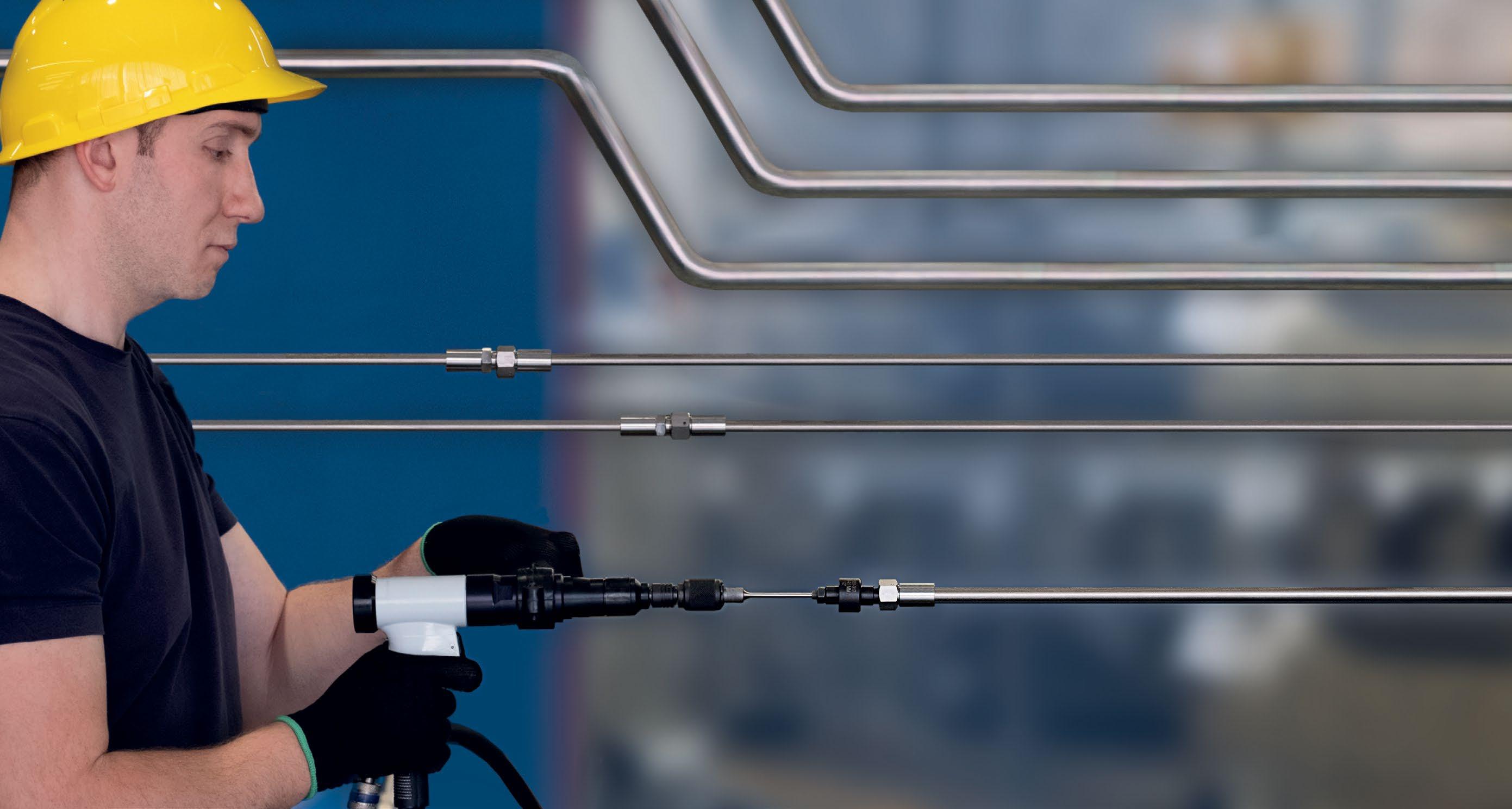

THE WELDLESS STEEL PIPE CONNECTION SYSTEM

MINIMISE RISKS ASSOCIATED WITH WELDING

NO NEED OF SKILLED WELDING TECHNICIANS

EASY AND FAST CONNECTION OF PIPELINE

A GREEN, RISK-FREE AND INNOVATIVE TECHNOLOGY

Thunder-lock is a mechanical sealing providing the same reliability as welding without the associated risks and costs. The installation process can be completed in less than 20 seconds without releases of toxic gas and risk of injuries. It doesn’t require post-welding treatments and testing. The technology is suitable for metric tubes and NPS pipes

• High pressure: sizes from 1/4 to 1 1/4” - WP up to 9000 psi

• Medium pressure: sizes from 1/2 to 2 1/2” - WP up to 900 psi

IN THIS ISSUE

July 2023

VOLUME 30 • ISSUE 7

Features

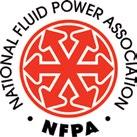

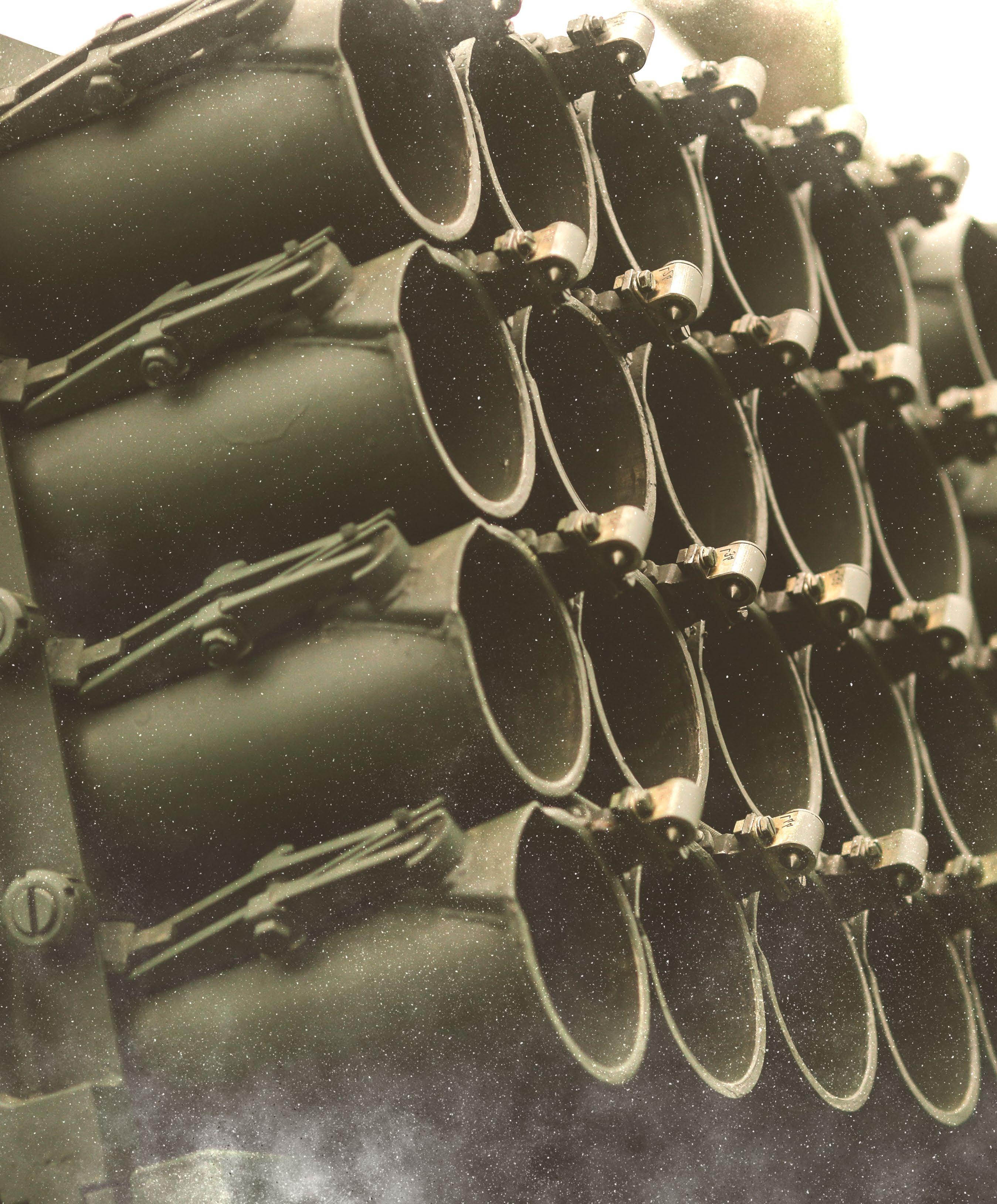

6 Cover Story

Ensuring Stability in Mobile Missile Launchers

Lessons and solutions for Missile Launchers Detailed.

10 What is a Deutsch-Style Connector and Why is it Important to Pick the Right One?

Commonly used in Fluid Power connectors are imperative for success.

14 Compact Hydraulics Is on the Move

Size changes in hydraulics leads to increasingly efficient and precise solutions.

29 University of Louisiana, Lafayette, Named Grand Champion University of Louisiana, Lafayette, takes the top prize at the Fluid Power Vehicle Challenge at Danfoss.

30 Test Your Skills

Understanding the Operation of Servo Valves

34 Wandfluh Launches New Modular Product Series

Targeted for mobile and marine equipment, new series manages higher flow and pressure applications.

Publisher’s Note: The information provided in this publication is for informational purposes only. While all efforts have been taken to ensure the technical accuracy of the material enclosed, Fluid Power Journal is not responsible for the availability, accuracy, currency, or reliability of any information, statement, opinion, or advice contained in a third party’s material. Fluid Power Journal will not be liable for any loss or damage caused by reliance on information obtained in this publication.

Fluid Power, Resolute as Gold

By Ian J. Ford» “TWO WEEKS TO slow the spread.” “Essential workers only.” How can we forget such phrases? The U.S. economy was brought to a screeching halt a mere three years ago. Yet, amidst these lockdowns, the core of American manufacturing carried on. In a dark and uncertain late winter, many resilient first, second, and third shift workers huddled behind their glowing dashboards and commuted to the shop floor as they always had. With a thermos of home-brewed coffee steaming in their cup holder, the backbone of domestic production persevered.

No industry was left unscathed in the year 2020. Media focused on hospitals, schools, and grocers, but glanced over the millwright in the steel mill, the machine operator at the papermill, or the floor manager of the injection molding plant. Small-to-medium sized businesses and mom-and-pop shops had to follow local, state, and federal COVID mandates. Workers retired in droves, lay-offs were made; however, many steadfast factories and plants remained a source of employment in uncertain times. Manufacturing persisted. Whilst operators had to have their temperatures taken and PPE meant more that safety glasses, ears, and steel-toes; power units still hummed, cylinders stroked, and conveyors turned.

The fallout of the pandemic lockdowns and other economic turmoil have subjected many industries to unprecedented volatility. The word “unprecedented” is vomitously recited in the news headlines, but it is an apt adjective to be used. Strange things have occurred of late.

We have seen sectors boom and bust in mere months. New ventures explode with success. Stalwart institutions recede. Banks collapse. Markets swing. Then, the moment the market even hints at becoming bearish, precious metal salesmen bombard advertising avenues with their slogans. “Gold protects against uncertainty!” “Protect your future with gold!” Perhaps with good reason, but this is something to discuss with one’s financial advisor.

Now, what of the readers of this Journal? What are we to think; we who learn, work, and live in the field of Fluid Power? Is there a “gold” we can turn to across industries? Workers, students, and investors carefully consider where to invest time, talent, capital, and ultimately their futures. What field should a student pursue? Where should the worker apply? In which sector should an investor place their assets?

If the tumults of the last three years have taught us anything; it is that fluid power is as resolute as the American spirit. It permeates across industries and powers the core productive forces in our economy. The student can trust that engineering and practical hands-on training will prepare them for success. The worker, new or experienced, can trust that advanced automation, manufacturing, and production must continue to sustain us in even the most trying times. The investor can trust that their life-savings or their next opportunity for capital growth lies in a tried and true, yet innovating technology. Fluid power is our gold standard.

If the tumults of the last three years have taught us anything; it is that fluid power is as resolute as the American spirit.

Innovative Designs & Publishing, Inc.

3245 Freemansburg Avenue, Palmer, PA 18045-7118

Tel: 800-730-5904 or 610-923-0380

Fax: 610-923-0390 • Email: Art@FluidPowerJournal.com www.FluidPowerJournal.com

Founders: Paul and Lisa Prass

Associate Publisher: Bob McKinney

Editor: Janis Adams

Technical Editor: Dan Helgerson, CFPAI/AJPP, CFPS, CFPECS, CFPSD, CFPMT, CFPCC

Marketing and

Social Media Consultant: Kristy O'Brien

Graphic Designer: Nicholas Reeder

Accounting: Donna Bachman, Sarah Varano

Circulation Manager: Andrea Karges

INTERNATIONA l F lu ID POWER SOCIET y

1930 East Marlton Pike, Suite A-2, Cherry Hill, NJ 08003-2141

Tel: 856-424-8998 • Fax: 856-424-9248

Email: AskUs@ifps.org • Web: www.ifps.org

2023 BOARD OF DIRECTORS

President: Scott Sardina, PE, CFPAI, CFPHSWaterclock Engineering

Immediate Past President: Denis Poirier Jr., CFPAI/AJPP, CFPHS, CFPIHM, CFPCCDanfoss Power Solutions

First Vice President: Jeff Hodges, CFPAI/AJPP, CFPMHM- Altec Industries

Treasurer: Lisa DeBenedetto, CFPSGS Global Resources

Vice President Certification: James O’Halek, CFPAI/AJPP, CFPMIP, CMPMM - The Boeing Company

Vice President Marketing: Chauntelle Baughman, CFPHS - OneHydraulics

Vice President Education: Daniel Fernandes, CFPECS, CFPSSun Hydraulics

Vice President Membership: Garrett Hoisington, CFPAI/AJPP, CFPS, CFPMHM - Open Loop Energy

DIRECTORS-AT-l ARGE

Stephen Blazer, CFPE, CFPS, CFPMHM, CFPIHT, CFPMHTAltec Industries

Cary Boozer, PE, CFPE - Motion Industries

Bruce Bowe, CFPAI/AJPP - Altec Industries

Bradlee Dittmer, CFPPS - Norgren/IMI Precision Engineering

Brian Kenoyer, CFPHS - Cemen Tech

Wade Lowe, CFPS - Hydraquip Distribution

Jon Rhodes, CFPAI, CFPS, CFPECS - CFC Industrial Training

Mohaned Shahin, CFPS - Parker Hannifin

Randy Smith, CFPHS - Northrop Grumman

Ethan Stuart, CFPS, CFPECS - Quadrogen

Bradley Wagner, CFPAI/AJPP - Manitowoc Crane Group

Brian Wheeler, CFPAI/AJPP, CFPMM, CFPMIPThe Boeing Company

CHIEF EXEC u TIVE OFFICER (EX-OFFICIO) Donna Pollander, ACA

HONORARy DIRECTOR (EX-OFFICIO)

Ernie Parker, CFPAI/AJPP - Hydra Tech

IFPS STAFF

Chief Executive Officer: Donna Pollander, ACA

Communications Coordinator: Victoria Piro

Technical Director: Thomas Blansett, CFPS, CFPAI

Assistant Director: Jenna Mort

Certification Logistics Manager: Kyle Pollander

Bookkeeper: Diane McMahon

Administrative Assistant: Beth Borodziuk

Instructional Designer and Layout: Chalie Clair

Fluid Power Journal (ISSN# 1073-7898) is the official publication of the International Fluid Power Society published monthly with four supplemental issues, including a Systems Integrator Directory, Off-Highway Suppliers Directory, Tech Directory, and Manufacturers Directory, by Innovative Designs & Publishing, Inc., 3245 Freemansburg Avenue, Palmer, PA 18045-7118. All Rights Reserved. Reproduction in whole or in part of any material in this publication is acceptable with credit. Publishers assume no liability for any information published. We reserve the right to accept or reject all advertising material and will not guarantee the return or safety of unsolicited art, photographs, or manuscripts.

New Problem loud Noise Heard When Shutting Off a Hydraulic System

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training» THE ATTACHED CIRCUIT for a guillotine type press worked well for a paper mill that was using it to cut scraped 5-to-6-foot diameter paper rolls. They would bring a roll that was approximately 4 to 6 feet long and cut it in half length wise. They would then haul it over to the pulp mill that recycled it into pulp that would finally result in new rolls of paper.

A problem developed with the hydraulic system each time they turned the system off. The electric motor and pump assembly would make a loud rumbling noise as if the pump was turning backwards at high speed and would slowly decelerate to a stop. As usual you find older systems where all the gages are missing or broken.

For the solution, see page 37.

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com. Visit fluidpowerjournal.com/figure-it-out to view previous problems.

IN MOBILE

By Kyle Sendatch, Mechanical Engineer, York Precision Machining & Hydraulics

continued on page 8

accidentally or intentionally. The environment can be made safe, the component replaced, and the risk of death, injury and system loss is mitigated. The system creates added stability during launch but also removes the risk of suddenly shifting or falling if a hydraulic system has any type of failure. It will keep safe any load, explosive ordnance, crew, and vehicle. This innovative failsafe hydraulic rod locking device can be customized.

Another scenario in the deployment and stabilizing of a missile launcher is elimination of the need for cribbing. Because outriggers equipped with a failsafe load-holding system provide a reliable structural solution, there is no need to provide cribbing or other attempts to provide fill material to support launchers and other mobile equipment.

The innovative fail-safe hydraulic rod locking device can provide all the benefits of a high-quality hydraulic stabilizer and has as an added advantage the ability to lock in place at any point along the piston’s stroke. This allows infinite adjustability to accommodate all types of surfaces on which the launcher may be situated. This infinite position locking ability improves the stability and control of the launcher when compared to conventional hydraulics. Because it locks instantly without shudder or other movement, it also assures precision in aim and operation.

Long-term Positioning without Drift

Elevation actuators are used to position missile launchers. One common challenge is the need to hold position for an extended period of time without drift. When a hydraulic cylinder relies exclusively on fluid pressure to maintain position, it becomes susceptible to unwanted movement due to leaking valves, lines, or couplings as well as thermal expansion of fluid. The hydraulic rod locking device can be incorporated here as well. When it is used in an actuator/lock configuration, it can be moved into position then locked in place and will hold the load indefinitely—even for months or years--without drift.

The system also allows maintenance to be performed safely on equipment as it is mechanically locked and not relying on hydraulic pressure or valves to keep it in position. Even under heavy loads the mechanical locking properties it will provide superior performance and provide high stability within the system.

Performing maintenance is another scenario in which a positive mechanical lock is highly advantageous. Especially when service is required in the field, there is limited time and manpower to install auxiliary lockout systems to protect personnel. This hydraulic locking device allows maintenance to be performed safely and quickly as it is mechanically locked and not relying on hydraulic pressure or valves to keep it in position.

Eliminating Backlash During Launch Events

Backlash, or recoil, presents another challenge for missile launchers, because it can adversely affect accuracy of the missile trajectory, which can result in mission failure and put personnel at risk. Most hydraulic systems are capable of achieving the initial desired position, however, they lack the rigidity to withstand the impulse of a launch event. This is vital to mission success, because even small degrees of movement off initial trajectory from backlash at the launch site could multiply the effect over distance and cause the flight path of the missile/rocket to deviate from its target. This is another instance in where a hydraulic rod locking device has been integrated into launcher design as they will not move when launch forces are exerted on them. These locks are most often integrated into the main elevation actuators, however, they have also been incorporated in parallel to an alternate source of actuation.

Inn conclusions, this same design can benefit other mobile and fixed load holding equipment such as cranes, and hydraulics on any other engineering system. It can also benefit testing applications, construction equipment and civil engineering hydro control hydraulic systems. Other applications that could benefit from this feature include anything that requires precise positioning to be maintained without slipping or drifting while maintaining a load.

The system is a proven failsafe option for hydraulic load holding and locking. These systems have been incorporated into the current generation of long-distance missile launching systems.

The hydraulic rod locking device is manufactured with high quality precision components. To this day the it has proven to be reliable over many decades of field use It can be customized for any size application and requires no more maintenance than a standard hydraulic cylinder and can be tailored to the needs of each individual application. It is offered as a standalone lock or lock and actuator combination. This means it can be added to existing systems to increase stability or be incorporated as a full system into new designs where needed. •

The innovative fail-safe hydraulic rod locking device can provide all the benefits of a high-quality hydraulic stabilizer and has as an added advantage the ability to lock in place at any point along the piston’s stroke.

WHAT IS A DEUTSCH-STYLE CONNECTOR AND WHY IS IT IMPORTANT TO PICK THE RIGHT ONE?

By Todd Harmon, Vice President of Canfield IndustriesWhile we live in a wireless world, many of the systems that we rely on require a dependable, wired connection. This is especially true in fluid power applications where a disconnect can result in a loss of productivity, revenue, and sometimes even create a safety risk.

But what can be relied on when you need to operate heavy machinery, agricultural equipment, or machines within industrial environments?

For years this answer has been Deutschstyle connectors.

Deutsch-style connectors are a type of electrical connector that is commonly used in fluid power applications. These connectors are designed to withstand the harsh environments and demanding conditions that are typical of fluid power systems. Deutsch-style connectors are known for their durability, reliability, and ease of use while being an essential component of many industrial and commercial applications. Historically, electrical connectors for the fluid power industry have suffered from a range of limited functions that have hindered their dependability across their wide array of applications.

Connectors for valve systems may still cause some to think of trudging through a wiring process that involves patience, careful crimping, and finding a connector kit that has everything required to ensure that the connection would not detach at the least opportune moment.

This headache is multiplied when considering the number of connections required for the system at hand, bringing the burden of labor, parts, and the inevitable human element of error that comes with any complicated process.

Luckily today, the advancements in the area of connectors by manufacturers such as Canfield Connector provide a different solution for OEMs who are looking for more reliable and cost-effective ways to bring power to hydraulic valves.

Here are some areas to check before selecting a connector solution for a hydraulic system as well as some industries that benefit from a well-designed Deutsch-style connector.

Assembly

One of the main areas to check for in Deutschstyle connectors is whether or not they provide a completely over-molded jacket to protect the cables inside. This helps to prevent damage from environmental factors such as dust, dirt,

and moisture. This over-molded construction also provides additional strength and durability, making the connector resistant to impact and vibration. One should look for a connector

solution with a proven IP67 rating that proves that the connector is resistant to the harsh factors that may damage the connector and result in a loss of functionality.

continued on page 12

continued from page 11

Indicator Lights

Another key feature of high-quality Deutsch-style connectors is the use of indicator lights. These lights provide a visual indication of the status of the connector, allowing operators to quickly and easily identify any problems or issues. This is especially important in fluid power applications where downtime can be costly and time-consuming. With indicator lights, operators can quickly diagnose any problems and take the necessary steps to resolve them, minimizing downtime and maximizing productivity.

Surge Suppression

It is extremely vital in fluid power applications to make sure that a Deutsch-style connector is chosen that offers sufficient surge suppression. Electrical surges can occur in fluid power systems due to a variety of factors, including lightning strikes, power outages, and electromagnetic interference. These surges can cause significant damage

to electrical components, including connectors, if they are not properly protected.

In an electrical connector, surge suppression works by limiting the amount of voltage that is allowed to pass through the connector and protecting the internal components from damage. Electrical connectors with surge suppression divert this excess energy away during an electrical surge from sensitive components and dissipate it harmlessly. This protects both the connector and the entire system in the event of an electrical surge.

Ease of Use

Selecting a connector that is easy to install and maintain is something that can save a great deal of time and money with a plugand-play solution. Canfield Connector has heavily invested in providing this ability for their customers by taking it a step further and providing connectors that provide easy prewired, push-on connections on both sides of the cable. This technological step completely removes the need for the hassle of terminating

hundreds of wires on the part of OEMs in all relevant industries.

Now the question is asked, “What industries benefit the most from Deutsch-style connectors?”

Dairy Industry: Deutsch-style connectors are used in the dairy industry for their durability and ability to withstand wash-down environments. They are commonly used in milking machines and other equipment that requires frequent cleaning.

Lubrication Industry: Deutsch-style connectors are commonly used in the lubrication industry because of their ability to withstand exposure to oil and grease. They are often used in oil dispensing systems and other equipment that require frequent lubrication.

Choosing a quality Deutsch- style connection eliminates the need for terminating wires and specialized crimping tools. One should also ensure that the selected connector is as rugged as need be for the environment in which it will operate. IF necessary, choose a Deutsch-style connector that is resistant to dust, heat, oil, and shock.

Connectors today may also be found that provide useful features such as powerful indicator lights. When troubleshooting a piece of equipment is necessary, indicator lights prove to be an invaluable tool to show where power is (or is not)

applied and where a problem may be present.

Overall, the importance of Deutsch-style connectors in fluid power applications cannot be overstated. These connectors provide essential protection and functionality that are necessary for the safe and reliable operation of fluid power systems. Choosing a connector solution with over-molded construction, indicator lights, and surge suppression capabilities can make them an ideal choice for use in harsh environments and demanding conditions. •

Automation Industry: Deutsch-style connectors are widely used in the automation industry for their ability to handle high-speed data transmission and complex control signals. They are often used in industrial automation equipment, robotics, and control systems.

Process Industry: Deutsch-style connectors are commonly used in the process industry for their ability to handle a wide range of temperatures, pressures, and corrosive chemicals. They are often used in pumps, valves, and other equipment that is used in chemical processing, food processing, and pharmaceutical manufacturing.

Oil and Gas Industry: Deutsch-style connectors are widely used in the oil and gas industry because of their ability to withstand harsh environments such as exposure to saltwater, extreme temperatures, and high pressure. They are often relied on in these environments and it is imperative that the connector can sustain the harshest of conditions in these no-fail applications.

In Conclusion

Technological developments have brought savings in time and money in every area of life — with electrical connections for the fluid power industry being no exception.

COMPACT HYDRAULICS IS ON THE MOVE

By Ben Dupré, Sr. Technical Writer, HydraForce, Inc.

By Ben Dupré, Sr. Technical Writer, HydraForce, Inc.

you ask of it. This dramatic increase in accuracy opens the door to all sorts of precision applications, including autonomous vehicle functions.

Distribute control for flexibility and efficiency

The EDG-OBE is a plug-and-play CAN control compatible with the SAE J1939 standard used primarily in mobile machinery applications. It can be added easily to any vehicle with a Controller Area Network. As an independent CAN device on the network, the main vehicle control needs only to send a command telling the valve to open at some percentage of maximum. The onboard electronics do the rest. The OBE is also able to send messages back to the vehicle controller, reporting status, opening position, and diagnostic messages (DMs).

The OBE handles all the functions needed to provide a stable output from the valve. It operates the PID control loop and allows very precise tuning for the needs of a particular application. It controls the piloting of the main spool, adjusting forces many times per second to maintain the provided setpoint.

Using CAN to employ distributed control lightens the load on the main vehicle controller allowing you to use a more economical main vehicle control with less total I/O. A distributed control architecture can even allow multiple independent controllers to operate the EDGOBE. For example: a truck-mounted crane may have a vehicle mounted control station and a remote “belly box” control. A mobile elevating work platform typically employs ground controls and platform controls. These separate control stations can operate the valves independently, and the long wire loom to the platform only needs to carry a low-voltage CAN signal, not heavy current-carrying conductors with a large voltage-drop. An application may even include redundant controls for safety reasons.

Close the loop on hysteresis

Closing the loop with spool position feedback has many benefits and allows the EDG-OBE to self-compensate for variations such as coil resistance, temperature, and hydrodynamic forces. Even manufacturing variation is overcome with position feedback. The net effect is accuracy approaching that of very expensive servo-controls, faster response, and very low hysteresis.

Optimize your controls for the needs of each function

The PID control loop is tunable to optimize for different performance needs. One function on the machine may require very fast operation while another may be intolerant of overshoot. With closed-loop control, you can also change the response of the control to match the actuator. One function may require a wide deadband while another may require a quick response at the beginning of the stroke, and a slow response near the end. With EDG-OBE each section can be tuned and shaped independently. You also have the traditional options available such as optimizing the metering profile though the use of alternative spool configurations.

With software you can perform Input/ output scaling and curve shaping, and with closed-loop control you can do this very accurately. Imagine you have a section of the valve bank dedicated to controlling attachments, possibly used with an ISOBus display/controller: the control curve and performance can be adapted to the different needs of each attachment without any hardware change required. Or an operator of a mobile elevating work platform must position the boom very carefully around electrical transmission wires, you can design a creep mode that slows the boom movement for precise placement.

continued on page 16

Operate safely

With failover-redundant control circuits, EDG-OBE is Pld (Performance level d) compliant as per ISO 13849 making it suitable for use in applications such as mobile elevating work platforms and truck-mounted cranes where operator safety concerns demand a very high level of reliability.

The on-board electronics are compatible with CANsafe networks for use on machines with elevated safety and security concerns. CANsafe is an extension of the Controller Area Network

Build flexibly

Bosch Rexroth compact directional valves are very modular and scalable in nature. You can mix and match valve sections to build your entire hydraulic system in one unit. In addition to EDG-OBE, the EDG line of 4/3 and 4/2 pre-compensated, bankable spool valves has on-off modules (EDG-DO), direct-acting proportional modules (EDG-DP), and electro-hydraulically piloted proportional modules (EDG-PP) that can be combined in one bank. All of these are customizable with various

space is maximized, the empty spaces between pallets and cartons shrink. The technology is essential to performing material movements safely as warehouse space is often shared with inventory workers and even big-box retail customers.

(CAN) protocol designed for use in applications where safety is of paramount importance. CANsafe adds a number of features such as: error detection and reporting, fault tolerance, diagnostics, and encryption to CAN that make it more suitable for safety-critical applications.

Save space

With smaller more efficient machines being developed today, space claim can be an important factor when choosing hydraulic system components. The EDG line of bankable compact directional valves is the most compact and lightweight solution available in the industry for flow rates up to 60 lpm (15 gpm).

Save energy

The EDG-OBE uses smart energy control. Compared to electrohydraulic piloted control EDG-PP, the OBE piloting element consumes less power while holding spool position. On battery-powered vehicles, every amp counts, and even small

port-relief, anti-cavitation, counterbalance, PO checks, and load-sense relief valves. Additionally, dedicated inlet or intermediate elements are available to adapt other frame sizes to form a complete hydraulic solution for any flow rate.

Depend on precision

Responding to the demand for more autonomous machines and machine functions, closed-loop control is becoming a key component in many applications. The enhanced precision and reliability these controls provide are essential for functions like automatic steering on machines that track a repetitive course. Whether plowing a field or grading a building site, any error in the hydraulic steering can quickly compound as the vehicle moves row by row across the field/site.

Material handlers that place bulky pallets precisely in high storage bays rely heavily on the accuracy and repeatability of closed-loop controls. As every cubic foot of material storage

Truck-mounted cranes may unload cargo onto the street, or may be expected to place building materials precisely on upper stories and rooftops. Mobile elevating work platforms require greater precision in their controls when operating while the platform is in the air. Both types of machines employ long booms that can store kinetic energy and may become wildly unstable if not carefully controlled.

Align your vision

Bosch Rexroth is committed to providing powerful compact solutions for your mobile equipment that stretch the market’s expectations. In a world that is rapidly moving to maximize sustainability and energy efficiency, hydraulics continue not only to remain relevant, but also to provide the most optimized solutions where power density and compactness are a major concern.

HydraForce cartridge valves and electronic controls have recently been added to the compact hydraulics family. As ONE company, HydraForce and Bosch Rexroth Compact Hydraulics are already strongly aligned with a vision for the future of hydraulic controls. •

At Ultra Clean Technologies, our focus is on contamination control. We educate our customers on why it’s important to clean and seal out contamination from hose, tube, and pipe assemblies.

Each step of the fabrication process generates contamination. Whether from the cutting and crimping process of a hose or the drawing, bending and flaring process of a tube; rubber, metal, and other contaminants enter these assemblies. If these contaminants are not removed properly, they will cause catastrophic and costly equipment failures.

After cleaning the assembly, it is recommended to use one of our Clean Seal Capsules. Utilizing heat shrink technology, sealing the ends of a hose or tube assembly with a Clean Seal Capsule eliminates potential re-contamination that is problematic with traditional capping and plugging methods.

Re-contamination occurs when ill-fitting caps and plugs forced onto an assembly fall off or are forcibly removed causing plastic particles to shear off and re-enter a cleaned hose or tube. Clean Seal Capsules are a more effective, less expensive, and easier to use option.

Benefits of Clean Seal Capsules

• Capsule Seals in under 1 second

• Eliminates excessive cap and plug inventories.

• Just 19 capsule sizes needed for all applications up to 3”

• Packaging and system options for low or high production

• Seals straight and elbow fittings

• Custom color private labeling available

sales@ultracleantech.com | 1-800-791-9111 www.ultracleantech.com

THE FACE OF HYDRAULIC CYLINDERS

YATES CYLINDERS

yates Proudly Serves All Industries for over 50 years!

yates Industries manufactures and rebuilds hydraulic and pneumatic cylinders of world-class value. Established as a fluid power distributor by William H. yates II in 1972, yates has evolved into a state-of-the-art familyowned company with over 335,000 + sq. ft. of manufacturing and repair space.

Going strong for over 50 years, we proudly serve all industries, from agriculture, aerospace, and defense, to construction and steel. The viable demand for yates's quality products and services grew, prompting several expansions in Georgia, Alabama, and Ohio. Adding these facilities gave yates greater capacity for our welded and mill-duty cylinder lines, enabling us to provide faster turnaround times and increase our service area throughout the southern U.S. yates strives to maintain our reputation as one of the country's largest, most complete pneumatic and hydraulic cylinder manufacturers. Contact us today to handle ALL your cylinder needs! Proudly made in the USA.

586.778.7680 | sales@yatesind.com yatesind.com

THE FACE OF SERVO VALVES HYDRAULEX

At Hydraulex, we have a servo and proportional valve team that is second to none. We remanufacture, rebuild and repair servo valves every day in our state-of-the-art environmentally controlled lab - on test stands built and designed specifically for servo and proportional valves. We can handle all valve sizes from all the major manufacturers. Our standard turnaround for repairs is 2-3 days with same-day service available as well.

In addition to our repair capabilities, we stock an impressive inventory of Hydraulex Reman (remanufactured) servo valves, ready for immediate delivery. Hydraulex Reman valves

provide you a much more cost-effective solution and minimize downtime when considering lead times from OEMs. Did we mention that our reman products are backed by a 24-month warranty?

With Hydraulex you get guaranteed quality, the best selection and the best value. So, give us a call or email us with your servo valve needs. We’d be happy to help!

1-800-422-4279 or 586-949-4240 sales@hydraulex.com www.hydraulex.com

OPEN TO A ll IFPS MEMBERS!

2023 IFPS Annual Meeting and Hall of Fame Awards Dinner

» THE IFPS ANNUAL Meeting will be held in-person and virtually September 25-28, 2023. The in-person meeting will take place at the Pfister Hotel, Milwaukee, WI.

Why attend? You’ll meet a dedicated (and fun) group of professionals who exchange ideas and technologies, on ways to improve and educate the fluid power workforce. Our board members have diverse backgrounds and work in many different segments of the industry. So, the discussion is lively and informative. Imagine the things you’ll learn!

Each of our committees, Education, Certification, Membership, Marketing and Finance, follows a mission statement and each team works together on projects to meet those goals. Our members’ input is vitally important, so if you can’t attend in person, consider joining one of our committees. Contact Jenna Mort at jmort@ifps.org.

In addition to committee meetings, tours, and networking, a Technical Workshop, Hydraulic Fluid - The “Life Blood” of Hydraulic Systems – Purpose, Performance Characteristics, Maintenance & Monitoring, will be held on Monday, September 25th Register by visiting ifps.org

IFPS Releases Mechanic Training Modules

» THIS ONLINE AT-YOUR-OWN-PACE training module takes the IHM and MHM study manuals and brings them to life! The mechanic training modules heavily emphasize maintaining, repairing, and troubleshooting hydraulic systems. These modules also include the basic principles of fluid power and the operation and construction of the most common hydraulic components found in the system.

These modules are a great tool for someone preparing for an IHM or MHM certification test, someone looking to boost their skills, and even makes an excellent onboarding tool for entry-level mechanics!

Our IHM and MHM certification study manuals were transformed from traditional black/white print into a full color, animated, interactive online learning platform!

• Schematics are color coded and animated

• Contains ISO 1219 symbology

• Full-color graphics

• Chapter review questions - interactive (you’ll know immediately if you’ve grasped the chapter information)

• Voice-over for text for auditory learners

• Three additional online pre-tests

• Safety and Energy Tips throughout

Cost is $349. Multiple-user pricing for five or more! E-mail sales@ifps. org for details. Visit https://ifps.learnupon.com or call 856-424-8998.

IFPS Releases Math Training Modules

»A RECENT STUDY found that more than 68% of participants cited a lack of confidence as the biggest stumbling block to a student’s ability to succeed in math. If math is a stumbling block for you, or if you are preparing to take a certification test, this online at-your-own-pace training module transforms the IFPS math book into an interactive learning tool!

Dan Helgerson, CFPAI, will teach fundamental fluid power math skills and build on that foundation to explain the calculation of more complicated formulas. Each section includes step-by-step video instructions on how to solve complex fluid power math problems.

Outline

1. Welcome to the Fluid Power Math Workshop

2. Understanding the Order of Operations –PEMDAS

3. Units used in IFPS Fluid Power Math Equations

4. Math Basics

5. Circles

6. Various Math Equations

7. Fluid Power Formulae

8. Calculating, Volumetric, Mechanical and Overall Efficiency

9. How to Size and Select a Fluid Power Cylinder

10. Calculating Fluid Velocity

11. Detailed Explanation and the Importance Triangles in Fluid Power

12. Understanding Reaction Forces

13. Jib Boom Calculations

14. Understanding Toggles

15. Misc. Reservoir Equations

16. Understanding Compressed Air

17. Coefficient of Velocity

18. Sizing Accumulators

19. Coefficient of Friction

20. Understanding Cartridge Elements

21. Electric Formulae - Ohm's Cost is $199. Multiple-user pricing for five or more! E-mail sales@ifps. org for details. Visit https://ifps.learnupon.com or call 856-424-8998.

Newly Certified Professionals

April 2023

Connector and Conductor (CC)

Gerried Brizendine, Controlled Fluids, Inc.

Kendra Bryant, Controlled Fluids, Inc.

Laurie Culbertson, Controlled Fluids, Inc.

Carrie Bustamante, Devine Hydraulics

Jared Mitchell, The Boeing Company

Joshua Trout, The Boeing Company

Wade Bennett, The Boeing Company

Electronic Control Specialist (ECS)

Christian Berg, Cascade Corporation

Hydraulic Specialist (HS)

Seth Davis, Pueblo Community College

Andrew Patience

Industrial Hydraulic Mechanic (IHM)

Ariel Garza, Controlled Motion Solutions

Mechanic Hydraulic Mechanic (MHM)

George Moore, Altec Industries, Inc.

Colton Maxwell, Altec Industries, Inc.

Derek Salmi, Altec Industries, Inc.

Jason Hale, Altec Industries, Inc.

Jessie Hornback, Altec Industries, Inc.

Jordan Hayes, Altec Industries, Inc.

Josh Scudder, Altec Industries, Inc.

Mark your Calendar

Nicholas Carella, Altec Industries, Inc.

Paul Turner, Altec Industries, Inc.

Robert Brady, Altec Industries, Inc.

Roberta Hart, Altec Industries, Inc.

Sam Wolf, Altec Industries, Inc.

Steven Costa, Altec Industries, Inc.

Robert Jones, Altec Industries, Inc.

Darren Slowik, City Utility Equipment Sales Leasing

Andrew Sullivan, Dominion Energy

Brad Lane, Dominion Energy

Cliff Wallace, Dominion Energy

Derick Dwyer, Dominion Energy

Eric Robichaux, Dominion Energy

Jonathan Gross, Dominion Energy

Matt Comer, Dominion Energy

Mike Chamberlain, Dominion Energy

Carter Hudson

Michael Veitenheimer

Pneumatic Specialist (PS)

Aaron Jankins, Loram Maintenance of Way Inc.

Trent Jensen, Loram Maintenance of Way, Inc.

Aaron Abele, Parker Hannifin Corporation

Grant Noll, Parker Hannifin Corporation

Jacob Scohy, Parker Hannifin Corporation

Logan Mills, Parker Hannifin Corporation

Matt Brightman, Parker Hannifin Corporation

Zach Hickey, Parker Hannifin Corporation

Jake Naumann

Nathaniel Hook

Adam Rakow

Zeke Brallier

Specialist (S)

Aaron Jankins, Loram Maintenance of Way Inc.

Trent Jensen, Loram Maintenance of Way, Inc.

Aaron Abele, Parker Hannifin Corporation

Grant Noll, Parker Hannifin Corporation

Matt Brightman, Parker Hannifin Corporation

Zach Hickey, Parker Hannifin Corporation

Jake Naumann

Nathaniel Hook

Adam Rakow

Zeke Brallier

upcoming Workshops

Accredited Instructor (AI) and Authorized Job Performance Proctor (AJPP) Workshops

August 29-30, 2023, Cherry Hill, NJ

For more information, visit www.ifps.org/web-seminars.

UPCOMING WEB SEMINARS

Electronic Load Sensing

When: July 20 12-1 p.m. [ET]

How to Read Hydraulic/ Pneumatic Schematics

When: Aug. 17, 12-1 p.m. [ET]

Principals of Hydraulics: Is It Really Magic?

When: Sept. 14, 12 p.m. [ET]

Conductor Identification

When: Oct. 5, 12 p.m. [ET]

Calculating the Useable Amount of Oil from a Pneumatic Accumulator

When: Nov. 2, 12 p.m. [ET]

» THE AI WORKSHOP is a one or two-day workshop to acquaint you with the IFPS certification program and to assess your instructional abilities. It is not a program to teach instructor skills, but rather, to measure your instructor skills.

IFPS AIs have extensive backgrounds and instructional experience in the fluid power industry. In addition to their instructor accreditation, they are committed IFPS members and hold various levels of IFPS certifications.

IFPS AJPPs are certified to proctor all mechanic and technician and Connector and Conductor job performance (hands-on section) tests, an individual must hold the certification they plan to proctor and must be an IFPS Member.

Registration: deadline August 9, 2023. Visit www.ifps.org/certified-accredited-instructor to register.

Written Certification Test Locations

Al ABAMA

Auburn, AL

Birmingham, AL

Individuals wishing to take any IFPS written certification tests can select from convenient locations across the United States and Canada. IFPS is able to offer these locations through its affiliation with the Consortium of College Testing Centers provided by National College Testing Association.

Contact Kyle Pollander at Kpollander@ifps.org if you do not see a location near you. Every effort will be made to accommodate your needs.

Calera, AL

Decatur, AL

Huntsville, AL

Jacksonville, AL

Mobile, AL

Montgomery, AL

Normal, AL

Tuscaloosa, AL

Al ASKA

Anchorage, AK

Fairbanks, AK

ARIZONA

Flagstaff, AZ

Glendale, AZ

Mesa, AZ

Phoenix, AZ

Prescott, AZ

Scottsdale, AZ

Sierra Vista, AZ

Tempe, AZ

Thatcher, AZ

Tucson, AZ

Yuma, AZ

ARKANSAS

Bentonville, AR

Hot Springs, AR

Little Rock, AR

CAlIFORNIA

Aptos, CA

Arcata, CA

TENTATIVE TESTING DATES FOR A ll lOCATIONS:

August 2023

Tuesday 8/8 • Thursday 8/24

September 2023

Tuesday 9/12 • Thursday 9/21

October 2023

Monday 10/2 • Thursday 10/26

November 2023

Tuesday 11/7 • Thursday 30/26

Bakersfield, CA

Dixon, CA

Encinitas, CA

Fresno, CA

Irvine, CA

Marysville, CA

Riverside, CA

Salinas, CA

San Diego, CA

San Jose, CA

San Luis Obispo, CA

Santa Ana, CA

Santa Maria, CA

Santa Rosa, CA

Tustin, CA

Yucaipa, CA

COlORADO

Aurora, CO

Boulder, CO

Springs, CO

Denver, CO

Durango, CO

Ft. Collins, CO

Greeley, CO

Lakewood, CO

Littleton, CO

Pueblo, CO

DEl AWARE

Tallahassee, FL

Tampa, FL

West Palm Beach, FL

Wildwood, FL

Winter Haven, FL

GEORGIA

Albany, GA

Athens, GA

Atlanta, GA

Carrollton, GA

Columbus, GA

Dahlonega, GA

Dublin, GA

Dunwoody, GA

Forest Park, GA

Lawrenceville, GA

Morrow, GA

Oakwood, GA

Savannah, GA

Statesboro, GA

Tifton, GA

Valdosta, GA

HAWAII

Laie, HI

IDAHO

Boise, ID

Coeur d ‘Alene, ID

Idaho Falls, ID

Lewiston, ID

Moscow, ID

Nampa, ID

Rexburg, ID

Twin Falls, ID

IllINOIS

Carbondale, IL

Carterville, IL

Champaign, IL

Decatur, IL

Edwardsville, IL

Glen Ellyn, IL

Joliet, IL

Malta, IL

Normal, IL

Peoria, IL

Schaumburg, IL

Springfield, IL

University Park, IL

INDIANA

Bloomington, IN

Columbus, IN

Evansville, IN

Fort Wayne, IN

Gary, IN

Indianapolis, IN

Kokomo, IN

Lafayette, IN

Lawrenceburg, IN

Madison, IN

Muncie, IN

New Albany, IN

Richmond, IN

Sellersburg, IN

JOB PERFORMANCE TEST lOCATIONS

Arizona

California

Colorado

Florida

Georgia

Maine Michigan

Minnesota

Montana New Jersey

Nova Scotia Pennsylvania Texas Washington Wyoming Western Australia

Dover, DE

Georgetown, DE

Newark, DE

FlORIDA

Avon Park, FL

Boca Raton, FL

Cocoa, FL

Davie, FL

Daytona Beach, FL

Fort Pierce, FL

Ft. Myers, FL

Gainesville, FL

Jacksonville, FL

Miami Gardens, FL

Milton, FL

New Port Richey, FL

Ocala, FL

Orlando, FL

Panama City, FL

Pembroke Pines, FL

Pensacola, FL

Plant City, FL

Riviera Beach, FL

Sanford, FL

lOuISIANA

Bossier City, LA

Lafayette, LA

Monroe, LA

Natchitoches, LA

New Orleans, LA

Shreveport, LA

Thibodaux, LA

MARyl AND

Arnold, MD

Bel Air, MD

College Park, MD

Frederick, MD

Hagerstown, MD

La Plata, MD

Westminster, MD

Woodlawn, MD

Wye Mills, MD

MASSACHuSETTS

Boston, MA

Bridgewater, MA

Danvers, MA

Haverhill, MA

Holyoke, MA

Shrewsbury, MA

MICHIGAN

Ann Arbor, MI

Big Rapids, MI

Chesterfield, MI

Dearborn, MI

Dowagiac, MI

East Lansing, MI

Flint, MI

Grand Rapids, MI

Kalamazoo, MI

Lansing, MI

Livonia, MI

Mount Pleasant, MI

Sault Ste. Marie, M

Troy, MI

University Center, MI

Warren, MI

MINNESOTA

Alexandria, MN

Brooklyn Park, MN

Duluth, MN

Eden Prairie, MN

Granite Falls, MN

Mankato, MN

MISSISSIPPI

Goodman, MS

Jackson, MS

Mississippi State, MS

Raymond, MS

University, MS

MISSOuRI

Berkley, MO

Cape Girardeau, MO

Columbia, MO

Cottleville, MO

Joplin, MO

Kansas City, MO

South Bend, IN

Terre Haute, IN

IOWA

Ames, IA

Cedar Rapids, IA

Iowa City, IA

Ottumwa, IA

Sioux City, IA

Waterloo, IA

KANSAS

Kansas City, KS

Lawrence, KS

Manhattan, KS

Wichita, KS

KENTuCKy

Ashland, KY

Bowling Green, KY

Erlanger, KY

Highland Heights, KY

Louisville, KY

Morehead, KY

NEW JERSEy

Branchburg, NJ

Cherry Hill, NJ

Lincroft, NJ

Sewell, NJ

Toms River, NJ

West Windsor, NJ

NEW MEXICO

Albuquerque, NM

Clovis, NM

Farmington, NM

Portales, NM

Santa Fe, NM

NEW yORK

Alfred, NY

Brooklyn, NY

Buffalo, NY

Garden City, NY

New York, NY

Rochester, NY

Syracuse, NY

NORTH CAROlINA

Apex, NC

Asheville, NC

Boone, NC

Charlotte, NC

China Grove, NC

Durham, NC

Fayetteville, NC

Greenville, NC

Jamestown, NC

Misenheimer, NC

Mount Airy, NC

Pembroke, NC

Raleigh, NC

Wilmington, NC

NORTH DAKOTA

Bismarck, ND

OHIO

Akron, OH

Cincinnati, OH

Cleveland, OH

Columbus, OH

Fairfield, OH

Findlay, OH

Kirtland, OH

Lima, OH

Maumee, OH

Newark, OH

North Royalton, OH

Rio Grande, OH

Toledo, OH

Warren, OH

Youngstown, OH

OKl AHOMA

Altus, OK

Bethany, OK

Edmond, OK

Norman, OK

Oklahoma City, OK

Tonkawa, OK

Tulsa, OK

SOuTH CAROlINA

Beaufort, SC

Charleston, SC

Columbia, SC

Conway, SC

Graniteville, SC

Greenville, SC

Greenwood, SC

Orangeburg, SC

Rock Hill, SC

Spartanburg, SC

TENNESSEE

Blountville, TN

Clarksville, TN

Collegedale, TN

Gallatin, TN

Johnson City, TN

Knoxville, TN

Memphis, TN

Morristown, TN

Murfreesboro, TN

Nashville, TN

TEXAS

Abilene, TX

Arlington, TX

Austin, TX

Beaumont, TX

Brownsville, TX

Commerce, TX

Corpus Christi, TX

Dallas, TX

Denison, TX

El Paso, TX

Houston, TX

Huntsville, TX

Laredo, TX

Lubbock, TX

Lufkin, TX

Mesquite, TX

San Antonio, TX

Victoria, TX

Waxahachie, TX

Weatherford, TX

Wichita Falls, TX

uTAH

Cedar City, UT

Kaysville, UT

Logan, UT

Ogden, UT

Orem, UT

Salt Lake City, UT

VIRGINIA

Daleville, VA

Fredericksburg, VA

Lynchburg, VA

Manassas, VA

Norfolk, VA

Roanoke, VA

Salem, VA

Staunton, VA

Suffolk, VA

Virginia Beach, VA

Wytheville, VA

WyOMING

Casper, WY

Laramie, WY

Torrington, WY

CANADA

AlBERTA

Calgary, AB

Edmonton, AB

Fort McMurray, AB

Lethbridge, AB

Lloydminster, AB

Olds, AB

Red Deer, AB

BRITISH

COluMBIA

Abbotsford, BC

Burnaby, BC

Castlegar, BC

Delta, BC

Kamloops, BC

Nanaimo, BC

Prince George, BC

Richmond, BC

Surrey, BC

Vancouver, BC

Victoria, BC

MANITOBA

Brandon, MB

Winnipeg, MB

NEW BRuNSWICK

Bathurst, NB

Moncton, NB

NEWFOuNDl AND AND l ABRADOR

St. John’s, NL

NOVA SCOTIA

Halifax, NS

ONTARIO

Brockville, ON

Hamilton, ON

London, ON

Milton, ON

Mississauga, ON

Niagara-on-the-Lake, ON

North Bay, ON North York, ON

Ottawa, ON

Toronto, ON

Welland, ON

Windsor, ON

QuEBEC

Côte Saint-Luc, QB

Montreal, QB

SASKATCHEWAN

Melfort, SK

Moose Jaw, SK

Nipawin, SK

Prince Albert, SK

Saskatoon, SK

Kirksville, MO

Park Hills, MO

Poplar Bluff, MO

Rolla, MO

Sedalia, MO

Springfield, MO

St. Joseph, MO

St. Louis, MO

Warrensburg, MO

MONTANA

Bozeman, MT

Missoula, MT

NEBRASKA

Lincoln, NE

North Platte, NE

Omaha, NE

NEVADA

Henderson, NV

Las Vegas, NV

North Las Vegas, NV

Winnemucca, NV

OREGON

Bend, OR

Coos Bay, OR

Eugene, OR

Gresham, OR

Klamath Falls, OR

Medford, OR

Oregon City, OR

Portland, OR

White City, OR

PENNSylVANIA

Bloomsburg, PA

Blue Bell, PA

Gettysburg, PA

Harrisburg, PA

Lancaster, PA

Newtown, PA

Philadelphia, PA

Pittsburgh, PA

Wilkes-Barre, PA

York, PA

WASHINGTON

Auburn, WA

Bellingham, WA

Bremerton, WA

Ellensburg, WA

Ephrata, WA

Olympia, WA

Pasco, WA

Rockingham, WA

Seattle, WA

Shoreline, WA

Spokane, WA

WEST VIRGINIA

Ona, WV

WISCONSIN

La Crosse, WI

Milwaukee, WI

Mukwonago, WI

yuKON TERRITORy

Whitehorse, YU

uNITED KINGDOM

Elgin, UK

GHAZNI

Kingdom of Bahrain, GHA

Thomasville, GHA

EGyPT

Cairo, EG

JORDAN

Amman, JOR

NEW ZEAl AND Taradale, NZ

CFPMM Certified Fluid Power Master Mechanic (Must Obtain CFPIHM, CFPMHM, & CFPPM)

CFPIHM Certified Fluid Power Industrial Hydraulic Mechanic

CFPMHM Certified Fluid Power Mobile Hydraulic Mechanic

CFPPM Certified Fluid Power Pneumatic Mechanic

CFPMIH Certified Fluid Power

Master of Industrial Hydraulics (Must Obtain CFPIHM, CFPIHT, & CFPCC)

CFPMMH Certified Fluid Power

Master of Mobile Hydraulics (Must Obtain CFPMHM, CFPMHT, & CFPCC)

CFPMIP Certified Fluid Power

Master of Industrial Pneumatics (Must Obtain CFPPM, CFPPT, & CFPCC)

CFPCC Certified Fluid Power Connector & Conductor

CFPSD Fluid Power System Designer

Tentative Certification Review Training

IFPS offers onsite review training for small groups of at least 10 persons. An IFPS accredited instructor visits your company to conduct the review. Contact kpollander@ifps.org for details of the scheduled onsite reviews listed below.

HyDRAulIC SPECIAlIST

May 1-3, Mukwonago, WI, MSOE. Written test: May 4.

May 8-11, Fairfield, OH, CFC Industrial Training, Written test: May 12.

Aug. 14-17, Fairfield, OH, CFC Industrial Training, Written test: Aug. 18.

Dec. 4-7, 2023, Fairfield, OH, CFC Industrial Training. Written test: Dec. 8, 2023.

ElECTRONIC CONTROlS SPECIAlIST

July 24-27, Fairfield, OH, CFC Industrial Training. Written test: July 27.

PNEuMATIC SPECIAlIST

June 19-22, Fairfield, OH, CFC Industrial Training. Written test: June 23.

Nov. 13-16, Fairfield, OH, CFC Industrial Training. Written test: Nov. 17.

CONNECTOR & CONDuCTOR

May 23-24, Fairfield, OH, CFC Industrial Training. Written and JP test: May 25.

Nov. 15-16, Fairfield, OH, CFC Industrial Training. Written and JP test: Nov. 17.

MOBIlE HyDRAulIC MECHANIC

June 26-29, Fairfield, OH, CFC Industrial Training. Written and JP test: June 31.

Oct. 23-26, Fairfield, OH, CFC Industrial Training. Written and JP test: Oct. 27.

Online Mobile Hydraulic Mechanic certification review for written test is offered through CFC Industrial Training. This course surveys the MHM Study Manual (6.5 hours) and every outcome to prepare you for the written test. Members may e-mail for a 20% coupon code off the list price. Test fees are not included.

INDuSTRIAl HyDRAulIC MECHANIC

June 5-8, Fairfield, OH, CFC Industrial Training. Written and JP test: June 9.

INDuSTRIAl HyDRAulIC TECHNICIAN

For dates, call CFC Industrial Training at (513) 874-3225 or visit www.cfcindustrialtraining.com/.

MOBIlE HyDRAulIC TECHNICIAN

Sept. 18-21, Fairfield, OH, CFC Industrial Training. Written and JP test: Sept. 22.

PNEuMATIC TECHNICIAN and PNEuMATIC MECHANIC

For dates, call CFC Industrial Training at (513)874-3225 or visit www.cfcindustrialtraining.com/.

JOB PERFORMANCE TRAINING

CFC Industrial Training offers an online Job Performance Review that includes stations 1-6 of the mechanic and technician Job Performance tests. Members may e-mail IFPS for a 20% coupon code off the list price. Test fees are not included. CFC also offers live distance learning Job Performance Station Reviews. To register or purchase, contact CFC Industrial Training at (513) 874-3225 or visit www.cfcindustrialtraining.com/.

upcoming In-Person Review Training

» WE'RE EXCITED TO announce that our highly sought-after In-person Hydraulic Specialist Review Training is now available in two new locations! Join us in Memphis, TN, or Windsor, Ontario CA, and gain the confidence you need to ace your certification test and take your career to the next level.

Make sure to mark your calendars for the upcoming training dates:

• Memphis, TN: August 21 - 25, 2023

• Windsor, Ontario CA: November 6 - 10, 2023

Limited seats are still available, so register today and take the first step toward becoming a Hydraulic Specialist! https://www.ifps.org/in-person-certification-review-training

If you are looking for customized in-person or online certification review training for your company, please contact Donna Pollander at dpollander@ifps.org

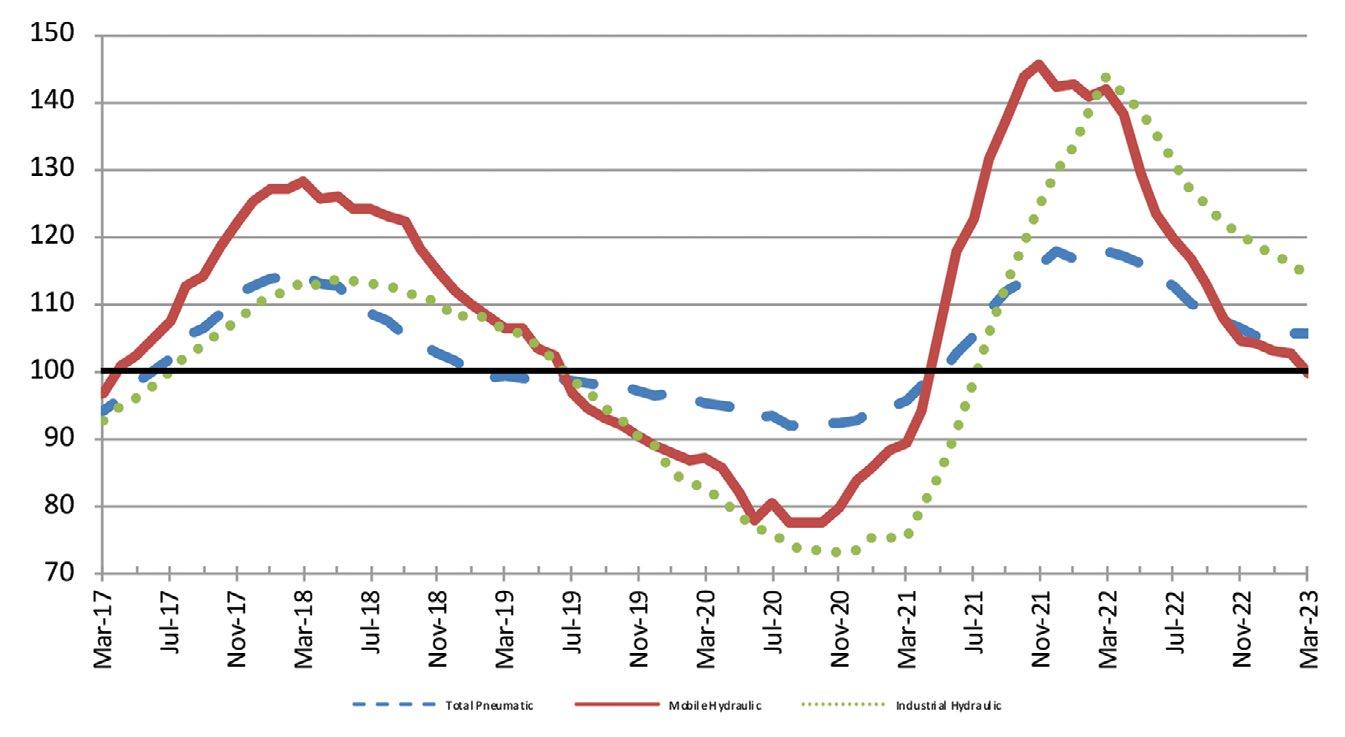

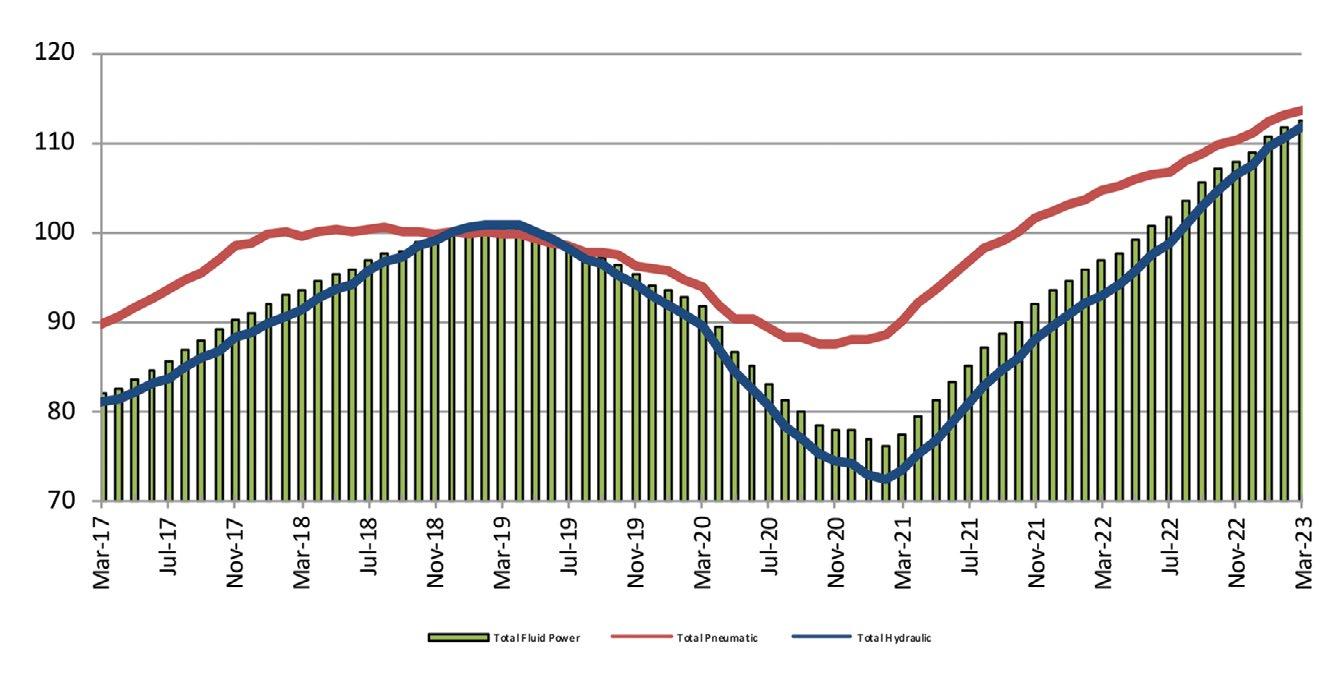

NFPA Reports Continued Growth in March

The latest data published by the National Fluid Power Association shows the 12-month moving average of shipments for pneumatics, hydraulics, and total fluid power continue to grow. The year-to-date % change for total fluid power shipments in February 2023 is 13.6%. Mobile hydraulic orders received from April 2022 to March 2023 are currently 98.0% of the orders received from April 2021 to March 2022. When looking at raw index data, pneumatic, mobile hydraulic, and industrial hydraulic shipments increased when compared to last month. These charts are drawn from data collected from more than 70 manufacturers of fluid power products by NFPA’s Confidential Shipment Statistics (CSS) program.

Hydraulic and Pneumatic Shipments

Raw Index Data, Index: 2018=100

This graph of raw index data is generated by the total dollar volume reported to NFPA by CSS participants and compared to the average monthly dollar volume in 2018. For example, the March 2023 total dollar volume for pneumatic shipments is 132.0% of the average monthly dollar volume in 2018. (Base Year 2018 = 100)

*Preliminary data subject to revision.

Shipments – Cumulative year‐to‐date % change (2023 vs. 2022)

The table above is expressed in terms of cumulative percent changes. These changes refer to the percent difference between the relevant cumulative total for 2023 and the total for the same months in 2022. For example, March 2023 pneumatic shipments figure of 9.6 means that for the calendar year through March 2023, pneumatic shipments increased 9.6% compared to the same time-period in 2022.

Pneumatic, Mobile, and Industrial Hydraulic Orders 12/12 Ratio

Each point on this graph represents the most recent 12 months of orders compared to the previous 12 months of orders. Each point can be read as a percentage. For example, 113.3 (the March 2023 level of the industrial hydraulic series) indicates that industrial hydraulic orders received from April 2022 to March 2023 were 113.3% of the orders received from April 2021 to March 2022.

(Base Year 2018 = 100)

Total - Hydraulic and Pneumatic Shipments 12 Month Moving Average

This graph of 12-month moving averages shows that in March 2023, total fluid power, total pneumatic, and total hydraulic all increased. (Base Year 2018 = 100)

UNIVERSITY OF LOUISIANA, LAFAYETTE, NAMED GRAND CHAMPION

The University of Louisiana at Lafayette was named Grand Champion at the 2023 Fluid Power Vehicle Challenge Final Competition hosted by Danfoss Power Solutions in Ames, IA.

The Vehicle Challenge is a competition that combines two technology platforms that are not normally associated with one another— human-powered vehicles and fluid power. Teams are tasked with designing and building their own fluid power vehicles over the course of a school year. The program culminates in final competitions at two separate locations.

Nine schools competed in four races, and were judged by fluid power industry professionals. In addition to the races, students gave presentations on their vehicle construction, testing, and lessons learned. Each team also met individually with the industry judges to assess their vehicle design. •

The Grand Champions of the Danfoss-hosted event are:

UNDERSTANDING THE OPERATION OF SERVO VALVES

continued from page 31

appropriate ports. At the “null” position, the spool is centered in the sleeve, just covering the P and T port openings. Spool motion to either side of the null position allows fluid to flow. With a constant pressure drop across the valve, flow to the load is proportional to the spool position.

Another common type of servo valve is the jet pipe design (Fig. 5.12). The pilot stage consists

mainly of a torque motor, jet pipe, and receiver. A current through the coil displaces the jet pipe from its neutral position. This displacement, combined with the jet pipe's unique shape, directs a focused fluid jet towards one side of the receiver. The jet now produces a pressure difference across the ends of the spool. This pressure difference causes a spool displacement,

which, in turn, results in control port flow. The pilot-stage drain is through the annular area around the nozzle to tank.

The relative position of the edge of the spool land and the edge of the matching sleeve’s slot for the port opening is critical. This is known as spool timing, and in the centered null position, it is referred to as the spool lap condition.

The three normal conditions are over-lapped, zero-lapped, and under-lapped spool designs (Fig. 5.13).

The over-lapped spool lands have additional (cover) material beyond the edge of the port. Therefore, the spool must move this distance from the null position before flow through the valve begins. This effect is called deadband. Once the spool land clears the edge of the port, the flow rate (Q) will be directly proportional to the amount of spool movement for a given pressure drop across the valve. The shape of the slots in the sleeve and whether there are notches in the spool lands will determine if this flow is linear. With over-lapped spools, there is a “minimum” input signal required to create flow through the valve. Any signal less than this minimum will not open the valve path ports, and the system will not be susceptible to small input or error signals.

TEST YOUR SKILLS

1. Servo valves are used:

a. For applications when feedback is not available.

b. When the hydraulic fluid is highly contaminated.

c. When a low-cost solution is needed.

d. In applications requiring a high degree of precision or responsiveness.

e. Only for replacements on old machines.

2. An under-lapped spool:

a. Is over-sized to provide a tight fit in the housing bore.

b. Has spool lands that are wider than the ports to block the flow in the null position.

c. Has spool lands that match the port openings to block the flow in the null position.

d. Has spool lands that do not fully block the port when in the null position.

e. Is the result of removing the spool and polishing it with emery cloth to remove the scratches.

3. Which valve has the highest contamination sensitivity?

a. 4/3 directional valve with low-watt DC coils.

b. Non-feedback proportional valve.

c. Proportional valve with spool position feedback.

d. High-performance proportional valve with feedback.

e. Flapper-nozzle servo valve.

See page 37 for the solution.

Zero-lapped spool lands align precisely with the edge of the ports. Under-lapped spool lands do not fully cover the port in the null position. The amount of over-lap or under-lap is usually expressed as a percentage of the total spool movement or as a percentage of the full-input signal.

Under-lapped spools do not fully block the ports, so the actuator may drift if there is an

external load when the hydraulic power is off. Loss of electrical control may also cause drifting.

The applications that require the higher performance of the servo valve also commonly utilize sensors to provide feedback to a controller. When diagnosing these applications, the control system must be reviewed as an entirety, not just component by component. •

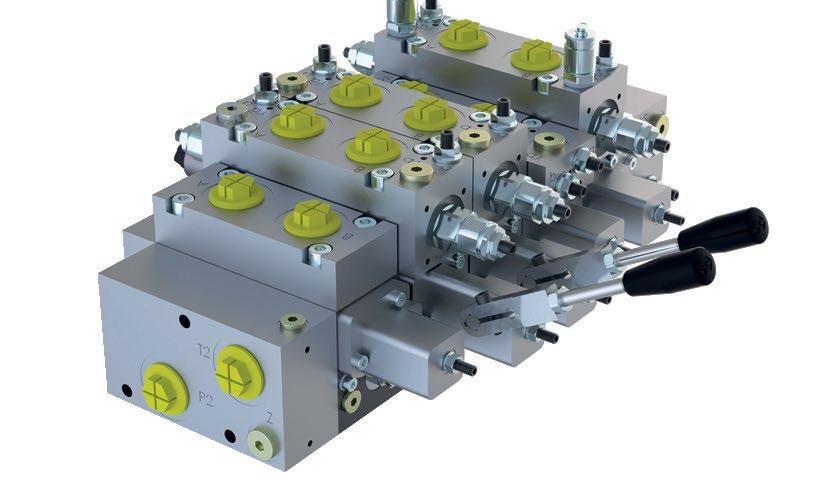

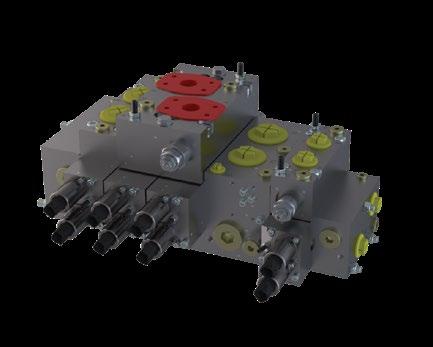

WANDFLUH LAUNCHES NEW MODULAR PRODUCT SERIES

to optimize the flow control needed and save space. The ability to efficiently combine different size valve sections means functions that need fine control of only a few l/min (<1 gpm) can be combined with brute functions that need up to 700 l/min (185 gpm) in one PMV module without having to compromise machine operation or operator productivity.

This exceptional modularity also allows optimizations and adaptations to be made very easily in the field. Most valve sections can be exchanged on site without removing the complete unit from the machine, reducing downtime during maintenance, but also improving development and commissioning times when changes need to be made. Oscillation or vibrations can occur in complex hydraulic installations, so the PMV design allows for damping orifices to be inserted in various key places, all of which are accessible from the module’s external surfaces.

Sustainable and efficient

Worldwide demands for sustainable products are well known and increasing, so during development, special attention was paid to high power density. With the maximum continuously rated operating pressure of 42 MPa (6,000 psi) and optimized internal flow paths that provide the lowest possible pressure drop, there is minimal power loss through the module. This makes more power available at the actuator with reduced heat generation. The PMV also uses small, compact pilot valves with the lowest available electrical power consumption for proportional solenoid control. Pressure safety cut-off is accomplished by small, fast acting, direct operated relief valves. Low pressure drops (Δp), low actuation electrical power, optimized flows, compact dimensions, and ease of maintenance, prove that the PMV system is designed to meet the global demands for efficiency and sustainability.

Outstanding metering control by either electrical or manual operation can be further enhanced with the use of a load compensator that is available for each control section. With an adjustable compensator, the flow rate is set to within +/one liter per minute and this flow accuracy is constant over the entire pressure range.

Features and expansion options

Various functions are easy to expand or already included in the standard module version. For more complex applications, an anti-saturation function can be mounted on the inlet plate so that all loads share the available flow. With this system, no actuator is starved for fluid. All actuators will slow proportionally but with minimal loss in productivity. If the load sense (LS) signal is too weak due to longer pump lines, it is possible to mount a small module with an LS amplifier on the inlet plate.

Modern mobile and marine equipment require the use of increased surface protection against corrosion. To meet this demand, the PMV Build Parts come with zinc/nickel coating as our standard protection, giving up to 1000 hours to red rust in the recognized ISO salt spray test.

To compliment the manual handle control or for full remote or general electrical control, Wandfluh offers a range of amplifiers, controller formats, and control options in its standard product offering. When targeting mobile and marine applications, the MD2 module is recommended. This bulkhead mounted unit is fully sealed with shock & vibration certification and uses 2-part connectors for easy cable assemblies. Depending on the chosen model, it can drive up to 8 independently current-controlled proportional solenoids. It can also be interfaced with a wide variety of analogue command signals, including the common PWM signal. For digital control systems the MD2 has the option of CANopen, and SAE J1939 field bus integrated into these electronics. Other functions such as on-board electronics (OBE) and spool position control (LVDT) are already being developed and will soon be available as a standard solution for the PMV.

Wandfluh is proud to further expand its already extensive product range and offer the global market a well-designed and viable modular product for sophisticated machine controls in the mobile and marine hydraulics sectors. Many of the advanced features mentioned here are available as standard and from stock. This adds a lot of positive value to the whole supply chain which is an important consideration where delivery time challenges may cause machines to miss shipping deadlines. •

PRODUCT SPOTLIGHT

KR Media Separated Valve line Designed for Harsh Chemical Handling

Coxreels® TDMP

Dual Hydraulic reel!

TDPM reel is robustly built for capacities up to 50’, with triple axel support, dual arm guides, and stainless-steel hose guide rollers. As with all Coxreels spring retractable reels, it features heavy gauge steel construction, durable CPC powder coat, rolled and ribbed discs, 2-year warranty, and USA made.

www.coxreels.com

Manufactured with all-stainless steel working components, the 4BKR and new 4DKR valves are engineered to be easily mounted on a machined manifold with one inlet and multiple outlets, requiring less labor by diminishing leak points and fittings needed. Perfect for medical, chemical washing, the food industry and more, to bring reliable solutions to valve systems in various applications.

learn more about our products at www.spartanscientific.com.

customerservice@spartanscientific.com

230 McClurg Rd. Youngstown, OH 44512

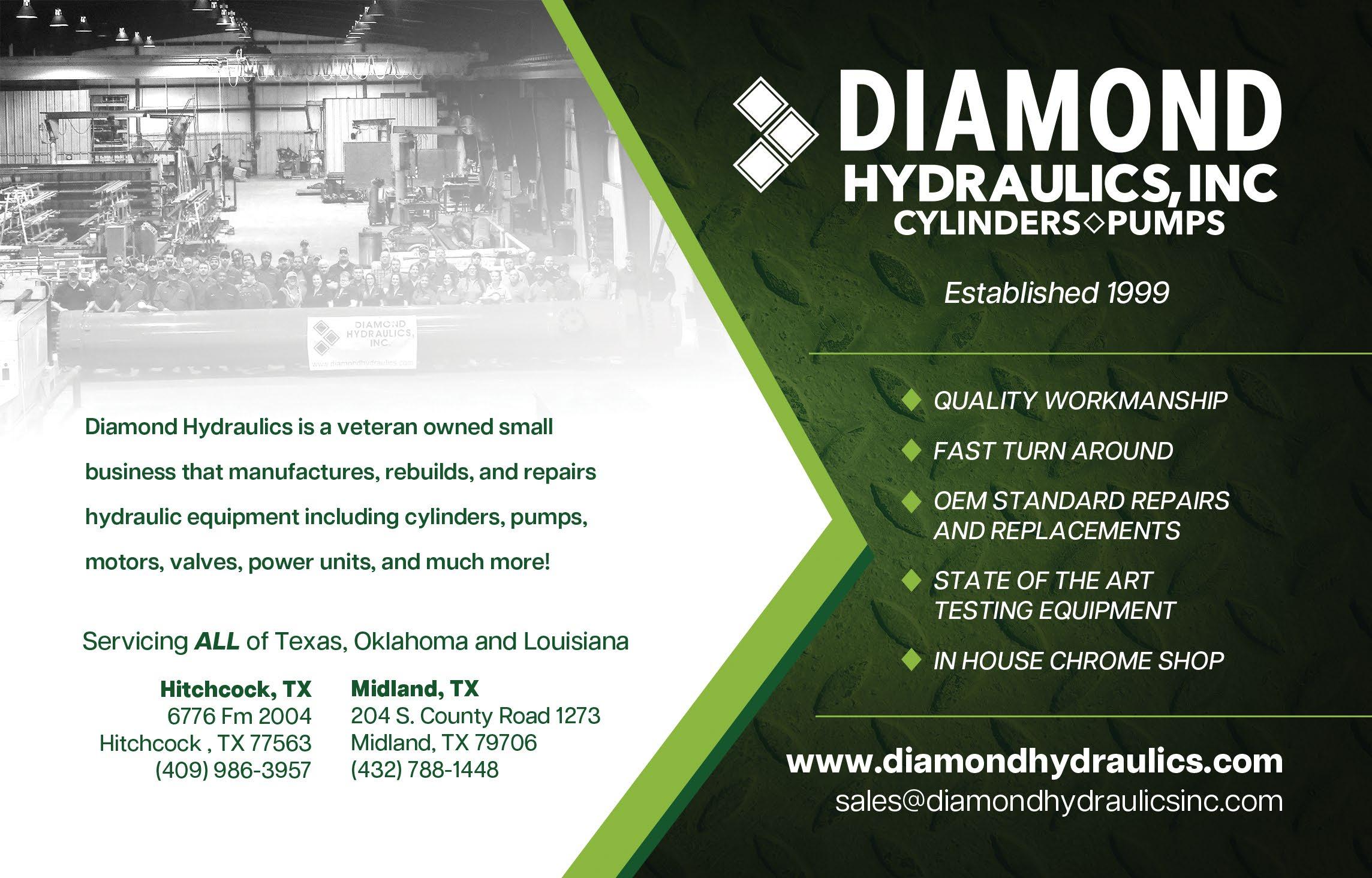

Diamond Hydraulics Inc.

Diamond Hydraulics is a veteran owned small business that manufactures, rebuilds, and repairs hydraulic equipment including cylinders, pumps, motors, valves, power units, and much more. We were established in 1999, and have over five decades of experience in hydraulic equipment repair.

Diamond Hydraulics provides quality workmanship, extensive industry knowledge, and fast turnaround time on repairs and replacements. All repairs are brought back up to OEM standards and tested with state-of-the-art test equipment.

Diamond Hydraulics Inc.

409-986-3957 (Office)

409-986-7437 (Fax)

sales@diamondhydraulicsinc.com

Max Machinery, Inc.

Skip counting teeth and join the revolution. By measuring the gear’s rotation, we can double your resolution and accuracy across all your process flows. From 1 cc/min to 240 liters/ min, Max Gear Meters provide 0.3% accuracy and data up to 500 pulses/cc. See what flow you’re missing and how to improve your process by using a Max Precision Gear Meter.

Max Machinery, Inc.

33A Healdsburg Ave.

Healdsburg, CA 95448

707-433-2662

www.maxmachinery.com

Go ahead. Push me. Ordinary heavy duty not heavy enough?

Heavy-Duty Mill Cylinders for:

• Induction-Hardened, Chrome-Plated Rods

• Heavy Wall Tubing

• Replaceable Glands & Retainer Rings

• High-Load Piston Design

Think indestructible and call yates.

www.yatesind.com

yates Industries (HQ)

586.778.7680

yates Cylinders Alabama

256.351.8081

yates Cylinders Georgia

678.355.2240

yates Cylinders Ohio

513.217.6777

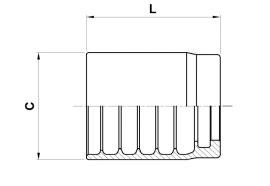

Texcel is pleased to announce the introduction of a new range of 2 piece hydraulic crimp fittings. The new 2 piece product range will have over 325 insert and ferrule part numbers covering most thread configurations including NPT, JIC, OFS, O-ring Boss, SAE, Code 61, 62 & Cat Flanges, British, DIN and Japanese. Contact Texcel today for your 2 piece hydraulic crimp fitting needs.

4444

texcelrubber.com

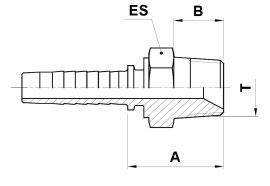

your Servo & Proportional Valve Experts

• State of the Art Valve Testing with Mobil DTE Lite, MIL-5606 & Skydrol

• 13 test stands including the Hagenbush Hydraulic System.

• High Quality Rebuilt Units w/ 1 Year Warranty

• Fast Repair Turnaround & 24 Hour Service Available

• Over 17,000 units in stock!

• Advanced Engineering & Crossovers

• 24/7 Technical support

SOLUTIONS

Here is the solution to Figure It Out on page 5.

»THE PROBLEM WITH the pump spinning backwards was caused by a faulty check valve that was located close to the pump. It had a broken spring that caused the poppet to stick in the open position.

PROuDly SERVING OuR INDuSTRy SINCE 1975 38422 Webb Dr Westland MI 48185 734-326-6666 | info@ncservo.com NCSERVO.COM

The correct answers to Test Your Skills on page 33 are 1-d, 2-d, and 3-e.

Clippard PTFE or PEEK Media Isolation & Medical Grade Pinch Valves

Ideal for use with sensitive or corrosive media, this line is an excellent alternative to traditional mechanical valves when media contamination is a concern, as they interact with medical grade tubing, PTFE or PEEK, and never touch the material being dispensed!

The NIV solenoid-operated isolation valves utilize a flexible diaphragm to isolate the actuation mechanism from the fluid path. These valves are commonly used for a wide variety of applications including those that require precise, repeatable dispensing of media.

Electronic and pneumatic pinch valves are designed to open and close tubes for controlling flow of liquids and gases. Other valve types have internal passages that may cause small amounts of fluid to remain in the valve. Pinch valves have no areas where fluid can become trapped. Medical and food grade tubing included.

Many features include low power consumption, superior design and construction, low dead volume, high cycle life, fast response and more. Many sizes, styles and options available. Proudly made in the uSA.

HIGH FLOW

LEAD TIMES OF HOURS. NOT WEEKS.

1.800.422.4279 sales@hydraulex.com www.hydraulex.com

GEAR REDUCERS for mobile and industrial applications. From 200 to 1.5 million LB-FT

WHEEL-TRACK-WINCH DRIVES From 700 to 400,000 LB-FT SLEW BEARING-SLEW DRIVES From 12 to 200 INCH Dia. HYDRAULIC MOTORS Orbital, Axial Piston, Radial Piston HYDRAULIC ACTUATORS Helical and Rack-and-pinion

CLOSE SYSTEM PUMPS-MOTOR From 0.85 to 4.15 CIR

ADVERTISER INDEX

SUBSCRIBE BY MAIL

FI ll O u T THIS CARD COMPl ETE ly, DETACH, AND MAI l IT TO START yO u R S u BSCRIPTION

MAI l TO: PO BOX 293142 • KETTERING OH 45429

YOU CAN ALSO SUBSCRIBE ONLINE AT WWW.F lu IDPOWERJO u RNA l .COM.

YES! Please start/continue my complimentary subscription to the Fluid Power Journal 02 NO. Not interested.

Check here if you would like to keep your name, address, phone and fax numbers confidential, and not released to third parties The address above is my:

Address Which edition would you like to receive? Print

Digital Both (View a sample of our PAPERLESS digital edition at www.fluidpowerjournal.com)

1. Do you specify, select or influence the purchase of components & systems, on new or existing machinery?

If yes, which technologies? (check all that apply)

2. What is your primary job title? (check only one)

Secretary, Treasury, General Manager, Owner, Business Manager, Director, etc.

MY COMPANY SHOULD BE ADVERTISING IN OR SUBMIT AN ARTICLE TO THE FLUID POWER JOURNAL.

PLEASE CONTACT THIS PERSON: NAME:

National Tube Supply’s fluid power products are precisely manufactured and expertly finished to minimize leakage and ensure longer seal life and optimum performance.

Our experienced team is always available to help customers identify the best product for their project specifications, quality requirements and bottom line. We’ll even work with you to set forecasts for JIT delivery management!

Hydraulic Fluid Line Tubing

Cylinder Barrels

Pneumatic Cylinder Tubing

Pump Barrels

Honed Steel Tubing

Chrome ID Tubing

Chrome OD Tubing

DOM Tubing

Seamless Steel Tubing

Chrome Plated Piston Rods

1045 Steel

Ductile Iron & Alloy

We have a massive inventory at your disposal with 5 locations across North America – most orders ship next day!

The Right Supply, Right On Time.

• Resolution ≤5 mV

• Accuracy ±0.25% of full scale

• Real-time adjustable PID control

• Integrated 0 to 10 VDC, 4-20 mA signal, or 3.3 VDC serial communication

• 0 to 10 VDC feedback pressure monitor

• Virtually silent

• No integral bleed required

• Multiple pressure ranges from vacuum to 150 psig

• 2.7 to 65 l/min flow control

Take Control with Cordis

The future of proportional control has arrived— and it’s digital. The Clippard Cordis is a revolutionary microcontroller primed for escape velocity from a proportional control market that has grown stagnant.

With unparalleled performance and flexibility not possible with current analog proportional controllers, the Cordis makes everything from calibration, to sensor variety, to future development opportunities more accessible and less complicated.

Linear Digital Pressure Control

Contact your distributor today to learn more about how the Cordis can provide precise, real-time control for your application, or visit clippard.com to request more information.

877-245-6247

Precise, CINCINNATI