29 minute read

IFPS Update

CELEBRATING 60 YEARS

Geared-Up Grad Sweepstakes

»SWEEPSTAKES OPEN TO all college and tech school freshmen, sophomores, juniors, and seniors.

The IFPS “Geared-Up Grad” Sweepstakes is a chance to connect with industry personnel and win some prizes! The IFPS will highlight your graduation goals on our professional social media platforms for a chance to get noticed by the industry. TO ENTER THE SWEEPSTAKES, simply E-mail one photo of yourself, your resume and a pic of your student ID or class schedule to Stephanie at scoleman@ifps.org.

Submissions accepted until May 10, 2021. For questions or additional details, contact Stephanie at scoleman@ifps.org or 856-424-8998 ex. 7251.

Outline of the soon-to-be-released upgraded mobile hydraulic mechanic study manual

Job responsibility 1.0: Understand hydraulic components and their operation.

• Understand hydraulic symbols. • Understand the function and operation of system components. • Understand component model code breakdown.

Job Responsibility 2.0: Understand Loads and Motion.

• Understand the units and terminology. • Understand force, pressure, area, and flow relationships. • Using Pascal’s Law. • Using flow and area relationships.

Job Responsibility 3.0: Maintain and repair Hydraulic Systems.

• Understand commissioning a hydraulic system. • Understand component installation. • Hydraulic pumps. • Coupling types. • Hydraulic valves. • Hydraulic cylinders. • Hydraulic motors. • Gas-charged hydraulic accumulators. • Fluid conductors. • System fluid. • Fluid cleanliness. • Understand proactive (scheduled) maintenance (PM).

Job Responsibility 4.0: Troubleshoot Hydraulic Systems.

• Understanding troubleshooting. • Component testing. • Accumulators. • Contamination control. • Hose assemblies.

Job Responsibility 5.0: ElectroHydraulic Control Systems.

• Electrohydraulic valves. • Sensors. • Basic control theory.

Job Performance Stations (Hands-on)

Station # 1 Identify Fluid Power Symbols:

Identify 20 components by their symbolic representation on a schematic drawing. The schematic at this station will be either Mobile Hydraulic, Industrial Hydraulic, or Pneumatic depending upon your test. You will be required to give a written explanation for each component. This is not a multiple-choice station.

Station # 2 Identify Fasteners and Fittings:

This station has ten (10) fasteners and ten (10) fittings that require identification as to type, size, length, thread, and grade. Each item has five (5) multiple choice answers from which to choose.

Station # 3 Use of Multimeter:

This station is for testing the candidate in the use of a Multimeter. There are 14 questions for readings taken on a test circuit board. It is not multiple choice. The readings are for voltage, amperage, and resistance.

Station # 4 Measure a Pump Piston and Spool:

This station tests your ability to take measurements of a part that range from 1/16” to .0001” and requires using scales, calipers, and micrometers. A pump piston and a hydraulic valve spool are used for the measurements. This is not a multiple-choice station.

Station # 5 Fluid Conductors:

Requires identifying size, type, and pressure ratings of two (2) steel tubes, two (2) rubber hoses, one (1) copper, and one (1) nylon tube. Dial calipers and datasheets are provided to aid in this task. This station is not multiple choice.

Station # 6 Tube Bend and Flare:

Bend and flare a tube assembly to fit a fixture testing the skills of measuring, cutting, flaring, and assembly for compound bending to fit a fixture. All tubing, tools, and datasheets are provided.

IFPS Spring Meeting Set

CELEBRATING 60 YEARS

»THE INTERNATIONAL Fluid Power Society’s in-person and virtual spring meeting takes place May 3-6 at the Embassy Suites San Antonio Riverwalk Downtown in San Antonio, Texas.

IFPS set a technical workshop for the meeting:

Maximizing the Use of PowerPoint and PDF Files Thursday, May 6, 8 a.m. - 2 p.m. Only available in-person includes lunch

Discover your inner designer during Dan Helgerson’s deep dive into the underutilized tools of PowerPoint. Learn how to spice up your slide show by adding animation, motion paths, morphs, and how to work with graphic reproduction. You’ll also learn how to link and bookmark in PDF files. This is a hands-on workshop, where attendees will be “doing” as Dan “teaches.”

Register by visiting ifps.org or call 856-424-8998.

SCHEDULE OF EVENTS

Monday, May 3 2:00 PM - 4:00 PM New Board Member Orientation* 6:30 PM - 11:00 PM Board of Directors Dinner* Tuesday, May 4 8:00 AM - 9:00 AM Strategic Planning Committee Meeting 9:00 AM - 11:00 AM Education Committee Meeting 11:00 AM - 12:00 PM Membership Committee Meeting 12:00 PM - 12:30 PM Hosted Lunch 12:30 PM - 1:30 PM Membership Committee Meeting (cont’d) 1:30 PM - 5:00 PM Certification Committee Meeting 6:00 PM - 9:00 PM Dinner Wednesday, May 5 8:00 AM - 10:30 AM Marketing Committee Meeting 10:30 AM - 12:00 PM Finance Committee Meeting 12:00 PM - 12:45 PM Hosted Lunch 1:00 PM - 2:30 PM Board of Directors Meeting 2:30 PM - 3:00 PM Strategic Planning Committee Meeting 3:30 PM - 5:00 PM Riverwalk Boat Tour (optional) 6:00 PM - 9:30 PM Reception & Trivia Night Thursday, May 6 8:00 AM - 2:00 PM Technical Workshop & Box Lunch * invitation only

The Trusted Prime Mover of Fluid Power Products.

New!

Hydraulic Fluid Line Tubing Cylinder Barrels Pneumatic Cylinder Tubing Pump Barrels Honed Steel Tubing Chrome ID Tubing Chrome OD Tubing DOM Tubing Seamless Steel Tubing Chrome Plated Piston Rods 1045 Steel Ductile Iron & Alloy

We have a massive inventory at your disposal with 5 locations across North America – most orders ship next day!

Service. Inventory. Experience.

800-229-6872 nationaltubesupply.com

FLAT FACE DESIGN “TVF” SERIES QUICK DISCONNECT

• Up to 6,000 PSI Operating Pressure—Coupled or Uncoupled • Full 4:1 Safety Factor • Superior Flow Characteristics—Minimal Pressure Drop • RoHS Compliant Plating • Multiple Port Options—Female NPTF, Female SAE O-Ring, Female BSPP, Code 61 & 62 Flange Port/Head

P.O. Box 6479, Fort Worth, TX 76115 V. 817/923-1965 www.hydraulicsinc.com

February 2021 Newly Certified Professionals IFPS CERTIFICATION

AUTHROZED JOB PERFORMANCE PROCTOR

Adam Smith, Controlled Fluids, Inc,

PNEUMATIC SPECIALIST

Oscar Arellano Sevilla, IMI Precision Engineering Kurt Reinschmidt, IMI Precision Engineering

HYDRAULIC SPECIALIST

Andoni Acosta, GCC, Inc. Dale Adams, Alfred State College Ali Ardakani, Applied Industrial Technologies Michael Floyd, GCC, Inc. Andrew Froland, Applied Industrial Technologies Joshua Jacobs, Alfred State College Nathan Miller, Alfred State College Brandon Mott, Alfred State College Chris Romaniuk, Applied Industrial Technologies Trevor Sax, Alfred State College Brett Watson, GCC, Inc.

INDUSTRIAL HYDRAULIC MECHANIC

Quest Duperron, Coastal Hydraulics, Inc. Chris Williams, Coastal Hydraulics, Inc.

MOBILE HYDRAULIC MECHANIC

Jason Carter, Altec Industries, Inc. Cody Hendrickson, Altec Industries, Inc. Scot Hollinday, Altec Industries, Inc. Cole Kielty, Altec Industries, Inc. Kevin Kruger, Altec Industries, Inc. James Pierce, Altec Industries, Inc. Andrew Trautman, Altec Industries, Inc. Jacob Vaughters, Altec Industries, Inc. My goals are to become more well-rounded and to open more doors in the mechatronics and fluid power industries. I believe that obtaining the Hydraulic Specialist Certification and eventually obtaining the Pneumatic and Electronic Controls certifications will help to eventually fulfill the role as an engineering specialist for Heil Environmental. Eugene Elliott, Engineer I, Hydraulics, CFPHS, Heil Environmental

Your Hydraulic Motor & Gearbox Provider

Contact us for more information.

Certification Testing Locations

Individuals wishing to take any IFPS written certification tests can select from convenient locations across the United States and Canada. IFPS is able to offer these locations through its affiliation with The Consortium of College Testing Centers provided by National College Testing Association.

Contact headquarters if you do not see a location near you. Every effort will be made to accommodate your needs.

If your test was postponed due to the pandemic, please contact headquarters so that we may reschedule.

TENTATIVE TESTING DATES FOR ALL LOCATIONS:

June 2021

Tuesday 6/1 • Thursday 6/24

July 2021

Tuesday 7/13 • Thursday 7/29

August 2021

Tuesday 8/3 • Thursday 8/26

September 2021

Tuesday 9/14 • Thursday 9/30

ALABAMA Auburn, AL Birmingham, AL Calera, AL Decatur, AL Huntsville, AL Jacksonville, AL Mobile, AL Montgomery, AL Normal, AL Tuscaloosa, AL

ALASKA Anchorage, AK Fairbanks, AK

ARIZONA Flagstaff, AZ Glendale, AZ Mesa, AZ Phoenix, AZ Prescott, AZ Scottsdale, AZ Sierra Vista, AZ Tempe, AZ Thatcher, AZ Tucson, AZ Yuma, AZ

ARKANSAS Bentonville, AR Hot Springs, AR Little Rock, AR

CALIFORNIA Aptos, CA Arcata, CA Bakersfield, CA Dixon, CA Encinitas, CA Fresno, CA Irvine, CA Marysville, CA Riverside, CA Salinas, CA San Diego, CA San Jose, CA San Luis Obispo, CA Santa Ana, CA Santa Maria, CA Santa Rosa, CA Tustin, CA Yucaipa, CA COLORADO Aurora, CO Boulder, CO Springs, CO Denver, CO Durango, CO Ft. Collins, CO Greeley, CO Lakewood, CO Littleton, CO Pueblo, CO

DELAWARE Dover, DE Georgetown, DE Newark, DE

FLORIDA Avon Park, FL Boca Raton, FL Cocoa, FL Davie, FL Daytona Beach, FL Fort Pierce, FL Ft. Myers, FL Gainesville, FL Jacksonville, FL Miami Gardens, FL Milton, FL New Port Richey, FL Ocala, FL Orlando, FL Panama City, FL Pembroke Pines, FL Pensacola, FL Plant City, FL Riviera Beach, FL Sanford, FL Tallahassee, FL Tampa, FL West Palm Beach, FL Wildwood, FL Winter Haven, FL

GEORGIA Albany, GA Athens, GA Atlanta, GA Carrollton, GA Columbus, GA Dahlonega, GA Dublin, GA Dunwoody, GA Forest Park, GA Lawrenceville, GA Morrow, GA Oakwood, GA Savannah, GA Statesboro, GA Tifton, GA Valdosta, GA

HAWAII Laie, HI

IDAHO Boise, ID Coeur d ‘Alene, ID Idaho Falls, ID Lewiston, ID Moscow, ID Nampa, ID Rexburg, ID Twin Falls, ID

ILLINOIS Carbondale, IL Carterville, IL Champaign, IL Decatur, IL Edwardsville, IL Glen Ellyn, IL Joliet, IL Malta, IL Normal, IL Peoria, IL Schaumburg, IL Springfield, IL University Park, IL INDIANA Bloomington, IN Columbus, IN Evansville, IN Fort Wayne, IN Gary, IN Indianapolis, IN Kokomo, IN Lafayette, IN Lawrenceburg, IN Madison, IN Muncie, IN New Albany, IN Richmond, IN Sellersburg, IN South Bend, IN Terre Haute, IN

IOWA Ames, IA Cedar Rapids, IA Iowa City, IA Ottumwa, IA Sioux City, IA Waterloo, IA

KANSAS Kansas City, KS Lawrence, KS Manhattan, KS Wichita, KS

KENTUCKY Ashland, KY Bowling Green, KY Erlanger, KY Highland Heights, KY Louisville, KY Morehead, KY LOUISIANA Bossier City, LA Lafayette, LA Monroe, LA Natchitoches, LA New Orleans, LA Shreveport, LA Thibodaux, LA

MARYLAND Arnold, MD Bel Air, MD College Park, MD Frederick, MD Hagerstown, MD La Plata, MD Westminster, MD Woodlawn, MD Wye Mills, MD MASSACHUSETTS Boston, MA Bridgewater, MA Danvers, MA Haverhill, MA Holyoke, MA Shrewsbury, MA MICHIGAN Ann Arbor, MI Big Rapids, MI Chesterfield, MI Dearborn, MI Dowagiac, MI East Lansing, MI Flint, MI Grand Rapids, MI Kalamazoo, MI Lansing, MI Livonia, MI Mount Pleasant, MI Sault Ste. Marie, M Troy, MI University Center, MI Warren, MI

MINNESOTA Alexandria, MN Brooklyn Park, MN Duluth, MN Eden Prairie, MN Granite Falls, MN Mankato, MN

MISSISSIPPI Goodman, MS Jackson, MS Mississippi State, MS Raymond, MS University, MS MISSOURI Berkley, MO Cape Girardeau, MO Columbia, MO Cottleville, MO Joplin, MO Kansas City, MO Kirksville, MO Park Hills, MO Poplar Bluff, MO Rolla, MO Sedalia, MO Springfield, MO St. Joseph, MO St. Louis, MO Warrensburg, MO MONTANA Bozeman, MT Missoula, MT

NEBRASKA Lincoln, NE North Platte, NE Omaha, NE

NEVADA Henderson, NV Las Vegas, NV North Las Vegas, NV Winnemucca, NV NEW JERSEY Branchburg, NJ Cherry Hill, NJ Lincroft, NJ Sewell, NJ Toms River, NJ West Windsor, NJ

NEW MEXICO Albuquerque, NM Clovis, NM Farmington, NM Portales, NM Santa Fe, NM

NEW YORK Alfred, NY Brooklyn, NY Buffalo, NY Garden City, NY New York, NY Rochester, NY Syracuse, NY NORTH CAROLINA Apex, NC Asheville, NC Boone, NC Charlotte, NC China Grove, NC Durham, NC Fayetteville, NC Greenville, NC Jamestown, NC Misenheimer, NC Mount Airy, NC Pembroke, NC Raleigh, NC Wilmington, NC NORTH DAKOTA Bismarck, ND

OHIO Akron, OH Cincinnati, OH Cleveland, OH Columbus, OH Fairfield, OH Findlay, OH Kirtland, OH Lima, OH Maumee, OH Newark, OH North Royalton, OH Rio Grande, OH Toledo, OH Warren, OH Youngstown, OH OKLAHOMA Altus, OK Bethany, OK Edmond, OK Norman, OK Oklahoma City, OK Tonkawa, OK Tulsa, OK

OREGON Bend, OR Coos Bay, OR Eugene, OR Gresham, OR Klamath Falls, OR Medford, OR Oregon City, OR Portland, OR White City, OR PENNSYLVANIA Bloomsburg, PA Blue Bell, PA Gettysburg, PA Harrisburg, PA Lancaster, PA Newtown, PA Philadelphia, PA Pittsburgh, PA Wilkes-Barre, PA York, PA SOUTH CAROLINA Beaufort, SC Charleston, SC Columbia, SC Conway, SC Graniteville, SC Greenville, SC Greenwood, SC Orangeburg, SC Rock Hill, SC Spartanburg, SC TENNESSEE Blountville, TN Clarksville, TN Collegedale, TN Gallatin, TN Johnson City, TN Knoxville, TN Memphis, TN Morristown, TN Murfreesboro, TN Nashville, TN

TEXAS Abilene, TX Arlington, TX Austin, TX Beaumont, TX Brownsville, TX Commerce, TX Corpus Christi, TX Dallas, TX Denison, TX El Paso, TX Houston, TX Huntsville, TX Laredo, TX Lubbock, TX Lufkin, TX Mesquite, TX San Antonio, TX Victoria, TX Waxahachie, TX Weatherford, TX Wichita Falls, TX

UTAH Cedar City, UT Kaysville, UT Logan, UT Ogden, UT Orem, UT Salt Lake City, UT VIRGINIA Daleville, VA Fredericksburg, VA Lynchburg, VA Manassas, VA Norfolk, VA Roanoke, VA Salem, VA Staunton, VA Suffolk, VA Virginia Beach, VA Wytheville, VA WASHINGTON Auburn, WA Bellingham, WA Bremerton, WA Ellensburg, WA Ephrata, WA Olympia, WA Pasco, WA Rockingham, WA Seattle, WA Shoreline, WA Spokane, WA WEST VIRGINIA Ona, WV

WISCONSIN La Crosse, WI Milwaukee, WI Mukwonago, WI WYOMING Casper, WY Laramie, WY Torrington, WY CANADA ALBERTA Calgary, AB Edmonton, AB Fort McMurray, AB Lethbridge, AB Lloydminster, AB Olds, AB Red Deer, AB

BRITISH COLUMBIA Abbotsford, BC Burnaby, BC Castlegar, BC Delta, BC Kamloops, BC Nanaimo, BC Prince George, BC Richmond, BC Surrey, BC Vancouver, BC Victoria, BC

CELEBRATING 60 YEARS

MANITOBA Brandon, MB Winnipeg, MB NEW BRUNSWICK Bathurst, NB Moncton, NB

NEWFOUNDLAND AND LABRADOR St. John’s, NL

NOVA SCOTIA Halifax, NS

ONTARIO Brockville, ON Hamilton, ON London, ON Milton, ON Mississauga, ON Niagara-on-the-Lake, ON North Bay, ON North York, ON Ottawa, ON Toronto, ON Welland, ON Windsor, ON

QUEBEC Côte Saint-Luc, QB Montreal, QB

SASKATCHEWAN Melfort, SK Moose Jaw, SK Nipawin, SK Prince Albert, SK Saskatoon, SK

YUKON TERRITORY Whitehorse, YU

UNITED KINGDOM Elgin, UK

GHAZNI Kingdom of Bahrain, GHA Thomasville, GHA

EGYPT Cairo, EG

JORDAN Amman, JOR

NEW ZEALAND Taradale, NZ

CFPAI Certified Fluid Power Accredited Instructor CFPAJPP Certified Fluid Power Authorized Job Performance Proctor

CFPAJPPCC Certified Fluid Power Authorized Job Performance Proctor Connector & Conductor

CFPE Certified Fluid Power Engineer CFPS Certified Fluid Power Specialist (Must Obtain CFPHS & CFPPS) CFPHS Certified Fluid Power Hydraulic Specialist CFPPS Certified Fluid Power Pneumatic Specialist CFPECS Certified Fluid Power Electronic Controls Specialist CFPMT Certified Fluid Power Master Technician (Must Obtain CFPIHT, CFPMHT, & CFPPT) CFPIHT Certified Fluid Power Industrial Hydraulic Technician CFPMHT Certified Fluid Power Mobile Hydraulic Technician CFPPT Certified Fluid Power Pneumatic Technician

CFPMM Certified Fluid Power Master Mechanic (Must Obtain CFPIHM, CFPMHM, & CFPPM) CFPIHM Certified Fluid Power Industrial Hydraulic Mechanic CFPMHM Certified Fluid Power Mobile Hydraulic Mechanic CFPPM Certified Fluid Power Pneumatic Mechanic

CFPMIH Certified Fluid Power Master of Industrial Hydraulics (Must Obtain CFPIHM, CFPIHT, & CFPCC) CFPMMH Certified Fluid Power Master of Mobile Hydraulics (Must Obtain CFPMHM, CFPMHT, & CFPCC) CFPMIP Certified Fluid Power Master of Industrial Pneumatics (Must Obtain CFPPM, CFPPT, & CFPCC) CFPCC Certified Fluid Power Connector & Conductor

CFPSD Fluid Power System Designer CFPMEC (In Development) Mobile Electronic Controls

CFPIEC (In Development) Industrial Electronic Controls

Tentative Certification Review Training

IFPS offers onsite review training for small groups of at least 10 persons. An IFPS accredited instructor visits your company to conduct the review. Contact kpollander@ifps.org for details of the scheduled onsite reviews listed below.

HYDRAULIC SPECIALIST CERTIFICATION REVIEW September 13-16, 2021 - Fairfield, OH - CFC Industrial Training | Written test: September 16, 2021 September 27-30, 2021 - Milwaukee, WI, MSOE | Written test: September 30, 2021

PNEUMATIC SPECIALIST July 27-29, 2021 - Fairfield, OH - CFC Industrial Training | Written test: July 29, 2021

ELECTRONIC CONTROLS CERTIFICATION REVIEW August 9-12, 2021 - Fairfield, OH - CFC Industrial Training | Written test: August 12, 2021

CONNECTOR & CONDUCTOR CERTIFICATION REVIEW November 16-17, 2021 - Fairfield, OH - CFC Industrial Training | Written and JP test: November 18, 2021

MOBILE HYDRAULIC MECHANIC CERTIFICATION REVIEW Online Mobile Hydraulic Mechanic Certification Review (for written test) offered through info@cfcindustrialtraining.com. This course takes you through all chapters of the MHM Study Manual (6.5 hours) and every outcome to prepare you for the written MHM test. Members receive 20% off. (Test fees are additional - separate registration required.) August 30 - September 1, 2021 - Fairfield, OH - CFC Industrial Training | Written and JP test: September 2, 2021

INDUSTRIAL HYDRAULIC MECHANIC CERTIFICATION June 14 - 16, 2021 - Fairfield, OH - CFC Industrial Training | Written and JP test: June 17, 2021

INDUSTRIAL HYDRAULIC TECHNICIAN CERTIFICATION REVIEW TRAINING Call for dates. Phone: 513-874-3225 - CFC Industrial Training, Fairfield, Ohio

MOBILE HYDRAULIC TECHNICIAN CERTIFICATION REVIEW TRAINING Call for dates. Phone: 513-874-3225 - CFC Industrial Training, Fairfield, Ohio

PNEUMATIC TECHNICIAN and PNEUMATIC MECHANIC CERTIFICATION REVIEW TRAINING Call for dates. Phone: 513-874-3225 - CFC Industrial Training, Fairfield, Ohio

JOB PERFORMANCE TRAINING Online Job Performance Review - CFC Industrial Training offers online JP Reviews which includes stations 1-6 of the IFPS mechanic and technician job performance tests. Members may e-mail askus@ifps.org for a 20% coupon code off the list price or get the code in our Members Only area for the entire IFPS Job Performance Review; test not included.

LIVE DISTANCE LEARNING JOB PERFORMANCE STATION REVIEW E-mail info@cfcindustrialtraining.com for information.

The number of motorized vessels has remained steady over recent years, with an estimated 2.9 million operating globally in 2018 despite efforts to reduce fleet sizes, notably in Europe in 2000 and China in 2013. At the same time, the overall development of capture fisheries has resulted in the use of fewer fishing boats, making efficiency more crucial than ever to maximize productivity while at sea. Reliability and uptime are also vital to revenue. Shipbuilders rely on rugged and dependable products when building new vessels or repairing existing ones.

MODULARITY

Hooks Scandinavian Fishing Trawlers

By Benny Hansen, Senior Account Manager, Danfoss Power Solutions

For the last 40 years, Danish shipbuilder Thyborøn Skibs and Motor A/S has built and repaired fishing vessels for fishing fleets worldwide. Toward the end of the 1970s, the company decided to take a modular approach to creating new fishing vessels to operate in the harsh environment of the North Sea.

The benefits of this tactic are twofold. It enables the latest digital technology to be incorporated into the boats, and it is relatively simple for customers to implement the technology without significant redesigns.

Modular products

Danfoss Power Solutions provides several components for the Thyborørn Skibs and Motor shipyard, including valves, pumps, motors, and joysticks. The shipbuilder has installed Danfoss hydraulic systems on countless ships, the latest being the new Sulehav fishing vessel. The 34 x 10-meter (111 x 33-foot) breadth ship operates in the North Sea along the Norwegian Coast and can carry up to 40 tons of fish.

With a coastline stretching more than 83,000 km (51,573 miles), Norway is one of the world’s leading fishing nations. The country’s vast marine areas, including many fjords and islands, provide ideal conditions for aquaculture production and are among the most productive globally. Despite this, the number of fishers and registered vessels has sharply dropped since 2000 due to regulations and quotas.

To ensure the highest productivity, when it’s at sea, Sulehav is managed by six persons. Its total crew is twelve working rotationally for four weeks on and four weeks off. This arrangement means that Sulehav can operate all year round – except for a Christmas break – ensuring that it brings in significant revenues.

Flexibility in hydraulic system design

Danfoss’s portfolio of valves includes the high-flow PVG 128 and PVG 256 models, which have a flow of up to 1,200 liters (317 gallons) per minute and pressure of 420 bar (6,091 psi). The high-flow range of valves offer greater flexibility in system design. This kind of flow is especially suited for fishing vessels that perform many functions at the same time. Valves allow thrusters, net drums, and winches of various sizes to perform different tasks and cylinder functions on the boats. The PVG 32, PVG 128, and PVG 256 valves control up to 30 functions on ships built or repaired by Thyborøn Skibs and Motor.

The PVG 32 model has been a popular valve for over 30 years, largely due to its modularity, as it can be designed in millions of different combinations. Danfoss can create a valve that fits precisely to a customer’s individual needs and demands. The PVG 32 valve is suitable for applications across the marine, mobile, and industrial markets.

The valve can be easily integrated with the newer PVG 128 and PVG 256 valves to create a combined valve stack. Each section of a valve stack controls a different function on the Thyborøn Skibs and Motor vessels. The PVG 128 and PVG 256 models can be engaged with up to

500 liters (132 gallons) per section, when higher flow and pressure are required for functions such as thrusters and rope winches, while the PVG 32 can be used when a flow of a maximum of 130 liters (34 gallons) per minute is needed for tasks undertaken by small winches, brakes, and cranes. Any combination of the three valve models is possible, with valve stacks of up to 10 sections in use on ships built or repaired by Thyborøn Skibs and Motor.

Danfoss PVG valves can be controlled manually by a handle or electronically via a proportional valve electrical actuator controller. The dual control provides security to vessel operators. If, for whatever reason, the electronics won’t work at sea, they can still manually use the valve.

Because the Danfoss valves and actuators are modular, they are easily interchanged or upgraded without replacing the entire valve stack. This makes it easier to perform repairs at sea, which is a significant benefit for operators, as every hour spent at the dock rather than fishing equals lost revenue. Furthermore, as digitalization continues to advance, shipbuilders such as Thyborøn Skibs and Motor can easily replace the actuators with the latest technology, enabling even more precise control.

High-level steering system

The Sulehav fishing trawler also uses ergonomic PVREL joysticks, which are capable of withstanding saltwater and the harsh conditions often found on deck. These joysticks feature a built-in switch for external equipment and can directly control the PVG valves. The PVREL joystick forms part of a sophisticated onboard steering system capable of handling all functions on the ship directly from the wheelhouse.

Danfoss offers a number of other products for marine applications. The D1P axial piston pump integrates with the load-sensing PVG valves. A load-sensing LS hydraulic hose connects the D1P pump and PVG valves. When the PVG valves activate, a signal sent through the LS line tells the D1P pump exactly how much oil and pressure the operator needs and regulates this demand.

One of the latest additions to Danfoss’s range of marine products is the PLUS+1 DM430M display, which comes precertified by the American Bureau of Shipping (see article on page 8). This certification means that customers do not need to independently test and document its performance, significantly streamlining its time to market. The display also meets strict electromagnetic emissions requirements. Specifically designed for use in marine applications, the display underwent salt mist and IP66/67 testing to hold up to the high seas and all weather conditions with the same viewability and reliability as seen in applications in other sectors, such as off-highway. The DM430M display operates digitally, allowing up to six extra inputs to be added without an additional I/O module. The display can be paired with other Danfoss propulsion systems on the navigation bridge, cranes, winches, or other areas.

A changing industry

The marine sector is under constant pressure to modernize and become more efficient. Global organizations and government bodies constantly increase the number of regulations relating to areas such as fishing and emissions.

Switching to alternative, cleaner modes of power such as hydrogen or electrification may not yet make commercial sense for some shipyards and operators. However, it is clear that the vast majority are looking for ways to improve the efficiency of vessels without requiring massive alterations to existing designs. Unlocking the power of modularity could pave the way for greater standardization across the industry.

Precision Machining for Quality Hydraulics

Contact us today 419.496.0964, ext. 203 Sales@TahomaEngineeredSolutions.com ISO 9001:2015 532 County Road 1600 • Ashland, Ohio 44805

ROVs

By Steve Barrow, Regional Sales Manager, Wandfluh of America

THE WORKHORSE OF SUBSEA HYDRAULIC SYSTEMS

Offshore and subsea equipment faces challenges unparalleled in other industries. Difficulties can include crushing ambient pressures, corrosive environments, and remote locations.

Why would anyone choose to work in such difficult and harsh conditions? Since 71% of the earth is covered in water, humans have learned to work in and around it. The market for subsea equipment is large and includes alternative energy, oil and gas, military, fishing, and scientific.

Valves are critical to the operation of subsea hydraulic equipment. Valves used offshore and subsea must have exceptional reliability, operate precisely and responsively, be compatible with a wide range of fluids, include corrosion protection, and be compatible with electronic control systems.

Hydraulic systems on ROVs

Though many types of subsea equipment use hydraulic power, remotely operated vehicles (ROVs)

Figure 1: A workclass remotely operated vehicle.

offer an excellent example of complex mobile electrohydraulic subsea systems. These robotic systems work in depths unsafe for human divers or in hazardous polluted environments such as those created by maritime disasters. ROV equipment can operate at depths greater than 13,000 feet (4,000 meters). ROV hydraulic components require special modifications to withstand the rapid pressure change from sea level to the abyss, where the ambient pressure exceeds 6,000 psi (414 bar).

Most work-class ROVs use hydraulic power for primary operational equipment, including thrusters, manipulators (robotic arms), and auxiliary tooling. An onboard hydraulic power unit (HPU) typically provides hydraulic power in the range of 150 to 250 horsepower. The HPU runs on electricity transmitted from a surface vessel to the ROV through an electrical “umbilical” cable. A proportional pressure-relief cartridge controls the output pressure of the variable displacement pump providing hydraulic power throughout the system.

As is true for most offshore equipment, minimizing the size and weight of ROV equipment is critical to its successful function. Hydraulic systems offer an excellent powerto-weight ratio (power density) in the smallest possible mechanical envelope. Higher pressures allow the use of smaller hydraulic actuators and components, which in turn limits the total volume of hydraulic fluid required for the system. Both factors reduce system weight. For safety, longevity, and reliability on these high-cost vehicles, the hydraulic valves must be fully compatible with the subsea operating environment. Special features such as pressure compensation ensure proper operation at extreme depths. Hydraulic fluids must tolerate water ingression – an accepted inevitability for subsea operations – and support long-term environmental friendliness (figure 1).

Critical hydraulic equipment is not limited to the subsea vehicle. The host vessel has a launch-and-recovery system that includes a high-tension winch. Because the ROV’s watercooled electric motor would overheat very quickly in air, a deck HPU tests on-deck vehicle function and flushes the system of water after a dive. A crane lowers subsea hardware or tooling to the ROV. All this equipment must be robust, reliable, and able to function in corrosive and sometimes explosive environments.

Reliability

Equipment reliability is critical to the cost-effective operation of subsea hydraulic equipment. For example, to accomplish their tasks, ROVs frequently remain submerged for weeks without maintenance. If a system failure occurs and an ROV must be recovered for repair, it takes about eight hours to raise the ROV to the surface vessel and return it to a depth of 13,000 feet (4,000 meters). Repairing the failed components takes additional time, and the limited availability of spare parts in the middle of the ocean can make repairs difficult or even impossible. If the ROV’s task is critical to the vessel’s mission, the down ROV can bring the vessel and crew to a standstill.

Because reliability of hydraulic components is critical to operations in subsea systems, Wandfluh tests valve products to ten million cycles of service life. Wandfluh designs and manufactures solenoids in house to ensure quality and conformity to subsea specifications and standards. The solenoid tube assembly, critical for smooth valve operation, is constructed of the highest quality materials. It is also designed to ensure the strongest magnetic field at the lowest power levels, resulting in reduced hysteresis.

Pressure compensation

Although oil is generally considered incompressible, oil and the gas molecules entrained within the oil do compress slightly under high pressure. Compressibility varies

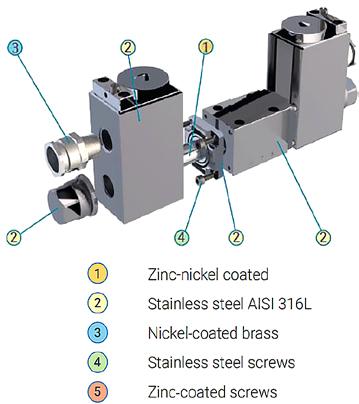

Figure 2: K10 corrosion protection.

by fluid type and other factors, but a common rule of thumb is that oil compresses 0.5% per 1,000 psi (69 bar). This compression, at an ambient pressure of 6,000 psi (414 bar), produces a volumetric change of 3%. Temperature difference between the deck of the surface vessel and the ocean depths exacerbates this volume change. Without compensating for the volumetric change inside an enclosure, stresses build that could cause the equipment to deform or implode. To allow for volume changes, Wandfluh modifies the solenoid housing and coil in its valves to allow small amounts of oil to pass freely, preventing differential pressures. Electronics testing ensures that they can withstand cycling of ambient temperature and pressure as the hydraulic equipment repeatedly descends and returns to the surface.

Efficiency and responsiveness

The inherent design of a spool valve allows controlled leakage around the spool to reduce friction and improve response time and performance. However, this leakage can reduce the valve’s efficiency and reduce the amount of fluid available for system functions. Wandfluh designs spool valves with tight tolerances and precision finishing processes that reduce leakage rates, resulting in greater efficiency and greater fluid availability. The increased efficiency allows a smaller pump to provide weight reduction and additional cost savings. Proportional spool valves commonly control the precision motion of an ROV’s manipulators. The manipulators can be powerful, capable of lifting more than 500 pounds (225 kg) in air, but they must also be responsive, with smooth, refined control that allows the ROV to adjust sensitive components on subsea equipment. Wandfluh’s compact NG3 Mini WDPFA03 or the larger flow NG6/CETOP3 WDPFA06 proportional directional control valves are commonly used for manipulator control and auxiliary tooling functions.

ROVs are propelled through water by a set of seven or eight powerful thrusters mounted on the ROV frame, with each thruster driven by a hydraulic motor. Some ROV manufacturers use Wandfluh’s proportional D05 directional valves to control the speed and direction of flow for each thruster. Other manufacturers control the torque at each thruster using a pair of MVPPM33 proportional pressure-reducing and pressure-relieving valves. Both methods enable moving the ROV through the water with precise vertical and horizontal positioning.

Hydraulic fluid compatibility

Hydraulic fluid for subsea equipment needs to meet standard terrestrial requirements such as wear reduction, lubricity, viscosity range, and environmental friendliness, but it must also allow some tolerance to water ingression.

In recent years, industries have increasingly turned to more environmentally friendly and fire-resistant hydraulic fluids, but these fluids pose significant challenges due to their lower lubricity, reduced corrosion inhibitors, and lower viscosity. Some of these fluids have high water content, making standard valves unsuitable in terms of useful lifetime, safety, reliability, and cost effectiveness.

To meet the demands of subsea hydraulic systems that use environmental fluids, Wandfluh developed the Z595 valve, a special design with new materials and construction techniques. The internal components of these valves use various grades and hardness of stainless steel to prevent galling. They are compatible with fire-resistant HFC and HFA fluids as well as water-glycol-based fluids with water content as high as 95%. Optimized spool design, offering higher resistance to internal cavitation caused by the lower-viscosity fluids at high pressure, extends the valve’s life.

Valve packs

Subsea valve packs commonly consist of valves installed into a manifold. Solenoid valves and an electronic communication and control card are enclosed in an oil-filled housing to prevent water from directly contacting the valves and coils. CETOP and sandwich valves allow each stack to be customized with valves of differing sizes and functions, as shown in the photograph below. Proportional control of flow rate/direction and pressure is available. Pilot-operated and cross-pilot control valves can also be installed.

Subsea valve pack with the enclosure cover removed, showing a variety of valves and an electronic control card.

Cartridge valves installed on the lower faces of the manifold, outside the oil-filled protective enclosure, allow easy access for manual adjustments. The external faces of these valves are directly exposed to seawater.

Support equipment on the deck of a vessel is continuously exposed to the harsh marine environment. Valves on this equipment require materials and coatings specially designed for these conditions.

Wandfluh’s protection options safeguard valves against corrosion. Standard K8 protection on valves uses a zinc-nickel coating on the valve body and solenoid housing exterior, with zinc-coated fasteners. K8 valves rate highly, with n>500 hours of rust protection in the globally accepted ISO 9227 standards for red-rust, salt-spray tests. The K9 valves use high-grade AISI 316L acid-resistant stainless steel for the external valve components and zinc-nickel coating for the solenoid housing. K9 valves have a rust protection rating of n>1,000 hours in testing. K10 valves offer the highest level of corrosion protection. All external elements of K10 valves, including the solenoid housing, are made of high-grade stainless steels. K10 valves also have the superior rating of n>1,000 hours of rust protection (figure 2).

Electronic control

Precision electronic control systems achieve wide versatility and optimal control of hydraulic systems. Amplifier or controller electronics mounted directly onboard the solenoids control the solenoid valves. They can also be wired to pressure-tolerant, smart-valve pack control cards, controlled through serial (RS-232/485), ethernet, or CAN bus communications.

Multiple electrical connection styles on the solenoid include the popular DIN 43650-A/ISO 4400, Deutsch, AMP Junior Timer, and Phoenix connectors, as well as flying leads. Because of their low profiles, flying leads save space. But if the leads are damaged close to the solenoid, repair may not be possible. The small Phoenix connectors provide a good compromise between space savings and component protection.

Valves are critical to operating hydraulic subsea equipment. Many field-proven standard options become building blocks that create the exact solution for a challenging application.