When preparing, renovating and maintaining concrete with high and ultra-high-pressure water, the focus needs to be on safety and ergonomics for the operator. This is important, but it is also undeniable that downtimes and delays on construction sites cost a great amount of time and money, are often nerve-wrecking, and mess up an already strict schedule. Therefore, you should trust a powerful and reliable system for your high-pressure applications, where all crucial components are designed to flawlessly operate with one another. From the high-pressure pump to the water tool down to the nozzle inserts - Hammelmann offers perfectly matched components from a single source. Our field-tested high-pressure systems offer a wide range of possible applications in concrete preparation and surface treatment with water jet technology.

For you, and for ourselves, we run extensive tests in our modern Technology Center to see how and where water jet technology can be used in an economical, beneficial and ecological way. This is where modern technology and our innovative spirit go hand in hand to test product developments, new ideas, and specific customer requests in a practical setting and to put them through their paces.

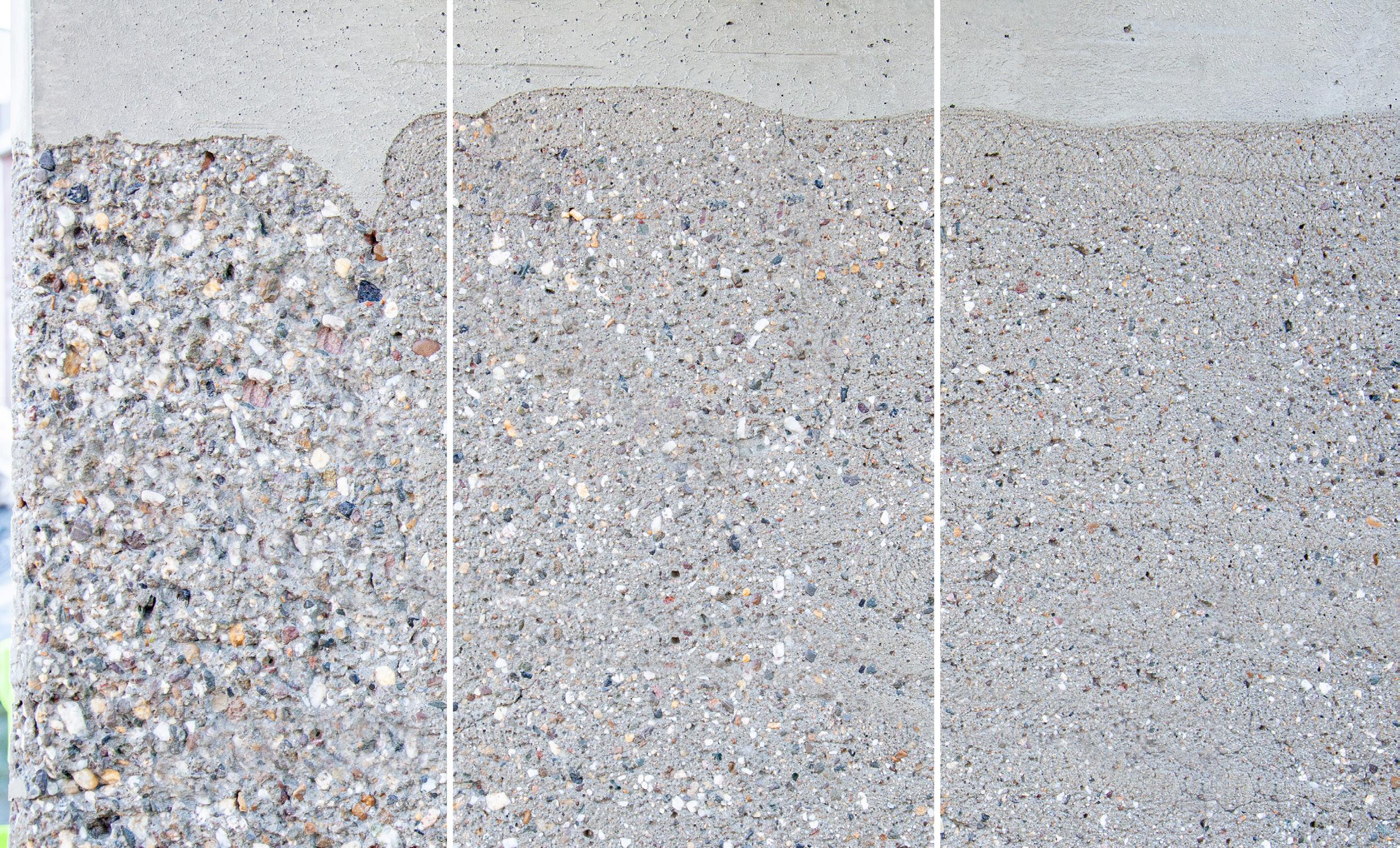

Some of the pictures in this brochure were taken on our test site in order to better illustrate the results and possibilities of concrete preparation and may not reflect the real construction site environment. Such images are marked accordingly.

From the high-pressure pump to the water tool down to the nozzle inserts - Hammelmann offers perfectly matched components from a single source. Rely on a powerful and reliable system where all crucial components are designed to flawlessly operate with one another.

The safety and protection of the operator should always be the priority, even in hectic daily work. All product solutions from Hammelmann are subject to the strictest safety standards and are developed for maximum ergonomics and usability.

Combine your diesel or electric high-pressure unit with a large selection of different waterjetting tools to master any challenge safe and easy.

Working with water offers many advantages in direct comparison to removing and renovating concrete with caulking or dry blasting tools. Among other things, the concrete can be removed without damaging the reinforcement, welded wire mesh or surrounding areas. In addition, no chemical or thermal stress is generated when working with high-pressure water.

Sometimes it can be enough to thoroughly clean concrete surfaces in the course of a renovation if they are neither damaged nor weathered. We have developed product solutions to treat both small and large areas thoroughly and safely. The product range extends from hand-held high-pressure blasting guns to ergonomic work aids and high-pressure surface cleaners.

A high-pressure blasting gun can be used in combination with a rotor jet for roughening different concrete surfaces. Equip your MASTERJET with 2, 3, 4, 5 or 6 inserts and decide the degree of roughening yourself. The amount of water is evenly distributed over the number of nozzle inserts. With 6 inserts, the individual jet exerts significantly less force on the target surface than with 2 nozzle inserts. According to this rule, you can decide for yourself how you want to roughen the surface.

When renovating and maintaining structures, buildings, monuments and facades, it is not uncommon to be faced with the challenge of having to remove damaged concrete in order to re-shutter these areas in the further course of the work and then pour new concrete. With water jet systems, concrete can be removed layer by layer up to the complete exposure of the reinforcement. Systems can be combined and adjusted in such a way that different water jet strengths are possible and a correspondingly large or small amount of material can be removed at once. A spot-jet nozzle or a MASTERJET rotor jet can be used for this purpose.

Gentle exposure of iron or steel reinforcements as well as structural steel meshes is a major advantage when processing concrete with modern water jet systems. In this process, only the damaged concrete is removed until the reinforcement is partially or completely exposed. The steel remains completely undamaged after exposure and the surface to be processed is optimally prepared for further work steps. Water jetting also enables precise work on specific areas of a concrete surface. This enables precise exposure and even complete breakthroughs in the wall.

Working with high-pressure water jets is versatile and flexible. In this way, almost all areas of a construction site where concrete has been used can be covered! Since no vibrations and shocks are generated during water jetting, structures such as tunnels, underground car parks or adjacent buildings can also be renovated.

Gentle and precise work without damaging the reinforcing iron

No unwanted damage to adjacent areas

No chemical load on the surface

No vibrations on surrounding surfaces

No thermal stress on the surface

Minimal wear and tear as no pry tools are used

Long lifetime of all high-pressure components due to optimal valve and sealing technology use of top quality materials and precise series production with most modern machines.

Permanent corrosion resistance of the fluid end

High operational reliability and long maintenance intervals through the hermetical sealing of the gear end by a patented bellows sealing system

Leak-free pump due to the arrangement of all pressurized high-pressure components inside the pump housing

Significant operating cost advantage thanks to the crank section with pressurized lubrication system which is designed for at least 25,000 operating hours under full load

High reliability in continuous duty due to the performance reserves of the high-pressure pump drive engine and all components

Operating pressure

Flow rate up to 3200 bar up to 437 l/min.

Engine power Pump performance up to 839 kW up to 800 kW

A variety of water tools can be operated with AQUAJET® high and ultra-high pressure units. This includes all product solutions for efficient concrete preparation - from manual rotor jets to innovative turn-key systems for removal and decoating.

important operating data

Fully galvanized, high-quality tandem chassis with

point

lugs for easy

AQUAJET®

pump units are available

Rotor jets convert the high effectiveness of round jet nozzles into area performance through rotating nozzle heads. Various nozzle configurations and adjustable speeds open up many possibilities for surface treatment. The lightweight and compact design also enables work in areas that are difficult to access.

Operating pressures up to 3200 bar.

Due to the very low weight (~ 1.0 kg), compact design and low-vibration operation.

The optimum internal flow allows the pump’s total performance to be used without loss of energy.

Many configuration options guarantee optimal design for a wide variety of applications.

SPEED ADJUSTABLE BY HAND

Full control over the speed by simply sliding the protective cover. No tools required!

UNSURPASSED SERVICE LIFE

HPS (High Performance Sealing) is a patented sealing system for MASTERJET rotor jets that work with the highest operating pressures.

Service friendly design with few components.

The great advantages of the MASTERJET can be seen in the ability to adapt quickly to changing work situations as well as in the controlled influence on the removal results. From gentle cleaning to strong removal, everything is possible. In order to adapt the removal result to the job requirements, two different work steps can be followed, which can be carried out independently of one another.

Option 1: Hammelmann offers various nozzle holders with different configurations and designs. The rotor jet can then be equipped with 2 or 4, 3 or 6 or 5 nozzles, depending on the nozzle holder. Option 2: The rotational speed can be adjusted independently of the nozzle configuration simply by moving the outer sleeve (magnetic brake).

The different nozzle configuration of the MASTERJET allows the use of 2, 3, 4, 5 or 6 nozzle inserts. The MASTERJET rotor jet thus offers a wide range of possible uses and proves to be a unique all-rounder in practice. The following rule applies here: the more nozzles there are, the more the force is distributed over the surface being processed. The force acting on the surface is therefore less with a 6-jet application than with a 2-jet application. With just one MASTERJET, sensitive surfaces can be gently cleaned and concrete surfaces in need of renovation can be roughened and removed.

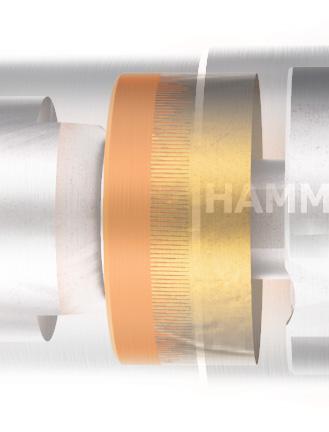

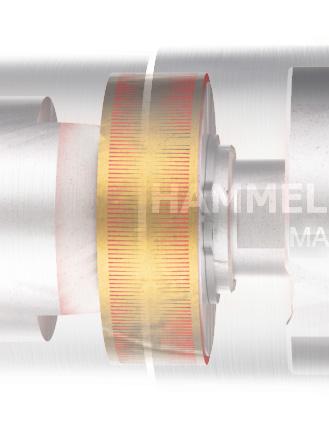

The speed is set by simply moving the outer sleeve. A copper strip in the outer sleeve then overlaps a rotating magnet inside either completely (high braking effect ), halfway (medium braking effect) or not at all (no braking effect ). With this simple movement, the speed can be adjusted quickly and easily, regardless of the nozzle hub. The further the outer sleeve is pulled towards the nozzle hub, the slower the nozzle holder rotates and the more the surface is processed, as the water jets stay longer in one place.

Slow speed

Medium speed

High speed

With 2 nozzle inserts MASTERJET rotor jet With 4 nozzle inserts MASTERJET rotor jet Example: Nozzle holder for 2 or 4 nozzle insertsConfigure your high-pressure blasting gun for your daily challenges. Available in mechanical, electrical and bypass versions.

Mechanical

Operating pressure: up to 400 bar Weight: 3.2 kg

Operating pressure: up to 1000 bar

Weight: 3.6 kg

Electrical

Operating pressure: up to 3200 bar Weight: 3.5 kg

Electrical / With continous flow channel

Operating pressure: up to 3200 bar Weight: 5.0 kg

Mechanical/Electrical

Operating pressure: up to 1000 bar Weight: 4.6 kg

Electrical

Operating pressure: up to 3200 bar Weight: 4.2 kg

Mechanical bypass/Two-hand operation

Operating pressure: up to 3200 bar

Weight: 6.5 kg

Mechanical bypass

Operating pressure: up to 3200 bar Weight: 3.7 kg

Electrical/Two-hand operation

Operating pressure: up to 3200 bar

Weight: 4.6 kg

A simple lever mechanism makes the trigger of our blasting guns child’s play to operate. The operator can use the gun without feeling strain and physical stress which enables longer, more concentrated working periods.

An ergonomically formed handle and various extensions can be easily combined. Each operator can find the working posture that best suits him, saving him effort and increasing workplace health and safety.

The ergonomic work tools of the JETBOY series offer fatigue-free water jetting for a wide variety of working positions.

JETBOY S is an ergonomic water tool with an adjustable handle and a variable working height for a secure standing position when working overhead

You can adapt the JETBOY L to a wide range of different work positions. For cleaning ceilings, floors, and corners.

JETBOY XL allows virtually effortless work. This results in a significantly greater area performance.

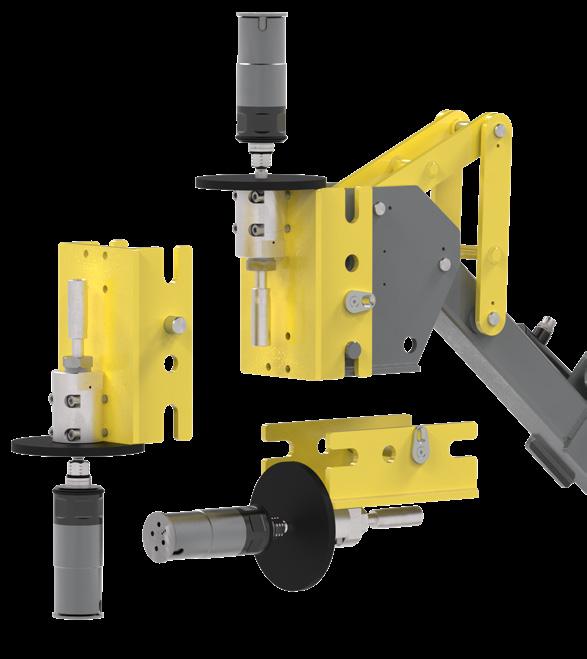

JETMATES are ergonomic, free-floating work aids that absorb recoil forces from all directions.

enable safe and body-friendly work.

The JETMASTER is a highly flexible and universally applicable

pressure robot. For cleaning, roughening and removing a wide variety of substrates.

The JETMASTER is a radio-controlled, semiautomatic work aid. Built on a mobile carrier vehicle the unit can be equipped with a flexible boom that can be used in a variety of ways, and can hold various water tools, such as a MASTERJET rotary nozzle or an AQUABLAST® surface cleaner, depending on the application. With its highly flexible working positions, the JETMASTER reliably eliminates recoil forces and is a real allrounder, regardless of water pressure and flow rate - from cleaning and roughening to removing a wide variety of surfaces.

Safety. Always. Personal protective equipment and clothing for high and ultra-high-pressure applications with various combination possibilities.

Hammelmann offers a wide range of high and ultra-high-pressure hoses and various accessories for all nominal diameters, operating pressures and hose lengths.

with hand protection

Gloves Trousers

A hose protection provides additional safety by covering particularly critical areas such as the hose connection or screw connections and protecting the operator against possible leaks.

Gaiters

Hose protection

The Hammelmann frost protection system prevents your system from freezing, so you are always ready for action - even in winter or at particularly low temperatures.

The compact swivel connector makes working with spray guns easier without interference caused by hose resistance, and increases freedom of movement for the operator.

Foot valves and foot switches for switching the pressure on and off are available in different versions, optionally also with safety standards and Ex-protected.

A wide variety of components are exposed to massive load and dirt in professional industrial use. This leads to increased wear, often to higher weight of the parts, and an exchange of the components is necessary frequently. Regular cleaning of the elements noticeably extends the service life, handling is improved by the lower weight and physical stress is reduced.

The elements are usually cleaned manually with a high-pressure gun. A manual process that is timeconsuming and certainly has the potential for injury.

Hammelmann‘s unique cleaning line is a semi-automatic system that makes cleaning easier, faster and easier to plan. Occupational safety is significantly improved and the costs for wages and energy use are also reduced.

Hammelmann has been a successful manufacturer of high-pressure systems for over 70 years, which are used for cleaning and cutting purposes as well as in production processes. With over 500 employees in the Hammelmann Group, in Oelde and the subsidiaries in the USA, Australia, Spain, China, France and Switzerland as well as 40 other agencies, we are a company that operates worldwide.

For you and for our own R&D we run extensive tests in our modern Technology Center to see how and where water jet technology can be used in an economical, beneficial and ecological way. This is where modern technology and our innovative spirit go hand in hand to test product developments, new ideas, and specific customer requests in a practical setting and to put them through their paces.

Product quality and customer satisfaction are most important to Hammelmann. For this reason, products are not only tested under ideal conditions and then sold, but put to the test under extreme conditions.

In order to simulate the toughest and most demanding conditions possible at your site, we have a number of tanks and containers, concrete and metal walls, pipes, lines and components that we prepare and then process accordingly. The extensive tests can be carried out indoors with the help of automated robots and systems, or outdoors.

If desired, simulations can also be developed in cooperation with you. Together we will examine possible solutions for your particular application and provide you with fully documented test protocols and reproducible results. We are looking forward to your challenge.