11 minute read

Pine Workshop Boosts Fence Building

by IdeaSoil

Advertisement

Construction was started in the rough 2015 winter and fi nished that April. Exterior boards were installed diagonally for better wall strength and weather resistance.

Main Line Fence replaced a metal warehouse with an eastern white pine workshop that provides more space, better working conditions.

The team at Main Line Fence, Cumberland, ME, knew they had a problem. Their existing 1970s-era workshop, originally built as a warehouse for industrial chain-link fi ttings and where much of their fence building takes place, wasn’t working. The building was too small, it was metal, uninsulated, and there was zero room for expansion.

In the mild Maine summers, temperatures inside the workshop would frequently top out at 15 degrees hotter than the outdoor temperature. Cold indoor winter temperatures made work almost impossible.

Ryan Cianchette, project manager with Main Line Fence, realized it was time for a change. The solution? A brandnew building, designed specifically for their needs, offering room to grow, and with an unmatched level of energy efficiency.

Construction began in early 2015 and the new workshop was completed that April. The new building offers 4,000 sq. ft. of workshop space, primarily used by fence-construction teams. Interior and exterior sheathing consists of 1x10-in. rough-sawn eastern white pine boards.

WHY PINE? “Bottom line: it’s locally grown, it’s energy effi cient, and it insulates incredibly well,” said builder Bob Vail, owner of Vail General Contracting Inc., Cumberland Center,

ME. “I love it, and work with it every chance I get!”

Vail’s company was called upon by Cianchette to help solve their growth challenges.

“They came to me saying they’d outgrown their space and needed a larger, well-insulated building to allow them to grow, now and in the future,” said Vail. “I wanted this building to be something beautiful and useful, so we engaged an architect to help us place the building using the existing footprint.” The architect was Dick Reed, Reed Architecture, Portland, ME.

While the interior of the building features pine boards installed in the traditional horizontal method, it’s the exterior that caught everyone’s attention: the 1x10 roughsawn eastern white pine boards were installed shiplapped, on the diagonal.

Vail chose the diagonal exterior installation because it results in a much stronger, more energy-efficient structure than the conventional horizontal approach. Among the results he’s experienced over the years: Wall ri

The new Main Line Fence workshop features interior and exterior eastern white pine sheathing, which contributes signifi - cantly to the energy effi ciency of the structure.

The interior of the Main Line Fence workshop is spacious, with plenty of room for company growth. Pine sheathing provides an extra layer of insulation, helping the company reduce heating and cooling costs.

gidity starts at the sill plate, lending greater strength to the walls, and the entire structure stands up to weather better because of the natural insulating nature of the wood. The pine boards are twice as thick as OSB, the traditional sheathing choice, which results in greater abilities to cool and heat the interior of the structure. This equals less heating and cooling costs for the company.

“One of the biggest problems with the old building was we didn’t have a workable interior,” said Cianchette. “All we had to work with was the metal framing of the building and the backside of the exterior metal-wall sheathing. We needed something different and useful for the new building. You can’t lean anything up against drywall without causing damage. We needed something strong, durable, and natural. The [pine] is so strong we can hang things on it, and it stands up to the sections of wood frequently leaned against it as we build fences.”

Sustainability is another reason Vail chooses to build with eastern white pine. “In Maine, eastern white pine is locally grown and easily available,” continued Vail. “It’s been a traditional building product in New England since Columbus came over, and it lasts for hundreds of years. Bottom line: you can’t get any greener than a renewable wood board.”

According to Jeff Easterling, president of the Northeastern Lumber Manufacturers Association (NELMA, Cumberland Center, ME), the grading agency for eastern white pine, and to NELMA members, this build is an exciting first. “Traditionally, eastern white pine is used in residential applications—flooring, paneling, and the like— your typical appearance-grade opportunities. To see the product used in a commercial build and to see it used with such overwhelming success is very exciting. This opens up a whole new world for builders and for our manufacturing members.”

While no building-code challenges were encountered throughout the process, the building itself turned out to be the biggest challenge of all. According to Cianchette, “We needed to build the new workshop on the same footprint as the old one. Except the new building needed to be much larger. With the help of Bob Vail and an architect, the solution was created: The new building is L-shaped to fit in between our other buildings and really maximize the available space on the lot.”

EXCELLENT RESULTS The workshop got its fi rst workout during the summer of 2015, with Cianchette reporting only good results: “We have more room than ever before, lots more equipment storage, and it’s much more comfortable inside—which means our team is willing to put in longer hours. Used to be when our guys would return from an install early, no one wanted to go back into the workshop due to the extreme temps. Now they will!”

A natural-gas heat source was installed in the structure to prepare for winter. Thanks to the natural insulation provided by the wood sheathing, it only takes 10 minutes to raise the interior temperature when it’s cold. Additionally, a comfortable temperature is maintained throughout the night, allowing employees to jump right into work upon arrival in the morning.

A once drafty, hard-to-use building has been successfully replaced with an energy-efficient workspace, a structure that contributes daily to the success of Main Line Fence. Phone and Internet were recently installed in the new building, something that was impossible before due to the drafty and sometimes wet conditions within the previous structure. The insulating envelope provided by the pine sheathing is directly related to the expansion and continued success of the business: What was once a phoneless, tiny building is now a connected extension of the main office—and there’s plenty of room for expansion.

“In the past, only two crews could build fence sections at a time,” stated Cianchette. “Now we have room to spare. When we’re ready, we can add two more jig tables and additional crews to increase production even more. Wood is becoming a very strong part of our business. We’ve been in business since 1948 and have continuously adapted to the times and the market—when the original metal building was built, we never thought we would be building residential wood fences. Who knows what we’ll be doing in another 30 to 40 years; but now we have a building that can adapt right along with us. There’s nowhere to go but up.” CA

Want more information? The resources below are linked on our website at commercialarchitecturemagazine.com and our digital magazine at commercialarchitecturemagazine.com/ digital/mar2016.

Circle 3 on the Reader Service Card.

Visit the Northeastern Lumber Manufacturers Assn. website.

Download eastern white pine technical facts.

Download eastern white pine grade sheets.

Building wrap with detachable rainscreen

Slicker HP:

Building wrap with rainscreen Rainscreen feature can be removed 20-yr. system warranty

Slicker HP building wrap provides moisture protection for exterior walls. For use with wood, ber-cement, stone veneer, or stucco cladding systems, the product provides a water-resistive barrier and rainscreen in a single solution including drainage and ventilation. Vertical channels direct bulk water out of the exterior by creating a 1/4-in. space for drainage and drying. e rainscreen feature can be removed without compromising the wrap. When installed with the company’s ashing accessories, the product has a 20-yr. system warranty.

Benjamin Obdyke, Horsham, PA Circle 67 benjaminobdyke.com

Retrofi t projects Information detailing the company’s architectural metal wall and roof systems in retrofi t projects includes a variety of building types. Before-and-after photos detail the transformative and aesthetic benefi ts of the exterior systems. Each project description reviews how goals were achieved for a building’s thermal and moisture performance and sustainability goals.

Centria, Moon Township, PA Circle 69 centria.com

Through-wall fl ashing R-Guard SS ThruWall fl ashing material is a full, single sheet of 304-stainless steel bonded on one side to a layer of polymeric reinforcing fabric. Designed for cavity wall and masonry veneer construction, the material complements conventional waterproofi ng and air-barrier components or can be used as part of a building-wide R-Guard air-barrier system. The product does not stain and is said to offer superior puncture resistance and tensile strength. Available widths include 12, 18, 24, and 36 in. x 60 lineal ft. Fire- and mold-resistant, the product is fl exible, cuttable, and can be hand formed.

Prosoco, Lawrence, KS Circle 68 prosoco.com

Air, water barrier system ForceField air and water barrier system uses engineered-wood sheathing panels laminated with an air/water barrier. After installation, panel joints are taped with ForceField seam tape, reportedly eliminating the need for building wrap. Panels are available in 7/16 thickness in sizes 4 x 8, 4 x 9, and 4 x 10 ft.

Georgia-Pacifi c, Atlanta Circle 71 gp.com

Metal-roof sealant MetaLink silicone-based metal-roof sealant for applications including standing-seam detail work, fl ashing and gutter seams, and mechanical duct work, adheres to Kynar 500 PVDF and handles temperatures from –80 to 400 F. Recent enhancements have improved the product’s joint movement from 25% to 50% while retaining its non-shrinking, non-toxic, and non-solvent properties.

Chem Link Inc., Schoolcraft, MI Circle 70 chemlink.com

Textured panel TuffBlock is a textured panel that provides façade-differentiating accents for buildings. Available in four colors (steel, pewter, walnut, and bamboo), the 5/8-in. thick panels have a 50-yr. manufacturer warranty and a 15-yr. fi nish warranty. Panels install with the company’s Ultimate Clip system that also creates a 10-mm drained and back-ventilated rainscreen.

Nichiha USA, Atlanta Circle 72 nichiha.com

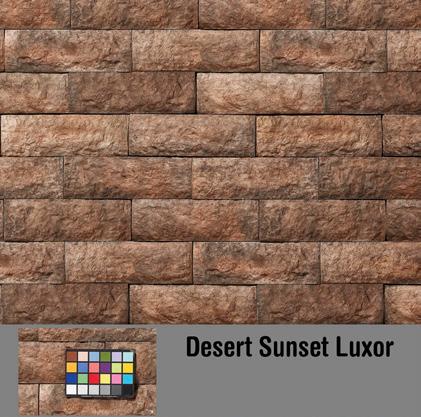

Stone-veneer profi les Additions to the company’s line of stone panels include Desert Sunset Luxor, Taupe Imperial, and Cream Tivoli. Desert Sunset evokes a natural setting of mountain-range surroundings. Taupe provides a warm look with subtle texture. Cream Tivoli features clean, crisp panels.

Environmental StoneWorks, Centennial, CO Circle 73 estoneworks.com

Wall-system accessory products A mesh corner-bead standard and drip-edge profi le are accessory products for the company’s wall systems. Used with StoTherm ci and StoQuik Silver wall systems, the products are said to improve the durability and aesthetics of the cladding systems. The corner bead provides true and straight corners that are resistant to chipping and cracking and is made of an angled mesh strip and reinforced with a plastic rail. The edge profi le is a PVC product with reinforcing mesh that creates a drip edge and plaster return to control the direction of dripping water and protect against moisture intrusion.

Sto Corp., Atlanta Circle 76 stocorp.com

The Ultimate Waterproofing System

Cool-roof colors Color options for EcoBlend polymer roofi ng include Tahoe, Autumn, Brownstone, and Slate Gray. Approved by the Cool Roof Rating Council to refl ect sunlight and heat away from a structure, the colors join the Weathered Gray and Castle Gray shades.

DaVinci Roofscapes, Lenexa, KS Circle 74 davinciroofscapes.com

Rainscreen drainage WaterWay rainscreen drainage and ventilation mats create space for moisture drainage and promote air circulation through convection. Mats consist of polypropylene fi laments bonded to a moisture-resistive fi lter fabric that functions like an additional layer of weather-resistant barrier. The material is designed for use with stucco, EIFS, manufactured and natural stone, fi ber-cement, brick, lap and cedar sidings, and other wall-cladding systems.

Stuc-O-Flex International Inc., Redmond, WA Circle 75 stucofl ex.com

MFM SubSeal ™ is a pre-fabricated, self-adhering, self-sealing waterproofi ng membrane that stops water and moisture in its tracks! This advanced system aggressively bonds to prevent damage caused by water penetration.

Multi-Purpose Waterproofi ng Protection for:

• Through-Wall Flashings • Foundation Walls • Plaza Decks • Sills, Pot Shelves, Parapets • Parking Garages

Realize maximum protection, increased savings and more than 55 years of waterproofi ng experience. Call 800-882-7663 to get a quote or visit www.subseal.mfmbp.com for more information.

ICC-ES AC38, ICC-ES ESR 2783, ASTM D 1970

800-882-7663 www.subseal.mfmbp.com • Ideal for Below Grade

Foundations and

Structures

• Vertical or Horizontal Applications • Aggressive Bonding

Characteristics

• Extreme Moisture

Protection

• Available in 40 or 60

Mil Thickness

• Self-Adhering for Fast

Installation