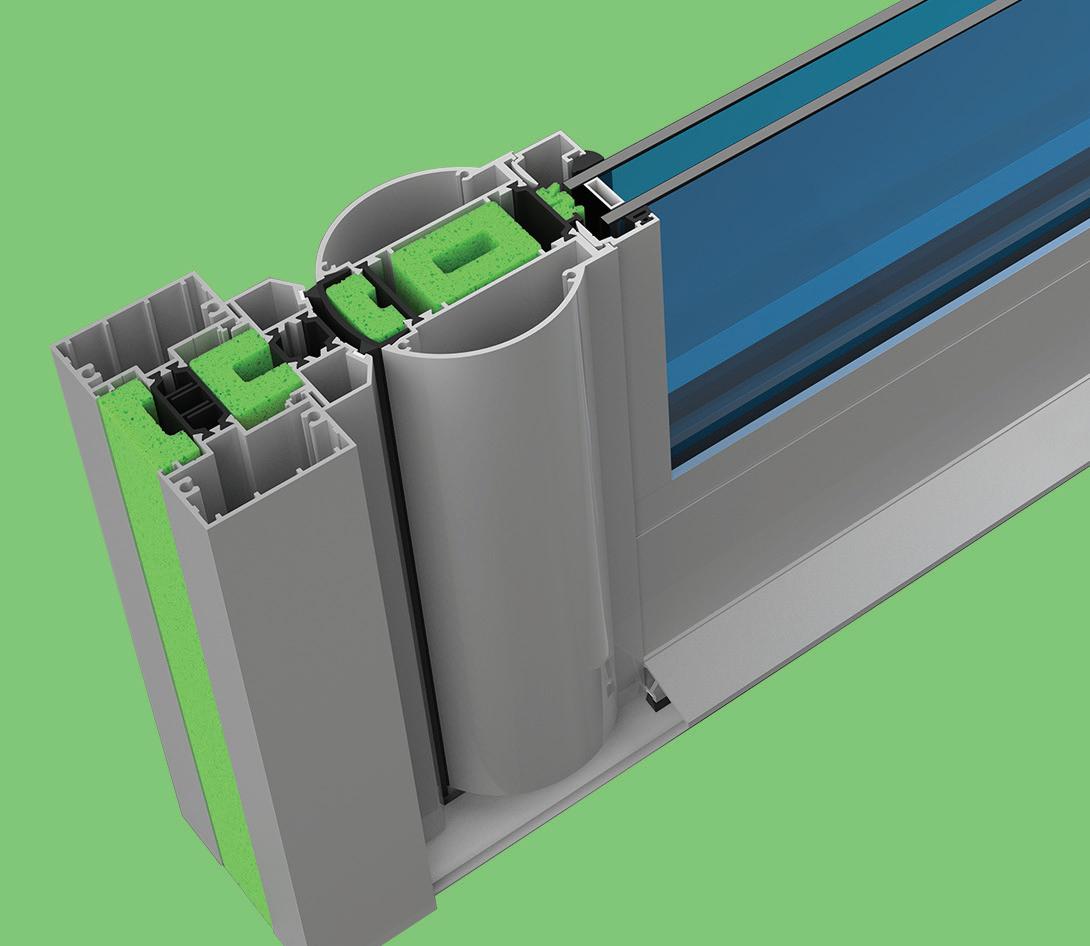

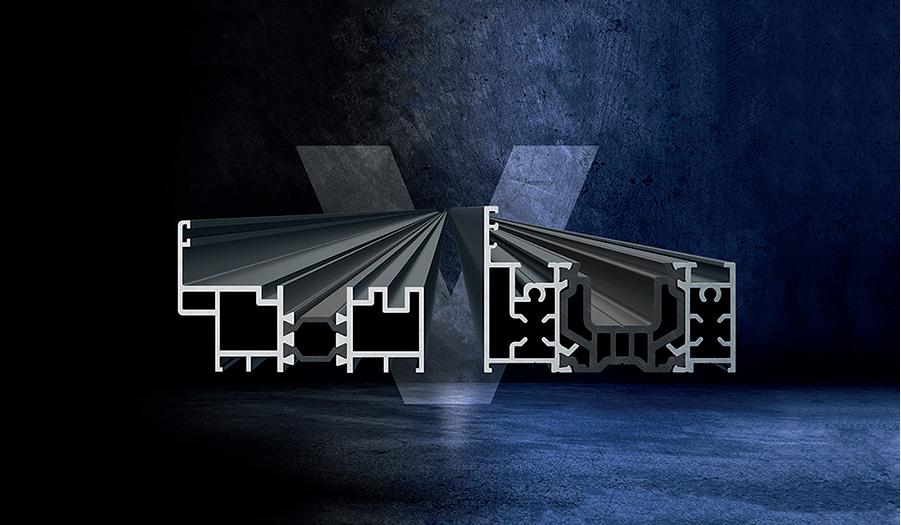

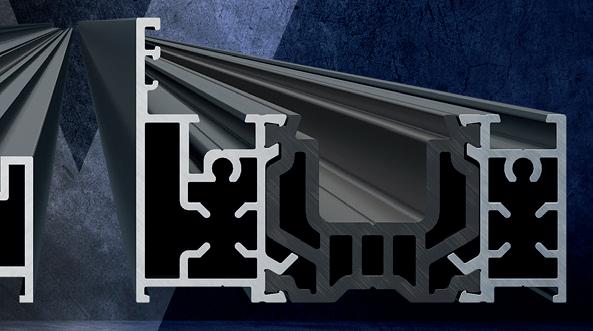

INNOVATION TO ELEVATE YOUR OFFERING

STEEL-STYLE MEETS UNPARALLELED THERMAL PERFORMANCE POWDERCOATED IN-HOUSE

MANUFACTURED IN THE UK HIGHLY DESIRABLE INDUSTRIAL DESIGN

THURSDAY 22 ND MAY 2025 | 09:00AM

Makita has added a new 18V LXT Framing Nailer to its range of high-performance cordless tools. The new DBN900 offers significant advantages over pneumatic and gas nailers including improved ease of use and greater working flexibility.

The DBN900 18V LXT Framing Nailer, designed specifically for first fix framing applications, can be used in the same way as a pneumatic nailer but without the additional setup time, complication and restriction of a compressor and air lines. In addition, unlike gas nailers, the DBN900 has no additional consumables, reducing the cost and inconvenience of replacing the cartridges.

The latest addition to Makita’s range of cordless nailers, the DBN900 is compatible with clipped head nails between 50 mm and 90 mm and nail gauges between 2.9 mm and 3.3 mm. Its magazine will accommodate up to 58 collated nails and incorporates a quick and easy reloading mechanism. The inspection window makes it simple to check the number of nails remaining. It also features a variable drive depth, with the required adjustment made using the easy-touse dial on the nose of the tool.

Furthermore, the DBN900 features two operation modes. In sequential actuation mode, it drives a nail each time the trigger is pressed, while the contact actuation mode allows continuous nailing, with a nail driven every time the tip is pressed to the material for as long as the trigger is held. Using a Makita 6.0Ah LXT battery (BL1860B), it can drive up to 1000 nails on a full battery charge at a rate of up to two nails per second.

The DBN900 has been designed for both convenience and enhanced safety. The anti-slip nose of the tool makes working on angled materials easier and more accurate, while the LED job light with pre-glow and after-glow function improves visibility of the work surface. It features both a rafter hook and belt hook, allowing it to be hung on ladders, scaffolding and timbers or clipped to the user, keeping it close at hand. The DBN900 also includes both an anti-dryfiring mechanism, which activates before the last nails in the magazine are driven to prevent missed nails, and an antirestart function to prevent accidental activation.

Kevin Brannigan, Marketing Manager at Makita UK said: “Our new, long awaited DBN900 18V LXT framing nailer is an excellent alternative to the conventional pneumatic or gas nailers and has been engineered to streamline framing tasks and similar first fix work. It is easy to use, even in restricted spaces and offers far greater flexibility when compared to traditional pneumatic tools.”

To find out more about the DBN900 and Makita’s wide range of 18V LXT tools and equipment, visit www.makitauk.com.

Installers using a revolutionary discount scheme from Leads 2 Trade are achieving more than double the industry-standard conversion rate average.

Recent data from December 2024 shows that Leads 2 Trade installer members using its TLS discount scheme were the lowest price on 85% of quotes provided to consumers, successfully converting an impressive 70% of these quotes into orders.

With typical conversion rates in the home improvement industry standing at around one order per 3.5 quotes, installers offering the TLS discount scheme are achieving one order per 1.4 quotes.

The innovative discount scheme, exclusive to Leads 2 Trade members, enables installers to offer customers a substantial 20% discount while maintaining healthy profit margins. This competitive edge has resulted in members using the scheme growing their businesses by between 50% and 100% in the current market, with average order values holding steady at over £7,500.

Installers have been reporting substantial business growth despite challenging market conditions. Kieran Mitten of AWC Windows and Home Improvements, which operates in the North West, commented: “Since using the TLS discount scheme, in the last six months our turnover has gone up by 60-70%. It has meant we are much more competitive and my advice to any installer is to go for it – it really has transformed our business.”

Shaun Ellison of Barriertherm UK, which is based in the North East, said: “Being able to provide the discount has had a massive effect on our growth and we’ve doubled our turnover since adopting it.”

Another benefit of the scheme is that, provided installers are buying leads from Leads 2 Trade, they can use the discount tool on their own generated leads too.

Andy Royle, co-founder and Managing Director of Leads 2 Trade, commented: “Since launching the TLS discount scheme last year, our installer members are experiencing remarkable growth in record time, with many doubling their turnover while maintaining their profit margins.

“They are effectively offering significant savings to the end user which is helping them secure significantly more business than they would typically expect. And the results –anyone trying to compete with one of our installers simply won't be able to.”

For more information on how the discount app, and to become an accredited installer, telephone 0800 124 4308 or visit: https://leads2trade.co.uk/discount-offer-supplier/

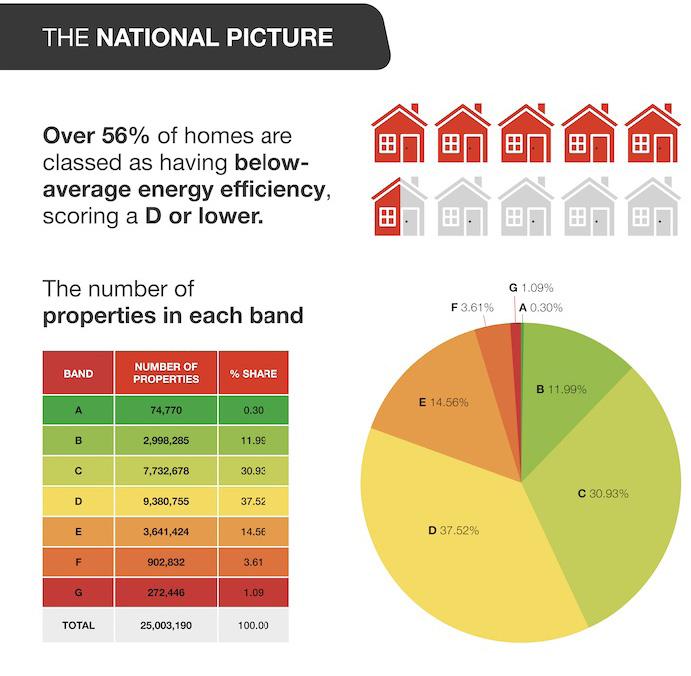

Over 56% of the total properties in England have belowaverage energy efficiency, presenting a major opportunity for the window and door industry to identify where to target retrofit projects and how they can optimise marketing to homeowners - according to new research from Eurocell.

To examine the scale of inefficient housing stock in England, Eurocell analysed national Energy Performance Certificate (EPC) data, revealing the regions most in need of urgent efficiency upgrades and demonstrating where the biggest opportunities are for fabricators and installers to support homeowners in upgrading their property’s energy performance.

It’s no secret that England has an ageing housing stock that needs modernising to today’s energy efficiency standards. But Eurocell's analysis reveals that there are 32 areas that have a portion of properties with a below average EPC rating (D to G), above 65 per cent - with Isles of Scilly topping the list with 84.90 per cent - laying bare the scale of the challenge the industry faces.

A further 232 areas in England out of a total of 308 analysed, also have a portion of properties with a below average EPC rating, at above 50 per cent.

According to Eurocell’s research, Eden in Cumbria has the highest proportion of least energy-efficient housing in England. 4,319 (17%) of the 24,361 homes here are classed as either an F or G on the rating scale.

The latest data from the ONS on energy-related home improvements found one in three adults still say cost is the reason why they don’t consider investing in efficiency upgrades.

In 2024, Eurocell launched a new programme of support for its fabricator network, ‘Eurocell Grow’ to help fabricators grow their business and stand out in their markets - a full list of benefits for fabricators can be found at: www.eurocell. co.uk/fabricator-account-benefits. For more information about Eurocell’s EPC research, visit: www.eurocell.co.uk/ blog/englands-worst-areas-for-efficiency-unveiled.

As the UK’s leading PVC-U door panel manufacturer, we offer a high-quality collection with diverse styles, colours, and glazing options. Now featuring seven new contemporary designs, our range is available with Securicore™ reinforcement - a proven PAS 24 compliant option which delivers enhanced security without compromising on style.

Discover the latest styles today.

Each month our special correspondent Danny Williams* replies to a reader’s letter...

“I’m not sure how to keep expanding my installer business. I’ve been taking on new staff and training them up as we need to get new fitting teams and it has worked well. Margins are always keen so I don’t know what will happen with all these new taxes and NI contributions…I’ll probably have to increase my prices but the homeowners are pressed for cash, too. I’m wondering if my business is now going to contract rather than expand….any ideas?”

Name withheld by request. Retail Installer Staffordshire

I received your letter before Christmas when frankly everything felt a little different, though perhaps more out of hope rather than expectation. So I called you for a chat. And, whilst your note seemed quite hopeful if perhaps wary, now you are on the verge of letting people go and have now asked for complete anonymity… and that is a huge disappointment. For all of us, because I believe that your situation is indicative of our industry irrespective of location.

The world according to the current government is constantly evolving (including ministers as they too get found out for various and corrupt and immoral behaviors) as they try to get a hold of running a country instead of heckling from the sidelines. Sadly however, every dip and turn succeeds only to make things worse.

You tell me now that flat New Year sales and the higher, government-imposed employment costs, have resulted in a position in which you will have to let as many as 10 of your current employees go within the next six weeks, once current orders have been fulfilled. This is a reversal of annual growth that your company has enjoyed since you went out on your own a decade ago.

Usually I like to leave my reader with a positive note. But I am simply unable to do so in the current climate. The Bank of England’s February rate cut may have sparked reductions in mortgage rates, but for around 600,000 homeowners whose fixed rate mortgage terms end in the first half of this year, it still means a doubling at least of the interest rates they will face when they negotiate new loans within the next few weeks.

* Danny Williams is managing director of

“Usually I like to leave my reader with a positive note. But I am simply unable to do so in the current climate. The Bank of England’s February rate cut may have sparked reductions in mortgage rates, but for around 600,000 homeowners whose fixed rate mortgage terms end in the first half of this year, it still means a doubling at least of the interest rates they will face when they negotiate new loans within the next few weeks.”

For all of us, energy costs are set to rise again from April, by as much as 5.7%. And whilst inflation has reduced this does not mean that prices will fall, just that they do not rise so fast. The huge increases that all of us have experienced in our weekly essential household bills will continue to rise.

A further shadow looming over us is the prospect of stagflation, which is being widely predicted by some very knowledgeable people. Based predominantly as our industry is, in the home improvement market our sales are dependent almost entirely on how confident we are feeling, almost irrespective of how much money we have in the bank. And confidence is as low as I can recall seeing it, after 35 years in this industry. Which means that we have the perfect breeding ground for stagflation of a stalling economy combined with costs continuing to rise substantially. And no prospect so far of the government having any more idea how to deal with this than they have shown so far, though the prospect of further increases in taxation are on the cards rather than actually doing something to stimulate sales. Any reasonable increases in wages that we might give our employees simply cannot keep pace with the increases in the cost of living. And whilst my firm enjoys the fortunate position of being a public sector supplier and with it the promise of increased activity especially with NHS estates,

many companies in our sector – and across British industry generally - are faced with the very real prospect of making staff redundant. Then I watch PMQ’s and endure the stupid, self-righteous, smug looks across the three stooges’ faces, and wonder: ‘Do you realise how much damage and hardship you are causing’?

According to a poll undertaken by the think tank the Institute for Government, just 22% of those polled believe that this government is being effective at improving their lives. This compares with 28% that now think the last Conservative Government was effective, months after they were booted out of office. This does not bode well for the Labour government as they continue to show that ineptitude, which is the only thing at which they excel, especially now our health secretary is a Llama.

My politics are well known to my reader. But even the staunchest Labour supporter (if there is such an animal reading this glorious organ) cannot be impressed by their performance so far. Of course, they will continue to blame the previous Conservative government, but that rant has lost its gleam now and Starmer and co must show some of their own mettle.

By my reckoning it has around a year to show up and shift direction, to put UK PLC on track. After getting on for a couple of years in Government by that time the whiff of the next General Election will reach our noses and scrutiny will be more intense than ever. And with Labour MPs facing the very real prospect of being booted out of office after enjoying just a few years of sucking up the privileges of power, a Palace of Westminster revolution must surely be a distinct possibility: if Starmer and his acolytes don’t do something radical to turn the corner, he will face the chop. And who will come next?

I do not believe in miracles however and I will continue to look closely, as must you my faithful and beleaguered correspondent, at finding ways to increase business whilst reducing costs. Both will require an extraordinary level of ingenuity, just as we have when the brown stuff has hit the fan in the past. But whilst we coped with the aftermath of Covid for example, the bug was not consciously acting against us. Which this government most certainly is.

“Freefoam

As an independent business we don’t compete with customers. We help PVC stockists , merchants , and installers grow, because it helps us grow. Our high-quality cladding , roofline , rainwater , window trim , and interior panel ranges come in a variety of colours/finishes (plus accessories), with many RAL-matched to windows and doors for upselling.

• Market-leading guarantees

• Continuous New Product Development

• Full marketing and sales support

• Sustainably Produced

Learn more about Principality’s experience with Freefoam:

Marketing Manager, Mark Walker, talks about a challenging market and why you should Connect with Selecta at FIT Show 2025.

In the current market, it’s become imperative that fabricators and installers partner with a systems company that can provide them with more than just a range of products. Every systems company can supply fabricators with ‘sticks of profile’, but not all can provide a personal and comprehensive service and support package. By this, I talk about providing you with a personal marketing support package, which is backed up with the sales and marketing tools to help you generate more sales leads and win new business.

It’s widely reported that the industry is down by approximately 10-15%, with some stating it could be as high as 20-25% in certain sectors of the market. With the industries home improvement boom now a distant memory, it now appears that we have somewhat returned to pre-covid levels, a time we seem to have forgotten.

Businesses may have become more accustomed to the reactive nature of doing business, which they experienced with the home improvement boom over the last few years. The current downturn may require businesses to take a more proactive approach to generating sales leads and winning new business. In turn, this may involve companies undertaking a totally different marketing strategy and plan to which had worked previously and of which they are used to.

Dependent on current resources and infrastructure, there will be some who would benefit from additional support and tools to aid them in implementing and realising their strategy and plan. The marketing support package, which Selecta have invested heavily in, provides fabricators and installers with exactly that! 2025 will see more innovative developments in place to further push the boundaries of support including the tools to take our Connect customer support portal to a completely new level.

Connect provides fabricators and installers with a host of technical and general information and guidance, with an excellent resource and news centre. However, marketing support sits at the very heart of Connect, providing a comprehensive package that’s designed to help businesses generate more sales leads and win new business.

Identified as Branded Mode, our Window & Door Designer with Home Visualiser has

already been touted as a real game changer when it comes to lead generation and sales. It is fully loaded with all of Selecta’s window and door solutions, styles and configurations, and as the name suggests can be branded in-line with your business.

Customers can explore a wide range of window and door styles, choose from a variety of colour options to suit, upload property photos to visualise how they

would look and request a survey and quote based on their design. Branded Mode is a fully immersive user experience, whether done in their own home, in your showroom or by your representative at the customers property.

With Selecta inviting you to Connect at FIT Show 2025, the April show will see the launch of a host of new features and modules within Connect and the designer. The added features are aimed at connecting fabricators, installers and their customers

together with additional quoting, pricing and fabrication modules being integrated within the Window & Door Designer. This groundbreaking and integrated system will provide fabricators and installers with the ultimate sales lead generation, sales management and fabrication management tool. The software will link the initial lead, to quoting and pricing, through to workshop fabrication.

In Connect, you also have access to the Website Support Package, which features two ready-made themed websites, one for fabricators and one for installers. Fully equipped with all of Selecta’s window and door solutions, photography and text, you can have a modern and ready-to-go website up and running within 5 days! All that’s needed is your logo, chosen colour theme, a company bio and your contact details to get started. It takes out the headache of a website build.

The themed websites have been purposely designed to grow as you grow, allowing you to add new products, services and features. Upgrades include adding the Window & Door Designer, so that you can have a fully branded and professional on-line package that’s ready to start generating leads and winning new business from the outset.

This comprehensive marketing support package is key to building a trustworthy and effective partnership. In challenging times, we believe it’s imperative that you receive the right support and back-up from your systems company. This is why we are confident that Connect will provide even more added value and benefits to every fabricator and installer who choose to #bepartofthefamily

The Glass & Glazing Federation’s enhanced presence at this year’s FIT Show will bring together in one place the increasing number of its latest initiatives and projects that are having an impact on its members.

Partnering with FENSA, the stand (G40) will specifically focus on the latest information about the GGF’s recently launched online training platform, with a special appearance by its knowledgeable avatar GRACE. Visitors will be able to see a demonstration of the platform and gain a clearer idea of what needs to be done to ensure its workforce remains fully MTC compliant going into 2026.

Following the training theme, the GGF will also be sponsoring the show’s seminar programme, drawing attention to the importance of keeping up to date with changing work accreditations,

competencies, technical innovations and overall industry knowledge. Over the three days it will host a number of talks and presentations to ensure visitors have access to the latest industry updates.

“The industry is going through a massive amount of change this year in an unpredictable economic environment that has already proven to be very challenging,” commented GGF managing director Ben Wallace. “Training and filling the skills gap is going to be crucial when it comes to maintaining a robust position within the marketplace with a fully accredited, valued, workforce. Our members know that the opportunities available to them through the GGF Training platform will keep them ahead of the curve when it comes to proving competencies and stealing a march on the competition.”

As well as training for specific industry related competencies, the GGF Training platform also has a wealth of courses across operational practices for window and glass companies. Visitors to the stand will be able to come away from the stand with a clearer idea of what they need to do to upskill

themselves and their staff, and how that can be achieved through the GGF platform.

“The impact of the end of grandfather rights has not yet been felt, and there is still time to make the changes that will guarantee a smooth transition,” added FENSA operations director Lis Clarke. “The GGF Training platform completely simplifies the road to competency compliance in a way that is highly accessible and cost effective.

At FIT Show we will be demonstrating to window companies how FENSA can structure a failsafe route for them through these complex changes”.

Also having a presence on the stand will be Installsure, the industry’s biggest Insurance

Backed Guarantee provider which is also celebrating its 20th anniversary this year.

“In a challenging economic climate, protection against the unpredictable is more important than ever,” said Installsure’s director and head of insurance, Irene Akpojaro. “Our presence on the GGF stand will give window companies the opportunity to better understand how we can help build confidence and give reassurance.”

Finally, the GGF has also joined forces with Business Pilot to co-host the PiGs event on the GGF stand.

The GGF and FENSA will be available on stand number G40 throughout the three days of the show.

This state-of-the-art lock offers a seamless blend of smart technology and high-quality security credentials.

Key features at a glance

• Retrofit Ready

Fits any door handle with the Kenrick 3-Star Cylinder

• Invisible Design

Internal fit, no external signs of the lock

• Multiple Entry Options

Touch, keypad, fob, key or voice activated

• Smart App Control

Manage remotely with ease

• Versatile Use

Perfect for homes, offices and residential complexes

• Smart Security

End-to-end encryption for peace of mind

• Access Control

Set timed or temporary access

• Quiet Operation

Smooth, quiet operation

• Fast Locking

Secure in under 2 seconds

App-controlled

Manage the lock remotely via the dedicated app. Check the door status from your smartphone.

Glazpart’s plans for FIT Show 2025 are well underway as the award-winning glazing components company gets ready for the biggest event of the year with some special features for their presence at the industry’s largest UK exhibition.

Glazpart is pleased to announce the company will launch several new products in its Glazing Accessories and Trickle Vent ranges at FIT Show (April 29-May 1) at

Birmingham’s NEC. The new products will feature at the show with special displays and promotional materials.

Also on Glazpart’s stand space (of over 100m2), visitors can expect to see strong promotion of the award-winning Glazpartners programme which was launched at FIT Show in 2023 and now has over 50 companies signed up to the marketing partnership initiative. FIT Show itself is a Glazpartner

and will be promoted from the Glazpart stand (No.J70, Hall 9).

On the forthcoming event, Dean Bradley, Glazpart Sales Director commented, “In previous years, the FIT Show has proved to be the perfect platform to showcase our products and to network with so many in the industry. This year we expect will be even better as we not only have our new products at the show but we will also be promoting all our Glazpartners and

Brighouse based fabricator Quickslide has decided to take the spotlight at this year’s FIT Show, stand number E23.

The importance of face-toface conversations has always been part of the Quickslide ethos, and the business has consequently invested in a space where existing and new trade partners can gather and discuss marketing and product strategy with a view to growing their installer business.

Quickslide will be showcasing its latest enhancements for its Legacy sash window, including the authentic slim midrail and the newly refined sash horns. Plus, expect exciting new developments designed for modern-day living, all while keeping the ever important aesthetics of traditional sash windows intact. In addition, Quickslide will feature the popular Quick-Glide slide and fold doors, which have been a standout success since their launch last year.

“The level of trade partner support that we offer is among the most comprehensive in the industry, and FIT Show provides us with that time and space to address individual partner needs in a stimulating and buzzy environment,”

commented sales director Tom Swallow. “We have always found that for us, the focus is never on the products – their excellent reputation precedes us anyway. Rather, visitors to our stand have always been more interested in how we can help them succeed in an increasingly competitive market.”

The Quick-Glide system will, nonetheless, take centre stage at the show. Unlike traditional bifold doors with a concertina swing arc, this unique slide and fold door tackles common British household challenges, such as restricted space. The QuickGlide panels slide and fold individually, allowing them to be fully stacked for an unobstructed opening, partially opened, or closed for a sleek span of glass.

Refined through joint development with Invisifold Systems, the Quick-Glide

celebrating the start of our 40th anniversary.”

Nickie West, Managing Director of FIT Show added, “Glazpart has been supportive of FIT Show since the outset and we are delighted to be Glazpartners. FIT Show is built on connecting people and products, it’s the whole premise of our campaign for 2025, so we align perfectly with the Glazpartners initiative and I am looking forward to seeing Glazpart at this year’s FIT Show.”

Dean Bradley added, “With so much to promote and launch as well as our new stand design, we are looking forward to FIT Show. In the coming months we will be providing more information on our new products and activity

planned for the show. It promises to be an exciting week in April at the biggest exhibition for the glazing and fenestration sector.” www.glazpart.com

This year’s FIT Show is set to be extra special for the Glazerite UK Group, with the leading trade fabricator taking the opportunity to celebrate 25 years in business. The fabricator is also returning as VIP lounge sponsor at the event, which takes place from 29th April - 1st May at NEC Birmingham.

aluminium slide and fold door offers a sleek, space-saving solution with slim sightlines, modern square sashes, and an innovative “tap-in” bead for faster installations. It is the culmination of market testing and researching for the perfect door system that can fulfil everything today’s homeowners are looking for.

“We’re synonymous with sliding sash windows, so of course, we’ll have a selection on display,” added Tom Swallow. “We’ll also be showcasing our new wheeled sample cases for installation companies who are looking for more than just a supplier, but a genuine supply partner. Ultimately, we want to show our trade partners the wealth of support and opportunities that working with Quickslide gives them.”

www.quickslide.co.uk

Michelle Wright, Head of Group Marketing, says: “We’re delighted to be exhibiting at this year’s FIT Show in what marks our 25th year in the industry. We will be welcoming visitors to Stand F79 to learn more about the value we can bring to installers, including our unique marketing and technical support, which is tailored to meet the specific needs of our customers. We will also be showcasing our comprehensive product portfolio, including some great new additions to our product range from VEKA, Deceuninck and DoorCo.”

Michelle adds: “As the industry’s biggest event, the FIT show is the ideal meeting place for the Glazerite team to catch up with existing and prospective customers, suppliers and other industry stakeholders. 2025 is a pivotal year for our business, with significant investment across our operations to broaden and

enhance our offering.”

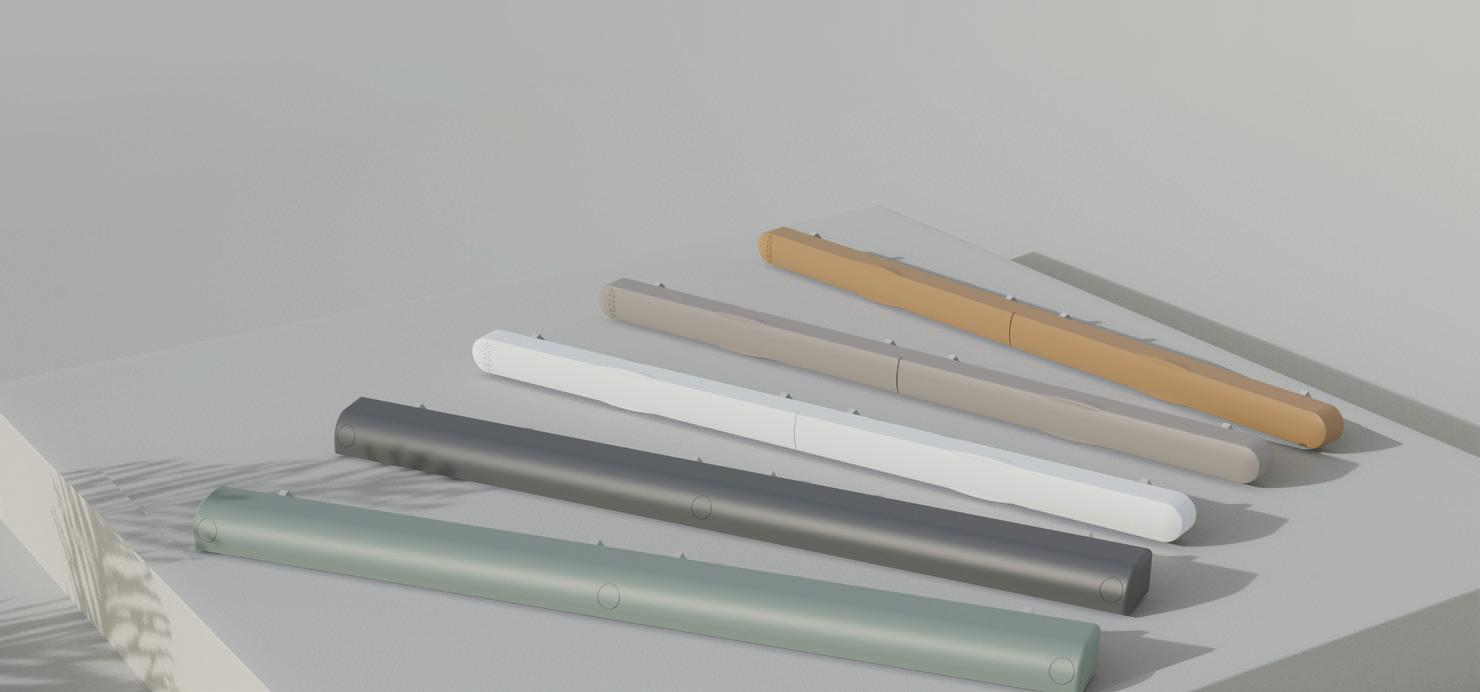

Glazerite’s stand will showcase VEKA’s innovative OMNIA flush sash system, and the premium hardware, door furniture and smart technology on offer from Glazerite partners, Ultion, Ultion Sweet and Kubu. There will be a chance to see some exciting new additions to the door range, including the fabricator’s flood door collaboration with G24 Award finalists, M3 Floodtec, and the Triple Track Slider from Deceuninck. The exhibition will also be an opportunity for commercially-focused installers to explore Glazerite’s commercial product offering, including its ALUK aluminium casements and Deceuninck 2500 windows.

Meanwhile, visitors will be able to take a look at the new locks and gearing

collaborations on offer from Glazerite’s new supply partners, Yale, Roto and Carl F Groupco, and learn more from Glazerite about the range of enhanced benefits and warranties on offer.

FIT Show event director, Nickie West adds: “We are delighted to welcome Glazerite back to FIT Show 2025, especially as they celebrate their 25th anniversary. Their presence on the show floor and sponsorship of the VIP Lounge reinforces their commitment to driving innovation and excellence in the industry. Visitors can expect an exciting showcase of their latest products, expertise, and services. We’re looking forward to seeing them connect with customers old and new at what promises to be our biggest and best event yet.” www.glazerite.co.uk

Ab Initio is launching an industry first on its stand number M40 at this year’s FIT Show – a WhatsApp integration with its market leading AdminBase CRM system. Text-based conversations can now be funnelled throughout the process, and window companies can now communicate directly with customers at every stage of the sales process using this universally popular messaging service.

Doubling up on the unique offering, the company is also celebrating its 30th anniversary. Visitors booking an onstand demonstration of AdminBase will not only receive a

premium gift to mark this 30th milestone, but will also have the unique opportunity to win an all expenses paid luxury weekend in London, overnighting in one of the capital’s finest hotels, while taking in dinner and a West End show. You can book by emailing the company direct at sales@abinitiosoftware.co.uk.

“The WhatsApp integration will be a game changer for window companies – the UK has over 40 million WhatsApp users, and it has become the ‘go to’ method of communicating,” said Ab Initio’s founder and director Rhonda Ridge. “As the first and only industry CRM to offer this as standard, we know that our customers will reap the benefits immediately.

“During our 30 years in business we have consistently stayed ahead of the curve in evolving and updating AdminBase. While WhatsApp has always been prohibitively expensive – potentially costing thousands for clients to absorb it into their system – Ab Initio has managed to streamline the process and integrate it as part of our overall offering. Consequently, there is less reliance on emails - which can get

lost among spam and go unread – giving instant, real time updates to all involved.”

Ab Initio has always focused on the smoothness of the journey when evolving its AdminBase system. Over its 30 years of business the company has worked side by side with its customers, improving the process of selling and installing their products. This systemisation has not only helped them to become more agile and more efficient, but has also helped them to focus their minds on the most important area of their business as a whole – the customer journey.

Ab Initio will be demonstrating its AdminBase software on stand number M40. We recommend you book an online demonstration as the stand is always notoriously busy. Please book by emailing the company direct at sales@abinitiosoftware.co.uk . Everyone with a genuine appointment will receive a special gift to mark our 30th anniversary, and their names put forward into a prize draw for a luxury weekend in London.

For more information go to: www.abinitiosoftware.co.uk

Made for Trade (MFT), the award-winning manufacturer behind Korniche Aluminium Glazed Products is set to take centre stage at FIT Show 2025 (April 29th – May 1st) with an unmissable presence at Stand J30, right at the entrance to Hall 9. With a 10x12m open stand, MFT is once again leading from the front, showcasing why its products are true ‘Trade Heroes’; engineered for exceptional speed and ease of installation while delivering premium homeowner appeal that drives trade sales.

In an industry where every minute on-site counts, taking time away from projects might seem like a challenge. But with the latest advancements from Made for Trade, FIT Show 2025 is the place to see firsthand how innovative glazing solutions can save time, reduce hassle, and maximise profitability for installers and builders alike.

Live demonstrations at Stand J30 will bring Korniche’s industry-leading products to life, proving why they have become the trusted choice for thousands of trade professionals across the UK. Whether you're an installer, fabricator, builder, or home improvement retailer and merchant, MFT’s stand is where you’ll discover ‘What’s New’ – and why you won’t want to miss out.

Building on a legacy of over 40 years in business and engineering excellence, Made for Trade continues to set the benchmark for innovation, service, and trade support. At FIT Show 2025, visitors can expect:

• NEW Products: Be the first to see the newest Korniche solutions engineered to deliver even greater efficiency and answer the latest homeowner demand and appeal.

• Live Product Demonstrations: Watch first-hand how onsite installation speed can transform your workflow.

• Exclusive Show Offers: Discover unbeatable trade deals and promotions available only at the show.

• Meet the Experts: Get insights from MFT’s experienced team on how Korniche products can give you a competitive edge.

Made for Trade’s commitment to innovation and quality continues to be recognised at the highest level:

• King’s Award for Enterprise: Innovation 2024

• National Fenestration Awards: Fabricator of the Year 2021-2024

• National Fenestration Awards: Product of the Year 2021-2024

These accolades reflect what the trade already knows, MFT products deliver the best products with the best service at the best prices.

Don’t miss your chance to experience the ‘Trade Heroes’ at FIT Show 2025. Secure your VIP tickets now by registering at: www.madefortrade.co/fitshow25-mft/

Join us at Stand J30, Hall 9, from April 29th to May 1st and see why Made for Trade continues to lead the way in innovation, service, and trade support.

Scan the QR Code to secure your VIP Tickets!

Uncompromising. That’s the standard your windows should always meet when it comes to quality. And if it costs a little bit more, you know that you will get that back manifold in terms of eliminating costly call-backs and multiplying recommendations and repeat business. Quickslide’s stellar success is down to its commitment to instil that quality ethos in every area of the company – from the manufacture of its products to the development of its people.

When a window – whether a standard casement or more complex VS (Vertical Slider) – moves along the Quickslide production line, it has to pass multiple quality checks on the company’s comprehensive inspection list. These checks are in place to help the team catch even the smallest imperfections, all to ensure every window meets Quickslide’s quality promise.

“Cheap windows fill a gap – period. Quickslide Windows solve a gap beautifully, on and on,” said the company’s managing director Ben Weber. “To achieve this, investment in automation has been and continue to be a cornerstone of our business strategy.”

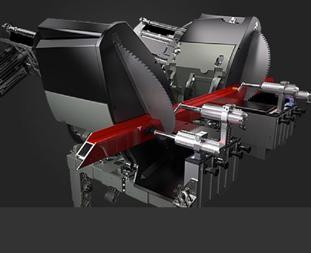

21 months ago, the company took delivery of its biggest investment to date – a £1.71 million Schirmer machining centre for its 150,000 square foot VS factory. Quickslide collaborated with German based Schirmer on an exclusive design, specifically to replicate that repeated, consistent quality that Quickslide pursues so fervently. The machine covers a footprint of 4,120 square feet and can operate to an accuracy of 0.02mm.

“We needed to reduce the risk of human error,” continued Ben Weber. “No matter how well-trained an operator is, when individuals are working 24 hours a day, six days a week, there are going to be errors. With the increasing number of VSs going through our production lines, it made sense to work towards a solution that was going to enhance the overall quality of the product, eliminate human error, and provide us

with repeatable quality. The centre has now been fully up and running for 18 months, and we’ve been able to exceed every quality target we set ourselves.”

It is the high level of repeatable quality and automation that makes the VS range more accessible and affordable to a much wider range of potential trade partners. With customer expectations becoming more demanding each year, being able to offer a premium product like the Quickslide VS with a fast lead time can give them a competitive edge. Even during more challenging economic times, homeowners looking to invest in home improvement products will veer towards better quality rather than a cheaper alternative, knowing that it will last the test of time and look so much better.

“I once attempted to calculate the number of VS design configurations that we offer and without including bespoke colourbonding we’re looking at more than a trillion. Our designs and options are ever more complex and the Schirmer means we can do all these configurations without adding to the lead time with the confidence that we have mastered the art of getting it right, fast and every time. I believe that we already offer the fastest VS lead time in the industry but can do so whilst also offering the greatest choice of design and specification options,” continued Ben.

VS manufacturing processes can be more complicated, such as fully mechanical joints and the inclusion of the slim mid-rail. These complex and labour-intensive options

“The £1.71 million investment in our machining centre demonstrates our commitment to long-term quality and growth with many of our trade partners seeing the financial benefits”.

have traditionally been limited by capacity constraints due to how difficult and labour intensive they are to mass manufacture. However, with the introduction of automated processes those capacity limits can now been lifted.

Quickslide believes that today’s installer does not need to be worrying about the quality of a product. Manufacturing techniques and technologies have advanced to such a degree that there is no reason for cheap, below grade windows to even be considered a viable option. Cutting quality corners will only negatively impact an individual business, and the industry as a whole.

“We love working with trade partners who take great pride in their work,” said Ben Weber. “They recognise that quality in our product range, and in turn the selling process becomes so much easier for them, because they believe in what they are

selling. They become the craftsmen that have preceded this industry, rather than the ‘double glazing salesmen’ that have blighted the industry’s reputation for too many years. Having confidence in not just the aesthetics of a window, but its performance and quality leads to a more confident sales pitch, that will always lead to more sales. The £1.71 million investment in our machining centre demonstrates our commitment to long-term quality and growth with many of our trade partners seeing the financial benefits”.

Automating the quality processes in the factory also allows Quickslide to focus more on providing support to its trade partners in other ways. Which is why its marketing support packages – whether it is providing individually tailored marketing campaigns, innovative and intuitive tools and dedicated training – are making waves throughout the industry.

www.quickslide.co.uk

Fairco, a trusted name in premium windows and doors across Ireland, is set to bring VEKA’s award-winning OMNIA double flush system to the Irish market in 2025.

Approaching 5 years of partnership with VEKA, Fairco has built its reputation on providing high-quality, innovative products to both the trade and retail sectors. The introduction of OMNIA marks the next step in this commitment, offering a cutting-edge solution that blends performance, durability, and design.

OMNIA, unveiled by VEKA in 2024, is the first PVCu system of its kind delivering a sleek, symmetrical finish that sits flush inside and out. Combining the perfect balance of timeless elegance and 21st century performance, the OMNIA range is revered for creating a contemporary, streamlined look whilst achieving superior energy efficiency, thermal and acoustic performance. The system has already won New Product of the Year at the National Fenestration Awards, and it is quickly becoming the flush system of choice in both the UK and Ireland.

JIM TOAL, OWNER OF FAIRCO, EXPRESSED HIS ENTHUSIASM FOR OMNIA’S POTENT

"At Fairco, we’ve always set the standard for premium windows and doors in Ireland. Our partnership with VEKA has been built on trust, quality, and a shared vision for innovation.

“OMNIA is an exciting addition - its unique design offers the best of both worlds: the clean, modern lines sought after in new builds and the authentic, heritage styling needed for conservation projects.

“We see this system transforming streetscapes across Ireland, from sleek urban developments to classic period homes. We’re excited to bring OMNIA to our customers and lead the way in the next generation of window design."

Loredana Emmerson, customer marketing manager at VEKA, also shared her excitement about Fairco’s momentum with OMNIA: "It’s fantastic to see Fairco’s commitment to OMNIA. Their passion for delivering high-quality, innovative solutions to the Irish market aligns

"It’s fantastic to see Fairco’s commitment to OMNIA. Their passion for delivering highquality, innovative solutions to the Irish market aligns perfectly with VEKA’s ethos. It’s been a pleasure assisting them with marketing efforts so far, and we look forward to seeing the impact OMNIA will have as they roll it out in 2025."

perfectly with VEKA’s ethos. It’s been a pleasure assisting them with marketing efforts so far, and we look forward to seeing the impact OMNIA will have as they roll it out in 2025."

With Fairco’s expertise in high-performance fenestration solutions and VEKA’s industry-leading innovation, the

launch of OMNIA in Ireland will provide trade professionals and homeowners with a versatile, high-quality solution that meets both aesthetic and performance demands, all with one system.

For more information on OMNIA and Fairco’s product offerings, visit www.fairco.ie.

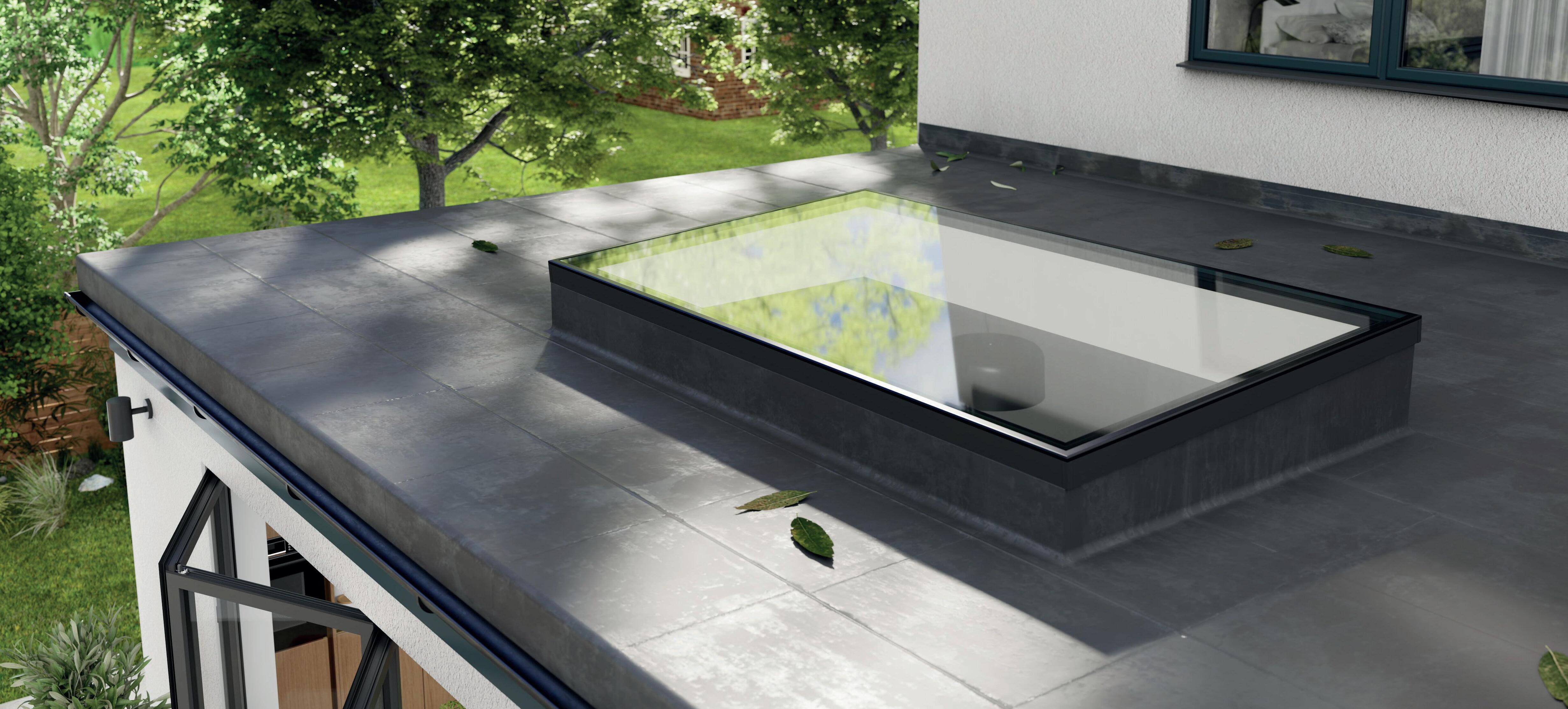

with unique replaceable glass unit

Fitted in minutes

PAS24:2020 Security as standard

Bespoke sizes up to 3mx1.7m

28mm double or 44mm triple glazed options

Replaceable glass unit

3 stock colour options: Grey matt, Black matt or White gloss.

Bespoke RAL or BS colours also available

Free site delivery*

The Residence Collection transforms substantial period property in Oxford with new Residence 7 windows.

Collaborating with installer Andy Glass Windows and fabricator, HWL Trade Windows, R7 windows were installed in the internal and external colourway Grained White to sympathetically upgrade the property with a like-for-like window structure and modern functionality.

The project with R7 is being done in stages and currently showcase a number of windows and two bay windows all complete with a square bead and satin chrome pear drop Regal hardware. The mechanical jointing manufacturing method was used by HWL Trade Windows for this project to directly replicate the authenticity of the original sash windows.

The selection of Residence 7 windows was driven by both aesthetic and efficiency considerations within the R7 window system. With a flush external and internal profile, these windows offer maintenance-free finishes and a variety of styles, meaning versatility without complication.

Beyond their appealing design features, the R7 windows excel not only visually but also in their efficiency properties, boasting A++ energy ratings and achieving a u-value of up to 0.8Wm2k with triple glazing. This collection is also available in 22 different colourways.

“We completed this project in stages with the residents noticing a great improvement on heat retention and energy efficiency following the installation of the first windows.”

Sarah Greening, Administrative Co-Ordinator at Andy Glass Windows, commented: “It’s always a pleasure to install Residence Collection windows in properties around Oxfordshire and in particular it’s been exciting to see this property come to fruition.

“We completed this project in stages with the residents noticing a great improvement on heat retention and energy efficiency following the installation of the first windows, so we are pleased to have now completed this project so they can continue to reap the benefits of their investment.”

Jo Trotman, Marketing Manager at The Residence Collection, added: “This is a beautiful project setting a great example of everything that our Residence 7 windows have to offer from colourways and manufacturing methods to traditional design and modern performance.

“This collaboration with Andy Glass Windows and HWL Trade Windows is just one in many that we have completed together in Oxford and the surrounding areas, and it's fantastic to see installations in this location continue to grow. We look forward to many more in the future.”

To find out more about The Residence Collection’s R7 collection, please visit: https://www.residencecollection.co.uk/collections/r7/

Keystone Market Research is delighted to announce the release of its Winter 2025 Consumer Fenestration Trends Report, a highly detailed analysis of homeowner preferences, buying behaviours, and market trends. This comprehensive report continues to build on the success of previous publications and explores material preferences, glazing styles, energy efficiency priorities, and the implications of the upcoming Future Homes Standard.

This year’s report is made possible through expanded sponsorship, with leading industry players Endurance Doors, Epwin Window Systems, the GGF, Liniar, and VEKA supporting the initiative. Their contributions ensure greater accessibility of this unique resource across the fenestration industry, with sponsors able to share the report throughout their supply chains, helping businesses make informed decisions based on detailed consumer insights.

Key findings from the report include:

• Triple Glazing and uPVC Lead Preferences: Triple glazing continues to dominate, while uPVC emerges as the most popular material for both windows and doors this time, offering affordability and energy efficiency.

• Rising Popularity of Sliding Patio Doors: Younger and wealthier homeowners are driving demand for sliding patio doors, which have overtaken bifold doors as the preferred style.

• Low Awareness of the Future Homes Standard: With only 18% of homeowners familiar with the standard, the report highlights that the onus is on the

industry to promote energy-efficient upgrades as it looks unlikely currently that the standard will drive additional homeowner sales.

Charlotte Hawkes, founder and director of Keystone, shared her perspective: “Amid the continuing economic pressures our market is dealing with, this report provides actionable insights to help businesses navigate shifting consumer priorities and outline the pockets of opportunity still available. I’m especially proud of the expanded sponsorship, which underscores the industry’s commitment to understanding homeowners’ needs and delivering data-based support throughout the supply chain.”

Businesses interested in to supporting the fenestration industry, and their customers, with Keystone’s trusted consumer insights are encouraged to reach out as a limited number of sponsorship opportunities remain available.

For more information about the Winter 2025 Consumer report and Keystone’s research services, visit: www.keystonemr.co.uk.

A 15-year partnership between leading warm edge technology pioneer Edgetech, a Quanex company, and Padiham Glass has played a big part in the prominent IGU manufacturer’s continued growth.

That’s the view of John Spiby, Divisional Director for the Emplas Group and MD of Padiham Glass.

As part of the Emplas Group, Padiham Glass has established itself as a major force in both trade and new build sectors, currently producing over 1,700 units daily with ambitious plans to increase volume by 50% in the next year.

The relationship with Edgetech began with Padiham Glass initially taking small roles for shaped units before transitioning to full production – and has proved particularly valuable following Padiham’s recent investment in a highly automated IGU line to meet growing demand and maintain quality standards.

“Edgetech’s technical team has worked closely with us to implement lean manufacturing processes, improving unit performance and efficiency

thanks to the automatic spacer application,” said John.

“Branding is also key for us, and Edgetech’s strong market presence adds significant value to our proposition. Using Edgetech enables us to offer leading-edge products with leading-edge performance, which is crucial in an industry focused on window energy ratings and U-Values.”

With Edgetech’s reliable delivery and quality as a spacer supplier also scoring highly, John added: “People, products, and professionalism set Edgetech apart. I have known the team at Edgetech for many years and the expertise they bring, and share is invaluable.”

Tony Palmer, Edgetech’s Head of Sales, said: “Our 35-year track record of supporting IGU manufacturers is built on providing not just outstanding products, but technical expertise and support, and our partnership with Padiham Glass ss the perfect example of our commitment to being more than just a supplier.

“It’s been particularly rewarding to support Padiham’s transition to automated Super Spacer application. The results they’re achieving validate our belief that automation is key to meeting the increasing demands of the modern IGU market.”

For more information, please call 02476 639931 or visit www.edgetechig.co.uk.

VBH, the company behind the greenteQ furniture and hardware brand, has announced that it has been shortlisted as a finalist at the 2025 Installer Awards.

The company has reached the final in the Best Installer Support Program/Service Initiative category with the greenteQ furniture guarantee that was introduced during 2024.

The guarantee covers the finishes of the company’s own brand greenteQ Suite and stainless steel architeQ ranges of resi-door, window, and patio door furniture for 20 and 25 years respectively. VBH stress that the guarantee covers ALL finishes, providing ‘no nasty surprises if someone needs to make a claim.’

Gary Gleeson, Marketing Manager at VBH says, “This is the first time that we have entered these awards. This year we felt that our new greenteQ Furniture Guarantee gave us

something that has real relevance to installers of all sizes, so we went for it.

“Happily, the judges agreed, and we are very pleased that our guarantee has reached the final cut.”

VBH advise that the guarantee goes further than a simple 20 or 25 year term. If a customer qualifies for the enhanced guarantee, VBH will deal with any claims directly with the consumer.

Gary explains, “The enhanced guarantee takes away all the hassle and expense that installers and fabricators get if they receive a claim. We will ascertain the problem and, if it is a product fault, we’ll replace the item of furniture directly without quibble. If it’s misuse, we’ll explain the issue to the consumer and offer advice for the future. Either way, the consumer gets their issue sorted quickly, and the manufacturer and installer are left free to do what they do best. That’s selling windows and doors!”

The winners will be announced on 13th March.

Kenricks has announced that Silent View Windows has become the latest launch partner for its AK Touch Secure™ smart door lock.

The AK Touch Secure™ has been designed to revolutionise door security and offers a seamless blend of smart technology and high-quality security credentials. It is compatible with any door handle fitted with a Kenrick 3 Star Locking Cylinder and can be retrofitted in a matter of minutes with no need for any major hardware modifications. This standout feature particularly impressed Silent View Windows. Rose Evlat, Marketing Executive at Silent View Windows, said. “One of the most exciting features of this smart lock is its ability to be retrofitted onto existing doors. This opens up a whole new market opportunity for homeowners who want to upgrade their security without replacing their entire door. It’s a game-changer in terms of added value, convenience and ease of installation.”

The AK Touch Secure™ operates using touch-sensitive technology, a secure keypad, encrypted key fob, or voice commands via Google Home or Alexa. There’s also a manual override option, meaning the door can always be opened with a key.

Using the AK Touch Secure™ app, users gain features such as remote locking and unlocking, a status check and access logs. They can also give temporary, timed access,

making it invaluable for Airbnb properties or where contractors need access to a building.

Andy Laird, Area Sales Manager at Kenricks, commented: “AK Touch Secure™ reflects our commitment to offering advanced hardware solutions that meet the evolving needs of today’s fast-moving market. We are delighted to have Silent View Windows on board and confident of the new opportunities it will deliver for the business.”

Founded in 2010, Silent View Windows has grown to become one of Oxfordshire’s and Buckinghamshire’s most respected names in window and door installation. The familyrun business based in Thame, specialises in PVC-U, aluminium and timber frames and work closely with homeowners, developers and builders.

Rose concluded: “As a business, we pride ourselves on being at the cutting edge of market trends. The introduction of AK Touch Secure™ will further enhance our commitment to delivering the highest standards of security and technology to our customers.”

As one of the UK’s most experienced and accommodating specialists in the art of steel and aluminium window refurbishment, Associated Steel Window Services (ASWS), makes use of multiple skills and strategies to ensure the fulfilment of clients’ ambitions. One such project was carried out within London Shoreditch’s ‘Tech City’ district where ASWS had to work outside of working hours to address some challenging problems affecting relatively modern W40 windows; and utilising their abseiling team.

The project came about after one of the capital’s leading property consultancies asked ASWS to conduct a full condition survey on the 1990s fenestration; with the detailed paperwork, drawings and proposed interventions providing the basis for the eventual tender documents. As is often the case with such demanding window repair projects, ASWS was subsequently invited to tender on the work by all four main contractors bidding. The technical challenges were further exacerbated by the pandemic restrictions ending before work started on site, which necessitated all the window repairs being carried out at times when the offices were empty of their computer-game designers. Furthermore, the very narrow pavements along one side of the sixtiesbuilt office block prevented scaffolding being erected and so ASWS had to bring in a team of abseilers, who also undertake glazing upgrade work, while its site engineers addressed the repair issues from within.

Managing Director at ASWS, Laura Mercer, explained: “When the W40 series windows were first introduced 30 years ago to offer improved energy performance and a more modern aesthetic, they were ‘gasket glazed’ similar to aluminium framed systems. Unfortunately, however, the in-situ installed W40 gaskets, back in the 80’sand 90’s were not vulcanised and tended to break

Owen Coop, CEO of leading independent hardware supplier Carl F Groupco, has sounded the alarm on using disclaimers to avoid installing trickle vents as a means of complying with Part F of Building Regulations.

Owen says: “A recent report from RISA, which inspects window and door installations for compliance with Building Regulations and FENSA requirements, notes instances of signed disclaimers being provided as a means of avoiding fitting trickle vents. But it’s very clear that these disclaimers are not valid. Installations will be non-compliant and installers put their businesses at real risk if they use them.” Owen cites guidance issued by the Ministry of Housing, Communities and Local

Government and the Department for Levelling Up, Housing and Communities when the regulations came into force.

“The guidance explicitly stated that disclaimers and indemnities would not cover installers. It said: ‘A disclaimer signed by the homeowner stating that they do not wish to have background ventilators or that they will be installed in future is not a suitable way of complying with the Building Regulations. Work must comply with the Building Regulations and competent person schemes must monitor their registrants and take action against any registrant who is found to have carried out non-compliant work. Purchasing an indemnity policy is also not a suitable alternative to meeting the requirements of the Building Regulations in full.’”

down quite quickly, which has required a complicated technique to replace them. What we do to mitigate the problem now is to top cap them both inside and out, which offers a far more effective and enduring seal. So, on this City project, the gaskets were actually hanging out of the frame and, therefore, offered almost no performance in terms of air leakage; and the draught excluder had also become brittle and failed. Our proposals were to carry out a ‘light touch’ service and overhaul of the various lights cleaning out the rebates and oiling the mechanisms. Not only were the draught excluders replaced with contemporary alternatives, the perished gaskets were removed and new top cap silicone fillets, which were RAL 9005 Black to match the old gaskets, inserted as a two-stage operation.” ASWS’s technique was to leave the 4-20-4 sealed units in-situ and remove the internal gasket replacing it with the top cap silicone sealant. Once that had dried, the procedure was repeated externally. In addition to replacing the half dozen glazing units which had failed, ASWS also undertook the repair of minor damage which had occurred to the powder coated ironmongery and replacement where necessary.

Despite ASWS’s interventions totalling some five months’ works, these weekends and other out-of-hours shifts were spread over a whole year, with the abseilers last to complete their weather dependent duties. Finally, to save the architects and other members of the project team having to undergo protracted training as abseilers, detailed photographs and reports were supplied of all the completed external window restoration work.

For more information on ASWS, please visit asws.co.uk.

The research from RISA finds that over a quarter of inspection failures are due to non-compliance with Document F, which suggests the regulations are taking a while to bed in.

Owen offers reassurance, saying: “Here at Carl F Groupco, we’re on hand to support our customers to ensure they comply with industry regulations. Our team is highly knowledgeable and experienced so we can offer all the guidance, input and advice that’s required.”

Alongside valuable technical expertise, the company also offers a comprehensive range of trickle vents. It includes the popular Glazpart Link Vent MK II, as well as options from Yale, RW Simon Ltd and Greenwood.

Carl F Groupco prides itself on being the hardware supplier that goes beyond order processing to solve problems, offer advice and find solutions. It’s an approach that’s evident in its offer to customers around compliance with Part F.

Tel: 01733 393 330

www.carlfgroupco.co.uk www.smartsecure.co.uk www.carlfdirect.co.uk

It’s that time of year with award ceremonies for BAFTAs, Oscars and the like, and it’s easy to forget how important those supporting acts are – not just the principals and stars of the show but those who make it happen.

In our industry we have the ‘stars’: the system houses, the fabricators, the glass companies plus machinery and hardware but what of those software companies, the ad agencies, PR companies and even, dare I say the trade papers and magazines? All part of that important industry support. But a significant and easily forgotten and unsung hero is surely the tooling companies? Without them nothing works. There’s no swapping of profiles for fabricators and no ongoing development of those profiles or launching of new ones. Step forward Jade, arguably the best supporting act! Unless you are aware of the need for tooling you are unlikely to have heard of Jade, but apart from being highly skilled engineers and toolmakers they are probably the best informed individuals in the industry. Regrettably for us journalists, Sean and Adam are also the most private and trustworthy individuals such that although they know of every change of supplier, who is moving to which profile and when it will happen, they remain tight-lipped and can, quite simply, keep a secret!

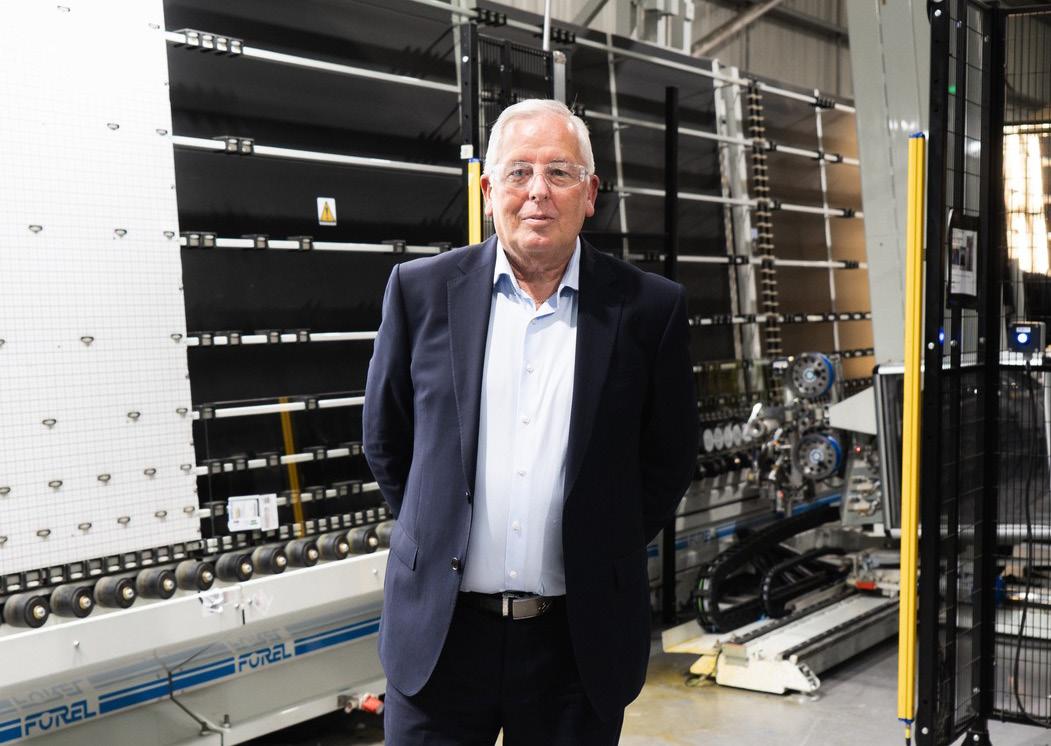

From my original visit to Jade, things have changed dramatically. Their original premises, just around the corner, was a small but highly productive engineering works. Now, approaching the new building, you are faced with an impressive façade with a vast Jade sign facing the approach road. It’s funny how things work out: the new premises which was, originally, three separate units and owned by different companies, allowed Jade to purchase one unit and then find that the other two could also be purchased, hence a large and impressive home for Jade. Now the renovation and refurbishment are complete providing an impressive 30,000 sq ft facility in Coventry and is the culmination of a £4 million investment plan that positions the company for significant year on year growth both in the UK and into the wider world.

Adam Jones and Sean Mackey are down to earth and very realistic individuals. Yes, they are hugely talented with Adam’s design skills and Sean’s background in accounting, but they realised for the company to grow they needed to

move beyond the ‘owner managed’ business and introduce a polished and professional structure to the company. To their credit they recognised the need to bring in a Managing Director to take the business forward – not an easy thing to do when you have had nearly two decades of running the show yourselves. Finding the right person to join the team turned out to be remarkably easy with Gareth Davies being known to Adam and Sean through a business club they have been involved with. Gareth has all the knowledge and expertise required to take Jade to its next stage of development and beyond.

“For nearly two decades we have had an amazing time working with everyone from the major systems houses to many smaller independent fabricators, solving manufacturing problems and helping them achieve greater efficiencies and improved product quality. But it was clear to us that operationally we needed to make some major adjustments if

“Every aspect of the manufacturing process requires a subtly different approach, from designing and developing the tooling, to integrating different processes, storage and maintenance.”

we wanted to continue with that good faith and those strong relationships in the future,” commented Sean Mackey. “And while investment in the new facilities has given us the physical ability to grow, there has also been massive operational restructuring going on behind the scenes.”

Gareth has been instrumental in that restructuring and it is clear that, in only a year, the relationship between the three main players is comfortable and productive giving Adam and Sean the time to do what they do so well and to develop and grow the customer base. Although Jade is so well known in the industry the team are keen to show their abilities to a wider audience and that may well include looking at opportunities overseas. Back in 2017 Jade made some significant acquisitions including Saltech Machines Ltd, Edgwick Sheet Metals and 50% of Kombimatec which widened their scope.

“Jade faced a choice – it had carved out a comfortable groove for itself in the industry where it could happily coast along, but probably end up losing market share,” added Gareth Davies. “However, I could sense that both Sean and Adam had the hunger and the ambition to continue growing, and the market itself still had massive opportunities that could be enjoyed by reframing the way in which the company organised itself. The skills and the expertise were there – Jade just needed to refine its messaging.”

A large part of that messaging has been to move away from the ‘engineering’ focus of Jade and highlight the key solutions that they bring to manufacturers. This formed the basis of its initial rebrand a couple of years ago, when it clarified key service areas through separate divisions –JadeTooling, JadeMachines and JadeConsult. The company is now launching a fourth ‘division’ – JadeBespoke – a sheet metal fabrication solution which specifically creates ancillary products such as racking and assembly benches for window manufacturers.

“Every aspect of the manufacturing process requires a subtly different approach, from designing and developing the tooling, to integrating different processes, storage

and maintenance. It was important to create a framework which gave us, and our customers, the clarity to see where challenges might lie and solutions found,” continued Adam Jones. “We now have a clear-cut route for manufacturers to take, from the moment the profile comes through the door, and the finished product leaves it.”

Sean and Adam were particularly cognisant of the fact that Jade had been built on strong personal relationships, and that could potentially leave Jade, and its customers, vulnerable.

“While we have every intention of continuing to be the ‘face’ of the business – and indeed there are so many people out there we consider close personal friends – establishing systems that could run without us was a crucial element of futureproofing for both Jade and our customer base,” said Sean Mackey. “In the very unlikely event that we won the Euromillions and decided to see out our days on a tropical beach somewhere, we wanted to make sure our customers would not notice our absence! The reality is, though, that

this investment has freed up our time. So our customers will probably be seeing even more of us.”

It seems a long time since 2007 when Adam and Sean acquired J Tools and eventually bought Jade Engineering in 2014, developing a successful and important business that has served the PVCu and Aluminium industry so well. Nudging their way into their 50s what do they do? Enjoy the fruits of their labour or take the business even further? Recognising that need to change the company from being known as a purely engineering business to take it forward was key. They had always been more than engineers and the design engineering and consultancy side needed to be formalised as an integral part of the business. They have worked with many system houses and fabricators to find solutions to a problem and then developing the tools to bring the vision to fruition, hence Jade Consult. Basically, Jade Consult can engineer the problems away and the design team is already growing apace with 6 individuals in the team and…..wait for it….Jade are looking for staff! Now that’s a

real opportunity for budding design engineers to join a very successful company that is looking to double its turnover in the next three years.

Seeing what they have done with their new premises and listening to them describing their vision for the future, there is little doubt that Jade will continue to succeed. With Gareth joining them, Adam and Sean have been released to do what they do so well, talking to customers about problems and developing and building solutions.

Jade certainly gets my vote for being the industry’s best supporting act!

The Student Learning Centre at the Royal Veterinary College’s Hawkshead Campus is the largest single capital development project in the institution’s history.

Designed by NORR, the project comprises teaching labs, a library, a main lecture theatre, communal areas, and informal social learning spaces.

A range of Metal Technology’s high-performance, architectural glazing products were expertly installed by fabricator Duplus Architectural Systems, to help meet the development’s stringent energy efficient standards. The project was dual colour white powder coat inside and bronze anodised externally.

SYSTEMS INSTALLED WERE:

• System 17 Capped Curtain Walling

• System 4-35 Thermal Casement Window

• System 5-35 Thermal Tilt & Turn Window

• System 23 Louvres