LOTS OF LITTLE CHANGES MAKE OUR NEWEST GENERATION WORK GLOVE EVEN BETTER THAN THE ORIGINAL

Our new-and-improved Work Glove 2.0 features buttery soft goatskin construction for maximum comfort, plus suede cowhide in the palms for added durability and traction. Padded expansion panels on the index and second fingers improve dexterity for operating hand controls. The glove’s one-piece

palm construction features an external seam around the perimeter to eliminate chafing and pressure points against the fingers. Available in two colors and six sizes, Work Glove 2.0 is the perfect addition to every motorcyclist’s riding kit. www.biltwellinc.com THE UPDATES WE MADE FROM ONE GENERATION OF OUR WORK GLOVE TO THE NEXT WERE SUBTLE, BUT MAKE A BIG DIFFERENCE. HERE ARE THE

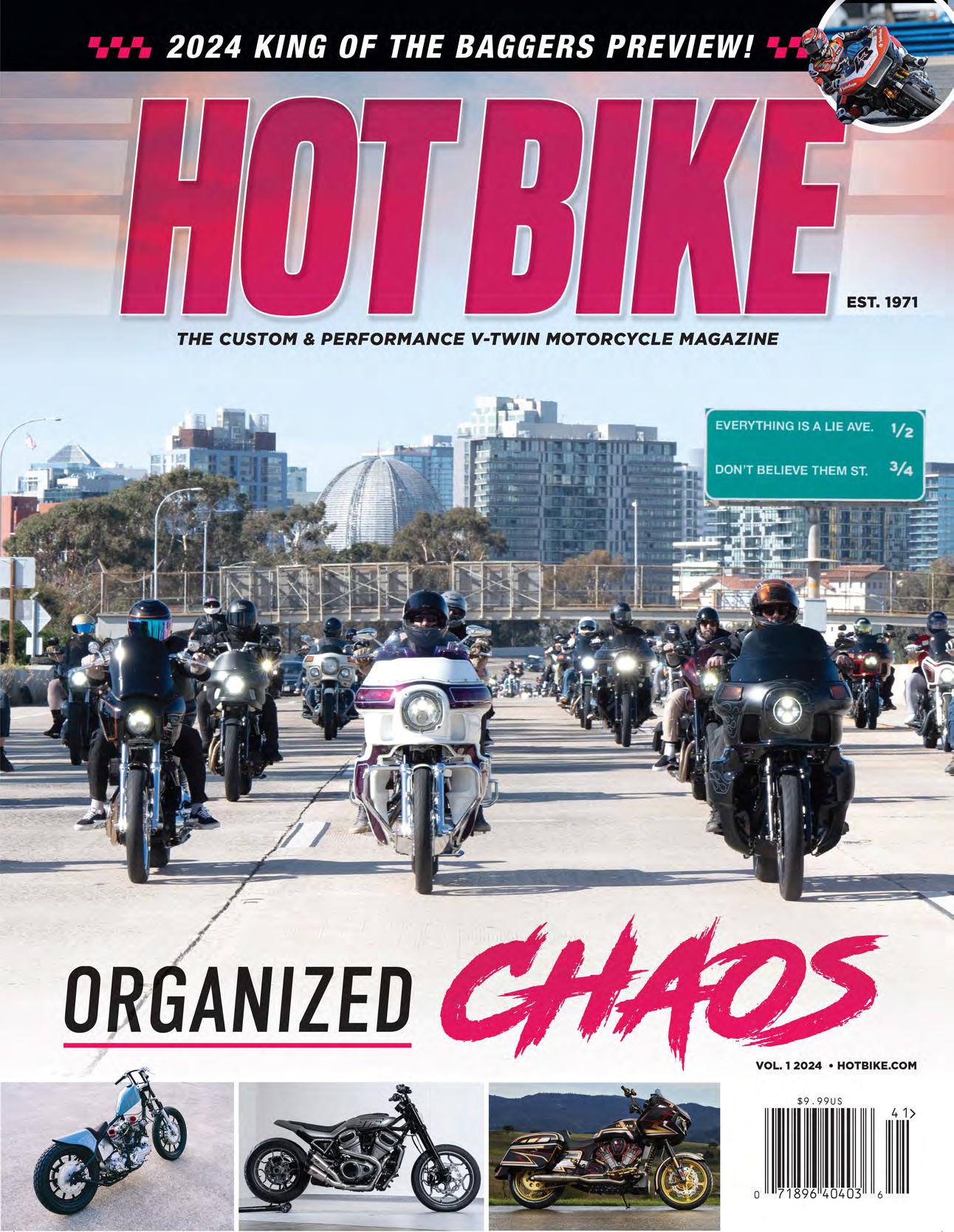

Here we are ladies and germs, Volume Numero Uno, 2024. Last year was crazy, but it was also very fulfilling. We’re still on the gas in 2024 and we’re excited for what the future holds. We are grateful to share our stories with you in a manner that won’t just immediately go away with the scroll of your screen. These stories will live here forever, cemented in time, and they will continue to be here when you thumb through these pages every time you go take a shit. There’s something about reading your favorite magazine when the time comes to move your bowels, right?

I wish I had a crystal ball. Actually, I don’t. But I have seen a glimpse into the future and it looks pretty damn glorious. I’m talking about my hour-and-a-half long stint on the mighty Buell Super Cruiser prototype I got to ride during Daytona Bike Week. I was amazed at how much fun I could have riding a motorcycle on the street. I almost forgot, actually. I’m ashamed to admit that, but riding has become more of a by-product of necessity for me lately, but the Buell brought me back to my roots of why I started riding so many years ago. It’s fun. It’s also so much more.

I’ve been riding motorcycles for over 30 years so I’ve experienced my fair share of mileage on several different types of bikes (20 of those years as a hack journalist). From BMC Choppers to every Harley-Davidson, Victory, Indian, Big Dog (remember those guys?), American Ironhorse, Big Bear Choppers (remember the BBC GTX Bagger thingamajig?), the list goes on… Basically, I’ve had my butt on the seats of a lot of different motorcycles.

Buell’s Super Cruiser prototype is unlike anything I’ve ever experienced in my life. I did ride Nigel Patrick’s nitrous-powered V-Rod and that was pretty incredible too. But the Super Cruiser as a production vehicle is unmatched.

First of all, the entire package is tight. What I mean by that is that everything works together harmoniously: suspension, braking, acceleration, cornering. It’s just fluid and an overall complete experience. Hammering on the throttle is instantaneous fun. Halting the bike is almost immediate as well. It’s just smooth overall and it’s hard to put it into words. But I think Buell’s new Super Cruiser will do wonders for the future of performance cruisers and the customers who are seeking something truly unique. Not only is it fast as shit with 185 hp at the rear wheel, it’s the type of riding that I think the future of cruisers need to evolve to. In other words, low-end torque is fine and dandy, but high-range RPM bands might be the future of this genre.

When I rode Buell’s new prototype I was riding it wrong, according to Bill Melvin, CEO of Buell Motorcycle Co., and my riding buddy for my 90-minute rip. Bill instructed me to shift down to Second while doing 85 mph. I couldn’t understand what he was motioning me to do, because he was flashing what looked like a peace sign. But in all actuality he was telling me to shift into 2nd. “But we’re doing 85 mph, Bill,” I thought. I was hesitant but obliged his request anyway. Then it clicked. I was riding it wrong. You see I was in Fifth gear at 85 mph because that’s what I’ve been so used to doing for so many years with air-cooled V-twins. Not that there’s anything wrong with that, but I forgot how to ride a sport bike so to speak. But it came

back. Maybe the “Cruiser” delineation of the model name messed with my head. But long story short, I don’t think I shifted to Fourth, Fifth and definitely not Sixth after Bill’s instructions. This bike does not need to be ridden in the lower RPM band at all. It certainly can be, but all the fun is between 7,000 and 11,000 RPM. And then Bill went on to quote the late, great Carroll Shelby… “There’s a point, 7,000 RPM, where everything fades. The machine becomes weightless, just disappears. All that’s left, a body moving through space and time.”

My overall take after riding the Super Cruiser prototype, which I’m told will essentially be what will go into production for the 2025 model year (still TBD on actual release date) but maybe, just maybe X-amount of models might trickle off the showroom floor as “race-only” products in 2024. Either way, we’re excited to see the overall impressions of customers after they first purchase their new Buell Super Cruisers because we can’t wait to share the joy, the excitement and the giddiness of feeling like a kid having his first dirt bike experience once again. This thing is for real and it’s coming for you. Until then…

Bye for now,

Jordan

President/Editor-In-Chief JORDAN MASTAGNI

The Real Boss ASHLEY MASTAGNI

Creative Director ROBERT MARTIN

Managing Editor IRENE GONZALEZ

CONTRIBUTORS

CHOPSKEE, ROB FORTIER, PETER JONES, JOHNNY LANEY, MICHAEL LICHTER, MARK MA SKER, KAZUO MATSUMOTO, MATTIA NEGRINI, REAMONN RYAN, JARED SMITH

SPONSORS

Hot Bike is grateful for these awesome supporters! ALPINES TARS, ARCH MOTORCYCLE, AVON GRIPS, BILTWELL, BUELL MOTORCYCLE CO., FACTORY 47, FEULING PARTS, GALFER USA, HORSEPOWER, INC., JW SPEAKER, KEN’S FACTORY, KRAUS MOTOR CO., LAW TIGERS, MINT SPEED SHOP, MOTUL, RAMJET RACING, ROLAND SANDS DESIGN, SAWICKI SPEED SHOP, THRASHIN’ SUPPLY CO., TRASK PERFORMANCE

Irecently got blown up. Not in the sense that my phone was ringing uncontrollably. I literally (not figuratively, people) got blown up by Alpinestars. And it was awesome.

Technically, I volunteered to have the Alpinestars team blow me up because I was curious about how the airbag in the all-new TechAir 3 Leather Airbag Vest worked. I wanted to know how it felt. And while I wasn’t keen on voluntarily ghost riding the Harley-Davidson Hydra Glide Revival I was riding during my evaluation, I figured the next best thing was to have the crew deploy the bag with a “tester” vest. I saw James Rispoli do it at a product demo and I thought to myself, “Self, that looks cool. Where do I sign up?” As it turns out, having the vest deployed on me was not as gnarly as I anticipated. It was instantaneous, and even though I was prepared for it to go off, it was still shocking. And that’s when it clicked, “I should wear one of these when I ride.”

Let’s dive into the tech and materials first. Alpinestars’ crash detection triggering algorithm has been developed and refined with millions of kilometers of riding data and tens of thousands of crashes, allowing the system to accurately assess when to deploy the airbag ahead of an impact or other dangerous situation like a lowside, or highside crash. In the event the Tech-Air 3 detects the start of a crash, the system will activate the protective airbag in milliseconds, providing upper body protection, and reducing up to 95 percent of the impact energy transferred to the rider anywhere the airbag protects, which includes the full chest and back.

The Tech-Air 3 also features Bluetooth connectivity to a TechAir App, which allows monitoring of both the system’s operational status and battery status, and mapping your journey via MyRide.

I’ll be honest, I’m not really a vest guy. I mean, if I’m going to take a tumble I know my arms would be pissed if they got road-rashed because I didn’t protect them. The Tech-Air 3 was designed to be worn with a motorcycle jacket, especially one with CE-rated armor. In fact, I wore the Alpinestars’ Moto Streetwear Equipment Tartan Shirt in addition to the vest and I felt super confident. It’s a half shirt, half hoodie riding garment creating a totally unique approach to motorcycle apparel and individual rider style, while at the same time providing full protection.

In terms of styling, less is always more in my opinion. Alpinestars nailed it. They have two versions available, and both are minimally designed. There are no doo-dads or conches or spikes anywhere. Just the goods. We opted for the leather Tech-Air 3 (only available in black for $749.95), as opposed to the Canvas Tech-Air 3 (available in tan or black for $699.95). I honestly liked both, but because I felt like if I was going to go full “vest mode,” I better go for the gusto, right?

The vest is a bit hefty, which I’m not complaining about since I know it’s equipped with a freakin’ deployable airbag for crying out loud. And because the weight is pretty evenly distributed, I didn’t feel fatigued in one section of my body over another after a full day of riding.

Overall, I really liked the Tech-Air 3. While I wasn’t a vest guy before, I think you’ll see me wearing one a bit more often these days. Even if it’s under my jacket, because you can’t put a price on protection and the Alpinestars Tech-Air 3 is a great option that ticks all the boxes of performance, comfort, styling, and safety.

SOURCE: ALPINESTARS alpinestars.com

EDITOR’S NOTE: Our main man, Dumptruck, gets around. In fact, this dude sees more miles in a year than most see in a lifetime. So he’s seen a thing or two during his travels. He also knows pretty much everyone worth knowing so we asked him if he’d be up for interviewing someone for The Hot Seat. It just so happened we asked him right as he was gearing up for Mama Tried in Milwaukee, so we agreed that Warren Heir, Jr. from Jr’s Cycle Products and Mama Tried Show were the perfect fit. Dumptruck caught up with Warren during Mama Tried to pick his brain on life. Enjoy!

DUMPTRUCK: Describe yourself in three words. WARREN HEIR, JR.: Hard Working Man

DT: How did you end up in the motorcycle industry?

WH: I was born into it. My dad has an Aftermarket H-D shop. I was raised on motorcycles with lots of dirty finger nail uncles. He still has his shop today. Now he comes and works for me!

DT: What do you see in this industry’s crystal ball?

WH: I see lots of creative new fresh-idea folks joining the ranks. Taking the past and spinning it on its head in a progressive way. I also see a little bit of a changing of the guard. My peers and folks that I have come up with in the industry are making strides to be leaders in an industry that I love. I really get pumped seeing my buddies being successful. They have worked so hard for it. I hope to be able to support them on their journey.

DT: What is your greatest accomplishment?

WH: Owning multiple businesses for over 10 years while raising two beautiful boys, as well as keeping my relationship with my wife healthy and happy.

DT: Do you have a favorite motorcycle of all time? If so, what is it?

WH: My 1944 Harley-Davidson Knucklehead. The “Death Dealer” currently residing at the H-D Museum.

DT: Who or what inspires you?

WH: People who go after their dreams. Unafraid of fucking it up. Staying the course no matter what.

“MY DAD HAS AN AFTERMARKET H-D SHOP. I WAS RAISED ON MOTORCYCLES WITH LOTS OF DIRTY FINGER NAIL UNCLES. HE STILL HAS HIS SHOP TODAY. NOW HE COMES AND WORKS FOR ME! ”

— WARREN HEIR, JR.

DT: What is your biggest regret?

WH: Not caring for my body earlier in my life. I realized a few years ago I have gotten away with a whole bunch over the past 40 years. Now to change that.

DT: What is your proudest moment?

WH: Seeing both my boys riding together in the yard. Max is 10 and Hank is 4. That was a pretty awesome moment.

DT: Favorite place on Earth?

WH: On my motorcycle, sun setting, headed west, in the mountains listening to my favorite song.

DT: Biggest pet peeve?

WH: Making excuses.

DT: What are you currently working on that you’d like to share?

WH: I have a few sport bike projects that I am working on. Way out of my comfort zone. One is a 1989 ZX7 and the other a 2001 RC51. Both will be Jeff Wright inspired. He told me one day when I was drooling over his Kawasaki that I should build one. So now I am building two.

DT: Anything else you’d like to add?

WH: Keep on pushing forward. Be kind and thoughtful of people around you. Don’t be afraid to mess it up. Because that’s the way to learn. Oh, and “It’s not what you know, it’s who you know!” HB

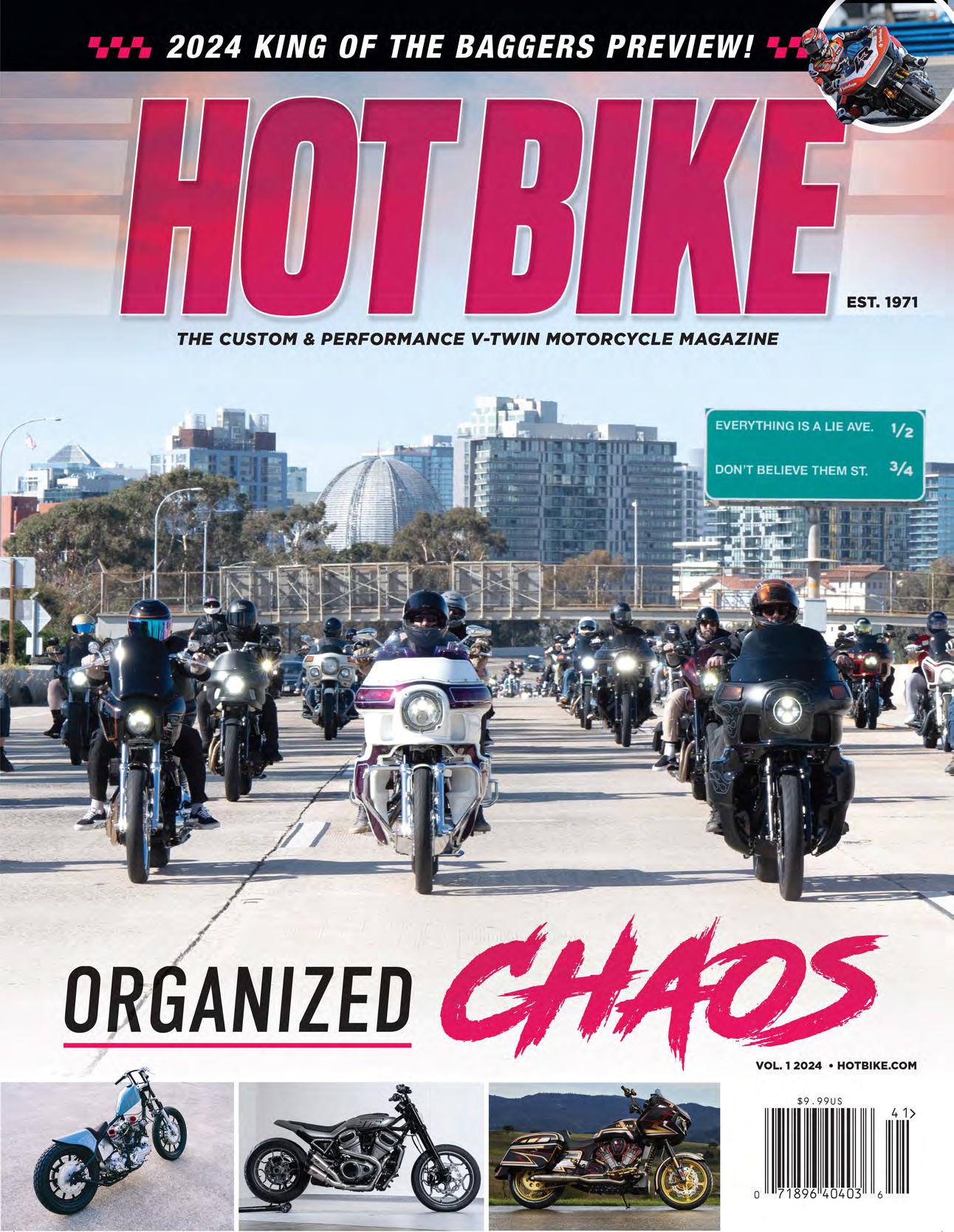

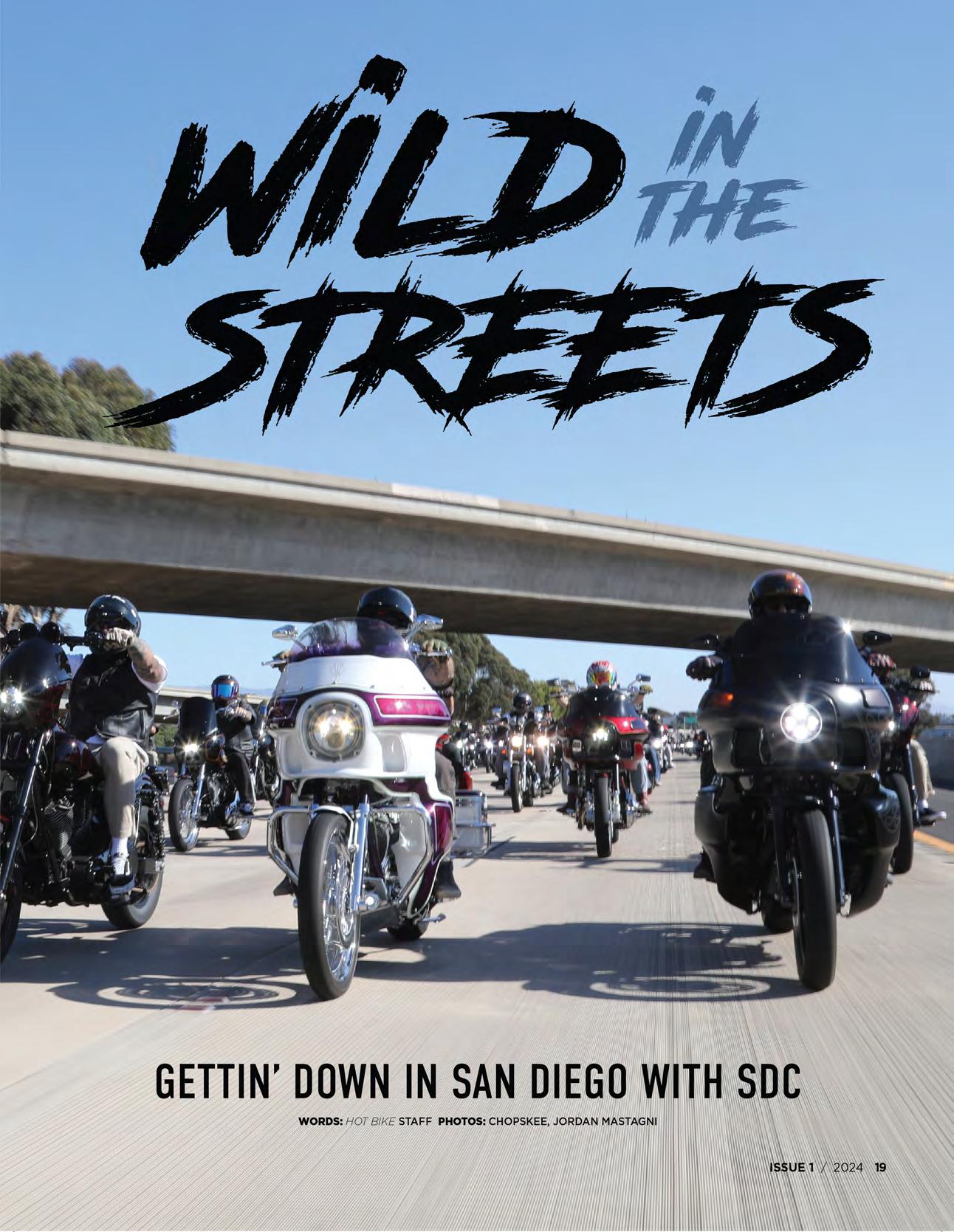

FXRs, food, drinks, stunts… What else do you need for an epic day on your bike? Throw in a somewhat-organized ride down Interstate 5 in San Diego with a few hundred friends and you have a recipe for success… or disaster. Whichever floats your boat.

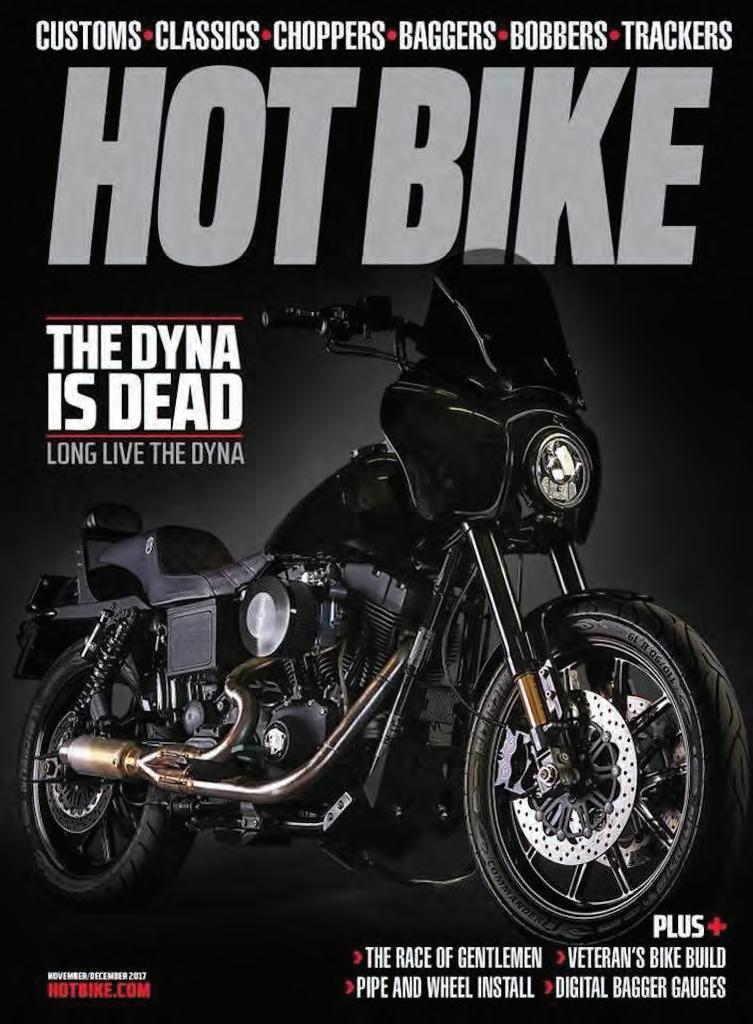

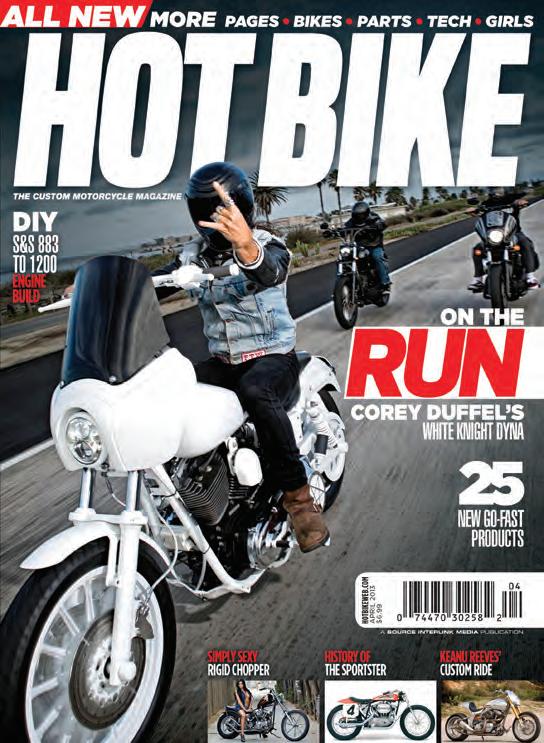

Back in 2014, the editor, Jeff Holt, and the guys at San Diego Customs (SDC) teamed up to shoot a cover shot where Chip and Mikey wanted to do something substantial, so they invited a couple hundred of their friends. This lead to the idea of SDC Mikey shooting the cover of the October 2013 Issue of Hot Bike. They rode, they ate, they partied. An epic day was had as a result. We wanted to recreate that historic event’s 10-year anniversary by recreating that shoot, so we called Chip and Mikey to see if they’d be interested in doing it again. After a quick call, they were all-in. As were a bunch of other rad people like the Concrete Cowboys and their crew, Bike Life Mikey and CJ Barham. Oh, and we grabbed their resident photographer, Chopskee, to nab a bunch of shots (including this issue’s cover shot) too. The day went smooth, people had a great time, and we have some pretty rad memories as a result. Win-win. See ya’ll in 2033.

SPECIAL THANKS TO ALL THOSE WHO SHOWED UP TO SUPPORT THE CAUSE, AND THE VENDORS WHO CAME TO SET UP: FEULING PARTS, FXR DIVISION, SPEED-KING’S CYCLE, SADDLEMEN, GUERRILLA CABLES, V-TWIN NOW, HOT DOG KUSTOM PAINT, FDR FOUNDATION

ABOVE: Lining up a group of hundreds of bikes of all makes, from FXRs, Dynas, baggers, Softails, and more isn’t the easiest thing to coordinate. Luckily some repeat offenders from 2014 showed up to help get everyone in line. That and SDC Mikey’s bullhorn… BELOW: This shot was snapped right before everything came unglued and everyone started going in separate directions. Luckily, Chopskee still got the shot as he hung out of the back of our Sprinter van, almost becoming minced meat in the process.

Italians do custom bikes differently. They look at two wheels, a motor, a chassis and everything that comprises a motorcycle and their approach is well… just different. Where others might take a more practical, straightforward modus operandi, Italians tackle projects from a different lens: top, bottom, left, right, front, center, far away, up close, you name it… They painstakingly dissect every little component individually, every little nut and bolt, every nook, every cranny, and rethink how to make every piece come together in order to flow into something beautiful. Such was the case with Ivan Rovelli’s 2022 Harley-Davidson Nightster from Bad Boys Garage (BBG) that was completely reimagined.

Backing up a bit… It’s been a few years since we attended Motor Bike Expo (MBE). Our first trek to Verona, Italy was in 2012. And we were absolutely floored by the city that is home to Romeo and Juliet (Casa Di Giulietta). Verona was mind-blowing, to say the least. But it was very inspiring to see what the Europeans (mostly the Italians) were doing with American-made iron. There were so many great bikes on display that our necks were sore by the end of each day. After that first visit, we made it our goal to revisit MBE every year from then on, and we did so until 2019.

After a little hiatus, we were honored to attend Motor Bike Expo in Verona, Italy again this year, and this Nightster was the bike that stood out immediately. No joke, we were roaming the MBE halls for about 30 minutes when out of the corner of my eye I noticed this silver number where the owner of Bad Boys Garage, Ivan Rovelli, was demonstrating the adjustable seat for an event attendee. I stopped what I was doing, sped over to also take part in the demo, and that was that. I’d already picked my favorite bike for the Hot Bike Pick at Motor Bike Expo. It wasn’t hard. It didn’t take long. And that’s when I knew it was special. Then I started analyzing everything about this motorcycle. First of all, the overall bike has a nice balance. It’s not bulky, or bulbous. The lines flow seamlessly. The stance is strong. You can tell there was a lot of thought and effort that went into the tank shroud because the Nightster doesn’t have a traditional fuel cell. It’s an airbox cover. In case you didn’t know, the fuel cell is located under the seat. The tank shell is purely cosmetic. I love how they incorporated the high performance air filter into

the shell to let the component itself be the star.

Next, the heft was ditched for a more minimalist approach. You can see the bulky radiator shroud is gone, the stock bodywork is completely gone and was replaced with a one-piece steel sculpture made from 1mm thick stainless steel sheet that was cut, formed, welded, and finished into what really makes the bike. Plus, the seat was incorporated with a nifty little hinge to lift up for filling the fuel cap with ease.

The sub-chassis was also ditched for a much more svelte and functional single-sided swingarm built from scratch from the Bad Boys. The single-swingarm is a functional piece for racers so swapping wheels/tires in a jiff makes it much easier. While we’re not sure if the BBG Nightster plans on seeing any track time, we’re definitely certain we’d like to run a couple of laps with it!

We awarded the Bad Boys Garage Nightster with our Hot Bike Pick at the 2024 Motor Bike Expo event because it was different. There were a lot of great motorcycles on display, but this one was unlike anything else, which is exactly why we loved it! HB

BIKE OWNER

IVAN ROVELLI

SHOP NAME BAD BOYS GARAGE

SHOP PHONE 00390391181482

SHOP WEBSITE/SOCIAL

IG@BAD_BOYS_GARAGE

YEAR/MAKE/MODEL H-D/NIGHTSTER/975

FABRICATION BAD BOYS GARAGE

ASSEMBLY BAD BOYS GARAGE

BUILD TIME 6 MONTHS

ENGINE

YEAR/MANUFACTURER

2022 H-D

TYPE/SIZE REVOLUTION MAX/975CI

CASES STOCK

CYLINDERS STOCK

HEADS STOCKROCKER BOXES STOCK

EFI/CARB STOCK

AIR CLEANER BAD BOYS GARAGE

EXHAUST BAD BOYS GARAGE / V-PERFORMANCE

SPECIAL FEATURES STAGE I

TRANSMISSION

YEAR/MANUFACTURER/TYPE

2022 H-D

CASE STOCK

CLUTCH STOCK

PRIMARY DRIVE STOCK

FRAME

YEAR/MANUFACTURER

2022 H-D

RAKE STOCK STRETCH STOCK

SUSPENSION

MANUFACTURER FRONT REBUFFINI

LENGTH 85 CM / 33.965 INCHES

TRIPLE TREES REBUFFINI (SPECIAL ORDER)

MANUFACTURER REAR ÖHLINS FOR INDIAN FTR 1200

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT-TYPE PEDRALI WHEELS (SPECIAL ORDER)

WHEEL HEIGHT-WIDTH

TIRE HEIGHT-WIDTH

19 X 4.00

100-90/19

CALIPER REBUFFINI

ROTOR GALFER

MANUFACTURER REAR PEDRALI WHEELS (SPECIAL ORDER FOR US)

WHEEL HEIGHT-WIDTH 16 X 5.50

TIRE HEIGHT-WIDTH 150-80/16

CALIPER REBUFFINI

ROTOR GALFER

FINISH-PAINT

COLOR SAME AS STOCK ENGINE PAINTER DOX ART FACTORY

GRAPHICS DOX ART FACTORY

SPECIAL FINISHES DOX ART FACTORY

ACCESSORIES

FRONT FENDER BAD BOYS GARAGE

GAUGES STOCK 975

GAS TANK/CAP STOCK UNDER THE SEAT

DASH STOCK UNDER THE SEAT

HANDLEBARS BAD BOYS GARAGE

HAND CONTROLS/GRIPS H-D

FOOT CONTROLS/PEGS STOCK / REBUFFINI

HEADLIGHT HUSQVARNA AFTERMARKET LED TAILLIGHT AFTERMARKET

TURN SIGNALS KELLERMANN ATTO

LICENSE MOUNT BAD BOYS GARAGE

SEAT L.R. LEATHER

MISC COMPLETE BODY IN 1 PIECE HANDMADE BAD BOYS GARAGE FROM 1 MM STEEL

No tale of dark magic would be complete without a touch of evil to it and the story of this motorcycle starts with one of the Seven Deadly Sins: a healthy dose of envy. One of Majik Mike’s customers wanted one of Mike’s personal bikes. That would be all well and good if Mike wanted to part with said motorcycle (spoiler alert: he was not). “He asked me if I would build one for him just like it and I agreed. I normally wouldn’t build the same bike twice but I made an exception,” Mike told us. “I asked him what he wanted done differently on his bike and he asked for a blacked-out engine and black and gold paint with some red.” And that’s basically how this ’79 H-D Shovelhead found itself up for some choppery.

That’s how he avoided the whole same-bike-twice issue: keep it enough like the other motorcycle but tweak that design just enough to personalize it to the customer. That also made it a prime candidate for busting out Mike’s new skill set on a project (while also providing a certain magazine writer with inspiration for the title of this story). “I recently started powdercoating my own parts so I decided to do everything in black. To keep to

the customer’s request of black and gold, I added some brass to the bike rather than chrome. Brass rocker nuts, oil lines, oil pressure gauge, velocity stack, pegs and grips.” Rather than just leave the brass polished, he clear cerakote the parts to preserve the shine while laying down black cerakote on the knurled parts on the grips and pegs.

The inspiration for both customs came from the world of BMX racer designs. Overall, the idea was for a clean ride reminiscent of a BMX bicycle, with clean BMX style handlebars and a short design. Mike wanted it to “Look fast while sitting still as well as the rider sitting into the bike rather than on top of the bike. I always thought these color combos looked good together too, and I think the paint design Ryan Evans came up with fits the look perfectly.”

If you’ve seen Mike Rabideau’s iron, you most likely know how much he likes to keep the bike as clean as possible. That’s why he opted for a foot clutch and omitted a front brake. This keeps the bars clear with an internal throttle. To keep the bike with a race look he ran a solid rear rim and a spoke hub rim up front.

Which isn’t to say that the transformation was as simple as leaving out a brake and adding an internal throttle. Real-deal bikesmith that Mike Rabideau is, he brought his fabrication skills into the mix, especially with regard to the pipes. “The most challenging part of the build was the exhaust pipes. I didn’t want to just have normal slash cut tips, so I cut and made an oval style tip,” he says. “I also wasn’t happy with the flow of the pipes being all chrome, so as a last-minute decision I made heat shields. After installing them, I was much happier with the flow of the chrome pipes against all the black.”

All told, the entire transformation took eight months to complete. When it was all done, he of course had to sit the two

machines side-by-side. That was the most rewarding part of the process: “I think I successfully built the bike he originally wanted but with his personal requests. This bike is exactly what I pictured when I first thought of what I wanted to do for him. Not just adding black and gold to the paint but also in the hardware and details on the drivetrain.” The paint by Ryan Evans also tied the whole thing together, as Mike elaborated: “I love the black fade on the bottom of the gas tanks and fender. The oil tank has just enough gold and red without pulling your eye to that section. I think he killed it on the paint job and I couldn’t be happier.”

Well, maybe Mike couldn’t be happier. If his next project turns out as well as this one did, that might do the job, and let him party in the Caribbean to boot. “I’m currently working on a bike for the High Seas Rally. I was picked as one of four builders (Pat Patterson, Rick Brey, Xavier Muriel) to build a giveaway bike for the cruise in late October,” he says. “I’m doing a 1971 Shovelhead, hand-shift, kick-only bike. This will be another blacked-out bike but with purple flames done by Ryan Evans.”

Ryan’s contribution made for a killer machine but there were others whose hard work on it can’t be understated. “I want to thank Joe for choosing me to build his bike. Tank (@tankbilt) for helping jump in and making the frame with me. Ryan Evans (@ryanatcounts) for never disappointing me with his paint job, and Dean (@ mammymade_upholstery) for doing the seat. I had fun building this bike. Sometimes there’s a lot of pressure doing a custom bike for someone, but Joe was very patient and let me pretty much do what I wanted to do with very small limitations. I will be starting another build for him shortly. If you want to follow along, you can do that on my Instagram @majikmikesdesigns.”

SPECIAL FEATURES SLEEVED TUBES WITH FORK BOOTS

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT-TYPE

WHEEL HEIGHT-WIDTH 19X3-INCH WITH 40 SPOKES

TIRE HEIGHT-WIDTH 19X3-INCH AVON SPEED MASTER

MANUFACTURER REAR HARLEY-DAVIDSON

WHEEL HEIGHT-WIDTH 16X5-INCH TIRE HEIGHT-WIDTH 16-INCH AVON

EXILE CYCLES ROTOR SPROTOR

FINISH-PAINT HOUSE OF KOLOR COLOR RED, BLACK, AND GOLD LEAF PAINTER RYAN EVANS

GRAPHICS RYAN EVANS

SPECIAL FINISHES GOLD LEAF AND HAND-PAINTED STRIPES

ACCESSORIES

REAR FENDER LOWBROW GAS TANK/CAP LOWBROW

TANK CUSTOM MADE BY HANDLEBARS CUSTOM MADE BY MAJIK MIKE DESIGNS

HAND CONTROLS/GRIPS SPEED DEALER GRIPS FOOT CONTROLS/PEGS SPEED DEALER FOOTPEGS

“I WANTED TO GET THE BIKE UP OFF THE GROUND A BIT MORE, BUT DO IT PROPERLY WITH SUSPENSION ADJUSTMENTS. NOW THE BIKE FEELS A BIT TALLER UNDER HARD FRONT BRAKING INTO TIGHT CORNERS.”

For as superbly engineered as the Indian Challenger is, there’s always room for improvement. Or, at least, personalization. If there weren’t you’d be reading about a different custom job than this one from Carey Hart. He and his shop, Hartluck Designs, go way back in the bagger world. When the latest Challengers hit the market, he saw a chance to focus on fine tuning. Specifically, tweaking the ride position, seat height, and ergonomics.

With performance baggers taking center stage in the limelight right now, precision handling is a must for canyon-carving on the bigger bikes more than ever before. You probably know about Carey’s motocross origin story. With that experience comes great specificity on how his motorcycles are set up. Now that he’s logged well over 100k miles on the Challenger model, Carey Hart took all of that input from the bike and started fine tuning the ride position, handling, and braking. He also played with some of the ergonomics on the bike while fine tuning the suspension and ride height to his exact specs. As he puts it, “I’ve always been about performance because of my MX background. Luckily for

me it’s what is popular now. My first couple of projects were a little ahead of their time, but now I feel I’m in a good place. So now I can focus on pushing the performance aspect on small details rather than playing catch up.”

Power wasn’t an issue but Carey still made a set of pipes for the Challenger. He also brought in Indian’s performance cams and a Dynojet tuner. That’s exactly what you’d expect on a fine tuning project where you’re not trying to reinvent everything. The upgrades give him exactly the bump in grunt he wanted

Now, handling was another matter. We say “fine tuning” but in order to get that when it comes to overall ride quality, that meant changing out the suspension, brakes, and even a Barnett chain conversion at the driveline level. Getting a little extra lean angle in the twisties comes courtesy of the two-inch extension in the GP Suspension forks and matching shocks. “Though I never had any major issue with dragging the stock floorboards,” he says, “I wanted to get the bike up off the ground a bit more, but do it properly with suspension adjustments. Now the bike feels a bit taller under hard front braking into tight corners.”

And then there’s the wheels and brakes equation. Carey made the HartLuck signature Jade Affiliate wheels (19-inch front, 18-inch rear) for the bike and chose Dunlop rubber for traction duty. Both wheels are finished in badass gold anodizing. Swapping in Brembo Monoblock racing calipers up front also gave his machine a boost in stopping power. “I wanted to get rid of the bulky stock rear brake master, so went to work and figured out an adapter to use a larger diameter Beringer rear master and Rizoma reservoir. It gives the bike more of a racing feel and aesthetics.”

Both the racer feel and the look continued into the handlebars and controls, starting with the ODI Hartluck V-twin bar. Matched with ODI HartLuck grips and ODI end caps, the hand control setup

not only screams, “MX racer,” it also has the ergonomics to match. Carey completed the hand controls with a Beringer clutch perch and front master cylinder. He crowned the bars off with a Rizoma mirror. Down low, Kraus Motor Co. floorboards and passenger pegs sport custom shift and brake levers courtesy of San Diego Customs.

Not all of the changes came from performance upgrades, though. Others were a little more about the look: “I’ve always wanted to play with the location of the bags on my bike,” Carey continued. “In the end, the lids on the saddlebags are now flush with the top of the rear fender. Flush mounting them also gives more visibility to the swingarm and exhaust, as well as giving the

Challenger more of an aggressive profile.” Carey also cleaned up the rear fender and hid the rear indicators. He made a license plate mount to keep the rear fender similar to stock, just cleaner.

For as much work as all of those changes were, the biggest hurdle was the one that plagues us all: the merciless march of time. Carey was really set on getting the above changes done in a mere three months while still allowing time for actually riding it as much as possible. “I have a few long haul trips this year and I wanted to make sure I got everything done. I’m not about fashion, but function! That way I can see what works for a real long haul, and what doesn’t, for future projects,” he says.

But Carey also got by with a little help from his friends. “I’d just

like to thank my right hand man Big B (@feedbigb). When I’m under a harsh timeline like this one, he jumps at the opportunity for a long road trip to pick up parts or paint. I think he prefers to stay at a distance when I’m in this process. My favorite part is when the bike is complete, he lets me know ‘what he would have done,’ or ‘what I should have done.’ LOL.”

Carey would also like to thank Indian Motorcycle for allowing him all the freedom on his projects, Progressive Insurance, Dunlop, Kraus Motor Co., San Diego Customs, Fox shocks, Saddlemen, ODI, Airtrix, and “all the builders who always take my calls when I have a question. The V-twin world is an awesome community, and I’m so lucky to be a part of it.” HB

BIKE OWNER CAREY HART

SHOP WEBSITE/SOCIAL @HARTLUCK / HARTLUCK.COM

YEAR/MAKE/MODEL

CHALLENGER

FABRICATION CAREY HART

ASSEMBLY CAREY HART

BUILD TIME 3 MONTHS

ENGINE

YEAR/MANUFACTURER

TYPE/SIZE STOCK

CASES

CYLINDERS

HEADS

ROCKER BOXES

EFI/CARB

AIR CLEANER

INDIAN MOTORCYCLE

INDIAN MOTORCYCLE

INDIAN MOTORCYCLE

INDIAN MOTORCYCLE

INDIAN MOTORCYCLE

INDIAN MOTORCYCLE

EXHAUST HARTLUCK

SPECIAL FEATURES INDIAN MOTORCYCLE CAMS AND DYNOJET TUNE

TRANSMISSION

YEAR/MANUFACTURER/TYPE

MOTORCYCLE CASE INDIAN MOTORCYCLE

CLUTCH BARNETT CLUTCH

PRIMARY DRIVE BARNSTORM CHAIN CONVERSION

SUSPENSION

MANUFACTURER FRONT

GP SUSPENSION LENGTH 2 INCHES OVER

TRIPLE TREES

MANUFACTURER REAR

WHEELS, TIRES, AND BRAKES

GP SUSPENSION

GP SUSPENSION

MANUFACTURER FRONT-TYPE HARTLUCK JAD AFFILIATES WITH GOLD ANODIZING

WHEEL HEIGHT-WIDTH 19-INCH

TIRE HEIGHT-WIDTH DUNLOP

CALIPER BREMBO MONOBLOCK RACING CALIPERS

ROTOR GALFER

MANUFACTURER REAR HARTLUCK JAD AFFILIATES WITH GOLD ANODIZING

WHEEL HEIGHT-WIDTH 18-INCH

TIRE HEIGHT-WIDTH

DUNLOP

CALIPER STOCK

ROTOR GALFER

REAR MASTER BERINGER REAR MASTER, RIZOMA RESERVOIR

FINISH-PAINT

COLOR BLACK, RED, GOLD LEAF, SILVER LEAF, GOLD PAINTER AIRTRIX

ACCESSORIES

FRONT FENDER

INDIAN MOTORCYCLE

REAR FENDER INDIAN MOTORCYCLE WITH FILLED IN LIGHT MOUNTS

FAIRING/WINDSCREEN KLOCKWERX WINDSHIELD, TRIMMED UP GAUGES INDIAN MOTORCYCLE

GAS TANK/CAP INDIAN MOTORCYCLE

DASH BARNSTORM RELOCATION KIT

HANDLEBARS ODI “HARTLUCK” SIGNATURE V-TWIN BAR HAND CONTROLS/GRIPS BERINGER CLUTCH PERCH AND FRONT MASTER, ODI HARTLUCK GRIPS, ODI BAR END CAP, RIZOMA MIRROR FOOT CONTROLS/PEGS KRAUS MOTOR CO. FLOORBOARDS AND PASSENGER PEGS, SAN DIEGO CUSTOMS SHIFT/BRAKE LEVERS

HEADLIGHT BAJA DESIGN

TAILLIGHT RIZOMA

TURN SIGNALS RIZOMA

LICENSE MOUNT

CAREY HART

SEAT SADDDLEMEN “HARTLUCK” SEAT WITH THE BUMP MOVED FORWARD 2 INCHES

AUDIO INDIAN MOTORCYCLE

MISC 2-INCH SADDLE BAG RAISE/RELOCATION, REAR MASTER CONVERSION FABRICATION, REAR INDICATOR RELOCATION, HARTLUCK INSPECTION COVER HARDWARE PRO BOLT TITANIUM GOLD

CLUTCH CABLE BARNETT

BRAKE LINE GALFER

PHONE MOUNT ROKFORM

Drawing inspiration for a build can be found in many places. Finding inspiration for rebuilding something that took almost 9 months to complete the first go-round, only to have the engine seize and then crash into oblivion two weeks after its debut…well, finding inspiration is damn near impossible. Unfortunately, but fortunately, Jared Smith, of Smith Process, was put into this predicament, but his approach to correcting an unfortunate situation demonstrates an unparalleled level of resilience.

What might break most men, only encouraged Jared. And where each creation tells a unique story, Jared’s is pretty hard to beat. His tale of passion, perseverance, and personal craftsmanship leaves an indelible mark within the custom motorcycle world.

Built for Born-Free 14, an event that epitomizes the essence of motorcycle culture, this particular bike is more than just a machine; it’s a labor of love meticulously crafted by an enthusiast for the sheer joy of riding.

Jared embarked on a mission to build a high-performance machine that not only pushed the boundaries but also reflected his personal style and vision. Eschewing the conventional route of customer builds, he set out to create a bike that resonated with his soul—a bike that would be his ultimate riding companion.

With a clear vision in mind, the journey began. Every aspect of the build was meticulously planned, with a focus on crafting as many parts as possible by hand. The goal was clear: to create a skinny, high-performance machine that would be an absolute

joy to ride. A bike that would turn heads and set hearts racing.

Among the myriad challenges faced during the build, one stands out: the modification of the heads and the intricate process of cutting the XR-750 primary cover into five different pieces to fit it onto a big twin. It was a daunting task, but one that was met with determination and skill. The result? A testament to Jared’s ingenuity and craftsmanship.

Another memorable moment in the journey was the exhilaration of firing up the engine for the first time. Despite the challenges posed by a magneto and two giant carbs, the thrill of hearing the engine roar to life was unparalleled—a moment of triumph after hours of hard work and dedication.

However, the true essence of the journey was experienced upon arrival at Born-Free. Surrounded by fellow builders who poured their hearts and souls into their creations, there was a sense of camaraderie and mutual respect that transcended words. It was a moment of validation. A realization that the blood, sweat, and tears poured into the build were not in vain.

Inspired by the aesthetics of late ’80s MotoGP racers, Jared’s bike is a nod to the past while it embraces the future. It’s a fusion of style and performance—a personal interpretation of a genre that holds a special place in Jared’s heart.

Two weeks after its Born-Free debut, the motor seized and Jared crashed the bike, which he had to completely rebuild (you’re seeing round two of the Born-Free debut in these photos). Despite the challenges faced and the setbacks Jared encountered, he remained undeterred. As a dedicated father and enthusiast, his focus and passion for bikes remains

BIKE OWNER

JARED SMITH SHOP NAME SMITH PROCESS SHOP WEBSITE/SOCIAL @SMITHPROCESS

YEAR/MAKE/MODEL 1960 HARLEY-DAVIDSON FLH PANHEAD FABRICATION JARED SMITH ASSEMBLY JARED SMITH BUILD TIME 9 MONTHS

ENGINE

YEAR/MANUFACTURER 1960 HARLEY-DAVIDSON

TYPE/SIZE FLH PANHEAD LOWER END WITH DUAL FRONT CYLINDERS/HEAD SHOVELHEAD TOP-END 88.8CI CASES STOCK 1960 H-D

CYLINDERS S&S DUAL FRONT SHOVELHEAD CYLINDERS HEADS STOCK H-D SHOVELHEAD FRONT HEADS, HEAVILY MODIFIED TO RUN DUAL CARBS AND LEFT SIDE EXHAUST ROCKER BOXES SMITH PROCESS ROLAND ROCKER BOXES EFI/CARB DUAL 39MM KIEHIN FCR AIR CLEANER VELOCITY STACKS EXHAUST DUAL OPEN SHOTGUN

SPECIAL FEATURES OUTSIDE OILING AND RETURNS TO AND FROM TOP-END, CUSTOM ROCKER SHAFTS FOR THROUGHOILING TO S&S ROLLER ROCKERS, LEINEWEBER L51 CAM GROUND FOR TWO FRONT HEADS (REVERSING LOBES FOR REAR CYLINDER), CUSTOM STAINLESS INTAKE RUNNERS

TRANSMISSION

YEAR/MANUFACTURER/TYPE 2023 BAKER 6-INTO-4 CASE CLUTCH AMERICAN PRIME PRIMARY DRIVE BDL

FRAME

YEAR/MANUFACTURER 2023 SMITH PROCESS 1-OFF DOWN-TURNED REAR TRIANGLE RAKE 30º STRETCH 0”

SUSPENSION

MANUFACTURER FRONT 2 DIFFERENT YAMAHA 41MM FRONTENDS EXTENDED AND CUSTOMIZED TO WORK TOGETHER LENGTH

TRIPLE TREES MODIFIED MULLINS CHAIN DRIVE NARROW TREES MANUFACTURER REAR

SPECIAL FEATURES THE HANDLEBAR HOLD-DOWNS ARE INTEGRATED INTO THE FORK TUBE TOP CAPS, WITH WINDOWS IN THE HANDLEBAR RISERS FOR ADJUSTING THE SUSPENSION PRE-LOAD INSIDE VIA A CAPTIVE PIN NUT IN THE RISERS.

WHEELS, TIRES & BRAKES

MANUFACTURER FRONT-TYPE DUNLOP K180 / LYNDALL WHEELS

WHEEL HEIGHT-WIDTH 21X3

CALIPER DUAL ISR 6-PISTON

ROTOR ISR SOLID MOUNT

MANUFACTURER REAR DUNLOP K180 / LYNDALL WHEELS

WHEEL HEIGHT-WIDTH 18X4.5

CALIPER ISR 6-PISTON

ROTOR ISR SOLID MOUNT

FINISH-PAINT

COLOR VW L31 DOVE BLUE PAINTER MIKE BARON

ACCESSORIES

REAR FENDER CUSTOM BEAD-ROLLED SHEET METAL SEAT COWL AND INTEGRATED REAR FENDER OIL TANK CUSTOM ALUMINUM XR STYLE TANK

HANDLEBARS CUSTOM T-BARS WITH INTEGRATED FORK TUBE AND TOP TRIPLE TREE HOLD-DOWNS WITH SUSPENSION PRELOAD INTEGRATED HAND CONTROLS/GRIPS CONTROLS ARE BY ISR, GRIPS ARE TOMMASELLI

FOOT CONTROLS/PEGS CUSTOM ALUMINUM REARSETS AND PEGS MADE ON THE MANUAL MILL HERE HEADLIGHT MODIFIED BAJA DESIGNS LP4 MOUNTED TO A XLCH SMOOTH EYEBROW TAILLIGHT 1-OFF VINTAGE GLASS LENS

“THAT

AND PUSHING

IN EVERY POSSIBLE WAY, THEN BEING REWARDED BY IT COMING TOGETHER, IS A FEELING I WILL NOT SOON FORGET. ”

unwavering. While he may not have any immediate plans for another “performance chopper,” the journey—and quite possibly the asphalt itself—has left quite the impression on Jared.

In the end, yes, the motor may have seized, and the bike may have crashed, but what remains is a testament to the resilience of the human spirit. A reminder that setbacks are just another opportunity to rise again, stronger than before.

In the world of custom motorcycle builds, the journey is as important as the destination, and the memories forged along the way are what truly endure.

Jared would like to thank the following (Instagram handles): Adam Munz @speed_research, Michael Barragan @evil_spirit_ engineering, Thom Jones @semigoods, Christian Newman @ ctnewman, Max Schaff @4q69, Taylor Cole @roadkill.cowboy, Megan Fradley-Smith @the.backyard.naturalist. HB

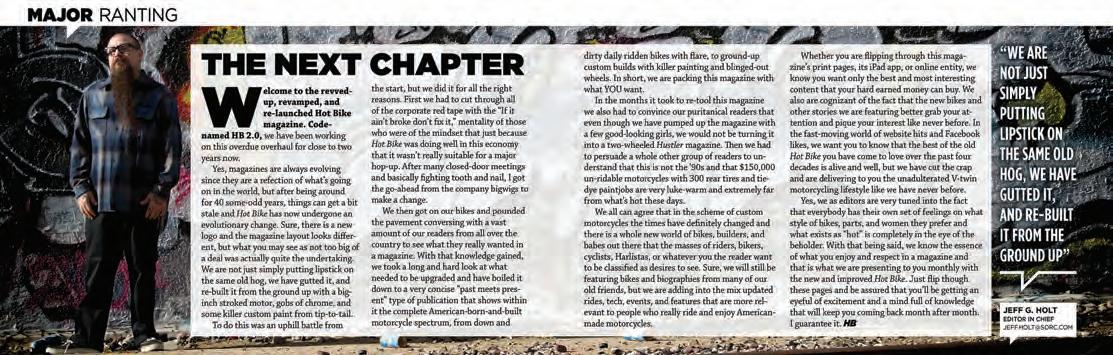

In the early 2010s, the world was still pretty hungover from the 2008 financial crisis, and as a result, industries started to pivot. The custom bike world changed too. The ground-up custom chopper business literally evaporated overnight and 300mm wide-tire kits started to fall by the wayside. Instead folks started converting their stock Harleys with the latest and greatest new parts to hit the market, and voila, the parts boom ensued as a result. Hot Bike also went through some changes, going from a 300-page print media package in the 2000s to then juggling magazine production, web production, this newer thing called social media, and trying to reach audiences via smartphone (the iPhone 4 was in full swing by 2010). And it all happened so fast. The tech world shifted the paradigm to be driven off of instaneous gratification, and then everyone became a robot. Beep-boop-bop.

Every later-model bike I’ve ever owned, one of the first things I’ve always done is convert the final drive from belt to chain. And of all those bikes, not a single one needed it from a horsepower standpoint, but rather an aspect of convenience on my behalf… as I found myself dealing with varying wheel sprocket combos and whatnot, more often than not.

So, when I had Danny Wilson, aka Motorwitch, upgrade the clutch on my 2021 FXLRS last year (from stock to Evolution Industries), I figured since we were getting that deep into the primary, why not go ball’s deep and swap out the stock belt for an FXR Division complete chain drive conversion kit. Literally, once the inner primary was removed, it didn’t take but 30 minutes to complete the swap.

Will it add horsepower/torque to your bike? Nope. Is it messier and require more maintenance than the stock H-D belt? Yep. Akin to putting solid machined-aluminum risers in place of the stock isolators, I’ll continue swapping out the belt drives for chains if only for the aesthetic aspect and the bit of convenience it poses… as long as they’re quality kits as such, not the Amazon or IG special junk!

FXR Division’s kit (for the M-8) consists of their own 51T machined/anodized high-grade steel rear sprocket with 7/8” Vulcan Engineering spacer and polished stainless ARP hardware, PBI 24T trans sprocket, and a D.I.D. VMX 530 O-ring chain (varying color options available). All rear chain drive conversion kits are available on their site—but to have one installed by Danny, you’ll need to make an appointment with the fine folks at Motorwitch Industries!

SOURCES:

FXR DIVISION

www.fxrdivision.com // (480) 953-3255

MOTORWITCH INDUSTRIES

www.motorwitchindustries.com // (602) 919-3595

ABOVE/RIGHT: FXR Division’s 2018–up Softail rear chain drive conversion consists of everything you see here: powdercoated/hardened-steel 51T rear sprocket with Vulcan offset spacer and polished ARP hardware, PBI 24T trans sprocket, and D.I.D. 530 O-ring chain. While Danny “Motorwitch” Wilson was doing our Evolution Industries/Baker Driveline clutch and primary drive upgrade (Vol. 2, 2023), we decided no better time than the present to swap out the stock belt drive for the aforementioned FXR Division (USA Made) kit… just had to continue the primary disassembly down to the engine/trans.

While Danny was searching for a sharp Swazall blade, Moody came to the rescue to rid the poor belt of its existence with his handy bolt cutters. Now, not that I’ll be tearing into the Softail like I would on a regular basis with any of my Evo bikes, but the convenience that servicing the chain offers is pretty much the main reason I chose to swap.

Danny made sure to point out that when installing/fitting a new chain, position the rear wheel as far forward as possible in the swingarm—that will allow for future chain stretch and enough room for adjustment when the time comes!

With the rear wheel/chain set, the axle nut is torqued to 90 ft-lbs (the additional tool he’s using allows him to do so without having to drop the exhaust… in case you were wondering, like I was!).

I do want to point out that the Evolution Black Ops clutch assembly features a 49-tooth hub, as opposed to the stock Harley 46-tooth… Ultimately, that will bring the RPMs down on the top-end while giving you more off-launch.

LAST NOTE: to keep the grease sling to a minimum—or at the very least, keep it off my pants—Danny reinstalled the stock belt guard, cautioning that “the chain may slightly rub at first…” but to date, I’ve yet to experience any chain/guard interference (and the grease cleanup off the rear wheel/fender has not been nearly as bad as anticipated!). For lubrication purposes, I’ve been using Maxxima’s Chain Guard Crystal Clear since the initial install.

SOURCE: THRASHIN’ SUPPLY CO. thrashinsupply.com

WORDS: JORDAN MASTAGNI PHOTOS: REAMONN RYAN

Fine-tuning the fi t of your brake levers isn’t something you’re thinking about every time you ride. You’ve probably just gotten used to your setup and haven’t thought about it again. But that’s because you haven’t had many options for tailoring the adjustment to fi t your fat foot. With Thrashin’ Supply Co.’s new Adjustable Brake Linkage for Softails, it’s now possi ble to do just that.

your overall setup with one of Thrashin’s new Softail Brake Arms, too. This new billet aluminum Brake Arm increases lean angle, it features a delrin plastic scrape plate and it’s finished in black anodize or chrome for 2018–2023 Harley-Davidson Softails with mid-controls.

The Thrashin’ brake linkage allows you to fine-tune the height of your brake arm without having to remove the linkage from your bike. It fits Milwaukee-Eight Softails with mid-controls, includes all mounting hardware and is available in black anodize or chrome. And if you’re going to go that route, you might as well update

Both the Brake Linkage or Brake Arm can work separately with your stock components but are even better paired together. We popped over to Thrashin’s all-new Headquarters in Moorpark, California, to dive into how these new brake bits function on an M-8 Softail. Thrashin’s very own Juan Arceo, who has an aerospace engineering degree (doesn’t that make him a rocket scientist?) walked us through the step-by-step installation. HB

The Thrashin’ brake linkage is available in either chrome or black anodize. It allows you to fine-tune the height of your brake arm without having to remove the linkage from your bike. Made specifically for Milwaukee-Eight Softails with mid-controls, the reverse heim joints are what allow you to make the adjustments.

While he was at it, Juan installed the Thrashin’ Brake Arm too, which helps with cornering clearance and adds a bit more style and function to the equation. It’s available in chrome or black anodize too.

1. Juan used a 1/4-inch drive socket, 1/2-inch open end wrench, 5/16-inch deep socket, 3/16inch Allen bit, a T-27 Torx bit, and some blue threadlocking compound for the new supplied hardware.

4. Juan was able to remove the brake arm and linkage as one unit, but he had one bolt left to remove, the 3/16 Allen socket. Note: Be mindful of the stock linkage’s orientation to the brake arm. You’ll want to mirror that setup when installing the Thrashin’ Linkage and the supplied spacers in place.

12. Here’s a di erent view of both new components installed after being set to the desired location. This simple installation provides some great options for adjustability based on your riding specifications. 1 2 3 4 5 6 7 8 9 10 11 12

10. Once he found the desired location for his riding position, Juan checked for any clearance issues, and also that he had full range of motion of the brake arm. Once that checked out, he tightened down the front heim joint jam nut.

2. Juan started by removing the factory linkage’s 3/16 Allen bolt up front. Notice the Thrashin’ Brake Arm was already installed.

5. Make sure you use some blue threadlocker when installing the new Thrashin’ Linkage. You’ll also want to make sure that the supplied Thrashin’ spacers go on the inside of the linkage when installing the bolts.

8. Once everything was installed…

And

3. …And then Juan removed the rear aluminum ARP bolt from the Thrashin’ Brake Arm (which will be a T-27 Torx for stock applications).

6. Starting with the front 3/16 Allen bolt, Juan installed the new Linkage in place with the spacers behind the heim joints.

9. …Juan was able to make adjustments to the Brake Arm height with one hand before tightening down the jam nuts.

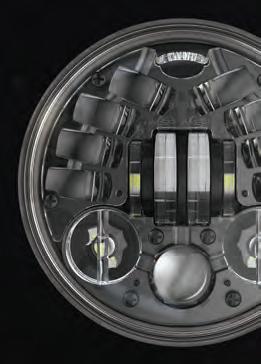

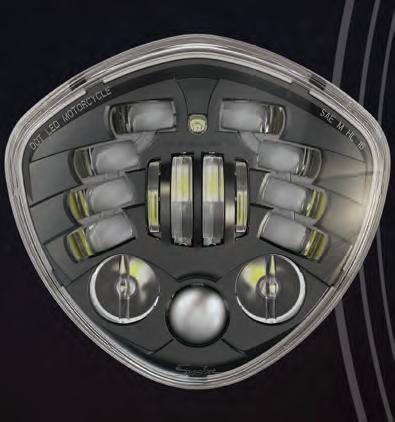

The Adaptive 2 Series® of LED Motorcycle Headlights dynamically fill in the dark corners as the bike turns left or right. Embedded sensors in the headlight work in real time to calculate banking angles and speed to adjust and direct precise beam patterns for maximum comfort and safety for the rider.

No matter what you ride, we’ve got you covered. The Adaptive 2 Series® Headlights fit over 1,000 styles of motorcycles.

Spain with its silly running of the bulls ain’t got nothing on us.

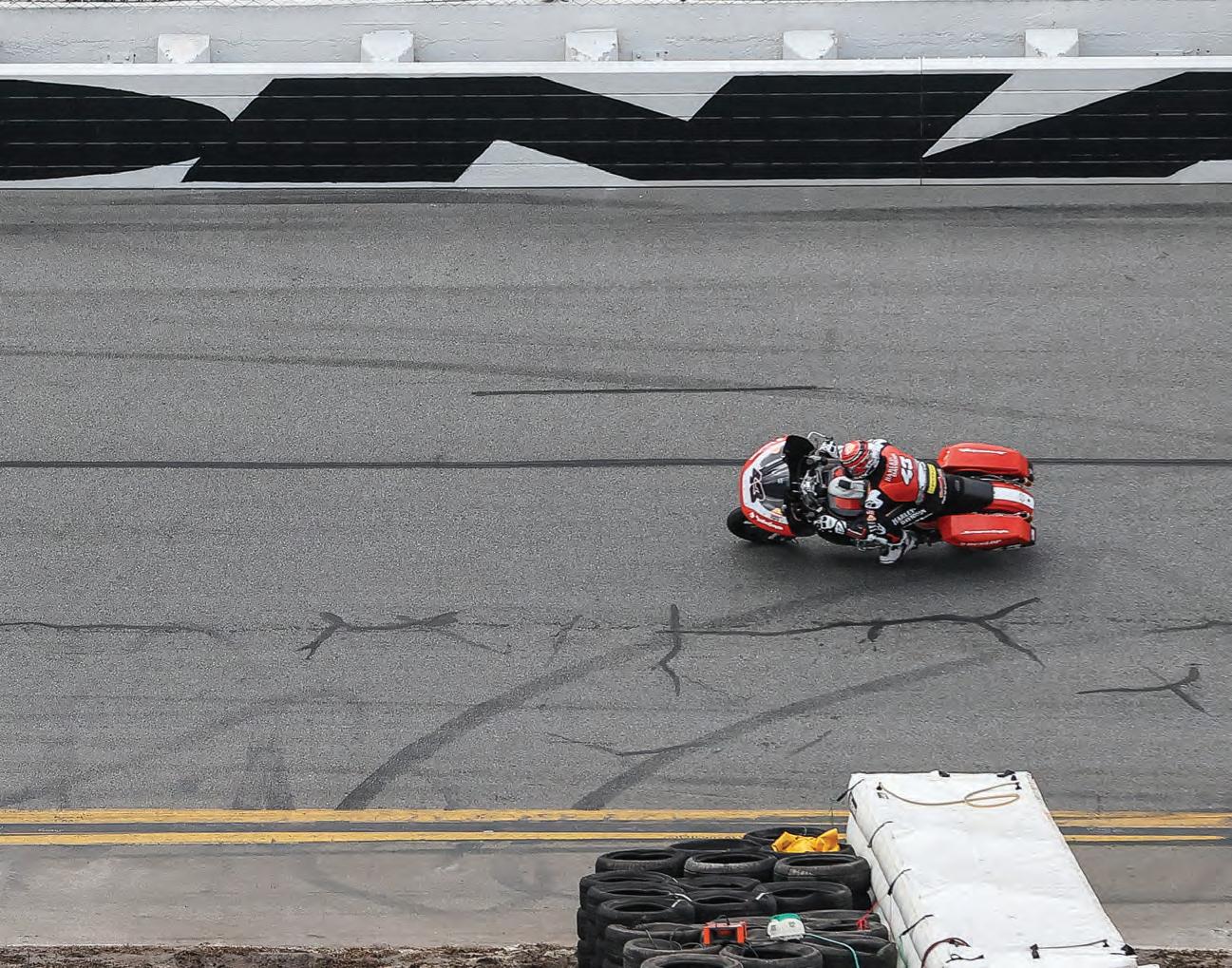

The USA has the running of behemoth baggers, coming to a racetrack near you from Daytona International Speedway to Laguna Seca. The Mission King Of The Baggers class of the MotoAmerica road racing series is a thundering horde unlike any other racing class. That means these baggers race on paved courses with turns in both directions, hard braking, lots of fullfisted accelerating, backing-it-in cornering, fighting wheelies. It’s loud, it’s riveting, it’s highly competitive, the bikes are stupid fast, the racers are dead serious. Yet, it’s also a bit funny. It’s hard to watch the big baggers road racing without the morbid eye of a “hold-my-beer” witness.

Wait, stupid fast? Is that reasonable to say? On the high banks of Daytona International Speedway this year, Tyler O’Hara’s Indian Challenger was clocked at 187.4 mph. None of the teams will share horsepower or torque numbers, but these baggers leave superbikes behind from a dead stop to 60 mph. These road racing baggers are akin to Fantasia’s animated hippos in tutus, who gracefully danced to Ponchielli’s Dance of the Hours… with crocodiles. Baggers do have grace and belong on racetracks.

This magazine does preach the joys of baggers, those low-

ass, iron-framed, big-bore narrow-V-twin powered machines, for which weight is a performance advantage on the big roads across America. But road racing these monsters is an answer to a question no one asked, not even us. The thing is, it’s a freaking awesome answer.

Many spectators couldn’t stop laughing throughout the first baggers race at WeatherTech Raceway Laguna Seca, in 2020, just outside of Monterey, California. That one-off exhibition race started as a silly bore, with Tyler O’Hara blasting away to an insurmountable lead on his Indian, until he made it surmountable by running off the track in turn two, dropping back to third place. That made it interesting. O’Hara had a lot of ground to make up, catching the two bikes ahead of him, which he did manage, putting himself in the record books as the first-ever winner of this baggers-specific road racing class. Yet it all seemed somehow misguided. But entertainingly misguided.

That inaugural race was just too much fun so, the Mission King Of The Baggers (KOTB) class was added to the MotoAmerica calendar, now in its fourth year with multiple races around the country. Kyle Wyman took ownership of the KOTB championship in 2021 on a Harley-Davidson, with O’Hara winning it in 2022 on

an Indian and Hayden Gillim earning the 2023 championship, again on a Harley. It’s that competitive.

The teams competing are primarily factory teams from HarleyDavidson and Indian, plus factory-supported teams and V-twin aftermarket accessory teams, managed or supported by the familiar brands of Vance & Hines, S&S, Saddlemen, Roland Sands Design, Trask Performance, Feuling Parts, SDI, RevZilla, and more.

The list of racers in this class are from around the world and with astonishingly accomplished records. Probably best known is Feuling Parts rider Reuben Xaus, former MotoGP racer with one visit to the top-class’ podium, and a multi-time WorldSBK winner and runner up in the 2003 championship.

Troy Herfoss, riding for the Mission Foods/S&S/Indian team, is a three-time and current Australia Superbike Champion. He has also won championships in Australian Dirt Track, Supermoto, and Supersport, is the 2008 AMA Supermoto champion, and a Moto X-Games silver medalist. Herfoss’ teammate Tyler O’Hara has won titles in motocross, flat track, and Supermoto, is a two-time MotoAmerica Super Hooligan champion, on top of his previously mentioned KOTB successes.

Harley-Davidson Factory Racing has second-place finisher in the 2023 KOTB championship, James Rispoli, alongside 2021 KOTB champion, Kyle Wyman. The RevZilla/Motul/Vance & Hines/ Harley-Davidson team boasts last year’s KOTB champion Hayden Gillim, with new teammate Rocco Landers who is a two-time MotoAmerica Junior Cup Champion, the 2020 MotoAmerica Twins Cup Champion, and race wins in Supersport.

The riders on the Saddlemen/Harley-Davidson team are Travis Wyman, Jake Lewis, and Cory West. Wyman has twice finished runner-up in the Stock 1000 class and was twice second in the KOTB championship. Lewis has won the Stock 1000 Championship and Superbike Cup. In the Daytona SportBike championship Lewis has finished second in the championship and was AMA Superbike Rookie of the Year in 2015. West, owner of Froggy’s Moto Tours in the Ozarks, comes from a family of racers including his two great uncles, AMA Hall of Famer and off-road racing pioneer, Leroy Winters, and AMA National Flat Tracker, road racer, and Daytona 200 winner, Robert “Bobby” Winters. Cory’s Father, Denton West, was a novice flat tracker and raced AMA Superbike and F1, while Cory was a three-time Daytona 200 runner up, and an AMA Superbike Rookie of the year.

Two other well-known riders in the KOTB field are Shane Narbonne riding for Trask Performance, makers of turbochargers, and Bobby Fong on the SDI/Roland Sands Racing/Indian Motorcycle team. Narbonne was crowned “King of the Classic” having won the Loudon Classic seven times, which is the longest-running motorcycle race in America, going back to its early days as an off-road event founded in 1934. Fong is a former MotoAmerica Supersport champion and multi-time Superbike race winner. In total, the top half of the KOTB grid is basically a race of champions, with a combined 738 years of experience between these riders.

Yeah, well, okay, we just made that number up. Math is hard. But our point remains.

Teams were willing to share some technical information with us, but not everything. For instance, the rules have a minimum weight for the motorcycles of 620 pounds. This is heavier than some teams would like, so they add lead to make up the difference. The good news about this is weight can be added where the teams desire it to be, helping to best balance the bike for braking, cornering, and accelerating.

Gary Gray of the Mission Foods/S&S/Indian team told us: “We wish we could get them to lower the weight rules. The suspension, tires, brakes, chain… are designed for bikes that weigh a few hundred pounds less. The Challenger has an aluminum frame already so reading the minimum was too easy. We could be sub-600 pounds for sure.”

We also were told by the Indian Challenger team that the race bikes carry Mission tacos in the side bags. Having them empty just seemed wrong. Meanwhile, the Saddlemen team uses the bags to house fluid reservoirs. Per the rules, the bags are required to open and be stock sizes, which isn’t a problem with ground clearance since the bikes are jacked up to an incomprehensible height to improve geometry and ground clearance. Be sure to watch the start of a KOTB race to witness that even the tallest of riders can reach with only one foot.

Many teams refresh their engines after each race, but O’Hara’s team shared that he is hard on the engines, so they often provide him two during a race weekend. Winning can earn that. O’Hara’s team say the goal is to go half a season with the engines, so they’re working on the reliability things. Both the Harley-Davidson and Indian use quick-shifters, but only the Indians have slipper clutches, we were told. By rule, none of the bikes have traction control, ABS, or any electronic rider aides. The traction control is the palm at the end of each rider’s right arm.

It’s an easy guess that both brands’ engines are pumping out around 200 horsepower to drive those big fairings and wide bags up over 180 mph. There’s a lot of air to push out of the way at that speed, the difficulty of which is witnessed by how quickly a drafting advantage drops off when a rider pulls out from behind another on any of series’ tracks long straights. They seem to hit a wall and stall.

Roland Sands shared that his team “Goes through a motor a weekend if we are lucky. We’re pushing these motors way beyond original intentions. We’ve had to start building our own motors in house just to save on the shipping and decrease the time to get motors built. It’s been an insane process, but the juice is hopefully worth the squeeze.” Sands also shared that his team’s bikes carry beer in the side bags, but we haven’t confirmed that.

Sands shared some very cool additional details: “The suspension is massively upgraded and jacked up to the moon. We use our new Dymag collaborative wheels in 17 x 3.5” and 17 x 6”, so we can use super-sticky Dunlop slicks with massive Brembo racing brakes. The ergonomics are highly modified for racing with repositioned foot controls and bars. The wiring looms and ECUs are completely new. Pretty much the main chassis is the only thing that hasn’t been touched, pertaining to the rules. The Baggers make almost double the HP from stock.” That pretty much confirms our horsepower estimate.

“WE’VE HAD TO START BUILDING OUR OWN MOTORS IN HOUSE JUST TO SAVE ON THE SHIPPING AND DECREASE THE TIME TO GET MOTORS BUILT. IT’S BEEN AN INSANE PROCESS, BUT THE JUICE IS HOPEFULLY WORTH THE SQUEEZE.”

— ROLAND SANDS

“WE’VE NOTICED A BIG BUMP IN ATTENDANCE AND YOU CAN SEE THE GROWING NUMBER OF BAGGERS PARKED IN THE MOTORCYCLE LOTS AT OUR RACES, WHILE AT THE SAME TIME ALL OF MOTOAMERICA’S CLASSES HAVE GAINED IN POPULARITY.

— PAUL CARRUTHERS Communications Manager for MotoAmerica

KING OF THE BAGGERS

Harley-Davidson’s Public Relations Manager, Paul James, shared that teams running Harley-Davidson are generally using either the 131 cubic inch MilwaukeeEight twin-cooled or air-cooled pushrod V-twin. They are also allowed to use S&S or JIMS air-cooled pushrod Twin Cam or twin-cooled engines. The forced-induction aircooled pushrod V-twin engines are allowed a maximum displacement of 107 cubic inches, which would, for instance, be the engines running Trask Performance turbochargers.

The Indian teams are running original-equipped watercooled V-twin engine, with maximum displacement of 112 cubic inches up from the stock 108 ci and normally aspirated, limited in size due to the four-valve heads and liquid cooling of the Challenger engine. Or Indian teams can run the original-equipped air-cooled pushrod V-twin engine, maximum displacement of 131.95 cubic inches and normally aspirated, or a forced-induction air-cooled pushrod V-twin engine with maximum displacement of 111 ci, again, those being turbocharged.

Most teams we asked confirmed that they are running Öhlins suspension on both ends of their race bikes, which isn’t a surprise since that company has stepped up to the V-twin market in a big way. At least one exception is Roland Sands team, which runs K-Tech suspension and S&S triple clamps modified by Roland Sands Design (RSD).

Currently, it’s a two-brand class, with only HarleyDavidson and Indian qualified to compete. Paul Carruthers, the Communications Manager for MotoAmerica, tells us, “You know how it goes, if you have more than one of anything, you should race them. In all seriousness, the idea was kicked around for a while. I wasn’t a fan of it but that all changed when I saw them racing.” As it did for most of us.

Since taking over the AMA-sanctioned road racing series in 2015, MotoAmerica has witnessed a steady increase in spectators. Having personally attended many of its events over the last decade I can attest to that. In its initial year at Road Atlanta, for instance, I noticed that I had raced in front of more spectators at that track while competing in the WERA National Endurance Series in the early 1990s. But solidly, as of the last couple few years, that is far from true, with happy spectators at every corner around the track. The same goes for all of the current MotoAmerica events, though some venues have changed for 2024.

Carruthers added, “We’ve noticed a big bump in attendance and you can see the growing number of baggers parked in the motorcycle lots at our races, while at the same time all of MotoAmerica’s classes have gained in popularity.

“There is so much interest in KOTB right now it was a natural to show the racing to the rest of the world and MotoGP was enthusiastic about having the new class at Circuit of the Americas.” Enthusiasts

worldwide have been able to access the KOTB on the MotoAmericaLivePlus.com website or app which is available to anyone for purchase. So, many Europeans are learning about the series and are fans already.

We asked a few of the racers, prior to the season’s opening race at Daytona International Speedway, how the baggers differ from what is normally road raced. Harley-Davidson Screamin’ Eagle Factory Racing’s James Rispoli told us, “The Harley moves around a lot and I regularly slide the rear. They’re loose, they wiggle, they slide, things drag. But in my two years on the bikes, they have gotten more stable and

faster. I did 175 mph last year at Daytona.”

Kyle Wyman added, “The biggest difference is the weight. But we can throw them around. Stopping and steering are getting closer to sportbikes, but ground clearance and lean angle are still less than we’d prefer.”

Rispoli also shared, “The bikes are so heavy compared to normal race bikes, so optimizing the tires is difficult. The tires drop off and it’s hard to manage them. The bikes are aircooled, so you need to keep them cool and can’t ride as hard as you might like. They are easier at some tracks and it’s easier to find what seems to be the limit, but the limit is so high and

getting higher so we’re still pushing more and more in every session and at every track we go faster than before.”

Troy Herfoss told us, “They’re different as far as inertia goes and they have a lot more torque. So, learning to manage that is different. But the power delivery is very linier, making the bikes very rideable. A plus is, the bike gives more feedback than a superbike.”

The best answer we heard when asking how the KOTB riders are perceived by other racers was also from Herfoss, riding for the S&S/Indian Motorcycle team. “A bagger racer is like Austin Powers; guys want to be him, girls want to be with him.”

As alluded to above, the opening two races of the KOTB series this year took place at Daytona International Speedway. Both races were blindingly competitive despite having the exact same podium results of Kyle Wyman winning, with Troy Herfoss taking second, and James Rispoli in third, for a Harley, Indian, Harley result. Race 1 saw a crazy 0.018 differential at the finish line between first and second, while the Race 2 split was only an amazing 0.137.

Because Daytona is an anomaly of a racetrack, it is certain that numerous other players will be on the podiums once the

series moves to tracks with shorter straights, more complicated turns, and heavier braking. On top of the practice, qualifying, and two KOTB races at each event is the two-lap KOTB Challenge, in which an insane bit of rider desperation and risk taking abounds for maximum entertainment.

Added big news this year, as mentioned earlier, is that the KOTB class will be competing at the USA round of MotoGP at the Circuits of the Americas, Austin Texas on the weekend of April 12–14. There, the hippos in tutus will share the track that weekend with the crocodiles of MotoGP, but not at the same time. We will be there, for sure.

The KOTB class will also be competing at seven of the remaining nine MA events; Road Atlanta, April 19–12; Road America, May 31–June 2; Brainerd International Raceway, June 14–16; Laguna Seca, July 12–14; Mid-Ohio, August 16–18; Circuit of the Americas, September 13–15; New Jersey Motorsports Park, September 27–29. The two MotoAmerica events missing from this list are Barber Motorsports Park of Birmingham, Alabama and Ridge Motorsports outside of Seattle, Washington.

Sometimes what’s wrong is completely right. Long live the King Of The Baggers. HB

Since 2002, Koji Oda and his crew (consisting of one helper) at Indian Orange have focused on building unique custom ’60s and ’70s Harley-Davidson choppers. No baggers, no tourers, nothing fitting the description of the aforementioned has a place in the shop. Indian Orange is mostly just ’60s and ’70s Harley-Davidsons. It’s like our pappy always said, “if you want to be successful in life, pick one thing and stick to it.” Koji picked choppers and he’s been in the game for 22 years amidst all the competition within the Japanese custom scene.

Our pal and righteous photographer, Kazuo Matsumoto (@steeldog_photo, AKA “Kaz”) caught up with Koji and sent in some great shots of the shop and helped us gain a better understanding of Indian Orange and provided a little insight into Koji’s ethos.

“Indian Orange refers to the orange color used for the lining of the MA-1 flight jacket,” says Koji. “This orange is the color that is most easily recognized by the human eye, so it is said that in an emergency, wearing it inside out can be an effective way to signal SOS. I wanted to create a store that would be easy for people to find and be helpful to people who have had trouble riding a motorcycle or are wondering how to make their motorcycle look cool, so I decided to open my store and name it Indian Orange. Also, since orange is the color of crisis, it fits my desire to create a sense of tension.”

Inspired by the likes of Arlen Ness, Yukio Sato of Motorcycle DEN, David Mann, Joe Strummer, Ed Ross, Robert

“TAKE WHAT COMES AND LET GO OF WHAT LEAVES.”

Williams, Indian Larry, Von Dutch, Joe Smith, and others, Koji is a huge fan of rock ‘n’ roll and constantly has something playing in the background of the shop while he works on the many different projects he has going on. In fact, Koji is an excellent guitar player and has played in several bands too.

Koji says that he doesn’t think the current custom bike scene in Japan is excellent at the moment. “Motorcycles have become too expensive; old bikes have become icons and lost their true value,” Koji says. He added that the Japanese motorcycle market expanded, and the technology for making motorcycles at motorcycle shops improved; however, he feels that there haven’t been any cool bikes recently, and even if there were, they were not appreciated. “I feel like fewer people are riding them because they truly love them and that motorcycle builders, the media, and those who select awards at shows should go back to basics.”

When asked about how Indian Orange can best be described, Koji left us with these words of wisdom. “Take what comes and let go of what leaves” and to “Be as proactive as possible.” Well put, Koji-San. Thanks for letting us poke around your shop.

TOP AND BOTTOM: “The Blower Bike” consisting of a Magnacharger Shovelhead digger where the frame was built around fitting the gargantuan motor and the girder front fork was made by Joy Ride Speed Shop. The Blower took home “Best Chopper” at the 2020 New Order Chopper Show.

AND

WITH DANNY WILSON

SCAN THE QR CODE & CHECK OUT THE VIDEO IF YOU NEED SOME HELP DOING THIS YOURSELF ON THE HOT BIKE YOUTUBE CHANNEL

Welcome back to Hot Bike’s Tech Tips. In this issue we are going to cover something that seems pretty basic but is absolutely necessary. And if not done correctly, can cause some serious damage: bleeding brakes and hydraulic clutches.

Since liquid can’t be compressed, if you confine it to a space and try to compress it, force is applied to everything in that confining space. As it relates to a brake system, we have a master cylinder that is holding the fluid. And inside that master cylinder is a piston that applies force to the fluid. That pressure is run down the brake line, where at the end of said brake line is a set of pistons in your brake caliper. The force pushes the brake pads against the brake rotor which then causes the bike to stop.

So really it’s not that complex of a system. If you have ABS you will have an hydraulic control unit (HCU) and an electronic control unit (ECU) in line, which is what actuates the antilock brakes. The key to these systems all working correctly is that there can’t be any air in the system, which is where brake bleeding comes into play.

You’ll notice a little valve on the brake calipers. These are the bleeder valves. These need to be opened to allow fluid and air to escape. The trick here is only having the valve open while fluid is exiting. It will need to be closed at any point there isn’t vacuum or pressure on the system so that you don’t draw any air back in. It really is that simple.

There are multiple ways to go about doing this, but we’ll start with the most efficient method, which is to use a pneumatic vacuum bleeder. This device will draw all the fluid from the master cylinder through the system very quickly. If you have ABS, a pneumatic pump is by far the most efficient method.

The second best way is to use a hand-operated vacuum pump. This will get you the same result as the pneumatic pump but at a much slower rate.

Option three is to reverse bleed it with a syringe. Basically open the

valve and push fluid through, close the valve and repeat the process. This is time consuming but will get the job done.

Your last option is good old gravity. Open the valve and let the fluid slowly work its way through the system, bring a lunch and stay for the day if you’re going to try this because it takes forever. This process will not work if you have ABS, it will only work on non-ABS bikes where there is nothing in line between the master cylinder and the caliper.

If you are going to bleed your hydraulic clutch, it is the exact same process as the brakes, only difference is the bleeder valve is on the clutch slave cylinder.

There are a couple things I want to cover as it relates to brake fluid. As a Harley-Davidson owner you will either be dealing with DOT 5 or DOT 4 fluids. DOT 5 is used in earlier models and is non-corrosive. It needs to be clean fluid from a clean container that has not been exposed to water.

DOT 4 went into use when H-D introduced antilock brakes. This fluid is highly corrosive and will eat paint and powdercoat rather quickly, so if you have a spill it needs to be cleaned up immediately. It is in your best interest to cover any painted or powdercoated parts so that if you do have a spill you won’t have your finishes at risk. If you are doing this yourself use good quality brake fluid. At the shop we used the appropriate Motul product.

As with all the fluids on your motorcycle brake fluid has a serviceable life, and should be fully flushed every couple years. The only other time you would need to bleed the brakes would be if you introduced air into the system either by replacing a part or having a failure at a fitting somewhere in line.

I would suggest if you are going to be working on your own bike that you invest in the appropriate service manual. It will be the best tool you have as you learn your specific motorcycle. Scan the QR code for an in-depth look into how to bleed brakes and clutches. HB

BILTWELL

BAJA GLOVES

$59.95

The ’80s were the Golden Age of American motocross— and bad hairdos, which served as the inspiration for Biltwell’s new Baja glove. Featuring a goatskin palm and thumb reinforcement for added toughness the stretch polyester construction on ring and pinky fingers provide the ultimate flex, maximum flexibility. The molded two-ply neoprene wrist wrap with adjustable Velcro closure keeps the Baja’s snug as a bug in a… you get the idea.

biltwellinc.com

SX5 FORKS

$5,990

KEN’S FACTORY

NXT-S1 NEXT LEVEL BILLET SWINGARM

$3,299

KRAUS MOTOR CO.

Upgrade your HarleyDavidson Low Rider S/ST with the SX5 Inverted Front End Kit from Kraus Motor Co. The SX5 improves your Low Rider’s tracking, stability, and braking, giving performance riders confidence to push their pace. The SX5 also features improved geometry and stiffer components to take full advantage of the new Öhlins FF inverted fork. This kit includes Öhlins inverted front forks, new SX5 triple trees, Kraus radial brake mounts, and Kraus fender mounts ensuring top-of-the-line quality and performance. krausmotorco.com

GALFER USA

Ken’s Factory’s Next Level Swingarm fits ’09–later Harley-Davidson Touring models and is made from high-grade 2017 billet aluminum with three-position adjustable height options (Stock, +1/2” and 1”). It works with OEM calipers/brackets and comes with a notch adjuster for the perfect belt/chain line. Weighing just 20.7 pounds, the NXT-S1 is available in raw, black, gold or red anodize and comes with stainless steel hardware and ARP fasteners.

kensfactoryusa.com

SAWICKI SPEED

MID-LENGTH M-8 BAGGER EXHAUST

Starting at $1,349

advantage of the new Öhlins FF inverted

OVERSIZE BRACKETS TO FIT OVERSIZE ROTORS

Brackets $124.99 each; Rotors $346.95 each

Galfer USA’s SP064K and SP065K oversize brackets allow Harley-Davidson Touring riders to install oversize rotors for increased braking power without the need to change their calipers while also providing perfect pad sweep across the rotor friction surface. This is an affordable, plug-and-play upgrade for both solid, spoke-mount wheels and hub-mount wheels if using wide-band floating rotors. These brackets come complete with new mounting hardware and are left and right side specific. gbrakes.com

Designed with performance and additional ground clearance in mind while offering a custom look and a powerful sound. All pipes are made with mandrel bent, aircraft quality 304 Stainless Steel featuring a hand-formed merge collector that allows for precise flow performance. Available in Brushed, Ceramic Coated Black, and Mirror Polished for ’17–’24 Harley-Davidson FLH/FLT/Special/Limited/ ST Milwaukee-Eight models; ’17–’22 CVO models. sawickispeed.com

HORSEPOWER INC.

HIGH-FLOW FUEL RAIL

$230

Horsepower Inc.’s High-Flow Fuel Rail applications provide a higher volume of fuel delivery, specifically for larger cubicinch engines and supercharged bikes. The HPi Fuel Rails eliminate the quickconnect of the fuel tank and allow for full fuel flow through HPi’s custom design. Available for ’08–’16 Big Twin Throttle-By-Wire and MilwaukeeEight Harley-Davidson Baggers only.

horsepowerinc.net

TRASK PERFORMANCE

POWER PLATE

$149.95

Trask Performance just released its direct-bolt-on Power Plate for Big Twin and Milwaukee-Eight Slipper Style Clutches. Engineered to extract the maximum potential from your motorcycle’s power plant, the Power Plate practically eliminates clutch slippage and ensures your engine power is efficiently transferred to the road. This is achieved through the Power Plate’s over 300 pounds of pressure being applied to the clutch pack, compared to the stock 198 pounds. Overall, this results in unparalleled clamping force so riders can now experience a seamless connection between the throttle and the asphalt. traskperformance.com

BA AIR CLEANER

$599.95–$639.95

The Feuling BA Air Cleaner was specifically engineered for ’17–later Milwaukee-Eight Engines and is packed with expertise garnered from years of enhancing cylinder heads, combustion chambers, and intake manifolds. Feuling’s cutting-edge BA Series bolt-on air cleaner was designed exclusively for those looking for a quick and stylish upgrade as well as a much needed boost in the performance and looks departments. feulingparts.com

RAMJET RACING

DYNA BREMBO CALIPER BRACKET

$289.99

With the success of the Ramjet front caliper adapter brackets, they decided to offer the same solutions for the rear of your Dyna. The Ramjet rear Brembo caliper bracket kit fits 2000–later Dyna models so you can ditch your OEM brake setup and upgrade to a 2008–later rear, H-D Touring Brembo caliper on your Dyna. Available in black or raw finish, the kit comes with the bracket, chrome caliper bolts, and alignment shims and rubber bumper for isolation (OEM P/N: 42863-06). ramjetracing.com

SUPERTECH R10 SOLID HELMET

$999.95

The result of over 10 years of intensive study, development, and testing, the goal of the Supertech family of helmets was to create the most advanced, protective, and performance-enhancing helmets possible for racers and riders worldwide. The Supertech R10’s focus of the design was to ensure the highest level of performance, protection, and a new level of safety. The S-R10 Helmet blends ventilation, comfort, and the lightest weight possible without compromising overall integrity. Available in XS–2XL, the Supertech R10 Solid is available in White Glossy/Matte Black or Black Carbon/Matte & Glossy colors (other Supertech helmet colors are also available). alpinestars.com

AVON GRIPS

ROLAND SANDS DESIGN X KRIEGA ROAM 34 BACKPACK

$299

The Roland Sands Design X Kriega Roam 34 Backpack is constructed from wax cotton and combined with Kriega’s groundbreaking Quadloc-Lite harness for some seriously legit functionality. Featuring a waterproof roll-top 15-inch laptop pocket, a 4-liter fold-down zip compartment packed with organizer pockets and a spacious main compartment with heavy-duty YKK zip access, expandable from 22 to 30-liters when needed. Available in 2 color options: Black or Ranger. Did we mention the Roam 34 fits a full-face helmet? rolandsands.com

DIAMOND CONTOUR GRIPS

$74.95