The Parker Hannifin Pump Motor Division plant at 2745 Snapps Ferry Road marked 50 years of operation in Greene Coun ty this year.

The plant originally opened in 1972 as TRW Ross Gear Division. Parker Hannifin bought the plant in 1993 and the company has continued to operate the Greene County plant since then.

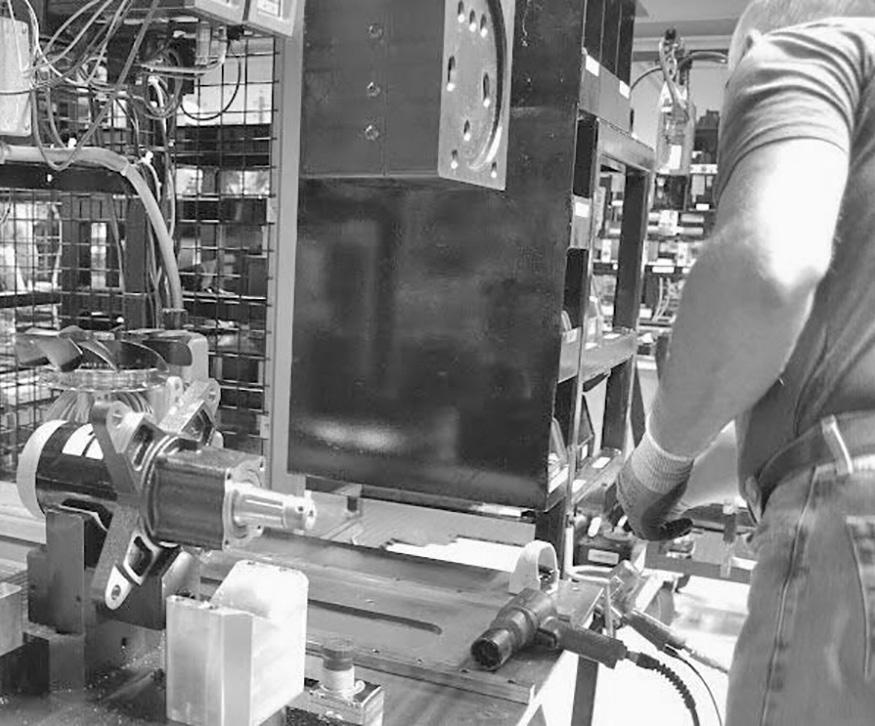

The Greeneville plant manufactures hydraulic, low-speed, high-torque motors and hydrostatic pumps and transmissions.

According to Parker Hannifin’s website, Arthur L. Parker founded the Parker Appliance Compa ny in 1917 in Cleveland, Ohio, along with his busi ness partner, Carl Klamm.

In its early days, the company built pneumatic brake systems for trucks, trains, buses and indus trial machinery, as well as leak-free fittings for avia tion pioneers. The compa ny now spans the globe.

The company endures in Greene County, and Jared Adams, the business unit manager of the Greene County plant, plans to keep it that way.

“We are going to keep investing in this facility and in Greene County for the future,” Adams said.

Adams worked in Green eville’s Parker Hannifin plant from 2014 to 2018 before he was moved to another division. How ever, he returned to the Greeneville plant in late 2020.

Throughout the years, the local plant has evolved in its production. Starting in motors and steering be fore getting into light duty hydrostatic pumps in the early 2000s, according to Adams. The plant then be gan manufacturing its first generation of hydrostatic transmissions in 2008 and its second generation of transmissions in 2010 for large-frame machinery. In 2015, the plant introduced transmissions for smallframe machinery, as well. Most of the products

“If a professional buys a zero-turn mower you’re going to have a Parker pump transmission in it,” Adams said.

However, Parker Han nifin products from the Greeneville plant can also be found in winches, booms, brush chippers and skid steers.

The Greeneville plant puts out close to 1 million finished units per year, according to Adams, while also sending some parts to other assembly centers. However, Adams said that over 80% of products produced in Greeneville are finished assemblies put together from start to finish.

“It’s really humming a bit right now. In the past it has been somewhat seasonal because of being tied so closely to the turf industry. With how we have diversified now, the busy season is all year long now. We are looking at an all-time record this year in terms of output,” Adams said.

To make that mil

lion-product output happen, Parker Hannifin employs just shy of 600 people in Greene County.

“We have hired over 60 people just in the last cou ple months,” Adams said.

The plant has about 50 open positions currently. Often, employees are hired as seasonal or temporary workers before they are converted over for full time work at the plant. Over the next several months, Adams said that the plant will be looking to add over 100 new employ ees incrementally.

Parker Hannifin prod ucts manufactured in Greeneville are shipped to every corner of the world, Adams said.

To Adams, the plant rep resents the importance of American manufacturing.

“This facility represents United States manufactur ing. Everything is sourced here domestically, and the manufacturing is all here. Whether it is forging, heat treating, or final grind and paint and pack.

Everything is done here in Greeneville, and that is rare to find,” Adams said.

“Companies that have supply chains that reach

across the world haven’t fared as well as we have. We are doubling down on it here in Greeneville with capital investment and job growth. Overall, this is one of the rare facilities that will do it all. It represents Made in the USA better than 90% of the facilities you’ll find.”

As for what the future holds, Adams said that Parker Hannifin will continue to innovate and manufacture at the Green eville plant.

“We have different process that are integral to this facility, and we are going to keep investing in those and this facility. We are going to start making components we haven’t made before due to supply chain issues, and we are going to continue do that given what is going on in the current environment,” Adams said. “Electrifica tion is also going to be a priority. You will see that in automobiles before you see that in skid steers or small construction and turf business, but it is coming. We will maybe be making a new product here in Greeneville.”

When it comes to the

longevity of the plant’s operation in Greeneville, Adams credits the people of Greeneville who work at the plant, and the quality of product that is pro duced at the plant.

“It is the people and the work ethic here in the region and in Greeneville. What sets this plant away from the rest is its ver tical integration and the capabilities we have, and the dedication from the people here that helps us be successful. Even through the pandemic

and everything that came along with that, everybody has come together to work through those challenges. We are looking at growing jobs here in Greeneville. That is the goal here,” Adams said. “The second part is the products. Our engineering and perfor mance is the cream of the crop of low speed, high torque motors. You won’t find a better product in the world. That’s why we have been here for 50 years and that’s why will still be here into the future.”

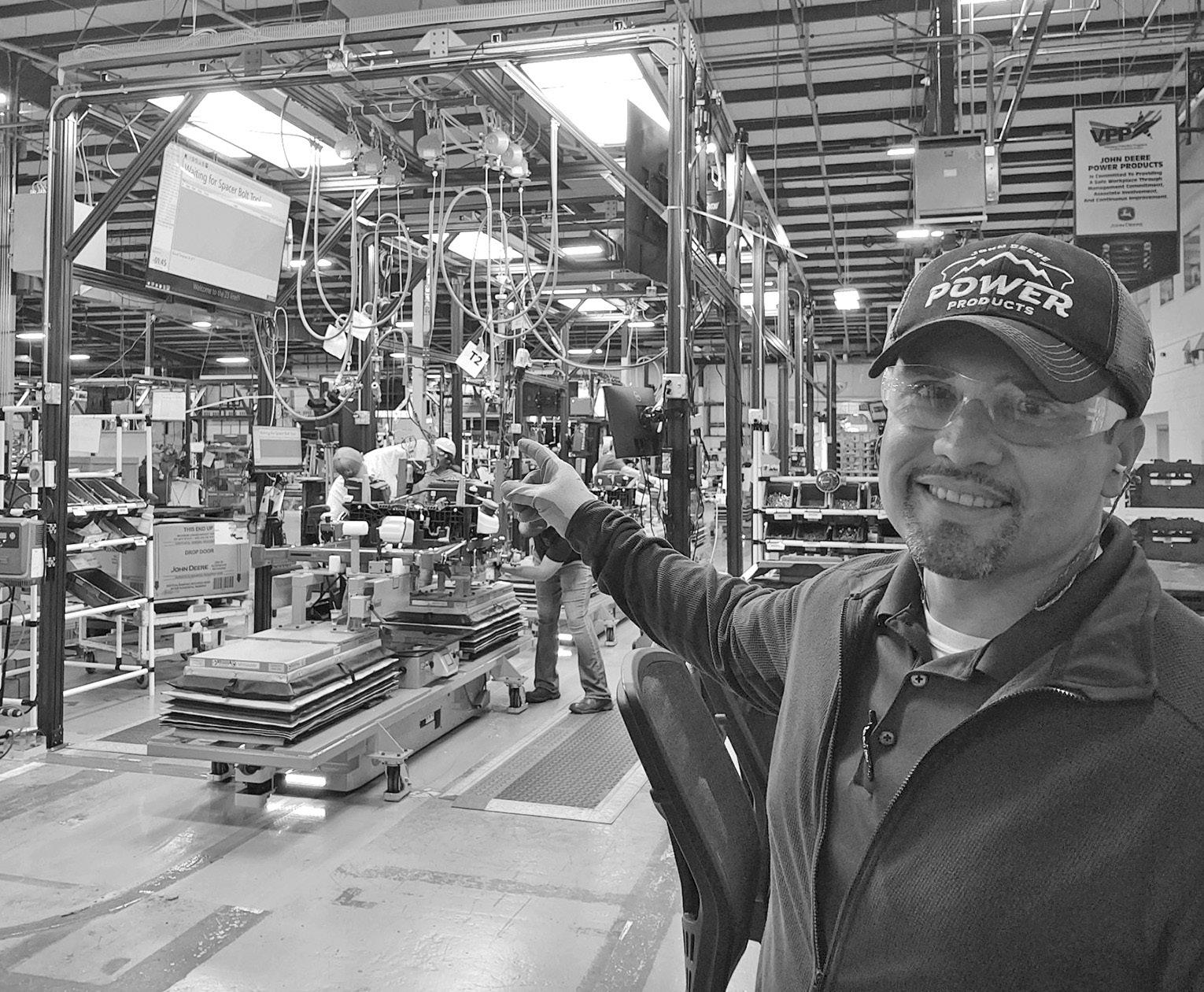

If you own a John Deere riding lawnmower, chances are it was manufactured right here in Greene Coun ty.

Since 1988, the company has been building lawn equipment at its John Deere Power Products (JDPP) facility in Greeneville.

From the early days of manufacturing walk-behind mowers to now building some of the most advanced zero-turn riding lawn equipment in the indus try, the facility has grown and changed a lot over the years, according to back ground provided by the company.

On Oct. 3, a new assembly line for larger zero-turn mowers started full pro duction at the Greeneville plant. The line is the fourth at the local plant and adds a total of about 100 new employees, 50 per shift.

Andrew Schlesing, em ployee services manager, said the factory was a sort of “grand experiment” when it began because it was one of the first to build John Deere products away from the company’s headquar ters and historic roots in Moline, Illinois.

“We wanted to be closer to our customer base for riding lawn equipment,” Schlesing said. “Grass grow ing conditions and U.S. population density mean we see higher mower sales in the southeast, so building a factory here in Greeneville meant lower transportation costs for product delivery.”

Fabio Castro, factory manager at John Deere Power Products, said that while JDPP’s proximity to John Deere customers has been critical to the factory’s success, even more import ant is the great team they’ve built. The factory employs close to 1,000 people.

“The bedrock of the organization is a culture of teamwork, employee recognition, continuous improvement, and opera tional excellence,” Castro said. “Our products have

changed over the years, but those fundamentals remain the same, and are essential to the future of the busi ness.”

When JDPP first opened, John Deere built walk-be hind mowers at the facility, later transitioning to riding lawn equipment under the names Sabre and Scotts. Both were sold by John Deere dealers and The Home Depot, later adding Lowe’s, Schlesing said.

In 2003, the factory began manufacturing John Deere-branded mowers, which soon after became recognized as a Consumer

Reports “Best Buy,” leading the industry in quality and customer satisfaction, Schlesing said.

“That product growth was accompanied by facility expansion from the initial 50,000 square feet to over 500,000 square feet today,” he said.

Schlesing said many people don’t realize that all John Deere riding lawn mowers, including those sold outside the U.S., are manufactured either at the Greeneville facility or at another Deere plant in Horicon, Wisconsin.

In 2014, the factory began

building zero-turn mowers, a rapidly growing sector of the riding lawn equipment industry, Schlesing ex plained.

“With the zero-turn we had considerable market growth,” Schlesing said, “and in 2018 we reconfig ured the factory to capital ize on the opportunities we saw. The demand for larger, more capable machines in the residential space even tually gave birth to the new Z500 series of zero-turns.”

John Deere has long been a pioneer in safety, Castro said, developing the first commercially available

rollover protection sys tem (ROPS) on tractors, then promptly donating all the patent rights and

make the world amor e thoughtful & caring place every.single.

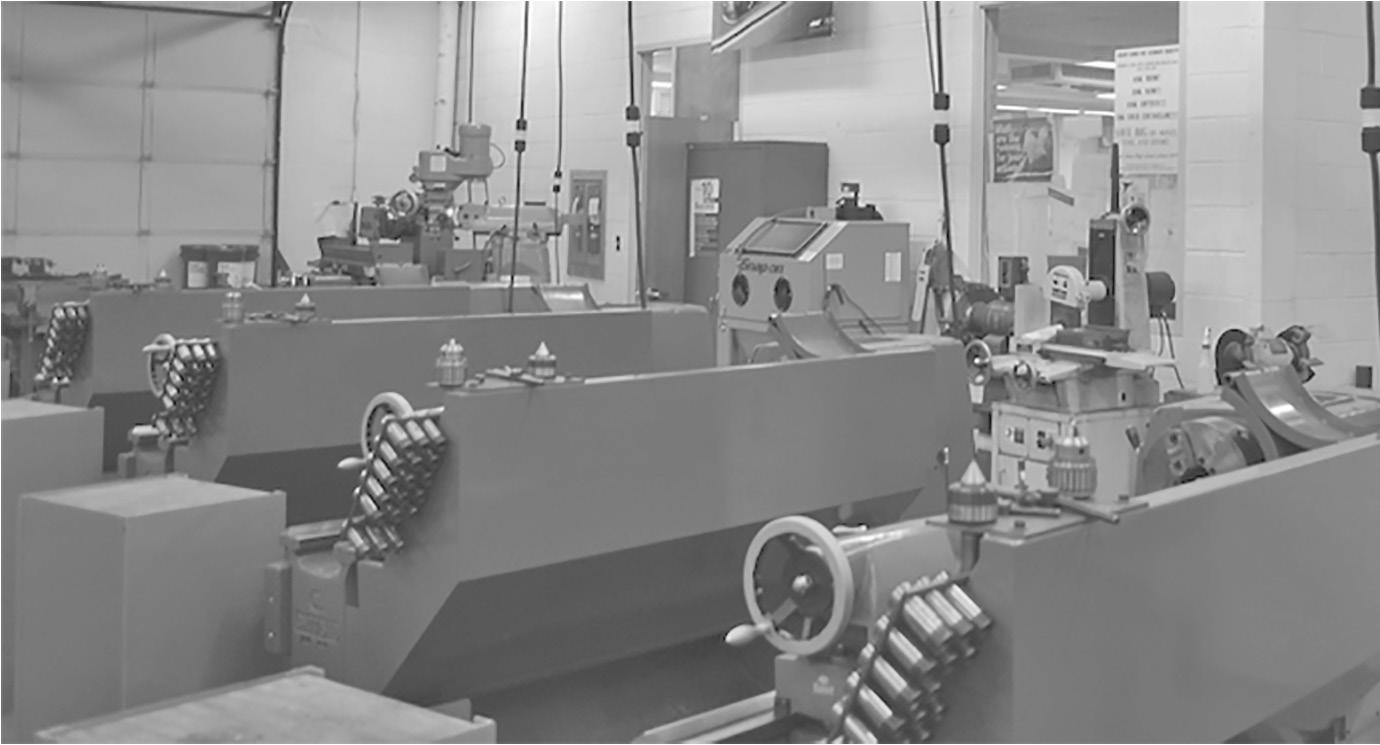

Twenty-four hours a day, seven days a week, the Swiss Screw and CNC lathe machines at Precision Turn ing Specialties spin, drill and mill to produce metic ulously crafted parts for a wide range of industries.

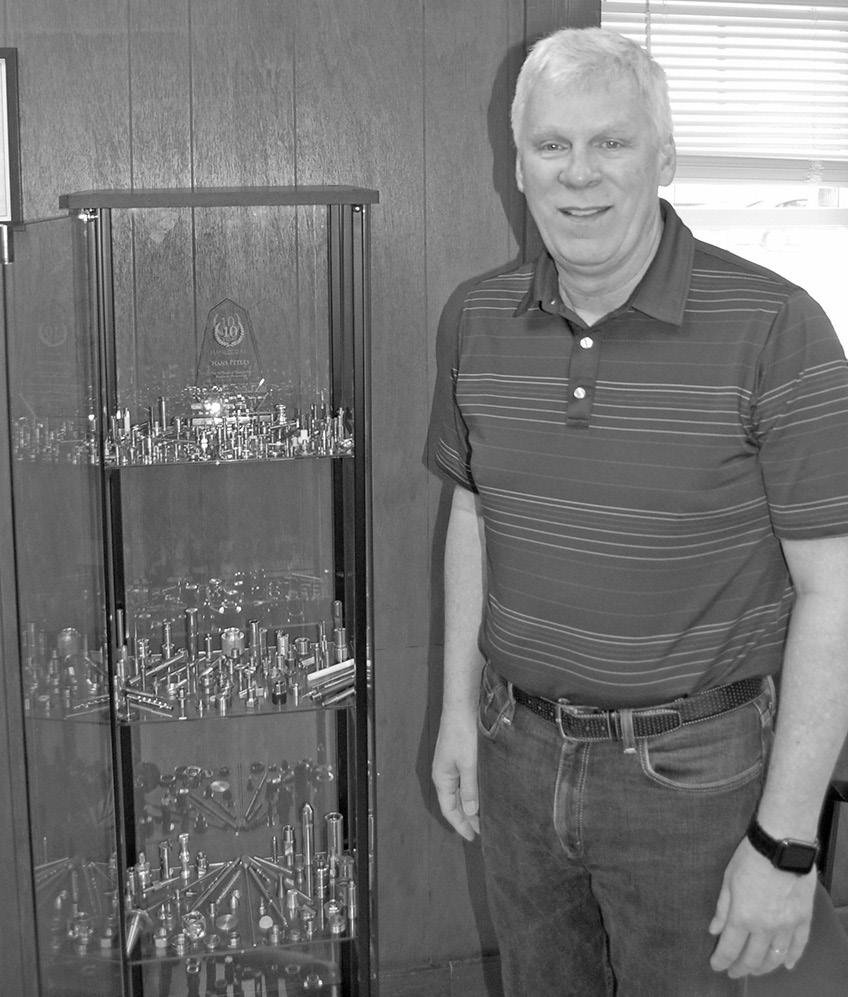

The family operated manufacturing company, at 906 W Irish St., has been in located in Greeneville since its inception. Owner and operator Hans Peters bought the company in 2009.

According to its website the manufacturing com pany helps to produce parts for industries such as “aerospace, agriculture, automotive, defense, dental, electrical, electronic, food service, firearms, hydrau lics, medical, paintball, racing and more.”

Originally from Dela ware, Peters bought M & M Specialties (the company’s original name) from Kermit and Mike Monk in Novem ber 2009. His son Garrett Peters, who is one of three Peters sons working at Pre cision Turning Specialties, said the name change better reflects what they do and helps potential customers find their business.

The Peterses value the local operation of their business. Garrett spoke about how meaningful it was to have the business as a family operation.

“It feels good to build something that is a part of the family,” Garrett said.

Hans spoke about how he didn’t set out for Tennessee specifically when he was searching for companies, but that he is glad Preci sion Turning is located in Greeneville.

“It’s a great place,” Hans said.

If what goes into operat ing a parts manufacturing company may seem like a complex business, well, it is. Employees at Precision Turning, from technical ma chinists to quality manag ers, are well trained in their part of the process.

Alex Myers, programmer and machinist, has been at the company for 17 years. He started out sweeping the floors in the afternoon while attending Northeast State Community College. He has transitioned into more of a veteran role at Precision and helps newer employees learn the machines. Just a few weeks ago, as Precision Turning was getting a new parts production machine, Myers was showing Ben Douphat how to program and assemble components for new the machine.

“As my skill set grew, so did my ability to help other people. I just sort of worked my way into an entry level machinist position,” Myers

said, “It just kind of grew from there. When my programming skills grew, I started quoting parts and taking on more challenging work.”

Hans Peters said he came from more of a business rather than machinist back ground. So during the first years of Peters owning the company, he said, he leaned on the machinists and gave them more autonomy for growth in their skills and role within various ma chine-driven processes at the business.

“Alex took that oppor tunity and ran with it. He handles all aspects of the work,” Peters said.

Myers said the best part of the job is how it is differ ent every day. He embraces the complexity of the many roles he works in during the day.

“That’s why I’ve been here for so long. We make hundreds of thousands of different parts every year,” Myers said. “It’s always challenging, even after 17 years; it’s something new to do every day.”

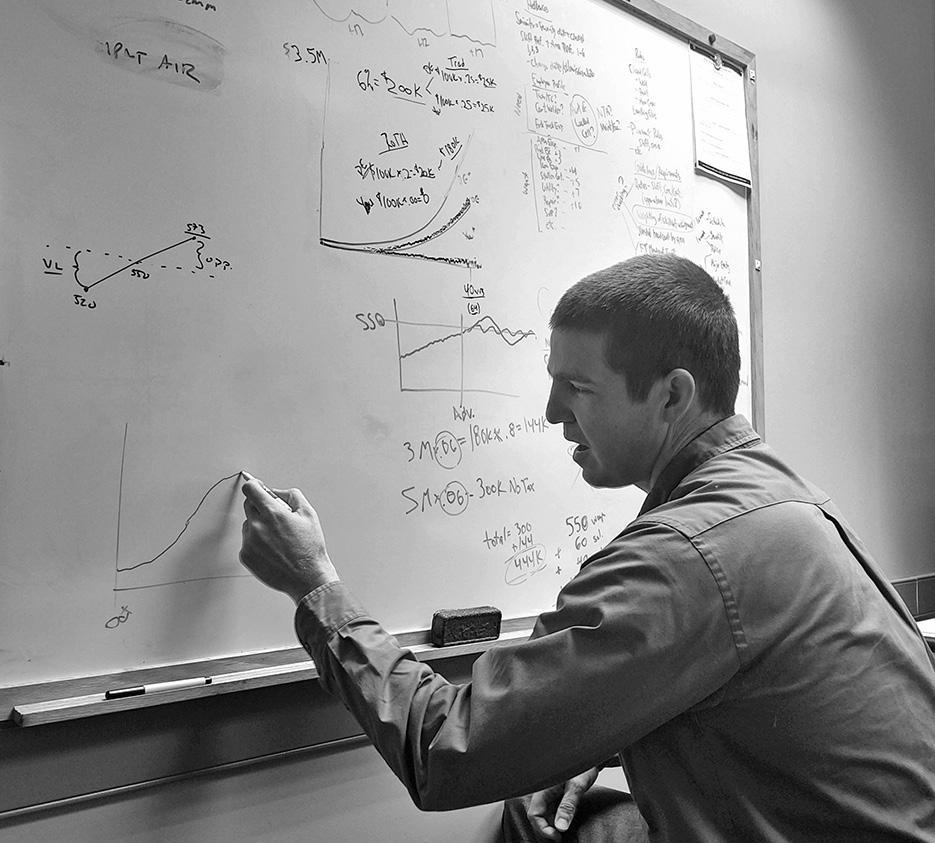

The programming Myers is referring to is the pro gram needed to set up on a CNC machine in order to accurately produce the parts given the designs from customers. The most common form of program ming for CNC machines is G-Code. A simple explana tion of this complex system is that the program creates paths for the tool within the machine to carve away at blocks of raw metal.

The process starts with a design that customers bring to Precision Turning. The customers send prints to the business and describe

“The Z500 with ROPS led the industry in making the safety system standard equipment in this large residential use case,” Cas tro said.

Customer adoption of John Deere zero-turns continues to grow, to the point that JDPP launched a new manufacturing line this month for the Z500.

“We’re very proud to be launching a new techno logically advanced assem bly line solely dedicated to the production of Z500 machines,” Castro said.

In June 2020, John Deere announced a new operating model and strategy to accelerate the company’s success in the integration of smart technological innovations, Castro said.

This new model launch has been a success, despite higher costs that came with supply chain issues related to the pandemic of recent years. The secrets to that success, according to Castro and Schlesing, are

the

On the other hand, the pandemic-related lockdown resulted in more home improvement

what parts they are looking for and for what operation. The next step is acquiring the materials. Precision Turning fulfills the orders by purchasing materials. Though, with global supply chain issues, this has prov en a bit of a strain.

“You used to be able to buy materials one day and get it the next, but with supply chain issues, we are having to buy material well in advance,” Peters said.

Garrett Peters explains the next part of the process after acquiring the materi als: “We start with a round bar stock and then we feed that into our machine, and the machine has different tools and operations, and

they are able to make the parts that we see that have high precision and tight tolerances.”

The machines are programmed to design a part with the material the customer has chosen. Each part is examined by machinists and other oper ators. They ensure the parts meet the required specifi cations. The parts are of a high industry standard.

As of April 2022, Pre cision Turning obtained a certification through an American National Stan dards Institute-National Accredited Board registrar. This means the company’s quality management system meets requirements within

the international standard.

According to an email from quality manager Michael Owens, the purpose of Precision Turning’s quality management system is to “document the company’s business practices, ensure the expectations of its customers are consistently met, and it provides the framework to continuously improve the company’s overall performance to ensure sustainable profit ability and growth.”

Each step of the process is examined for quality, as well as the parts them selves, to uphold the inter national standard for parts manufacturing. One of the last steps of the process is

After the parts are pro duced, there may be some left over material the ma chine did not use to make the parts, these are called “remnants.” Precision Turning sells this raw metal material to East Tennessee Iron & Metals, which comes once a week to pick up.

projects,

Over the time Hans Peters has owned the company, he said that about 80% of the customers from the original owners have stayed in partnership and that the company has added many more new customers.

Peters said Precision Turning is producing four to five times more than it did back in 2009. In fact, he said the company is “financially very stable.”

As of the beginning of October, Precision Turning is breaking ground on a new 6,000-square-foot addition for manufacturing. The company is adding two new machines this year, and added three new machines last year.

Looking to the future, Peters said that he hopes Precision Turning will continue to grow and that it will continue to be family operated.

More information can be found at www. precisionturning.com or by calling 423638-1410.

Timeless Fence Sys tem is one of the smaller manufacturers in Greene County, but they have seen tremendous growth in the past couple of years.

Located on Wilson Hill Road near the Greeneville Municipal Airport, the 11-year-old company spe cializes in making unique fenceposts from recycled polyvinyl chloride (PVC) scraps.

“We use mostly recycled materials to manufacture this product which otherwise would end up in landfills,” said Lissa Morrison, director of marketing. “The prod uct we produce solves real problems for farmers and ranchers around the world.”

Morrison explained that the Timeless Fence prod uct starts as PVC scraps from windows and doors and goes through a melting and shaping process at the local facility.

The end product is a flexible but sturdy, weath er-resistant fencepost available in three sizes that come with a 20-year warranty.

The posts do not rust or rot like steel or wooden posts, and if damaged, they bend back into their origi nal shape, Morrison said.

It’s a product that no other company in the world provides, she said.

Timeless Fence does much more than manufac ture fenceposts.

They sell all the mate rials needed to build an electric or barbed wire fence. They also offer knowledgeable assistance with pricing and building fences.

“People just love the fact that they can contact us and we can help them from start to finish,” Morrison said.

Timeless Fence partners with resellers throughout the United States, most of whom are farmers look ing to supplement their income.

They have 230 resellers in all and six other coun tries. The nearest reseller is located in Rogersville.

In Greene County, the company has a full setup of fencing for landown ers to view, along with a greenhouse, hoop house, and numerous raised bed gardens.

This area is used for educational opportunities to help landowners find more efficient and effective ways of raising animals and growing food without the use of many harmful chemical inputs, Morrison said.

Timeless Fence partners with the USA Regenerative Agricultural Alliance, Inc., and the corporate offices for both are located in the Greene County facility.

The goal of the nonprofit Alliance, according to its website, “is to educate and empower every individ ual to embrace a holistic regenerative approach to managing land and animals in ways that result in far-reaching positive im pacts on themselves, their families, their communi ties, and the environment.”

The manufacturing facility is careful to recycle the cardboard, paper and wooden pallets it uses, Morrison said.

Timeless Fence began in 2011 with one production line and recently added a third line.

Demand grew through the pandemic, Morrison said, because more people started focusing on home steading as a way of life.

Another recent increase in demand comes from YouTube users who share videos about their success with using the products, she added.

Timeless Fence’s local workforce includes approx imately 25 employees.

The company owner is Russ Israel, and the Chief Operating Officer and General Manager is Brad Moore.

For more information on Timeless Fence System, visit www.timelessfenc esystem.com .

For more information on the alliance, visit www. usaregenalliance.org .

We salute our local industries for their outstanding contributions, exceptional performance and continued dedicated commitment to Greeneville and Greene CountyPHOTO SPECIAL TO THE SUN Timeless Fence System operates three product lines for manufacturing unique fenceposts. SUN PHOTO BY AMY ROSE Timeless Fence System fenceposts are made from PVC scraps from doors and windows. PHOTO SPECIAL TO THE SUN A Timeless Fence System is shown standing after surviving a fallen tree. PHOTO SPECIAL TO THE SUN This aerial photo shows the Timeless Fence System headquarters in Greene County. SUN PHOTO BY AMY ROSE Longtime employee Jesus Davila is shown at the Timeless Fence System facility. SUN PHOTO BY AMY ROSE A unique process is used to manufacture the fenceposts of Timeless Fence System.

Since its origins in the early 1990s, the Greene County-based 411 Indus tries, LLC, has dramatically grown and evolved into a company with two manu facturing facilities and three businesses.

The name “411” was derived from company’s original location on the Old Newport Highway, where operations first began as a tobacco greenhouse.

In the mid-1990s, thanks to a partnership with Meco Corporation, the com pany found itself with a completely new mission: product packaging and assembly.

By 1997, the business had switched its focus entirely to subassembly and sub contracting work for other area companies around the region.

In April 2018, 411 In dustries received its ISO 9001 certification, which ensured its customers that the company was adhering to a documented quality management system and guidelines. It was this quality assurance certifica tion that paved the way for further growth and custom ers for the company.

Today, 411 Industries is comprised of manufactur ing facilities at 1301 Old Newport Highway (Plant 1), and at the Mt. Pleasant Industrial Park at 310 T. Elmer Cox Drive (Plant 2).

There is also a location at 407 Bohannon Ave. In ad dition to assembly, 411 now has divisions for employee placement as well as ship ping, receiving and storage of products.

411 Services is a “contin gent workforce placement company,” and 411 Ware house handles “inbound and outbound shipments,

storage and some logis tics for multiple sites,” according to the 411’s Vice President of Business Oper ations Brian Hixson. Both divisions are located in the Mt. Pleasant Industrial Park within the Tevet building.

Hixson refers to the three 411 entities as a “one-stop shop” for area companies and their operational needs.

“We hire people, make

products, store products, and ship products,” Hixson said.

“As a contract manu facturing company, we partner with several local companies, ranging from Morristown, Greeneville, Newport and Elizabethton,” he continued.

“Our organization is equipped with our own box trucks, and we have

transportation partners for larger loads that can handle all transporting needs to and from your location,” he added.

Hixson noted that 411 also has “multiple sites for both the warehousing and the manufacturing loca tions, which makes us an ideal partner for many com panies in terms for logistics and operations.”

He said, “We offer three phase power, air, etc., so moving operational equipment to our facility and making products is one of many specialties. If pre ferred, we also specialize in kitting products, shipping orders for clients, ware housing and storage, etc.”

“We are an ISO 9001 cer tified company and working toward an ISO 13485 certifi

cation,” he said. “411 In dustries is wanting to build new lasting partnerships. We have brought manufac turing lines in from Ohio, New York, and several from Tennessee.

“In addition, we do many subassembly and kitting jobs. We feel we can be a one-stop shop for any

BY MARIO MICALLEF STAFF WRITER

BY MARIO MICALLEF STAFF WRITER

The Greene Technology Center is more than just a center for technology, it’s a center with resources and industry-level instruction capable of shaping the ca reer paths of Greene County students.

Located at 1121 Hal Henard Road, GTC is a

satellite campus for the Tennessee College of Ap plied Technology.

GTC provides classes in machine tool technology, industrial electricity, weld ing, health science/nursing, emergency medical services, culinary arts, cosmetolo gy, computer technology, criminal justice, automotive service and even aviation flight.

The Greene Technology Center continued its strong partnership with local industry during the week of Oct. 7-14 as it hosted Crenlo technologies as the school’s featured employer for advanced manufactur ing month. Representatives from Crenlo were at the GTC open house which took place on Oct. 6. The technical school

hosts Greene County and Greeneville City high school students from grades nine through 12.

Freshmen high school students attend classes at the center in the morning and gain experience in sev eral entry level practicums. Once they gain experience in the first level classes and choose a field they want to pursue, they enroll in the

higher level classes for the rest of their time in high school.

Greene Technology Center Assistant Principal Kim Cook gave a tour of the advanced manufacturing classrooms during the open house.

The first stop was with Elliot Gefellers, who is the machine tool technology instructor at GTC. Gefellers

has industry level certifi cations that help prepare students to launch into the work force. Students get to use high-end indus try-grade machines that carve out parts or molds from raw metals.

The example he gave for what goes on in the ma chine technology class was

client. We can move manu facturing equipment to our facility (we have 3 phase power and equipment), manufacture and store the products, and assist with shipping if needed, etc.,” Hixson continued.

The company current ly employs around 300 workers across its three divisions, Hixson noted. He lauded the 411 work family

and attributed the compa ny’s continued success to them.

“We have a very talented group that works well as a team,” Hixson said.

At some of the locations, he noted that the company offers flexible work sched ules to help support em ployees with certain family and childcare needs.

“Our commitment is to our partners, our commu nity, and our work family,” the company’s website states. “When you decide

on 411, you elect to build a partnership. 411 industries will work diligently to meet and exceed your expec tations and ship quality product on time.”

Hixson also added, “411 is a business built on faith. We believe that God has moved and worked in our business and we give him the glory for helping us grow. We not only pray for our business, but we also pray for the people and their families within our four walls. “

For the past 50 years, Walters State Community College has worked closely with industry and other employers to provide training matching local needs. The college expanded its focus during the last year to provide unique opportunities to the workforce of the future.

In March, the college’s Niswonger Campus hosted a Tiny House Build for Greeneville Middle School students. Students traded their pencils and quizzes for hammers and nails. Working together, the class completed the challenge of building a tiny house in just four hours. The chance to actually use math on a building project was a first for many students. Mentors also taught students the importance of strong eye contact and a firm handshake.

The Tiny House Build was supported with funding from STEM.

LD through the Niswonger Foundation and

one he gives to his students: “Look at the bottom of your shoe. That mold of the sole was created in a 3-D modeling software, then you take that model and implement that into machine like we have here.”

Students learn programming and machinist technology and techniques for using CNC lathe and Swiss machines.

Gefellers said once the students get involved using the machines and learning the components, they soon find an enjoyment in the processes.

The next resource students have at Greene Technology is the welding instruction class.

The welding class is one of the advanced manufacturing classes taught at the school. No prior experience is needed to join the class as it hosts freshmen through seniors. While taking the class, students receive credits toward obtaining a certified welding accreditation via the partnership Greene Technology has with Tusculum, Northeast Community College, TCAT and Walters State Community College.

Cook pointed out how the students’ experience in the classes at GTC count toward the time needed to obtain a degree in welding from those higher education schools. Having credit built up before entering a higher education welding program means having to take fewer classes,

which means saving money.

“You are saving a ton of money,” Cook said. “You are way ahead of the game.”

is the

lationship for the students. “It shows students that they can have a career in manufacturing and make a good living in Greeneville,” Cook said.SUN PHOTOS BY MARIO MICALLEF Some of the CNC lathe machines are shown that students use to develop the hands-on experience in making parts during the machine technologies class. Gerald Austin, right, helps a student with a welding technique. Austin teaches the welding class, which is one of the advanced manufacturing classes at Greene Technology Center.

from the Nuts, Bolts and Thingamajigs (NBT) foundation.

A weeklong underwater robotics camp was of fered at four campuses in May. This camp stemmed from the popularity of the subject during the col lege’s annual Talented and Gifted (TAG) Program.

The Aquatic Hitchhikers, a team formed from TAG students, competed in the first underwater robotics

tournament at East Ten nessee State University. Underwater robotics challenges students both mentally and physically. Working in teams, stu dents build, design and test a SeaMATE AngelFish ROV underwater robot. Campers demonstrate how robots are used in the workforce. Students also gained workplace safety skills. Camps were funded by STEM.LD through the Niswonger Founda tion and Nuts, Bolts and Thingamajigs. Greene County sponsors are

Parker Hannifin, ArtaZN, CNC Millwright and J&J Warehousing.

The college’s first welding camp was held at the Niswonger Campus in July. Students learned both gas metal arc (MiG) welding and Shielded metal arc (STiCK) weld ing. The students used the same equipment adults use for non-credit welding classes. Student left with solid welding skills and ca reer knowledge. This camp was also made possible by a grant from the STEM. ID through the Niswonger

Foundation.

For workers needing training now, Walters State is expanding the number of apprenticeships available in its 10-county service area. Funding is provided by a grant from the Department of Labor and Workforce Develop ment. Each apprentice receives training from an experienced mentor or master craftsman. They at tend noncredit and credit programs at Walters State.

At the end of the training period, the apprentice re ceives a nationally recog

nized credential.

For companies interest ed in starting an appren ticeship program, the process is streamlined.

“We first meet with employers to see what the needs are. We look how we might be able to meet those needs within the apprenticeship frame work provided by the Department of Labor and Workforce Development guidelines,” Dr. Anita Ricker, assistant dean of workforce training, said.

WSCC has served over 200 apprentices with more

than 50 currently enrolled in Greene County.

“Many of our appren ticeship packages in clude professional and technical certifications including OSHA safety, ServSafe (food services management), AWS (Welding), and those related mechanical and electrical training,” Ricker said.

For more information on beginning an appren ticeship program, contact Ricker, assistant dean of workforce training, at Anita.Ricker@ws.edu.