Cutting-Edge Rendering Technology

At West Coast Reduction, nothing is important to us. Because when there’s nothing left — that’s when we’ve done

collect food waste and by-products from food

like farms, restaurants and even supermarkets, transforming them into ingredients used in animal feed, renewable energy, and thousands of other products we use

orts contribute to a

and help us all live

Remove as much water as possible at the start of your rendering process. Less water in your cooker means less steam required - and therefore lower operating costs.

In the Haarslev Waste Heat Dewatering system, a coagulator and a press remove the majority of the water in your continuous dry rendering processes.

A straightforward but effective conversion or add-on module to any existing continuous dry rendering line. You get up to 40% reductions in your steam energy costs, because the WHD module uses waste heat to evaporate water.

A big added benefit will be extra throughput – without spending money on a bigger cooker.

Successful formulation with natural antioxidants demands a thorough understanding of how processing impacts the quality and stability of a rendered protein meal and fat. Selecting the right antioxidant at the right dosage level is key to achieving desired targets. That’s why Kemin provides a wide range of industry-leading natural antioxidant solutions, extensive product application expertise and thorough laboratory and technical support. We’ll partner with you to pick the best natural solution and ensure your product is protected every step of the way.

Learn more at www.kemin.com

North American Renderers

Montgomery St., Ste. 310, Alexandria, VA 22314

683-0155 Fax (571) 970-2279

www.nara.org

(ISSN 0090-8932) is

bimonthly

the auspices of the North American Renderers

by Clear Point Communications as a public service to the North American and global rendering industry. It is intended to provide a vehicle for the exchange of ideas and information pertaining to the

and associated industries.

is distributed

of charge to qualified individuals upon written

reserves the right to determine

Periodical postage paid for at Benbrook, TX, and additional mailing offices.

rights

P.O.

address

126041, Benbrook, TX

About a year ago, I was at the post office to rent a mailbox for Render. Hearing our conversation, the man behind me asked what the magazine was about, which was my first opportunity to explain what rendering is to a member of the general public. I don’t recall exactly what I told him — something along the lines of taking animal by-products and upcycling into products like pet food and biofuels.

While that covers the basics, there is so much more to rendering and I’ve been looking for a better elevator pitch ever since. What do you say when someone outside of the industry asks what rendering is? How do you convey the significant role rendering plays in the big picture of sustainability in about 60 seconds? Do you have different answers depending on whether the person you’re talking to is a regular consumer or a businessperson in another line of work?

If you are planning to attend the North American Renderers Association convention this month in California, I’d love to visit with you and hear your elevator pitch. Convention planners have set an exceptional agenda for the business portion of the meetings and there is no better place to network with renderers and our friends in allied businesses. The convention will be Oct. 24-28 and more details can be found on page 20. To register, visit www.convention.nara.org. See you then!

Sharla IshmaelRender is the only print publication to serve the international rendering industry.

your company is selling products or

targeting

market, you need to get in front

our readers.

The Inflation Reduction Act, formerly known as Build Back Better, delivers tax credits anew for renewable energy.

When most thought the game was over, Sen. Joe Manchin, D-W.Va., continued to play ball. Taking Washington by surprise, Manchin and Senate Majority Leader Chuck Schumer delivered an agreement on President Joe Biden’s signature Build Back Better proposal with some rebranding, a smaller price tag and a slew of clean energy tax breaks, renamed the Inflation Reduction Act.

“Build Back Better is dead, and instead we have the opportunity to make our country stronger by bringing Americans together,” Manchin announced, along with his support for the newly renamed legislation that is now law. “I will do everything I can to usher in a new era of compromise and common sense that will make America more energy secure, financially sound and a more united country for this generation and the next.”

The 755-page, $740 billion tax, climate and health care package was approved on a strictly partisan vote in the House and Senate by using an arcane budget process known as reconciliation. Reconciliation is a parliamentary process that allows the Senate to bypass filibuster rules requiring 60 votes and instead allows a simple majority vote to pass bills. In this case, the final vote was 51-50 with Vice President Kamala Harris casting the tiebreaker. Reconciliation bills cannot include policy changes but can only add or cut federal spending. For the Inflation Reduction Act, this meant several multibillion-dollar spending items for climate and clean energy tax incentives.

Chief among those incentives is an extension of the $1 per gallon biodiesel blenders credit, originally set to expire at the end of this year. The biodiesel credit is now good for two additional years, expiring at the end of 2024. That expiration, along with the remaining transportation fuel credits, will then automatically reset to a new clean fuel production credit named the 45(z) credit. The clean fuel production credit is authorized through 2027, yet oddly its value can be claimed through 2030.

Before then, the Treasury Department and the Internal Revenue Service must develop new guidance and rules for claiming the credit. That process will take at least a year or more and is complicated by the fact that the value of the credit will be determined by a carbon reduction scoring system.

Determining the value of the credit, like most tax items, will require arithmetic. To determine the amount, the fuel’s carbon intensity (CI) must be subtracted from 50 then divided by 50. For a fuel with a CI score of 45 the credit value is 10 cents per gallon. For fuel with a CI of 40, the value is 20 cents regardless of feedstock. This so-called, technology-neutral approach applies to all transportation fuels except renewable aviation fuel, which for the first time receives its own tax subsidy for the next two years, then receives its own credit value with a maximum limit of $1.75 per gallon.

For 2024 and 2025, a new sustainable aviation fuel credit is set at $1.25 with a 50% carbon reduction from petroleum jet fuel. For every percentage decrease beyond 50%, the credit increases by 1 cent, maxing out at $1.75 for a fuel that delivers

a 100% greenhouse gas (GHG) reduction from petroleum jet fuel.

William Shakespeare wrote, “What’s in a name? That which we call a rose by any other name would smell just as sweet.” For Build Back Better, a name change and a different focus in the end delivered a bill that 50 senators could support. For biofuels and clean energy tax breaks, the future smells just as sweet.

Months, even weeks, seem like an eternity as the political winds blow through the halls of Congress. A few months ago, most political analysts agreed a Republican sweep of the House was likely, if not inevitable, and that a GOP-controlled Senate wasn’t out of the question. Today, those assumptions are tempered, although the time remaining between now and Election Day leaves plenty of room for sentiment to change.

Republicans need only five seats to reclaim the House of Representatives majority, roughly three of which are expected to be easy targets due to redistricting. While this is just a slice of the expected Republican gains, it now looks like a critical insurance policy for a Republican majority in the next Congress. A combination of the Supreme Court’s Dobbs ruling reversing Roe v. Wade, declining gas prices, Trump-backed candidates seen as unable to win over moderates, and recent legislative action — such as the Inflation Reduction Act — have helped Democrats gain some ground with moderates and independents.

For the president’s party, strong headwinds persist mostly from high inflation, high crime rates and post COVID resentment. The consumer price index (CPI) rose 0.1% in August, after staying flat in July and food prices are up 13.5% over the past year.

The Senate sitting at an even 50/50 split once looked promising for Republican gains, but that opportunity appears to have narrowed. In Arizona, the race between incumbent Democrat Mark Kelly and Republican Blake Masters has moved from a toss-up rating to a

lean-Democratic rating — with the top GOP super PAC, Senate Leadership Fund, cancelling millions in planned advertising and directing the money elsewhere.

The four remaining toss up seats — Georgia, Nevada, Pennsylvania and Wisconsin — were carried by President Biden in 2020. Democratic voters are also expressing a higher level of interest in the upcoming election than previous forecasts suggested, with 66% saying they are highly motivated to vote in November, compared to Republicans’ 68%. That’s an increase of 17 points from March and eight points in May. With fewer members and a current split down the middle, the Senate outcome remains truly a toss up.

The Indo Pacific Economic Framework for Prosperity has been gaining speed and recognition across the Hill and within the trade community. Secretary of Commerce Gina Raimondo and U.S. Trade Representative Katherine Tai hosted counterparts from the 13 IPEF partner countries — representing over

40% of the global economy and 28% of global goods and services trade — at the first official in person ministerial meeting in Los Angeles, California. During the meeting, member countries discussed and reached a consensus on ministerial statements for each of the four IPEF pillars: trade, supply chain, clean economy and fair economy.

India grabbed headlines at the ministerial by standing out as the only country of the 14 present that declined to participate in the pact’s trade pillar.

As a formidable ag exporting competitor, and one that often comes into friction with the U.S. over tariff and nontariff barriers, this was a notable development. The agriculture section of the newly released trade pillar goals in IPEF stresses that countries will “avoid unjustified prohibitions or restrictions on food and agricultural exports.”

This stands in sharp contrast with India’s wide range of tariff and nontariff barriers on U.S. farm commodities, such as tree nuts, apples, dairy, rice, ethanol, distiller’s grains, poultry and pulses, as well as India’s problematic approach to approving genetically modified organisms. India still has not approved biotech corn used to make fuel ethanol and distiller’s grains. However, Tai gave a hopeful response to India’s exemption, stating that “India is not now in the trade pillar,” with particular emphasis on “now.”

In August, prompted by reports on the death of 600 pigs in Vietnam that had been vaccinated with the African Swine Fever vaccine, known as NAVET-ASFVAC, the Vietnamese government temporarily suspended use of the vaccine. The deaths are under investigation by the agriculture ministry. However, the U.S. Department of Agriculture, which developed

the vaccine that has been identified, said it cannot confirm it actually was the vaccine being distributed by NAVETCO. USDA’s Agriculture Research Service has partnered with NAVETCO on vaccine research and development for ASF for a couple of years. ARS is said to be awaiting further information from local officials on the situation.

Infectious-disease experts from 18 U.S. federal agencies and academic institutions met at Texas A&M University recently to discuss working together to combat the viruses, bacteria and other emerging pathogens that threaten the nation’s agricultural economy, food supply, wildlife and public health.

The workshop marked the first membership meeting of RAV3N — Research Alliance for Veterinary Science and Biodefense BSL-3 Network — a national network of biosafety level 3 labs engaged in biodefense research for infectious animal diseases. RAV3N receives funding support from U.S. Department of Agriculture. Texas A&M University’s Global Health Research Complex serves as the network’s headquarters.

“Our workshop focused primarily on determining how the federal and academic labs across the United States can cooperate to improve our ability to detect and respond to emerging pathogens,” GHRC Director Kurt Zuelke said. “We also considered how to improve the development of countermeasures that will help slow or stop the spread of these pathogens and the diseases they cause.”

RAV3N formed in 2020 during the COVID-19 pandemic, which delayed the group’s first meeting until this August. Representatives from all 18 members attended the three-day workshop.

Membership in RAV3N includes labs belonging to USDA and two of its agencies, the Animal and Plant Health

Inspection Service and the Agricultural Research Service: the USDA National Bio and Agro-Defense Facility in Kansas; the USDA-ARS National Animal Disease Center and the USDA APHIS National Veterinary Services Laboratories, both in Iowa; the USDA-APHIS Foreign Animal Disease Diagnostic Laboratory in Iowa and New York; the USDA-ARS Foreign Animal Disease Research Unit in New York; the USDA-APHIS National Wildlife Research Center in Colorado; and the USDA ARS Southeast Poultry Research Laboratory in Georgia.

Federal level membership also includes the U.S. Department of Homeland Security’s Plum Island Animal Disease Center in New York; the Center for Disease Control and Prevention’s Division of High Consequence Pathogens and

Pathology in Georgia; the U.S. Geological Survey’s National Wildlife Health Center in Wisconsin; and the National Institute of Allergy and Infectious Diseases’ Rocky Mountain Laboratories in Montana.

In addition to the GHRC at Texas A&M, academic membership includes the Galveston National Laboratory at the University of Texas Medical Branch; the Plant and Animal Agrosecurity Research Facility at The Ohio State University; the Laboratory for Infectious Disease Research at the University of Missouri; the Biosecurity Research Institute at Kansas State University; the Infectious Disease Research Center at Colorado State University; and the National Emerging Infectious Diseases Laboratory at Boston University. R

A Q&A with some leading manufacturers on the state of technology today and where they see it going in the future.

By Sharla IshmaelRendering may be an old industry, but the technology being adopted today, and likely in the future, is sophisticated and will require changes in perspective and processes from both management and employees — especially for attracting and retaining future workers. At least that’s what our panel of experts has to say in this virtual roundtable with leaders from companies that manufacture technology and equipment for renderers.

Meet the panel: Richard Weeks, executive manager with The Dupps Co.; Henning Haugaard, chief commercial officer, and Anders Svehag, innovation and engineering director, both with Haarslev; Jimmy Rios, president and chief operating officer with Orthman Manufacturing; Hans Nissen, president, and Brian Schoeberl, area sales manager, both with Oestergaard; and JR Onken of Onken Inc.

R: What is the most cutting-edge technology currently being employed by the rendering industry?

Weeks/Dupps: Real-time, near-infrared analysis (NIR) of rendered products has significantly raised the bar on how to control the quality of end products. NIR has been utilized as an industry standard for many years; however, time lags associated with samples and inconsistencies with sample procedures have historically been very challenging. Having the ability to achieve consistent sample procedures and real-time data has created a tremendous opportunity to optimize processes and profits.

Haugaard and Svehag/Haarslev: Rendering operations are changing on many different fronts — all at once. The key technological innovations we see include better control over key processes with the help of sensors that measure and monitor changing operating conditions, leading to fewer fluctuations and inconsistencies in product specs. Such capabilities also help achieve improved compliance with agreed standards involving quality, hygiene and environmental impacts.

Also, advanced process controls help reduce risk of human error. For example, Haarslev’s patented algorithmic CORE process controller provides greater consistency and higher yields as well as significantly reduces energy consumption. Energy reduction and energy recovery technologies that result in reduced carbon footprints and reductions in operating costs because of lower utilities bills will be important.

Advanced odor abatement systems that make processing plants more acceptable to nearby communities and also make the rendering company a better neighbor. This can transform the overall perceptions and, sometimes, the stigma associated with rendering operations. Another key is flash drying that ensures short retention times and leads to significantly higher-quality products featuring better digestibility with improved shelf life.

Rios/Orthman: In our own experience at Orthman, we use a 6K laser that we are cutting our parts with, which produces a higher-quality, cleaner product, partly due to accuracy and higher speed for more throughput. We then form our flights on

a state-of-the-art horizontal flight press, which also produces a tighter tolerance for higher quality and throughput. We are using Radan software on our press break that reduces layout time.

Nissen and Schoeberl/Oestergaard: We see a focus on high end product quality, combined with the lowest possible energy consumption. Cutting-edge technologies are processes with enzymatic treatment of raw materials to achieve a specific food or feed ingredient. For example, utilizing a slurry evaporator process with low-energy consumption for high-capacity plants. Also, feather processes with high digestibility in the feather meal.

In addition, converting conventional high-temperature cooking with mechanical dewatering and evaporation helps to save energy. With high energy prices and customer expectations for end products, waste heat utilization is key to reduce fuel consumption — for example slurry evaporators with waste heat recovery or, alternatively, wet rendering (which uses low temperatures with a waste heat evaporator).

The use of state-of-the-art metal detection on both raw materials and finished products is also cutting edge. Hygienic designs also make for easy cleaning. The industry is moving towards the use of “metal detection,” along with utilizing magnets throughout the process. Metal detection is a much more thorough process to identify and remove all of the various types of metals used in the processing plants, and not only for removing ferrous metals.

Automatization is critical to control processes and optimize yields, which can also be set up for preventive maintenance and easy troubleshooting as well as for safety reasons. Also, in-line monitors greatly assist in analyzing proteins, fat and moisture in real-time (NIR).

Onken: As manufacturers for the rendering industry, supplying leak-proof storage for cooking oil is key, so we use robotic welding and laser cutting to ensure our product is consistent and leak proof.

R: What types of next-level technology do you foresee being adopted in the near future? And further out, say in 10 to 20 years?

Weeks/Dupps: Automation and software enhancements have been and will continue to be important for next-level technology. However, the benefits of these technologies are driven by the data they receive. Therefore, the real focus will continue to be on sensor technologies, their ability to provide real-time data, and also on enhanced diagnostics for preventative maintenance. Remote access to this data via digital tools, such as tablets and smart phones will be equally important. Our friend, Chad Mullane (at JBS Foods), is fond of using a phrase that’s very appropriate and needs to become a mantra within the rendering industry: “What gets measured, gets managed.”

Haugaard and Svehag/Haarslev: Haarslev discussions with customers worldwide tend to highlight the following developments.

Predictive maintenance solutions that improve operating efficiency and reduce downtime are vital. Monitoring solutions will increasingly be incorporated into the control

systems for equipment, particularly when they provide direct connectivity to supplier.

Artificial intelligence (AI)/machine learning as well as advanced process control, automated processes and advanced robotics will reduce the overall need for manpower. Higherlevel or different skill levels will be required for future plants. There will also be increased interaction with suppliers, and those suppliers will have greater vested interests in their customers’ operations.

Transitioning away from so much steam use and a move toward greater use of renewable energy to run plants and ancillary equipment will be of greater importance in the future, along with recovery and reuse of energy from the cooking and thermal oxidation processes.

Furthermore, enzymatic processing is a new approach to rendering that will require completely new machinery configurations, control technologies and operator skills, and a new mindset about how to apply these resources and skills.

Rios/Orthman: We are looking at robotic welding to be the future.

Nissen and Schoeberl/Oestergaard: Enzymatic processes in which you can produce specific food and feed ingredients, as well as upgraded processes from which finished products can compete and be used in human consumption, will be more important in the future.

Environmental processing developments will also be adopted more in the future to further improve the air and water quality being discharged from the plants to the atmosphere and waterways. Plant and worker environments will continue to be improved to attract and retain quality staff. Competition for quality personnel will dictate that we continue to improve the plant’s working environment.

Computer operating systems are being utilized in all of the new plants, but we will need to work towards retrofitting the older facilities. Our customers are becoming more sophisticated and are beginning to see the benefits of the “real-time” data that can be collected and utilized in finished product traceability.

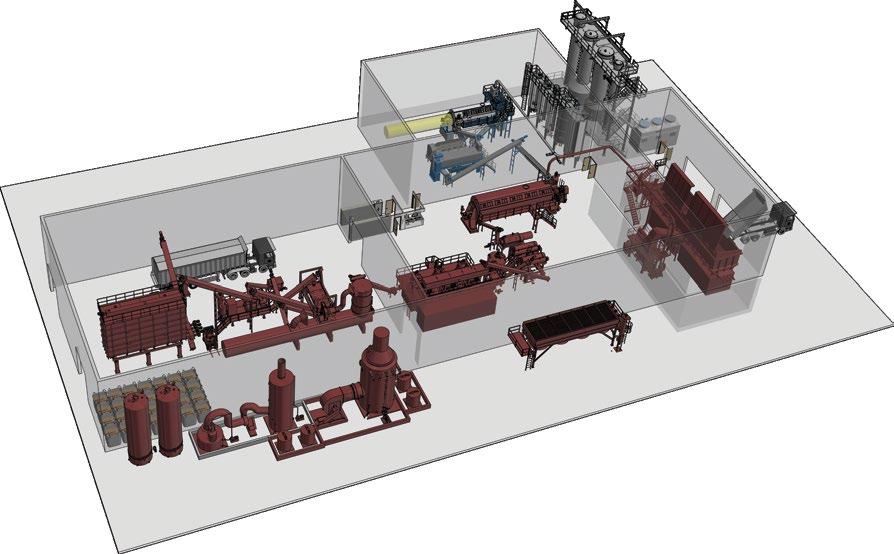

A simple but proven design in new plants is process segregation. The plant designs provide for separate rooms and air handling systems for the four main areas of the plant: raw material intake, processing (cooking or drying), the grinding room and finished product loadout.

Rendering Technology Continued from page 11

Onken: Our engineering team is currently in development of a robotic solution for transporting cooking oil from the restaurant to the outdoor cooking oil storage container.

R: How will this affect the products, the employees and the overall business at the plant level?

Weeks/Dupps: The hardest part of any business is the people component. Finding good people and then keeping them has been a challenge for many years and this problem has been further accelerated over the past several years. In order to attract and retain employees, we need to ensure they are provided with best in class digital tools and training.

Haugaard and Svehag/Haarslev: The effects Haarslev is currently encountering are many and widespread. For example, greater differentiation between raw materials and more focus on hygiene will make it easier to customize end-products to specific customer or operator needs and requirements. Also, effective raw material control is critical for generating better outputs with higher value. Better material flow through plants will be required to limit any possible cross-contamination.

The increasing technology level of rendering plants will result in a growing need for operators with a different mindset, new skill sets and greater flexibility. There’s also a big need for higher levels of ongoing collaboration and know-how sharing between customer and supplier in terms of training and operator learning enrichment.

Significant health, safety and environment (HSE) improvements will be crucial going forward. Improvements to employee welfare will be critical for successfully attracting the right kinds of workers to the plants of the future and better conditions for the workforce as well as surrounding communities.

Companies will be looking for opportunities to move further up the value chain, in order to reduce market vulnerability and improve their profit margins. Examples of the pursuit of valueadded products include growing interest in low phosphorous tallow and high-grade, high-quality pet food ingredients.

We anticipate greater end to end focus on limiting environmental impacts and improvements in environmental, social and governance (ESG) profiles help ensure greater longterm commercial viability for particular rendering operations.

Rios/Orthman: Robotic welding will produce a more consistent quality, more efficient, more reliable weldment, therefore producing shorter lead times, less downtime and repair.

Nissen and Schoeberl/Oestergaard: New technologies used in the future will lead to improved finished-product quality and less contamination, as well as cleaner and safer work environments, increased revenues, lower costs, improved employee retention and lower workman’s compensation costs.

Onken: A robotic grease caddy will provide a safer alternative for an employee of the restaurant who is risking injury while taking out the used cooking oil.

R: What are the limiting factors to renderers adopting cutting-edge technologies?

Weeks/Dupps: Product and process training has improved in recent years, but still has a long way to go with respect to the rendering industry. Digital training tools, such as 3D scanners, interactive product animations, virtual reality and augmented reality are providing a solid foundation for training that’s more in keeping with how current and future generations will learn and absorb product and process knowledge. Providing employees with first-class training needs to be a top priority for the rendering industry.

Haugaard and Svehag/Haarslev: Owners and operators usually prefer to stick with what they‘re familiar with, and as such, some may have an innovation-averse mindset and a reluctance to take on perceived risk. A “we have always done it this way” mentality, sticking with familiar processing and equipment setups, will probably result in companies getting left behind or even going out of business.

Continued on page 14

There is only limited familiarity with the big opportunities that advanced processing control provides. Furthermore, protein related technologies and markets are unfamiliar territory for most people in rendering operations. This means there is a big need to develop and educate the whole market via “thought leadership” initiatives, knowledge sharing, etc.

Rios/Orthman: Cost is always a limiting factor. Some of this cutting-edge technology has a long return on investment, but we are in it for the long haul. Time is also an issue; it takes time and resources to investigate and implement.

Nissen and Schoeberl/Oestergaard:

Having a very fresh and noncontaminated raw material coming to your plant is a

limiting factor. Rendering facilities will possibly move closer to the processing plants to achieve this. In these days, with a demand for skilled workers, the renderer needs to ensure they can compete for workers with modern processes, training and safety. Wages will need to continue to improve to attract quality, trained staff to fill ever-changing jobs with more and more technical training.

With Camlin Fine Sciences you have options. You’ll get the shelf life performance you need with our NaSure® and Xtendra® antioxidant solutions, backed by our complete customer application testing.

camlinfs.com

Haugaard and Svehag/Haarslev: There are many different avenues for payoffs from better technology. In our experience, these include greater processing efficiency, less downtime, less waste and reduced energy consumption, all of which provide significant financial benefits for rendering operations. Greater operational consistency and better quality management provide greater revenue from end products that have higher value because they are better tailored to customers’ exact requirements.

Reduced energy consumption results in lower operating costs, more acceptable carbon profiles and compliance with ESG targets. Better ESG compliance leads to more attractive investment profiles, financial credit ratings, etc. Many investors, financial partners, customers, and suppliers now consider ESG profiles an integrated part of the risk profile. Effective ESG reporting is increasingly seen as a prerequisite for doing business with any particular rendering operation.

Rios/Orthman: For us, it is about increasing throughput with a smaller footprint (efficiencies), allowing technology to produce more while meeting or exceeding our standard of quality.

Much higher prices for feed and food ingredients compared to traditional meat and bone meal means you can pay for more sophisticated plants, which in turn means energy savings, optimized yields, improved operation and less down time. More finite control over operating inputs moving forward will lead to lower operating costs and lower human resource costs, with potentially improved employee retention as well.

Onken: By advancing technology, we are able to become more efficient in our manufacturing, which will result in lower costs.

R: Do you have any other thoughts on the topic you’d like to share?

Weeks/Dupps: Educating employees with respect to products and processes is certainly important; however, equally important is the need for inspection and maintenance services. It can be very difficult for rendering companies to provide these services in house. Thus, we’ve seen and will continue to see, a trend to outsource these services. Vendors to the rendering industry need to be prepared to step up to the plate in order to staff and provide these critical services.

Haugaard and Svehag/Haarslev: There are many fundamental rethinks in the pipeline that we consider will have substantial end-to-end impacts on our industry. We have identified a clear need for reconsideration of vulnerable,

high carbon, global supply chains. Such rethinking will include a need for more local plants that can react faster to changing needs, with significantly reduced logistical footprints that benefit the ESG profiles for global rendering operations.

Such changes will also mean future plants will no longer reflect the one size fits all business model that favors standardization. There will be an accelerating focus on more responsive, customizable processes that combine attention to variations in the raw material and differentiated customer or end-user requirements. This will probably be accompanied by moves towards optimization of end products into “building blocks” that provide customers with revenue boosting opportunities for new kinds of products, processes and materials.

There will also be greater cross fertilization of ideas and technologies from other disciplines (including biotech, protein sequencing, pharma, chemical/ genetic engineering, etc.). This will, in turn, open up new kinds of products, processes, capabilities and markets.

Rios/Orthman: In the not so distant future, we will be losing a lot of manual equipment operators with tribal knowledge expertise (baby boomers).

The millennials who will be taking over this great country will lean heavily on technology, so let’s start now to be on the forefront.

We will need to develop relationships with local community colleges and trade schools to develop a continuous pipeline of quality, trained candidates. As an industry, we may need to begin formally training employees in specific disciplines to fulfill the next generation of operations and mechanic personnel.

Onken: At Onken, we are always looking for the next opportunity to make advances in our technology. In the past year, we have added a new laser table as well as an additional robot for welding our grease tanks and other products. R

Birdseye view of the enzymatic process, photo courtesy of Oestergaard

Micro-Solve® is NOT an enzyme, a bacteria or a quick fix emulsifier. Micro-Solve® attacks grease and odor at the root and aids in phase oil separation, making hard grease loose and soluble. This releases bound oxygen and trapped micronutrients that become food eaten by the microorganisms that already live in the system. This increases the facultative microorganism populations and anaerobic and aerobic populations. All these benefits accelerate the bioremediation process at point of application and downstream and will not re-solidify. This process sends the water resource recovery facility more microorganisms with food that is in a better state for bioremediation. With regular applications, Micro-Solve® eliminates grease build-up in the collection and treatment system and lowers H2S almost completely. Micro-Solve® is 100% biodegradable and will save you money!

By Dr. Louis Russel, retired, APC; Dr. David Meeker, senior vice president of scientific services, North American Renderers Association; and Leah Wilkinson, vice president of public policy and education, American Feed Industry Association

Montezuma’s Revenge.

Travelers’ diarrhea. Don’t drink the water.

Who has not experienced an upset digestive system after eating or drinking something questionable? We all recognize that if food or water becomes contaminated with a pathogen, we can get sick after consuming it. It is the same for livestock. If the feed we deliver to the pig barn is contaminated with a virus, pigs could get sick after eating it.

Over the past few years, there has been a lot of research documenting the potential for viruses to survive on different feed ingredients for extended periods of time. In addition, recent research demonstrates that if a contaminated feed ingredient is brought into a feed mill, dust from that ingredient sticks around and is likely to contaminate the feed mill itself, potentially contaminating even more feed.

As a result, many in the industry were left wondering if potentially contaminated feed or feed ingredients represent a risk factor contributing to vast disease spread within the swine industry. Quantifying the actual risk in modern swine production systems is a critical next step in understanding how to mitigate the actual risk, and we needed to know the answer.

To quantify and prioritize the extent to which contaminated feed ingredients contribute to disease outbreaks in modern swine production systems, a group of industry organizations, including the Institute for Feed Education and Research, North American Renderers Association and North American Spray Dried Blood and Plasma Producers, jointly funded a research project at North Carolina State University to answer this question.

Drs. Gustavo Machado and Jason Ardila Galvis, NCSU College of Veterinary Medicine, have been developing a mathematical algorithm that is able to analyze multiple risk

factors and predict when a pig farm is most likely to break with a disease. The industry organizations approached Dr. Machado and asked: Could the risk factors included in the model be expanded to include porcine origin feed ingredients (e.g., meat and bone meal, choice white grease and spray-dried porcine plasma) and feed delivery? Further, could the algorithm estimate the relative risk of each factor?

After some discussion, the experts concluded the model could be expanded to include these additional risk factors and, since the model identified the risk factor that a particular disease break would be attributed to, the relative risk of each factor could also be estimated. The research team collected detailed data for approximately one year, including weekly disease status of porcine reproductive and respiratory syndrome virus (PRRSV) and porcine epidemic diarrhea virus (PEDv) of individual pig farms within a large, pig dense region.

After collecting detailed information, the data was subjected to the algorithm, and the model predicted the most likely risk factor responsible for each disease outbreak. On average, 94% of the disease outbreaks were attributed to four risk factors.

• Local transmission, farm to farm proximity.

• Pig movement, between farms.

• Vehicles, pig movement between farms.

• Vehicles, feed delivery.

Inclusion of porcine origin feed ingredients were not among the high-risk events linked to the spread of PRRSV or PEDv.

It is very important within all steps of the feed chain — beginning with ingredients, including transportation, milling, feed manufacturing and delivery — that sites of potential contamination are identified and procedures that mitigate risks are implemented. However, in the modern swine production system studied in this research trial, porcineorigin feed ingredients were not identified as a big leg of the stool contributing to disease outbreaks (PRRSV or PEDv). Biosecurity protocols in place protected these ingredients from contamination.

This data should be kept in mind when designing biosecurity protocols, which should be focused on mitigating the risks attributed to 94% of disease spread. The data highlights that because of regular feed deliveries to pig farms, feed delivery trucks represent a risk of spreading virus throughout the swine production system. It is also important to recognize that this data represents the risks associated with a particular system, reflecting a particular set of biosecurity practices. The data should not be extrapolated to all systems, which may include a different set of biosecurity practices.

Feed delivery is a necessary part of swine production. Therefore, future research should be conducted as to where and how feed trucks become infected and to help identify specific biosecurity practices to mitigate these risks R

For more information on the study, visit news.ncsu. edu/2022/03/vehicles-prrsv-transmission/.

Reprinted from the American Feed Industry Association’s Feed Bites.

Renderers and those in allied industries will enjoy the natural beauty of the Pacific coast at the 89th annual convention of the North American Renderers Association at the Ritz Carlton Laguna Niguel in Dana Point, California, Oct. 24-28. In addition to an exceptional agenda of educational and networking opportunities, attendees and guests have their choice of unique tours and activities.

On the business side, amid committee meetings and industry issue forums, special speakers have been invited, including Jim Wiesemeyer with the American Sugar Alliance, who will speak on the 2022 mid-term elections, the farm bill, future agricultural policies, regulations and trade trends during the opening general session. Attendees will also be treated to an engaging presentation on how to be more effective at making meaningful professional and personal connections by Mark Scharenbroich of Worldwide Speakers Group during the welcome luncheon.

Other expected speakers include Kevin Good with CattleFax and his outlook on U.S. livestock and protein markets, and Randy Russell of the Russell Group, which is NARA’s lobbying partner in Washington, D.C.

AC Corporation (336) 273-4472 www.accorporation.com

AC Corporation provides process condensing and air scrubbing equipment from a small component sale to a turnkey complete plant installation.

Alfa Laval Inc. (866) 253 2528 www.alfalaval.com

Alfa Laval is a long-established, process equipment company that has equipment installed within industry processes by supplying pumps, valves, separators, decanters, evaporators, membrane systems, wastewater treatment equipment and plants.

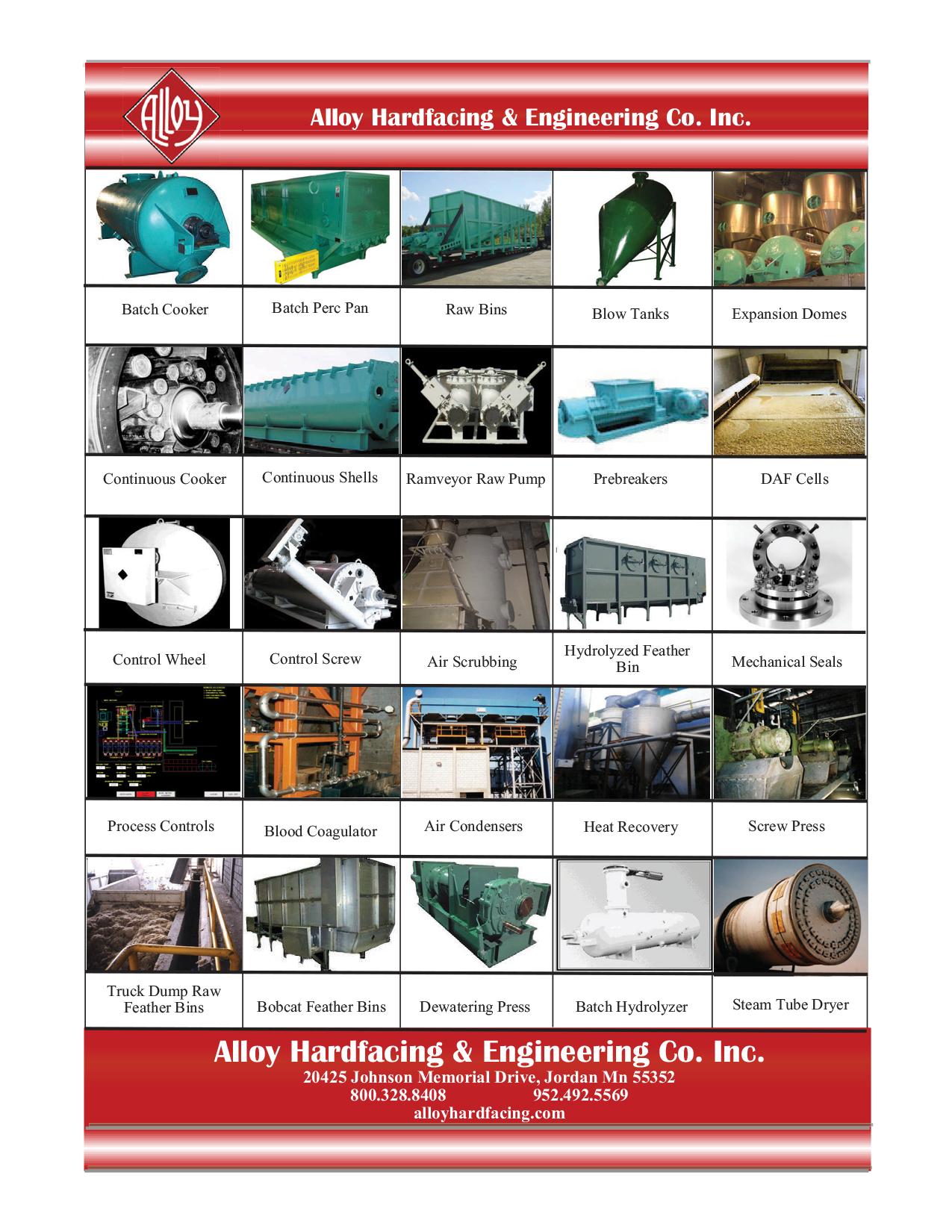

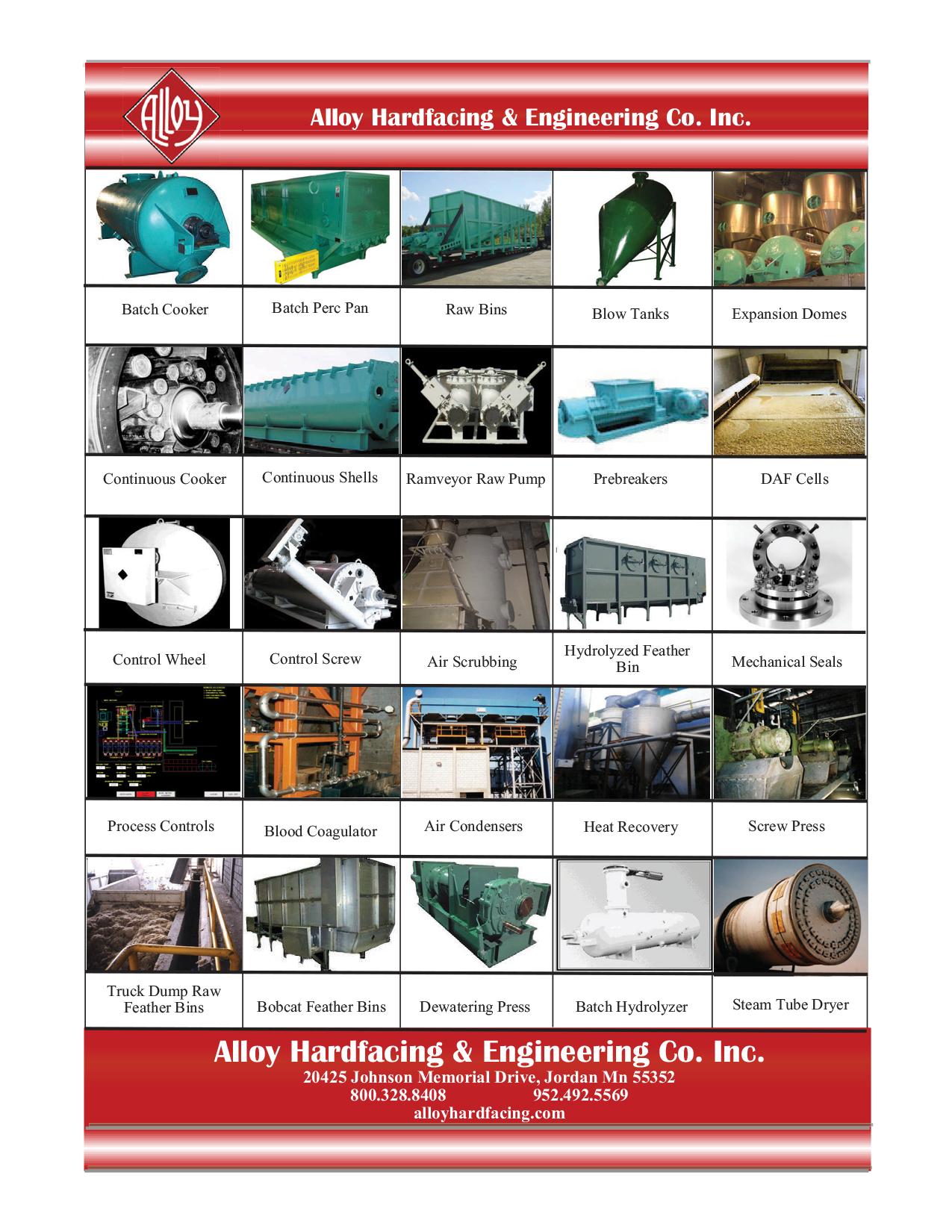

Alloy Hardfacing & Engineering Co. Inc. (800) 328-8408 www.alloyhardfacing.com

Alloy offers a complete line of batch, continuous, feather rendering equipment, and used cooking oil equipment and services — from raw material receipt and grinding, to feather dewatering to cooking, pressing, fat purification, meal grinding and finish product storage. Other services include air pollution control, condensing and heat recovery, and wastewater systems. Engineering services include, plant layouts, appraisals, fire evaluations, ROI calculations, thickness testing and ASME-related work.

See ad on page 16.

This is a notable year for the Fats and Protein Research Foundation, which will hold the annual Innovate Conference, with speakers including: Dr. Dominique P. Bureau of the University of Guelph, Dr. Craig Coon of Four Rivers Kennel and Dr. Rhett C. Smith of Clemson University. There will also be an FPRF 60th anniversary reception on Tuesday evening to celebrate the foundation’s longtime work funding research to enhance usage and development of new applications for rendered animal products that add value to rendering, associated industries and customers.

Optional tours and activities include the annual golf tournament, handbag designing, deep sea fishing, sailing, guess the wine, and picking lipstick shades. There is also a game day planned for Friday afternoon and a visit to the Canine Companions Training Center on Tuesday. Registration is still available at convention.nara.org.

Registered participants and guests will also get to meet valuable industry partners at the Tabletop Exhibit and Reception on Thursday evening. These are companies that have generously chosen to sponsor NARA’s convention and their latest innovations will be on display. The following is an alphabetical guide to this year’s convention sponsors and exhibitors who responded to the invitation by press time.

(844) AES-ALLY (844-237-2559) ally energy.com

AES designs and implements energy saving and RNG projects and programs for our national client base, with over 40 energy professionals and offices in Kansas City, KS, Denver, CO, Loveland, CO and Grand Junction, CO. In the oil and gas sector, our design and engineering team has over 175 years of combined experience consisting of electrical, chemical, mechanical, and civil engineers, master electricians, CEMs, CEPs, CDSMs, and BEPs.

Ameri-Pac (800) 373-6151 wilburellisnutrition.com

Ameri Pac, a brand of Wilbur Ellis, has 30 years of manufacturing expertise and a strong industry reputation for providing products with integrity and quality service. Ameri-Pac developed two high-performance lines of customized antioxidants that have become leading suppliers to the rendering industry. Oxy-Gon is a natural antioxidant while Oxy-Block is the synthetic antioxidant line. Both products are used for the preservation of animal fats, meals, and other materials subject to oxidation.

ANCO (336) 855-7800 ancoeas.com

Rendering equipment and solutions. We do what we do, to help you do what you do… without the B.S. www.WelcomeToTheNextChapter.com.

ad

19.

Anderson Chemical Co.

(320) 693-2477

www.accomn.com

Anderson Chemical was established in 1911 as a family-owned business. We develop and maintain water management programs for process water, RO, boilers, wastewater, filtration, scrubber treatment along with a cleaning and sanitation division.

(816) 505-9900

andritz.com

Andritz Separation is the world’s leading separation specialist, with the deepest knowledge, broadest technical resources and most comprehensive service solutions. For more than 150 years, we have helped our customers respond to the world’s environmental, energy resource, health and nutrition challenges by leveraging our extensive knowledge to create, develop, implement and service innovative separation solutions. By solving these fundamental challenges, we create lasting value and drive growth across every industry we serve.

Anguil Environmental Systems Inc. (414) 365-6400 anguil.com

Anguil provides highly engineered, environmental equipment and service solutions that help solve complex industrial air and water challenges across the globe. From thermal and catalytic oxidizers for air pollution and odor control applications to custom integrated systems for wastewater treatment, Anguil is committed to protecting the environment with unmatched engineering, innovative equipment, guaranteed compliance and reliable service.

Anitox (678) 376-1055

www.anitox.com

Delivering clean feed is a complex challenge. Each feed producer, each mill and even each ration type, has unique requirements and constraints. At Anitox, we have more than 40 years expertise tracking contamination sources, sampling feeds and raw materials, choosing chemistry and application rates, and installing and maintaining safe, efficient application technology. Our team works in partnership with the world’s feed producers to deliver complete clean feed programs that meet specific needs.

(855) 422-5370

www.bakercommodities.com

Baker Commodities Inc., a leading provider of rendering and grease removal services since 1937, is a completely sustainable company. Baker recycles animal by-products and used cooking oil into valuable products used to feed livestock, power vehicles and act as a base for everyday items such as high protein ingredients for poultry feed and pet food, tallow, a valuable ingredient in soaps, paints, cosmetics and more. Baker has a network of more than 21 facilities across the U.S.

See ad on Back Cover.

BHT ReSources

(800) 990-5638

www.bhtonline.com

Resource, from the latin “resurgere,” is a verb meaning to raise again or to restore. Birmingham Hide & Tallow Co. Inc. has always had a simple business philosophy: Take care of your customers and the rest will take care of itself. Now operating as BHT ReSources, the company will remain a trusted resource for its customers as they “resurgere” animal by-products and used cooking oils into valuable commodities, all in their ever-expanding service area.

Brown Industrial Inc. (937) 693-3838 www.brownindustrial.com

Brown Industrial is a third generation family owned business. Their WaBo line is a leader in mobile aluminum, steel and 409 stainless steel rendering equipment offering container grease, bucket, vacuum barrel, vacuum, combination, deadstock and rendering end dump units. Brown Industrial is continuously improving and expanding its product line. Its newly expanded facility has allowed the company to grow to meet industry needs. Brown thanks the rendering industry for its many years of patronage and looks forward to many more.

See ad on page 25.

Brown’s Milling Supply (402) 721-7899 www.brownssupply.com

With more than 150 customers in 30 states and three countries, we believe that our service, competitive pricing and quick and reliable delivery schedules position Brown’s Milling & Industrial Supply as the best choice for your supply vendor. As the marketplace changes, so does Nebraska Milling Supply. But Brown’s continues to remain dedicated to your needs, dedicated to giving you the best products available at the most competitive pricing in the industry.

CALDIC USA (847) 468-0001 www.caldic.com/en us Caldic serves as a one-stop shop meeting all the needs of the North American Pet Food Industry — sourcing, R&D, warehousing and distribution — not to mention a huge tool kit brimming with functional ingredients! We also offer technical formulation and processing support, shelf-life and analytical testing, and comprehensive regulatory documentation.

Calpine Energy Solutions LLC (310) 686-5702 www.calpinesolutions.com

There are many forces impacting natural gas and electricity markets. Regulatory changes, supply/demand balance, weather shocks, geopolitical influences, sustainability initiatives, environmental legislation, innovation and overall macroeconomic conditions will all influence the volatility, overall price movement and liquidity of energy markets. Let Calpine Energy Solutions ensure your company has the gas and power needed for operations. It can develop a successful portfolio risk management program that is measured and quantified.

Renderers Convention Continued from page 21

Camlin Fine Sciences (844) 808-2063 www.camlinfs.com/cfsna

Camlin Fine Sciences (CFS) is the leading integrated manufacturer of the most preferred traditional antioxidants available. We focus on four key businesses — shelf-life solutions, aroma ingredients, health and wellness, and performance chemicals. Besides high-quality traditional antioxidants for the food, petfood, and animal nutrition industry, we have a product basket catering to a wide range of industries. Over the past three decades, we have earned customer loyalty with our market knowledge and expertise, product offering and customer service.

See ad on page 14.

Centrisys CNP (262) 425-9933 www.centrisys cnp.com

Centrisys Corporation is a USA manufacturer of decanter centrifuges for sludge dewatering and thickening. Since 1987, Centrisys has been a leader in decanter centrifuge service and repair for all brands of centrifuges on the market today. The Centrisys/CNP resource intensification portfolio is both an integrated process solution and/or an individual equipment approach to sludge and biosolids handling; leveraging proven technologies to provide viable alternatives to conventional treatment processes.

CentriTEK (866) 769-3900 centritek.com

CentriTEK is a proud American company that specializes in the sales and service of horizontal decanter and tricanter centrifuges for rendering, grease capture and DAF/ wastewater sludge processing.

See ad on page 37.

Chem-Aqua Inc. (866) 209-3373 www.chemaqua.com

With nearly 100 years of experience in the chemical and water treatment industry, Chem-Aqua has the knowledge and experience to meet your plant’s unique needs. The company has an in depth understanding of the issues its customers face and are dedicated to providing quality solutions. Chem-Aqua’s full line of customized products, developed especially for the rendering industry, allow the company to provide the best in water treatment chemicals, equipment, technology, and services to meet the industry’s every need.

Chemol Company (800) 849-3050 www.chemol.com

Chemol is a leading manufacturer of oleochemicals made from natural fats and oils. These eco-friendly derivatives serve a variety of markets including paper packaging, metal working, agriculture, personal care and plastics.

Cherokee Chemical Inc. (C.C.I.)

(800) 767-9112

ccichemical.com

C.C.I. Chemical is a rapidly growing, privately held industrial chemical supplier. Since 1957, C.C.I. has provided custom-blended chemical solutions for applications ranging from wastewater treatment to water treatment chemical programs for boilers, cooling towers, water loops and closed loops to proprietary cleaners used in applications ranging from warehouse floors to fleet vehicles. We feature over 150 USDA approved cleaning formulas for the foods industry and a complete line of process chemicals for the production of printed circuit boards.

Darling Ingredients Inc. (800) 800-4841 www.darlingii.com

Darling Ingredients Inc. continues to expand its United States presence in low-carbon biofuel production with its expansion at the Diamond Green Diesel facility in Norco, Louisiana, increasing annual capacity to 690 million gallons of renewable diesel. By converting animal fats and used cooking oil into high quality renewable diesel, Darling is meeting the global demand for low carbon biofuels.

Eastman Animal Nutrition (612) 214-3266 www.eastman.com/Markets/Animal-Nutrition

Founded in 1920, Tennessee-based Eastman is a global specialty materials company that produces a broad range of products found in items people use every day. With the purpose of enhancing feed/food-safety in a material way, Eastman works with customers to deliver innovative products and solutions while maintaining a commitment to safety and sustainability. To learn more, contact the Eastman animal nutrition team.

Flottweg (859) 448-2300 www.flottweg.com

Flottweg Separation Technology Inc., based in Germany and Independence, Kentucky, is a manufacturer of centrifuges, belt presses and processing systems. We have more than 60 years’ experience building mechanical solid-liquid separation equipment. Flottweg’s continuous processing centrifuges that are utilized for two (solid/liquid) and three (solid/liquid/liquid) phase separation applications in many industries.

FoodChain ID Testing (703) 222-8700 www.foodchainid.com/testing

For more than two decades, FoodChain ID has been at the vanguard of the New Food industry, providing expertise worldwide to navigate the requirements of an increasingly regulated food economy and technical services to support the demand for clean label standards.

Food Safety Net Services (FSNS) (888) 525-9788 fsns.com

Food Safety Net Services (FSNS), a Certified Group company, offers an industry-leading network of 30 ISO/IEC-17025 accredited testing laboratories across North America, and has been a trusted partner in the food safety industry for decades. FSNS provides microbiological and chemical analyses of all food matrices and environmental samples, regulatory consulting and a comprehensive educational program. Additional services include extensive research and development and an industry leading certification and audit program.

FOSS +45 7010 3370 www.fossanalystics.com

FOSS offers analytical instrumentation for quality control of critical parameters within the agricultural, food, feed and rendering industry.

G.A. Wintzer & Son Co. (800) 331-1801 www.gawintzer.com

G.A. Wintzer & Son Co. has been one of the “original recyclers” since 1848. Today, the company operates a modern fleet of trucks throughout a five-state region. These trucks run regularly scheduled routes picking up food scraps and used cooking oils. All collected materials are processed and converted into animal and pet feed ingredients, as well as biofuels. Finished products are then sold and shipped to pet care companies and animal feed suppliers in the U.S. and abroad.

Gavilon Ingredients LLC (888) 428-8723 www.gavilon.com

For over 20 years, many of the largest animal foods manufacturers and regional producers around the world have relied on Gavilon Ingredients’ team of experts to provide a reliable source of animal nutrition, including animal feed and ingredients for beef cattle, dairy cattle, swine, poultry, aquaculture and pet food. We are your animal nutrition experts. Gavilon Ingredients has one of the most comprehensive ingredient networks in the marketplace and a team of dedicated experts you can count on.

GEA North America (844) 432-2329 www.gea.com/unitedstates

GEA manufactures and markets disk and decanter centrifuges for use in processing animal by products, including fish. They are used in wet and dry rendering as well as blood meal recovery.

Genesis III Inc. (815) 537-7900 www.g3hammers.com

Genesis III supplies hammer mill components that are “Built for The Grind.” Over the past 15 years, the company has redefined the industry with significant market innovations,

including its proprietary Duraweld hardfacing and patented forged hammers. Genesis will work to provide the best solution for specific applications and products that deliver, backed by a guarantee you can count on.

G Tech (713) 503-4546 www.gtechus.com

G Tech is a provider of new and remanufactured decanting and vertical disc centrifuges and it services and repairs most brands of centrifuges used in the rendering industries.

Haarslev Inc. (785) 527-5641 haarslev.com

Haarslev Industries is a leading supplier of processing solutions for recovering oils, proteins, minerals and other high value coproducts. They help customers raise the bar on processing efficiency and end-product value, with upgrade and services that enable companies to boost yields, improve output quality and reduce operating costs. Haarslev is a global company with manufacturing facilities in Denmark, the United States, Spain, Brazil and China, with over 1,100 employees worldwide, and sales representatives in 17 countries.

See ad on page 1.

Hychem Inc. (800) 327-2998 hychem.com

Hychem’s product line includes a complete and comprehensive portfolio of polymers and specialty chemicals for applications in industrial wastewater treatment. These include coagulant aids, single polymer programs for superior solids capture and turbidity improvement as well as polymers for liquid-solids separation. Hychem employs a staff of experienced application consultants and engineers who determine the most effective chemical treatment program and application technique for every customer application.

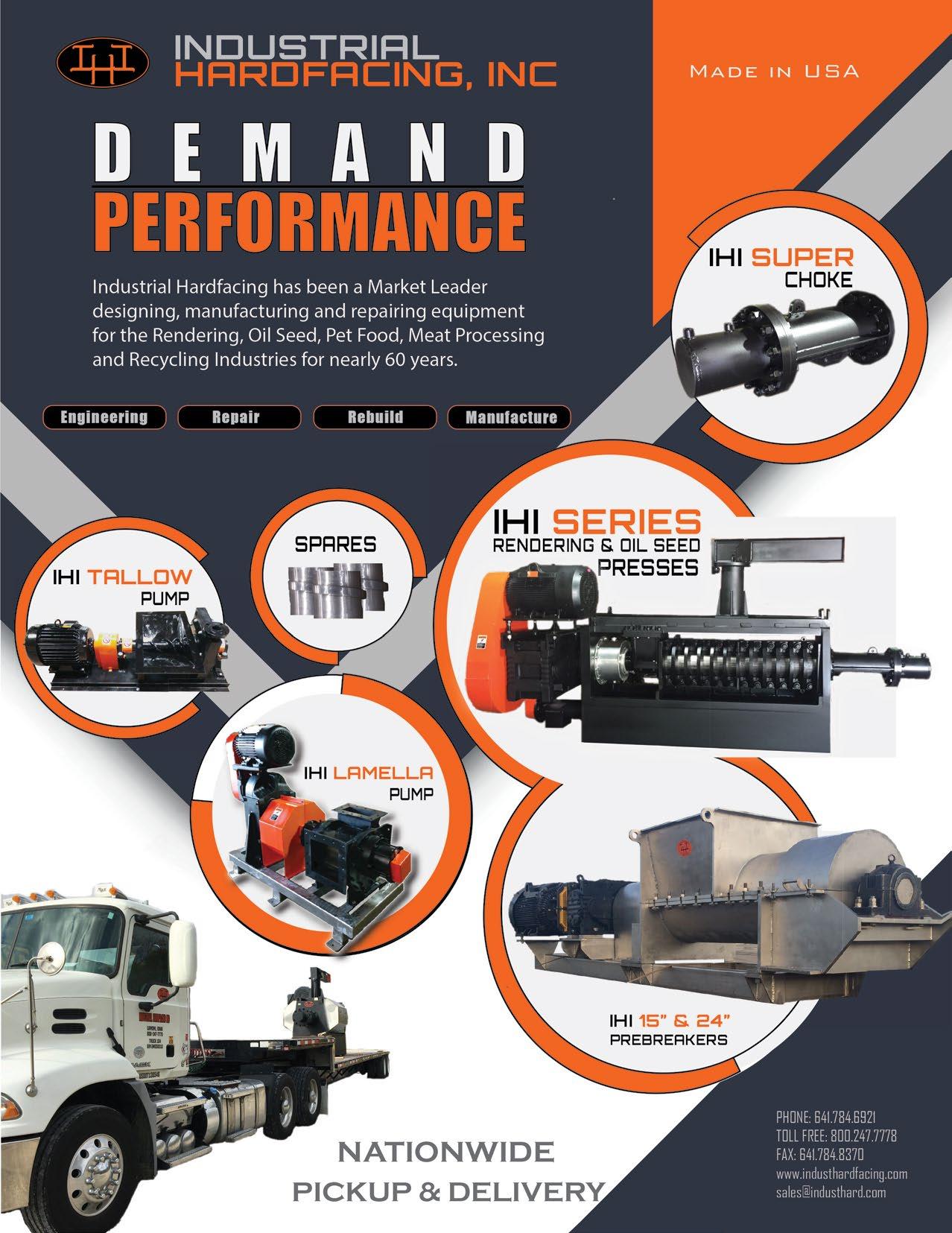

Industrial Hardfacing Inc (IHI) (800) 247-7778 www.industrialhardfacing.com

Industrial Hardfacing has been a market leader designing, manufacturing and repairing equipment for the rendering, oil seed, pet food, meat processing and recycling industries for over 60 years.

See ad on page 33.

International Feed (952) 249-9818 www.internationalfeed.com

International Feed is a pioneer in the U.S. containerized export space and has decades of experience providing our customers industry best export service across a broad spectrum of commodities. Our success is in the promotion and development of new markets, which allows our rendering partners to maximize coproduct values.

Renderers Convention Continued from page 24

J.B. Hunt Ag Services

(800) 452-4868 www.jbhunt.com

J.B. Hunt Transport, one of the largest transportation logistics companies in North America, provides safe and reliable transportation services to a diverse group of customers throughout the U.S., Canada and Mexico. J.B. Hunt’s Dedicated Contract Services® specializes in the design, development and execution of supply chain solutions that support virtually any transportation network. Our customers’ dedicated designs are customized with guaranteed capacity, industry leading service levels, optimum efficiency, partner-to-partner transparency and dynamic cost savings management.

JBS USA/Pilgrim’s (970) 506-8000 jbsfoodsgroup.com

JBS USA is a leading processor of beef, pork and lamb in the U.S., and beef in Canada and the largest cattle feeder in the world. A majority shareholder of Pilgrim’s Pride Corporation, JBS USA represents the North American arm of JBS S.A., the world’s leading animal protein processor and enjoys a strategic relationship with JBS Australia, the largest processor of beef and lamb and one of the largest livestock feeders in Australia.

(800) 635-1431 www.jenkinscentrifuge.com

Jenkins Centrifuge is a family-owned centrifuge rebuilder and manufacturer in business for over 50 years. Our whole purpose is to provide the renderers and meat packers a place to go to keep their plants running with 100% guaranteed promise to do repairs the right way with a competitive price.

Kemin (515) 559-5100 www.kemin.com/rendering

Leading pet food manufacturers, renderers and ingredient suppliers recognize that Kemin is Assurance , delivering specialized expertise, superior products and unrivaled support at every step of the pet food and rendering value chain — from oxidation control and food safety to palatability and nutrition — with a dedicated team of technical experts, application engineers and scientists.

See ad on page 2.

Laidig Systems Inc. (574) 256-0204 www.laidig.com

Laidig Systems Inc. engineers and manufactures automated, large-capacity storage and reclaim systems for non-flowing and semi-flowing materials, such as meat, bone, blood, feather and poultry meal.

MAC Trailer Enterprises (800) 795-8454 www.mactrailer.com

Almost 30 years ago, Michael A. Conny started a one man operation, repairing wrecked trailers in a single-bay garage. Since then, MAC Trailer has grown to be the nation’s foremost manufacturer of dumps, flatbeds, drop-decks, transfers, dry bulk pneumatic tanks, straight truck bodies and liquid tank trailers. The MAC Trailer Enterprise now encompasses 13 facilities totaling over 1 million square feet, spread across eight states, serving both national and international markets.

Mahoney Environmental Solutions LLC (800) 892.9392 www.mahoneyes.com

For over 65 years, Mahoney Environmental has helped foodservice companies turn used cooking oil and other waste products into useful products. We control the entire recycling process — from equipment set-up, to collection, to processing, to finished product so we can capture more value from used oils and pass that added value on to you. Mahoney creates value for restaurant operators and the environment.

MATERIA Hnos. S.A.C.I.F. +54 223 4993000 www.materiaoleochemicals.com

MATERIA Hnos. is among the world leaders in the production of oleochemicals and derivatives reaching high levels of quality, with facilities and equipment for various processes that meet international quality and safety standards. The application of our products in modern industry is of great diversity, cosmetics, soaps, pharmacy, food, paints, plastics and rubbers. Our oleochemicals have earned a place in such competitive markets as the U.S., Canada, Japan, China, the European Community and all of Latin America.

Michelli Weighing & Measurement (504) 733-9822 www.Michelli.com

Michelli Weighing & Measurement provides sales, service and ISO 17025 accredited calibration of measurement equipment, ranging from high-precision instruments to heavycapacity scales. With 24 locations in 10 states, top-quality manufacturer B-TEK Scales, a full team of product specialists and service experts, Michelli is your partner for weighing and measurement. We show the world what measurement can do.

MP Biomedicals (800) 854-0530 www.mpbio.com

SafTest equipment and kits provide rapid testing of the quality and stability of foods and for key parameters of quality before, during and after processing. Interest areas include analytical, food structure and functionality, forum health and nutrition, industrial oil products, lipid oxidation and quality.

National Beef Packing Company LLC (800) 449-2333 www.nationalbeef.com

National Beef Packing Company LLC, based in Kansas City, Missouri, is a premier beef company that has built relationships with America’s leading ranchers and farmers. The company processes and markets a comprehensive line of fresh beef, consumer-ready products, and beef by-products. National Beef employs over 8,000 individuals across its production plants and office locations, with facilities in Dodge City, Liberal, and Kansas City, Kansas; St Joseph, Missouri; Moultrie, Georgia; and Hummel’s Wharf, Pennsylvania.

Oestergaard Inc. (913) 754-8108 www.oestergaardus.com

Oestergaard is a global family owned company headquartered in Denmark with over 40 years’ experience in designing and manufacturing energy- and time-efficient equipment for the meat rendering and fish processing industry. We supply North America with state-of-the-art solutions from our 60,000-square-foot facility based near Kansas City, which houses a rebuilding and manufacturing workshop, a spare parts warehouse and a sales and engineering office.

See ad on page 3.

Onken Inc. (309) 562-7271 www.onkens.net

Onken’s Inc. was founded in 1983 by Donald Onken, after receiving patents pertaining to his bulk container and trailer system designed for collecting used cooking oil. Since then, Don and the Onken’s team have continued to innovate and expand the product line to include additional solutions like enclosed and outdoor containers for cooking oil, single- and double-wall tanks for automotive oil and cooking oil, as well as recycling trailers, plus more innovations on the horizon.

See ad on page 22.

Par-Kan Company (800) 291-5487

www.par-kan.com

Founded in 1958, Par-Kan Company is a privately held company and a Certified Minority Business Enterprise. ParKan manufactures quality liquid recycling steel containers and has various lid options available for the industry. We have five manufacturing facilities located in the Midwest and offer various manufacturing capabilities. We pride ourselves in listening to our customers pain points and working together to develop a solution. We look forward to serving you!

See ad on page 32.

Rome Grinding Solutions offers grinding equipment, spare and wearable parts, and service and audits for grinding

operations in the rendering industry. Headquartered in Sheldon, Iowa, Rome Grinding Solutions is a third-generation, familyowned business. Rome prides itself on high-quality grinding equipment with industry-leading turnaround times and worldclass customer service.

RoseDowns (833) 922-2447 www.Rosedowns.co.uk

RoseDowns’ history dates back to 1777 and it has continuously invested in design and development, in order to be at the forefront of pressing technology. RoseDowns has an unrivalled reputation for supplying processing equipment and replacement parts to the rendering industry. RoseDowns’ U.S. Service Center is in a prime location in Kansas City, Missouri, offering a complete pick-up and delivery service, to strip and rebuild all press models, using top-quality parts manufactured by RoseDowns.

See ad on page 26.

Sanimax (888) SANIMAX www.sanimax.com

Sanimax provides quality environmental services to customers in the agri food industry in the U.S., Canada, Brazil and Colombia. We reclaim animal and meat by products, used cooking oils, and organic materials that would otherwise end up in a landfill. We renew and transform them into useful products and then return them to the marketplace as high-demand goods like tallow, protein, and leather. Reclaim, renew, return: It is what Sanimax does proudly every day and has for many generations.

Scoular (402) 342-3500 www.scoular.com

A 130-year-old company with $6 billion in sales, Scoular creates safe and reliable supply chain solutions for end-users and suppliers of grain, feed ingredients and food ingredients. With more than 100 offices and facilities in North America and Asia, Scoular’s 1,000-plus employees lead the way by buying, selling, storing, handling and processing grain and ingredients, as well as managing transportation and logistics for customers domestically and around the world.

Smithfield Foods Inc. (970) 978-6423 www.smithfieldfoods.com

Smithfield Foods is a $15 billion global food company and the world’s largest pork processor and hog producer. In the U.S., the company is the leader in numerous packaged meats categories with popular brands including Smithfield, Eckrich and Nathan’s Famous, among others. Smithfield Foods is committed to providing good food in a responsible way and maintains robust animal care, community involvement, employee safety and environmental, food safety and quality programs.

The Annual Convention mobile meeting app offers you yet another exclusive opportunity to network and build community. Chronicle your Convention experience by sharing your favorite events and activities and rating speakers and sessions. Use the app to send direct messages and connect with fellow attendees as well as upload your favorite photos, which we’ll add to our online convention gallery. And don’t forget! Those who check-in early on the app will be eligible for prizes. Watch your inbox for details on how to download and use the meeting app.

Contact Marty Covert at co@martycovert.com or call 703. 754. 8740

Renderers Convention Continued from page 28

Stable

www.stableprice.com

Stable provides risk management solutions for nonexchange traded products.

Standard Fertilizer (812) 663-8391 standardfertilizer.com

The Standard Fertilizer Company is a full service rendering company serving Indiana, Northern Kentucky and Western Ohio. We provide prompt removal and recycling services to animal producers, slaughterhouses, grocery stores and the restaurant industries.

Sturtevant Inc. (781) 829-1431 www.sturtevantinc.com

Sturtevant Inc. is a family owned, global supplier of Whirlwind air classifiers/air separators used to reduce ash and increase protein in any species of rendered animal meals or fish meals. Sturtevant air classifiers separate meals into two products, a fines fraction and coarse fraction. The air classified fines fraction is sold for premium high-protein/low-ash pet food or aquafeed products. The air classified coarse fraction is sold for regular protein/regular ash feed products.

Summit Trailer Sales (800) 437-3729 www.summittrailer.com

Summit Trailer Sales Inc. has been in business since 1970 and continues to provide superior workmanship and customer service. Everyone at Summit Trailer strives to provide quality products to our customers, whether it is aluminum or steel trailers, dump bodies or parts. Our quality, hand-crafted work is what keeps Summits on the road since 1970.

The Dupps Company (937) 855-6555 www.dupps.com

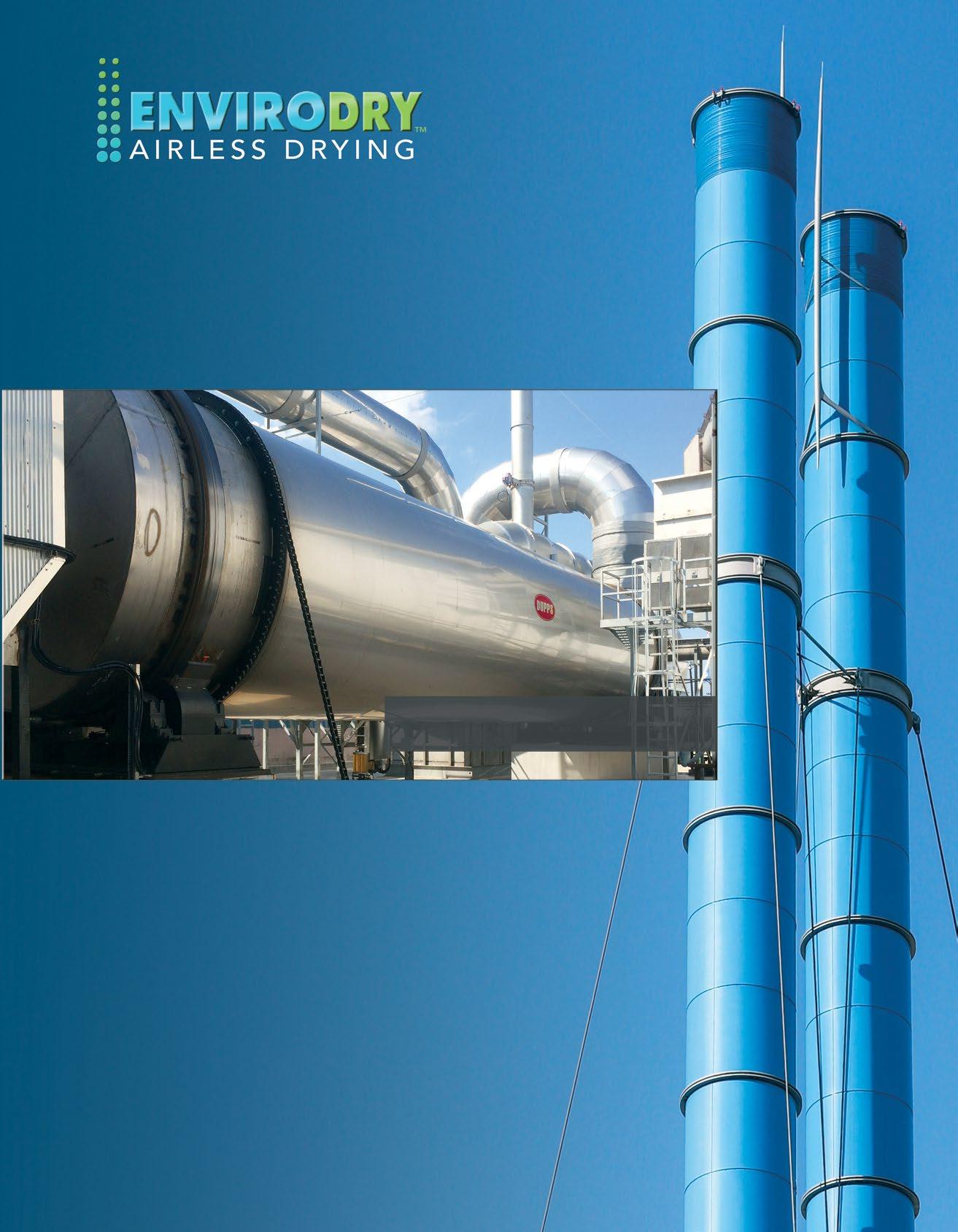

For over 86 years, The Dupps Company has been a leader in providing the highest quality equipment and service to the rendering industry. Our rapidresponse service team, the world’s largest, offers complete maintenance, repair and rebuild services to dramatically reduce downtime and increase profitability. New, innovative solutions include EnviroDry airless drying technology, the sustainable choice. With EnviroDry, heat-sensitive protein is protected, there’s no visible exhaust plume, minimal odor control is required and any excess heat energy can be recycled.

See ads on pages 9 & Inside Back Cover.

Travis Body & Trailer, Inc. (855) 679-0809 www.travistrailers.com

We are a leading manufacturer of trailers and truck bodies committed to enabling safe and efficient transportation

of material in the construction, environmental, waste and rendering industries. Each member of our team strives to exceed customer expectations with prompt delivery, exceptional quality and unmatched response times. We do this through the development of market-leading products with a commitment to continuous improvement of our employees, our production techniques and our product lines.

Tyson Ingredient Solutions (800) 950-2344 www.tysoningredientsolutions.com

Tyson Ingredient Solutions, part of Tyson Foods Inc., is a family and business of innovation, progress and momentum. The company produces 100% chicken-based protein and lipid ingredients for animal feed, pet food and aquaculture feed. With the acquisition of American Proteins, the company expects to use this combined knowledge and expertise to propel them forward in the rendering industry.

Uzelac Industries (414) 529-0240 www.uzelacind.com

Uzelac Industries is a rotary dryer manufacturing company with dryers in operation worldwide. We have over 40 years of experience behind the custom design and fabrication of our systems. Uzelac Industries is the leading provider of rotary dryers to the rendering industry in the U.S. We also offers parts and service for rotary drying systems.

See ad on page 37.

VanAire (800) VANAIRE vanaireinc.com

With 25 years of experience and more than 200 installations, VanAire’s custom design and engineering approach to wastewater has created solutions in multiple industries. Our unique dissolved air flotation (DAF) unit’s proprietary micro bubble design efficiently separates liquids from solids, eliminating TSS, BOD, FOG, while reducing surcharges. VanAire can supply a complete wastewater system or even upgrade your current system. Whether you’re looking to upgrade an existing wastewater legacy system to add efficiencies or you’re starting from scratch, count on VanAire.

Videka Solutions (269) 353-5536 www.videkasolutions.com

Videka offers natural and synthetic antioxidant solutions, as well as antimicrobial solutions for use in rendering and pet food production.

See ad on page 13.

Renderers Convention Continued from page 31

West Coast Reduction Ltd.

(866) 337-3355

www.wcrl.com

For more than 50 years, West Coast Reduction has been collecting and recycling used cooking oil from restaurants, cafeterias and other food providers. With its brand Redux, the company is continuing to provide a clean, safe and worry-free used cooking oil collection service that creates sustainable new products. To better service its used cooking oil customers, Redux now also provides grease trap cleaning adhering to West Coast Reduction’s tradition of exceptional service and sustainable products.

See ad on Inside Front Cover.

Williams Mullen

Environmental Practice Group (803) 567-4610

www.williamsmullen.com

Williams Mullen is a regional, full-service law firm with approximately 240 attorneys in offices across North Carolina, South Carolina, Virginia and Washington, D.C. Since our firm began in 1909, our goal has been to provide business and legal solutions to help our clients’ businesses thrive.

WWS Trading Inc. (952) 548-9300

wwstrading.com

WWS Trading, Inc. is a leading commodity trading firm specializing in fats, oils and proteins. WWS Trading takes the hassle out of buying and selling with its dedication to service, honesty and reliability, so renderers can focus on the parts of their business that matter most. R

For a complete list of sponsors and exhibitors at NARA’s convention, visit https://convention.nara.org. NARA thanks all the sponsors, exhibitors and attendees who so generously contributed to the success of this year’s convention. Their continual support of the industry is much appreciated.

It has been an exciting year for the rendering industry. Renderers are enjoying strong – and transitioning – markets. The biofuel market continues to grow, creating demand for rendered fats because of their low carbon intensity score. The fight against climate change is only going to intensify over the next decade and rendered products, including proteins, are well positioned to aid industries in lowering their carbon intensity and greenhouse gas (GHG) emissions.

The rendering industry has a good story to tell, and the North American Renderers Association is doing just that. Earlier this year, NARA was invited to give a presentation on the sustainability of the rendering industry at the 2022 U.S. Department of Agriculture’s Agricultural Outlook Forum, which had a theme of “New Paths to Sustainability and Productivity Growth.” The AOF is USDA’s oldest and largest annual gathering dating back to 1923, with an average attendance of 1,600 people.

The presentations can be found at www.usda.gov/oce/ ag-outlook-forum/2022-aof-program. NARA’s presentation was titled “Fat of the Land: Market Outlook for Low Carbon Intense Raw Materials from the Rendering Industry.” It was an honor for NARA to be invited to speak at this event and shows that our message is relevant and timely. We are in the right place at the right time, which means we must stay engaged.

As mentioned in my previous report, I testified July 15 before the Select Committee on the Climate Crisis hearing titled, “Climate Smart from Farm to Fork: Building an Affordable and Resilient Food Supply Chain.” On Aug. 2, NARA submitted answers for the record to follow up questions by Rep. Garret Graves of Louisiana regarding how the rendering industry contributes to reducing food waste and provide functional ingredients to U.S. and global agricultural markets.

Anna Wilkinson gave a presentation Sept. 14 at the USDA Food Loss and Waste Innovation Fair. The sessions can be seen at www.labroots.com/ms/virtual event/2nd usda food loss waste-innovation-fair. Her presentation was titled, “Rendering: The Unsung Hero of Sustainability.” She was one of 12 speakers discussing ways to prevent and/or repurpose food waste. Of interest, the U.S. Environmental Protection Agency’s Food Recovery Hierarchy Pyramid that we often reference was cited by several other speakers. The pyramid has been updated by EPA to now include “rendering.”

Also in September, Dana Downing addressed the sustainability of rendered products at the Congress of the Latin American College of Animal Nutrition at the International Congress Center in Mérida, Yucatán, Mexico. Additionally, she continues to represent NARA on the U.S. Sustainability Alliance. The rendering industry is highlighted in fact sheets on the organization’s website at thesustainabilityalliance.us.

Finally, NARA will continue to refine its sustainability efforts at our upcoming convention. Dr. David Meeker has organized a project to identify the most efficient and effective ways to meet the sustainability needs of NARA members and their customers in the next five years. We have hired Context Consulting to head up this project with the scope being to interview six respected stakeholders (e.g., renderers, customers, key influencers) to identify and prioritize their needs and expectations, specific to sustainability, in the next five years. An executive summary PowerPoint that includes insights and recommendations will be delivered to the NARA Sustainability Committee meeting on Oct. 26th in Dana Point, California.

Please plan to join us for the 89th NARA Annual Convention being held on Oct. 24-28, 2022, at The Ritz-Carlton Laguna Niguel, in Dana Point. Our room block is oversold for the convention as we anticipate an excellent turnout! R

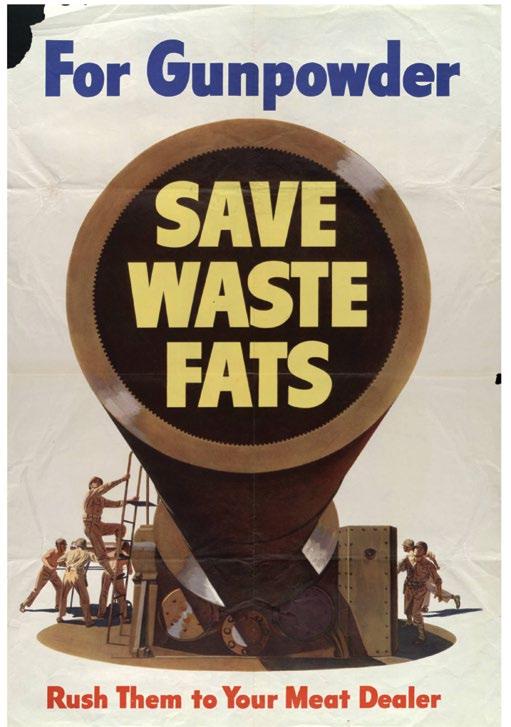

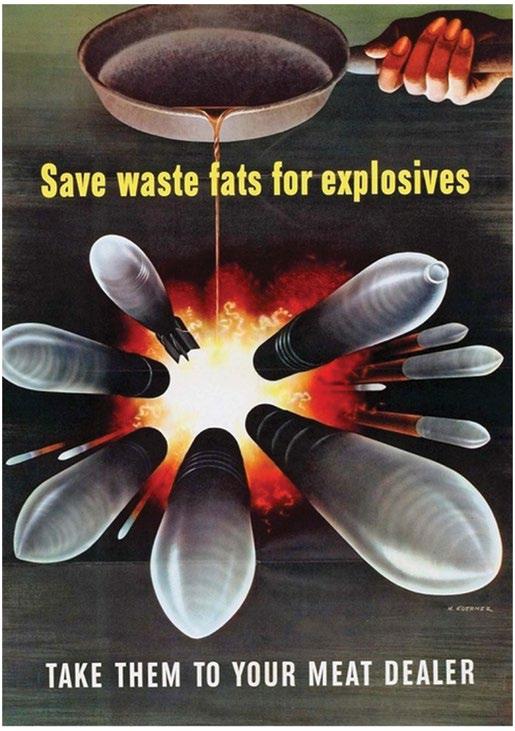

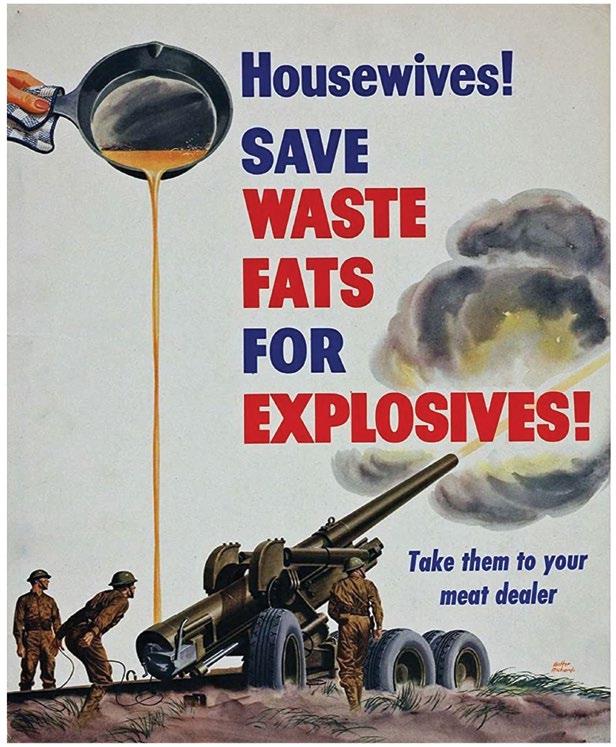

About 12 years ago, when I was going through the Smithsonian National Museum of American History in Washington, D.C., I came across a poster in the World War II section that caught my eye. It was a poster with the words, “For Gunpowder Save Waste Fats Rush Them to Your Meat Dealer.”