As I type the last column of 2023, one word comes to mind: Gratitude. It’s been the craziest year of my life (I really mean it this year ), and as I reflect back on what I set out to accomplish both professionally and personally, I’m incredibly grateful for many reasons.

I’m also kind of in shock. Relaunching a maga ine was uite the undertaking. It won’t be too hard, I thought. hat a fucking moronic way to think. I was wrong ignorant, actually. It was not easy. nd it proved that ignorance is not always blissful. To put it mildly, it hasn’t been easy doing this, especially with a skeleton crew, but it’s been absolutely worth every penny or ounce of energy I’ve put into this. nd the hard times and the low points are what make the good times and the struggles so much more enjoyable.

I de nitely pushed every single one of my vulnerabilities to the limit and I have a lot to be grateful for because of the sacri ces I’ve made. To be honest, I suck at recogni ing the good in my life. I’m working on it. Especially because I’ve been surrounded by so much good this year that it’s really opened my eyes to how beautiful this world can be if you just allow it to happen.

ersonally, I uit my steady job making good money to focus on doing Hot Bike full time. That brings on uite a bit of fear and uncertainty. But that was the only way I’d be able to take Hot Bike to where it is today. If I tried to juggle both the 9-to-5 and bringing the maga ine back, well, both would have su ered. nd that’s not okay. If I’m going to do something, it needs to be done well. That’s my goal at least. And it needs to be done with my absolute attention (whenever I can focus on something for longer than a wait what was I talking about? Oh well…).

Sometimes I’m not the most grateful or optimistic person either. I’m working on that too. I get caught up in my own head and I drive myself insane. ou suck, Jordan. ou’re not good enough. hy would anyone buy Hot Bike ou’re an idiot Just some of the ramblings I encounter with my subconscious on a daily basis. To say I’m neurotic would be an understatement. But I’m starting to tap into that to try and use it to my advantage. At least from the perspective of trying to deliver a uality product to you ne folks. I look at every page exhaustively, to the point where it starts to blend and flow together. And then when the magazine shows up in my mailbox, all I do is look at ways I could have done it di erently, or make it better, or try this versus that. It’s a blessing and a curse being an editor. ou’re never satis ed. But you’re also trying to always improve.

That right there used to drive me mad, and I used to self-medicate because of it. I’ve been o the sauce for three years now and I wouldn’t change a thing. aking that choice was the only way I’d be able to make progress in life, not take two or even three steps back. asking emotions or running from them was the norm since I was a teenager, but that wasn’t working for me anymore. So I made a change. The best change I’ve ever made. huge thank you is owed to my beautiful and patient wife for hanging in there with me. I’m sure it was not easy being on the receiving end of me (except in the bedroom, hehe!). She’s the reason I’m not dead or in jail. And I am incredibly grateful to her for helping me see the light and for sticking

by my side. nd for helping rebuild me. I’m still a major work in progress but I’ll always continue trying to be a better me. I’m incredibly blessed to have her by my side.

Most of you are probably fully functioning adults that can have a drink or two and be ne. For me, it was a spirited race to get to the next one. But the fact that I don’t have that level of stress or guilt anymore leads to so much more growth and beauty. I’m not clouded by self-loathing (as much) anymore and that feels good.

I’m still working on trying to be more vulnerable so you have some kind of a glimpse into my reality. hether you wanted it or not, it helps me to share these things because none of this would be possible without sacri ces. For that I’m grateful.

I know I kind of went o the rails a bit there. I’m also extremely grateful to everyone who supported making this dream a reality, from my entire family to the sta , to the advertisers to the subscribers and readers. T N Enjoy the last issue of . ave a appy New ear and a prosperous and beautiful start to

Bye for now, Jordan rew

The Real Boss ASHLEY MASTAGNI

Creative Director ROBERTMARTINDESIGN.COM

Managing Editor IRENE GONZALEZ

CONTRIBUTORS

ALEX CHAPMAN, JASON CRUZ, ROB FORTIER, ANTHONY GONZALEZ, BRYAN HEIDEN, ALEX HENRIQUEZ, OLIVER JONES, CHIP KASTELNIK, MICHAEL LICHTER, JOSE LOPEZ, KAZUO MATSUMOTO, TIM SUTTON, DANNY WILSON

SPONSORS

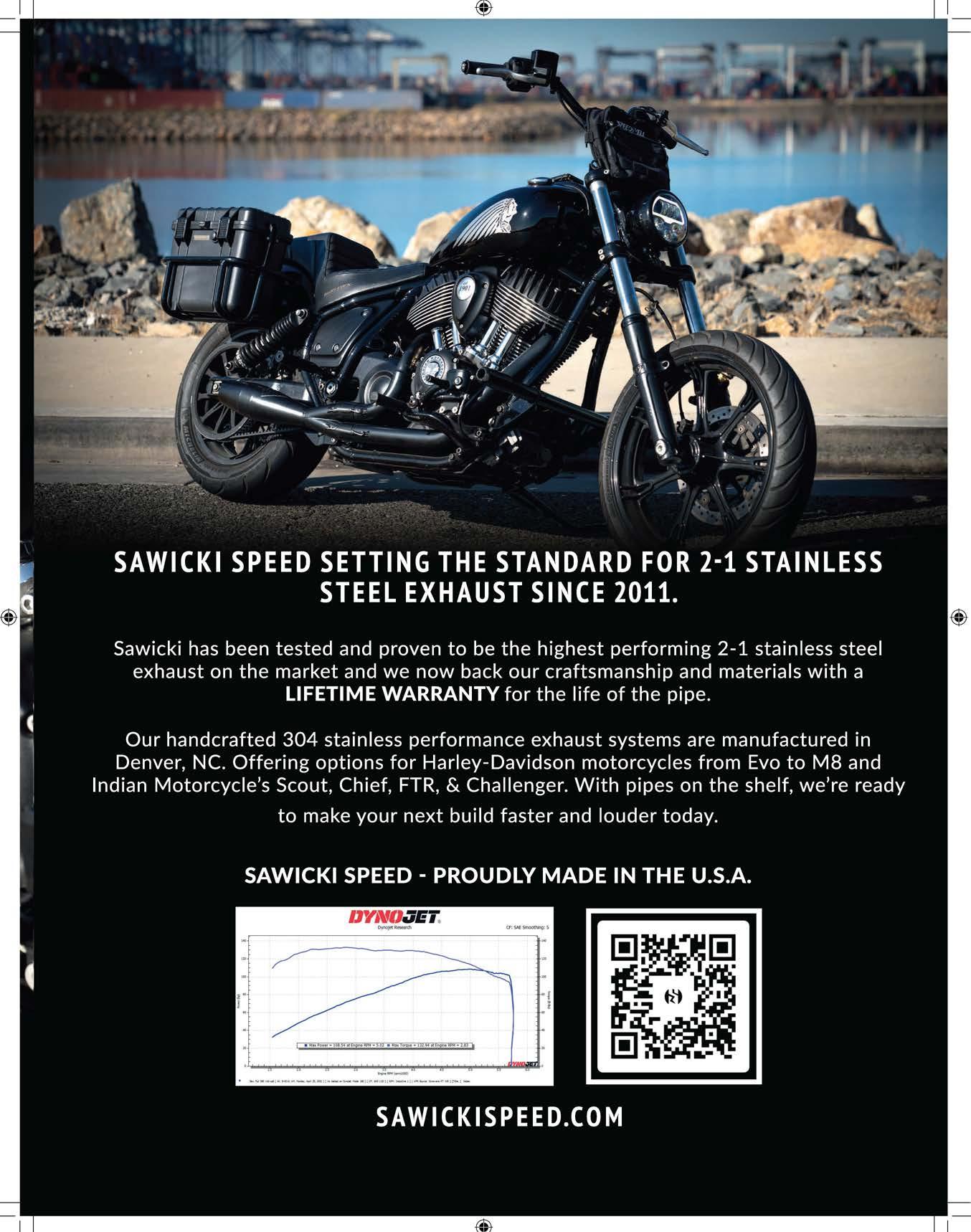

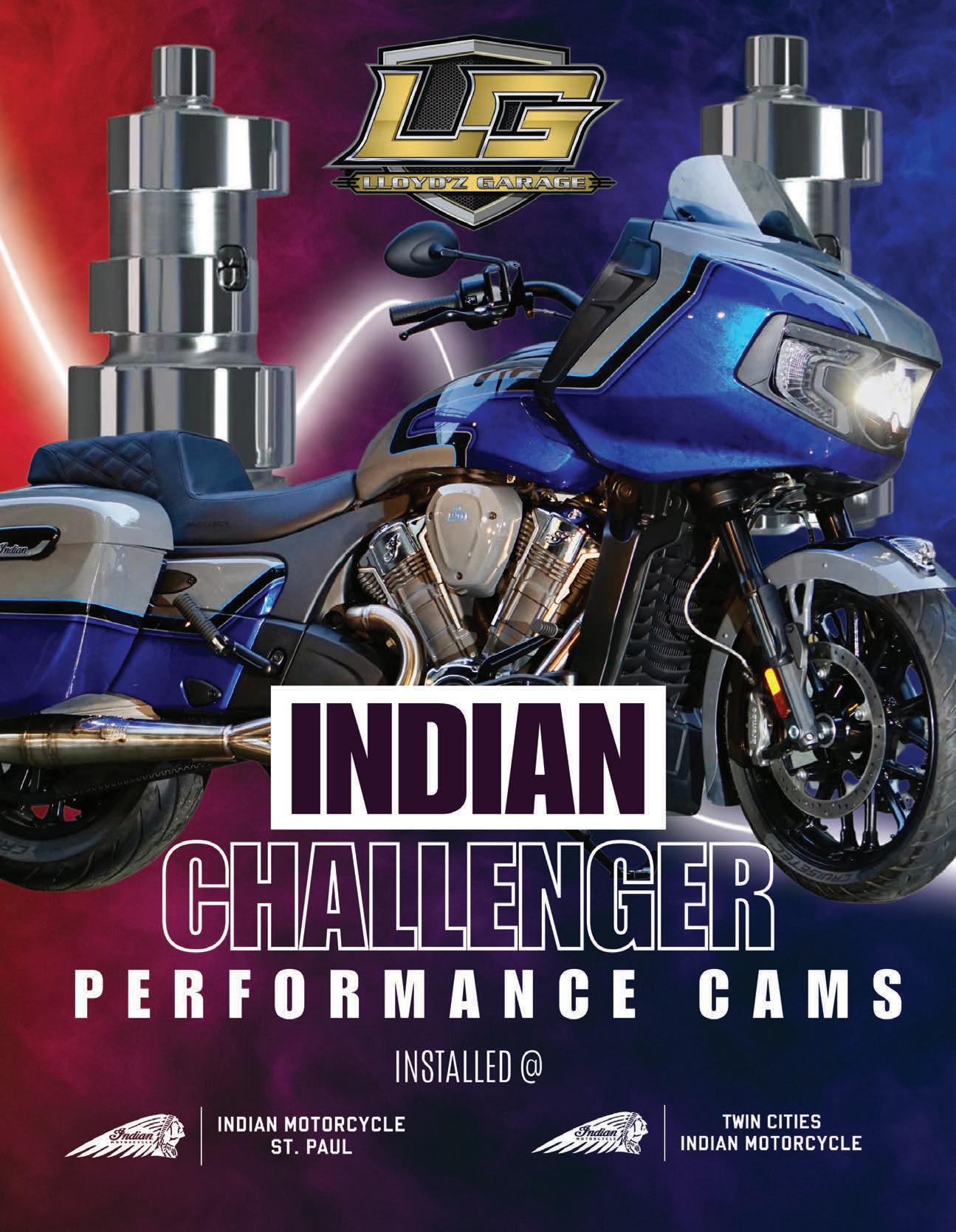

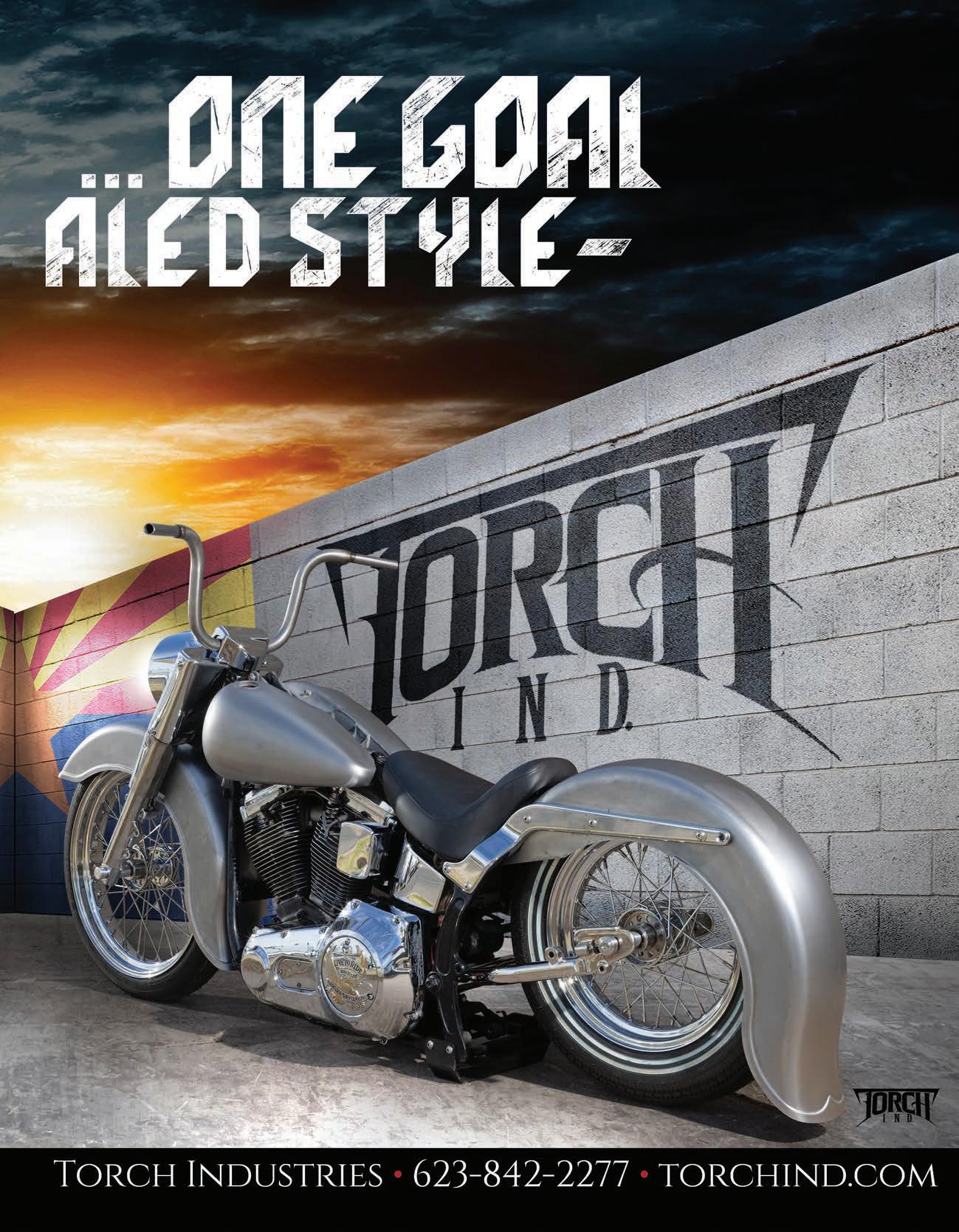

Hot Bike is grateful for these awesome supporters! ARCH MOTORCYCLE, AVON GRIPS, BILTWELL, FACTORY 47, FEULING PARTS, FXR DIVISION, GALFER USA, GUERRILLA CABLES, JW SPEAKER, KEN’S FACTORY, KRAUS MOTOR CO., LAW TIGERS, LLOYDZ GARAGE, JW SPEAKER, GALFER USA, MOTUL USA, FXR DIVISION, TORCH INDUSTRIES, KRAUS MOTOR CO., LAW TIGERS, LLOYDZ PERFORMANCE, MINT SPEED SHOP, MOTOR BIKE EXPO, MOTUL USA, ODI GRIPS, PAINTHUFFER METALFLAKE, RAMJET RACING, REVOLUTION SPEED, ROLAND SANDS DESIGN, SADDLEMEN, SAWICKI SPEED, THRASHIN’ SUPPLY CO., TRASK PERFORMANCE

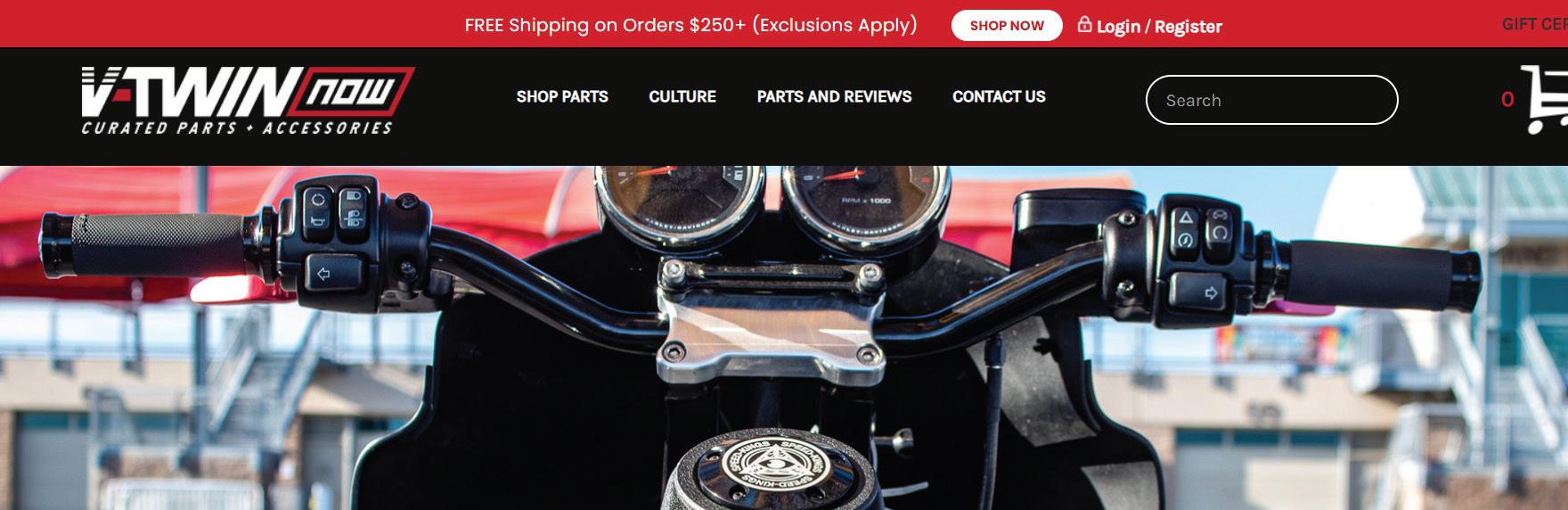

I‘ve been spending a lot of time in Utah this winter. Yes, Utah is beautiful, but year-round riding in a hoodie or a light jacket is a thing of the past. And I am a complete baby when it comes to being cold. This is where properly layering up comes in. I found some uber-comfy goods from Indian Motorcycle’s Performance Collection to help combat the elements and to also keep us comfy and cozy. We also found some new riding jeans and moto compression socks from Saint so we had to give those a go too.

INDIAN PERFORMANCE COLLECTION

MEN’S ATHLETE HOODIE, $69.99

MEN’S LONG-SLEEVE T-SHIRT, $54.99

SAINT COMPRESSION SOCKS

$49.99

SAINT ENGINEERED STRAIGHT FIT ARMORED JEAN

$199.99

Indian Motorcycle’s Performance Collection is soft, supple (it feels good on the nips) and it wicks moisture very well, which is incredibly helpful since I sweat like a pig. Developed for Indian consumers who were interested in garments they could wear on and o the bike, the Performance Collection proves to be a versatile and comfortable line. The materials incorporate the built-in 50-plus UV protection from the sun and the anti-odor technology (I wish my pits had anti-odor technology builtin). The black Athlete Hoodie is made from 80% Nylon and 20% Elastane, which makes it soft and pliable. The grey long-sleeve t-shirt is made from 50% polyester, 40% Nylon and 10% Elastane to give it an even more comfortable and versatile t. I’ve worn both garments on and o the bike and they provide a nice barrier against the cold temps, especially when mixed with three other jackets, of course. I’ve also worn them jogging and because of their moisture-wicking and anti-odor technologies, my wife isn’t totally repulsed by me after a long run anymore. Win-win!

The Saint Compression Socks provide a snug and supportive feel to help you avoid cramps and fatigue while stimulateing your muscles on long rides. But they’re $49 for a pair. Yes, these are high-tech, medical-grade compression socks, but for 50 bucks, I’d rather keep the dough and just take a nap when I get tired. But that’s just me. If you’re into high-tech socks, look no further.

Riding jeans are tricky. I always try to shop for jeans that don’t look like they’re from the post-apocalypse. I’ve been a fan of Saint’s simplistic style because they pay attention to the things that matter like protection, comfort and style. With a timeless cut and comfortable stretch denim, the Saint Engineered Straight Fit jeans feature impact abrasion safety in the hips and knees with pockets and CE level 2 impact protectors that ensures the garment reaches a class AA CE rating.

EDITOR’S NOTE: We love the Instagram banter (or bromance?) between Chip Kastelnik from San Diego Customs and Jimmy Light from Horsepower, Inc. And since this is a community forum for folks to have their stage to vent, rant, ask questions, etc., we asked Chip to interview his pal, Jimmy for The Hot Seat. Fun was had, laughs were shared, bongs were cleared, and that’s pretty much it.

CHIP KASTELNIK: Tell us about yourself and how you got started in the motorcycle industry.

JIMMY LIGHT: Well, at a young age I was obsessed with dirt bikes and begged my parents for one. I nally got one and would ride it everywhere, then as I got older, my obsession turned into dirt open wheel racing, which is very expensive, so I knew if I wanted to be involved with anything with wheels, I better get a job. Luckily for me, my family owned a machine shop so in high school I did the co-op program and was able to work at the family business part of the day. I was top of my class in tech school but really not interested in normal school. My Principal once told me I would end up where my Grandma worked, which happened to be the prison, so I guess I proved him wrong so far, lol. I raced dirt midgets and sprint cars in my twenties while still being involved in the family business, then in my thirties I guess I gured it was time to be more involved and we started developing more parts, going to more events, meeting more people in the industry and HPI started to become a real brand.

CK: What was your approach or vision with HPI?

JL: It’s always been to make the best performing, highest quality, American made parts we can make. It was in 2018 when we really built a house bike the way we wanted. We got involved with a race team with the Bagger Racing League for a few years and that was fun. It’s been cool to get outside the box a little and do more than just make the hard parts. It’s hard to get to some of these things, even the rallies with how busy the parts industry is, you don’t want to let anyone down when you are running a small business and you only have so many employees. We really like to be out at the rallies and get to know and service those customers,

but a lot of times when we do that, production back at the shop stops. It’s a give or take…we take it year to year on what we can be involved in.

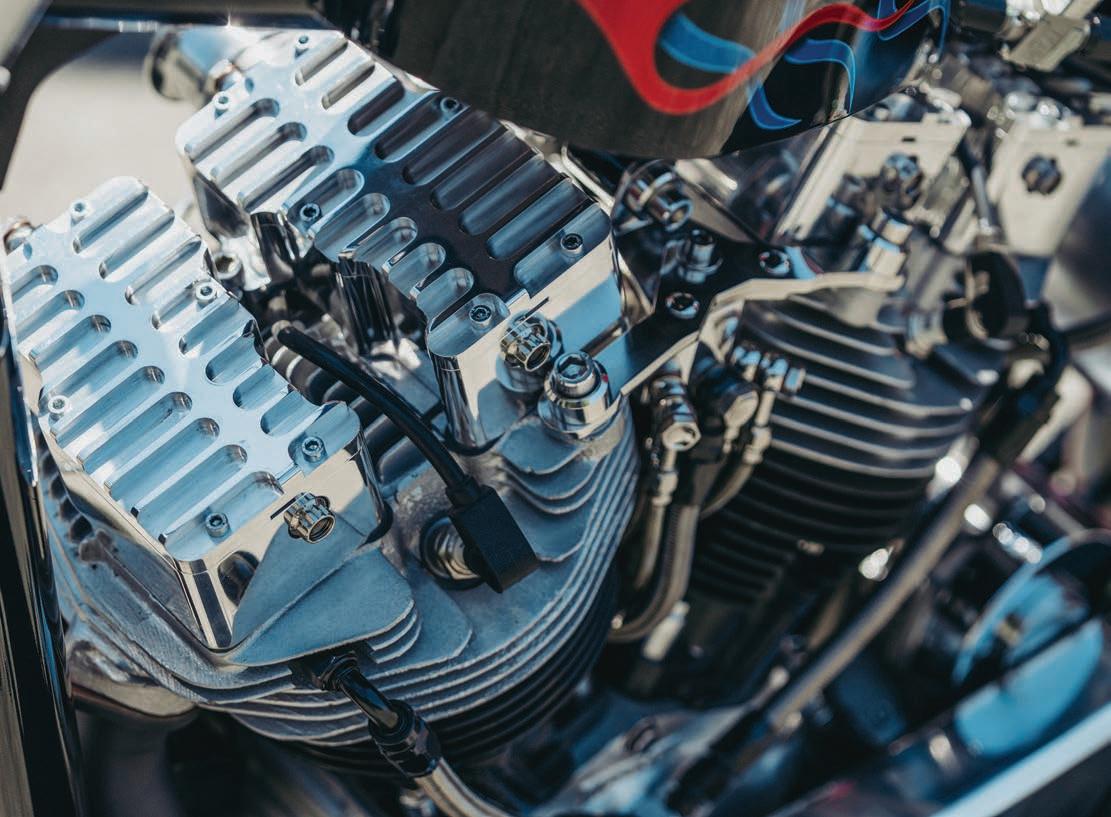

CK: What are some of your favorite components you make? Tell us about how your exhaust program has grown exponentially in the past four years to become one of the best in the biz?

Anything fuel injection?

JL: Well, the exhaust program has been wild. We’ve tried to expand to meet the demand as best as we can. The waiting list is long but when you’re trying to make a nonproduction style part a mass production piece, it’s di cult. The exhaust program started as a side gig with me and our head welder, Billy. We were working 2nd shift at my home garage building these things not knowing they would become our hottest item at the time.

CK: What are your best-selling components, do you have to deal with copycats?

JL: Right now, it would be the M-8 units. There will always be competition in this industry. We are heads down, doing what we have for the last 20-plus years, putting out the best parts there is to o er. opiers are de nitely hot right now, haha, but the fact is, all the companies that have been doing their thing for the past 50, 30, 20 years all know of each other, work with each other and don’t step on each other’s toes. We all share our knowledge in the industry and work together to keep improving. It’s a deeper, old-school relationship on another level of respect, and I’ll just leave it at that.

CK: What is your proudest moment with HPI?

JL: My proudest moment…there’s been so many really, and time

“MY PRINCIPAL ONCE TOLD ME I WOULD END UP WHERE MY GRANDMA WORKED, WHICH HAPPENED TO BE THE PRISON, SO I GUESS I PROVED HIM WRONG SO FAR, LOL.”

— JIMMY LIGHT

de nitely flies. I guess you could say I’m the nd generation owner as of now, so I’m proud of my family’s hard-earned work in the whole company and getting through a recession in , and then the cra iness of the era. I’m also excited for the future of the business and just thankful we have built a product and brand that a bunch of people seem to love.

CK: hat’s your current daily rider

JL: y FX XI

CK: ist some of the substantial upgrades that you feel are re uired in these modern - customi ation times.

JL: ll ya need on the new bikes these days is a bolt in cam, exhaust, throttle body, air cleaner, and a good tune and they run really good

CK: ow many miles have you racked up on her JL: , I think, haha

CK: re you glad Hot Bike is back, and I get to do this interview

JL: I think it’s very important that Hot Bike is back. It’s a big part of the history in this industry, it’s important that these companies stay alive and they should be appreciated.

CK: ho is faster in the San iego ustoms x orsepower, Inc. war, you or me

JL: Everyone knows you’re fast and even you think you’re the fastest, but you’ve turned down my money multiple times. hen you nally put a bike on the line you may lose but that has yet to be determined.

CK: nything else you’d like to add or anyone you want to thank

JL: ur employees for busting their asses to get parts out the door, and our loyal customers and friends in the industry for choosing to use I HB

SIGNATURE FULL-WAFFLE GRIP SET

•Proprietary Medium-Compound Materials provide excellent durability and comfort

• Full-Waffle Moto-Pattern reduces vibration/ provides improved grip in all conditions

•Heavily knurled base-pattern delivers solid traction and control

•Billet-aluminum clutch-side clamp ensures 100% slip-free security (eliminates the need for set-screws)

•T15 Torx bolts ensure extra-secure clamping for solid, twist-free mounting

WORDS:

When it comes to choppers, the Born-Free Motorcycle Show procures the best in the business. To be chosen as an Invited Builder is quite the honor. This past year, Brian Jessop got the call. And he delivered.

Brian Jessop emerged as a trailblazer, leaving an indelible mark with his latest creation, a 1968 HarleyDavidson FL that transcended the boundaries of any one particular genre.

Choosing a style reminiscent of the custom muscle bikes from the ’80s and early ’90s, Jessop set out with a singular goal—to push his limits, both in design and fabrication. Every inch of the bike tells a story of dedication and creativity, with nearly every part being custom-made, heavily modi ed, or exceptionally rare.

A centerpiece of this two-wheeled masterpiece is the iconic Storz/Ceriani 43mm fork, harkening back to the early days of performance ingenuity. The frame itself is a testament to bespoke craftsmanship, a one-o creation built to precise speci cations by the skilled hands of Ben Je ries. The seat, a luxurious piece adorned in supple leather, was meticulously covered by Je at BN ycles, featuring a custom pan seamlessly integrated with an LED taillight, a distinctive touch by Jessop Cycle.

The intricacies of this mechanical marvel extend to the Magneto drive cam cover, a collaborative design by ShintySix Jessop and precision N -made by hris eiss ShintySix. The rocker boxes bear the signature style of artin at Snowflake ustoms in Finland, displaying a Kennedy Style that elevates the Shovel’s aesthetic.

Yet, beneath the surface lies the challenge and reward of Jessop’s endeavor, like the internal linkage within the primary cover, the dual magneto cam cover setup, and the seamlessly integrated seatpan/LED taillight. All require a keen eye for both design and mechanics.

The true triumph, however, came in the form of personal accomplishment: Completing the bike in time for Born-Free! Just being able to turn his vision into a reality lled Jessop with a sense of pride, knowing he had exceeded his own expectations, thanks to the support of his family, friends, and peers. His success was further solidi ed with accolades from the BornFree Show—Best Shovelhead and Harley-Davidson Design Team Awards.

Jessop injected a dose of drag bike influence into his creation. The goal was to forge a wild drivetrain, making the bike appear as if it were all engine hurtling down the road with a mere bike in tow. Functionality paralleled aesthetics as Jessop ensured the bike could stop as impressively as it could go, emphasizing big motors, big brakes, and a design built for the ride.

The flamed paint scheme, carefully chosen, blends technical prowess with the classic chopper aesthetic,

a visual testament to Jessop’s vision. Influences from past Born-Free builders and contemporaries in the chopper scene propelled him forward, adding layers of inspiration to the already intricate narrative of his creation.

s the dust settles on the success of Brian’s build, Jessop takes a breath before diving into future endeavors. hile catching up on neglected maintenance for his other bikes, he has plans for a tough ci Shovelhead build in the coming winter a testament to an unyielding passion that continues to drive him forward.

Jessop extends appreciation to the collaborators and supporters who stood by him during the countless hours spent in the shop. hris eiss, Ben Je ries, ole Jabusch, arren olfe, Je Bieberdorf, and family and friends all played pivotal roles in bringing this vision to life. nd, of course, a heartfelt thank you to ike and rant from Born-Free for extending the invitation that set this remarkable journey in motion. Brian Jessop’s legacy in the world of custom motorcycles stands tall, marked by innovation, craftsmanship, and an un uenchable passion for the open road. HB

Harley-Davidson’s VP of Design and Creative Director, Brad Richards, hands Brian Jessop the H-D Design Team Award at Born-Free 14. PHOTO: JOSH KURPIUS FOR HARLEY-DAVIDSON.

BIKE OWNER

BRIAN JESSOP

SHOP NAME JESSOP CYCLE

SHOP PHONE (306)220-7982

SHOP WEBSITE/SOCIAL

INSTAGRAM @JESSOP.CYCLE

YEAR/MAKE/MODEL 1968/HARLEY-DAVIDSON FL

FABRICATION

BRIAN JESSOP

ASSEMBLY BRIAN JESSOP

BUILD TIME 9 MONTHS

ENGINE

YEAR/MANUFACTURER

TYPE/SIZE

1968HARLEYSHOVELHEAD

91CU IN. / 4-3/4” STROKE

CASES 68 HARLEY

CYLINDERS 80”

HEADS HARLEY MODIFIED

ROCKER BOXES KENNEDY STYLE BOXES BY SNOWFLAKE CUSTOMS

EFI/CARB S&S TWO THROAT

AIR CLEANER VELOCITY STACKS

EXHAUST CUSTOM STAINLESS BY JESSOP

SPECIAL FEATURES ONE OFF DUAL MAGNETO CAM COVER BY CHRIS WEISS

TRANSMISSION 4-SPEED WITH HYDRAULIC ACTUATED CLUTCH

YEAR/MANUFACTURER/TYPE CAL CUSTOM CASE, ANDREWS GEARS, BAKER KICKER GEARS

CLUTCH PRIMO RIVERA

PRIMARY DRIVE ONE-OFF CUSTOM CASE WITH INTERNAL SHIFT LINKAGE MID-CONTROL

FRAME CUSTOM SINGLE LOOP BY BEN JEFFRIES YEAR/MANUFACTURER BEN JEFF RAKE 29° STRETCH 1.5”

MANUFACTURER FRONT 90’S STORZ / CERIANI 43MM LENGTH 2’ OVER STOCK

TRIPLE TREES STORZ/CERIANI

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT-TYPE GRIMECA HYDRAULIC DUAL DISC BRAKES

WHEEL HEIGHT-WIDTH 19” MORRIS MAG

TIRE HEIGHT-WIDTH DUNLOP K180

CALIPER DUAL GRIMECA 1050S

ROTOR 11” PRISM

MANUFACTURER REAR

WHEEL HEIGHT-WIDTH MORRIS 15”

TIRE HEIGHT-WIDTH DUNLOP QUALIFIER

CALIPER GRIMECA 1055

ROTOR PRISM 11”

FINISH-PAINT

PAINTER COLE JABUSCH

GRAPHICS DUAL FLAMES

SPECIAL FINISHES PINSTRIPING BY DARREN “CSIK” WOLFE

ACCESSORIES

FRONT FENDER MODIFIED CIRCLE IND. FORK BRACE

REAR FENDER 5’ AFTERMARKET

GAS TANK/CAP CUSTOM ALUM BY JESSOP

OIL TANK SAMS MC KIT BUILT BY JESSOP

HANDLEBARS 1-1/8 TO 7/8” CUSTOM ALUMINUM BARS & RISERS BY JESSOP

HAND CONTROLS/GRIPS 7/8” MAGURA CONTROLS/GRIPS/THROTTLE

FOOT CONTROLS/PEGS CUSTOM BY JESSOP

HEADLIGHT

TAILLIGHT

SEAT

VINTAGE GUIDE SPOTLAMP

CUSTOM BUILT INTO SEAT PAN

CUSTOM LEATHER SEAT BY B&C CYCLES

Kully Millage, the builder of this 1960 custom Ironhead, was still in high school when he built his first custom bike. Coming from a racing background, he wasn’t even into street bikes when he took it upon himself to complete what he describes as a “tastefully put-together catalog bike” as a tech-class project. It too, was an Ironhead Sportster, only he built that one on a Paughco frame with a Cole Foster fuel tank and early Triumph rear fender, amongst many other improvements. It came out well enough that the very self-confident, talented, and creative teenager submitted photos of it to AMD, to be in their big annual Sturgis Motorcycle Rally in 2011, which also included the World Championship as part of the same show. Sure enough, it was accepted, and, in what later proved to be a very fateful decision, it was placed right beside Lock Baker’s bike. Kully was familiar with Lock’s work from magazines and his scouring of the internet and had actually called him six months earlier to ask about how he etched and antiqued his alloys. Lock was very friendly and without any hesitation, answered all his questions, so Kully was convinced he was a “Badass!”

Kully describes Lock as, “the most underrated bike builder of our times who has set and reset the bar in terms of craftsmanship.” They hung out a lot that week in Sturgis, and before it was over, Kully asked if he could come to Connecticut to hang out in Lock’s shop and learn from him what he could. He arrived back East that fall, thinking he may be there for a couple of weeks, but they got along well, and after realizing how much there was to learn, weeks turned into months, and months into nearly a year. Looking back, he now describes this time with Lock as more of an apprenticeship.

In the ten years that followed, Kully—operating under the name KULLYCO—developed quite a reputation for himself fabricating exhaust pipes. e made them for many di erent types of race and race-style bikes, o ering them to both privateers and race teams.

More funded race teams commissioned Kully to design custom exhausts and had him traveling on weekends to be a race tech at races around the country. This worked both ways, as he learned a lot from the engineers and team owners like Ricky Howerton and David Zanotti. Then when Indian entered flat track racing in , ully worked for them, which was certainly the best of times, as they podiumed , , and two years running.

Kully still fabs exhausts, but over the last few years, he’s developed quite a successful real estate business that accounts for about fty percent of his time and income. e does both ground-up home builds as well as flips, where he buys houses, remodels them, and puts them back on the market, but motorcycles are still his passion.

By , he was ready to build another custom, which would be his third. ( e also built a s inspired chopper right after high school.) ully went back to a arley- avidson cc Ironhead tted with a Linkert Side-Bowl carburetor because he loves the sound, the aesthetic of the engine, and the culture surrounding it. He went on to say, ost entered flat track racing importantly, knowing I was going to build a flat track inspired bike, I wanted a unit style power plant that incorporates the engine and gearbox together so that it would look closer to an XR . I ended up with a beautiful engine that didn’t cost , as an XR would.

This time around, however, Kully was determined to build a ground up street-tracker starting with the frame. He wanted it to be unique, and to reflect his race background, fabrication experience, as well as show the impact of those that inspire him, like his friend Lock Baker, as well as a group of Japanese builders including Tatsuya Fujii at Duas

Caras Cycles, Hideya Togashi at Hide Motorcycles, Masayuki Sugihara at Luck Motorcycles, and Hot Dock’s Keiji Kawakita.

The frame itself was made from grade five 6AL4V titanium alloy and has a 25-degree rake. Its most interesting feature is the torsion-bar spring housed inside the bottom right frame rail, as this is the heart of the torsion-bar suspension that makes this bike so unique. It is connected to the swingarm via a torsion bar arm that crosses to the left side of the bike, where it connects to the swingarm with a turnbuckle that can be adjusted to preload the tension on the torsion bar. There may be another one out there, but personally, I’ve never seen a bike with this type of suspension. You may be wondering now about the rear shock, but this, in fact, is just used as a dampener to control the speed of the movement of the suspension.

Other parts of note include the swingarm made from 4130 chromoly steel, and the exhaust, Kully’s specialty, made from 1mm titanium. The sheet metal bodywork was the biggest challenge he encountered building the bike because Kully had less experience in metal shaping, but he pulled it off by first creating it in foam and then used this as a model for the metalwork. It was all made from 5056 aluminum, which he hand-fabricated using sheet hammers, an English wheel, and dollies.

Kully turned to his skill on the computer to design the foot controls in CAD and then sent his designs off to be made on a CNC. The headlight shroud and intake were also modeled on CAD, only these were 3D printed at a local shop.

To help the bike go fast, the package sits on 19” Excel Racing Wheels fitted with Hoosier Flat Track tires and Grimeca Brakes. While it may not make it go fast, the great black and white paint scheme laid down by Jeff Gjerde makes the bike surely look fast.

Perhaps you may want some of Kully’s talent on your own bike in the form of his pre-made exhaust should you be lucky enough to have a model he supports. And if he doesn’t support your model, you can always talk to him about a custom set. Any way you slice it, Kully Millage, regardless of the fact that he hasn’t built many bikes, is clearly a young gun we all need to keep our eyes on. HB

REAR TORSION-BAR REAR SUSPENSION WITH ÖHLINS DAMPER

TRIPLE TREES INDIAN RACING FACTORY TRIPLE CLAMPS

SPECIAL FEATURES PROPRIETARY TORSION-BAR REAR SUSPENSION

WHEELS, TIRES, AND BRAKES 19” FLAT TRACK EXCEL WHEELS / DURRELL RACING QUICK-CHANGE HUBS / HOOSIER FLAT TRACK TIRES / GREMECA REAR BRAKE

MANUFACTURER FRONT-TYPE EXCEL

WHEEL HEIGHT-WIDTH 19” BY 2.5” FRONT WHEEL

TIRE HEIGHT-WIDTH 19” HOOSIER FLAT TRACK TIRE

MANUFACTURER REAR EXCEL

WHEEL HEIGHT-WIDTH 19” BY 3.5” REAR WHEEL

TIRE HEIGHT-WIDTH 19” HOOSIER FLAT TRACK TIRE

CALIPER GREMECA

ROTOR GREMECA

FINISH-PAINT CUSTOM DESIGN

COLOR GLOSS BLACK / MATTE BLACK / WHITE

PAINTER JEFF GJERDE / SPIRIT LAKE, IA

SPECIAL FINISHES HARLEY-DAVIDSON TANK BADGES

ACCESSORIES

FAIRING/WINDSCREEN CUSTOM CAD MODELED / 3D PRINTED DESIGN

GAS TANK/CAP AIRCRAFT FUEL CAP / AIRCRAFT SPRUCE OIL TANK CUSTOM ALUMINUM FUEL TANK

HANDLEBARS PRO TAPER FLAT TRACK BARS

HAND CONTROLS/GRIPS RENTHAL RACING GRIPS

FOOT CONTROLS/PEGS CUSTOM CAD MODELED CNC DESIGN

HEADLIGHT STANDARD HEADLIGHT TAILLIGHT LED

SEAT

FOAM / RACING DESIGN

LICENSE MOUNT MAGNETS ON THE OIL TANK :)

WORDS: OLIVER JONES (@THECUTRATE) PHOTOS: KAZUO MATSUMOTO (@STEELDOG_PHOTO)

Editor’s Note: We’ve long been fans of the Japanese style of customizing hot rods and motorcycles. We’ve also been longtime fans of the Mooneyes Hot Rod Custom Show (HRCS) in Yokohama Japan. When we had the opportunity to present a “Hot Bike Pick” at the 31st Annual HRCS event, we jumped at the opportunity. We wanted to take a unique approach for selecting the “Hot Bike Pick”, so we asked our pal, Oliver Jones from The Cutrate, if he’d be interested in selecting the bike you see on this issue’s cover. Luckily, he obliged. Oliver’s a rad custom builder himself who used to live in Japan for many years. And he speaks Japanese. Could this have worked out more perfectly? Nope. It gets better. Because Oliver was there–and we weren’t–we asked Oliver to give you the skinny on Humongous Cycle’s Evo Softail by writing the article too. Enjoy!

Let me start this o by entering a little context into this article. I am not a writer by trade. In fact, I would go as far as to say I’m not very good at writing in general, so when Hot Bike asked me to present an award at the ooneyes ot Rod ustom Show and subse uently write an article about it, I was a little hesitant. But I do know bikes custom bikes, that is. nd Japan. So here we are. hile at the show in okohama Japan, I was cruising around the halls, checking out all the bikes and Jordan asked me to send him my best ve, which I did. e went back and forth until we decided on umongous ycle’s FXST Softail. ou might be wondering if there was something more wild or flashy es, there was plenty of that. hen I was thinking about what Hot Bike represents, and its history, and what the current Hot Bike is, I wanted to choose something that was contemporary but not cookie-cutter.

This year omatsu (the builder and owner of umongous ycle) built multiple bikes new Indian, a Sportster, a badass FXR chopper, and this Softail. The FXR was right up my alley, and it was hard not to choose it, but I felt like that was the easy choice. The Softail, however, an Evo Softail at that, is about the last bike most builders would choose to customi e in . That’s what drew me in. I personally think Evo Softails are at the bottom in terms of ranking right now, but they are due for a come-up. The umongous Evo Softail is a great example of what could be done to one, and have it look really tough It’s not overly fabricated, and it’s simple, clean and to the point. ost importantly, it has a great stance.

ase in point, the stretched frame ( -inch up) with a -degree rake, features a nice, straight backbone. The -inch rear, -inch front combo for the wheels only adds to its stance, and nally with -inch fork tubes, it made it even easier to pick this bike because it sits just right.

The long shotgun pipes with the blacked-out billet struts and a standard Shovel yna rear fender really gives the back of the bike a much more menacing look, too. I have known r. omatsu for a long time, and he has a good history of building bikes in Tokyo. e has worked for legendary Japanese custom shops, herry’s ompany, and ot- ock ustom ycles, and he refers to his style as Tokyo style.

Essentially, Tokyo is a very fashion-forward city, and the apparel scene is very interwoven with the motorcycle scene. is sleek black bikes t right in on the street or inside some of the most fashionable bouti ues in the world. They’re designed, not just put together. hat you see is very premeditated. omatsu’s client list includes some heavy hitters around Japan, too. nd he’s always booked solid.

Reflecting on past trends and looking forward to what is next is such a big part of what I look at when getting inspiration for builds. I have had an Evo Softail in the works for a few years now. I just pick at it when I have free time, but I honestly think that given how good the new bikes are and how inflated prices of older bikes, and FXRs have become, I think there is only room for cheap (for now) EvoSoftail-based customs. Just a few years ago it was a no-no to build an eco-chopper for a show like Born-Free. Now it’s become more than accepted. Softails are no newcomer to the world of custom, but it’s been a while. This bike should prove that these things can and should be done in a cool contemporary style. Step out of that box and make the doubters love it. HB

BIKE OWNER NATSUKI SEO

SHOP NAME HUMONGOUS CUSTOM CYCLES

SHOP PHONE 81-3-5941-6647

SHOP WEBSITE/SOCIAL

YEAR/MAKE/MODEL

FABRICATION

WWW.HUMONGOUS-TOKYO.COM

1997/HARLEY-DAVIDSON/FXST

HUMONGOUS C/C

ASSEMBLY HUMONGOUS C/C

BUILD TIME 2-3 MONTHS

ENGINE

ROCKER BOXES H-D WITH BLACK POWDERCOAT

EFI/CARB S&S E CARBURETOR

AIR CLEANER S&S TEARDROP, POWDERCOATED BLACK EXHAUST HUMONGOUS ONE-OFF 1-3/4 HI-PIPE

TRANSMISSION

YEAR/MANUFACTURER/TYPE 1997/H-D/5-SPEED

CLUTCH BDL, PRO-ONE HYDRAULIC COVER; HUMONGOUS ONE-OFF SUICIDE CLUTCH SYSTEM

PRIMARY DRIVE BDL WITH HUMONGOUS ONE-OFF COVER FRAME STOCK SOFTAIL BASE

YEAR/MANUFACTURER

2023/HUMONGOUS C/C

RAKE 29°

STRETCH 1-INCH UP

SUSPENSION

MANUFACTURER FRONT H-D 39MM

LENGTH 2-INCH OVER

TRIPLE TREES H-D SMOOTHING

MANUFACTURER REAR H-D 1-INCH LOW DOWN

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT-TYPE SUNDANCE ENKEI 7 CAST ALUMINUM

WHEEL HEIGHT-WIDTH 19X2.5-INCH

TIRE HEIGHT-WIDTH 100/90-19 AVON AM26

CALIPER PERFORMANCE MACHINE 4-PISTON

ROTOR RSD MORRIS 11.5-INCH DUAL DISC

MANUFACTURER REAR SUNDANCE ENKEI 7 CAST ALUMINUM

WHEEL HEIGHT-WIDTH 18X4-INCH

TIRE HEIGHT-WIDTH 130/70-18 AVON AM26

CALIPER PERFORMANCE MACHINE 4-PISTON

ROTOR RSD MORRIS 11.5-INCH

FINISH-PAINT

COLOR BLACK, SILVER, FLAT BLACK

PAINTER S PAINT WORKS (OSAKA&BAN)

ACCESSORIES

REAR FENDER H-D FX BASE HUMONGOUS ONE-OFF; HOT DOCK ORIGINAL FENDER STRUTS (BLACK ANODIZED)

GAUGES MOTOGADGET MOTOSCOPE MINI

GAS TANK/CAP HUMONGOUS ONE-OFF TANK WITH CHERRY`S COMPANY GAS CAP

OIL TANK H-D

HANDLEBARS HUMONGOUS SUPER BAR/TODD’S CYCLE 8-INCH RISER

HAND CONTROLS/GRIPS PERFORMANCE MACHINE/AVON GRIPS

FOOT CONTROLS/PEGS HUMONGOUS ONE-OFF, ALL-ALUMINIUM CONTROLS/AVON GRIPS

HEADLIGHT H-D

TAILLIGHT DUO

TURN SIGNALS

NEOFACTORY LED

LICENSE MOUNT HUMONGOUS SEAT SKUNK ONE-OFF LACE-UP SEAT

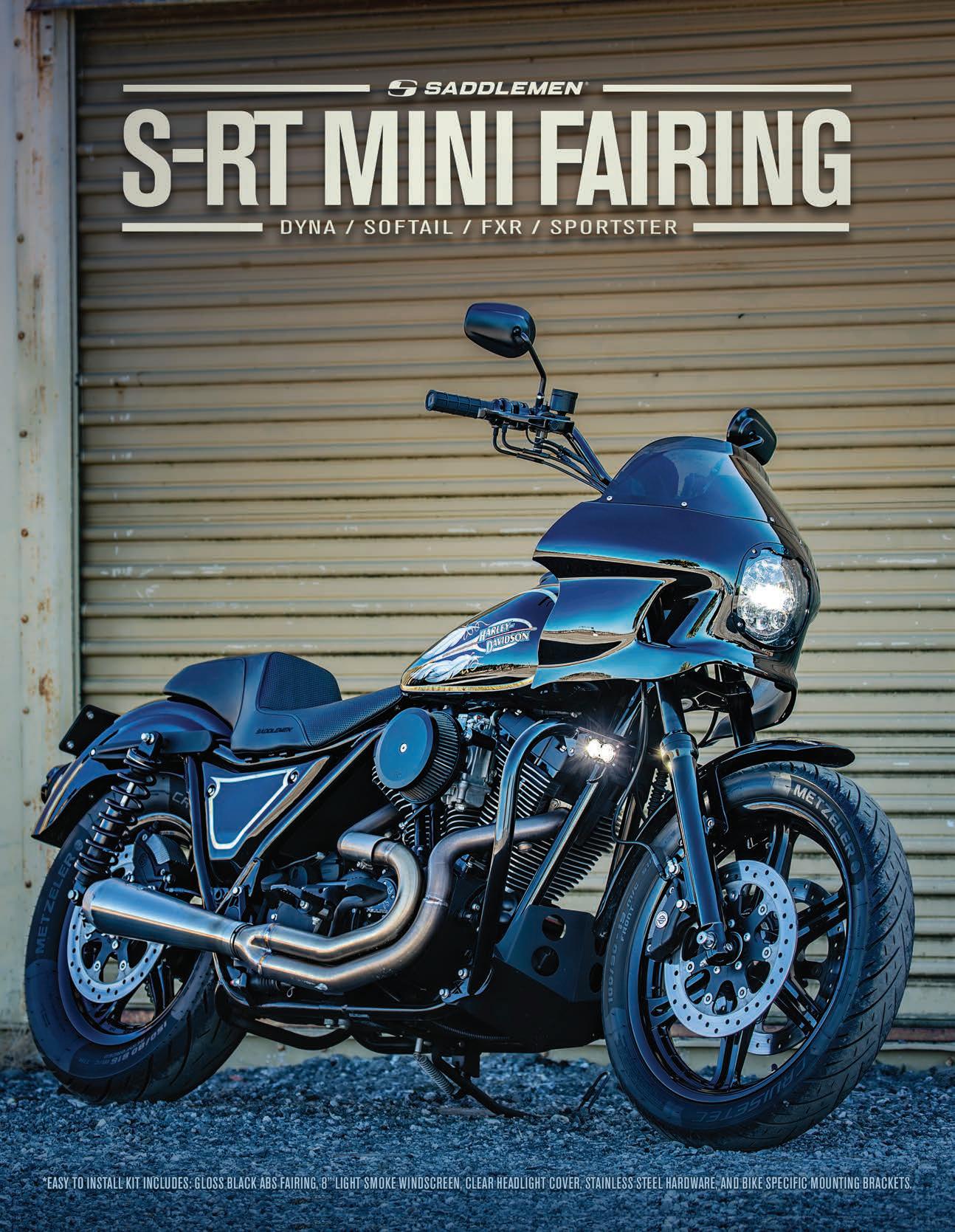

At the heart of Saddlemen lies a bustling hive of creativity and craftsmanship. Operating in the old West Coast Choppers building in Long Beach, California, Saddlemen’s R&D/Race Department headquarters is not just a workplace; it’s a central hub where creativity, passion, and ingenuity collide.

Yes, Saddlemen makes high-quality motorcycle seats and parts, but the R&D crew also makes some pretty complicated, headscratching components that just make sense. The team is known for producing private label seats for various brands and runs two race teams for the King of the Baggers series and the Super Hooligans series. In 2023, Saddlemen’s roster included racers like Cory West, Patricia Fernandez-West, Frankie Garcia, and Jake Lewis. Beyond building bikes, the Saddlemen R&D crew also serves as Saddlemen’s pit crew come race weekend, managing logistics with an infectious enthusiasm and a determination to win, not just on race day… but in business, and in life.

But the R&D guys also like to build their own bikes. And they’re usually pretty damn cool (remember Fury’s Ironhead Desert Sled from Hot Bike Vol.1 2023?). Now it’s Saddlemen ‘s Heath Pinter

and Kris Echert’s turn to have a go. This time with some badass FXRs built for the FXR Tour this past October.

Heath Pinter is no stranger to meticulously custom-crafted machines, be it two wheels or four. Yes, Heath has built quite a few hot rods and custom bikes during his tenure, but his latest FXR is one of our favorites to date.

Heath initially set out to build this bike for his own personal enjoyment, but he found his passion further ignited after an invitation to the FXR Tour this past October, which was a ride with other FXR builders that would create their own version of the beloved platform and ride their newly created custom from Durango, Colorado to Born-Free Texas. Heath was honored for the invitation and accepted.

When asked about the main goal of the project, Heath expressed a desire to construct a simply stated bike suitable for long rides. Drawing inspiration from the classic styling of Evolution and older Harley Touring models, Heath aimed

for a timeless design that would be functional for racking up thousands of miles, but also be a blast to ride that hauled ass and could get down in the corners.

The bike’s unique features include a custom-designed fairing, lowers, chin pan, and front fender, all crafted at Saddlemen.

eath revealed that Saddlemen plans to o er the distinctive fairing to the public in 2024. While the end result is somewhat of a meticulous and clean looking project, the journey was not without its challenges, with the bags posing a particularly intricate puzzle. Crafting the hinges, seals, and latches for the bags made from carbon ber in-house at Saddlemen re uired meticulous planning and problem-solving.

Amidst the hurdles, the most rewarding aspect of the build for the creator was the paintwork. Despite not being a frequent painter, Heath likes to challenge himself, and he found immense satisfaction in returning to the booth for this project.

The stylistic inspiration for the bike came from a re ned interpretation of Harley-Davidson’s original FXR designs. Heath aimed to enhance the fairing, bodywork, and engine with a touch

of modern flair, resulting in a pumped-up S S Evolution engine.

Currently juggling multiple projects, Heath is occupied with redesigning Saddlemen’s H-D Pan America race bikes during work hours, but his attention is turned towards a slow build of a 1958 Panhead after hours, with plans to complete it in the Summer of 2024.

Heath mentioned that during the build of this bike he shared a humorous anecdote about the camaraderie developed during the FXR Tour group text. Describing it as a highlight, the group exchanged playful banter and questionable advice, creating a memorable and enjoyable experience throughout the build process. verall, the interview o ers a glimpse into the passion, challenges, and camaraderie that de ne the world of custom motorcycle building.

Heath would like to thank the following friends and brands that played a pivotal role in the project: Saddlemen, FXR Division, Performance Machine, Progressive, FLO, Alloy Art, Speed erchant, iamond ane, Suicide achine o, I, atty , S S, and Baker Drivetrain.

BIKE OWNER HEATH PINTER

SHOP NAME SADDLEMEN

SHOP PHONE 310-638-1222

SHOP WEBSITE/SOCIAL SADDLEMEN.COM / INSTAGRAM @SADDLEMENRACEDEVELOPMENT

YEAR/MAKE/MODEL 1992 HARLEY-DAVIDSON FXR FABRICATION HEATH PINTER

ASSEMBLY HEATH PINTER

BUILD TIME 5 MONTHS – AFTER HOURS

EFI/CARB S&S SUPER E

CLEANER S&S EXHAUST SUICIDE MACHINE CO ONE-OFF

TRANSMISSION

SUSPENSION

MANUFACTURER FRONT PROGRESSIVE CARTRIDGES LENGTH STOCK

TRIPLE TREES SPEED MERCHANT

MANUFACTURER REAR PROGRESSIVE 970

SPECIAL FEATURES DIAMOND LANE BLACK FORK TUBES

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT-TYPE PERFORMANCE MACHINE FORMULA

WHEEL HEIGHT-WIDTH 19X3

TIRE HEIGHT-WIDTH SHINKO 100/90/19

CALIPER PERFORMANCE MACHINE 4 PISTON

ROTOR PERFORMANCE MACHINE DOMINATOR

MANUFACTURER REAR PERFORMANCE MACHINE FORMULA

WHEEL HEIGHT-WIDTH 18X4.5

TIRE HEIGHT-WIDTH SHINKO 140/70/18

CALIPER PERFORMANCE MACHINE 4 PISTON

ROTOR PERFORMANCE MACHINE DOMINATOR

FINISH-PAINT

COLOR BLACK BASE – GOLD INLAY WITH ROOT BEER & TANGERINE FADE

PAINTER HEATH PINTER

GRAPHICS HEATH PINTER

SPECIAL FINISHES COATED/PROTECTED BY ANTHONY AUTO SPA

ACCESSORIES

FRONT FENDER HEATH PINTER – HAND-BUILT

REAR FENDER STOKE FXR

FAIRING/WINDSCREEN SADDLEMEN FXRS

GAUGES INTELLITRONIX FUEL GAUGE

GAS TANK/CAP STOCK

DASH FXR CENTER FILL

OIL TANK STOCK FXR

HANDLEBARS PERFORMANCE MACHINE PHATBAR

HAND CONTROLS/GRIPS PERFORMANCE RADIAL / ODI GRIPS

FOOT CONTROLS/PEGS FLO MOTORSPORTS V2

HEADLIGHT MOONS

TAILLIGHT MOONS

LICENSE MOUNT HEATH PINTER – HANDMADE

SEAT SADDLEMEN CUSTOM STEP-UP MISC. ALLOY ART SWINGARM

In Saddlemen’s R&D department, a group of enthusiasts embarked on the journey of building FXRs in recent years. However, lacking a concrete deadline, the projects languished until the beginning of 2023 when a collective decision was made to complete the bikes for a ride to Sturgis. Despite missing that initial deadline, the team shifted gears, making a concerted e ort to nish the bikes in time for the Born-Free Texas event. This newfound motivation was further fueled by Heath’s invitation to be a builder on the FXR Tour, prompting ris and others to join in and get their bikes ready for the ride too.

s an annual Sturgis rider, ris found himself among a dwindling number of riders still loyal to the -speed Twin am bikes, resisting the trend towards ilwaukee-Eight baggers. With the primary objective of creating a reliable bike capable of enduring long rides and keeping pace with the pack, the completed FXR surpassed expectations. aving covered over , miles since the Born-Free Texas event, the bike proved to be a formidable presence on the road.

Working within the Saddlemen Race Development building, ris aimed to showcase the Saddlemen team’s capabilities. The bike featured uni ue, one-o carbon ber parts, initially not intended for production. However, the positive reception prompted a change of plans, with the team now considering o ering a line of parts for fellow FXR enthusiasts. Notably, the bike also sported a prototype carbon Saddlemen S-RT fairing, with a production BS fairing set to hit the market in the coming month.

The construction of the bike presented its challenges though, with the dash being the most formidable. After deliberating for

a month on whether to incorporate a MotoGadget gauge pod for the carbon dash, a decision was made to let the dash stand alone, becoming the focal point of the bike.

ris completed his bike just days before the FXR Tour, which now came the true test: riding his newly built bike 2,500 miles from ong Beach, alifornia to urango, olorado, to meet up with the rest of the FXR Tour builders. Then of course, from urango to the one Star State for Born-Free Texas. The FXR Tour provided an opportunity to connect with some of the top builders in the country and indulge in seven days of riding FXRs.

ris’s commitment to keeping the build FXR -inspired while showcasing the Saddlemen crew’s talents led to a seamless collaboration. urrently, ris is working on a FXR , which ris intends to infuse with an , traditional feel, coupled with high-performance components. The collaborative e ort of the Saddlemen team, involved various individuals contributing their expertise in carbon ber, fairing development, assembly, wiring, seat crafting, engineering, and - printing.

nder the leadership of ave Echert, the team includes talented individuals such as eath inter, ento Fury ketani, at irgil, John Sanders, and more. Their collective expertise extends beyond crafting high- uality motorcycle seats it encompasses a full-fledged ing of the Baggers Race team, complete with four race bikes and a dedicated crew.

The crew’s commitment is nothing short of inspiring. Fueled by passion and creativity, they embrace challenges, making the impossible seem routine. The Saddlemen team is known for its es mentality, tackling complex projects with enthusiasm while constantly pushing boundaries.

Amidst their responsibilities making motorcycle seats, the

BIKE OWNER KRIS ECHERT

SHOP NAME SADDLEMEN

SHOP PHONE (310) 638-1222

SHOP WEBSITE/SOCIAL @KECHERT

YEAR/MAKE/MODEL 1994 HARLEY-DAVIDSON FXRP

FABRICATION KRIS ECHERT

ASSEMBLY KRIS ECHERT/MAT VIRGIL/KENTO OKETANI

BUILD TIME ON AND OFF FOR A COUPLE YEARS

ENGINE S&S V111 LONG BLOCK

TYPE/SIZE EVOLUTION/111CI CASES S&S

BOXES S&S

EFI/CARB

MIKUNI HSR 45MM

AIR CLEANER K&N RK-3933B AIR INTAKE SYSTEM

EXHAUST BASSANI 2-INTO-1 SUPER BIKE PIPE

SPECIAL FEATURES ALLOY ART MOTOR MOUNT/PIVOT BLOCKS

TRANSMISSION BAKER OD6

CASE STOCK CLUTCH BARNETT

FRAME STOCK H-D FXRP

YEAR/MANUFACTURER 1994/H-D

SUSPENSION

LEGEND AXEO 39TS

MANUFACTURER FRONT LEGENDS/DIAMOND LANE BLACK TUBES

LENGTH 26.25”

TRIPLE TREES SPEED MERCHANT NARROW GLIDE TREES

MANUFACTURER REAR LEGENDS REVO ARC

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT-TYPE PERFORMANCE MACHINE

REVOLUTION WHEEL

WHEEL HEIGHT-WIDTH 19X3”

TIRE HEIGHT-WIDTH 100/90 R19

CALIPER H-D BREMBO TOURING CALIPERS

ROTOR PERFORMANCE MACHINE DOMINATOR 11.8”

MANUFACTURER REAR PERFORMANCE MACHINE REVOLUTION WHEEL

WHEEL HEIGHT-WIDTH 18X5.5”

TIRE HEIGHT-WIDTH 150/70 R18

CALIPER H-D BREMBO TOURING CALIPER

ROTOR PERFORMANCE MACHINE DOMINATOR 11.8”

FINISH-PAINT

COLOR GLOSS BIRCH WHITE/MATTE CLEAR CARBON PAINTER KRIS ECHERT

ACCESSORIES

FRONT FENDER SADDLEMEN R&D CARBON SPORT FENDER

REAR FENDER SADDLEMEN R&D CARBON REAR FENDER

FAIRING/WINDSCREEN SADDLEMEN S-RT CARBON FAIRING GAUGES MOTOGADGET

GAS TANK/CAP DRAG SPECIALTIES POP-UP CAP DASH SADDLEMEN R&D FXRP DASH

OIL TANK STOCK

HANDLEBARS FXR DIVISION STAINLESS SPLIT ANGLE T-BARS HAND CONTROLS/GRIPS PERFORMANCE MACHINE

RACELINE CONTROLS/ODI HART LUCK GRIPS

FOOT CONTROLS/PEGS APEX MINI FLOORBOARDS

HEADLIGHT MOONS MC FLY EYE V2

TAILLIGHT MOONS MC LOW PRO TAILIGHT V3

TURN SIGNALS INTEGRATED

SEAT SADDLEMEN R&D SOLO PROTOTYPE

team, with some assistance from Harley-Davidson Motor Company, manages a semi-factory race team. Yet, it’s their passion that propels them to build bikes, showcasing a relentless work ethic. This dedication becomes evident in the story of Kris Echert and Heath Pinter, who meticulously crafted two exceptional FXRs just in time for the FXR Tour event.

The FXR Tour event, serving as a riding precursor to the BornFree Texas Motorcycle Show, set the stage for Kris and Heath’s outstanding creations. The Saddlemen R&D department initiated a collective e ort to complete FXR builds, driven by a shared goal to ride them to Sturgis, although they ultimately redirected their focus to the Born-Free Texas event.

Heath Pinter, recognized as an invited builder on the FXR Tour, motivated his colleagues attie and others to nish their bikes for the ride. The result was not only aesthetically pleasing FXRs but

also reliable machines capable of covering substantial distances, reflecting the team’s commitment to uality and performance.

“I think just about everyone at our shop touched something on this bike,” Kris says. “I’d like to thank Dustin Peeken (@ dust inkredible) for making all my carbon ber dreams come true. Tri, Alan and Peter you too. Heath Pinter (@heathpinter) for all the help with the S-RT fairing, our master race tech Mat Virgil (@mattie_veee) for all the assembly help, and Kento Oketani (@ fury36) and my Dad (@davidechert) for all the wiring expertise. Ezekiel and Ramon, the seat masters. Enrico Gutierrez (@ enricog1) engineering and printing. Justin and Chris (@fxrdivision) for answering all my dumb uestions and supplying some of the best FXR parts in the game. I really want to thank all the great companies who got behind the build and supported this one like they always do.” HB

HANDLEBAR BAG

EXPEDITION SADDLEBAGS

PASSENGER BAG

HARD MOUNT BRACKETS

& Tested By Riders Since 2014

LANCE ROCKING THE PASSENGER BAG AND EXPEDITION SADDLEBAGS. THESE BAGS FEATURE CORRESPONDING BUCKLES WHICH ALLOW FOR DIRECT ATTACHMENT. NO SISSY BAR NEEDED.

In crafting the Audette Velos Motorcycle, Anthony (Tony)

Audette, a former design engineer for a high-end manufacturer, sought to challenge prevailing industry trends that prioriti ed aesthetics over performance. Influenced by iconic gures and unconventional inspirations, he envisioned building the best merican motorcycle, undeterred by his initial lack of nancial resources.

The elos, a result of years of dedication and sacri ce, emerges as a pure expression of Tony’s engineering expertise and passion for unadulterated motorcycle performance. issatis ed with the industry’s emphasis on electronic systems, he aimed to refocus on the fundamentals, creating a lightweight machine tailored for backroad riding without the distractions of technology.

The motorcycle reflects meticulous design, incorporating innovative features like the “Ram Air System” to cool critical components. From the repositioned oil lter for enhanced serviceability to the suspended gas tank and adjustable rear fender, every detail showcases the protagonist’s commitment to both form and function.

The Velos represents a departure from mass-market compromises, o ering a visceral and dynamic riding experience. cknowledging the contributions of collaborators, supporters, and key individuals, Tony is extremely grateful for their role in bringing the elos to life.

Inspired by early merican motorcycles, the elos pays homage to utilitarian machines while incorporating contemporary twists. Tony’s background in aerospace contributes to the functional aspect of the design, ensuring a seamless integration of aesthetics and foundational elements.

The journey to showcase the elos at prestigious events reflects Tony’s resourcefulness and determination. From creatively securing spots at renowned shows to o ering the motorcycle for podcast features, he navigates challenges with ingenuity.

The elos transcends being a mere mode of transportation it symboli es Tony’s determination, expertise, and passion for pure

motorcycle performance. s he reflects on the journey, gratitude is expressed to family, friends, and customers for their role in bringing the elos to life. This narrative encapsulates not only the technical prowess behind the elos but also the human story of relentless pursuit, sacri ce, and triumph over challenges.

e chatted with Tony to get the scoop on his Indian elos bespoke production models, and he broke it all down by section, so we’ll let Tony tell you in his own words.

ompletely fueled, the elos weighs pounds. To achieve that I developed a reinforced - hannel, twin-spar frame system. This allowed me to N -machine all the frame components. I used Finite Element Analysis (this is the type of analysis that measure stress people maga ines typically shows these results in a picture of the part in the predator vision slightly deformed) to determine where I needed the internal bracing for optimal structural integrity while reducing weight as much as possible. nother development I came up with was the front cowl, if you look at it compared to a cowl on a jet engine you will see where the inspiration was pulled from. This cowl, mounted radially increases torsional rigidity, keeping the engine in line with the frame and wheels as the bike is leaned over, creating gyroscopic harmony. This means that the gyroscopic e ect of the engine is in plane in-line with the wheels and tires, meaning the motorcycles rotating tires is not ghting the engine rotating crank, leading to ease of handling, ease of flick-ability. elos the engine is also used as a semi-stressed member to prevent the frame from wallowing.

I really wanted to use an merican -twin engine, but the S S engines I have used in the past are fairly generic even in the high-end of the market space. I decided to start with Indian Thunderstroke otor and beef it up, I took an engine completely

apart and 3-D scanned and reverse engineered it into a CAD model, so I knew exactly where the mounting points were and the exact weight distribution of the engine and the modi cations I planned to make. I left the transmission and engine cases the same as stock as the gears were exceptionally high-quality and could handle more power easily. The engine was lacking the torque that I was looking for, this led to punching out the bores to obtain a , cc of total displacement. To flatten out the tor ue curve I used hotter cams that bene ted the over the tor ue. The result of this means you can keep twisting the throttle and it will keep pulling throughout the power curve. These engines are also internally balanced with a counterweight at the crank as opposed to the drilling and lling method of balancing. The valves remained the stock size, larger capacity valve springs were added and the valves get a Diamond Like Coating (DLC). The heads are polished by me in house. The performance out of the engine I was looking for is the instant-on power when you hit the throttle and the feeling of never-ending waves of torque. For an example of how flat the tor ue curve is, we are making just over ft-lbs of tor ue at idle and a peak of ft-lbs of tor ue at , rpm (max rpm is , ). The engine case is a semi-wet sump, meaning the oil tank is internal to the engine case itself while also being separate from the engine components.

I wanted this motorcycle to be comfortable and more importantly, nimble. The frame geometry was inspired by sport touring motorcycles and then re ned to the elos. Because the elos has a large amount of tor ue and minimal electronics, I canted the engine at negative two degrees. This is so when the rider hammers on the throttle, the crank must overcome itself before it reaches level and then some before it has the potential to pop a wheelie… essentially acting as mechanical anti-wheelie control. The weight distribution with a pounds, ’ rider on board is biased slightly toward the front at -percent to 48-percent. This also aids in the anti-wheelie while contributing to a better turn-in to a corner. The wheelbase is . making it signi cantly shorter than that of the R R T in class. This shorter wheelbase allows for better tracking of the wheels in the twisties and easier low speed handling. The steering head angle of -degrees and . inches of trail. This trail allows for great low speed handling, while maintaining exceptional performance in the curves and in a straight line. The swingarm itself was designed and engineered by Audette and utilizes geometry typical of a sports bike, however where most sport bike swingarms are asymmetrical the Audette swingarm was designed to be symmetrical with the shock in a cantilever set up.

I love using carbon ber wheels which come standard on the elos. ost people don’t truly understand the value these add to the overall handling of the motorcycle, they see the price tag and go spend it adding more weight to their motorcycle. I use carbon ber wheels because they contribute signi cantly to a smooth ride on the road because of the lower inertia, meaning the suspension is not working as hard. For tire I use irelli iablo Rosso III’s because they get up to temp incredibly fast and get super sticky, the tire pro le also lends to better handling than standard tires. ost companies in the high-end use a fat rear tire, all that does is suck handling capabilities from the bikes while adding absolutely nothing to the aesthetic, in my opinion they are stupid and should not be made.

The aesthetic goal of the elos was to make the structural components the nished components. So, there are no body panels. Every piece on the motorcycle serves some sort of mechanical function. hich is part of the allure, what is on the surface is the motorcycle, as opposed to being covered in cladding, fairings, and body panels like almost all modern bikes.

Stock instruments were kept however, I have re-faced the gauges with udette branded face. This meant making a new, domed glass face machined from crylic and polished clear. This had to be done because the stock gauges have the clear cover glued to the bottom portion making it almost impossible to disassemble without destroying it. But this means we can customi e any gauge face to the customer’s specs and still provide all the information the factory intended the rider to have.

This is cool, and also helped with the nal design of the intake itself. The taillight and turn signals are totally integrated into the seat. (In this case only the rear, but we can integrate them on the front headlight cowl as well). sing the software I was able to integrate E lights and create completely seamless lenses into the seats subframe. These lenses are machined crylic, then polished to be transparent and sprayed a transparent red or amber. Because crylic is a transparent, petroleum based, thermoplastic it will not fade or yellow in light. I discovered

“EVERY

this (actually, talking to a retired chemical engineer at a hristmas party that I didn’t know anyone at) I cracked the code for the air intake system. Because I wanted a transparent system to see the throttle body working, being able to contour a transparent material without the fear of fading in or applying an additional coating allowed me to develop the optimal airflow in the intake system as well as create the new gauge glass without fear of yellowing fading over time.

The seat shape was derived from a ’s tractor seat before they were e uipped with suspension, but the farmers still had to sit in the seat all day long. Each seat is built for the individual owner. So, we have seats that have been made with bison hide, carbon ber fabric, black leather, and for this example a white leather with laser etched hounds tooth pattern. e machine all our seat pans and prep them, but all the foam, embroidery and stitching are completed by the incredibly talented uin Simpson of Black Stitch abel. Funny story on her, she was working on a seat for one of our customer’s elos I called just to see how it was coming along. The call went to voicemail, I left a message and didn’t think much more of it. She called back a couple hours later and said, Sorry I missed your call, I was sewing my parachute with my mom. I already knew she was talented, but it was at that moment that I knew she was con dent in her work, and I will never use anyone else. HB

BIKE OWNER

SHOP NAME

SHOP PHONE

AUDETTE MOTORCYCLES

AUDETTE MOTORCYCLES

860-500-0933

SHOP WEBSITE/SOCIAL VELOS.AUDETTEMOTORCYCES.COM/ @AUDETTEMOTORCYCLES

SHOP EMAIL

SHOP PHONE

YEAR/MAKE/MODEL

SALES@AUDETTEMOTORCYCLES.COM OR TONY@AUDETTEMOTORCYCLES.COM

860-500-0933

2023/AUDETTE VELOS (VEH-LOS)

FABRICATION CNC-MACHINED FROM BILLET ALUMINUM ASSEMBLY BUILD TIME PROTOTYPING THE FIRST MOTORCYCLE TOOK 3.5 YEARS. CUSTOMER’S PRODUCTIONS BIKES ARE FINISHED WITHING 34 MONTHS

ENGINE INDIAN THUNDERSTROKE X AUDETTE MOTORCYCLES

YEAR/MANUFACTURER

2023/INDIAN X AUDETTE

TYPE/SIZE AIR COOLED, 49-DEGREE V-TWIN, INTERNALLY BALANCED. CUSTOMER CAN CHOOSE ENGINE DISPLACEMENT OF 1,811CC (CR-9.51) , 2,064CC (CR-111), OR 2,147CC (CR-11.71)

CASES INDIAN MOTORCYCLE

CYLINDERS

AUDETTE CNC-MACHINED AND NIKASIL PLATED BY REVOLUTION PERFORMANCE

HEADS STOCK VALVES WITH DIAMOND LIKE COATING, LARGER CAPACITY VALVE SPRINGS AND POLISHED HEADS ROCKER BOXES AUDETTE DESIGNED AND CNC-MACHINED, PORTED FOR BETTER COOLING OF THE HEADS

EFI/CARB CLOSED LOOP BOSCH FUEL INJECTION / SINGLE 54MM BORE THROTTLE BODY (RIDE BY WIRE)

EXHAUST C3 V-TWIN 2-INTO-1 STAINLESS STEEL EXHAUST (TITANIUM OPTIONAL)

AIR CLEANER

TRANSMISSION

AUDETTE FILTERED VELOCITY STACK AIR INTAKE SYSTEM AND K&N FILTER

YEAR/MANUFACTURER/TYPE

INDIAN/ 6-SPEED CASE INDIAN

CLUTCH

PRIMARY DRIVE

FRAME

YEAR/MANUFACTURER

MULTI-PLATE, WET CLUTCH

AUDETTE 530 CHAIN, 25 TOOTH FRONT SPROCKET WITH 47 TOOTH REAR

AUDETTE PROPRIETARY TWIN SPAR, INTERNALLY BRACED C-CHANNEL. CNC MACHINED FROM AIRCRAFT GRADE ALUMINUM.

RAKE 26-DEGREE RAKE / 4.31-INCH TRAIL

WHEELBASE 63.5 INCHES

GROUND CLEARANCE 5.1 INCHES

SUSPENSION

MANUFACTURER FRONT CUSTOM RACETECH G6, 800MM LONG, 43MM INNER TUBE, 54MM OUTER TUBE LENGTH 800MM

TRIPLE TREES

AUDETTE DESIGNED AND CNC-MACHINED

MANUFACTURER REAR CUSTOM RACETECH G3, FULLY ADJUSTABLE

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT-TYPE BST RAPID-TEK SPLIT SPOKE WHEELS

WHEEL HEIGHT-WIDTH 17X3.5 INCHES

TIRE HEIGHT-WIDTH 120/70 ZR17 PIRELLI DIABLO ROSSO III

CALIPER DUAL BERINGER 4-PISTON AEROTEC CALIPERS

ROTOR 310MM FLOATING GALFER WAVE ROTORS

MANUFACTURER REAR-TYPE BST RAPID-TEK SPLIT SPOKE

WHEEL HEIGHT-WIDTH 17X6 INCHES

TIRE HEIGHT-WIDTH 180/55 ZR17 PIRELLI DIABLO ROSSO III

CALIPER BERINGER 2-PISTON AEROTEC CALIPER

ROTOR 2-PISTON BERINGER AERTEC CALIPER / 220MM GALFER ROTOR

FINISH-PAINT

COLOR

VINTAGE PORSCHE ENAMEL BLUE PAINTER JAYME SCHMIDT OF BLUE MOON KUSTOMS IN OSHKOSH, WI (FENDERS AND COWLING) POWDERCOAT B&C POWDER COATING IN MERIDEN, CT

ACCESSORIES

FRONT FENDER

REAR FENDER

AUDETTE 1-PIECE ABS-LIKE POLYMER

AUDETTE 1-PIECE ABS-LIKE POLYMER

GAUGES INDIAN X AUDETTE

GAS TANK/CAP CNC-MACHINED ALUMINUM 4-GALLON FUEL TANK DASH AUDETTE

HEADLIGHT HOGWORKZ HALO-MAKER

TURN SIGNALS KURYAKYN/KELLERMANN ATTO TURN SIGNALS

LICENSE MOUNT AUDETTE SEAT AUDETTE

2

The Adaptive 2 Series® of LED Motorcycle Headlights dynamically fill in the dark corners as the bike turns left or right. Embedded sensors in the headlight work in real time to calculate banking angles and speed to adjust and direct precise beam patterns for maximum comfort and safety for the rider.

No matter what you ride, we’ve got you covered.

The Adaptive 2 Series® Headlights fit over 1,000 styles of motorcycles.

WORDS:

In the world of motorcycles, where enthusiasts constantly seek to push boundaries and create unique rides that reflect their personal style and dreams, one individual embarked on a journey to build a custom XR motorcycle that would not only ful ll a lifelong dream but also pay homage to a rich motorcycle lineage. This venture resulted in the creation of The Beast, a one-of-a-kind XR machine by Laurel Classics in Laurel Canyon, California, that stands out for its old-school merican race muscle setup on the street.

The creator of The Beast , ade arradine, started this project with a clear vision to have a streeted XR that would complement his ncle’s Silver XR nicknamed Satan. rawing inspiration from the two-wheeled Bee lebub he had been exposed to, the goal was to build a bike that would be worthy of the time and mentorship bestowed upon him

during that period of his life.

hat makes The Beast truly exceptional is ade’s meticulous attention to detail and the commitment to achieving the most authentic, old-school merican race muscle setup for being ridden on the street. ade’s XR boasts a factory chromoly frame, a rarity in itself. It’s not just a bike with custom elements practically everything on The Beast is custom-made, with minimal stock parts. Even the -inch arley handlebar riser, used ingeniously to mount the exhaust cones to the frame, was a uni ue touch.

The distinctive hicago olice Spotlight serving as the headlight adds a touch of uni ueness, while the battery tray, cleverly concealed under the tailsection and originally from a B police bike, underwent reworking to t seamlessly into the design. The Barnes rotors, single-puck Brembos

resembling the old rimecas, and the knock-o rear hub contribute to the period dirt track aesthetics, coupled with the ustomTech hand controls, emphasi ing simplicity and cleanliness.

The road to completing XR was not without its challenges. The rear frame was discovered to be bent after nickel-plating, leading to a trip to see r. John for resolution. The tight rea r space posed issues, particularly with modern hlins shocks and a chain. reative problem-solving was re uired to customi e the hlins shocks to t within the constraints of the frame.

ade faced additional challenges, including limited resources and an -mile commute (each way) to work on the bike in his uncle’s driveway. This re uired making signi cant sacri ces in his personal life, highlighting the passion and determination invested in this project. Transporting the bike in the back of a borrowed -year-old diesel hevy added an extra layer of adventure to the process.

The collaborative e ort with individuals who provided support and mentorship during challenging moments became one of the most memorable aspects of the project. The camaraderie and shared passion for motorcycles made the journey enjoyable, turning obstacles into opportunities for growth and learning.

For ade, the street tracker XR represents a nod to the merican flat track style, inspired by motorcycle heroes like Jay Springsteen, ert awwill, Scott arker, evin therton, and hris arr. The decision to pursue the XR style was solidi ed after a signi cant moment riding away on his uncle’s Silver ert awwill XR , a surreal experience that fueled the determination to con uer the XR mountain.

aving explored big twins for a few years, ade developed a keen interest in the street tracker segment. Studying builds by Richard ollack’s ule and the desire to ride such bikes led to the creation of The Beast a bike designed to outperform and intrigue, challenging the ever-popular FXRs and ynas.

ooking ahead, ade has extended his passion for XRstyle motorcycles by assembling two replica XR-style Sportsters for a friend. This venture showcases a commitment to a preferred style of bike building, emphasi ing the joy of learning and working on motorcycles.

In conclusion, ade’s XR stands as a testament to a dream ful lled and the perseverance re uired to bring a custom motorcycle vision to life. From its uni ue features and challenging customi ation process to the camaraderie shared during its creation, The Beast is not just a motorcycle it’s a symbol of passion, dedication, and the pursuit of dreams on two wheels. HB

BIKE OWNER

CADE CARRADINE

SHOP NAME LAUREL CLASSICS

SHOP EMAIL LAURELCLASSICS@PROTONMAIL.COM

SHOP WEBSITE/SOCIAL @LAURELCLASSICS ON IG AND LAURELCLASSICS.COM FOR MERCH AND INQUIRIES

YEAR/MAKE/MODEL

1984 H-D XR1000

FABRICATION JIM WOODS MACHINE, JAMES BANKE, DR. JOHN, GLEB CHERNIY ASSEMBLY CADE CARRADINE / MICHAEL BOWEN BUILD TIME ABOUT 18 MONTHS

ENGINE XR1000

YEAR/MANUFACTURER

1984 HARLEY-DAVIDSON

TYPE/SIZE 1,000CC, ALLOY HEAD CASES H-D

CYLINDERS H-D

HEADS BRANCH ENGINEERING/XR750

ROCKER BOXES H-D XR750

EFI/CARB DUAL MIKUNI FLATSLIDE CARB 38MM AIR CLEANER VELOCITY STACKS

EXHAUST STAINLESS SUPERTRAPP XR750 HEADERS, CUSTOM REVERSE CONES

SPECIAL FEATURES THE ONLY “STOCK” PART ON THE MOTORCYCLE IS THE 1-INCH H-D HANDLEBAR RISER USED TO MOUNT THE EXHAUST BRACKET TO THE FRAME

TRANSMISSION

YEAR/MANUFACTURER/TYPE

1984 HARLEY 4-SPEED

CASE H-D

CLUTCH H-D WETCLUTCH DRILLED PER XR “RACE” BOOKLET SUGGESTION

PRIMARY DRIVE 520 CHAIN

FRAME FLAT TRACK CHROMOLY

YEAR/MANUFACTURER 1977 HARLEY-DAVIDSON FACTORY RACE RAKE 26, ABOUT 3.44-INCH TRAIL

MANUFACTURER FRONT YAMAHA R6 43MM CONVENTIONAL TELESCOPIC

MANUFACTURER REAR ÖHLINS

TRIPLE TREES BANKE PERFORMANCE 43MM

WHEELS, TIRES, AND BRAKES

MANUFACTURER FRONT TYPE SUN ALUMINUM

WHEEL HEIGHT-WIDTH 19”/2.75”

TIRE HEIGHT-WIDTH 130/80/19 - 27” OD

CALIPER BREMBO

ROTOR BARNES

MANUFACTURER REAR SUN ALUMINUM

WHEEL HEIGHT-WIDTH 19”/3.5”

TIRE HEIGHT-WIDTH 140/80/19 - 27.5” OD CALIPER BREMBO

ROTOR BANKE PERFORMANCE 10.5” FLAT TRACK

COLOR 60S CHEVY “SUPERSPORT BLUE”

PAINTER PACMAN JACK MCCANN

GRAPHICS HARLEY XR STYLE

SPECIAL FINISHES THE PINSTRIPE IS SPECIAL

ACCESSORIES

REAR FENDER “SCOTT PARKER” REPLICA, HOMEMADE SEAT PAN AND 1 SCREW MOUNTING - SEAT COVERED BY LEPERA

GAS TANK/CAP RACE STYLE W VENT

OIL TANK H-D XR750 ALUMINUM OIL BAG

HANDLEBARS FLANDERS #10

HAND CONTROLS/GRIPS KUSTOMTECH “GRIMECA” BRAKE AND CLUTCH, RENTHAL WAFFLES - “BANKE/BOWEN” MIRRORS

FOOT CONTROLS/PEGS STORZ PERFORMANCE REAR-SETS HEADLIGHT UNITY-GAIN, 60S CHICAGO POLICE SPOTLIGHT

TAILLIGHT CUSTOM DYNAMICS LED BAR SEAT CUSTOM PAN, LE PERA COVER

Suspension:

SX5 Road & Track Inverted Front-End with Ohlins Forks

Ohlins Max Length HD 506 Rear Adjustable Shock

Ergonomics:

Isolated Kickback Risers with Aluminum Moto Bars

LR/S Twin Guage Bucket

Controller Seat

Max Lean Mini Boards

Control Freak Adjustable Shi and Brake Levers

Braking:

Front and Rear Radial Brake Calipers

Race Proven BrakeTech 320mm Rotors

High Performance Braided Brake Lines

Trim:

Carbon Fiber Fenders

Carbon Fiber Side Panels

Billet Perch Clamps

Slider Derby Cover

DressUp Timing Cover

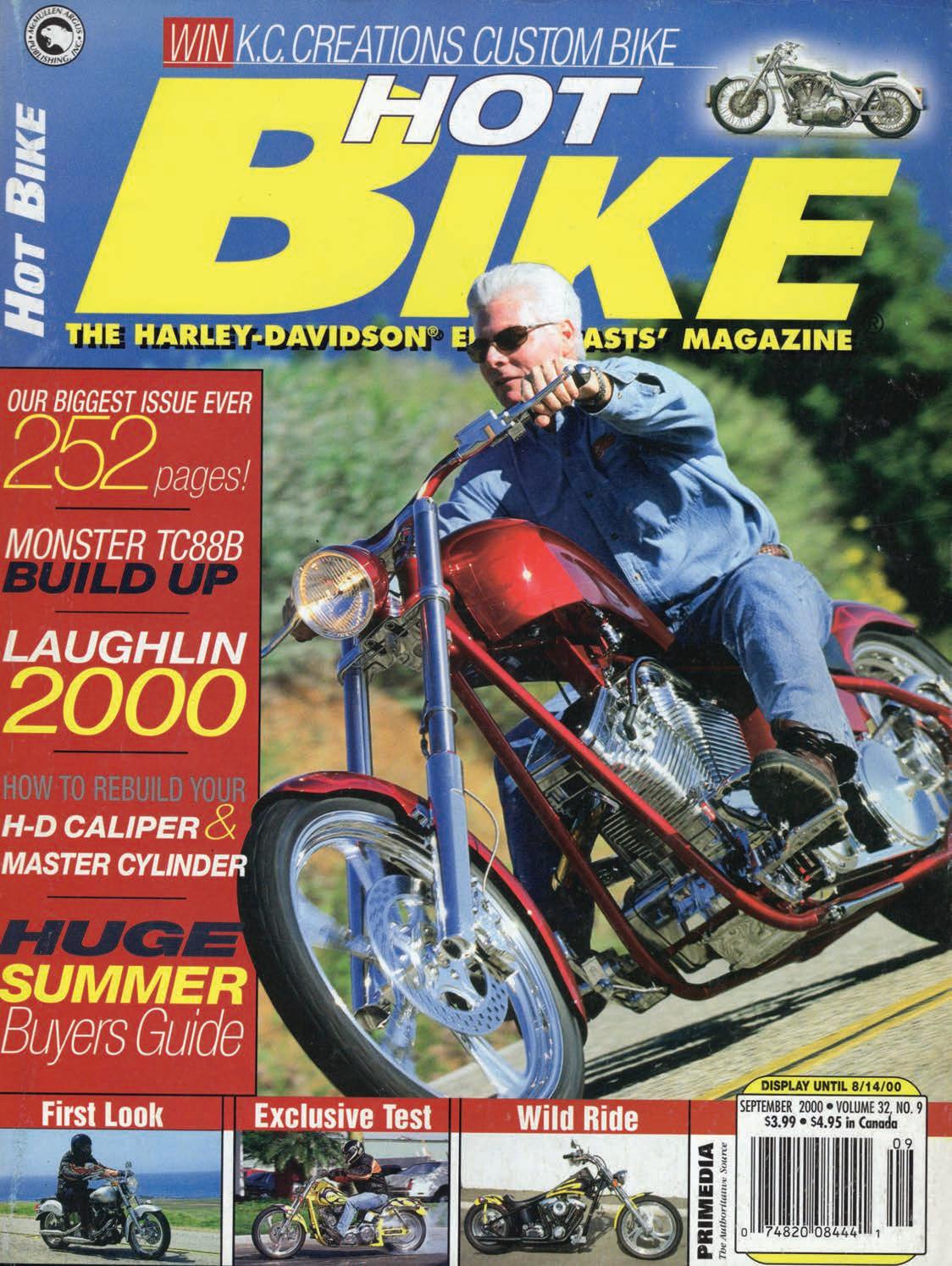

THE TURN OF THE CENTURY OR THE BEGINNING OF THE END?

How crazy were the 2000s? The turn of the century pretty much set the tone as the world lost its damn mind because of Y2K. In 2001, the September 11 attacks on the World Trade Center and the Pentagon killed 3,000 innocent people on US soil, which spawned the manhunt for Osama Bin Shithead and subsequently the Afghanistan and Iraq wars. In the 2000s, big tech companies became the titans of corporate American industry. Apple launched the iPod in 2001 and revolutionized how we listen to music. Facebook launched in 2004 and we all became robots who forgot how to socially interact. Hurricane Katrina wiped out the Gulf Coast. Six-figure choppers and customs were all the rage until the subprime mortgage crisis of 2008, but luckily The Twin Cam Engine was already born and the custom motorcycle industry turned into the bolt-on parts industry. The 2000s were nuts! Did the world already end and we’re living in a parallel universe?

Taking a break from our performance upgrades this issue (next installment we’ll show how Motorwitch provides proper breathing techniques for the cranky M-8 engine/trans with HPI and Trask Performance), this month I spent some time, for vanity’s sake, addressing the frontal aesthetics.

Originally, the plan was to source and install a Low Rider ST fairing—but then, it would just be a Low Rider ST clone. So, instead, still opting for the xed-fairing approach, I hit up my old friend Brian Klock of Klock Werks, to see how their progress on the Softail OEMstyle FXRT fairings was coming along. Turns out, they were ready to ship, so, I ordered one up! And, to spice up the lighting aspects, I then turned to Kieran and Justin at KleenMoto to see about using their new Rigid Adapt XP headlight kit, which I’m super stoked I did because not only did KleenMoto do their homework in developing a super user-friendly kit (from the wiring to the bracket tment), I now ride at night with utmost con dence that my blind ass can see! And that goes hand-in-hand with the user-friendliness of the Klock Werks fairing install, which I’m about to show!

ABOVE: As I mentioned, Anthony from V-Twin Now in Riverside, CA, donated his time (and shop) to help me out with the entire job—from the install to the ABS brake bleeding to the acquiring of parts (having Guerrilla Cables right next door comes in convenient for bar/riser jobs!). BELOW: First order of business once the stock headlight/fairing etc. are removed: installing the Klock Werks FXRT fairing brackets.

ABOVE: The main mounting bracket attaches to the tank mounts on the top, while the lower portion is attached to the front motor mount above the oil cooler with a secondary backet. BELOW: A quick mockup of the fairing to ensure fork leg clearance at full lock each side before we begin mounting.

But before we proceed, your esteemed editor Jordan had suggested that I also address the riser situation since I’d mentioned wanting to go taller in lieu of the new frontal accessories—and recommended contacting Satya at Kraus Motor Co., who not only graciously obliged by suppling the project with an array of his Straight and Kickback Isolated Risers along with his all-new integrated gauge mount and twin gauge bucket for us to work with. (And when I say “us”, I’m referring to Anthony at V-Twin Now, who donated his free time to assist me with the entire frontal upgrade!)

Whether using Klock Werks’ headlight mount using an OE 7-inch headlight or the KleenMoto/Rigid kit, the main attachment point for the fairing is the headlight bracket (*fairing mount adapter); the Rigid Adapt XP is already installed onto that bracket, as shown.

The fairing also uses a lower support bracket that attaches to both lower side flanges (inside, not below) and locates o the frame right below the upper bracket.

KleenMoto’s power harness (compensates for the additional draw) requires pulling the gas tank (no big deal), however, it does not require removing the battery (disconnect, of course) thanks to their clever power lead configuration! H-D doesn’t give you much room to play with—just enough to neatly tuck the wiring in place (ensure there’s nothing the monoshock will pinch while riding).

While Anthony was still fiddling around with the wiring, I installed the Klock Werks smoke-tinted Flare windshield, which attaches via the supplied well-nuts. (It’s not a bad idea to carefully chase the mounting holes with a Unibit—by hand—to remove any excess gelcoat… same with the headlight cover holes.)

Route the harness along the backbone of the frame and plug into the Rigid headlight pigtail; the headlight also pulls a CAN Bus signal via the factory headlight plug.

Now onto the next phase: addressing the handlebar situation…or, currently, lack thereof. (Notice the wiring emitting from the bars—that all needs to be disconnected at the frame and pulled through the top tree for the following procedures.)

Kraus Motor Co. supplied Straight and Kickback versions of their isolated riser systems in 8-, 10-, and 12-inch varieties. After some serious consideration/measuring, the decision was made to go with their 10-inchers… but which version?!

Since I was previously running kickback risers—on a setback plate no less—I initially figured the 10-inch Kickbacks would be the ticket, however…

Obviously, having to drain the brake fluid meant a quick front brake bleed, which, if you’ve ever had the pleasure of dealing with ABS, requires some additional “equipment” in which to perform properly. If you’re doing this at home and don’t have the interface and software for the ABS bleed, simply bleed the fluid as normal and then have a local shop or dealership reset the ABS.

Again, can’t say enough how impressed I am with the KleenMoto/Rigid headlight’s brightness along with the added benefit of being an “adaptive” system, providing illumination in corners like no other! Plus, it looks right at home in the Klock Werks fairing! (Will look even better once it’s painted…)

KleenMoto’s headlight bracket features a pretty clever adjustment system: Allen-head pivot and locking hardware on each side, which allows you to easily adjust up/down positioning… with the headlight cover o , of course.

And as for the risers/gauge setup—same conclusion… ergonomically and aesthetically, everything’s on point!

To sum things up: Klock Werks, KleenMoto, and Kraus all provided products that were beyond easy to install (all accompanied by detailed instructions!); the bike rides handles ama ingly with the xed fairing the adaptive headlight illuminates like no other; and the -inch straight risers o er the most comfortable riding position I’d hoped for, while the gauges situated right below your line of riding site keep you informed without distracting your vision. win-winwin for bettering the - HB

Speaking of which, after buttoning up/torquing down everything accordingly, the Klock Werks headlight cover was the last item to be installed.

SCAN THE QR CODE & CHECK OUT THE VIDEO IF YOU NEED SOME HELP DOING THIS YOURSELF ON THE HOT BIKE YOUTUBE CHANNEL

It’s cra y how time flies, but I’m excited to be back again with another tech tip for the last issue of . In this installment we are going to be covering the basics of how to do a top-end job on a arley- avidson ow Rider ST, so let’s get right to it.

I’m going to cover some theory and basic knowledge in this article that might be hard to nd elsewhere, the video will cover more of the speci c hands-on tech tips and tasks.

But at the most basic level hat is a top-end job I’m sure you’ve all heard that term before but what does it entail For the most part it means you are replacing the cylinders and pistons. In some cases, it can mean you are just tearing it down to replace the piston rings. To do this, the cylinder heads have to be removed to gain access to the cylinders and pistons. This is a job that has a lot of steps and has some detail-oriented tasks so if you plan on doing this yourself, you need to have the appropriate service manual and the necessary tools on-hand for the job.

For the bike involved in this article we are using a MotorWitch Industries it. This kit has a very di erent design than we’re used to seeing and is a billet aluminum cylinder body that has a ductile iron sleeve in it for the piston to ride in. This is a great kit and makes a lot of power while running signi cantly cooler.

When you look at big bore kits there are a lot of options that will increase your displacement, along with many options for compression ratio.

So, let’s rst talk about displacement. hat is displacement and more importantly, how do you determine displacement? Basically, displacement is the total amount of space available to charge with air and fuel. Displacement is determined by bore and stroke. Bore is the diameter of the piston and stroke is the distance the piston travels up and down.

NOTE: If you know those numbers, you can easily determine the displacement of any engine with this equation:

Displacement is calculated Bore x Bore x Stroke x Number of cylinders x 0.7854. So let me populate that equation for you with the data for a 131 the way I build it. The piston diameter is 4.250 inches (bore), and travels 4.625 inches (stroke) and a Harley engine has two cylinders so it will look like this: 4.250 x 4.250 x 4.625 x 2 x 0.7854 = 131.223.

Now that you know what displacement is and how to calculate it, let’s jump into compression ratio. First, what is it The compression ratio in the most basic sense is how tight you squeeze the air/fuel charge before you ignite it with the spark plug. Compression ratio is expressed as a number to a number.

“BASICALLY, DISPLACEMENT IS THE TOTAL AMOUNT OF SPACE AVAILABLE TO CHARGE WITH AIR AND FUEL.”

For this example, I’ll say because it’s easy to deal with and very common among Harley-Davidson motorcycles. So, your big number is how much volume of space is available for your air/ fuel charge when your piston is at Bottom Dead Center. Your small number is the space available at Top Dead Center.

In this example you are taking 10 units of air/fuel and compressing it into 1 unit of space.