All roads start with the guts to dream

Chasing it wherever it takes you

That dream is the fuel, required to create

Driven by passion, guided by expertise

Follow that path, to explore, to feel

All roads start with the guts to dream

Chasing it wherever it takes you

That dream is the fuel, required to create

Driven by passion, guided by expertise

Follow that path, to explore, to feel

Home of yacht building! It is no coincidence that the best shipyards in the world are found in Holland. Our passion for yacht building and our commitment to quality is unmatched. And that is what makes Heesen the world’s leading builder of high-performance yachts.

All of our yachts – displacement, semi-displacement and fast displacement – are engineered and built in the nine sheds at our shipyard in Oss. All our yachts are recognised for their innovative engineering and exceptional performance, stability and comfort. We build in-house using the hardest steel and the strongest aluminium.

We make sure your crew are fully involved throughout the build process, from start to finish. Even after the yacht is delivered, we continue to train them and proactively maintain your yacht on board, at our shipyard or at one of our maintenance and refitpartners around the world.

We all must take responsibility to better protect what we love. By introducing BlueNautech, we continue to support the future of sustainable yachting through improved efficiencies, alternative materials, energy savings and alternative production methods.

All of our Heesen Series yachts have a proven track record, based upon the experience we have gained from previous builds. These yachts are fully designed and engineered. We can deliver them faster because we build them as speculative ventures. Customisations to the interior can still be made but are dependent on delivery times and schedule.

Total proven yacht engineering and design

Fast delivery due to our speculation programme

Customisation options possible to a certain extent

6 | PROJECT GRACE

Our Smart Custom yachts are fully engineered above and below the main deck but can be offered with a custom- designed superstructure. These yachts benefit from our proven track record in hull design and technology. All together, our Smart Custom yachts enjoy a smart balance between performance, speed of delivery and customisation.

Proven hull engineering and design

Faster delivery due to shorter engineering times

Custom choice of superstructure and more elements

Our Full Custom offer starts with a blank sheet of paper or is inspired by one of our concepts. All the client’s wishes are fully considered by our naval architects and designers. If requested by the client, we offer ideas and insight based on our previous full-custom yachts. To highlight our design and building capabilities, we also create concepts to inspire potential clients and stakeholders in the market.

Start the design process from the beginning

One unique yacht in the water

Personalised value

At Heesen, we do not sit on our laurels. We like to embrace the future by crafting it. This is how the new 50-metre series came to be. The sales and marketing department and our engineers put their brains together to conceive the brief for a yacht that will stand the test of time. Harrison Eidsgaard put their pencils to paper inspired by our team’s vision.

Renowned design studio Harrison Eidsgaard created a profile that is not radical or extravagant, but refined in its simplicity, conceived to stand the test of time.

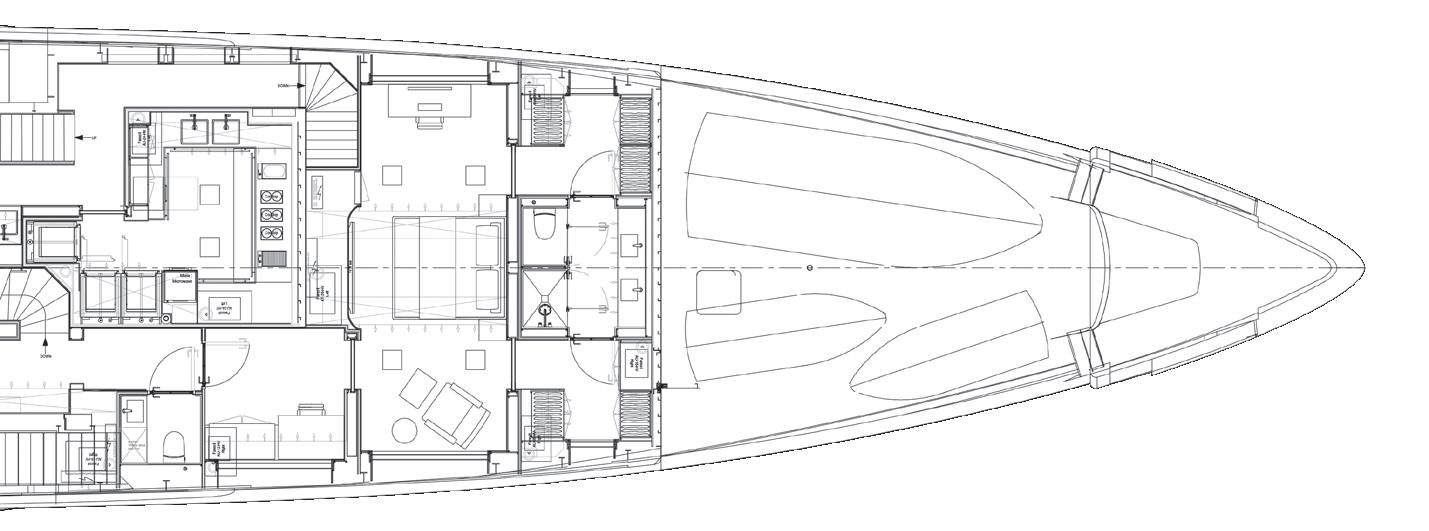

Grace is all about subtle sophistication and craftsmanship, with an interior penned by Harrison Eidsgaard to holistically complement her exterior lines and created in-house by Heesen artisans using the finest materials.

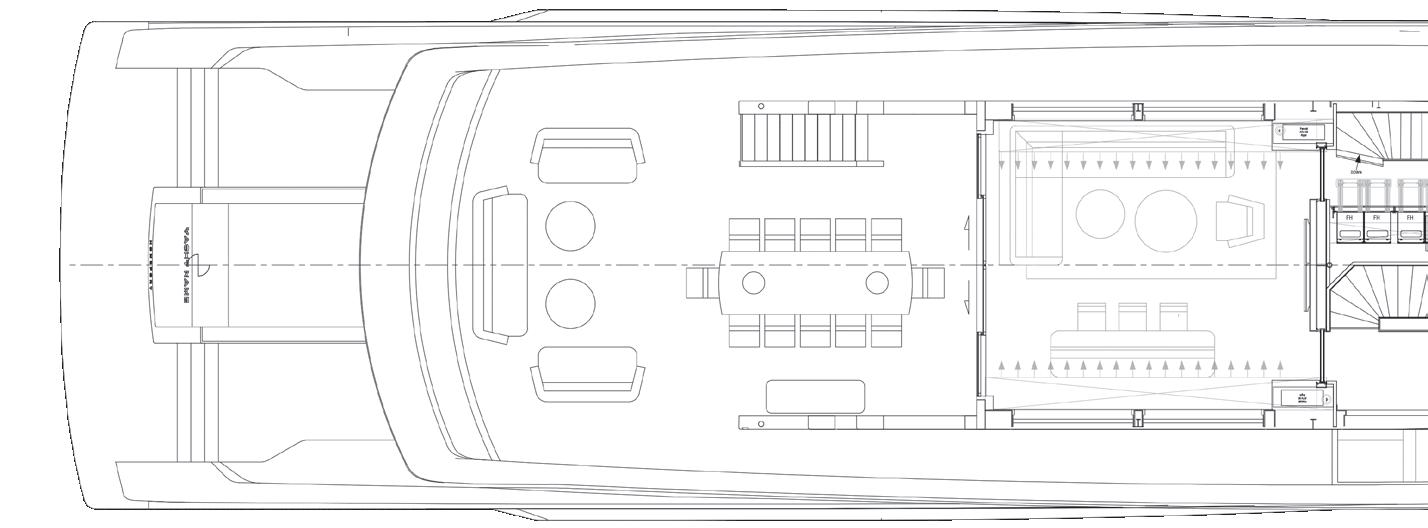

The interior layout offers optimal lifestyle space for the guests, while ensuring the perfect workflow for the crew to deliver a top-notch experience.

In keeping with Heesen’s DNA, the fast and sporty appearance reflects her dynamic performance. She’s available with Heesen’s hybrid technology offering intelligent power management and silent cruising.

At 50 metres and 499 GT, Heesen’s new series will feature a Fast Displacement steel hull of great seaworthiness for optimal comfort in all sea conditions.

The interior connection to the outdoors comes from plenty of natural light and fresh air from sliding windows in the main saloon on the main deck.

Bringing nature together with the visual language of luxury living in one bold and persuasive styling statement.

The latest 50-metre steel hulled yacht marks a bold departure for the shipyard, combining advanced sustainable technologies with visual inspiration drawn from across the luxury design industry.

“The design of Heesen’s 50-metre steel exudes confidence,” commented Peder Eidsgaard. “In keeping with the company DNA, it translates the fast and sporty look of the aluminium yachts into dynamic and agile forms. The profile is not radical or extravagant but refined and timeless. This is a yacht conceived to stand the test of time.”

Eidsgaard added: “The keys to a successful layout in a 499GT yacht are simplicity and versatility. We want to achieve the maximum possible lifestyle space for the guests while ensuring that the crew have the perfect working space to deliver a top-notch experience. Features such as the infinity pool, or the unique coffee table on the sundeck, which doubles as an atrium skylight, will be focal points that invite guests to gather together. The sundeck will be large enough to hold up to 20 guests for outdoor dining. Hospitality is such an important element in yachting, and we wanted to ensure that visiting day-guests can be properly entertained too.”

For the next six months, Heesen engineers and the Harrison Eidsgaard team will work together on translating this design into a perfectly engineered superyacht. Construction is scheduled to commence in Summer 2024.

Yacht number: 21350

Hull type: Twin propeller, FDHF

Naval architect: Van Oossanen / Heesen yachts

Exterior design: Harrison Eidsgaard

Interior design: Harrison Eidsgaard

Classification: Lloyd’s 100A1 SSC YACHT []LMC,

Large Commercial Yacht Code REG-YC

Hull: Steel

Superstructure: Aluminium

Main engines:

Maximum power:

Gearbox:

Propellers:

Main generators:

Bowthruster:

Stabilisers:

2 x MAN D2862LE438 (IMO TIER III)

2 x 882kW

2 x ZF marine

2 x Five blade fixed pitch

2 x Zenoro, 118kW, 50 Hertz

Electrically driven of 100 kW make ZF-Marine

Naiad Dynamics, 2 fins, type 575, zero speed

Length over all: 49.9 metres / 163 feet 8 inches

Beam over all: 9.30 metres / 30 feet 6 inches

Draft (half load): 2.55 metres / 8 feet 4 inches

Displacement (half load): Approximately 480 tons

Tonnage: Approximately 499 gross tons

Crew: 9

Guests: 12

Suites: Full-beam owner’s stateroom, one full-beam VIP suite, four double guest suites

Maximum speed (half load): 15.5 knots

Range at 12 knots: 3,800 nautical miles

Fuel capacity: 60,000 litres / 15,850 US Gallons

Fresh water: 20,000 litres / 5,300 US Gallons

We have long pursued one consistent mission: to create yachts with exceptional engineering and high attention to detail. We achieve this with a highly-skilled workforce and a passion for perfection.

The aim is to fulfill every customer’s dream. Each yacht is built in-house, using the hardest steel and the strongest aluminium. This craftsmanship is matched by a hunger for innovation and challenge. The result: designs that continue to push limits and set the industry’s benchmark. But the Heesen experience goes beyond building a perfect yacht. It’s about exceeding the client’s expectations with first-class service throughout the customer journey.

We have an impressive track record in creating lightweight and ultraefficient hull forms. The Fast Displacement Hull Form already decreases fuel consumption by 30%. Less weight means greater efficiency.

Alternative fuels may be the future, but there are still huge possibilities to increase the efficiency of diesel-powered yachts. These include our acclaimed hybrid propulsion system, standard applications of SCR emission control and more efficient propeller designs.

Reducing yachting’s footprint includes a sustainable build process.

3D Printing, electrostatic paint-spraying, waste reduction and recycling can significantly reduce environmental impact.

Improved waste management and electric-powered tenders are just two examples of how to reduce environmental impact and improve a yacht’s operational efficiency.

Each yacht is built from tons of steel, aluminium, wood and other materials that require sourcing and production. Innovation in this field includes extensive recycling and the use of alternative materials, such as sustainable woods.

On average, a yacht remains at anchor for 95% of the time. Sustainable power generators and waste heat recovery systems are therefore highly effective in reducing a yacht’s total energy consumption by increasing generator power and HVAC efficiency.

If you have any questions or would like to know more about our yachts or services, please do not hesitate to contact us.

Heesen headquarters and shipyard

Rijnstraat 2, 5347 KL, Oss

The Netherlands

+31 412 66 55 44 welcome@heesenyachts.com

Agent North America, Mexico, Bahamas & Caribbean

1819 SE 17th Street, Suite 2

Fort Lauderdale, Florida 33316 USA

+1 954 533 5040

© Heesen Yachts 2023. This brochure has been prepared for general marketing purposes. The information contained in this brochure (including without limitation any information concerning the dimensions, capabilities and performance characteristics of the subject yacht) is given in good faith but is not warranted to be accurate. All such information is subject to change at any time without notice. Heesen Yachts gives no warranty or representation, nor shall it be liable, in contract, tort or any other way, for any claims relating to or arising from any use made of any such information.