FREE TOTHE TRADE PMM PROFESSIONAL M OTOR M ECHANIC ENTER THE CPD ZONE! YOU COULD EARN ONE CPD CREDIT THIS MONTH DECEMBER 2023

inside:

AWARDS 2023

Also

CRANKCASE EMISSIONS EXPLAINED DIAGNOSTICS TROUBLESHOOTERS YOUR GUIDETOANTIFREEZE COOLANTS ALL THINGS GLOW PLUGS COVERED Q&A with IGA’SSTUART JAMES

WHATEQUIPMENT DO YOUNEEDTO SERVICEEVS?

13-28

63-65

Editor’s Picks

24 LET’S GET TECHNICAL

As part of this month’s CPD zone, febi takes readers through crankcase emissions and some common cases where the emissions ventilation system fails. This includes in models such as from Volkswagen, Audi, Skoda, Land Rover and BMW models fitted with the N20 engine.

30 IT’S THE FINAL CLAMPDOWN

In this special report, find out from Straightset how you can effectively use wheel clamping systems during wheel alignment.

50 EV WINNINGS

Not only are tool specialists Knipex giving its tips on the best tools for any modern workshop as part of our EV and hybrids feature BUT the company is also giving 10 lucky readers the chance to win a Cobra XS tucked inside a festive ornament.

57 AND THE WINNERS ARE...

The annual PMM Awards are BACK, celebrating the amazing contributions that help us put together a magazine that is equally informative and entertaining. Flip to the back of the magazine to find out this year’s winners!

45-47 ENGINES& EMISSIONS

49-55 HYBRIDS& EVS

VOLUME 24 ISSUE 11 DECEMBER 2023 Features Total Average Net Distribution 54,319 1st July 2021 – 30th June 2022 PMM DECEMBER 2023 3 37-43 BATTERIES&

AWARDS 2023 Regulars

NEWS & VIEWS

Contents

IGNITION 57-62

6-9

CPD ZONE

29-35 SPECIAL REPORTS

IN THE WORKSHOP

DATA day

It seems recently that every conversation I have ends up turning towards the topic of data and the problems independent garages can have accessing it. Ok, when I say every conversation I mean every work-related conversation. Outside of work I have plenty of non-data related conversations about food, rock music and books, but nothing else. But once car repair is involved, data, diagrams, information become the hot topic.

The timing is somewhat propitious: things seem to be going well on the motor vehicle block exemption front, with legislators finally listening to the needs of the aftermarket for fair access to data. But what has struck me lately is not the wider arguments surrounding data, but literally what it means for garages themselves. Ben Johnson, our Finland-based diagnostics expert, writes this month about the benefits of keeping your own data file – manually compiling a database of examples to compare future vehicles to; he also mentions scouring the web in search of the right diagrams.

Knowing how something is meant to perform is crucial to understanding when and how something is malfunctioning – usually necessary steps to take on the way to discovering why it is malfunctioning. It can pay dividends to assess what data you might need in the future and to gather as much as you can when you get the chance. In an ideal world everything you need would be neatly packaged for you in one place. That would certainly make this magazine obsolete and might even make your own job obsolete. The truth is that cars are chaotic, faults are endless and causes are often multiple. There never will be a “click here to resolve the issue” button, but fairer and easier access to vehicle data will at least allow you to provide the service your customers expect.

Let it snow, please let it snow!

By the time you read this we will be fully ensconced in the season formerly known as Christmas, now known the world over as Mariah Carey Season. It takes some effort to will myself into x-mas mode, seeing as we haven’t yet had Halloween or Guy Fawkes night (remember him?). However, it has been made a little easier by the supermarkets who have elected to leapfrog the spookier holidays and have been proudly stocking mince pies since, and I can’t quite believe this as I write it and had to double check, the start of September. September, if you remember, was this year the beginning of summer, not the end of it. Perhaps UK supermarkets are getting us prepared for a globally-warmed future in which christmas dinner is barbecued turkey skewers on the beach – don’t go for a dip though, by that point Thames Water will have dispensed with the niceties and every sewer in London will just pour directly into the river. But hey, we’ll still have Mariah!

Kieran Nee

VIEWPOINT

Editor KIERAN NEE News and Products Editor FREYA COLEMAN Digital Manager KELLY NEWSTEAD Group Manager ROBERT GILHAM Account Manager ALEX DILLEIGH Magazine Designer GEMMA WATSON Group Production Manager CAROL PADGETT Production Assistant CLAIRE SWENDELL Distribution Manager KARL CLARK Subscriptions PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30. EUROPE and OVERSEAS UK £30 post paid Air mail £80 post paid Europe £50 post paid Printed by PCP Telford Published by HAMERVILLE MEDIA GROUP Regal House, Regal Way, Watford, Herts, WD24 4YF. Tel: Watford (01923) 237799 Fax: (01923) 246901 E-mail: pmm@hamerville.co.uk Sales enquiries: pmmsales@hamerville.co.uk Website: www.pmmonline.co.uk Copyright © 2023 The publishers and editor do not necessarily agree with the views expressed by contributors,nor do they accept responsibility for any errors of translation in the subject matter in this publication. Listen on Amazon Podcasts Listen on Spotify Podcasts Listen on Apple Podcasts Associate member Find every episode at www.pmmonline.co.uk/podcasts Also available: JOIN M E EACH M ONTH ON THE PMM PODCAST

Editor

PMM NEWS

with Freya Coleman

DATES FORTHE DIARY EV qualified workforce grows...slowly

■ The IAAF annual conference and awards dinner takes place at DoubleTree by Hilton, Milton Keynes on Thursday 7th of December. The conference features a line-up of leading industry voices, and in the evening, delegates will be invited to the awards dinner, with Tom Allen, opening a show that recognises outstanding achievements across the automotive aftermarket.

Latest IMI analysis reveals that 20 per cent of the UK aftermarket population is now qualified to work, to some level, on electric vehicles.

In Quarter 2 2023 2,900 technicians achieved EV certification, bringing the total number of qualified EV technicians in the UK to an impressive 45,300.

However, the rate of EV qualifications appears to be slowing, with a 36 per cent decline in certifications year-on-year. And compared to the previous six-months there’s a 26 per cent drop in certifications. Early analysis by the IMI of quarter three data suggests that this trend is persisting with a 7 per cent decrease compared to the same period in 2022.

The IMI predicts that by 2030 the sector will need 107,000 EV trained technicians, increasing to 126,000 by 2032, increasing to 185,000 by 2035. This analysis comes as Rishi Sunak pushes back ban on new petrol and diesel cars back 5 years to 2035.

FOR UP-TO-DATE NEWS, SIGN UP FOR OUR WEEKLY E-NEWSLETTER. SIMPLY SCAN THE QR CODE

Net zero outlined

A week after Prime Minster Rishi Sunak announced the ban on the sale of new ICE vehicles has been shifted back 5 years to 2035, the government published a ZEV mandate.

This confirmed that 80 per cent of new cars sold by 2030, and 70 per cent of vans, will be required to be zero-emission by 2030.The mandate also means that 22 per cent of new cars sold in 2024 are to be zero emission,

Chief Executive of the SMMT Mike Hawes commented that “with less than 100 days to go, manufacturers finally have clarity on what they are required to sell next year and up to 2030.” Also stating that the mandate will “challenge” the industry.

Garage Hive’s The Blend 2023 saw some 330 attendees at this year's event. The event brought together workshops and business owners from the UK aftermarket, delivering advice on best business practices, with a wealth of industry expert speakers providing relevant and current topics. This included Matt Cleevely from Cleevely EV garage and Jennifer Webb from HR vitals.

NEWSIN QUOTES

“ It is a relief to at last see the Conservative Party recognising that motorists have been treated pretty poorly over the last decade...However, there is absolutely no mention of supporting the workforce that is fundamental to motorists – and businesses - being able to stay on the roads.”

Steve Nash, CEO of the IMI criticises the Government’s ‘plan for drivers’ which aims to protect drivers from “over-zealous” traffic enforcement.

PMM NEWS

with Freya Coleman

NEWSIN BRIEF

■ THE MOTOR OMBUDSMAN SEES RISE IN CASES Between the 1st of July and the 30th of September, the ombudsman saw a total of 1348 new submissions from motorists, up 10 per cent from the previous quarter.

■ ALLDATA AND SCHAEFFLER FORM PARTNERSHIP This partnership is giving Schaeffler’s REPXPERT members the ability to take advantage of original vehicle manufacturer repair data from Alldata.

■ AWARDS RAISE VITAL CHARITY FUNDS The IGA’s BIG Awards 2023 raised £10,000 for the automotive charity Ben. The event also celebrated the hard work of the independent garage community, winners including Garage Hive as garage management system of the year and Stourbridge Automotive Ltd winning large independent garage of the year.

■ AUTOTECH WINS RECRUITMENT AWARD Autotech Group is celebrating after being named ‘recruitment agency of the year’ in the small business category at the UK recruiter awards.

■ DELPHI LAUNCHES TRAINING PROSPECTUS 2.0 This comes in the form of a 66 page training perspectus, aiming to showcase the wealth of solutions now available to the aftermarket. Content includes information on the company’s BlueTech diagnostics platform.

ULEZ camera facing the wrong way?

Transport for London has apologised after 927 drivers in Harrow were incorrectly charged when a ULEZ camera was pointing in the wrong direction.

This forced TfL to switch off the camera, before reinstating it in the correct direction, and issuing refunds totalling £11,200.

The deputy leader of Harrow Council, Marilyn Ashton, has called this “unacceptable, incompetent and disgraceful” especially considering how long it took TfL to respond to the complaints she received, and the fact that the camera wasn’t actually in London at all.

Video series launched

New MOT measures

At the IGA member event in Runcorn, the Driver and Vehicle Standards Agency (DVSA) announced new annual training measures for MOT testers who fail to complete their annual training within the annual training year.

Currently, MOT testers failing to complete the year’s annual training are required to do a demonstration test with the DVSA and complete the current year’s

PMM Online has launched a new video series called 0-60, aiming to give you a fortnightly, one minute round-up of the latest from the industry. Scan the QR code to view the videos on our Instagram page!

annual training.

As of January 2024, MOT testers who fail to complete the year’s annual training who later want to be reinstated as an MOT tester, will be required to complete a DBS check, a DVSA demonstration and the current year’s annual training. The DBS check must be uploaded to the MOT admin hub and be available at the time of the DVSA demonstration.

8 DECEMBER 2023 PMM

Get the most profit on bulbs this winter

To prepare garages for winter, Ring Automotive has taken a look at what opportunities are regularly missed by workshops and offers suggestions on how to get the most profit with bulb sales.

One of these tips is replacing bulbs in pairs when replacing a blow bulb in a paired lighting system. If one headlamp or brake light goes, replacing the bulb in the other at the same time produces an even light output to aid driver’s vision. Plus, it provides a higher level of customer service. Headlamps

work at the same time, therefore it is logical to presume that if one headlamp bulb goes, the other bulb in the other unit will also fail shortly. A motorist would be frustrated to have to replace another bulb soon after having a car in the workshop, so it’s always worth replacing bulbs in pairs for these reasons.

This extra professional advice, delivered with confidence can lead to extra sales, but also opens the door to sell upgrade bulbs, which come as pairs.

Filthy MOTs

Dirty vehicles have been revealed as one of the top reasons for MOT refusals in 2023, with a total of 526 cars being refused, making it the fourth highest refusal reason.

This has been disclosed in a freedom of information request to the DVSA. So, if you’ve ever had to turn a filthy vehicle away at your garage, know that you’re not alone.

13.5 %

increase in MOT testing demand from 2016 to 2022 according to data from Garage Industry trends. This comes as the amount of MOT testers is on the decline, a fall of 1.8 per cent recorded from 2020 to 2021 which is expected to continue.

370 %

The increase in electric vehicle repair claims over the past few years as recorded by warranty company MotorEasy.

£

924

the amount the average car insurance now costs, increasing 19 per cent in the past 3 months. With car insurance increasing, technicians should be aware of customers being more hesitant to spend on their cars. This is according to the confused.com car insurance price index.

42 %

the amount of 16–24-year-old vehicle technicians who lack confidence in securing a well-paid job within the industry after completing their automotive course. However, 95 per cent still expressed their desire to carve out a career in the automotive industry.

PMM DECEMBER 2023 9 MESSAGE ME YOUR NEWS AT FCOLEMAN@HAMERVILLE.CO.UK

In pictures: Duckhams-sponsored Adam Smalley achieved a victory in the Porsche cerrera cup Great Britain 2023, marking his third British championship win.

NEWSIN NUMBERS

PMM THE PODCAST A look inside:

Morning Stuart. Could you explain why you feel the SERMI scheme is necessary for independent workshops?

For many years, garages worked on all makes, models, years, all types of cars. However, to access certain levels of information to repair those cars effectively for their customers has become a challenge over the years.

Each vehicle manufacturer has a different way of accessing their information, a different way of regulating the security of that information and ensuring that vehicle theft doesn’t increase in the UK. Inmany

cases the approaches used have been correct. However, it’s very frustrating and very difficult for garages to log in toa different vehicle manufacturer every time they want to get access to fix that car.

What this system brings is one login through a conduit called a trust centre that takes them to every manufacturer. So it's one route into all manufacturers. It's a revelation in the ability of independents to repair cars.”

This month we bring you a snippet of the chat between PMM editor and host of the PMM Podcast, Kieran Nee and CEO of the IGA, Stuart James. Here, the two discuss the SERMI scheme and why Stuart feels it’s important for the UK independent aftermarket looking to access security and repair-related vehicle data.

Are vehicle manufacturers trying to in some way restrict independent garages from accessing to security-related RMI?

Over 70 per cent of all service and maintenance work is carried out within the independent sector, I don't know if you're aware of that. If all drivers went to franchise dealerships, their lead times would be significantly larger than they are now. We are working very closely with the vehicle manufacturers on this, which in itself is quite unusual. We are

representing the independent garage sector and the vehicle manufacturers have been really quite agreeable all the way through this.

I think we can all see that this is the future and it will be good for the UK and for the consumer, the rigorous checks that a technician has to go through and prove their integrity can only be a good thing for our industry.”

“Over 70 per cent of all service and maintenance work is carried out within the independent sector.”

So which common jobs will be affected by the SERMI scheme? LISTEN

Routine servicing won’t be affected. However when you change a component, you may have to program that component in. When you replace keys or when you need to access an electronic control unit that has

security level components within it, you won’t be able to get in unless you have SERMI access. Also for newer systems like ADAS systems, sometimes you have to go through the security gateway.”

10 DECEMBER 2023 PMM

TO

THE

SO FAR ON THE PLATFORM OF YOUR CHOICE, SIMPLY SCAN THE QR CODE

ALL OF

EPISODES

YOU ARE NOW ENTERING

PMM has teamed up with the CPD Group to offer you the chance to gain CPD points while you read every issue!

Continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experience of a subject area and your role within it. To help professionals to better document and prove this process, our new CPD Zone features articles that have been checked, verified and accredited by a thirdparty specialist organisation.

The content within the CPD Zone will provide you with 1 CPD Credit, or 1 hour’s worth of continuous professional development.

Once you have read through the articles contained within, you will be able to scan the QR code at the end of the last article. This will provide you with a downloadable certificate, personalised to you. This can then be used as part of your ongoing CPD record, as needed to satisfy various organisations and schemes. Regular readers of PMM, therefore, could earn 11 CPD points just by reading the magazine each month.

DO NOT SCAN THE QR CODE UNLESS YOU HAVE READ ALL OF THE CONTENT WITHIN THIS SECTION!

CPD relies on self-certification, which in turn relies on professionalism and honesty from those who participate. We have great faith in the diligence and professionalism of our readers – we are called Professional Motor Mechanic, after all. It is fairly safe to assume that if you are picking up PMM each month, then you are already interested in reading and understanding technical content. Indeed, we are a lifeline for many in the industry who rely on us to spread the word on the latest changes and developments originating with the OEMs.

THIS PROCESS IS COMPLETELY FREE

Don’t worry – you won’t have to pay a penny to gain your CPD points each month. It’s on us!

All certificates are valid for one year from the issue date. If you have any issues downloading the certificate or using the system please email us at: pmm@hamerville.co.uk

NEW USERS

ACCESS YOUR BESPOKE CPD CERTIFICATE IN FIVE STEPS

Read ALL of the articles within this month’s CPD Zone

Fill out your details on the contact form

Download your certificate for use as part of your annual CPD record

PREVIOUS USERS

ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

Read ALL of the articles within this month’s CPD Zone

PMM DECEMBER 2023 13

CPDZONE READ ME TO COLLECT YOUR CPD POINT

–

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your email address

–

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your name and email address

Download your certificate for use as part of your annual CPD record

HOW TO

Vehicle Information

Manufacturer: Volkswagen

Model: Caddy 2.0

Year: 2017

Engine 2.0 TDI

Mileage: 101,000

Schedule time: 5.3 hours

Schaeffler LuK’s Alistair Mason is replacing the clutch assembly in a 2017 Volkswagen Caddy 2.0 TDI that has covered more than 101,000 miles. The vehicle has been booked into the workshop with clutch slip, which had been prediagnosed and confirmed with a short road test at the time of booking.

READ ME TO COLLECT YOUR CPD POINT CPDZONE

Replace the clutch on a Volkswagen Caddy 2.0TDI

With the vehicle placed on the lift, open the bonnet and remove the engine cover ( Fig.1 ), which reveals an engine bay full of emission control systems, such as EGR and Adblue, but with the removal of the airbox assembly, battery and battery carrier, access to the gearbox is pretty good ( Fig.2 ).

Disconnect the gear change cables from the selector arms, remove the cable bracket bolts and stow the cables in the bulkhead area, so they are out of the way, then remove

the gear selector arm/weight, which allows the gearbox mounting brace to be removed.

Disconnect the reverse light switch multiplug, followed by the wiring for the starter motor, then remove the two slave cylinder retaining bolts and ease the slave cylinder out of the bellhousing. This can now be stowed away from the gearbox without disconnecting the hydraulic system and provides good access to remove the upper bellhousing bolts. Raise the vehicle lift to waist height and remove the N/S/F wheel and wheel arch liner, unbolt the N/S/F inner CV

assembly, lower the transmission jack and remove the gearbox from the vehicle.

Clutch replacement

With the gearbox disconnected, remove the six clutch pressure plate bolts and the clutch assembly. At this point the clutch fault in this repair was evident, as the clutch plate lining had reached the end of its service life as it had worn down to the metal retaining rivets. As this vehicle is fitted with a solid flywheel, remove the clutch dust using clutch and brake dust cleaner, remove the glaze from the flywheel surface using an emory cloth and clean again

release bearing and fork assembly, then check the guide tube and pivot points for wear. In this instance, we replaced the guide tube, pivot point and release arm, as wear was evident (Fig.5). Clean the bellhousing area removing the old clutch dust using a clutch and brake dust cleaner, then apply a light smear of high melting point grease to the splines on the input shaft and mount the new clutch plate onto the shaft, which will confirm the clutch plate is correct, as well as evenly distributing the grease. Remove the clutch plate and wipe away any excess grease, then, using a clutch alignment tool,

torque required bolts to the manufacturer’s specification and these values are available on Schaeffler’s REPXPERT workshop portal.

After the battery lead has been reconnected, reset all electrical consumers and carry out a full road test to ensure that the repair has been successfully completed.

READ ME TO COLLECT YOUR CPD POINT CPDZONE 16 DECEMBER 2023 PMM WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABD001

TROUBLESHOOTER

Improving your diagnostics

Ben Johnson investigates how using an oscilloscope along with verified data can help you improve your diagnostic efficiency.

This month, I want to emphasise the significance of building your personal library of information and underscore why it holds such a vital role in our work. Let’s delve into the world of BMW, a company that continually provides us with an abundance of diagnostic challenges, keeping us on our toes. While this constant stream of issues keeps us engaged, what's less than ideal is BMW’s tendency to withhold crucial data –practically none at all. Even in the realm of technical training, based on my experiences working with both BMW dealerships and specialists, there’s a conspicuous lack of information regarding what things should look like when they go awry.

Finding the problem

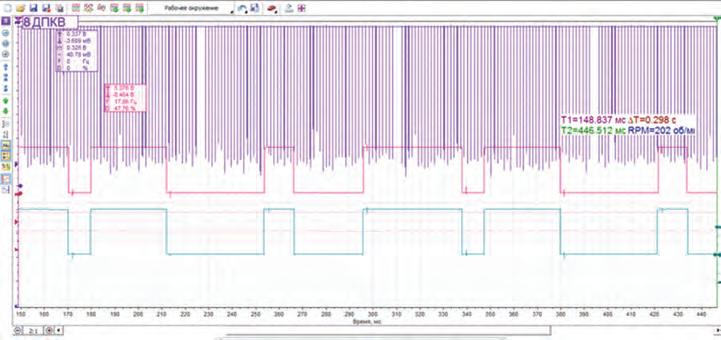

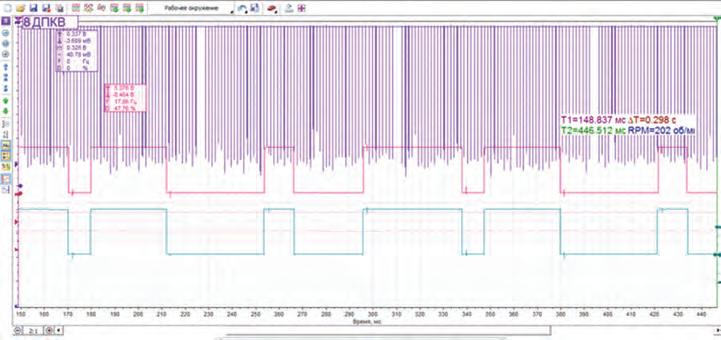

This week brought another typical job into my garage, an F15 X5 Hybrid. But unlike the usual suspects – BDC failures and gearbox meltdowns – this one presented a good old timing chain problem. Timing chain issues are no stranger to us, as they are a common occurrence in many workshops. However, what set this one apart was my decision to employ a scope to analyse it, capturing the waveform for my personal library.

Admittedly, my library is a bit scattered and disorganised, with data strewn all over the shop, but one thing is certain – I have an abundance of invaluable data and this is the point that I am making – all of us should maintain such a collection because, as you'll discover as you continue reading, knowledge not only saves a significant amount of time but can also pave the way for those coveted monthly bonuses we all strive for.

The engine sounded surprisingly smooth, but the ominous glow of the MIL (malfunction indicator light) in the corner

“Knowledge not only saves a significant amount of time but can also pave the way for those coveted monthly bonuses we all strive for.”

Ben Johnson, diagnostics expert.

was a silent testament that all was not right (Fig.1). The customer had thoughtfully provided us with the fault codes, most likely retrieved from a dodgy looking USB dongle that I had noticed plugged into the diagnostic socket during my attempt to connect the new Thinklink – the wireless diagnostic link from the Thinktool we recently acquired.

With the Thinktool at the helm, it swiftly retrieved the fault codes from the DME. Among them, the exhaust camshaft synchronisation with the crankshaft fault code appeared, immediately sparking my suspicion of a stretched timing chain. Yet, a dilemma arose. While I’ve scoped chains for potential stretching over many years, BMW makes it more complex due to the unique nature of each engine. Take the S series V8, for example – not a walk in the park to interpret, I assure you. The X5 I was dealing with featured the N20 engine with twin Vanos and a centrallymounted Valvetronic servo motor, easier to interpret the valve timing than a V8 however my problem was clear – I had no reference scope pattern to compare it to. A quick online search led me to an invaluable resource in Kyiv, Ukraine – Rotkee. Although they

READ ME TO COLLECT YOUR CPD POINT CPDZONE

18 DECEMBER 2023 PMM

Dreaded MIL illuminated

primarily deal in car diagnostic tools, their waveform repository proved to be a treasure trove. This is where I found a reference image of an N20 engine with a pristine timing chain – one free of defects such as stretching or vanos sprocket anomalies. It’s moments like these that highlight the paramount importance of having a well-organised reference library, wouldn't you agree?

The fault code 130F20 immediately caught my attention (Fig.2), as I’ve encountered this issue countless times in N20 powerplants, and it has consistently pointed to a stretched timing chain. However, in the spirit of thoroughness, I saw an opportunity to put the Thinktool scope through its paces and create a record for my personal library. The code 120308 could be as a result of the exhaust camshaft timing fault. I may be able to confirm that link in a future follow up article. This article primarily will focus on the timing issue initially.

Connecting the Thinkscope is a breeze –simply attach the USB to the Thinktool and insert it into the scope box, connect your BNC cables, and you’re ready to go. Backpinning wasn’t an option due to the DME’s small connectors (NANO MQS) and delicate wiring, so I opted to expose a small section of outer sheathing and attach crocodile clip probes for a secure and reliable connection. After configuring channel one for the crankshaft signal and channels 2 and 3 for both camshafts, all that remained was to press “auto”, and the Thinkscope handled the waveform – a substantial timesaver compared to the antiquated AVL Di-Test, now relegated to the scrap heap.

The scope revealed a vivid image (Fig.3), making it evident that the exhaust camshaft was out of alignment with respect to TDC (indicated by the yellow trace) on the crankshaft. However, here’s the catch: in

certain BMW engines, the valve overlap you see in the magenta and blue traces can appear deceptively similar, even in engines without any faults. The N20, on the other hand, offers a more straightforward and distinct pattern. It comprises exhaust and intake cams with no overlap, but once Vanos and Valvetronic come into play, things can change. Perhaps, on a future occasion, I should create a waveform to record the independent advancement and retardation of the camshafts. In its current state, the engine operates under no load, and the variable valve timing should be in a neutral position –or at least, it should be. To gain a better perspective, take a look at another waveform I found on Rotkee’s website (Fig.4).

Tackling the problem

To address this issue, my first step was to tackle the laborious task of removing the cam cover, a challenge exacerbated by the imposing presence of the X5 wrapped around me. With the cam cover out of the way, I could then directly access the exhaust camshaft to inspect why it was not synchronised. Employing a spanner, I turned the camshaft and scrutinised the Vanos sprocket – to my satisfaction, there was no play or slackness, effectively ruling out any mechanical problems. However, I strongly recommended replacing this sprocket, along with the intake sprocket, as using a new chain with old sprockets is a practice best avoided. Furthermore, there were no fault codes reported for the Vanos solenoids, which, on the N20, have established themselves as dependable, unlike the earlier N43’s long finger-type solenoids.

PMM DECEMBER 2023 19

130F20. A sign that the timing may be off.

The magenta trace shows the exhaust camshaft in relation to TDC at the crankshaft (yellow trace).

Both camshafts are in a similar position to the case study intake camshaft which was correct. Both camshafts are synchronised to the crankshaft correctly. Image courtesy of Rotkee/VWAUDI.

Upon closer inspection, the intake camshaft appeared to be in good condition, visibly aligned at the 12 o’clock position (Fig.5). However, the exhaust camshaft, as indicated by the earlier scope trace, was noticeably out of sync, resembling a position closer to 7 minutes past the hour, if that description makes sense (Fig.6).

For many years, BMW engines have embraced keyless design, lacking dowels or woodruff keys, even on the crankshaft. This feature elevates the importance of precise timing. Once the Vanos sprockets are removed and then replaced, and the timing chain is reassembled, the use of camshaft phase wheel locking tools becomes indispensable to ensure that cam timing is impeccably aligned. The phase wheels cannot be aligned without a specialised tool. Additionally, this tool proves handy as a visual guide to gauge the extent of timing misalignment on the exhaust camshaft before repair.

You may have noticed that I refrained from locking the crankshaft during this repair process. I found no need to invest additional time in this step, given the challenging location of the locking pin orifice, which would have consumed an unreasonable amount of time to remove the blanking pin and secure the engine. The compelling evidence lay in the absence of intake camshaft/crankshaft correlation fault codes, indicating that the crank timing was essentially correct and the intake camshaft timing also correct. In a situation where time was of the essence – as the customer surprisingly desired the car’s swift return – this decision was pivotal (Fig.7).

The replacement of the timing gear is scheduled for completion next week. However, on that very day, I had to ensure the car was ready to go back to the customer. Such is the relentless pace and pressure of a fault finder’s daily life.

I hold a strong conviction that a new chain and a set of Vanos adjusters (sprockets) will effectively resolve this problem. This case study serves as a reminder of the pivotal role that your own reference library plays. This job, from reading fault codes to setting up the scope, researching online to interpret values, and the final step of physically removing the cam cover for visual confirmation, took approximately three hours. It's essential to remember that when faced with a potential stretched chain, a swift and precise diagnosis can save a significant amount of time without needing to loosen a single bolt or getting one's hands excessively dirty. With the right library of data and a strategic approach, we can all work more intelligently, ultimately saving time for both ourselves and the customer while contributing to reaching that monthly bonus sooner. Until next time, keep learning and keep improving every day. I hope that this article has inspired you to begin building your very own reference library because it will be the best decision that you make as you continue down the path of self development.

20 DECEMBER 2023 PMM

READ ME TO COLLECT YOUR CPD POINT CPDZONE WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABD002

Not surprisingly, the exhaust cam phase wheel was a mile out.

Intake camshaft locked in place correctly.

Exhaust camshaft not at the 12 o’clock position as seen both visually and from the previous scope trace. Intake cam timed correctly. Note the QR code at the 12 o’clock position.

CHARGING WIRELESS POWER TRANSFER E V

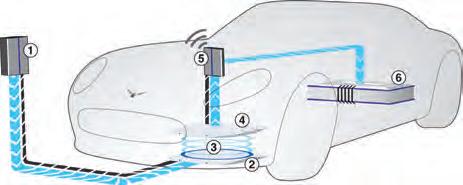

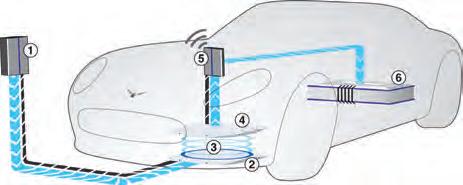

Wireless power transfer (WPT) is a system for wirelessly charging the batteries in electric vehicles. There are two main methods:

Stationary WPT

Dynamic WPT

With stationary charging, the electric energy is transferred to a parked vehicle. In dynamic wireless charging systems, the energy is transferred via a special driving lane equipped with a primary coil system at a high power level to a secondary coil of a moving vehicle. Because the range of most EVs is now good, the need for dynamic charging has reduced. I will, therefore, concentrate on static or stationary WPT.

To wirelessly charge, a suitably equipped electric vehicle simply parks over an induction pad and

charging commences automatically. Just like with wired connections, the rate of charge is set from within the vehicle. There are no visible wires or connections. A primary charging pad is buried or set on the ground (on a drive or in a garage for example) and a secondary pad is integrated onto the vehicle.

The power supply (Fig.1) takes a mains voltage input and produces high-frequency current (>20 kHz). Its output current is controlled and applied to the primary pad.

Power is transferred from the primary pad to the secondary pad using transformer action. The onboard charger takes power from the receiver pad and provides a controlled output to the battery. The controller is required to provide an output that

remains independent of the load and the separation between pads.

BMW has developed a wireless charging system. As soon as the vehicle has been parked in the correct position above the inductive charging station (Fig.2), a simple push of the stop/start button, starts the charging process. Once the battery is fully charged, the system switches off automatically just as if it was plugged in.

The system helps the driver to manoeuvre the car into the correct parking position with the help of a Wi-Fi connection between the charging station and vehicle. An overhead view of the car and its surroundings is displayed in the centre control display. Coloured lines help guide the driver into the correct spot. A graphic icon shows when the

correct parking position for inductive charging has been reached. This can deviate from the optimum position by up to 7 cm longitudinally and up to 14 cm laterally.

The contactless transfer of energy between the GroundPad and CarPad is conducted over a vertical distance of around 7.5 cm. The GroundPad generates a magnetic field. This induces a voltage in the CarPad, which then causes a current flow to the onboard charger (just as if the car was plugged in).

WPT is designed for slow charging so is ideal for home chargers where, for example, you simply park the vehicle as normal and charging automatically takes place overnight.

Sponsored by FOR MORE INFORMATION GO TO WWW.RDR.LINK/ ABD003

READ ME TO COLLECT YOUR CPD POINT

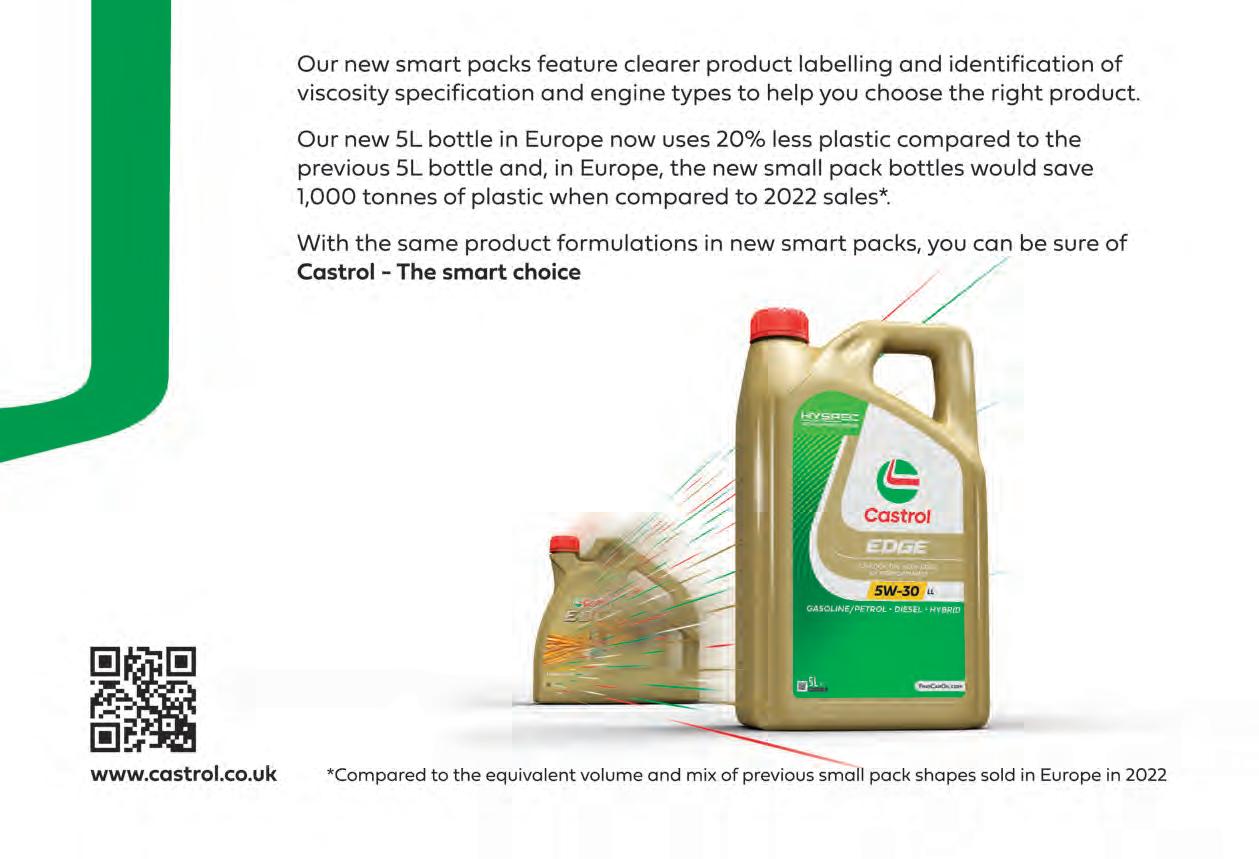

FIG.1 Inductive wireless charging: 1) power supply 2) primary pad 3) wireless electricity and data transfer 4) secondary pad 5) onboard charger and controller 6) battery

PMM THE PODCAST

WHAT DO CHANGING A BATTERY, CHANGING A BABY (JUST THE NAPPY) AND CHANGING YOUR MORNING RADIO STATION ALL HAVE IN COMMON?

THEY OFFER THE PERFECT OPPORTUNITY TO LISTEN TO THE PROFESSIONAL MOTOR MECHANIC PODCAST WITH KIERAN NEE.

HEAR ADVICE ON PRICING JOBS, MANAGING PARTS SUPPLY, ELECTRIFICATION, RECRUITMENT AND MUCH MORE.

Listen on Google Podcasts Listen on Apple Podcasts Listen on Amazon Podcasts Listen on Spotify Podcasts LISTEN NOW ON YOUR PODCAST PLATFORM OF CHOICE

KNOW YOUR PARTS

Positive Crankcase Ventilation

febi takes a detailed look at crankcase emissions, as well as outlining some common cases where the emissions ventilation system fails.

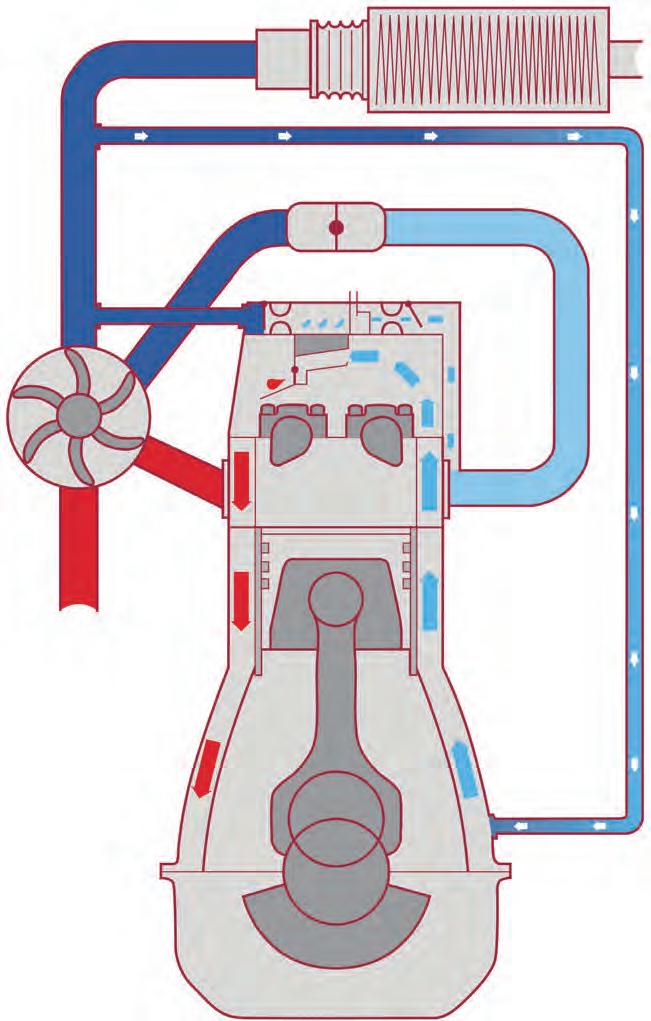

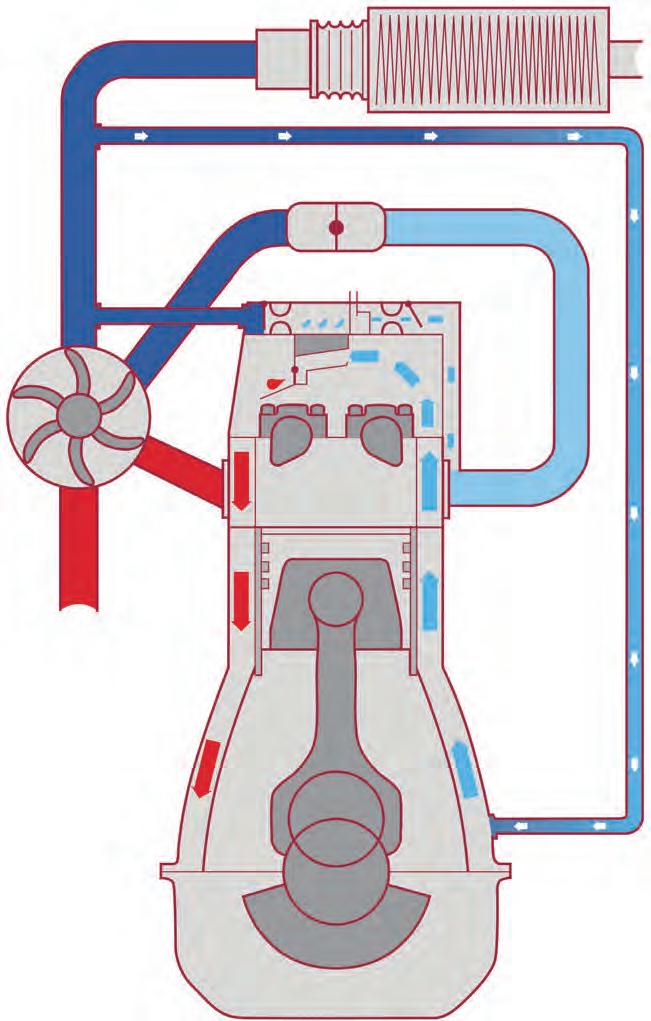

Crankcase emissions are produced as a result of the combustion process of the internal combustion engine. These are a by-product of this process, with exhaust gases escaping from around the piston rings and into the crankcase. The overall volume of these gases varies depending on cylinder pressure, piston ring pressure and component wear. The elements found in these blow-by gases include wear particles, oil, fuel, gas and air. The specific composition of the elements varies depending on the fuel, engine configuration, engine speed and load, and maintenance history of the engine.

How do they work?

These blow-by gases are typically made up of hydrocarbons (HC), carbon monoxide (CO), carbon dioxide (CO2), nitrogen oxides (NOx), water vapour and traces of sulphates and aldehydes. The crankcase hydrocarbon emissions are normally about 3 per cent of the total exhaust emissions tested at the midlife of the engine. However, due to piston ring tolerances, crankcase hydrocarbon emissions can increase to 20 per cent of the total hydrocarbon emissions.

If not controlled, these gases can contaminate the lubricating oil, resulting in sludge. The crankcase can be pressurised –causing oil seals to fail – which, in turn, can lead to oil leaks, as well as having an impact on the starting and the smooth running of the engine and exhaust emissions.

Positive crankcase ventilation is a system that was developed to regulate the internal engine pressure and remove harmful vapours from the internal combustion engine. This prevents these vapours from being expelled into the atmosphere.

24 DECEMBER 2023 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

The PCV system does this by using a manifold vacuum to draw vapours from the crankcase into the intake system. The separated droplets of oil flow back to the oil sump and the cleaned blow-by gases are recirculated into the intake area. They are then carried with the fuel/air mixture into the combustion chambers, where they are burned. Every car has some form of crankcase ventilation system, which can consist of several basic parts including hoses and connectors, an oil separator and a ventilation valve. These components can be separate or built into the engine.

The most typical defects of a crankcase ventilation system are a rupturing of the rubber valve membrane and blocked or split hoses or ducts. This leads to high oil consumption, burning oil, loss of power, misfiring, and high carbon deposits. Early signs of a failing PCV system include whistling noises from the intake, blueish smoke in the exhaust, high oil consumption, and thick white or yellow residue under the oil cap. However, many of these symptoms can go unnoticed or be misdiagnosed –mistaken for other issues or components. Here are a few common crankcase ventilation system examples:

Land Rover Freelander TD4 and Range Rover TD6

The engine oil is leaking – usually from the dipstick tube, because the dipstick has been pushed out under crankcase pressure. Other symptoms include lack of engine power (the engine will not increase in speed), black or blue exhaust smoke and excessive oil consumption.

These are caused by a blocked crankcase breather filter – this filter is located in the depression control valve assembly, which is fitted to the camshaft cover. Replace the blocked filter and the complete breather valve assembly, clean any excess oil leaks, and test.

Various Volkswagen, Audi, SEAT and Skoda models, fitted with the 1.8 or 2.0 FSi/ TFSi engine The engine crankcase is maintained in a constant vacuum while the engine is running. The engine is equipped with a crankcase breather valve installed on the rocker cover, directly connected to the intake manifold.

The crankcase blow-by gases are separated into two stages. Firstly, the primary oil separator in the oil filter housing removes the majority of engine oil from the gases. Secondly, the separator on the rocker cover removes the remaining engine oil vapour from the gases.

The turbocharged variants have a more sophisticated pressure control system. A twostage pressure control valve is located on the rocker cover. When the intake manifold vacuum is present, blow-by gas flows into the intake manifold. When turbo-boost pressure is present, the one-way valve in the breather valve assembly closes and blow-by gases flow into the valve cover.

Over time, contamination causes reduced air flow and the rubber membrane can split in the oil separator. Additionally, the sealing joints between the breather hoses become dry and do not seal.

The faulty oil separator or hoses cause the following symptoms: engine idle speed to fluctuate and stall, whistling noises from the engine at idle speed and increased oil consumption.

Various BMW models, fitted with the N20 engine

In earlier BMW engines, the crankcase ventilation system was designed to be outside the engine. In the N20 engine – and many others – the crankcase ventilation valve is built into the top of the rocker cover.

The blow-by gases pass through the opening in the intake side, with spring tab separators in the rocker cover. The oil in the blow-by gases is separated by the spring tab separators and flows along the walls, down through a non-return valve and back into the cylinder head. The blow-by gas cleaned by the oil now passes into the air intake system.

The most typical defect of this crankcase ventilation system is a rupture of the rubber valve membrane. The rocker cover, which is continuously exposed to heat cycles and vibration, can crack and leak. The oil separator galleries can clog with oil particles and residue.

PMM DECEMBER 2023 25 WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABD004

vent

Rocker Cover with

valve Breather Valve for crankcase

DIAGNOSTIC GUIDE

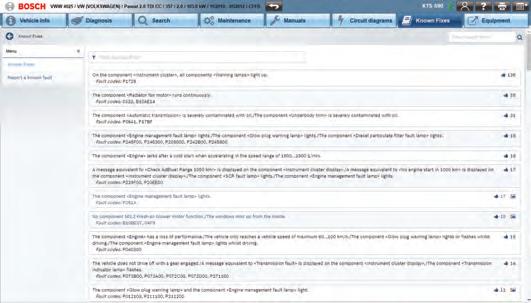

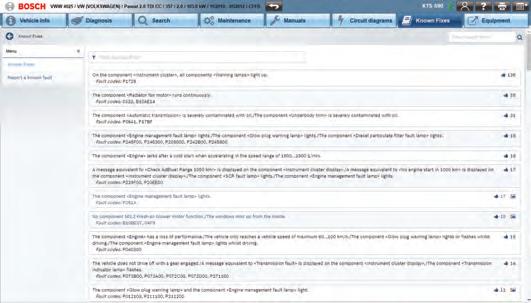

Using Bosch’s ESI[tronic] 2.0software: a monthly guide

A few years ago, PMM ran a guide from Bosch on its KTS diagnostics software, ESI[tronic] 2.0. We thought it would be a good idea to revisit the guide with Bosch and find out what’s changed. In this fourth instalment, we are looking at how to identify known fixes with experience-based repair.

Last time we delved into the time saving potential of the ‘service tasks’ tool. By putting all the tasks your workshop team need to complete right at their fingertips – in seconds – ‘service tasks’ gives your engineers a head-start on the work at hand. While the experience based repair (EBR) –known fixes feature helps them take efficiency to the next level.

With the online knowledge exchange growing by the day, many workshops are turning to Google for their repair instructions. While the internet is a huge data source, many results are unvetted and unverified. Leaving a lot of time-consuming legwork for your team, even if the initial search goes smoothly.

By aggregating knowledge from across a worldwide diagnostic community of 75,000 experts, EBR – known fixes aims to cut out potential hours wasted searching the web. From the technical hotline and internet forums to trending Google searches – the EBR-finder utilises an innovative algorithm to identify common problems from across a wide variety of sources and alert our experienced ESI[tronic] SIS authors of any emerging challenges being experienced in

the field. The team then check the entries forplausibility and validate the data to create Bosch-quality content to guide you through the fix.

Found under the known fixes tab, EBR –known fixes allows you to find the right solution in seconds. Once registered, you can freely type any text into our search agent to find common fixes by fault code, symptom, component or keyword.

Ranked by likes

Find the most popular fixes, fast. Thanks to the feedback feature, it is easy for technicians on the ground to rate a fix – helping you to easily see the industry’s best-ranked solutions (Fig.1). It also enables you to have your say on how useful you found a particular fix.

You can quickly and easily search the database of fixes by keyword. Just like you would if you were relying on traditional search engines. The biggest difference? Every result is Bosch approved (Fig.2).

Every Bosch approved fix follows the same format:

Complaint

A brief summary of the issue.

Your pathdiagto success!

General conditions

A list of any relevant symptoms.

Possible causes

The most common reasons why this fault may occur.

Remedy

The known fix for these challenges.

Quick and reliable repairs are the foundation for excellent results and satisfied customers. With more than 1,500,000 real life use cases – and growing – it’s never been easier to find the right solution for your problem.

As on online service that is updated automatically, EBR – known fixes aims to always bring you the very latest repairs and adaptations from its ever-growing database.

Next month we will discover how the Bosch ESI[tronic]’s service information system – or SIS for short – can guide you from symptom detection and associated trouble code to root cause and rectification.

26 DECEMBER 2023 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABD005

What was causing noise on the front wheels of the 2017Audi A5 Sportback?

Autodata helps one garage get to the bottom of why their customer’s Audi A5 was making a metallic noise from the front wheels when manoeuvring and parking.

The problem

“A customer's 2017 Audi A5 Sportback is in for a service and the owner has reported a metallic noise from the front wheels whilst manoeuvring or parking. We have heard the metallic noise and we suspected it was originating from the front brake pads due to them being very low. After replacing the front brake pads and road testing the car the metallic

noise is still apparent. Are you aware of other Audi owners who may have reported this type of metallic noise before?”

What does Autodata recommend?

Yes, this fault has been reported to us by A5 Sportback owners with late model year vehicles. The metallic noise is due to movement between the front wheel bearing housing and the front hub carrier. Remove the front wheel bearing housing from the hub carrier, but do not remove the wheel hub from the front wheel bearing. Thoroughly clean all corrosion

from the front wheel bearing housing and apply a light coating of Optimolpaste, available from Audi parts department, to the mating surfaces of the front wheel bearing housing and hub carrier. Refit the front wheel bearing housing to the hub carrier. Repeat the procedure for the opposite side and road test the vehicle to ensure the noise has been eliminated.

READ ME TO COLLECT YOUR CPD POINT CPDZONE WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABD006 Find more quick fixes from Autodata on the PMM website!

BEST PRACTICE

Working on suspension mounting kits

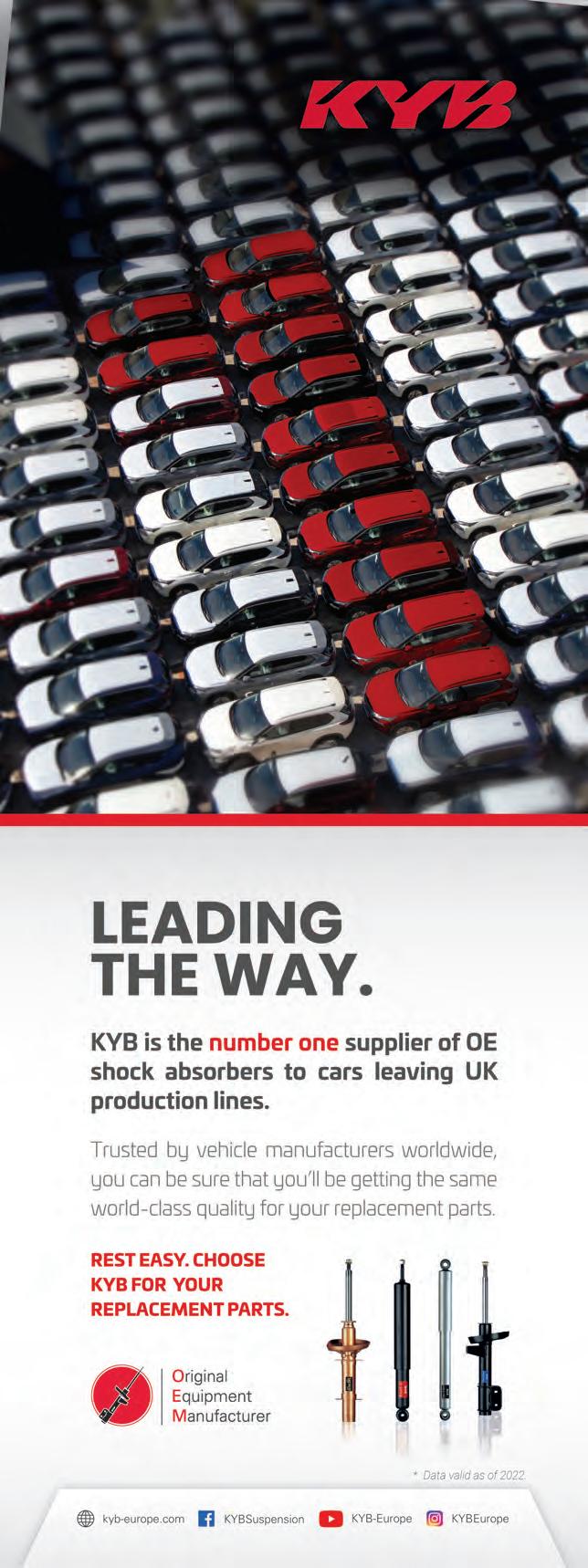

Suspension specialist KYB offers its advice on diagnosing and replacing suspension mounting kits.

Just like a shock absorber, a suspension mounting kit is pushed and pulled 1,500 times per mile –over the course of 50,000 miles that means this small but important component has moved up to 75 million times, deteriorating the rubber components in the mounting kit.

Worn mountings have an adverse effect on ride control and safety. Mount wear depends on the type of travel, however a good guideline is that if the struts are worn out, the mounts will probably be worn out too. Therefore, suspension mounting kits should be replaced every time the struts are replaced.

Mounting kits provide a rubber cushion between the chassis and suspension, helping to reduce stress on the suspension by absorbing vibration. There is also a bearing in front mounting kits which allows the steering wheel to turn the suspension column and the wheels. It returns the steering wheel smoothly back to its natural straight position if released. Suspension mounting kits can affect the angle of how the shock absorber sits – if the rubber is worn, it can cause extra stress upon it and its surrounding components.

How to diagnose worn mounting kits

Test driving vehicles is a key part of diagnosing suspension issues and helps to explain the issues to the motorist. Find a short circuit that includes the following:

Bumpy road surface/speed bumps (feel for ride harshness)

Listen for noises, feel for steering wheel vibration and any irregularities with the steering

Turn the steering wheel and release your hands – does it return to its natural straight position?

Seized bearing

Fixing points for the upper suspension mounting kit and the shock absorber to the vehicle.

Rubber element used to absorb vibrations transmitted from the chssis to the vehicle.

The bearing is often placed in a rubber cushion reducing friction and ensuring optimal movement of the shock absorber column while turning wheels.

Construction markings indicate the correct mounting position of the upper mounting.

Pick a route by your workshop that is quiet, and one you can use repeatedly

Aim for a 3-minute, 1 mile long route that includes a speed bump, a place where you can brake and accelerate quickly, and swerve safely. Your speed will not need to be over 30mph

When you return to the workshop, eliminate any other factors such as any excessive movement in the other suspension components such as the ball joints and bushes.

Broken/cracked metal – rubber joint

This could have been caused by aggressive driving or road conditions such as potholes and uneven surfaces. It can result in excessive vibrations transferred to the vehicle’s steering system and driver, decreasing comfort, increasing fatigue; changed damping parameters of the suspension; accelerated wear of the suspension and co-operating components.

This could have been caused by incorrect installation if the full weight of the vehicle wasn’t applied when tightening the nuts to the required torque. It can result in excessive vibrations transferred to the vehicle’s steering system and driver, increased force will be required to move the steering wheel, the steering wheel will not return to a straight position once the steering wheel is released, and there will be noise coming from the suspension.

Deformation of top support bearing

This could have been caused by excessive axle load, or aggressive driving or road conditions such as potholes and uneven surfaces. It can result in excessive vibrations transferred to the steering system, changed damping parameters of the suspension, and noise.

WANT TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/ABD007

REDEEM YOUR CPD CREDIT

Congratulations, you have reached the end of the CPD Zone!To access your CPD credit from The CPD Group, scan the QR Code below or

WWW.RDR.LINK/ABD008

28 DECEMBER 2023 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

Yourguideto ANTIFREEZE COOLANT

Operating at high temperatures…

The best cooling medium is water. However, when the engine reaches running temperature it will exceed the boiling point of water, 100˚C. If the water boils away, catastrophic damage can occur in the engine. To combat this, antifreeze coolants feature the addition of monoethylene glycol, which elevates the solution’s boiling point to around 108˚C.

…and low temperatures

If the engine has been at rest and the ambient temperature falls below 0˚C, water freezes, and the ice formed expands. This is a big issue in the engine cooling system as there is nowhere for the expansion to go. As the water freezes, high internal pressures are generated that can crack heads, cause splits in cylinder liners, make hoses leak, fracture radiators and break water pumps. By incorporating monoethylene glycol to the water it reduces the freezing point, potentially driving it down to -35˚C.

Inhibitors

Another important function of an antifreeze coolant is to prevent any metallic components from rusting or corroding, such as the engine block, water pumps or gaskets. It is therefore essential that the antifreeze coolant uses the

chemistry is referred to as either inorganic or organic acid technology.

Inorganic chemistry is extremely active and will seek out all materials in the cooling system, whether susceptible to rusting or corrosion or not. This constant level of activity results in it becoming depleted after around two years. At this point it should be drained and changed.

Organic acid technology only targets materials where rusting or corrosion is starting to take place. This chemistry is selective and does not become depleted as quickly and will work for up to five years. Some manufacturers may require a combination of these technologies and ‘hybrid’ antifreezes are available for specific engine designs.

And there’s more!

Additional chemistry may also be added to the formulation of antifreeze coolants such as antioxidants to stop corrosive acid formation as well as additional compounds to prevent hard water deposits and extra pH buffering agents to maintain an optimum pH level (around 8). The formation of foam can also inhibit the properties of the antifreeze coolant, therefore an antifoaming agent may be added to the formulation to prevent foam developing within the cooling system.

how the antifreeze coolant performs in terms of engine protection.

Choosing the correct antifreeze coolant

As engine designs become more complex and engines are manufactured from different metals and composite materials, the correct antifreeze coolant must be used. If not, the antifreeze coolant will damage the engine and reduce itsefficiency. When choosing the correct antifreeze coolant, you need to make sure it meets the specifications set by the engine manufacturer.

Antifreeze coolants perform in the engine all year round and do not just cover the winter months. Selecting the correct antifreeze coolant is vital and choosing a product based on colour should be avoided. Best practice is to select the antifreeze coolant based on the engine manufacturer’s specification. If there is any doubt as to which antifreeze coolant is required, check with the engine manufacturer, seek independent technical advice, or use online tools such as www.whatoildoineed.com

PMM DECEMBER 2023 29 SPECIAL REPORT

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABD008

Straightset outlines how you can effectively use wheel clamping systems during wheel alignment.

Working for the CLAMPDOWN

In the garage, precision is paramount. When it comes to wheel alignment, the importance of precise measurements cannot be overstated. Enter the unsung heroes of this crucial operation: wheel clamps. These unassuming, yet essential, tools come in various shapes and sizes, each offering unique advantages tailored to different needs.

The choice of wheel-clamping device does play an important part of any wheel aligner and alignment process, especially with the suspension set ups on modern vehicles where accuracy is dependent on fitting the clamps correctly, performing the all-important run-out compensation as well as using a fully calibrated machine and accurately level lift platform.

damage to alloy wheels and is still a popular choice amongst wheel alignment professionals today. This offers an alternative to a clamp system, and can cater to tyres from 12 inches to 24 inches.

Self-centring clamps

Initially there was only either a 3-point or 4-point claw type clamp available, though as nearly all vehicles had steel rims this didn’t present any problems with potential damage that can occur if the fingers of the claw grips are themselves damaged or broken. With most of today’s vehicles having alloy rims as standard, solutions to the potential problem of rim damage, as well as speeding up the wheel alignment process, have been available for some years now with the introduction of different clamping styles. Here are some of the systems available today:

Hang on system

The hang on system, with no clamping and the use of rim buttons, made popular by Supertracker, eliminated any potential

With advancements in product design, the self-centring clamp system, which has nylon feet that sit up against the rim with claws that wrap around to grip the tyre, are a very successful design which is still used today and available as an update to the Supertracker CCD system. These clamps automatically centre themselves on the wheel when applied, eliminating the risk of human error. This precision not only ensures more accurate alignments but also enhances the safety and performance of the vehicle and offer a solution to performing wheel alignment on lowered vehicles. With 3-point and 4-point clamps available, these are still going strong today and with suitable extensions that can be used on rims up to 28 inches in diameter.

Specialist clamps

Some specialist vehicles and vehicle manufacturers require specialised attention and that includes for wheel alignment. As a leading wheel alignment manufacturer, Beissbarth, began to produce individual clamps for BMW and Mercedes Benz initially, which used pin sets to locate the clamp against the hub with wrap around claws to grip the tyre tread. This type of clamp ignored the rim and measured directly from the hub, allowing for the runout compensation to be skipped but still giving a very accurate measurement.

This spilled out to other marques who wanted a unique, and accurate clamping method, notably Porsche, Tesla, Ferrari, Lamborghini and very soon the JLR range, who have opted for centre mount devices, all machined to very fine tolerances to fit in place of the rim’s centre cap. There are variations of clamp depending on the model.

Magnetic clamps

With the introduction of the Beissbarth ML3D wheel aligner another advancement in wheel clamping was launched: the magnetic

SPECIAL REPORT

30 DECEMBER 2023 PMM

clamp. By using strong magnetic studs they affix to the vehicle’s steel wheel studs. This has proved to be a quick and easy clamp for the technician to use, less cumbersome than most other wheel clamps on the market.

Quick clamps

In today’s fast-paced world, every second counts. Q.Grip clamps are designed with efficiency in mind. Their swift application, courtesy of a lever mechanism, streamlines the alignment process. For busy auto shops, these clamps translate into faster turnaround times, increased customer satisfaction, and higher productivity. The latest product from Beissbarth is the Q.Grip, to complement the Q.Lign wheel aligner range.

These are a patented design and provide the technician with a very quick clamp that wraps around the tyre at three points and with the all-important run-out compensation performed have proved to be as accurate as all other clamping devices. Wheel alignment isn't just about functionality; it's also about aesthetics. Nonmarking clamps come to the rescue by using rubber or soft material pads to prevent damage to wheel finishes. For high-end or custom wheel owners, this means preserving the appearance and value of their investment.

In conclusion, wheel clamps may not be the first thing that comes to mind when thinking about automotive maintenance, but they are integral to achieving precise wheel alignments. Their diversity caters to various vehicles and needs, from quick alignments in a bustling workshop to intricate precision work on specific vehicle manufacturers. By selecting the right clamp for the job, auto technicians can ensure safer, more efficient, and more accurate wheel alignments, ultimately benefiting both customers and their bottom line.

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABD009

INSIDE INTELLIGENCE

Providing safe, accurate vehicle repairs and getting customers back on the road quickly means starting with the right tools: ALLDATA Repair offers exactly that by providing up-to-date OEM mechanical/body repair information and procedures for 91,950 unique vehicle combinations – more than 95 per cent of all vehicles on the road today. The portal comprises of six million technical drawings and wiring diagrams, including electrical connector views, which are available in five languages.

To show how ALLDATA Repair can be used in the real world, let’s look at a recent case the team has dealt with.

ALLDATA PARTNERS WITH SCHAEFFLER

REPXPERT, a digital platform and community developed by Schaeffler, is dedicated to supporting automotive professionals with product and technical material; therefore, its collaboration with ALLDATA Europe, a provider of genuine OE repair and maintenance information, is a perfect fit.

REPXPERT members in the UK can access this invaluable resource by simply clicking on the ALLDATA Repair banner within the REPXPERT web portal. This will transport them to a new landing page where they can request a two-week free trial. This period will grant them unrestricted access to original repair and collision information for 36 VMs, all of which have licensing agreements with ALLDATA Europe.

2019 MY PEUGEOT 208 1.2I

The team at the ALLDATA Repair Info Centre Service was recently presented with an issue on a 2019 MY Peugeot 208 1.2i. The vehicle owner had been experiencing, what they described, a “dull knocking noise” coming from the front of the vehicle. Bizarrely, though, the motorist would only hear it during warm weather and when the vehicle was at idle. This made the problem difficult to pinpoint and diagnose, making the conversation between technician and customer awkward, potentially.

Solution

Thankfully, the ALLDATA Repair Info Centre Service experts were able to come to the workshop’s rescue. They had been presented with this issue before and managed to get to the bottom of the problem quickly.

The cause of the knocking noise was due to internal damage within the vehicle’s front right-hand engine mounting. To rectify, simply, the technician needed to replace the broken mounting, being careful to use the correct VIN number to ensure the correct, modified engine mounting was supplied.

Once the part arrived, to complete a professional and accurate repair, the technician required a specific torque of 6daNM –information available, of course, on ALLDATA Repair!

Mercifully, this intervention from the ALLDATA Repair Info Centre Service meant the technician was able to conduct the work and hand the keys back to a relieved and happy customer – no more knocking noises heard!

ADVERTORIAL

32 DECEMBER 2023 PMM

SIGN UP FOR A FREE TRIAL AT WWW.RDR.LINK/ABD010

OPTIMISED HANDLING FOR CAMPER VANS

Motorhomes and camper vans have been experiencing a steady upward trend for years and, according to experts, there is no end in sight to the ongoing boom. With the growing number of newly registered motorhomes, the demand for used ones is rising at the same time. However, to ensure that the dream of a holiday on wheels does not turn into a nightmare, buyers should pay particular attention to the suspension as well as the mileage and age of the respective components when purchasing a used model. In any case, a thorough suspension check in the workshop is recommended to owners of motorhomes past their prime. When passengers notice roll and sway or decreasing ride comfort inside the camper, this is often due to worn shock absorbers. Even before, this can be insidious because dangerous loss of control is already imminent, e.g. during sudden evasive manoeuvres, sharp bends or strong crosswinds.

To prevent this from happening, an upgrade with the BILSTEIN B6 Camper or Camper Advanced is advisable. Since the summer of 2022, the suspension specialist from Ennepetal offers these two high-performance shock absorbers developed especially for the challenges of such vehicle categories. They have been developed for campers, panel vans and semi-integrated vehicles based on the Fiat Ducato (from model

year 2006) and the largely identical vehicles from Citroën and Peugeot.

BILSTEIN B6 CAMPER

Motorhomes based on the platform of a transporter usually adopt this vehicle’s unmodified suspension. The new dampers from BILSTEIN should be the number one choice for retrofitting, in particular for the alcove models popular among families with small children. As the alcove is partly protruding over the cabin’s roof, it adversely affects the vehicle’s centre of gravity and critical driving situations can quickly arise. Evasive manoeuvres, response to strong crosswinds, but also sudden breaking manoeuvres can quickly lead to an unstable, critical situation of a vehicle with overcab bed.

This is where the improved OE replacement shock absorber B6 Camper can show its additional safety features, with no registration required. In crosswinds and on bends it convinces with optimum grip, offering a more intense driving experience due to high traction and precise handling. At the same time, campers can look forward to a more comfortable driving experience: The reduction of driving noise through better damping contributes to this just as much as the optimised rolling behaviour on cobblestones and at level crossings.

Advanced goes one step further, featuring the innovative DampMatic® technology. This ensures amplitudeselective shock absorption. With this purely mechanical technology, a control piston reacts to the vibrations transmitted from the road and automatically selects one of two characteristic curves. In the “soft setting”, the damper oil flows through both the main piston and a special DampMatic® bypass. In the “tighter” setting, the latter is closed so that the flow is reduced.

Thanks to the DampMatic®, rolling behaviour improves in terms of comfort because the vehicle effectively has two suspension systems in one. This can be felt for instance on bridge kerbs and on cobblestones. What is more, control over the vehicle is dramatically improved, for instance when cornering or changing lanes.

PMM MARCH 2022 1 ADVERTORIAL

BILSTEINB6 SHOCK ABSORBER SERIES INCREASES SAFETYAND IMPROVES HANDLING

B WWW.FACEBOOK.COM/BILSTEIN.UK D WWW.INSTAGRAM.COM/BILSTEIN_OFFICIAL F WWW.YOUTUBE.COM/BILSTEINDE I CAMPER.BILSTEIN.COM

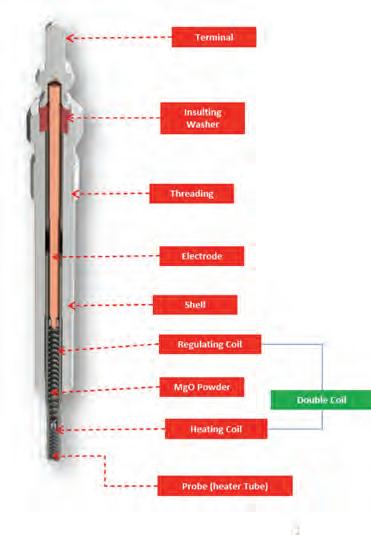

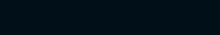

Why are the tips ofsome GLOW PLUGS grey/blue in colour?

One of the OE parts supplied by Denso are glow plugs, so the firm is in an ideal position to dispel an ongoing myth surrounding the part…

Alongside many other products, Denso is a glow plug manufacturer, supplying them as original equipment parts. It also supplies the independent service and repair sector and as its aftermarket range is produced on the same production lines to the same standards, the firm argues they can be relied on by automotive technicians and motorists alike. There is, nevertheless, a notion among workshops that the colour of a glow plugs’ tip can imply that it is not a genuinely new item.

According to the company, the fact that its aftermarket glow plugs are manufactured on the same production line as its OE range, should be enough to reassure those with any concerns over the providence of its glow plugs. However, to clarify the situation and

provide peace of mind for installers, Denso is explaining why the tips have this colouration.

In common with many highly engineered products, the manufacture of glow plugs is a complex process. This is particularly true for the production of the glow tube, which when installed, can be heated up to temperatures above 800°C within seconds. This component is needed to ensure a quick and reliable start when the engine is cold, and to reduce emissions when it is running.

Live testing

As this heating element is the most critical component of the glow plug and allows it to fulfil its role in the ignition system, its functionality has to be verified during the production process. It is for this reason, that at the end of the production line, the performance of each glow plug is thoroughly tested to ensure that it is working in accordance with the given specification, including its heat-up time and the temperature it needs to reach.

It is this in-line production test, that causes the glow plug’s tip to take on this grey/blue tone. This colouration is due to the oxidation of the metal, which is accelerated by the high temperature it is subject to during the test, but it does no harm to the glow plug,

“This colouration is due to the oxidation of the metal, which is accelerated by the high temperature it is subject to during the test”

nor does it degrade its performance.

Therefore, rather than being something of concern to technicians when opening the box, it should be regarded as a sign of reassurance, because it indicates that the glow plug they are about to fit has been tested and works according to its given specification, and will perform as they’d expect a large OE automotive parts supplier.

Denso’s R&D investment helps it to pioneer increasingly efficient and reliable diesel engines with minimal emissions. Its aftermarket division draws on this expertise, offering a comprehensive, all-makes glow plug programme intended to improve start-up performance with extended post-heating temperatures.

PMM DECEMBER 2023 37

BATTERIES & IGNITION

TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABD011

WANT

Colouring, rather than a cause for concern, in fact offers a reassurance of quality

PMM asked Ken Clark, managing director of Rotronics Battery Management Solutions, to give readers an understanding of the importance of maintaining the 12 V battery in an electric vehicle.

Lookafter the little BATTERY

As with traditional internal combustion engine and hybrid vehicles fitted with a 12 V battery, all electric vehicles have a 12 V “auxiliary” battery. The battery technology used in these vehicles are commonly AGM (absorbed glass mat), EFB (enhanced flooded batteries) and can be traditional (flooded) lead acid batteries, or in some cases lithium (LiFePO4) are used.

What may surprise you is that these batteries play a crucial role in managing the functions of the high voltage pack and still require the same maintenance and care practices as ICE vehicles. Improper care and maintenance can lead to acid stratification and sulphation of the battery, reducing its performance serviceable life, resulting in premature replacement and vehicle non-start, as well as an “unhappy driver” experience.

Potential failures

EVs experience roadside breakdowns due to “flat batteries” and when it comes to industry statistics, battery failure remains the top attributable factor for all vehicle roadside callouts. Recent roadside breakdown statistics show that 43 per cent of all roadside breakdowns are as a direct result of the starter battery and this includes both ICE vehicles and EVs. Despite the reduction in EVs’ maintenance requirements, these vehicles still have the same challenges, pitfalls and opportunities to maintain, support and replace the 12 V battery going forward.

What’s the purpose of the 12 V “auxiliary” battery in EVs, how can it fail and what can you do to minimise these risks?

The first table gives a brief overview of its role:

12 V battery purposeFailure problem Impact

Make the car run

(Auxiliary 12 V battery

No access to high voltageVehicle will not start controls EV pack)

Safety

(Power steering, airbags, No power to critical Vehicle will prevent user braking system, lights, signals andsafety functionsfrom driving much more)

Accessories

(In car entertainment, heated No power to vehicle

In car entertainment does sets, radio, navigation etc)accessoriesnot function

Vehicle access

(Doors, windows and boot)Locks are not electrifiedUser cannot access or exit the vehicle in the normal way

What can you do to maintain 12 V batteries?

■ As with all discharged 12 V batteries, charging is required to restore full power performance and maximise battery lifespan and can be achieved using widely available intelligent chargers: it’s the same straightforward process and no special equipment is required.

■ In contrast, the 12 V EV battery will require a unique diagnostic approach tailored to their application, which will assess available safety power capacity, to power critical vehicle systems.

■ As EVs have no engine to start, traditional

ICE

conductance testing is not a suitable measure of battery condition.

■ The development of Midtronics SafetyPower diagnostics platform will accurately measure the available capacity of a 12 V battery.

■ This cutting-edge technology and approach to 12 V “auxiliary” battery testing will provide a precise decision on a battery’s ability to power the vehicle’s low voltage loads.

The table below highlights the necessary evolution in 12 V battery testing, to ensure safer and correct vehicle functionality.

ICE, start-stop,hybridelectric vehicles

Vehicles needStarting the engineIn-vehicle loads, when Power for all systems “engine off”outside of propulsion

Battery FunctionCranking healthReserve capacity SPC (safety power capacity)

Battery TestingConductance Conductance profilingSPC diagnostics Diagnostics

BATTERIES & IGNITION

38 DECEMBER 2023 PMM

Are you getting EV service ready?

■ As many workshops plan and implement electric vehicle service strategies, the inclusion of necessary qualifications and equipment to the support their future needs become a key requirement.

■ While aftermarket tailored equipment solutions enabling high voltage battery maintenance are in development (enabling module balancing and cell replacement). Deployment of the most accurate diagnostic technology for 12 V batteries in electric vehicles is a positive step towards EV service readiness.

■ Unlike electric vehicle traction packs that are relatively reliable and come with up to 10 years manufacture warranty, the 12 V battery is typically backed by a 2-3 year warranty, and can be a simple “win” for aftermarket workshops aiming to keep their EV customers mobile through maintenance and/or replacement of the 12 V battery when the need arises.

■ Getting your workshop “12 V EV ready” by ensuring you have both the correct means to diagnose and charge 12 V batteries and implementing a proactive testing and charging programme as part of your workshop service plan, will ensure you keep your customers mobile, whilst increasing sales revenues and customer satisfaction.

What’s in it for you?

Ensuring your workshop is “EV service ready” begins with correctly matching the right technology to your service offering and ensuring you have the appropriate means to accurately diagnose and charge 12 V batteries in EVs.

Implementing a proactive testing and charging programme is essential in your workshops service plan, will:

■ Help keeping your ICE and EV customers mobile.

■ Boost customer satisfaction.

■ Identify battery problems, before they appear at roadside.

■ Increase revenues and replacement opportunities through pro-active charging and diagnosis.

TO

MORE? FOR MORE INFORMATION

WANT

KNOW

WWW.RDR.LINK/ABD012

GLOW PLUGS: AWarmerWinter

The winter months are the key selling period for glow plugs and Niterra is working closely with workshops to ensure they do not miss out on any service opportunities for its NGK ignition parts range.

NGK glow plugs provide over 70 per cent coverage of the 17.3 million diesel car parc in the UK, as well as frequent newto-range launches to ensure popular and new models join the coverage. The components are often noted for their fast start, reliability, and ability to perform in tough cold weather conditions, something which is becoming increasingly important for a glow plug to deliver. As an indispensable part of the exhaust and emissions system they are also essential for maintaining optimum emissions and play a role in preventing damage to related components, such as the clogging of the exhaust gas recirculation valve with excess deposits.

Seasonal peak

The winter months become a natural pinchpoint for glow plug demand due to seasonal changes and emissions testing, along with

standard servicing requests. Becca Knight, marketing manager, Niterra UK, said: “We work year-round to provide availability of our highly demanded NGK glow plugs ready for the seasonal peak, to ensure workshops have what they need to maximise their service opportunities this winter. Our Original Equipment quality glow plugs

“As an indispensable part of the exhaust and emissions system, glow plugs are also essential for maintaining optimum emissions”

provide workshops with the precision and performance their customers need.”

NGK glow plugs aim to provide workshops with OE quality performance for their aftermarket customers. In some cases, NGK glow plugs will have been the OE fitment of choice for the application, meaning that the workshop can continue to offer the high quality and performance their customers know and expect by stocking NGK for their servicing.