Unrolling bales the Kiwi’s way

The bale unroller is now available in many guises, however, New Zealand firm Hustler was the first to establish the concept and has stood the test of time. We look at one of the latest models and see how it has developed

WORDS HOWARD SHERREN IMAGES HOWARD SHERREN AND HUSTLER

Hustler Equipment has become known as one of the world’s leading bale feeding equipment specialists and have grown their UK market share considerably over the past decade. The company began in 1961 in Hawke’s Bay, New Zealand in the shed of the familyowned orchard of inventor Russell Currie. With the introduction of the widest boom sprayer in the

Below: The Unrolla from New Zealand manufacturer Hustler was one of the first bale unrollers to establish itself across the world before numerous copies were made. This original machine has proved itself with excellent reliability, now offering a four-year warranty from new.

southern hemisphere in the 1960s, to the launch of their revolutionary chainless bale feeders in the 1990s, the Curries have been improving the everyday lives of farmers around the world for six decades.

For farmers in Europe and the UK, the most notable product, and successful, was the SL350 bale unroller introduced in 2005. This remained in production for over 10 years and became particularly

well established in the UK. It was replaced by the SL360X in 2016 and the SL300X was introduced a year later in 2017. Hustler was then quick to offer the LM105 and Unrolla LX105 self-unlocking models in 2019, that could take up to 1.5m round bales. This was before the latest update when the models were simplified and the Unrolla LX104 launched in 2022 to replace the others. This included a new green

“They have grown their UK market share over the past decade”

and grey paint scheme over the green and yellow.

Background

The new LX104 mounted bale unroller was released in New Zealand at the end of 2022 and was progressively introduced from the start of 2023 in Europe. The Unrolla LX104 delivered improved feeding aggression and durability, with less maintenance and significant improvements in all key areas. A stronger build to handle the toughest bales, a more compact design for easier manoeuvrability, and improved feeding mechanisms for faster, more efficient unrolling. Hustler introduced a new model specifically for 1.2m-wide bales – one of the most popular in the world. This makes for improved manoeuvrability, visibility, and operator safety. Featuring new HardLine sprockets, an additional five extra feed bars that provide more feeding aggression, stronger teeth (now 8mm thick) for more power transmission, a new chain tensioner design, and an improved headstock design with extra gussets - all provide greater strength to weight ratio. The patented Snaplox auto-latching system was a game-changer in the industry, using the same hook system as the more conventional rope-pull-release type

TECHSPECS

Hustler LX104

Bale size 1.2m x 1.2m to 1.5m x 1.2m

Bale weight Up to 1,250kg

Overall width 2,055mm

Overall length 1,865mm

Overall height 1,050mm

Weight 565kg

Loading Selfloading with integrated tines, Snaplox autolatching system

Spool requirement 1 DA spool

Hydraulic requirement 30-60-lit/min

Chains Twin 5,443kg roller

but with automatic release (it could be used with or automatically without a rope) – it was idiot proof.

Heavy duty cradle

The bale cradle has developed and changed over the years of production

will have more room for a 1.5m bale. The design allows the feeding of bales to the left or the right with precise control thanks to the motor connected to the tractor spool. The chamber on the LX104 is now steeper and deeper, which helps stickier bales

“The patented Snaplox auto-latching system was a game-changer in the industry - it was idiot proof”

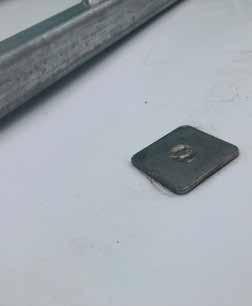

The bed is held together with these square headed bolts that clamp the edge to base. If the nuts become loose, they can catch the slats and will inevitably wear in time. These are readily available if required and ensure it is kept tight.

Right: There have been numerous models of Unrolla, offering manual or automatic latching or a larger model to handle 1.5m bales. The LX104 now offers automatic latching and easy handling of 1.2m round bales.

to roll, also preventing them from falling out of the machine. The optional roller bars that fit either end at around £400 extra are worth finding or adding, especially for un-chopped or sticky bales. The fully enclosed floor design extends over the drive shafts, protecting them from wrapping and eliminating wastage by preventing feed from falling out. The floor is made of 45mm polyethylene, that is UV and shock resistant, so no risk of corrosion, also reducing torque needed to slide across it. With age, it can get brittle so check for cracks and damage, also assess the clamping bolts that may become loose or go missing.

Stronger headstock

Compared to older designs, the LX104 headstock frame has been recently developed to make it stronger by using thicker steel, with extra gussets and an improved bale lead-in design to the front fence. The bottom of the headstock frame is narrower to allow the operator to spear the bale lower down, which ultimately offers an easier loading sequence. Improved high-mounted connection latches on both sides of the feeder take the load off the cradle, removing any load from the bale spears. The auto-latch spring is now fully encapsulated providing a

HUSTLER UNROLLA – TYPICAL USED PRICE GUIDE

more reliable, positive connection. The mounted Unrolla bale unrollers also benefit from the unique patented Hustler Snaplox auto connect/disconnect hands-free loading system, that saves time – and saves you having to tug on a rope to disconnect, and from twisting your back. Three-point linkage brackets are standard and now just bolt on, other options include Multi-Hitch (Euro-3PL), Manitou, Merlo, MX, Weidemann 3006, JCB Q-Fit and Bobcat, so check what is fitted. Also, asses the amount of play in the pins if a well-used example, these can be changed if required. Check the loading spikes to see if they have

been kept tight and are not loose in the holes.

Renowned driveline

The zinc-plated 5,000kg strong chains are claimed to be almost twice as strong as the competition. The greater wear surface on each roller increases chain life because they can’t stretch or snake. Fully enclosed chain and sprocket guides also claim to eliminate derailment. Servicing is excellent with just four grease nipples to maintain. Instead of bushes, Hustler uses long-lasting, fully sealed, self-aligning block bearings, with mounted outboard and cover to keep the debris clear. Check the bearings

The key to automatic hook-up, Hustler’s twin pin design. These pins will wear eventually. Assess for damage on the male and female hubs and look for play in the keyway that may occur.

The chains are completely zinc-coated, as are the slats and the gripping teeth –investigate wear in the joints and rollers as best you can, they can be changed if required. Ensure the teeth are all in place and bolts holding slats aren’t broken.

THINGSTOLOOKOUTFOR…

have been greased and for any excessive play, although these are relatively easy to change. The chain tensioners are built into the machine frame, should you ever need to adjust the pre-set chain tension.

Same as bulldozer blades

The LX104 has new 6-tooth HardLine sprockets made from high-tensile wear-plate Bisalloy 80 structural steel, the same material used in bulldozer blades, so they should last forever – but carefully check older

“Five extra feed bars on the latest model improve feeding aggression on tight and hard centre bales”

models here. With smaller diameter yet longer teeth, the 165mm sprockets should require less torque to drive the chains, giving more drive power. Being a fully enclosed design, it is virtually impossible for the chain to jump off the sprockets. Four 60mm long teeth are on each feed bars and are now 8mm thick to prevent bending or snagging of hay. They have also added five extra feed bars to the latest model to improve feeding

aggression on tight and hard centre bales and keep the chains running straighter. The section strength of bars has been increased to 40mm x 40mm x 4 mm, which are four to five times more resistant to torsion than angle-boxed type bars of the same size. These bars are bolted to the chain and can be replaced in a matter of minutes without breaking the

chain, if required – check condition of the bolts and bale teeth here.

In addition to the side bars, several other options are also available and help the machines feed almost anywhere including a side chute that extends the feed drop point and assists with feeding into troughs. The LM105T is available with a side elevator.

Above: Despite coming all the way from New Zealand, there is generally good stock of new, however due to the long warranty, second hand examples soon get snapped up!

The famous automatic locking pin –now a standard feature, this pin locks the carriage in place when lifted by the tines. Ensure its not bent and wear in the hole not to excessive that may lead to safety issues.