17 minute read

Figure It Out

New Problem

System Overheats on Custom Drum Crusher

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM CFC Industrial Training Solution to March 2021 problem: Pusher Cylinders

Stop Midway

The shredder that had problems with stopping midstroke was running when I arrived. I told them to make sure the “unloader” valve on the manifold with » A HORIZONTAL PRESS crushes empty 30- and 55-gallon drums, and a drip pan captures any liquid that is flushed out. As it crushes the drums, the machine punctures a hole inserting a spray nozzle in one end and several holes in the lower area of the opposite HITACHI FLANGELOCKTM the pusher cylinders was energized and, if it wasn’t, the computer was probably end for a drain. The company assumes the captured waste is hazardous, and they send it to another EPA-approved company. The drum material goes to a mill that melts it down and AND CAP KITS AVAILABLE works it into various shapes, like angles and bar stock. responding to a pressure transducer spike

The company had a problem with the hydraulic unit overheating and determined it was Part number Part description and de-energized the unloader valve. Applicable machines Number of parts Weight (kg) due to corrosion build up in the copper tubes in the four-pass water-cooled heat exchanger SWINGFLGLCK2062 Swing hose FlangeLockTM kit EX3600, EX5600, EX8000 16 x 2062U - red FlangeLockTM 6.7 used to remove excess heat. They routed out and cleaned the tubes and reassembled the SWINGCAP2062 Swing circuit cap kit Following up on the problem, they EX3600, EX5600, EX8000 16 x 2062 - cap 4.5 unit with new end-cap gaskets and zinc anodes. They were surprised that the system still confirmed that the computer told the experienced overheating problems. They were able to increase the water flow, but that TRAVELFLGLCK2462 Travel hose FlangeLockTM kit unloader valve to de-energize. Adding a EX3600, EX5600, EX8000 16 x 2462U - purple FlangeLockTM 7.7 did not help. TRAVELCAP2462 Travel circuit cap kit time delay in the computer program to EX3600, EX5600, EX8000 16 x 2462 - cap 6.4 Their outside hydraulic service company assured them that the system was operating as designed and that it must be a heat exchanger problem. The service company wanted to FRONTATTFLGLCK326162 Front attachment FlangeLockTM kit ignore momentary pressure spikes from a pressure transducer solved the problem. EX3600, EX5600, EX8000 14 x 3262U - black FlangeLockTM 4 x 3261U - black & silver FlangeLockTM 8.9 sell them a larger heat exchanger, FRONTATTCAP326162 Front attachment cap kit EX3600, EX5600, EX8000 14 x 3262 - cap 4 x 3261 - cap 9.5 but the customer balked at the cost because the existing one did Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid BOOMARCHFLGLCK3262 Boom arch hose FlangeLockTM kit To view previous problems, visit www.fluidpowerjournal.com/figure-it-out. EX3600, EX5600, EX8000 20 x 3262U - black FlangeLockTM 9.9 well for many years. power field. Email rjsheaf@cfc-solar.com or visit his BOOMARCHCAP3262 Boom arch hose cap kit EX3600, EX5600, EX8000 20 x 3262 - cap 11.3

What could be the problem? website at www.cfcindustrialtraining.com.CONTAMINATION CONTROL

THE ULTIMATE CONTAMINATION CONTROL TOOL

Routine and scheduled maintenance of hydraulic systems are vital to getting the most out of your Hitachi Mining Excavator. While maintenance plays the largest role in the prevention of unnecessary machine downtime, it can also expose the hydraulic system to high levels of contamination rapidly decreasing component longevity. The importance of contamination control is sometimes Stop the Mess overlooked when performing maintenance due to incorrect practices being used. THE FLANGELOCK™ TOOL AND CIRCUIT BLANKING CAPS The FlangeLock™ tool and caps are the ultimate contamination control tools for protecting your hydraulic system. The FlangeLock™ allows for the simple sealing of open hydraulic flanges without tools while the caps can be bolted in place of a flange connection. Easy on, easy off, they offer a leak-proof solution to hydraulic systems and environmental cleanliness. FlangeLock™ tools and caps stop the mess.

The FlangeLock™ Tool is the ultimate contamination control tool for protecting your hydraulic systems. It allows for the simple sealing of open SAE code 61, 62 HITACHI MAKING CONTAMINATION CONTROL EASY & CAT-Style hydraulic flanges without tools. Constructed from lightweight aluminum. Hitachi have packaged FlangeLock™ tool and caps specifically for Hitachi mining excavators. The Hitachi customised kits make sure no matter which component routine maintenance is being performed on, you will always have the exact Easy on, easy off. Offers a leakproof solution to hydraulic system and environmental number of FlangeLocks™* and caps to help reduce contamination. cleanliness. FlangeLock™ Tools stop the mess!*Note: FlangeLocks™ are not to be used under pressure

SAVE TIME SAVE MONEY SAVE LABOR SAVE OIL

This product is Patented, other Patents pending. • • • No tools required No expensive hardware needed No more rags stuffed into hoses • One hand installation • Eliminate hydraulic oil spills & clean up • Quick installation & ease of usage Call you local Hitachi Muswellbrook representative or the branch on 02 6541 6300 for more information. • No more messy plastic caps • Safe for personnel & environment • The ultimate contamination control tool • Industry acclaimed

For more information, call 203-861-9400 or email sales@flangelock.com. www.flangelock.com

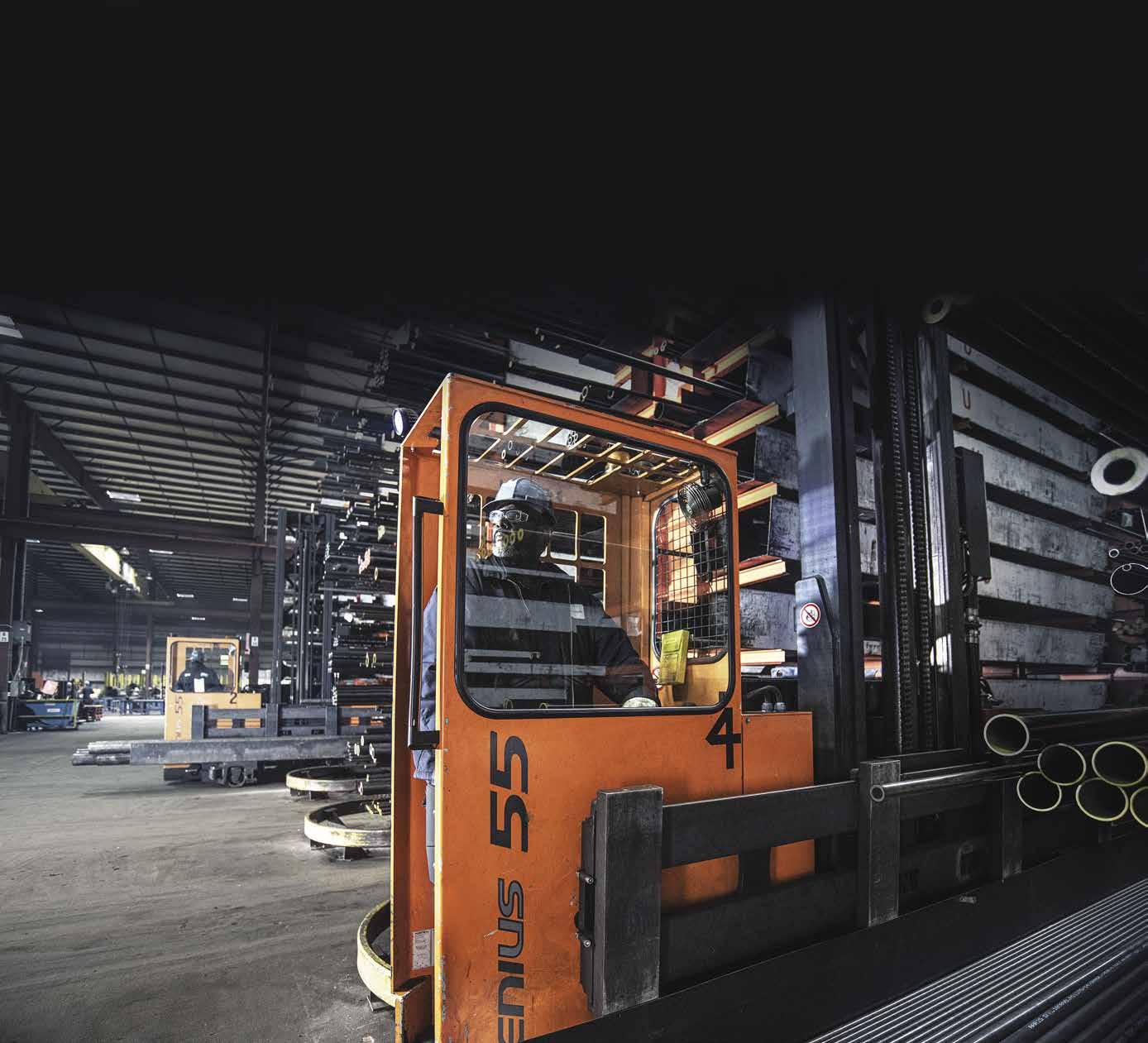

National Tube Supply’s fluid power products are precisely manufactured and expertly finished to minimize leakage and ensure longer seal life and optimum performance.

Our experienced team is always available to help customers identify the best product for their project specifications, quality requirements and bottom line. We’ll even work with you to set forecasts for JIT delivery management!

Hydraulic Fluid Line Tubing Cylinder Barrels Pneumatic Cylinder Tubing Pump Barrels Honed Steel Tubing Chrome ID Tubing Chrome OD Tubing DOM Tubing Seamless Steel Tubing Chrome Plated Piston Rods 1045 Steel Ductile Iron & Alloy

We have a massive inventory at your disposal with 5 locations across North America – most orders ship next day!

Service. Inventory. Experience.

Navigating the Rough Seas of MARINE

CERTIFICATION

By Thomas Shickel, Manager, Marine & Offshore, Bosch Rexroth Corp.

The marine industry presents a unique set of challenges, and among them is a myriad of regulations concerning marine and offshore products. A clear understanding of marine certifications and inspection documents for hydraulic products used in marine systems is crucial to making an informed decision.

Worldwide statutory provisions specify the rules and regulations with which ships and marine equipment must comply to obtain an operating license. The size, intended use, and type of ship, as well as the application of the ship’s operating equipment and installation room, define the mandatory inspection documents and certificates needed for approval. As the hazard potential grows, the requirements become stricter.

Certifications and inspection documents serve a key purpose: they confirm, either by the manufacturer or by a third-party verification service, that the equipment is in compliance with industry standards. Obtaining these certifications and inspection documents when ordering pumps, motors, valves, control blocks, and other shipboard equipment can result in significant time and cost savings.

Marine certifications involve many organizations. Let’s look at a few of them.

IMO

The primary purpose of the U.N.’s International Maritime Organization is to develop and maintain a comprehensive regulatory framework for shipping. Its mandate includes safety, environmental concerns, legal matters, technical cooperation, maritime security, and shipping efficiency.

IMO is the source of approximately 60 legal instruments that guide regulatory development to improve safety at sea, facilitate trade among seafaring states, and protect the maritime environment. Three of the most well-known of these instruments are the International Convention for the Safety of Life at Sea, the International Convention for the Prevention of Maritime Pollution, and International Convention of the Safe and Environmentally Sound Recycling of Ships, known as the “green passport.”

Classification societies

Classification societies add another level to the marine certification structure. A classification society is a nongovernmental organization that establishes and maintains technical standards for the construction and operation of ships and offshore structures based on IMO regulations. The society validates that the construction adheres to set standards and executes regular surveys to ensure compliance.

Societies also classify oil platforms and other offshore structures. Their extensive survey process covers diesel engines, important ship-board pumps, and other vital machinery.

Marine classification promotes occupational safety and protects property and the environment by verifying compliance with technical and engineering standards for the design, construction, and life-cycle maintenance of ships, offshore units, and other marine facilities. The standards and rules are established by individual societies.

The International Association of Classification Societies (IACS), headquartered in London, has 12 member societies. IACS is a nongovernmental organization that develops unified interpretations of international statutory regulations developed by IMO-member states. IACS-member societies apply these interpretations when certifying regulatory compliance on behalf of authorizing flag states.

Inspection documents and certificates

Whether a product needs approval from a classification society depends on its function. The societies establish product certificates and issue applicable approvals. Product certificates may be issued according to standard EN10204, while type-approval certificates require a specific format from the relevant society. According to EN10204 standards, certificates come in two categories.

The first involves nonspecific inspections for nonessential equipment. This means the inspected equipment is without a hazard potential for life or limb in applications such as cranes or winches. This category includes a declaration of compliance with the order (type 2.1) and a test report (type 2.2). In a type 2.1 declaration,

A test stand like this one can verify a pump’s performance and aid in its certification.

the manufacturer declares that the product is in compliance with the requirements of the order without the inclusion of test results. A type 2.2 report is the same except that it includes test results based on a nonspecific inspection.

The second category is defined by specific inspections for essential equipment with a hazard potential for life and limb. Hazardous equipment includes applications such as steering gears and propulsion systems. Like the nonspecific equipment, a manufacturer can issue a type 3.1 certificate that says a product is in compliance and has the test results to verify it. This document

Bosch Rexroth products certified for marine applications include, left to right, the A6VM axial piston variable motor, and the A4VSO, A4VSG, and A4CSG axial piston variable pumps. is validated by the manufacturer’s authorized inspection representative, who is independent of the manufacturing department. The other type, 3.2, is prepared by the manufacturer’s independent representative and either the purchaser’s authorized representative or an inspector designated by regulations. It also includes test results.

The American Bureau of Shipping, which is a member of IACS, is one of the largest certification bodies presiding over U.S. shipbuilding. It conducts engineering design reviews and inspection testing on components and machinery such as propulsion systems, cranes, winches, ballast systems, and stabilizers. Typically, classification societies provide general design standards.

There are a few shortcuts that can reduce some of the red tape. For example, if an OEM supplies shipboard drive and control equipment and incorporates high-pressure piston pumps, the OEM can ask the pump manufacturer to provide test certifications for the pump. This can reduce the needed inspection verifications when the system is installed at the shipyard. Also, for some certificates, manufacturers can transfer test results from an earlier inspection to the inspection certificate, provided the manufacturer complies with traceability procedures. It’s easy to get overwhelmed with the certification and inspection processes for marine products. With all the intricacies involved, companies capable of providing material and testing certifications for marine applications can save a customer significant time and cost on approvals. Ultimately, testing certifications at the individual component level support a faster comprehensive inspection process for a vessel’s final performance validation.

SOME THINGS ARE JUST BUILT TO LAST

Ace pumps may not last 4,500 years like the great pyramids of Egypt, but they are designed to be the longestlasting pumps on the market today. For more than 70 years, we’ve built our pumps with only the best components, backed by the strictest quality control standards in the industry. So, the next time you need a pump that stands the test of time, be sure to ask for an Ace pump.

To learn more, please go to www.acepumps.com or give us a call at 800-843-2293.

The Pump’s the Thing By David Blankenship, Senior Product Line Director, Pumps at Enerpac and Jon Bice, Director of Bolting, Enerpac Americas

FOR MARINE AND OFFSHORE BOLTING

As technology continues to improve rapidly for hydraulic pump systems – adding many more options and significantly increasing performance, quality, and safety – choosing and pairing the right torque wrench pump or tensioner pump for bolting applications in marine, offshore, and power generation makes a vital difference to jobsite safety and efficiency. A deeper understanding of hydraulic pumps and their many configurations can help a business become more efficient and carry out bolting work in any situation.

Pumps in controlled bolting

Controlled bolting is the process of applying an accurate bolt load to a mechanical joint to meet design specifications. Bolt load can be measured directly using hydraulic bolt tensioners, ultrasonics, or calculating torque values determined by the bolt material, size, and friction of the stud and nut. Having the means to measure bolt load during or immediately following the bolting process is essential for joint integrity and safety.

Torque wrenches apply rotational force onto a nut to stretch, not yield, the bolt to achieve bolt load. A hydraulic torque wrench, when coupled with a specially designed torque pump, creates the torque output, or torque load, necessary to create the clamping force to secure bolted-joint integrity.

While torque wrenches and bolt tensioners work to accomplish the same objective – to clamp nuts and bolts together for joint integrity – tensioning directly stretches the bolt against the flange rather than nut rotation from the torque wrench. Tensioning typically creates a more accurate load required on larger bolts.

The torque wrench or bolt tensioner itself does not do the work alone; it is part of a system that also includes a hydraulic pump, hose, and accessories. Choosing a pump

Where you plan to use your hydraulic pumps and the power types available are key in determining product selection.

Torque wrench pumps are available in battery, electric, and air-powered models from Enerpac. The power source you need depends on the requirements of your jobsite. For example, if you are working in a potentially explosive atmosphere and your site requires ATEX certification, such as on an oil rig or in a mine, an air-powered model is likely the only choice. Enerpac offers a variety of air-powered models in its LAT and ZA-Series pumps.

On worksites where there is no need for explosion-proof tools or where air compressors are not available or feasible, an electric-powered pump might be preferred. Enerpac offers electric-powered pumps in its E-Pulse, ZU-Series, and ZE-Series models.

If portability is a primary concern, a battery-powered model might work better. For example, if workers are performing bolting maintenance checks on a wind tower, battery-powered models like the Enerpac XC-series will be easier to transport and access tight spaces.

More multidimensional worksites might make a variety of pumps necessary. A shipyard, for example, may handle new construction and refurbishment of existing ships. The work may take place in a number of locations with some in close proximity to power and others not. A space like the engine room located at the bottom rear of a ship might be better handled by a battery-powered model that avoids the need to run extension cords to the work area.

Similar to torque wrench systems, bolt tensioner pumps are available in electric, air-powered, and manual models. An electric tensioner pump like the Enerpac ZUTP-Series high-efficiency electric pump is compact and

lightweight. The two-stage pump provides high flow at low pressure for fast system fills and controlled flow at high pressure for safe and accurate operation. An air-powered model like the ATP-Series tensioner pumps are likely the only option for working in environments like a gas-treatment facility. A manual tensioner pump like the Enerpac HPT tensioner pump is a lightweight and portable hand pump, and includes two-speed operation for reduced cycle times, a gauge, and an integrated relief valve. It’s best for test applications or occasional use.

Required performance

Application completion speed is another major consideration when choosing a pump. Someone constructing a wind tower, for example, who is fastening hundreds and hundreds of bolts a day, might require a pump powered by a large motor and cooled by a heat exchanger to achieve the needed speed and uptime. Consider that a larger electric pump moves the wrench approximately five times faster than a battery torque wrench pump: 60 cubic inches per minute at 10,000 psi (689 bar) versus 15 cubic inches per minute at 10,000 psi (689 bar).

The jobsite and weather conditions also play a role in the type of pump the work requires. A worker in a Louisiana refinery during a shutdown in the middle of the summer will be served better with a larger pump cooled with a heat exchanger than by a smaller pump that could fail in the heat.

There are tradeoffs for everything, of course. A smaller pump might suit you better in certain situations. A larger pump just might not fit in your workspace. Perhaps you are working alone in a location that is hard to access. You might not want to move a large pump to your worksite, and a lighter pump will better suit your needs.

Pump system technology continues to accelerate in many ways. Auto cycling is one feature more companies are offering with their pumps. The feature makes it unnecessary to manually press and release pump pendant buttons repeatedly to operate the torque wrench. This is especially important when the job requires tightening a large number of fasteners.

Beyond auto cycling, Enerpac offers intelligent auto cycle (IAC) on the E-Pulse torque wrench pumps. IAC reduces the amount of fastening time and heat buildup by eliminating the waste of the wrench going to full pressure with every stroke when not necessary. Increased productivity and longer pump life are key benefits of IAC.

Enerpac ZU4 Pro Series pumps allow operators to program the desired torque amount into the pump along with the torque wrench model they're using. With this feature, a worker does not need to use a pressure chart to complete a torque output-to-pressure conversion. The feature cuts out several steps of the manual process, saving time and reducing the opportunity for human error. In addition, users can get pump usage information, receive warnings, and see other diagnostic information.

Looking past price

The price of a pump will be a consideration, but the focus should be on value. In the big picture, a hydraulic pump, when paired with a torque wrench or tensioner, could help a company complete jobs more quickly and safely. As mentioned previously, the durability of the pump is also essential. The benefits of a durable pump include more reliability for a longer period, longer life cycle, and less need to keep backup pumps.

Buying from a company that emphasizes product support and service is also incredibly important. Tools need to work, and pumps need to perform. Remember that hydraulic pumps are industrial equipment, and they will almost certainly need maintenance at some point. Pumps are often used in rough environments, exposed to oils, solvents, debris, and have other tools piled on top of them when transported. Durability, part availability, and the ease with which the pump can be serviced are important considerations.

Picking the right pump and accessories takes careful consideration and a sharp focus on emerging technology, but it will be time well spent that will ultimately maximize a company’s capabilities.