GEOSYNTHETICS

Landfill containment: cost-effective longterm solutions

Arguably one of the most critical and farreaching infrastructure decisions, secondar y only to the selection and preparation of the landfill site, is the choice of liner and capping system to be put in place.

M

odern landfill best practice favours geomembranes as ef fective, durable barriers against liquid and gas leaching. To assure landfill owners and operators of a continuous, enduring seal across the entire area of the site, polyethylene geomembranes such as AKS Geoliner are specified as both lining and capping solutions.

It’s tough in a landfill Because of the demanding, often aggressive and hazardous environments of landfills, the installed lining should comply with various manufacturing standards and pass numerous pre-installation and in situ tests to ensure it will withstand a lifetime of harsh surroundings. Factors considered when designing and manufacturing AKS Geoliner include the on-site physical stresses likely to be encountered, the types of waste material, the expected depth of fill, the compaction methods envisaged, and the geophysical characteristics of the site. Making allowances for these factors determines the type of resin used, the thickness, and the asperity height of textured or smooth geomembranes.

Testing, testing, testing In AKS’s state-of-the-art laboratory, the company follows strict testing protocols, adhering to and usually exceeding international standards. For example, the US Geosynthetic Research Institute’s GRI – GM13 Standard Specification requires 10 checks for thickness control, while AKS performs as many as 36 checks in 36 zones. In fact, all Geoliner produced by AKS meets or exceeds international standards such as GRI-GM13 (HDPE), GRI-GM17 (LLDPE) and the local SANS 1526. Testing during production is done as a matter of course; continued pinhole detection is applied across the entire width of the sheet. For added peace

Geosynthetics

of mind, AKS invites customers to a plant visit to familiarise themselves with the integrity and quality standards at work in the company’s modern, easily accessible plant in Brackenfell.

Longevity Along with its excellent impermeability, AKS Geoliner is characterised by its exceptional durability, high chemical resistance, UV protection and superior weldability.

Karlo Wentzel, Sales Manager: Geomembranes, AKS

Easy installation

Traceability

The material’s excellent tensile properties and high elongation characteristics combined with flexibility make for a tough barrier that is highly resistant to tearing and puncturing. At the same time, AKS Geoliner is flexible enough to allow for ease of installation without compromising its integrity.

An inline marking system ensures on-site quality control and traceability. Instead of relying on a mere sticker or label to identify the brand and batch, a line indicating the wedge weld overlap width – 150 mm from the edge – is printed every linear metre together with the roll number. The number is linked to the AKS quality control system and provides manufacturing information such as the resin used, the master batch, the responsible operator and the MQC certification details. In large installations, the number is entered in a panel layout to provide a record of every square metre of lining used on the site.

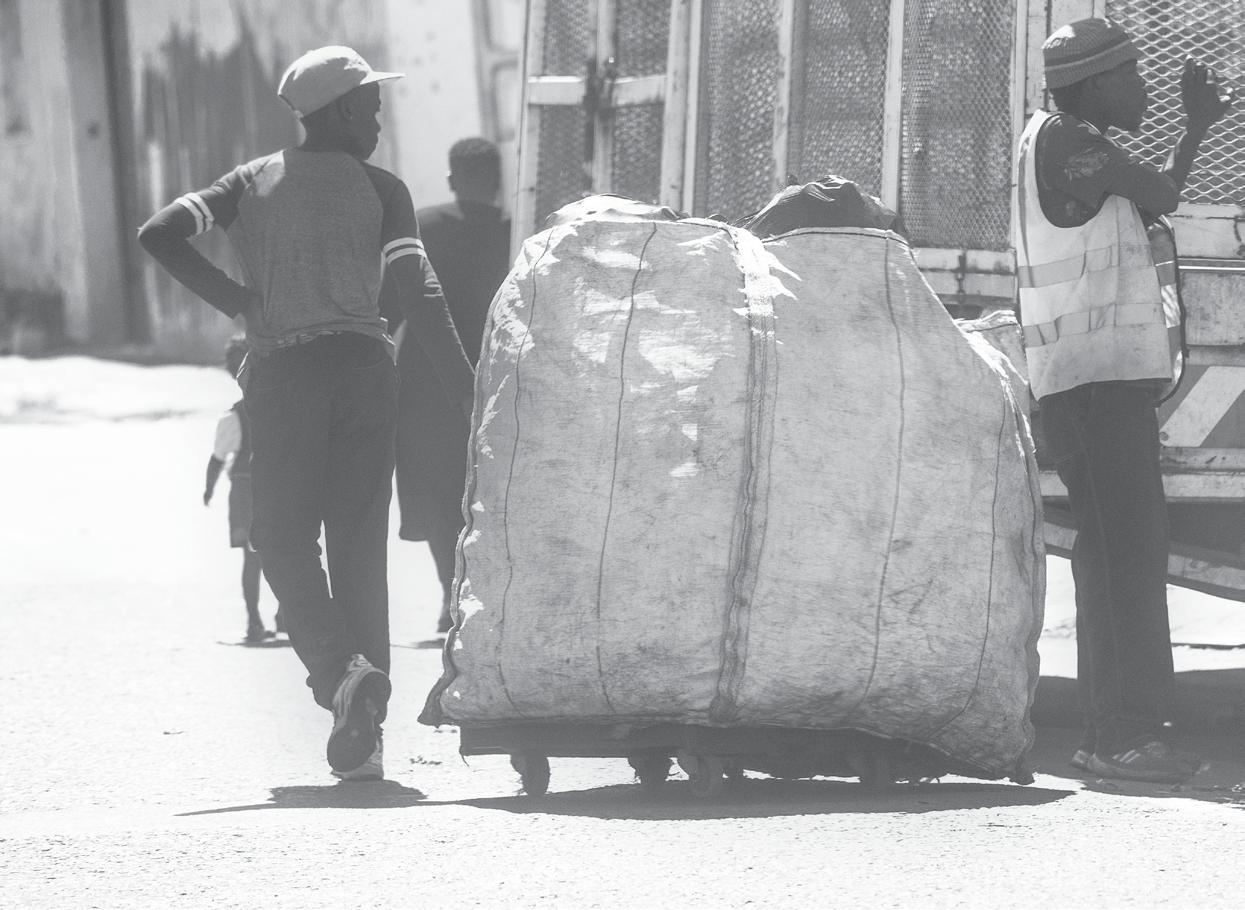

Options Geoliner is manufactured using the calendered ‘flat-die’ extrusion process, in 7 m widths, with thickness ranging from 1 mm to 3 mm. It is available in HDPE and LLDPE, with a smooth or textured finish, or a combination of smooth and textured, either on one or both sides of the sheet. AKS Megatextured Geoliner, offering a more enhanced textured surface, is available in HDPE or LLDPE with either single- or double-side texturing options. To ensure a consistent product with the highest level of accuracy, AKS liners are manufactured using European-made precision extruders. Geoliner can be custom-made to suit specific project requirements, taking into account installation needs, roll lengths, and truck and container loading configurations. When it comes to handling – to facilitate off-loading and moving the product on-site – each roll is fitted with two lifting slings.

Availability AKS Geoliner is manufactured at the company’s modern plant based in Brackenfell, Cape Town. A large yard with ample storage provides the shortest possible lead times to customers. For further information, please email info@aks.co.za or call +27 (0)21 983 2700.

www.aks.co.za M AY 2 0 2 0

|

ReSource

23