It always amazes me how these magazines come together. Sometimes they flow together as if the literary publishing gods blessed our efforts from on-high. This issue is one of those times. First of all, we do these mags with a skeleton crew, whi ch is a feat in and of itself. But we’re a passionate group of fol ks that like to see cool things featured. We also like to tell the tale s of said things. As it sometimes happens, we were struggling to figure out what our cover bike was going to be for this issue. That is until very serendipitously the Ken’s Factory powers that be pos ted their new build on Instagram. As soon as we saw this bike, we knew it was special.

We rang up our ace photographer (well, we WhatsApp’d him) and asked if he was available to snap some pics of Ken and his latest creation and it all just worked out. I always get excite d about featuring cool bikes with great stories, but this one was even cooler because of how seamlessly and easily it all came together. It’s like it was pre-destined. And when that happens, it’s really special. I guess you could say that’s what makes wh at we do here still exciting, especially getting to share our stok e and passion for these cool things with you fine people! But what’s even cooler is when I get to share something from someone I admire and respect immensely.

Ken Nagai, from Ken‘s factory, is about as cool as they come. He’s one of the most talented designers, builders, fabricators, to ever grace our pages, but he’s also a very humble guy. His creative vision is absolutely unique. His style is timeless. In fact, I was looking at an old hotbike.com post of a bike Ken built back in the late 2000s and it was something that was equally as cool today as it was then. Ken, in my opinion, is one of those rare talents that comes along, makes his mark, and does his thing with his head down. The result is a work of two-wheeled art that’s as functional as it is beautiful. Ken’s a man that I admire and respect, and one that I’m definitely honored to feature on this issue’s cover.

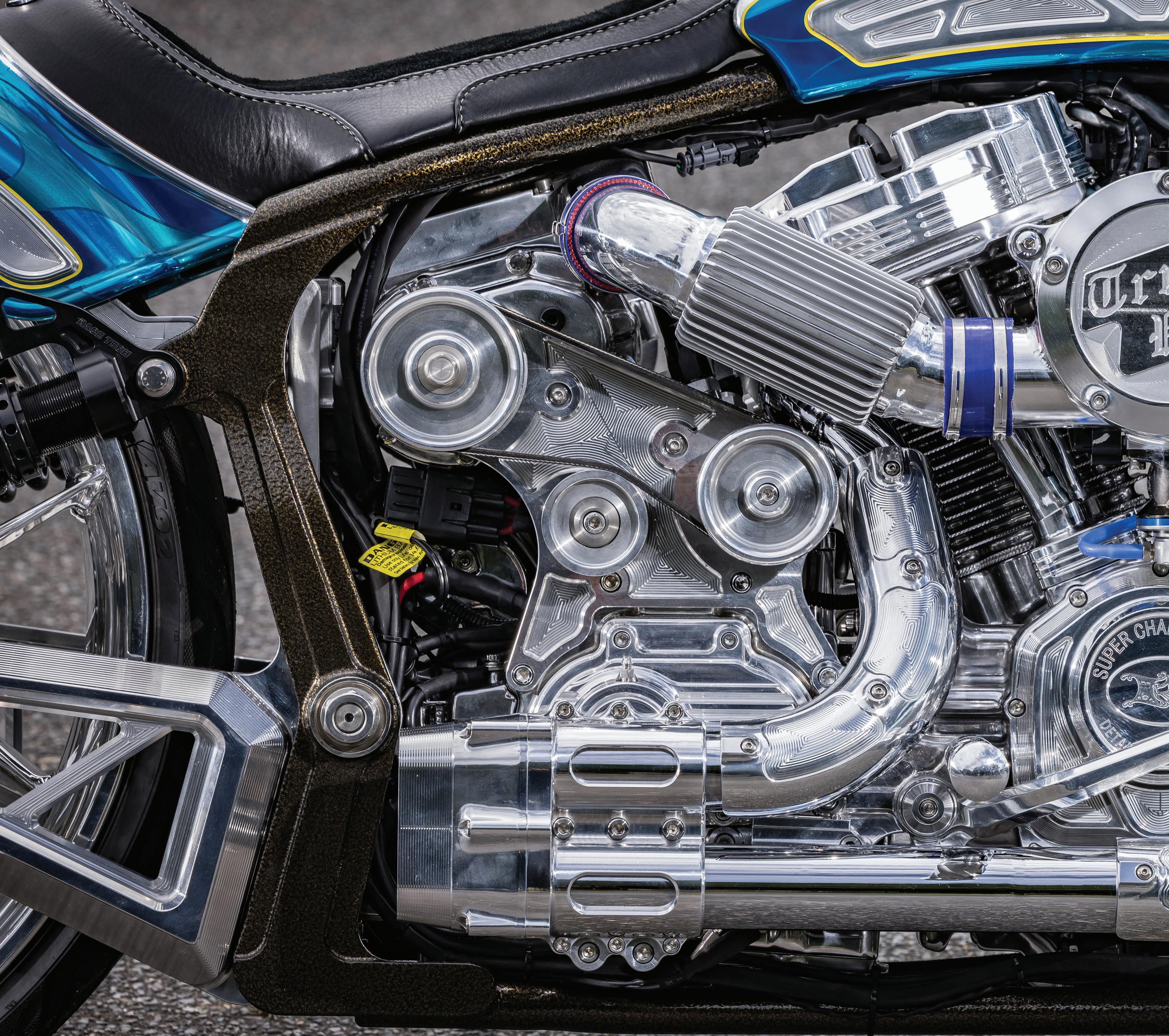

You may also notice a lot of the components of Ken’s new bike are one-off parts that he CNC-machined. I mena, these components are about as intricate and detailed as you can get. I mean look at the tool paths and just the overall design and aesthetic of the machined aluminum. It’s hard to find something as intricate and complex these days. These are the types of bik es that inspire generations. These bikes keep people amped on what we love. This bike helps riders think outside of their own proverbial boxes.

A lot of times I get lost in the search for what’s next or what ’s cool and then when something like this happens it’s a good reminder that sometimes the answer is right in front of me. I don’t know if that’s too esoteric or philosophical, but I do kn ow that is how this issue’s cover bike pretty much came to be. I’m excited to share it with you guys and gals because we’re told t hat this bike might just be Ken’s last custom. I guess we’ll see… I hope you enjoy it.

Bye for now,

Jordan

“KEN, IN MY OPINION, IS ONE OF THOSE RARE TALENTS THAT COMES ALONG, MAKES HIS MARK, AND DOES HIS THING WITH HIS HEAD DOWN. THE RESULT IS A WORK OF TWO-WHEELED ART THAT’S AS FUNCTIONAL AS IT IS BEAUTIFUL. ”

President/Editor-In-Chief

JORDAN MASTAGNI

The Real Boss ASHLEY MASTAGNI

Creative Director ROBERT MARTIN

CONTRIBUTORS

KAZ MATSUMOTO AKA STEELDOG PHOTO, ALEX CHAPMAN, ROB FORTIER, MICHAEL LICHTER, CHOPSKEE, TED NEWSOME, JEFF BRINKLEY, DANNY WILSON, BROCELIANDE STUDIOS

SPONSORS

Hot Bike is grateful for these awesome supporters! AMERICAN METAL WHISKEY, ARCH MOTORCYCLE, AVON GRIPS, BILTWELL, BUELL MOTORCYCLE CO., FACTORY 47, FEULING PARTS, GALFER USA, HORSEPOWER INC., JW SPEAKER, KEN’S FACTORY, KRAUS MOTOR CO., LAW TIGERS, MOTOAMERICA, MOTUL USA, RAMJET RACING, ROLAND SANDS DESIGN, SAWICKI SPEED SHOP, THRASHIN’ SUPPLY CO., TRASK PERFORMANCE, TURN 14

We’re always on the lookout for protective riding gear that looks anything but. There’s no need to look like you’re equipped for battle with every ride. But you can still be protected with some of the latest gear manufacturers out there. The latest from Roadskin and First Mfg. cover the safety and stylish bases. We’ve also been rocking this Cardo Packtalk Edge lately and it definitely gets the job done.

Roadskin’s Taranis Elite motorcycle jeans are comfy. Like really supple and plush. We’ve been riding with these jeans for about a year now, and they’re pretty much a go-to when it comes to a pair of riding jeans that we know will keep us protected should we need it, but also, doesn’t feel like we’re wearing battle armor every time we get off the bike.

The Taranis Elite armored jeans and the first to provide the AAA safety rating in a single layer, as tested by SATRA Technology Centre in the UK. This happens because Roadskin’s uses Kevlar fibers woven into its alreadypremium denim, so they feel and look exactly like a regular five-pocket pair of jeans but give you the peace of mind that comes with wearing AAAs. The Taranis also contains a good amount of elastane for stretch. This is where the comfort comes into play, especially after the big lunch when you’re out with the guys. They’ll give you an extra inch to get dessert. The Taranis Elite jeans are comfy, protective and don’t look like dorky riding jeans.

The Moto Shirt is cool. It’s also comfy (are you seeing a trend here?). And lastly, it is constructed from recycled canvas clippings, which are shredded and woven back into spools of new thread. Every new spool of thread is dyed and waxed to create a water resistant material for you to ride in. It’s also a great balance balance between a jacket and shirt. Crafted from 14-ounce Duck Canvas, and lined with a mesh panel with armor pockets. And for you big guys, you can get it up to 5XL!

We like the Moto Shirt primarily because it’s lightweight and the recycled canvas is comfortable on our skin.

The Packtalk Edge is also loaded with everything you need. It’s waterproof. It connects to pretty much any other Bluetooth comm system on the market. It allows voice activation: “Hey Cardo, what the hell am I doing with my life?” The Dynamic Mesh Communication (DMC) setup is crisp and clear with about a 1-mile range. It also adjusts your volume based on ambient noise. Slow down, the volume goes down. Speed up… well, you get the idea. There’s also built-in FM radio with RDS for automatic selection of the strongest signal for when your phone battery takes a shit. Maybe that’s a good thing? Maybe not. I can only imagine getting stuck on the show tunes station for hours on end.

If Bluetooth communicators are your thang, check out Cardo’s Packtalk Edge. It’s competitively priced at $399.95 for the single unit, but you can catch a break by shelling out for the Duo at $729.95. After all, talking to yourself in your helmet gets pretty old after a while. HB

HOT BIKE: Describe yourself in three words. BOBBY SEEGER: Real white man.

HB: Haha, nice.

BS: It’s the truth.

HB: All right. Talk about how you ended up in the motorcycle industry.

BS: I got into the motorcycle industry through Indian Larry. He and I had a very good friendship. He wanted me to stop breaking his balls about stuff. The only way that could happen is if we, in his eyes, became partners. That’s what got it going. I didn’t care to. He was brow beating me every fucking day, man. “What’s up? We’re going to be partners. It’s going to be great.” And me telling him, “No, it’s not. It’s going to suck. It’s queer. Just shit.” A lot of good shit talk, I’d say. And that’s how I got into it. All I ever would tell him was, “I don’t understand why you’re not making some money over here. How come you’re not making some money over there? Why are you letting this guy tell you this?” It was because he didn’t own Gasoline Alley. People thought he did, but he didn’t.

HB: Wait, I’m going to back up a little bit. You were going somewhere… you were working with the city… And then how the fuck did you and Larry even get to know each other? Talk about the very beginning and how you guys even met, and that relationship, and how you guys ended up becoming partners.

BS: Larry used to give hand jobs. At this point, I was working for the city of New York, and I had a good thing going.

HB: Doing what?

BS: Working for the MTA, the transit. They have one department that’s an emergency department, working on water pumps and ventilation fans. I just happened to get in on that. That was good. I was in a maintenance gang, and it was fantastic. It’s not like that anymore. I had 17 glorious years. But anyway, then I got in with Larry. It was fun because I had a lot of good times laughing and joking with him.

HB: How did you get in with Larry? How did you guys meet?

BS: Really from just riding around in the city. Just hanging out. I had a full dresser. I was the only one at 25 years old with a full dresser around ‘95, ‘96, ‘97. I ended up getting rid of that bike around 20022003. I’d been sober for a number of years at the time. Larry was dabbling in and out of sobriety. We had a few mutual friends who worked at a shop called American Dream Machine in Soho. Larry would also do motor work at his apartment, which was called Under the Stairs. That was decent for him. Then Jesse James asked him to do Motorcycle Mania. There was a lot of excitement. It was good. Then he

got Monster Garage, and that’s when they were talking about doing Biker Build-Off from there. Monster Garage was like a transformer. So that excited Larry.

HB: Got it. So you guys just became friends through riding and…

BS: Yeah, early on, it was a lot of mutual friends. I knew him through Iron Horse or knew of him. I couldn’t be bothered with Psycho Cycles and all the antics, so I never went around that. But I would see him

in this lady’s tattoo shop that started tattooing me. I started getting tattooed the end of ‘93 into ‘94. He would be in there because he hung out with her all the time. This lady, Andrea, showed up on the place called East Side, Inc. Her boyfriend at the time was this guy Frank, and Frank was Larry’s roommate. Then Kenny, who ran the shop in Soho, he needed a place to live, so he became Frank and Larry’s roommate. I hung out with Kenny just about every day. It was a little circus in Larry’s house. Then it was just breakfast and lunches and dinners, just hanging out. We didn’t really talk much about motorcycles. We’d talk about legit massage parlors, what’s a good place for coffee, and life stuff, how to get through certain life stuff. That’s really the basics on it. Then Elisa, my wife at the time, she was a buyer. She has her head on pretty good. I said, “Hey, Larry keeps asking about being a partner. What do you think? Maybe we go into the garment industry and do some parts and stuff like that, see where it goes. I think it’s something pretty good. I can’t fucking take him asking me anymore. Let’s see what’s up.” She was like, “Absolutely.”

HB: Nice. You’re like, how do I get this guy off my back? BS: Yeah, it was great because every day I would just show up for a couple of coffees, or I’d meet up with him and have breakfast. The last thing I wanted to do was be in business. Again, I worked for the city, and we had a four-family house. That was a big gamble at the time. Then it was like, “Oh, how do we put money into a thing that we’re going to help make when all these other things were up and down with Larry?” You know what I mean? Then having people that knew Larry for five, 10 years earlier saying, “Don’t do it. All these other guys that invested, all that shit just never worked,” and blah, blah, blah. I was just like, “No, man, we’ll go at with this. I got no desire to screw him or anybody else. I’m not into that. That got it moving. In the first week after we agreed on everything, the guy that had Gasoline Alley burnt himself out and burnt out his welcome. He left and we just went with Indian Larry, basically.

HB: So essentially with Larry, Gasoline Alley morphed into Indian Larry Motorcycle?

BS: Yeah. And it was really like, what took a change? The change being the guy that was in charge. Because the guy in charge, he really loved, say, Arlen Ness stuff. And as great as Arlen Ness was and the innovator made fantastic stuff. That’s not the style that Larry was making. You know what I mean? Then I was just like, “Look, I don’t give a fuck. I think you should just make the bikes you make, and we should have a good time. Let’s go around the world. You’re invited to all these places. Elisa will manage whatever you need…” And then to look back on it, I am still happy that I didn’t get involved with TV because I thought it was queer. And when Discovery would say something. Pretty much, they didn’t like me because my responses to them were never what they wanted. We’re not here to play games. They want to have a good time. In the long run, it was good. So it was like, did we want to be on TV even when he died? We didn’t want to be on TV. We were like, all these people are clowns that are getting on stage. They weren’t even in the shop every day. It’s like the one person that should have been up there was Paul or maybe Elisa because she fucking held hands with Larry, guiding him through a whole bunch of shit. But nobody else should have, but yet everybody else claimed to be... I learned a lot then, and I had refreshers as well. But I’ll say this, when we agreed on doing shit together, Larry and I, it was great. There was a good amount of excitement. I said, ‘Oh, motherfucker, we’re going to get your name in lights’ Bo went out and fucking had a neon sign made that said Indian

Larry on it, 6 feet. I thought Larry was going to jerk off. It was exciting. It was goofy. And nobody else would ever really commit to doing stuff like that. “Why waste the money on that?” That’s what most would say.

HB: So you go into biz together in 2002, and then he passes in 2004. When did you decide, fuck, do we carry on or do we close the shop? BS: Right out the gate. So right before he died, I was like, we’re going to have a block party. That’s something that you used to have in the street. Some blocks still have it, but not many. Because the turnover of people from who was here, say ‘60s, ‘70s, ‘80s, ‘90s, they moved or they died. Their kids don’t want They want to be in New York. They want to be in Jersey or Florida or California. You know what I mean? I thought, No, this is 2004. I want to have a fucking block party. Block parties are great. Then boom. We’re having a block party. Nobody wanted to have a block party because it’s really an undertaking. I said, “It’s not going to be a problem. And it worked out. We cooked a pig in the street. A fucking guy came with a jet car from Jersey with the engine off of a plane. It melted the street. The fire department came and they loved it. It was fun. This was in June 2004 and then Larry died in August. The outpouring we received because he’d been on two Biker Build-Offs, the Jesse James stuff, and a variety of magazines at this point. We’re going to have a block party. We’re going to just throw a fucking party. It’s going to be awesome. That’s what we did. A crazy amount of people came from around the world, more mind-blowing than you could imagine because after he died in the Carolinas, we got home and pulled up to the shop, and all there were flowers, cards and notes outside against the wall. And people were portraying it that Larry died doing a stunt. When realistically, that wasn’t the case. He was dehydrated and he blacked out and he fell off the bike, going very, very slow. It was just one of those freak things and he hit his head. It was like that. Then the choice to go forward with Paul Cox was fantastic, but none of us really knew. Paul was not a real... Paul was one of those super talented guys. If he doesn’t know it, he’s going to read up on it and he’s going to fucking dominate it. He’s just going to do it. That’s been him the whole time I’ve ever known him, and he hasn’t slowed down. But then it’s to the point of there was no time to mourn. It was just like green light, go. We finished off the easy ride a tour, then we had to finish this, finish that. From motorcycle building, clothing, some parts. It was like, Okay, what is this? It’s Larry’s legacy. Great. We’ll call it Indian Larry legacy. Fantastic. That lasted a little bit. Then Paul wanted to go break off on his own, which was really good. Then it was like, “Wow, I wonder what it would have been like, have we all been under one umbrella?” Paul is one of those few people I actually love. I tell him all the time. I think he’s a fantastic guy. He’s a great father. He’s a great husband. He’s an all-around, somewhat quiet man, but he’s on the ball. But when we split up, I call it the divorce because he went one way and we went the other, all Elisa and I wanted thought was how do we keep Larry’s name up? The offers to do stuff with the Walmart and stuff like that, we didn’t want to do that. We didn’t want to do it when he was alive. We said no to stuff. We didn’t want to do it when he died because we didn’t think there was longevity. And it wasn’t a money thing because have we been looking to have a money grab, we would have went for the deals and just said, fuck it. But we didn’t do that because we thought, longevity. Fuck it. We can make it, man. Come on. Sometimes I wonder. I should have been hitting that head a little bit more. I’ve been hitting that head a lot. I should have been maybe a little more.

HB: Okay, I think I got it. Thanks for providing the history of the shop, etc. What would you say is your greatest accomplishment?

BS: Well, I’ll tell you that it’s sticking through everything. The fact that

every storm that’s come my way, regardless of wanting to weather it or not, I’ve weathered it. And in a sense, I’ve prevailed. I’m above water. My glass has always been half-full. When I say to people, ‘Hey, you got kids? Yes. Where are your kids? I’d say, I had a boy, I had a girl. My boy got sick. He passed away. My daughter’s healthy and fucking just pumping along. They’re like, I don’t understand. How did he die? ‘Okay, this is how he died.’ But you’re not married anymore. I go, ‘No.’ What I’ve learned is when a when a child dies, usually a parent blows their brains out or they’re at least divorced. The relationships, there’s like a 2 percent chance that they’ll stay together. Me, I was a fan of staying together. I wasn’t interested in any other women. My wife wanted something different. She at least not to be married to me at the time. When I say to people, I go, You know what? It’s like my wife and I, in my eyes, we hit it off to where we had two Okay, great. She just happens to be that type that is the type A person. That type A person, had it not been for her and her personality and her drive, there wouldn’t have been any enactment to have a law of testing for this particular rare brain disease push forward, because many people tried, but they didn’t push. You know what I mean? The fact that we owned a relatively famous This motorcycle shop, that was surely a help, a stepping stone, if you will, with an outlet for around the world. You know what I mean? It’s like, Okay, Larry dies. Our son’s born. Larry dies not long after. A couple of years go by. Then if it wasn’t for being in the bike industry, I don’t think it would have gotten as much traction as it did. It can’t be that. Even before the bike industry, I knew somebody around the world, pretty much because I was always out, travel, run around, do stuff. The bike industry just fluffed up a little bit more for me. For me, I say, You know what? Just staying in the rowboat of life and at times just having to have a little Dixie cup to throw the water out because it’s filling. I don’t have the why me, but how did I learn to get through these things? It’s from other people’s experiences. It matters how you get through a particular thing? It’s just like, I’m not the famous guy. I’m not the guy that builds motorcycles. I’m not the guy that wanted this, but I’m the guy. Out of a whole group of fucking friends, everybody would have blown the next person if they could be the guy.

HB: What’s your favorite motorcycle of all time?

BS: The Grease Monkey. 100 percent. The Grease Monkey is badass. It’s the only bike I didn’t want to ride. I could have ridden it in ‘98. He was like, “Why don’t you just take it?” I was like, “I can’t afford to fix it.” And then even when he died, I’m like, I’m not riding the bike. That’s like the chalice. That bike’s badass.

HB: Who or what inspires you nowadays?

BS: I’m all about people, man. Regular people are the key. Don’t be a jerk off. That’s number one. It’s like my days are pretty much I must talk to my daughter who just turned 18 today. I talk to her 8-10 times a day on the phone every day. I could be in the mountains of Nepal. I could be in fucking Japan, Italy. It doesn’t matter. I’ll be cutting through Ohio. We talk.

HB: What would you say is your proudest moment?

BS: My proudest moment. I got to say, every day, man, it’s all about showing up. That’s where I’m proud. I’m happy, man. I show up. I may not always be the most level head in the room, but I’m one of those in the room. From the kids being born to the kids passing away, I’m there. And you show up, man. It’s one foot in front of the other. Sometimes

it’s a motherfucker, but goddamn, man, I show up. So I don’t have those standards. Everybody’s got that cookie cutter of your regrets or your proudest or what’s your favorite color? Shit like that.

HB: Good. All right. Favorite place on Earth.

BS: Italy. 100 percent. I love it all. I mean, the Amalfi Coast is by far my favorite. I got married there. I’ve been there a lot. I’ve been fortunate to go to Italy over 30-some-odd times. I’ve been to every US state, but Alaska. I’ve been all over.

HB: Is there anything you’re working on that you think you want to just talk about?

BS: We got two bikes that we’re taking our time building because we don’t care enough right now about them because we build bikes at our pace. And if we feel like selling them down the road, we do. If not, we keep them. But really, the big thing is the amount of parts we’ve been doing. A lot of them are for the newer style Harleys. We’ve still done stuff for guys that are at home building choppers or building bikes, little bobbers or however they want to change their lingo. But really, the more dominant thing for us has been these bagger parts. I say bagger parts, you know what I mean? From all these M8s, the diners, bars, risers, trees. Again, we’re not interested in knocking anybody else doing it. Who’s in the business? Who’s fucking who? None of that is any of our business, really. We’re more interested in quality over quantity. That’s really where it’s at. And we don’t give a shit. If this guy sells more, this guy sells less. We care primarily about quality. And good things take time and all that. But listen, we cost more, we take longer.

HB: What do you see in this industry’s crystal ball?

BS: I see it’s pathetic, but it’s going to still go because, shit, getting around on a motorcycle is a lot more fun. But industry-wise, it’s primarily full of retards. I’m not exempt from that by any means. But my outlook on life is most certainly different than most. I prefer to be at the beach all day and go do whatever John and Gabby in the shop want me to do, be it load CNC machines or sweep the floor and clean the bathrooms. If that’s what it must be, I’m going to go do it. But otherwise, everybody wants to, like I said, farm out and push and not give credit where credit’s do. Listen, at the end of the day, the only reason that this Indian Larry name stays up is because of teamwork. It doesn’t matter. There’s no I in any of this shit. It’s all teamwork. If there’s people that have been in my little team that didn’t feel they were part of the team, and you know what? They’re not part of the team anymore. HB

The Buell Super Cruiser is slated to release very soon. It’s been a little over a year since the new Buell emerged from the ashes, led by new ownership and one that’s poised to take a big delicious bite out of its cruiser market competition. But let’s not forget that there are plenty of cool Buells out there that are keeping Buell aficionados satiated.

With that being said, a gentleman by the name of Steven Lucas, aka Matao, built a custom Buell XB12 with plenty of elegance and grace. After Matao completed his project he exhibited at two of the motorcycle world’s most prestigious events—the Bike Shed in London and Wheels and Waves in Biarritz France. This bespoke build reflects a harmonious fusion of modern electronics, premium components, and meticulous attention to detail, all coming together in a striking display of form and function.

At the heart of this build is a seamless integration of cutting-edge electronics, achieved through a collaboration with Motogadget, a leader in motorcycle electronics. From the sleek indicators to the hidden M-Unit, every electronic component was carefully selected to maintain the clean lines of the bike while delivering top-notch functionality. The front and rear indicators were upgraded with precision Motogadget components, providing a modern touch without sacrificing the bike’s raw, aggressive appeal.

For lighting, Baja Designs’ signature front headlight was adapted to a custom steel front end. The bold and rugged look of the Baja Design headlight perfectly complements the muscular stance of the Buell XB12, ensuring that the bike performs as well in low-light conditions as it does in broad daylight.

One of the standout features of this Buell XB12 is the custom upholstery by Saddlery Fleury. The seat, made from premium Alcantara, is not only luxurious but also designed to withstand the rigors of long rides. The seat base, crafted from lightweight carbon, adds both performance and style to the build, reducing weight without compromising on strength.

The rear tubular chassis is a completely custom creation, designed and fabricated by the builder to perfectly suit the bike’s aggressive posture. The attention to detail extends to the mounting of the license plate, which was carefully crafted to integrate smoothly with the overall design. The battery, CDI, and entire electronic system were cleverly hidden under a false tank, keeping the bike’s aesthetic clean and uncluttered while maintaining easy access to essential components.

This Buell XB12 isn’t just about looks—it’s built to perform. The

engine was completely rebuilt by Twin Motor France, ensuring that the bike delivers the power and performance that Buell is known for. Every element, down to the original screws, has been nickel-plated, adding a touch of refinement to the raw mechanics of the bike.

When it comes to braking and suspension, no expense was spared. The builder opted for a Beringer master cylinder and Beringer brakes, offering unparalleled stopping power. Paired with an Öhlins shock absorber, the ride quality is smooth and responsive, providing the rider with confidence in both urban environments and on open roads.

The aesthetics of this Buell XB12 were taken to another level by the incredible paintwork, done by @abdecometal77330 and @latelier_ de_so. The striking finish emphasizes the bike’s aggressive lines while maintaining a sense of elegance. The overall vision of the builder was perfectly captured by Broceliande Studios (@lesstudiosdebroceliande), whose photography highlights every detail of this incredible machine.

This Buell XB12 stands as a testament to what can be achieved through a combination of innovative engineering, high-quality components, and a vision for design that pushes the boundaries of custom motorcycle building. Whether exhibited at the Bike Shed in London or Wheels and Waves in Biarritz, this Buell is a showstopper, embodying the essence of motorcycle culture with its unique blend of style and performance. HB

“I CREATED THE REAR TUBULAR CHASSIS WITH A SEAT BASE MADE OF CARBON...”

BIKE OWNER

STEVEN LUCAS

SHOP NAME MATAO BZH

SHOP WEBSITE/SOCIAL

MAKE/MODEL

FABRICATION

MATAO-BZH.COM

BUELL XB12

MATAO BZH

ASSEMBLY MATAO BZH

BUILD TIME 350 HOURS

ENGINE

YEAR/MANUFACTURER

BUELL-TWIN MOTOR FRANCE/1200CC

TYPE/SIZE BUELL/1200CC

CASES BUELL

CYLINDERS BUELL

HEADS BUELL

ROCKER BOXES BUELL

EFI/CARB BUELL

AIR CLEANER K&N

EXHAUST GPR

TRANSMISSION

YEAR/MANUFACTURER/TYPE

BUELL XB12

CASE BUELL

CLUTCH BUELL

PRIMARY DRIVE BUELL

FRAME BUELL

YEAR/MANUFACTURER BUELL

RAKE STOCK

STRETCH N/A

SUSPENSION

MANUFACTURER FRONT ÖHLINS

TRIPLE TREES

MATAO BZH MANUFACTURER REAR ÖHLINS

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT-TYPE

BUELL XB12

TIRE HEIGHT-WIDTH PIRELLI SUPER CORSA CALIPER BERINGER MASTER CYLINDER ROTOR BERINGER

MANUFACTURER REAR

BUELL XB12

FINISH-PAINT GRIS MAT-NOIR MAT-NOIR BRILLIANT COLOR BLACK AND GRAY PAINTER S. ATELIER DE SO GRAPHICS MATAO SPECIAL FINISHES MATAO MATAO ACCESSORIES MOTOGADGET FRONT FENDER MATAO

REAR FENDER MATAO FAIRING/WINDSCREEN MATAO GAUGES. MATAO GAS TANK/CAP MATAO DASH STOCK OIL TANK STOCK HANDLEBARS RIZOMA HAND CONTROLS/GRIPS MOTOGADGET

FOOT CONTROLS/PEGS LSL HEADLIGHT BAJA DESIGN TAILLIGHT MOTOGADGET

TURN SIGNALS MOTOGADGET LICENSE MOUNT MATAO SEAT SADDLERY FLEURY

WORDS:

Nick Trask of Trask Performance has never been one to shy away from bold, aggressive designs. As a fellow Hamster and V-twin junkie, it’s no surprise that Nick, known for his need for speed by creating on-tap, raw horsepower through his Trask Turbo Systems, brought his trademark style to the forefront with this FXR build. This project is not just another custom motorcycle—it’s a visceral, sensory overload that pulled out all the stops.

Nick and the owner of this fine machine, Steve Conklin, met through Hamsters club. They quickly bonded over their shared passion for anything with a motor and wheels. Nick’s personality is reflected in his creations, and when it came to building an FXR, it was clear the result would be something out of the ordinary. Trask’s style can be summed up in a few words: clean, masculine, rugged, and fast as fuck. The first time you hear the bike’s turbo whistle, you know it’s a Trask machine—a signature that’s hard to miss.

Nick and the Trask crew had a simple goal when taking on Steve’s FXR project: build a lightweight, high-horsepower machine that delivers performance as aggressive as its appearance. In the world of custom motorcycles, people often say “less is more,” but Trask took the opposite route with this project. The design is an all-out assault on the senses. The moment the Twin Cam roars to life, you’re bombarded with sound, vibration, and raw speed. The turbocharged V-twin is anything but subtle, delivering ridiculous power that Steve jokingly refers to as “Tradiculous.” The throttle response? Explosive. The speed? Beyond belief. It’s not just a bike—it’s a missile on two wheels as Steve refers to it.

The FXR platform has seen a resurgence in popularity over the past decade, becoming somewhat of a cult classic. Known for its nimble handling, low stance, and robust frame, the FXR is an ideal foundation for a custom build. Lightweight and compact, the FXR frame can handle big horsepower upgrades, which is exactly what Trask Performance aimed to do.

As with any ambitious custom project, the biggest challenge was time. Trask Performance is a world-renowned shop, churning out high-quality performance V-twin motorcycle products and they’re also in high demand for their elite builds. This FXR was no different. But, Nick is a loyal friend, and Steve’s FXR would have been built no matter what because Nick took on the project despite his busy schedule. As with most custom builds, patience is a virtue. Perfection takes time, and Nick Trask was determined to make this bike perfect. “It’s going to be badass,” became the recurring mantra whenever progress updates were requested. Hearing Nick say it in his Kiwi accent only added to the anticipation.

While the FXR may have classic roots, Trask Performance’s approach was anything but old-fashioned. Every inch of this bike was engineered with performance in mind. Moots McDonagh, another seasoned pro and Trask tech guru, helped bring the vision to life, transforming raw ideas into mechanical reality with uncompromised craftsmanship. Whether it was the frame modifications or the custom turbo setup, Moots’ handiwork is all over this bike. His skill in balancing function with form is evident in every detail.

“FROM THE ROAR OF THE TURBOCHARGED ENGINE TO THE RAZOR-SHARP HANDLING, EVERY RIDE IS AN ADRENALINE RUSH.”

The final product is more than just aesthetically pleasing—it’s a predator. Designed for performance, the Trask FXR feels like a weapon. Light, agile, and incredibly quick, it delivers massive horsepower while staying nimble enough to slice through traffic or carve corners on backroads. Riding this bike feels like you’re locked and loaded, ready to unleash it at any moment.

The FXR platform has always held a special place in the hearts of custom bike builders because it offered better handling and durability compared to other Harley-Davidson models of the time. It’s compact, relatively affordable, and, most importantly, it can handle a high-performance build. The variety of aftermarket parts available only sweetens the deal, allowing custom builders like Trask to take the platform to new levels of power and style.

This particular FXR started as an ’88 FXR-S, a bike with humble beginnings but ripe with potential. While FXRs have become somewhat nostalgic, this one is far from a museum piece. It’s a

modernized, turbo-charged monster, ready to take on the road with unparalleled performance.

No matter where this FXR goes, it turns heads. Whether it’s parked at a bike show or cruising down the highway, people can’t help but stare. The bike’s aggressive stance, combined with its muscular design and turbo whistle, leaves a lasting impression.

“What is it?” is the most common question from curious onlookers. The answer is simple: it’s the most radical bike they’ve ever seen.

The Trask FXR custom build is a testament to Nick Trask’s talent, vision, and relentless pursuit of performance. It’s more than just a bike—it’s an experience. From the roar of the turbocharged engine to the razor-sharp handling, every ride is an adrenaline rush. And as the author can attest, this build was well worth the wait. Trask Performance has once again proven why they are at the forefront of custom V-twin motorcycles, delivering a bike that’s not only visually striking but a true powerhouse on the road. HB

BIKE OWNER

STEVE CONKLIN (EAGLE, CO)

SHOP NAME TRASK PERFORMANCE / PHOENIX, AZ

SHOP PHONE (623) 879-8488

SHOP WEBSITE/SOCIAL WWW.TRASKPERFORMANCE.COM @TRASKPERFORMANCE

YEAR/MAKE/MODEL 1987 HD FXR

FABRICAJON TRASK PERFORMANCE

ASSEMBLY TRASK PERFORMANCE / MOOTS MCDONOUGH

BUILD TIME 5 MONTHS

ENGINE S&S

YEAR/MANUFACTURER

TYPE/SIZE 124 CI TWINCAM EFI

CASES S&S CYLINDERS S&S HEADS S&S ROCKER BOXES S&S EFI/CARB EFI

AIR CLEANER TRASK TURBO

EXHAUST TRASK CUSTOM HIGH OUTPUT TURBO SYSTEM

SPECIAL FEATURES TBW / THUNDERMAXX ECM

TRANSMISSION HD FL W/BAKER 6 SPD YEAR/MANUFACTURER/TYPE CASE OEM FL CLUTCH TRASK BILLET BASKET, DP PLATES, SE ADJUSTER, STAR RACING BILLET RAMP PRIMARY DRIVE HD FL 2001

FRAME TWINCAM CONVERSION DONE BY ROLLING THUNDER (SAINT-COME, QUE

YEAR/MANUFACTURER RAKE STOCK

STRETCH STOCK

SUSPENSION

MANUFACTURER FRONT SUZUKI HAYABUSA LENGTH STOCK/LOWERED

TRIPLE TREES BROCKS PERFORMANCE

MANUFACTURER REAR NOWASKEY REMOTE RESI SHOCKS, 12” SPECIAL FEATURES BROCKS PERFORMANCE SWING ARM

WHEELS, TIRES, AND BRAKES BST TWIN TEK BERINGER BRAKES

MANUFACTURER FRONT-TYPE METZLER

WHEEL HEIGHT-WIDTH 19” TIRE HEIGHT-WIDTH 110/90-19

CALIPER BERINGER RADIAL ROTOR BERINGER AEROTEC

MANUFACTURER REAR BST TWIN TEK

WHEEL HEIGHT-WIDTH 17” TIRE HEIGHT-WIDTH 180/60-17

CALIPER BERINGER RADIAL ROTOR BERINGER AEROTEC BERINGER REAR MASTER

FINISH-PAINT CERAKOTE

COLOR TUNGSTEN BASE, TITANIUM GREY HIGHLIGHT, BLUE PINSTRIPES

PAINTER KRASH / KOLOR CHOP / TEMPE, AZ

GRAPHICS VON BUTCH DESIGN

SPECIAL FINISHES WHEELS CLEAR COATED TO MATCH PAINT

ACCESSORIES

FRONT FENDER KRAUS DYNAMOTO CARBON FIBER

REAR FENDER ITALIAN PERFORMANCE LATE MODEL DYNA CARBON FENDER

FAIRING/WINDSCREEN N/A

GAUGES AUTO METER

GAS TANK/CAP LATE MODEL DYNA MODIFIED TO FIT FXR BACKBONE / HD FLUSH MOUNT CAPS

DASH CUSTOM FXR DASH, MODIFIED TO FIT LATE MODEL DYNA TANK OIL TANK N/A

HANDLEBARS TRASK MOTO BARS

HAND CONTROLS/GRIPS 06+ DYNA HAND CONTROLS FOOT CONTROLS/PEGS TRASK ASSAULT FOOT BEGS HEADLIGHT

BAJA DESIGNS LP6, TRASK CNC’S BRACKET TAILLIGHT KELLERMANN

TURN SIGNALS KELLERMANN

LICENSE MOUNT CUSTOM TRASK MOUNT SEAT GUYS UPHOLSTERY, MESA AZ AUDIO N/A

MISC FXR DIVISON STRUTS, ITALIAN PERFORMANCE SIDE COVERS

WORDS: JORDAN MASTAGNI PHOTOS: COURTESY OF INDIAN MOTORCYCLE

ou might remember Indian Motorcycle’s Forged Series from last year, where the brass at Indian Motorcycle tapped one of their most loyal ambassadors, Carey Hart, to select two other builders and take the then-new Sport Chief to new heights by customizing the bike for a special recipient. Yaniv Evan, from Powerplant Motorcycles, built a cool bobbed out rendition for Norman Reedus. Jake Cutler from Barnstorm Cycles, built a head-turner for TJ Dillishaw, of UFC fame, and Hart himself, built a sweet little paneled Sport Chief for his old FMX pal, Twitch.

Well, the Forged Series is back again this year, with an allnew host, Roland Sands from Roland Sands Design. Roland was tasked with fi nding two other builders to tackle an all-new platform: The 2025 Indian Scout. Designed with customization in mind, the all-new Indian Scout is a bike born from icons and ridden by legends. Each build in this sophomore eff ort of the Forged Series is rooted in a historical fi gure, machine, or era of inspiration taken from Scout’s 100-plus-year history

- highlighting icons of the past, through the eyes of today’s legends.

Roland and the Indian team selected Brittney Olsen, a vintage motorcycle afi cionado who has built several period-correct machines throughout her tenure. Her specialty is defi nitely old iron, so we’re excited to see what Brittney brings to the table in this new endeavor with a modern machine.

Roland and company also selected a Swedish customizer, Ronna Noren, from Unique Custom Cycles, with his clean and sanitary styling, making subtle yet signifi cant changes to the motorcycle the star of the show. Ronna will be building his take on the Indian Scout.

The 2025 Indian Scout was designed with customization in mind, and the all-new cruiser is a bike born from icons and ridden by legends. Each build in this sophomore effort of the FORGED Series is rooted in a historical figure, machine, or era of inspiration taken from Scout’s 100-plus-year history - highlighting icons of the past, through the eyes of today’s legends.

Roland Sands of Roland Sands Design was tasked with spearheading this year’s FORGED Series, where he and his crew, most notably RSD builder/fabricator, Aaron Boss, set out to build a rad new ripper for Twenty Pilots’ drummer, Josh Dun, using the all-new Indian Scout as the platform.

After the build was complete, Roland and Aaron invited Josh Dun over to RSD’s HQ in Long Beach to check out the new machine in the metal and go for a little shakedown rip around town.

Roland, Aaron and the RSD crew knew the performance stance was very important to achieve the level of performance they were after. The stock Scout gave them the chops to make it sit just right with 17inch RSD/Dymag wheels shod in Dunlop Q5 tires with dual disc front brakes and radial mount calipers. The list goes on…

“What makes an RSD bike an RSD bike is taking the performance of the machine and elevating it,” Roland says. “Right when you look at this bike you go, ‘oh, that thing’s high-performance for sure.’”

RSD has in fact always taken cruisers and turned them into sport

bikes. They built their business doing so. “We’ve done the same thing with this bike,” Roland says. “That silhouette… that’s an RSD silhouette.”

A lot of the credit goes to the all-new Scout platform because of its ease of customization. “The cool thing was how easy it was to make the Scout fit that RSD mold,” Roland says.

In fact, customizability is what helps modernize the all-new Scout. Indian understood its customers like to personalize their own bikes so why not make it easier for them do so, which was a main consideration when creating the updated Scout platform.

When Josh entered the shop and met with Roland and Aaron, it turned out that the Columbus, Ohio native, was no stranger to Indians. In fact he currently owns an Indian Scout Bobber and has ridden the FTR1200, which is a great segue into the bike he was presented. RSD and Indian have a long history with the Scout platform in all its iterations and this Scout/FTR hybrid turned out to be the perfect combo for the new owner since those are the only two Indians Josh has ever ridden.

When Josh saw his new machine, he was pretty much floored. “Wow, this thing’s perfect!” Josh says.

Aaron did a great job morphing a lot of the FTR components onto the Scout for this project.

“You can obviously see all the parts to adapt the FTR front fork, triple clamp and everything else to that neck. We had to modify the front fairing piece to hook up to these forks,” Aaron says. Aaron and the crew also had to modify the stock foot control brackets to fit the completely one-off custom exhaust. The motor was already pretty well dialed to receive the FTR swingarm too so it seemed like a natural fit. For the tail section, which was originally designed for the flat track tail sections RSD used to make for the Scout, which they basically just reimagined to work with the new platform. After fab was done, it was off to paint and the Saddlemen crew knocked out a one-off custom seat for the bike in about a day.

The RSD Scout was inspired by Ed Kretz, a legendary racer from the ‘30s and ‘40s who received attention after winning the inaugural Daytona 200 in 1937. Ed, aka the Iron Man, was a true original in those times, dominating the racing scene on an Indian Sport Scout.

“I think if Ed Kretz was building Indians today, this is the kind of project he would take on,” says Roland Sands.

If you’re a fan of vintage-meets-modern custom motorcycles, you’ll definitely appreciate Brittney Olsen’s take on a 2025 Indian Scout.

Brittney Olsen, of 20th Century Racing, was asked by this year’s FORGED host, Roland Sands, of Roland Sands Design, to be one of three to customize a brand-new Indian Scout. Brittney eagerly obliged and was inspired by the legendary two-wheeled trailblazer, Cecilia Adams, to build a bike for country singer, Nikki Lane.

Brittney is a vintage motorcycle aficionado. She builds and races old iron of all shapes and sizes, but she’s definitely no stranger to old Indian motorcycles. When Roland selected Brittney to build a new Indian Scout, we were excited to see where she’d take it. Her tribute to Cecilia Adams that ended up in the loving arms of its new owner, Nikki Lane, hit the proverbial nail on the head.

“Nikki’s Scout is so on-point to what Cecilia Adams’ bike was because her bike was fully custom,” Brittney said. “Nikki’s bike is fully custom, from the front to the back, there wasn’t anything we didn’t touch. It is 100 percent representative of the entire movement, not

only Cecilia Adams, but all of the women Sport Scout riders in the ‘50s.”

Well, Brittney and Roland flew out to Nashville to meet up with Nikki and deliver her new motorcycle, which would of course include a shakedown ride. Upon seeing the new “old” Indian Scout, Nikki was blown away by what Brittney and Roland presented her with. “This is insane!” Nikki said. “I did not know how you were going to make this look old.”

Brittney paid attention to every bit of the motorcycle, making it all flow together seamlessly, naturally. “Every bit of the motorcycle, the frontend to the handlebars, to the seat, fender, everything has been played with and touched,” Brittney said.

Brittney did quite a lot with this build, crafting a custom one-off girder frontend by hand for Nikki’s Scout, which features two springs and a shock unlike the traditional single-spring Sport Scouts. In fact, Brittney blended Chief parts into the frontend to get the front suspension just right. Brittney also incorporated some Flanders

I KNOW IT TOOK A LOT OF WORK AND I’M REALLY EXCITED BECAUSE I’M GOING TO PUT A LOT OF MILES ON IT,”

style bars, and a custom tank which incorporates more Chief parts by way of the iconic teardrop Chief tank sides that she morphed into the Scout center tunnel to keep the GPS and other modern Scout wiring harnesses and gauge components intact.

“I know it took a lot of work and I’m really excited because I’m going to put a lot of miles on it,” Nikki says.

After the maiden voyage, both Brittney and Nikki were grinning ear to ear. “Seeing Nikki on the bike, and how good she looks on the bike and seeing how it fits her personal style as well, it’s a huge honor for me,” Brittney says.

After seeing the reveal of Nikki’s new Scout and the meeting of Brittney and Nikki together, you can tell it was kismet that their worlds collided. Brittney’s build of Nikki’s new Scout couldn’t have been built by a better candidate.

“I survived 10 years of playing music before we were profitable by selling vintage and sharing those stories of finding things in a bin outside a flea market on our way across the country, and it just became a little bit of an addiction for me,” Nikki says.

Nikki’s love for two wheels runs in the family. Her dad was a motocross rider and her mom was a pit tootsie known as Hurricane Hannah who used to change Nikki’s dad’s tearaways on dirt bike trails.

Nikki, who found motorcycles on her own after moving back to Tennessee says she’s not good at meditating and that motorcycles help provide that. “It takes me to another place mentally,” Nikki says. “It allows me to free up my mind, look around in a different way, and getting away from this busy life you can tell that we have going on here.”

FRAME: CUSTOM FRAME WITH ONE-OFF STRUTS, SEAT MOUNTS AND UNDERSEAT FRAME COVER SHOCKS: HANDBUILT REAR STRUTS FORKS: CUSTOM HANDBUILT GIRDER FRONTEND WITH 1946 TO 1948 INDIAN CHIEF SPRINGS, SHOCK AND RISERS

FRONT WHEEL: CUSTOM LACED 19” FTR RIM TO STOCK SCOUT FRONT HUB

REAR WHEEL: CUSTOM LACED 18” FTR RIM TO STOCK SCOUT REAR HUB

FRONT BRAKES: FACTORY INDIAN SCOUT

REAR BRAKES: FACTORY INDIAN SCOUT

TANK: MODIFIED STOCK SCOUT GAS TANK USING STOCK SPRINGFIELD CHIEFTAIN TANK PANELS TO GET THE ORIGINAL INDIANSPORT SCOUT TEARDROP SHAPE. WE KEPT THE TOP AND BOTTOM TUNNEL RAM OF THE STOCK SCOUT GAS TANKS TO KEEP THE STOCK FUEL PUMP, AIR INTAKE BOX AND THE STOCK SCOUT GPS PANEL THAT ORIGINALLY CAME STOCK DASH: FACTORY CHROME DASH GPS UNIT COVER

REAR FENDER: EXTENDED REAR SUB-FENDER

SEAT: CUSTOM VINTAGE BATES SEAT AND REAR FENDER PAD

HANDLEBARS: CUSTOM POLISHED STAINLESS STEEL BARS WITH GAUGE/CONSOLE RELOCATION

EXHAUST: HANDMADE POLISHED STAINLESS STEEL EXHAUST FOOT CONTROLS: FACTORY MID CONTROLS WITH CUSTOM LONGER BRAKE LINE

PAINT: CUSTOM BLACK PAINT JOB WITH CUSTOM LETTERING, STRIPING AND HOLD AND SILVER LEAF DONE BY JEREMY PEDERSONX

Attention long chopper aficionados! Unique Custom Cycles’ raked out, long-fork Indian Scout may look simple, but it’s anything but. UCC owner, Ronna Noren, built the water-cooled performance cruiser into a long chop for recipient Mikkey Dee of The Scorpions. To say he knocked it out of the park would be an understatement.

The inspiration for Ronna’s build comes from legendary custom bike builder and drag racer, Stan Dishong, a trailblazer in the NorCal custom bike scene with Stan’s Cycle in Vallejo, California. Stan made long Springer frontends, sissy bars, tall risers and handlebars and much more. In fact, one of Stan’s early customers was Arlen Ness.

We think Stan would be proud of Ronna’s efforts with the new UCC Scout, which took a completely different approach than either Roland Sands Design’s Scout racer or even 20th Century Racing’s vintageinspired take. Mix in chopper styling with a reshaped frame, plenty of rake and long frontend with a performance-packed, water-cooled 1250cc V-twin and you have one badass machine.

It says a lot about a builder when a custom bike doesn’t look

modified. In other words, if someone builds a custom motorcycle that looks like it came that way from the factory, well that’s a testament to that builder’s quality craftsmanship and attention to detail.

After Ronna Noren was invited by his friend, and head of design for Indian Motorcycle, Ola Stenegard, to take part in this year’s FORGED Series, we knew he was going to bring something special.

“When you sweep your eyes over the bike, nothing really jumps out at you in a bad way,” Ola says. “It’s just totally consistent and sits really well and that to me is what sums up this bike. It’s the stance, it sits right, it’s totally clean, and that’s what makes it so special.”

Ronna’s built several custom bikes over his 40-year tenure as a premiere custom shop in Sweden. He’s kind of known as a fabrication genius. After seeing where he took the stock Scout in this year’s FORGED series, we understand why. The lines flow perfectly. Look at how well the rear shock blends into the frame that now swoops seamlessly up to the neck. The way he reshaped and redesigned the radiator shroud into the new downtube is also seamless. It’s like it

AND HAS A GREAT BALANCE. I REALLY ENJOYED THAT!”

came that way from the factory, which is the approach all the greats set out to achieve.

“The plan from the beginning was to strip down the bike and make it as clean as possible,” Ronna says. “I started with stretching the frame and making a smaller gas tank and bigger wheel. It feels lighter and works on the triple trees to get the trail right to handle really good. Of course it has a little bit longer fork like Stan’s bike and this is a twist on that.”

Ronna also took the factory gas tank and reshaped it, making it a tad smaller to fit the new chassis all together. “I took the stock tank and cut it down so it fits the chopper better,” Ronna says.

Roland Sands was on-hand at the custom reveals for each bike’s intended recipients. Roland and Ola hit the road to Prague to see Ronna’s creation and watch Mikkey’s jaw drop when he first encountered the performance chopper. When Roland got to Prague and saw what Ronna had built, he was impressed. “Simplicity is complicated,” Roland says. “It absolutely is when it comes to building simple-looking bikes. I mean the tank is simple, the paint is simple, but this is a water-cooled American twin by Indian Motorcycle in a beautiful chopper chassis. That’s a lot of goodness all smashed into one package.”

After the gents took a look at the bike, all that was left to do was go for a ride. Ronna, Roland, Ola and Mikkey suited up and hit the road for a very cool customer shakedown ride.

“Riding it all day was another experience,” Mikkey says. “It’s really light handling and has a great balance. I really enjoyed that!”

Another first, in all of Ronna’s 40 years of building bikes, was that Ronna took a ride with one of his customers. “Normally I never ride with the customer,” Ronna says. “That was the first day I rode with the customer, and to see how much he liked the bike for me was special.”

The 2025 Indian Scout was designed with customization in mind, and the all-new cruiser is a bike that allows just that. Ola says he couldn’t be more excited about working with such a diverse group of

custom builders, each unique in their own way, which was the goal in showcasing the Scout’s potential for customizability.

“Every year when we do the FORGED Program, we’re trying to pick the right builders that can really show the diversity of the platform,” Ola says. “All the builders took it in so many different directions and really showed what this platform can do. All the way from West Coast performance to old-school girder to East Coast bar hopper-bruiser, it really showed that the platform can do it all, which is really awesome.” HB

FRAME: ONE-OFF CUSTOM NARROWED UPPER FRAME BUILT AROUND A TRASK POWERFLOW AIR FILTER

SHOCKS: SHOCK MOUNTS MOVED BACK, 33-DEGREE ON THE NECK, 37 DEGREES ON THE FORK, 4” STRETCH FORKS: 8” OVER TOLLE ENGINEERING FORK LEGS AND HYDRAULICS

TRIPLE TREES: ONE-OFF BILLET TRIPLE TREES WITH 4 DEGREES OF RAKE

SHOCKS: IMC/FOX WITH BLACK ANODIZED ALUMINUM BODY

FRONT WHEEL: 80/90-21” CERAKOTED HUB AND RIM WITH STAINLESS SPOKES

REAR WHEEL: 180/55-18” CERAKOTED HUB AND 5.5” RIM WITH STAINLESS SPOKES

FRONT BRAKES: ISR 6-PISTON, ONE-PIECE, RADIAL CALIPER AND ISR PROTOTYPE BILLET ADAPTER KIT FOR SCOUT, 320MM FULL FLOATING DISC, ISR MASTER CYLINDER

REAR BRAKES: ISR 4-PISTON, ONE-PIECE, RADIAL CALOI[PER AND ISR PROTOTYPE BILLET ADAPTER KIT FOR SCOUT, IMC MASTER CYLINDER

TANK: SHORTENED, NARROWED AND SECTIONED STOCK SCOUT WITH CUSTOM TUNNEL AND REPOSITIONED FUEL PUMP, TOLLE ENGINEERING POP-UP FUEL CAP

REAR FENDER: CUSTOM MODIFIED

FRONT FENDER: ONE-OFF MODIFIED

SEAT: ONE-OFF STEEL SEAT BASE, SILVER MACHINE UPHOLSTERY

HANDLEBARS: HEAVILY MODIFIED STOCK BARS WITH INTEGRATED RISERS AND ONE-OFF SPEEDO HOUSING

EXHAUST: FULL CUSTOM ONE-OFF HEADERS AND MUFFLERS IN STAINLESS STEEL

FOOT CONTROLS: MODIFIED SCOUT PEGS AND CONTROLS PAINT: CUSTOM PAINT AND GLOSS BLACK FRAME/SWINGARM BY HAKAN LINDBERG

Josh Allison’s journey into custom motorcycle building and metal fabrication is deeply rooted in his artistic upbringing and passion for two-wheeled machines. Josh was born in Laramie, Wyoming. He grew up in a creative environment, spending time in his grandfather’s art studio. His love for motorcycles began early, drawing bikes as a child and learning to ride a dirt bike at 8 years old. Throughout high school, life revolved around two things: art and motorcycles. He excelled with art with a full-ride art scholarship at Mesa State College in Colorado. But after a short stint, Josh realized the traditional graphic design route wasn’t for him.

Josh then moved to Fort Collins, Colorado, to dabble in tattoo artistry but struggled with its demanding apprenticeship system. On offhours, this is where Josh discovered his talent for custom painting, starting with motocross helmets and expanding into custom motorcycle jobs. His first road bike, a 1980 CB 750, gifted by one of his clients, sparked his love for street riding and customization. Wanting to expand his skills beyond painting, Josh enrolled at Wyotech, where he learned metal shaping, welding, and advanced street rod techniques. This education, particularly learning how to shape metal, marked a pivotal moment in his career, allowing him to fully realize his custom bikebuilding ambitions.

After honing his craft at prestigious shops such as Tin Element, Pinkees Rod Shop, and Newstalgia Custom Paint, Josh shifted his focus back to motorcycles. One of Josh’s pivotal projects, a 1969 BSA chopper, garnered attention from the custom bike world and opened the door to the Handbuilt Motorcycle Show in Austin. His work caught the eye of industry heavyweights, and it also started a great relationship with Baleigh Industrial.

Josh’s career took another leap with his participation in the People’s Champ competition, followed by an opportunity as an Invited Builder for Born-Free. His 1951 Panhead project became a standout build, further establishing him as a serious contender in the custom motorcycle scene. After opening Cry Baby Cycles in Colorado, his work drew the attention of Orange County Choppers, leading to new opportunities in the bike and car customization world.

In a pivotal career move, Josh co-founded American Metal Customs with Chris Bishop in Danbury, Connecticut. Their vision was to create a one-stop shop for custom metal shaping, car and bike building, and restoration. The facility, which boasts 270-car storage, custom fabrication capabilities, and a speakeasy bar, embodies their unique blend of craftsmanship and lifestyle. Alongside partners Brian Stephenson and Randy Carlson, they expanded the brand to include American Metal Whiskey, further intertwining their

“I’M A VERY ORGANIC BUILDER AND WHEN I GET INTO SOMETHING, ONE PART BUILDS THE NEXT.”

love of craftsmanship with, well, their love of fine whiskey. Today, Josh continues to push the boundaries of custom motorcycles with meticulous attention to detail shown in this elaborately built beauty dubbed Zidan. “I’m a very organic builder and when I get into something, one part builds the next,” Josh says.

Zidan is more than just a custom chopper built for the BornFree show. It’s a line in the sand; a representation of built versus bought. While it’s designed as a showpiece, Zidan is far from just a static work of art. It’s fully functional, embodying both elegance and toughness, a balance that defines Josh’s style. “Zidan is definitely a show bike, but, you could go fire it up and ride it if you want,” Josh says. “It’s not just this thing that doesn’t function.”

The inspiration behind Zidan came from an unexpected source you wouldn’t necessarily find in custom bike building—a delicate China teacup. Josh was inspired by the gold-trimmed teacup’s fragility and grace, and he set out to replicate those qualities in a motorcycle. “If I could make a bike feel like that teacup, it would be insane,” he recalls. That vision translated into Zidan’s sleek, elegant design, complete with intricate gold leafing and polished chrome elements, which give the chopper its “bougey” yet hard-edged appeal.

One of Zidan’s most striking features is its motor—a rare 1938 Knucklehead. Finding this engine was a stroke of luck. Knuckles

are difficult to come by. They’re not cheap either. Not content with leaving the engine in its original state, Josh modified it extensively, incorporating a Magneto, open rockers and a dual carb setup. Synchronizing these components proved to be one of the biggest challenges, but it was essential to ensure the bike’s rideability.

Zidan’s craftsmanship is otherworldly. Nearly every element was handcrafted. The frame, originally a 1929 VL, was completely reworked—stretched by an inch and a half, modified with a 31-degree rake, and windowed at the neck. The result is a completely unique chassis that houses all of the custom features, from the handmade Springer frontend to the sleek sissy bar.

Josh’s meticulous attention to detail is evident throughout. The fuel petcocks are hidden inside the tank to maintain Zidan’s clean aesthetic, though this decision made the installation process particularly grueling. Every piece of the bike, from the tanks to the handlebars, was hand-shaped, resulting in a bike that’s as much a rideable machine as it is a sculptural piece of art.

Despite the difficulties and challenges, Zidan stands as a testament to Josh Allison’s skill and vision—a bike that merges old-world elegance with modern custom craftsmanship. It reflects the essence of what makes American Metal Customs’ creations stand out in the world of custom motorcycles: functional art with a soul. HB

BIKE OWNER

SHOP NAME

AMERICAN METAL CUSTOMS

AMERICAN METAL CUSTOMS

SHOP PHONE 970-556-1112

SHOP WEBSITE/SOCIAL

AMERICANMETALCUSTOMS.COM

IG/FB AMERICAN METAL CUSTOMS

YEAR/MAKE/MODEL 1938EL HARLEY KNUCKLEHEAD CUSTOM BOBBER

FABRICATION

ASSEMBLY

JOSH ALLISON

JOSH ALLISON

BUILD TIME 10 MONTHS

ENGINE

YEAR/MANUFACTURER

1938/H-D EL KNUCKLEHEAD

1938/H-D

TYPE/SIZE 61CI

CASES ‘38 KNUCKLEHEAD

CYLINDERS

KNUCKLEHEAD

HEADS CUSTOM KNUCKLEHEAD

ROCKER BOXES

KNUCKLEHEAD

EFI/CARB M5 LINKART

AIR CLEANER CUSTOM

EXHAUST CUSTOM

SPECIAL FEATURES

DUAL CARB SET UP WITH THE PORT GOING TO EACH HEAD INSTEAD OF A MANIFOLD. OPEN ROCKERS AND VALVES WITH FULLY POLISHED CASES. M5 MORRIS MAG AND CUSTOM PUSHROD COVERS

STRETCH 1.5 INCHES

SUSPENSION SPRINGER FRONTEND

MANUFACTURER FRONT HANDMADE

TRIPLE TREES CUSTOM

SPECIAL FEATURES HANDMADE SPRINGER FRONTEND/ CHROME AND GOLD LEAF

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT TYPE 21 INCH CUSTOM FROM OLD NIPPLE TWISTER

WHEEL HEIGHT-WIDTH 21/2.75 INCH

TIRE HEIGHT-WIDTH 21 INCH

MANUFACTURER REAR 16-INCH CUSTOM FROM OLD NIPPLE TWISTER

WHEEL HEIGHT-WIDTH 5.00/16

TIRE HEIGHT-WIDTH 72H

CALIPER SINGLE

ROTOR DUAL

FINISH-PAINT

COLOR

TRANSMISSION

YEAR/MANUFACTURER/TYPE

4-SPEED RACHET-TOP

1946/H-D/4-SPEED

CASE H-D POLISHED

CLUTCH

KNUCKLEHEAD

PRIMARY DRIVE CHAIN

FRAME

YEAR/MANUFACTURER

CUSTOM VL

1929/H-D

RAKE 31

CRACKLE PEARL WITH GOLD LEAF

PAINTER JOSH ALLISON AND JASON KNAPP

SPECIAL FINISHES GOLD LEAF

ACCESSORIES

REAR FENDER HANDMADE

GAS TANK/CAP HANDMADE

OIL TANK HANDMADE

HANDLEBARS HANDMADE

HAND CONTROLS/GRIPS KUSTOMTECH

FOOT CONTROLS/PEGS KUSTOMTECH

HEADLIGHT

UNKNOWN CUSTOM

TAILLIGHT LIGHT ASYLUM VINTAGE

SEAT HANDMADE

elcome back to The Parts Counter presented by Hot Bike Magazine. If you missed the last installment, our friends at Harley-Davidson sent us a whole batch of new Genuine Motor Parts and Accessories to install and evaluate on Thrashin Supply’s new 2024 Road Glide. This time, Harley sent us some great new components for Danny Wilson’s (aka The Motorwitch) new 2024 Street Glide. We headed to Danny’s Phoenix shop, Motorwitch Industries, to do the installation. Danny’s been working on Harley-Davidson motorcycles for over 25 years. He started as an H-D master technician and became so knowledgeable that The Motor Company hired him to train new techs at dealerships around the world, which he did for many years. Now, Danny’s got his own shop, Motorwitch Industries, and he has a great reputation of making motorcycles perform extremely well. He’s also a bit of a dyno-tuning guru and engine-building master. We hooked Danny up with the Long-Haul Touring package and some rad new Screamin’ Eagle components from Harley-Davidson’s Genuine Motorcycle Parts & Accessories catalog.

The Long Haul Touring Accessories package includes everything you need for a long road trip: H-D Detachables Two-Up Tour-Pak Mounting Rack, 4-Point Docking Hardware Kit, Sundowner Seat, Mid-Frame Air Deflectors, Heel Shifter, Streamliner Passenger Footboard and Mount Kit. And while we were at it–and since Danny and his wife like to ride together–a color-matched TourPak with the backrest pad was a great addition as well. Here’s a snapshot of the different components we installed.

Because we were enhancing Danny’s Street Glide’s touring capabilities, we couldn’t forget about adding Harley’s new Embedded Navigation System. This upgrade is a digital download that is seamlessly integrated with Skyline OS and the new 12.3-inch TFT color touch screen display. It unlocks the new Infotainment system’s full potential with options like turn by turn navigation prompts and the Tour display, expanding the map to nearly 80% of the 12.3-inch screen.

1. Long-Haul accessory Package – Black, Part Number: 50700117A

2. King Tour-Pak Backrest Pad – CVO Style, Part Number: 52300744

3. King Tour-Pak Luggage - (Color TBD), Part Number: 53001044(EYO)

4. Electrical Connection Kit, P/N 69203400

5. LED King Tour-Pak Run/Brake/Turn Lamp Kit, Part Number: 67801541

6. LOCK WITH 7586 (SPECIFY KEY NUMBER), 90300030

7. Harley-Davidson Embedded Navigation, Part Number: 76100034

For the Screamin’ Eagle Performance mods, we selected the following for Danny’s Street Glide: Screamin’ Eagle Stage II Kit, which includes a new cam, new pushrods, new lifters, and pushrod tube covers. We also opted for a new set of Titanium Slip-On Muffl ers and a new Screamin’ Eagle High-Flow Air Filter and Air Cleaner Trim. Of course, we’d need to tune everything once those bits were installed, so we grabbed a Screamin’ Eagle Pro Street Tuner to tackle the job.

The SE8-511 is a billet version of the camshaft installed in the ‘24 CVO Road Glide ST. The later intake closing is an indication of a higher horsepower camshaft. It will pick up torque at higher engine speeds the later the intake closes. With increased valve lift to take full advantage of the port fl ow, overlap is also increased to take advantage of scavenging as well as manage residual fraction for combustion control.

The Stage II Kit also includes the quick-install pushrods, which allow installation of the camshaft without removing the top end of the engine. This reduces mechanic time and cost signifi cantly. The Screamin’ Eagle lifters are a great upgrade in this bike, too. They have fl oating axles on the roller, which allows the axles to move so that the needle bearings are not rolling across the same portion of the axle under high load. Ultimately, this improves roller and axle life signifi cantly.

For improved airfl ow and exhaust, we selected the new Screamin’ Eagle air cleaner because it includes a washable and reusable performance air fi lter designed to increase air fl ow. For exhaust, we went with the Screamin’ Eagle Extreme Flow Titanium Slip-On Muffl ers because of the improved exhaust fl ow, signifi cant weight reduction and a deep, sporty exhaust tone. Plus, the Forged Carbon Fiber end caps are just plain cool.

To tune all these new components in perfect harmony, we grabbed Harley’s Screamin’ Eagle Pro Street Tuner, which is cool because you can easily tune via Bluetooth on your smartphone. and the Next generation performance tuning made even easier. Being 49-state emissions compliant the Screamin’ Eagle Pro Street Tuner allows you to adjust key parameters or simply upload the latest Engine Control Module (ECM) calibrations to match your bike’s state-of-tune and much more. Made for many different configurations, it was the perfect accompaniment for our performance combination.

The Screamin’ Eagle components we installed were a great combination of improving overall power, and even better, the power delivery. We gained some horsepower and torque fi gures, but the overall powerband is consistent from idle to redline. In other words, that linear torque curve you’re seeing in the graph is a great visual into how the power delivery works in real time given these new modifi cations. HB

SCREAMIN’ EAGLE PERFORMANCE COMPONENTS:

1. Screamin’ Eagle Stage II Kit, Part Number: 92500133

2. Screamin’ Eagle High-Flow Air Filter and Air Cleaner Trim, Part Number: 29400494

3. Screamin’ Eagle Pro Street Tuner, Part Number: 41001141

4. Screamin’ Eagle Extreme Flow Titanium Slip-On Muffl ers, Part Number: 64901365

WORDS: NELSON KANNO

PHOTOS: STEELDOG PHOTO (KAZ MATSUMOTO)

What do you do if you’re a motorcycle nut with fuck-you money? You call Ken’s Factory located in Nagoya Japan to build you something special. The result is certain to be a custom unlike anything you’ve ever seen. Kind of like the bike you’re seeing across these pages.

Ken Nagai’s hands have shaped, cut, welded, molded–you name it–American muscle cars and motorcycles for the last 40 years. And during those years he’s masterfully honed his craft, gaining a following among the most demanding clients. These clients have two things in common: the deepest pockets and the request for a true, one-off build from Ken’s Factory.

All Ken’s Factory ground-up builds have a six-figure starting point. And that’s just to get in the door. Specific requests can fluctuate prices, making them more than double at times. Occasionally Ken does get a client that drops some heavy coin and only asks for all his attention into personal creativity. This is when Ken plans a build using his shop’s mission statement: Details Create Style.

This client contacted Ken directly, seemingly out of nowhere. “He just called and asked about building three or four bikes at the same time,” Ken remembers. “And of those bikes, this is the most

complicated. And he did not have any input on the design.” This may sound a bit surprising. When asked about having full reign on this project Ken replied, “…he spent about $350,000 USD on this build alone, so I’m not sure what is unusual anymore.”

“After drawing this bike, I built a bagger for him which was easy–we used all our Ken’s Factory Next Level parts on it and quickly finished it for him to ride. Then it was right back to this build, which was started with chassis design.”

Frame angles, a small stretch and rake was carefully formulated then followed by the front end setup. Akin to most of Ken’s full builds, an exclusive billet girder fork was planned out in CAD. “Each girder fork we create for our full builds and for custom orders are all completely one-off. No two are alike in the world, they are all designed by me personally.” Thirdly, was wheel design and size, a 23x3.75 front and a 23x7 rear.

CAD was used again to plan a gas tank and fender. Multiple sections of 5052 aluminum were all CNC’d in-house, which led to Ken welding each piece together to make into the gas tank you see here. The rear fender was cut out of three separate pieces, then bolted together. This allowed Ken to cut more details and complexity into the body panels.

“EACH GIRDER FORK WE CREATE FOR OUR FULL BUILDS AND FOR CUSTOM ORDERS ARE ALL COMPLETELY ONEOFF. NO TWO ARE ALIKE IN THE WORLD, THEY ARE ALL DESIGNED BY ME PERSONALLY.”

Now a basic rolling chassis had come together, yet Ken’s Factory’s biggest hurdle stood in front of them: tackling the Milwaukee-Eight’s CAN bus-based fuel injection system and simplifying it.

“What kind of signal was coming out of the black box?” Ken says. “It was trial and error. And I do mean trial and error! At the time, nobody else had anything like that to work with. It was quite the task. But eventually we had it figured out.”

Getting the fuel injection setup was a sigh of relief which led to one of Ken’s favorite additions to his customs – a supercharger, screaming to an HPI throttle body. Ken found it very satisfying to see his plan of fitting an Eaton M62 system all under the seat.

Although he wishes there was more space for an intercooler, he decided against it to keep the look of the bike as tight as possible. “I made a cooling tube instead, and I like to think that it makes at least a little difference,” Ken says.

“Let’s be honest though, this bike is for blasting around the city or going down the boulevard. Nobody wants to take this style of bike on a really long ride.”

When stopping to really look at the intricacies of this build, one would have to put on the lenses of a bike builder, CAD designer, machinist, welder, mechanical/electrical engineer – all orchestrated into one build, at the hands of one man. But with a budget this deep, it demands all that is complexly interrelating, which is what Ken’s Factory had carefully honed for over 33 years.

“LET’S

BE HONEST THOUGH, THIS BIKE IS FOR BLASTING AROUND THE CITY OR GOING DOWN THE BOULEVARD. NOBODY WANTS TO TAKE THIS STYLE OF BIKE ON A REALLY LONG RIDE.”

And for the curious - not much could be mentioned about the identity of the client, who chose confidentiality. Only clues to be had was that he’s very money savvy, known to take high-risk ventures in business. Not much risk was taken with this build though. He got what he wished for, which was to add a few of Ken’s Factory’s bikes to his private Tokyo parking garage filled with his personal car collection. After all that, what’s next? Where does one go from here? Ken does have another build coming up, a knucklehead chopper he’s putting together for a different client. “But this may be my last build. I’m concentrating much more on parts development now - our Next Level series. But you never know, I’m a hustler. Maybe someone will offer more, I’ll make a comeback!”

SHOP NAME

KEN’S FACTORY

SHOP WEBSITE/SOCIAL KENSFACTORYUSA.COM, @KENSFACTORY

YEAR/MAKE/MODEL

FABRICATION

ASSEMBLY

2019 “BASE” BUT BUILT IN 2023

KEN’S FACTORY

KEN’S FACTORY

BUILD TIME 1 YEAR

ENGINE

YEAR/MANUFACTURER

2019 H-D MILWAUKEE-EIGHT

ROCKER BOXES KEN’S FACTORY

EFI/CARB HPI THROTTLE BODY/EATON M62 SUPERCHARGER

AIR CLEANER

EXHAUST

KEN’S FACTORY

KEN’S FACTORY

SPECIAL FEATURES SO MANY!

TRANSMISSION

YEAR/MANUFACTURER/TYPE

CLUTCH BARNETT

PRIMARY DRIVE NH

& KEN’S FACTORY FRAME

YEAR/MANUFACTURER

KEN’S FACTORY

RAKE MAYBE 38 STRETCH …LITTLE BIT, 2”

SUSPENSION

MANUFACTURER FRONT

KEN’S FACTORY

LENGTH MAYBE 2” OVER

TRIPLE TREES

KEN’S FACTORY

MANUFACTURER REAR RACE TECH

SPECIAL FEATURES PIGGYBACK

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT-TYPE

KEN’S FACTORY

WHEEL HEIGHT-WIDTH 23X3.75

TIRE HEIGHT-WIDTH 130/60R23

CALIPER

ROTOR

MANUFACTURER REAR

KEN’S FACTORY

KEN’S FACTORY

KEN’S FACTORY

WHEEL HEIGHT-WIDTH 23X7

TIRE HEIGHT-WIDTH 200/30R23

CALIPER

ROTOR

FINISH-PAINT

KEN’S FACTORY

KEN’S FACTORY

COLOR CANDY BLUE

PAINTER

COBOO – NAGOYA, JAPAN

GRAPHICS YES

SPECIAL FINISHES LOTS

ACCESSORIES

REAR FENDER

COBOO – NAGOYA JAPAN

GAUGES MOTOGADGET

GAS TANK/CAP

COBOO – NAGOYA JAPAN

OIL TANK H-D

HANDLEBARS

HAND CONTROLS/GRIPS

FOOT CONTROLS/PEGS

KEN’S FACTORY

KEN’S FACTORY

KEN’S FACTORY

HEADLIGHT DUAL, KEN’S FACTORY

TAILLIGHT KELLERMANN

TURN SIGNALS KELLERMANN

LICENSE MOUNT NOT YET!

SEAT ATELIER CHERRY

MISC EVERYWHERE

WORDS: JORDAN MASTAGNI PHOTOS: JEFF BRINKLEY

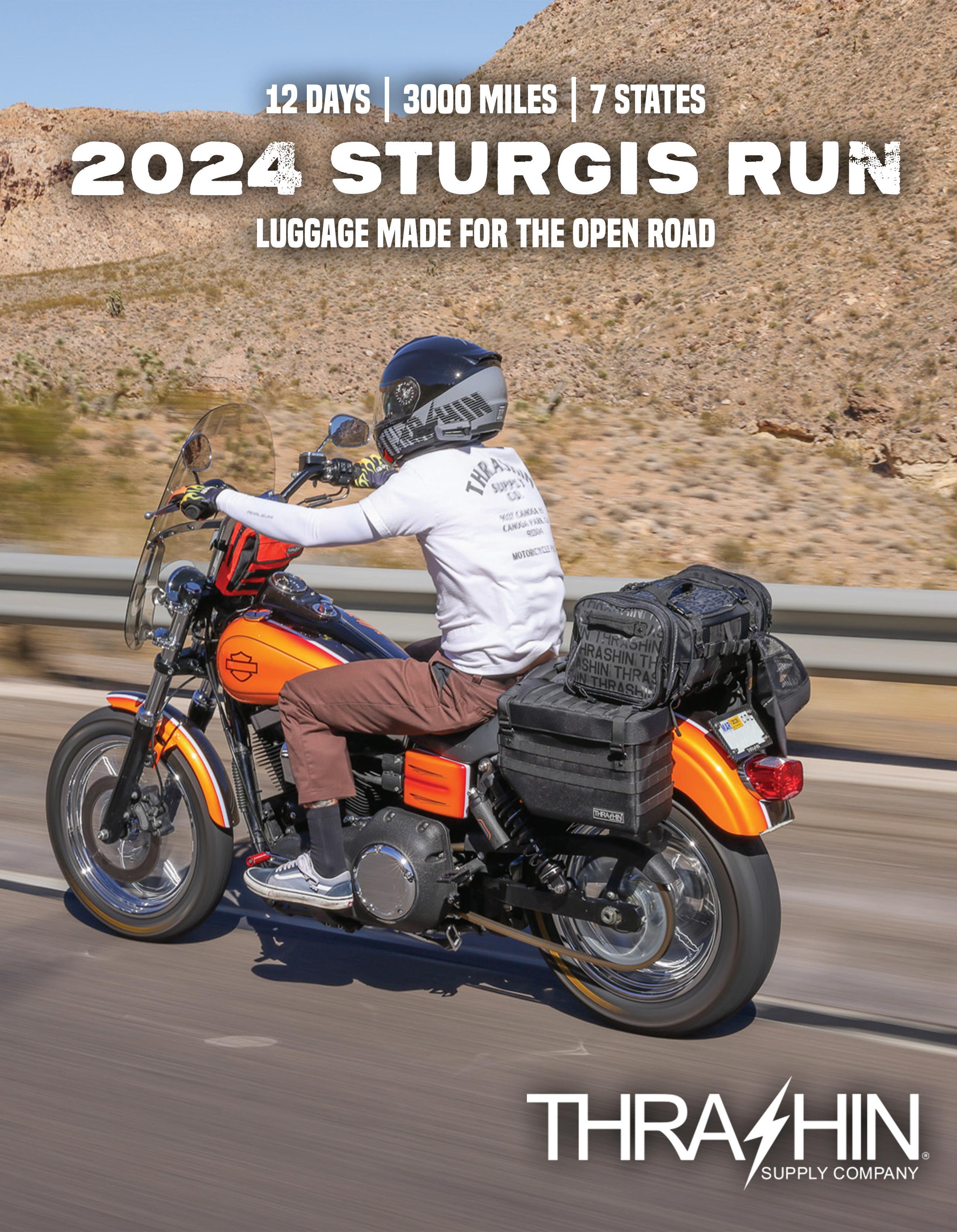

At this past Sturgis rally, we encountered a pretty rad Road Glide with some of the wildest paint we’ve seen to date. As it turned out, FOX (yes, the one that makes the rad rear shocks for Harleys) collaborated with Woodlawn Baggers to build a custom Harley-Davidson Road Glide, designed to showcase FOX’s aftermarket suspension products. This build was aimed at raising brand awareness in the Harley-Davidson market. Originally intended for SEMA, the project pivoted toward unveiling the bike at Sturgis due to time constraints. Despite challenges in sourcing carbon fiber body panels and tight deadlines, the bike, featurin g the iconic FOX logo and marking their 50th anniversary, turned out to be a stunning success.

The collaboration between FOX, spearheaded by and Woodlawn Baggers began in early 2024, with initial talks about building a custom bike for charity. However, time constraints led the team to shift their focus to creating a performance-oriented bike for FOX.

Meeting in person at Daytona Bike Week solidified their partnership, and despite being geographically distant, the team worked closely to bring the project to life. FOX representatives were thrilled with the bike’s unveiling at Sturgis.

This build represents FOX’s push into the V-Twin market, leveraging its long history in suspension technology. Known for excellence in mountain biking and off-road segments, FOX’s goal was to merge performance and aesthetics in the growing performance bagger niche. The Road Glide is designed for both show and go, delivering a top-tier riding experience.

FOX’s dedication to product testing ensures that all its shocks, across various markets, are finely tuned for peak performance, making them a trusted name in the motorcycle world. This project not only brought attention to FOX’s offerings for Harley-Davidso n motorcycles but also forged new friendships and connections in the custom bike community.

The Adaptive 2 Series® of LED Motorcycle Headlights dynamically fill in the dark corners as the bike turns left or right. Embedded sensors in the headlight work in real time to calculate banking angles and speed to adjust and direct precise beam patterns for maximum comfort and safety for the rider.

No matter what you ride, we’ve got you covered. The Adaptive 2 Series® Headlights fit over 1,000 styles of motorcycles.

Coleton Miller, founder of Woodlawn Baggers, is a third-generation motorcycle enthusiast from Greenwood, South Carolina, with deep family roots in the Harley-Davidson world. His grandfather was a Harley dealer and racer in the ‘50s and ‘60s, and Coleton grew up working in his granddad’s shop. Despite pressure to pursue a traditional career path, Coleton followed his passion for motorcycles. In college, at the tender age of 19, he launched Woodlawn Baggers, initially focusing on simple builds but eventually expanding to custom big-wheel bikes. Over the last decade, Coleton has transitioned to performance-oriented builds, combining luxury with high functionality, which has become his signature style.

Miller’s big break came through his work on Mike Denison’s 2022 Harley-Davidson Road Glide. This led to an opportunity with FOX, where he was given free reign to design a high-performance showcase bike for the company. The build exemplified Coleton’s attention to detail, from smoothing frames to splitting engine cases, resulting in a luxurious, over-the-top motorcycle designed for both show and high performance.

Woodlawn Baggers now operates with a tight-knit team, including Steve Hardy, previously from The Bike Exchange, who has a strong sales background, and a small crew of craftsmen. Together, they run two shops, handling everything from in-house powdercoating to complex custom builds. With over a decade in the business, Coleton has built a loyal following across the USA and continues to push the boundaries of custom motorcycle craftsmanship. HB

BIKE OWNER

SHOP NAME WOODLAWN BAGGERS PERFORMANCE DIVISION

SHOP PHONE 864-993-5422

SHOP WEBSITE/SOCIAL WOODLAWNBAGGERS.COM / @WOODLAWNPERFORMANCEDIV

YEAR/MAKE/MODEL