NOVEMBER 2022 fluidpowerjournal.com Avoiding Hydraulic Hose Disasters Circular Sustainability for Fluid Power All About Vacuum NFPA Shipments Report KEEPING PACE WITH MATERIAL HANDLING Nonprofit Organization USPostage PAID Bolingbrook,IL Permit#323 Innovative Designs & Publishing • 3245 Freemansburg Avenue • Palmer, PA 18045-7118

CONNECT WITH TOP MANUFACTURES

International Fluid Power Exposition

the place where engineers meet to:

new ideas

solutions

unique

new partners

suppliers

other

KEN ROSENBECKER SALES MANAGER NORTH AMERICA

happens

20% OFF REGISTRATION

WIPRO INFRASTRUCTURE ENGINEERING

INTERNATIONAL FLUID POWER EXPO MARCH 14-18, 2023 LAS VEGAS, NV, USA The

(IFPE) is

“ There’s no

show in the world I think that brings the OEM machine manufacturers and the suppliers as close together as this show. It’s a good place to meet and learn about what’s going on. In the Americas, in the Western Hemisphere, this is the show for fluid power.”

|

IFPE only

once every three years! SAVE

Register now at IFPE.com and type AD20 in the Promo Code box Discover

current

can offer to your

challenges. Find

among suppliers pushing the envelope on what fluid power can do.

CO-LOCATED WITH CONEXPO-CON/AGG (two shows, one price) Including Bosch Rexroth , Danfoss Power Solutions , Poclain , IFM Efector , Hawe Hydraulik , Husco , and 375+ more! Join your peers from these OEMs: ∙ Caterpillar Inc ∙ Volvo Construction Equipment ∙ Liebherr ∙ CASE Construction Equipment ∙ Komatsu ∙ John Deere Construction ∙ Doosan Bobcat ∙ KOBELCO Construction Machinery USA ∙ LBX Company Spark

with in-depth technical conversations with other engineers. The #1 Trade Show & Conference for Fluid Power, Power Transmission, and Motion Control IFPE20_210x285+3x4.5mm_Bleed_Registration_Ad_062722.indd 1 6/27/22 7:09 PM

Features 6 Cover Story Carry On: Fluid Power Keeps Pace with Material Handling Fluid power systems in advanced material handling applications with complex motion control. 10 Test Your Skills Sizing and Selecting Vacuum Pads 18 All Around the World: Circular Sustainability for Fluid Power Seeing manufacturing not as a linear process that ends in a landfill, but as a continuous cycle. 24 Checked: Avoiding Hydraulic Hose Disasters Some best practices to care for a crucial component to most systems. 28 Without Skilled Tradespeople, Who Builds It? Can fluid power lure young people to careers offering financial stability and job satisfaction? IN THIS ISSUE Publisher’s Note: The information provided in this publication is for informational purposes only. While all efforts have been taken to ensure the technical accuracy of the material enclosed, Fluid Power Journal is not responsible for the availability, accuracy, currency, or reliability of any information, statement, opinion, or advice contained in a third party’s material. Fluid Power Journal will not be liable for any loss or damage caused by reliance on information obtained in this publication. NOVEMBER 2022 VOLUME 29 • ISSUE 11 20 6 Departments 4 Notable Words 5 Figure It Out 12 NFPA Update 13 IFPS Update 20 Product Spotlight 22 Web Marketplace 23 Component Showcase 26 All About Vacuum 31 Classifieds Cer tification Empowers Opportunity. 18

ZF SERIES HYDRAULIC FLUIDS ECO

BIO-BASED GREEN SERIES

MARINE SAFE SERIES

Newark, NJ 07105 / Toledo, OH 43605 / 800-733-4755 To learn more visit us at: www.lubriplate.com INCLUDED AT NO ADDITIONAL CHARGE ES P Lubriplate’s Complimentary Extra Services Package COLOR CODED LUBE CHARTS & MACHINERY TAGS PLANT SURVEYS / TECH SUPPORT / TRAINING LUBRICATION SOFTWARE / FOLLOW-UP OIL ANALYSIS LUBRICANTS HYDRAULIC FLUIDS WITH THE POWER TO PROTECT VGP COMPLIANCE STATEMENT - LUBRIPLATE BIO-SYNXTREME HF Series Hydraulic Fluids are Environmentally Acceptable Lubricants (EALs) according to the definitions and requirements of the US EPA 2013 Vessel General Permit, as described in VGP Section 2.2.9 SYN LUBE SERIES 32-68 100% • High-Performance, 100% Synthetic, Polyalphaolefin (PAO)-Based Fluids. • Provides extended drain intervals and excellent compatibility with seals. • Available in ISO Viscosity Grades 32, 46 and 68. HO SERIES HYDRAULIC OILS PETROLEUM • Premium-Quality, Petroleum-Based Hydraulic Oils (ISO Grades 32-100). • Anti-wear fortified to protect hydraulic system components. • High aniline points ensure long seal life with fewer leaks. SFGO ULTRA SERIES 7-68 NSF H1 • NSF H1 Registered and NSF ISO 21469 Certified - Food Machinery Grade. • High Performance, 100% Synthetic Food Machinery Grade Fluids. • Available in ISO Viscosity Grades 7, 15, 22, 32, 46 and 68. • Fortified with Lubriplate’s proprietary anti-wear additive SYNXTREME FRH1-46 • High-Performance, FM Approved, Fire Resistant Hydraulic Fluid. • NSF H1 Registered and NSF ISO 21469 Certified - Food Machinery Grade. • ECO-Friendly, Readily Biodegradable (OECD 301F). • Fortified with Lubriplate’s proprietary anti-wear additive .

• Heavy-Duty, High-Performance, Extended Life, Hydraulic Fluids. • ECO-Friendly - Free of zinc or silicone compounds. • Provides long service life and extended fluid change intervals.

ECO • Vegetable-Based Oils for use in environmentally sensitive applications. • ECO-Friendly - Ultimately Biodegradable (Pw1). • Zinc-free additives provide exceptional anti-wear and anti-rust protection.

ECO • For equipment operating in environmentally sensitive locations. • Zinc-free and non-toxic to aquatic life. • Exceeds U.S. EPA LC50 and US Fish and Wildlife requirements. • Meets or exceeds the requirements of most hydraulic equipment BIO-SYNXTREME HF SERIES ECO • Advanced Synthetic Polyalkylene Glycol (PAG)-based hydraulic fluids. • Designed for environmentally sensitive industrial and marine applications. • Meets U.S. EPA Vessel General Permit (VGP) Requirements. Readily biodegradable. • Does not leave a sheen on the water. FM APPROVED FIRE RESISTANT NSF H1 REGISTERED FOOD GRADE SYNTHETIC PAO-BASED OILBASED REGISTERED FOOD GRADE ZINC-FREE FRIENDLY BIO-BASED FRIENDLY, NON-TOXIC TO AQUATIC LIFE (LC-50) FRIENDLY - MEETS VGP REQUIREMENTS Lubriplate’s complete line of ultra high-performance, hydraulic fluids has been designed to provide a wide range of benefits including: extended fluid change intervals, cooler operating temperatures, reduced friction and reduced downtime. Products include...

Fluid Power Rides a Wave of Change

By Kevin P. Vanderslice, Director of Mobile Sales, ifm efector

» THE LAST 18 MONTHS have been a challenge for everyone, as we deal with supply chain issues, the lingering effects of the COVID shutdown, and the inflationary prices of core commodities. In an ideal world, there are checks and balances to prepare, but these are unprecedented times we are dealing with. The world in fluid power started changing before 2020. Each of us is on a journey to digital transformation, and each of us is in a different phase in that journey.

In most of these conversations we do not discuss the why: Why is data important? Why are we using smart sensors?

As an example, let us look at telematics. Today we address a lot of the how and what commodities. Metrics, such as vehicle tracking, are used by 85% of fleet owners. This tells you where the vehicle is always located. However, it does not tell you how efficient the driver may be at planning the route. The car broadcasts data such as machine speed, fuel consumption, and temperature from the engine. It may also record additional inputs such as hydraulic oil, level, pressure, and humidity. This broadcast data is useful, but it does not tell you about impending maintenance issues. Finally, if we look at driver-performance monitoring, it is normally represented in data tracking accelerating or braking styles and how efficiently the driver followed the planned route. It does not explore the possibility of the driver looking down at his or her cell phone.

There is a shift in business models with this digital transformation, and each of us are in a different stage. For the past number of decades, most of us have navigated the waters of Wave 1. This is the classic ownership model, in which you pay a one-time price for a machine or after-sales service. An OEM provides a warranty for a limited time, and any service work beyond that follows the classic model of sending a technician or bringing the machine in for repairs. Wave 2 is the usage-based model, in which a customer pays for the actual usage of the machine but does not own it. In Wave 2, uptime becomes critical. If your machine is not performing at 100%, you may not get paid. Now you need more insights into the machine operation to detect wear and tear. With this information, you can schedule downtime for maintenance and repairs.

The term “digital transformation” is certainly buzzy these days. But how should fluid power companies manage this transformation? The manufacturing industry generates more data than any other sector of the economy, and because all this data is generated, companies are making data and analytics a priority. In a recent General Electric survey, 42% of manufacturers have said “big data” is a top priority. In the same survey, another 45% said that it is one of their three highest priorities. Today we talk a lot about the what and the how. What are big data, IIoT, and Industry 4.0? How are smart sensors, software, machine learning, and artificial intelligence connected?

Lastly is the final stage, Wave 3, the outcome-based model. The cus tomer only pays for the finished product and does not care which machine achieves it. However, you are responsible for the final product, and having a full understanding of the machine health and product quality is critical. The classic consumer example of Wave 3 is Uber.

As we mitigate these in the times in which we live, the digital trans formation movement is ongoing. We need to determine which wave we are in and which one our clients expect from us in the future. This could take a few months or many years. The main point is – we need to prepare ourselves for this change. •

4 NOVEMBER 2022 WWW.FLUIDPOWERJOURNAL.COM • WWW.IFPS.ORG NOTABLE WORDS

PUBLISHER

Innovative Designs & Publishing, Inc.

3245 Freemansburg Avenue, Palmer, PA 18045-7118

Tel: 800-730-5904 or 610-923-0380

Fax: 610-923-0390 • Email: Art@FluidPowerJournal.com www.FluidPowerJournal.com

Founders: Paul and Lisa Prass

Associate Publisher: Bob McKinney

Editor: Michael Degan

Technical Editor: Dan Helgerson, CFPAI/AJPP, CFPS, CFPECS, CFPSD, CFPMT, CFPCC

Director of Creative Services: Erica Montes

Graphic Designer: Nicholas Reeder

Account Executive: Kristy O'Brien

Accounting: Donna Bachman, Sarah Varano

Circulation Manager: Andrea Karges

INTERNATIONAL FLUID POWER SOCIETY

1930 East Marlton Pike, Suite A-2, Cherry Hill, NJ 08003-2141

Tel: 856-489-8983 • Fax: 856-424-9248 Email: AskUs@ifps.org • Web: www.ifps.org

2020 BOARD OF DIRECTORS

President: Denis Poirier Jr., CFPAI/AJPP, CFPHS, CFPIHM, CFPCCDanfoss Power Solutions

Immediate Past President: Rocky Phoenix, CFPMMHOpen Loop Energy

First Vice President: Scott Sardina, PE, CFPAI, CFPHS, CFPECS - Waterclock Engineering

Treasurer: Jeff Hodges, CFPAI/AJPP, CFPMHM - Altec Industries

Vice President Certification: James O’Halek, CFPAI/AJPP, CFPMIP, CMPMM - The Boeing Company

Vice President Marketing: Chauntelle Baughman, CFPHSOneHydraulics

Vice President Education: Randy Bobbitt, CFPAI, CFPHSDanfoss Power Solutions

Vice President Membership: Garrett Hoisington, CFPAI/AJPP, CFPS, CFPMHM - Open Loop Energy

DIRECTORS-AT-LARGE

Stephen Blazer, CFPE, CFPS, CFPMHM, CFPIHT, CFPMHT - Altec Industries

Steve Bogush, CFPAI/AJPP, CFPHS, CFPIHM - Poclain Hydraulics

Cary Boozer, PE, CFPE - Motion Industries

Lisa DeBenedetto, CFPS - GS Global Resources

Daniel Fernandes, CFPECS, CFPS - Sun Hydraulics

Brian Kenoyer, CFPHS - CemenTech

Jon Rhodes, CFPAI, CFPS, CFPECS - CFC Industrial Training

Mohaned Shahin, CFPS Parker Hannifin

Randy Smith, CFPHS - Northrop Grumman

Ethan Stuart, CFPS, CFPECS - Wainbee Limited

Brian Wheeler, CFPAI/AJPP, CFPMM, CFPMIPThe Boeing Company

HONORARY DIRECTORS-AT-LARGE AND EX OFFICIO

Donna Pollander, ACA Paul Prass, Fluid Power Journal

Liz Rehfus, CFPE, CFPS

Robert Sheaf, CFPAI/AJPP - CFC Industrial Training

IFPS STAFF

Chief Executive Officer: Donna Pollander, ACA

Technical Director: Thomas Blansett, CFPS, CFPAI Certification Logistics Manager: Kyle Pollander Communications Coordinator: Victoria Piro

Layout/Graphics Designer: Chalie Clair

Assistant Director: Jenna Mort Bookkeeper: Diane McMahon Administrative Assistant: Beth Borodziuk

Fluid Power Journal (ISSN# 1073-7898) is the official publication of the International Fluid Power Society published monthly with four supplemental issues, including a Systems

New Problem Relocating HPU Causes Start-up Problem

By Robert Sheaf, CFPAI/AJPP, CFPE, CFPS, CFPECS, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPMM, CFC Industrial Training

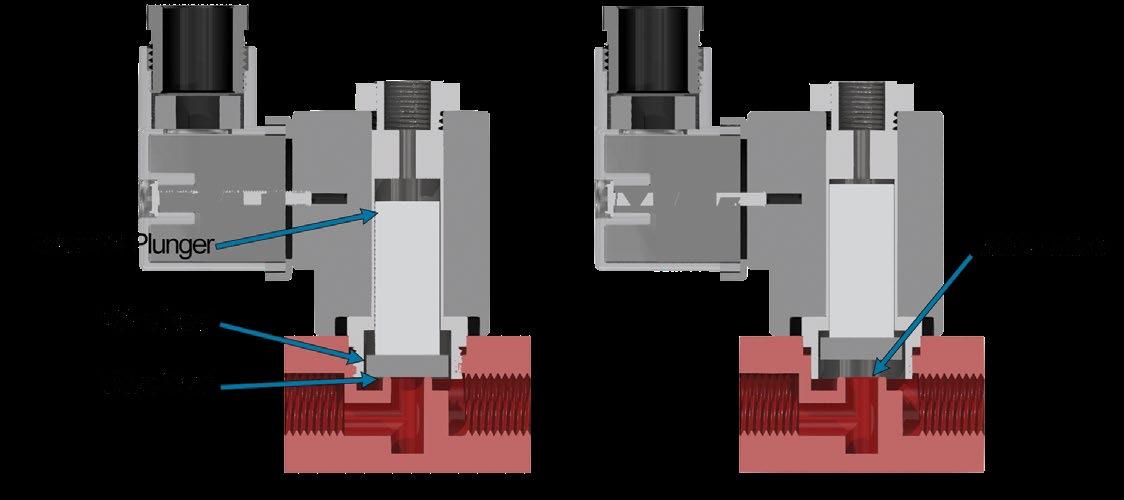

» A CUSTOMER WAS rearranging his shop floor to accommodate a new assembly line. They moved a clamp and grind machine to a location where there was too little room to place the HPU close to the machine. The existing hoses connecting the two were 30 feet long and routed through a hole in a wall to the unit.

The company realized that the longer hoses needed their size increased to account for the pressure drop caused by their new length.

But they encountered a problem during start-up. The cylinder wasn’t responding as in the past. It could not reach max speed extending, and there seemed to be little con trol of the retract speed. The counterbalance valve was mounted close to the cylinder.

They installed a new counterbalance valve, but there was no change. Even a new proportional valve didn’t help.

What could be the problem?

Solution to the October 2022 problem: Compactor Loses Pressure to All Circuits

After checking most of the normal causes for lack of pressure, I thought that the pilot orifice in the main pilot operated directional valve was plugged. When I removed the main stage of the directional valve, I found it had a check valve insert in the pressure port. This creates enough pilot pressure to shift the main spool and requires about 75 psi minimum. A piece of plastic was holding the check valve fully open. Removing the obstacle solved the lack of main system pressure. Further inspection then found that the bypass check in the pressure filter had failed and generated the plastic piece. We installed a new filter housing.

WWW.IFPS.ORG • WWW.FLUIDPOWERJOURNAL.COM NOVEMBER 2022 5

Integrator Directory, Off-Highway Suppliers Directory, Tech Directory, and Manufacturers Directory, by Innovative Designs & Publishing, Inc., 3245 Freemansburg Avenue, Palmer, PA 18045-7118. All Rights Reserved. Reproduction in whole or in part of any material in this publication is acceptable with credit. Publishers assume no liability for any information published. We reserve the right to accept or reject all advertising material and will not guarantee the return or safety of unsolicited art, photographs, or manuscripts. FIGURE IT OUT

15 H2O 3 MICRON 50 PSI BY-PASS CHECK 65 PSI CHECK SET @ 3500 PSI 5" B x 3.5" ROD x 36" LONG

CARRY ON Fluid Power Keeps Pacewith Material Handling

By Wendy Wu, Product Manager Hydraulic Hose & Couplings, Industrial Europe, Gates

Material handling takes place at every stage of the supply chain. It involves the movement, storage, protection, and control of raw materials and finished goods. Fluid power is a close partner with material handling. Fluid power systems are often used for advanced handling applications involving complex sequences of motion control. That control allows for mechanical tasks such as rotations, lifts, turns, and conveyer operations, or extremely difficult tasks, like tunnel excavation.

Optimizing material handling and improving supply chain efficiency have been constant challenges, but their scope is shifting considerably. Acceleration of e-commerce adoption on a larger scale, increased cus tomer expectations, the urgency of a green transition, and unexpected disruption of the supply chain ecosystem put additional pressure on both suppliers and buyers. Innovation is more critical than ever in supply chain management – and by extension, materials handling – for building resilience, tackling long-term challenges, and contributing to global CO2 emissions reduction targets.

Historically, material handling was not an industry that came to mind when people thought of the disruption or adoption of technologies. Now it’s a very dynamic field.

What are the focus areas and priorities for keeping up with the changing technology of the material handling industry and contributing to its future development? The answer is key for fluid power companies mapping their own innovation journey, as well as for equipment manufacturers choosing the right supplier. This article discusses major success factors of companies taking on challenges, grabbing opportunities, and thriving in this new era of material handling.

Material handling automation

The speed of the material handling industry’s embrace of automa tion and emerging technologies in recent years has been astonishing, although it varies among subsegments. Automation technology is advancing fast and creating disruptive change in material handling for product manufacturers, retail businesses, e-commerce players, and end customers. With automated conveyors, guided vehicles, and storage and retrieval systems, along with tools like warehouse cranes, goods movement can be almost entirely automated. Furthermore, artificial intelligence and the Internet of Things have paved the way for a new era of robotic material handling.

Industrial automation is not a new concept, and fluid power has several features that help automate manufacturing operations. Fluid power equipment can maintain constant and steady pressure, avoiding the overheating or failure of electric motors when exerting continuous force. This steady pressure permits the smooth motion of mechanical arms for functions such as lifting and holding heavy objects or gripping an object with a controllable force. Besides meeting technical requirements, fluid power is the preferred solution in many automation applications, especially when it is more economical than electrical power.

Digital transformation means more than adding automation. Mate rial handling is linked with advanced technologies such as self-driving, blockchain, and AI. Digital technologies are reinventing equipment, elevating it to the next level of user experience, safety, and efficiency.

The industry-first Gates GC20 crimper, for example, is supported by the Gates Cortex Intelligence automation platform. It offers real-time

6 NOVEMBER 2022 WWW.FLUIDPOWERJOURNAL.COM • WWW.IFPS.ORG COVER STORY

cloud connectivity and system integration, allowing operators of any skill level to intuitively crimp assemblies safely and error-free.

Regardless of debates about the negative effects of digitalization, we are in a digitized economy and business environment. Dig ital transformation is of strategic importance to leading fluid power manufacturers and players diving into new segments.

A ‘culture of innovation’

The remarkable shift toward increased automation and digitiza tion of material handling requires an accelerated adoption of tech nologies and adaptation to the trend. Introducing, implementing, and absorbing rapid changes in technologies can be challenging and complex. During the innovation journey, companies can fall behind simply because they do not fully understand the trend, they are reluctant to move, or they lack a system to support creativity.

The driving force is a culture of innovation. It encourages creative solutions for meeting customer needs and secures the continuous inno vation of products, processes, and services.

For example, Gates Corporation has historically been first-to-market with innovations, including the M3K constant-pressure hydraulic hose and Quick-Lok threadless snap-in hydraulic couplings. This type of inno vation culture leads people to challenge the limits, proved by the recent X-Series hydraulic innovations from Gates, featuring the MXT and MXG lines. In a disruptive age, every company needs to be a truly innovative solution provider. This is essential not only for business growth but also for surviving the transformation.

Material handling capability is a focal point for operations efficiency, supply chain optimization, and manufacturing productivity. Highly auto mated material handling systems significantly improve process efficiency. Major benefits also lie in their scalability and accuracy. They can be pro grammed to handle multiple tasks simultaneously, mitigating human mistakes and errors. However, system reliability is crucial to fully realize those benefits. Automated systems, in turn, have the ability to collect accurate data of operations and working conditions. This benefits new process and model implementation to improve system reliability, such as proactive maintenance service, which largely depends on condition-based issue prediction and data-driven activity.

Efficiency and reliability are inseparable because one requires the other for companies to increase profit and improve productivity. For components suppliers or producers of fluid power equipment, both effi ciency and reliability need to be considered when it comes to equipment development and optimization. Innovation must be compatible with reliability, helping to eliminate or greatly reduce any risk for customers who are early users of innovative practices.

Fluid power applications can impact efficiency and reliability in several ways. To illustrate, consider how the Gates MXG 5K hose contributes to system competency and dependability. It is 25% more flexible than

legacy hydraulic hoses. A more flexible hose makes it easier to get a flush mount at the manifold during installation, which reduces the risk of hydraulic fluid leaks. In dynamic applications, more flexibility means less power goes into moving the hose, so more power can be used for actual work. Tested to 1 million impulse cycles, the MXG 5K comes with an XtraTuff Plus cover that is both abrasion- and ozone-resistant, delivering long-lasting performance and reliability on the inside and the outside.

Most original equipment manufacturers find a simple solution to reduce downtime, mitigate risks, and tackle future uncertainty to increase the strength and longevity of the system. Premium-quality materials often equate to long-term durability and life. Selecting premium products is an effective way to attain product reliability and eliminate downtime in the field. High quality doesn’t mean high cost. Companies need to carefully evaluate the total cost of ownership, factoring in the original purchase price of the component, the installation time and effort, plus any maintenance costs during the operational life.

Long-term value

Mechanical reliability relies heavily on materials science and engi neering, plus operating conditions and environment. When fluid power components – fittings, hose, and tubing for hydraulic or pneumatic systems – all come from the same manufacturer, it hedges against the risk of shutdown caused by incompatible components. The Gates MXT wire braid hose and Gates MegaCrimp couplings are qualified to work together as matched systems. When assembled per Gates specifications, they are warrantied to exceed 600,000 impulse cycles, which is more than three times the industry standard. A Gates customer in Malaysia faced a leaking problem in its logistics operations every two months due to mix-and-match hose and couplings. The company resolved the issue by selecting and using the Gates MXT series and validated couplings. The Gates engineering process pays strict attention to minimizing the number of components, which reduces the number of leak paths and offers optimal longevity, efficiency, and reliability.

While efficiency and reliability improvements are primary focuses for business growth, to increase long-term business value sustainability is unignorable. It is of special concern today. In the context of business uncertainty, it raises new challenges. Every market has experienced a

WWW.IFPS.ORG • WWW.FLUIDPOWERJOURNAL.COM NOVEMBER 2022 7 Continued to Page 8

Gates’ GC20 crimper offers real-time cloud connectivity.

Continued from page 7

surge in energy prices due to rebounding demand after the COVID-19 pandemic. Global supply chains are expected to struggle amid constant volatility, and it is hard to predict when the backlog will end. Invest ment for establishing green supply chain or material handling systems undoubtedly creates value in the long term.

Material handling systems consume substantial amounts of energy over time. Electric consumption due to direct movements of products or materials by material handling is a macro-category in logistics chains. Obtaining and transporting energy is increasingly expensive. Energy savings are a strategic factor for many businesses, so the features of automated and robotic equipment they desire include energy efficiency and compact size.

Sustainability dynamics

Smart material handling enables automated procedures that employ less energy, provide real-time operational visibility, and turn data into actionable insights. There is no denying that using renewable energy in industry and power generation is a trend, but this transition will likely take some time. So the quickest way to tackle an energy crisis is with energy savings, where the adoption of lighter components of equipment can play a big role. Forklifts are one of the most widely used pieces of equipment for moving and managing materials in a warehouse and are typically outfitted with over 10 meters (32 feet) of hoses. Large scissor lifts can have hundreds of meters of hydraulic lines on one application. Weight reduction brings considerable energy-saving potential and is important for building energy-efficient hydraulic systems.

Fluid power is the preferred solution in many automation applications, especially when it is more economical than electrical power.

Every industry’s sustainable development relies on ecological sus tainability. Fluid power is no different. There is still a lot to be done to accelerate the transition toward sustainability dynamics. Steps in that direction include the formation of standards and principles in the design of green fluid power systems and advocating for environmentally safe fluids. Players with far-reaching vision have invested more in products that lessen environmental impacts, mainly by reducing noise emissions, heat generation, and oil leaks and spills from fluid power applications.

A human-robot interaction environment requires new health and safety measures.

In terms of energy conversion, pneumatics and hydraulics are effi cient solutions for a number of applications. Converting the energy of compressed air into motion, pneumatic actuators are highly efficient sources of motion control. Pneumatic control systems are economical and can be advantageously applied to other forms of power. In hydrau lics systems, pressurized fluids are transmitted over long distances and through complex machine configurations with little loss in power. An important contributor to sustainability improvement is an increased system life, reducing the impact of production and decommissioning.

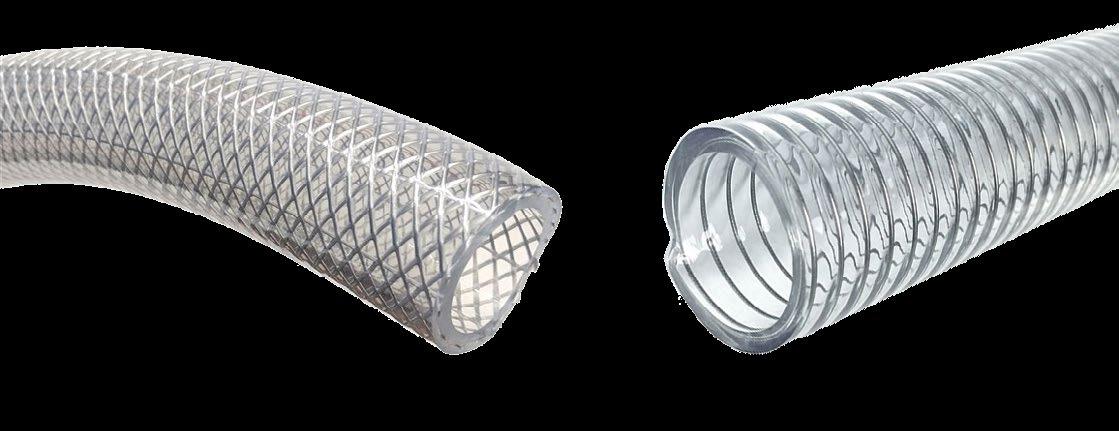

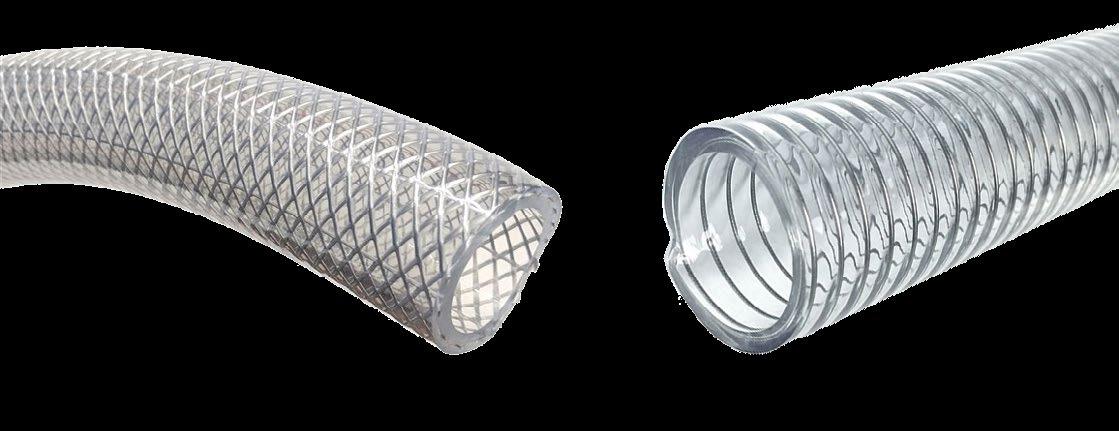

The leading trend in fluid power machinery is continuous improve ment in product flexibility, compactness, and weight. Hydraulic hoses are a shining example; high flexibility helps achieve high efficiency, allowing for shorter assembly time and easier routing during installation. As examples, Gates MXT hoses (with braided high-tensile steel wire reinforcement) and the recently launched Gates MXG series hoses (with patented Xpiral woven spiral technology) are remarkably more light weight – for improved fuel economy and longer time in the field before refilling – extremely more flexible, and much more compact compared to their premium legacy equivalents.

Gates was an early adopter of environmentally friendly materials in products. In 2003, Gates launched the EFG hose series. “EF” stands for EnviroFluid, indicating the product is compatible with even the most aggressive biodegradable hydraulic fluids, such as synthetic esters, poly glycols, and vegetable oils. Key players in fluid power go beyond product designs to implement energy-saving manufacturing practices that reduce their ecological footprint. Gates facilities in Belgium and Thailand employ solar energy to lower carbon footprints. The Belgium facility is 100% solar powered and generates up to 739 kilowatts peak. The Thailand facility achieved an energy savings of 24,336 kilowatt hours per year.

Last but not least, don’t forget about people. As companies progress to an era of highly automated manufacturing and distribution, the journey can be sustainable only when we prioritize people every step along the way. The design of fluid power systems, whether in manual or automated form, must consider improved ergonomics and mitigate new health and safety risks for people who interact with robots in so-called cobotic envi ronments. Highlighting attention paid to ergonomics during the design process, Gates fluid power products are lighter weight and more flexible for ease of installation and to help reduce stress and strain when handling.

Fluid power, material handling, and supply chain share key benchmarks: efficiency, reliability, and sustainability. Driven by components manufac turers, equipment and machinery OEMs, and industry organizations, fluid power innovation is essential for companies to cope with supply chain issues and win in the new reality. Advancements in material handling offer opportunities for fluid power to make a positive impact. Along with emerging technologies reshaping virtually every industry, material han dling has fast become the objective for a steady, nonstop flow of goods, which prompts fluid power to accelerate along its road to innovation.

Innovation is a journey, not a guarantee for success. A truly innovative culture leads to sound strategy and a well-developed actions frame work. Companies must identify their focus areas, coordinate efforts, and leverage sources to hurdle current obstacles and be ready to respond to future challenges.

8 NOVEMBER 2022 WWW.FLUIDPOWERJOURNAL.COM • WWW.IFPS.ORG

•

NOVEMBER 2022 9 +1 305 459 0763 www.teleradio.com sales@teleradio.com AN COMPANY Tele Radio America, LLC REMOTE CONTROL FOR HYDRAULIC APPLICATIONS SAFE SMART STRONG SCAN FOR INFO

SIZING AND SELECTING VACUUM PADS

Vacuum pads are primarily used for handling smooth-surfaced mate rial but can be used with textured or irregularly shaped material as well. Because sheet glass and other products that have a smooth surface generally have few to no places for attaching mechanical hooks and grippers, vacuum pad technology enables the material to be efficiently and safely moved.

Because of the many applications for using vacuum pad lifting tech nology, and the many possibilities of surfaces and working environments encountered, vacuum pads come in various shapes, sizes, and materials to allow a wide selection range.

The principle behind vacuum pad technology is simple. The area of the pad multiplied by the pressure applied results in a holding force. The pressure within the pad is less than atmospheric (vacuum). The differential pressure between atmospheric and the vacuum level within the pad is the effective pressure against the area of the pad contacting the surface of the material. This results in a force holding the material to the pad. The pad is attached by placing it against the surface and then drawing a vacuum. The force required to pull the cup away from the surface is proportional to the vacuum and size of the pad. The higher the vacuum, or larger the vacuum pad, the stronger the pull force required to detach the vacuum pad.

If the vacuum is provided in units of negative pressure (-psi or -kPa) then the calculation is the standard formula for force. If the vacuum is provided in a different unit of measure, the simplest solution is to convert the units to the equivalent negative pressure first.

Proper selection of vacuum pads is much more involved than the simple pressure-times-area calculations. The effective force used in the calcula tion must include the acceleration forces in all directions in addition to the weight of the workpiece. The interface between the vacuum pad and the workpiece is not a 100% seal. The accepted practice is to add a safety factor to the load based on the orientation and direction of movement. For applications that include only static holding, a safety factor of 2:1 is

acceptable. Vertical lifting and horizontal movement (which are shear forces) should use a minimum safety factor of 4:1. If the vacuum pads are positioned horizontally with the workpiece positioned vertically a minimum safety factor of 8:1 is recommended.

Example 1: The combined force for lifting and moving a workpiece is 24 pounds.

The vacuum is 7.8 in-Hg absolute (200 torr).

The oval-shaped pad has dimensions of 3 inches x 1 inch.

Using a minimum safety factor of 4:1, how many pads should be used?

Use atmospheric pressure of 14.7 psia.

Solution

Calculate pressure difference between atmospheric conditions and the vacuum:

1 in-Hg = 0.491 psi

7.8 • 0.491 = 3.83 psia

Pressure differential = 14.7 – 3.83 = 10.87 psi differential.

Calculate the area of the vacuum pad. The area of an oval pad is found by multiplying the major radius by the minor radius then multiplying by pi (π):

The oval pad has dimensions of 3 x 1 inch.

The major radius is 1.5 inches and the minor radius is 0.5 inches.

Area = 1.5 • 0.5 • π (3.14)

Area = 2.36 inches

Calculate the force of one vacuum pad:

F = p • a = 10.87 • 2.36 = 25.65 lb per pad.

Total force (required including safety factor) = 96 lb

Number of pads = 96 lb / 25.65 lb per pad = 3.74 pads.

Number of pads required = 4.

Example 2: What is the lifting capacity of a quantity of 10 vacuum pads, each with an effective diameter of 30 mm using a vacuum of -55 kPa? The recommended safety factor is 8:1.

Solution

Calculate the total area of the pads.

Each pad = 30² • 0.7854 = 707 mm².

Total area = 10 • 707 = 7,070 mm².

Calculate the theoretical lifting force.

(55 • 7,070) / 1,000 = 388.85 N.

Determine lifting capacity including safety factor. 388.85 / 8 = 48.61 N.

10 NOVEMBER 2022 WWW.FLUIDPOWERJOURNAL.COM • WWW.IFPS.ORG

TEST YOUR SKILLS

TORR (MM MERCURY) PSIA, (LB/IN ²) ABSOLUTE INCHES MERCURY ABSOLUTE INCHES MERCURY VACUUM GAUGE KPA ABSOLUTE 760 14.7 29.92 0 101.4 700 13.5 27.6 2.32 93.5 600 11.6 23.6 6.32 79.9 500 9.7 19.7 10.22 66.7 400 7.7 15.7 14.22 53.2 300 5.8 11.8 18.12 40 200 3.9 7.85 22.07 26.6 100 1.93 3.94 25.98 13.3 50 0.97 1.97 27.95 6.7 1 0.01934 0.03937 29.88 0.13 0 0 0 29.92 0 Note: Chart is referenced to sea level.

The surface of the workpiece will affects the quantity and profile of the vacuum pads that should be used. Multiple pads distribute the force to prevent damage due to deflection. Mul tiple pads also provide an additional margin of safety in the event of a pad's failure. Pads that have a bellows or oblong shape provide for a better sealing surface on rounded or uniquely shaped parts. The surface of the workpiece influ ences the pad's material. Softer materials form a better seal to reduce the amount of leakage, but they are subject to more wear. Residue of the workpiece manufacturing process and tempera ture also influence the material selection. Other considerations that should not be overlooked are nonmarking and antistatic requirements. Using pivoting ball mounts at the interface between the vacuum pad and the tooling, the vacuum pad can be positioned perpendicular to an oddly shaped workpiece. Nonrotating mounts ensure that oval-shaped pads maintain proper orientation. Mounts with springs permit greater positioning flexibility. An example would be a transfer line that removes product from a

Safety tip: Regular inspection of vacuum pads is necessary for continued safe performance. Any damaged pad should be replaced immediately to maintain proper safety margin.

TEST YOUR SKILLS

1. 2.

With a flat piece of sheet metal that weighs 100 lb and with atmospheric pressure at sea level – using 4 circular vacuum pads that each have a diameter of 4 in. What is the minimum required vacuum needed for static holding, with standard safety factor of 2:1, on each cup?

a. 10.2 in-Hg gauge. b. 26 in-Hg absolute. c. 8.1 in-Hg gauge. d. 14.7 psia. e. 700 torr.

What is the equivalent pressure of 300 torr in kPa (a) absolute?

a. 40.0 kPa (a).

b. -45.3 kPa (a).

c. 56.0 kPa (a). d. -56.0 kPa (a).

stack. As the stack height is reduced, the spring takes up the movement, rather than adding an actuator to sequentially lift the stack, or a com plicated control that either monitors the height of the stack or the number of parts transferred, to reposition the height of the pad.

A vacuum check is a simple solution to ensure that a momentary loss of vacuum will not cause the part to drop. However, it may hinder the release of the vacuum once the pro cess completes. Additional circuitry may be

required, including redundant systems apply ing vacuum from separate vacuum generators to multiple pads.

The actual application of the vacuum pad has many other unknowns that cannot be easily identified. Excessive dust or inconsistent surface finishes affect leakage that adversely impacts the vacuum level. Before approving the final design, the fixture must be extensively tested with several different workpieces to ensure proper long-term operation. •

WWW.IFPS.ORG • WWW.FLUIDPOWERJOURNAL.COM NOVEMBER 2022 11

See page 31 for the solutions.

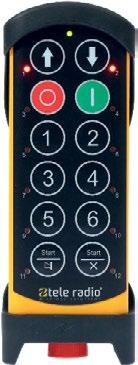

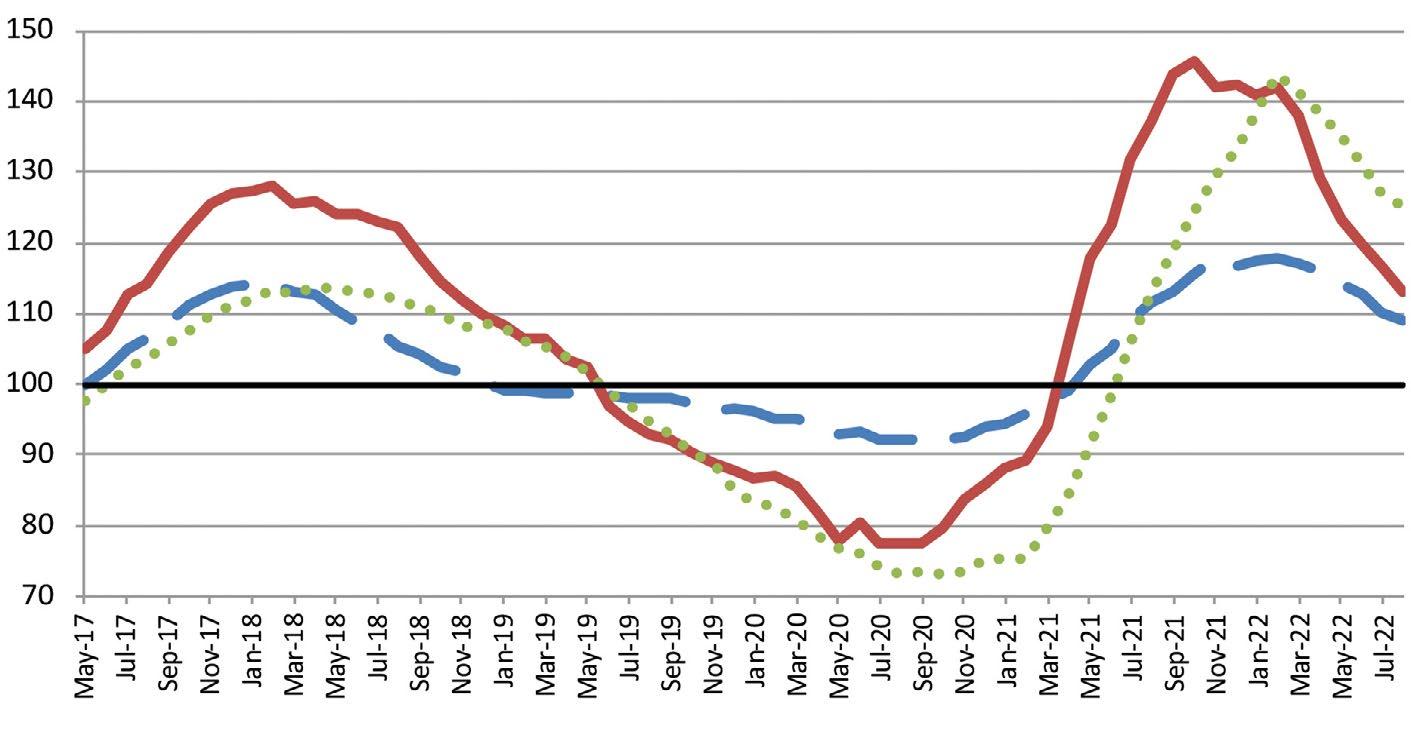

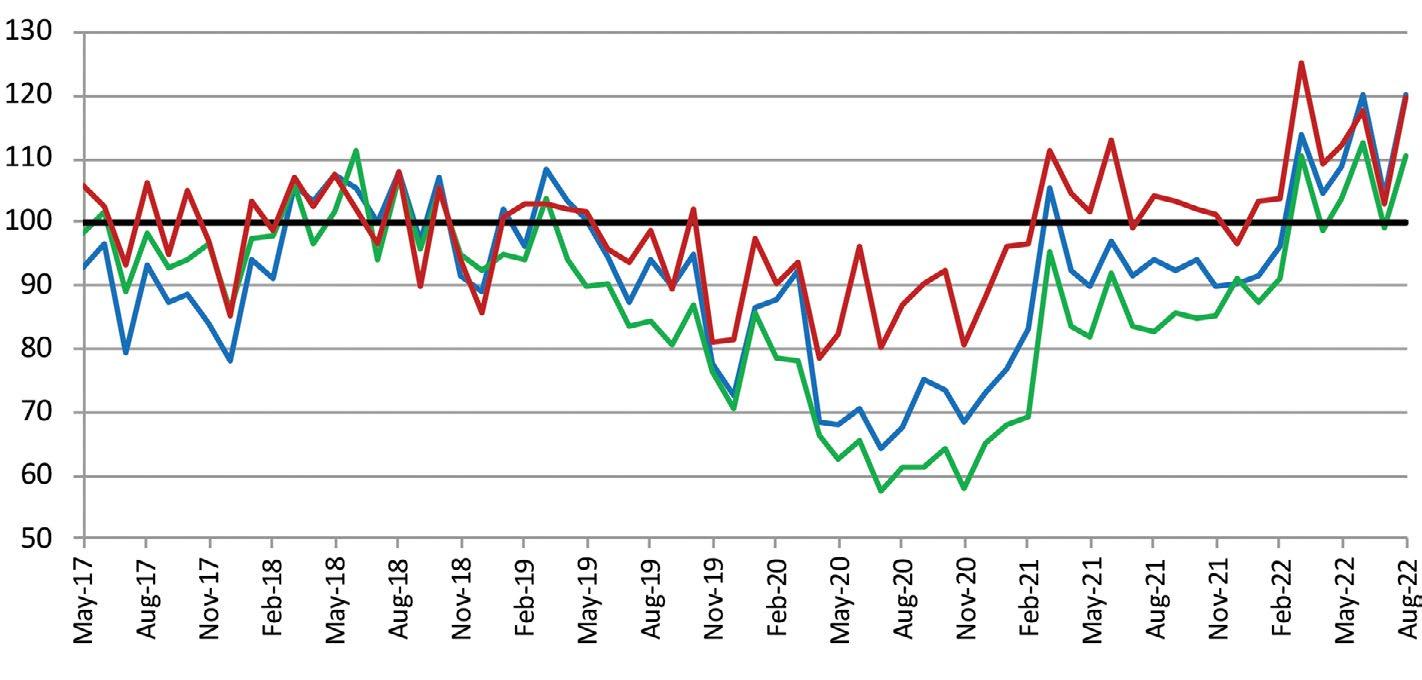

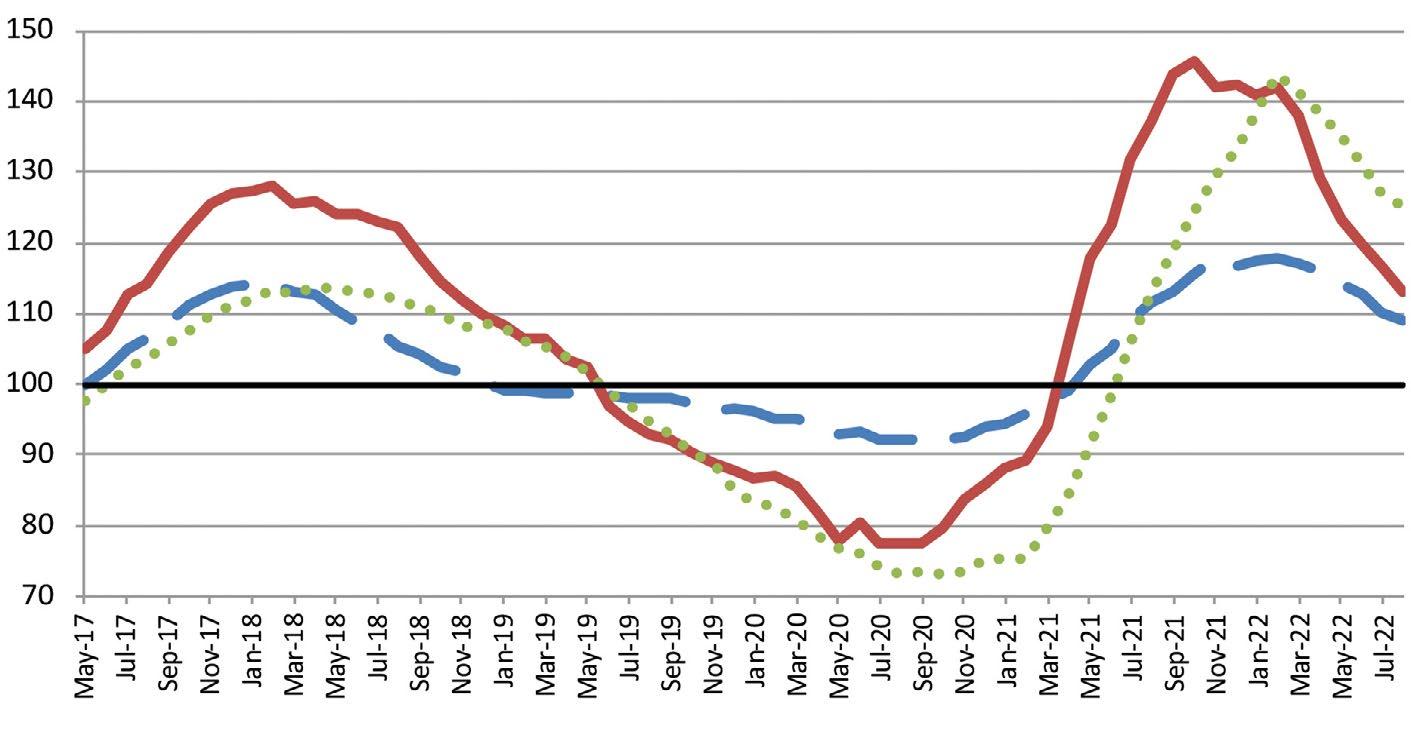

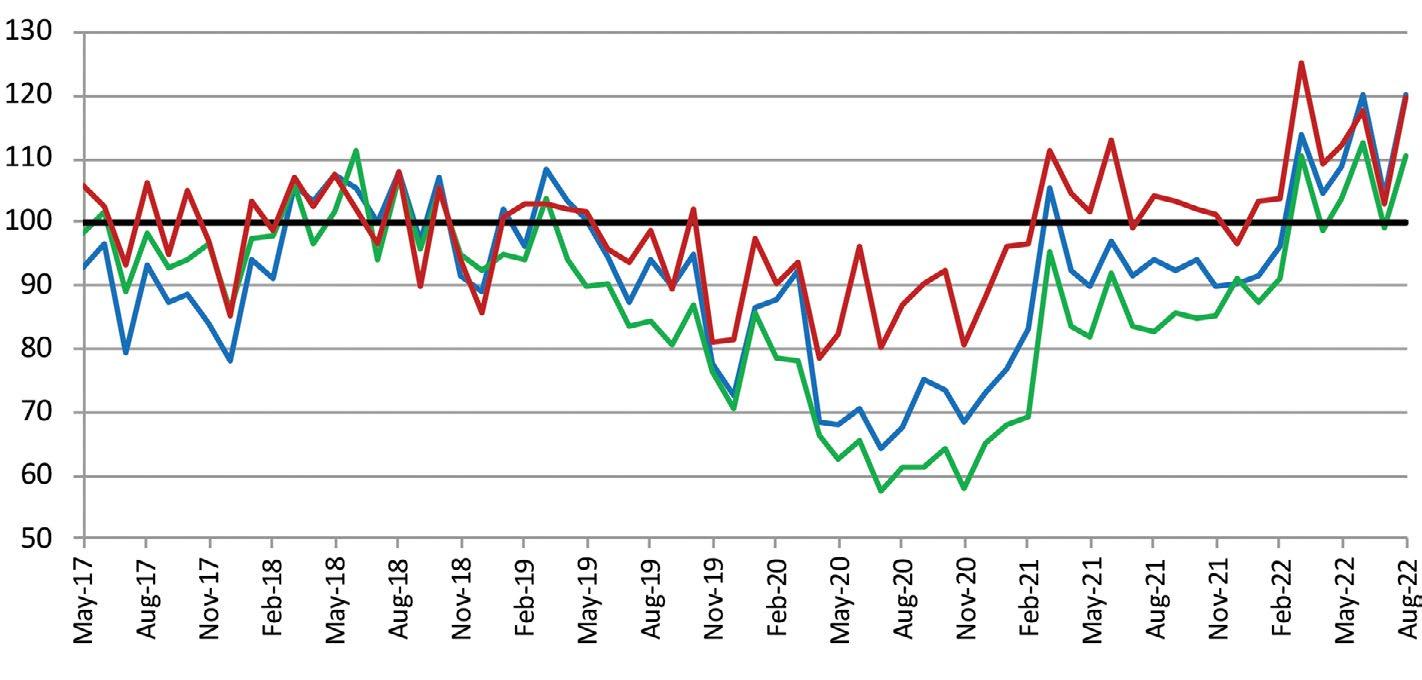

Shipments Up in August Rebound

After dropping slightly in July, shipments of fluid power products increased in August, according to data from the National Fluid Power Association. NFPA’s raw index data shows pneumatic, mobile hydraulic, and industrial hydraulic shipments all grew in August when compared to July. The year-to-date change for total fluid power shipments in August was 16.4%. The 12-month moving average of shipments for pneumatics, hydraulics, and total fluid power continues to grow. The data is from fluid power manufacturers in NFPA’s Confidential Shipment Statistics (CSS) program.

Hydraulic and Pneumatic Shipments

Raw Index Data, Index: 2018=100

This graph of raw index data is generated by the total dollar volume reported to NFPA by CSS participants and compared to the average monthly dollar volume in 2018. For example, the August 2022 total dollar volume for pneumatic shipments is 119.8% of the average monthly dollar volume in 2018. (Base Year 2018 = 100)

SHIPMENTS

MONTH TOTAL FLUID POWER TOTAL HYD. TOTAL PNEU.

Jun 2022 15.5 18.1 7.6

Jul 2022 15.2 17.8 7.1

Aug 2022* 16.4 19.0 8.1

*Preliminary data subject to revision.

Shipments – Cumulative year‐to‐date % change (2022 vs. 2021)

The table above is expressed in terms of cumulative percent changes. These changes refer to the percent difference between the relevant cumulative total for 2022 and the total for the same months in 2021. For example, August 2022 pneumatic shipments figure of 8.1 means that for the calendar year through August 2022, pneumatic shipments increased 8.1% compared to the same time-period in 2021.

Pneumatic, Mobile and Industrial Hydraulic Orders 12/12 Ratio

Each point on this graph represents the most recent 12 months of orders compared to the previous 12 months of orders. Each point can be read as a percentage. For example, 125.0 (the August 2022 level of the industrial hydraulic series) indicates that industrial hydraulic orders received from September 2021 to August 2022 were 125.0 % of the orders received from September 2020 to August 2021. (Base Year 2018 =100)

Total ‐ Hydraulic and Pneumatic Shipments 12 Month Moving Average

This graph of 12-month moving averages shows that in August 2022, total fluid power, total pneumatic, and total hydraulic all increased. (Base Year 2018 = 100)

12 NOVEMBER 2022 WWW.FLUIDPOWERJOURNAL.COM • WWW.IFPS.ORG

NFPA UPDATE

Newly Certified Professionals

August 2022

ACCREDITED INSTRUCTORS

David Rowe, Altec Industries

Seth Davis, Pueblo Community College

Kevin Lynk

CONNECTOR AND CONDUCTOR

Travis Barthalow, Manitowoc Crane Group

Joe Hege, Manitowoc Cranes

ELECTRONIC CONTROLS SPECIALIST

Andrew Patience

Evan Dimmerling

Erick Garza, HydraForce

Quinn Schmidt, HydraForce

Cole Yungerman, HydraForce

Orlando Arvelo

HYDRAULIC SPECIALIST

Andrew Blackstock

William Kapherr, Altec Industries

Tyler Miller

Jason Stewart

David Wyandt, Motion Industries Andrew Duncan, Altec Industries

MOBILE HYDRAULIC MECHANIC

Trevor Swanson, Altec Industries

Matt Barnes, Ameren Corporation

Jacob Cook, Ameren Corporation

Dale Hendricks, Ameren Corporation

Caleb Krotz, Ameren Corporation

Stephen Lindewirth, Ameren Corporation

Aaron Stengel, Ameren Corporation

Rolando Casas, AEP

William Bower Jr., Southern California Edison

Kyle Kemper, Altec Industries

Kyle Rush, Motion & Flow Control Products

Tyler Coots, Altec Industries

Matt Moreman, Altec Industries John Ronkainen, Altec Industries

Nicolas Heredia, Altec Industries

Juan Vega, Altec Industries

Bryce Trone, Altec Industries

PNEUMATIC SPECIALIST

Alana Torres Vidal, Norgren

Ryan Bumgarner, SMC Corporation of America

Gloriana Urdaneta Azuaje, IMI Precision Engineering

Bradley Wagner, Manitowoc Crane Group

Matthew Eckert, Gulf Controls Company

Joshua Pilkin, IMI-Norgren LLC

SPECIALIST

Holds HS and PS Certifications

Bradley Wagner, Manitowoc Crane Group Matthew Eckert, Gulf Controls Company

Mark Your Calendar

WEB SEMINAR: THE CONSTRUCTION, OPERATION, SIZING, AND APPLICATIONS OF USING ACCUMULATORS

Dec. 21, 12-1 p.m. ET

Presented by Medhat Khalil, CFPAI, CPFHS

IFPS SPRING MEETING

Feb. 27-March 2, 2023, New Orleans

IFPS ANNUAL MEETING AND HALL OF FAME AWARDS CEREMONY

Sept. 25-28, 2023, Milwaukee

For more information, visit www.ifps.org.

INTERNATIONAL FLUID POWER EXPOSITION

March 14-18, 2023, Las Vegas (Visit us at booth SL80126!)

IFPS SPRING 2024 MEETING

March 11-14, 2024, San Antonio, Texas

TRAINING

UPSKILL YOUR WORKFORCE!

direct, Industry

Hands-On Training

turnkey

WWW.IFPS.ORG • WWW.FLUIDPOWERJOURNAL.COM NOVEMBER 2022 13 CFCINDUSTRIALTRAINING.com 7042 Fairfield Business Drive Fairfield, Ohio 45014 +1 513.874.3225 info@cfcindustrialtraining.com

ONSITE

CFC provides

and/or Machine specific training to companies the world over. Electrical Techs & Engineers Hydraulic Techs & Engineers Pneumatic Techs & Engineers Our

Equipment is mobilized directly to your facility with Certified Instructors traveling on site. This

approach includes all books, materials, equipment, and travel arrangements. We have the capability to upskill your entire workforce NOW! Multicraft Techs & Engineers

IFPS UPDATE

IFPS Online Training Opportunities

IFPS has a range of online resources for professional study and training.

Interactive Hydraulic Specialist Study Manuals

Whether studying for the hydraulic specialist certification test, or you simply want to enhance your existing hydraulic skills in a convenient and flexible environment, the new interactive Hydraulic Specialist Study Manual can help. The cost is $349. Visit https://www.ifps.org/online-training to order.

Animated Hydraulic Circuits

Visually seeing a circuit perform along with a description of operation can increase the comprehension of a particular component’s operation and its function within the circuit.

These animated presentations can be used by:

• Anyone interested learning component function and circuit operation.

• Instructors to assist in hydraulic specialist certification review training.

• Individuals to enhance their preparation to take the hydraulic specialist certification test.

Online Hydraulic Safety Awareness Training

IFPS offers online self-paced hydraulic safety awareness training courses. They provide an awareness of hydraulic hazards in the workplace,

in-depth reviews of potential exposures to injury from hydraulic systems, and ways to reduce risk and eliminate hazards for workers, equipment, companies, and the environment.

IFPS offers four online hydraulic safety awareness training courses:

• Exposure Level

• High Risk Maintenance Level

• Hydraulic Safety in Construction

• Fluid Injection Awareness

Online Training

Each self-paced course delivers a broad-based understanding of the most important fluid power subject matter concepts. Courses begin with the basics: physics laws, systems basics and design, basic analysis, and basic components. The courses demonstrate how these systems apply to fluid power and how they interact with each other.

Each training course features 12 to 16 hours of trade-specific e-training that uses simulations, assessments, quizzes, tests, learning labs, and more.

Completing online training courses does not result in IFPS certification. However, completing courses better prepares you for certification tests.

Available online courses include:

• Mobile Hydraulics Course*

• Industrial Hydraulics Course **

• Industrial Mechanical Course *

• Mobile Electrical Course *

• Industrial Pneumatics Course *

• Industrial Electrical Course *

Air Compressors

Clean Dry Air Improves Performance...

Clean, Dry Compressed Air Starts with The Extractor/Dryer® Manufactured by LA-MAn Corporation

Point of Use Compressed Air Filter to Improve and Extend Equipment Life

Removes Moisture and Contaminates to a 5-Micron Rating: Lower Micron Ratings are Available

Models with Flow Ranges of 15 SCFM

500 SCFM Rated Up To 250psi are Standard

Differential Pressure Gauge Built in

• Electrical Theory *

• AC/DC Motors and Drives *

• Diesel Engines *

• PLC Fundamentals + *available in metric, ** available in metric, Span ish, and Spanish (metric), + available in Spanish

Online Certification Review Training

Here’s an excellent tool to prepare for IFPS certification at your own pace and from your own computer. You can enroll for this self-paced online certification review training through CFC Industrial Training’s Learning Management System. IFPS members receive a discount. Training is available for these certifications:

• Job Performance (for mechanic and technician certifications)

• Mobile Hydraulic Mechanic (writ ten test review)

Hardware

for Easy Installation

Drain is Standard; Float Drain

Electronic Drain

• Mobile Hydraulic Mechanic written and Job Performance (as a bundle)

• Connector and Conductor

Online Web Seminars

IFPS holds web seminars every month. View a list of archived webinars at www.ifps.org.

14 WWW.FLUIDPOWERJOURNAL.COM • WWW.IFPS.ORG

Cer tification Empowers Opportunity. IFPS UPDATE

•

•

•

to

•

• Mounting

Included

• Weep

or

Valves Optional

Revised Handbook Now Available

» A SECOND EDITION of the Fluid Power Reference Handbook is now available. Highlights of the second edition include:

• An expanded symbology section ISO 1219 compliant.

• New and enhanced graphics.

• Expanded topics.

• Updated charts that are ISO, ANSI, and SAE compliant.

The 388-page Fluid Power Reference Handbook is the gold standard on-the-job reference tool of choice for any fluid power professional. IFPS has sold over 2,000 copies since its first publication in 2020.

Soft-cover: Members - $74.95 | Retail - $125.95

Hard-cover: Members - $149.99 |Retail - $165.99

For more information and to purchase, visit www.ifps.org/training-resources-handbook.

IFPS Seeking Web Presenters

IFPS is looking for web presenters to conduct hour-long online presentations.

IFPS Names Pollander CEO

Donna Pollander, executive director of the International Fluid Power Society, has been promoted to CEO of the organization.

IFPS’s board of directors approved the move during its annual meeting in September. According to an IFPS press release, Pollander will continue to serve as key liaison to the board of directors and be responsible for dayto-day operations. She will continue to ensure the consistent achievement of IFPS’s mission and financial objectives, provide leadership in developing certification programs and other educational opportunities, and execute orga nizational and financial plans with the board of directors and staff.

Some of the advantages of participating include:

• You’ll receive recertification points.

• You’ll receive a free thank-you golf shirt.

• It's a great promotion for you and for your company.

• IFPS provides a template to use.

• You’ll be able to rehearse before going live.

If you are interested or would like more information, contact vpiro@ifps.org.

“IFPS is part of the fiber of who I am, and I am proud to see it flourishing,” Pollander said in the press release. “IFPS’s future is bright, and I am very excited to be at the helm of such an integral part of the fluid power industry!”

IFPS is a nonprofit 501(c)(3) professional organization of individuals dedicated to enhancing the quality of certifications, educational opportunities, technology evolution, and professionalism within the fluid power industry. IFPS was founded in Detroit in 1960 by a group of 30 profession als interested in supporting the future of the fluid power industry and the ever-chang ing technologies involved. Beginning with the first Fluid Power Hydraulic Specialist Certification in 1980, IFPS has become the recognized industry leader in fluid power and motion control certifications. Fifteen

“Donna was in reality performing the duties as CEO for quite a while,” Denis Poirier, IFPS board president, said in the press release. “So the board felt it was time to acknowledge her efforts.”

Pollander started her career in fluid power in 1995, working part time with the company that managed the Fluid Power Distributors Associ ation. She’s held various positions in the management company until her promotion to IFPS executive director in 2003. IFPS decided to hire the staff in 2014.

different certifications are currently offered, and two are in development. The certifications cover diverse job descriptions, including mechanic, technician, specialist, system designer, and engineer. To date, IFPS has issued over 34,000 certifications.

For more information, visit www.ifps.org.

WWW.IFPS.ORG • WWW.FLUIDPOWERJOURNAL.COM NOVEMBER 2022 15

IFPS UPDATE

Written Certification Test Locations

ALABAMA

Auburn, AL Birmingham, AL

Individuals wishing to take any IFPS written certification tests can select from convenient locations across the United States and Canada. IFPS is able to offer these locations through its affiliation with the Consortium of College Testing Centers provided by National College Testing Association.

Contact headquarters if you do not see a location near you. Every effort will be made to accommodate your needs.

If your test was postponed due to the pandemic, please contact headquarters so that we may reschedule.

Calera, AL Decatur, AL Huntsville, AL Jacksonville, AL Mobile, AL Montgomery, AL Normal, AL Tuscaloosa, AL

ALASKA Anchorage, AK Fairbanks, AK

ARIZONA

Flagstaff, AZ Glendale, AZ Mesa, AZ Phoenix, AZ Prescott, AZ Scottsdale, AZ Sierra Vista, AZ Tempe, AZ Thatcher, AZ Tucson, AZ Yuma, AZ

ARKANSAS

Bentonville, AR Hot Springs, AR Little Rock, AR

CALIFORNIA

Aptos, CA Arcata, CA Bakersfield, CA Dixon, CA Encinitas, CA Fresno, CA Irvine, CA Marysville, CA Riverside, CA Salinas, CA San Diego, CA San Jose, CA San Luis Obispo, CA Santa Ana, CA Santa Maria, CA Santa Rosa, CA Tustin, CA Yucaipa, CA

COLORADO Aurora, CO Boulder, CO Springs, CO Denver, CO Durango, CO Ft. Collins, CO Greeley, CO Lakewood, CO Littleton, CO Pueblo, CO

DELAWARE Dover, DE Georgetown, DE Newark, DE

Tallahassee, FL Tampa, FL West Palm Beach, FL Wildwood, FL Winter Haven, FL

GEORGIA

Albany, GA Athens, GA Atlanta, GA Carrollton, GA Columbus, GA Dahlonega, GA Dublin, GA Dunwoody, GA Forest Park, GA Lawrenceville, GA Morrow, GA Oakwood, GA Savannah, GA Statesboro, GA Tifton, GA Valdosta, GA

HAWAII

Laie, HI

IDAHO

Boise, ID Coeur d ‘Alene, ID Idaho Falls, ID Lewiston, ID Moscow, ID Nampa, ID Rexburg, ID Twin Falls, ID

ILLINOIS

Carbondale, IL Carterville, IL Champaign, IL Decatur, IL Edwardsville, IL Glen Ellyn, IL Joliet, IL Malta, IL Normal, IL Peoria, IL Schaumburg, IL Springfield, IL University Park, IL

INDIANA

Bloomington, IN Columbus, IN Evansville, IN Fort Wayne, IN Gary, IN Indianapolis, IN Kokomo, IN Lafayette, IN Lawrenceburg, IN Madison, IN Muncie, IN New Albany, IN Richmond, IN Sellersburg, IN South Bend, IN Terre Haute, IN

LOUISIANA

Bossier City, LA Lafayette, LA

Monroe, LA

Natchitoches, LA New Orleans, LA Shreveport, LA Thibodaux, LA

MARYLAND

Arnold, MD

Bel Air, MD

College Park, MD Frederick, MD Hagerstown, MD La Plata, MD Westminster, MD Woodlawn, MD Wye Mills, MD

MASSACHUSETTS

Boston, MA

Bridgewater, MA Danvers, MA Haverhill, MA Holyoke, MA Shrewsbury, MA

MICHIGAN

Ann Arbor, MI Big Rapids, MI Chesterfield, MI Dearborn, MI Dowagiac, MI East Lansing, MI Flint, MI

Grand Rapids, MI Kalamazoo, MI Lansing, MI Livonia, MI Mount Pleasant, MI Sault Ste. Marie, M Troy, MI University Center, MI Warren, MI

MINNESOTA Alexandria, MN Brooklyn Park, MN Duluth, MN Eden Prairie, MN Granite Falls, MN Mankato, MN

MISSISSIPPI Goodman, MS Jackson, MS Mississippi State, MS Raymond, MS University, MS

MISSOURI

NEW JERSEY

Branchburg, NJ Cherry Hill, NJ Lincroft, NJ Sewell, NJ Toms River, NJ West Windsor, NJ

NEW MEXICO

Albuquerque, NM Clovis, NM Farmington, NM Portales, NM Santa Fe, NM

NEW YORK Alfred, NY Brooklyn, NY Buffalo, NY Garden City, NY New York, NY Rochester, NY Syracuse, NY

NORTH CAROLINA Apex, NC Asheville, NC Boone, NC Charlotte, NC China Grove, NC Durham, NC Fayetteville, NC Greenville, NC Jamestown, NC Misenheimer, NC Mount Airy, NC Pembroke, NC Raleigh, NC Wilmington, NC

NORTH DAKOTA Bismarck, ND OHIO

Akron, OH Cincinnati, OH Cleveland, OH Columbus, OH Fairfield, OH Findlay, OH Kirtland, OH Lima, OH Maumee, OH Newark, OH North Royalton, OH Rio Grande, OH Toledo, OH Warren, OH Youngstown, OH

OKLAHOMA

SOUTH CAROLINA

Beaufort, SC Charleston, SC Columbia, SC Conway, SC

Graniteville, SC Greenville, SC Greenwood, SC Orangeburg, SC Rock Hill, SC Spartanburg, SC

TENNESSEE

Blountville, TN Clarksville, TN Collegedale, TN

Gallatin, TN Johnson City, TN Knoxville, TN Memphis, TN Morristown, TN Murfreesboro, TN Nashville, TN

TEXAS Abilene, TX Arlington, TX Austin, TX Beaumont, TX Brownsville, TX Commerce, TX Corpus Christi, TX Dallas, TX Denison, TX El Paso, TX Houston, TX Huntsville, TX Laredo, TX Lubbock, TX Lufkin, TX Mesquite, TX San Antonio, TX Victoria, TX Waxahachie, TX Weatherford, TX Wichita Falls, TX

UTAH

Cedar City, UT Kaysville, UT Logan, UT Ogden, UT Orem, UT Salt Lake City, UT

WYOMING

Casper, WY Laramie, WY Torrington, WY

CANADA

ALBERTA Calgary, AB Edmonton, AB Fort McMurray, AB Lethbridge, AB Lloydminster, AB Olds, AB Red Deer, AB

BRITISH

COLUMBIA

Abbotsford, BC Burnaby, BC Castlegar, BC Delta, BC Kamloops, BC Nanaimo, BC Prince George, BC Richmond, BC Surrey, BC Vancouver, BC Victoria, BC

MANITOBA Brandon, MB Winnipeg, MB

NEW BRUNSWICK Bathurst, NB Moncton, NB

NEWFOUNDLAND AND LABRADOR St. John’s, NL

NOVA SCOTIA Halifax, NS

ONTARIO

JOB PERFORMANCE TEST LOCATIONS

Arizona California Colorado Florida Georgia Maine Michigan Minnesota Montana New Jersey

Nova Scotia Pennsylvania Texas Washington Wyoming Western Australia

FLORIDA

Avon Park, FL Boca Raton, FL Cocoa, FL Davie, FL Daytona Beach, FL Fort Pierce, FL Ft. Myers, FL Gainesville, FL Jacksonville, FL Miami Gardens, FL Milton, FL New Port Richey, FL Ocala, FL Orlando, FL Panama City, FL Pembroke Pines, FL Pensacola, FL Plant City, FL Riviera Beach, FL Sanford, FL

IOWA

Ames, IA Cedar Rapids, IA Iowa City, IA Ottumwa, IA Sioux City, IA Waterloo, IA

KANSAS

Kansas City, KS Lawrence, KS Manhattan, KS Wichita, KS

KENTUCKY

Ashland, KY Bowling Green, KY Erlanger, KY Highland Heights, KY Louisville, KY Morehead, KY

Berkley, MO Cape Girardeau, MO Columbia, MO Cottleville, MO Joplin, MO Kansas City, MO Kirksville, MO Park Hills, MO Poplar Bluff, MO Rolla, MO Sedalia, MO Springfield, MO St. Joseph, MO St. Louis, MO Warrensburg, MO

MONTANA Bozeman, MT Missoula, MT

NEBRASKA Lincoln, NE North Platte, NE Omaha, NE

NEVADA Henderson, NV Las Vegas, NV North Las Vegas, NV Winnemucca, NV

Altus, OK Bethany, OK Edmond, OK Norman, OK Oklahoma City, OK Tonkawa, OK Tulsa, OK

OREGON Bend, OR Coos Bay, OR Eugene, OR Gresham, OR Klamath Falls, OR Medford, OR Oregon City, OR Portland, OR White City, OR

PENNSYLVANIA Bloomsburg, PA Blue Bell, PA Gettysburg, PA Harrisburg, PA Lancaster, PA Newtown, PA Philadelphia, PA Pittsburgh, PA Wilkes-Barre, PA York, PA

VIRGINIA Daleville, VA Fredericksburg, VA Lynchburg, VA Manassas, VA Norfolk, VA Roanoke, VA Salem, VA Staunton, VA Suffolk, VA Virginia Beach, VA Wytheville, VA

WASHINGTON Auburn, WA Bellingham, WA Bremerton, WA Ellensburg, WA Ephrata, WA Olympia, WA Pasco, WA Rockingham, WA Seattle, WA Shoreline, WA Spokane, WA

WEST VIRGINIA Ona, WV

WISCONSIN La Crosse, WI Milwaukee, WI Mukwonago, WI

Brockville, ON Hamilton, ON London, ON Milton, ON Mississauga, ON Niagara-on-the-Lake, ON North Bay, ON North York, ON Ottawa, ON Toronto, ON Welland, ON Windsor, ON

QUEBEC

Côte Saint-Luc, QB Montreal, QB

SASKATCHEWAN Melfort, SK Moose Jaw, SK Nipawin, SK Prince Albert, SK Saskatoon, SK

YUKON TERRITORY Whitehorse, YU

UNITED KINGDOM Elgin, UK

GHAZNI Kingdom of Bahrain, GHA Thomasville, GHA EGYPT Cairo, EG

JORDAN Amman, JOR

NEW ZEALAND Taradale, NZ

16 NOVEMBER 2022 WWW.FLUIDPOWERJOURNAL.COM • WWW.IFPS.ORG IFPS UPDATE

TENTATIVE TESTING DATES FOR ALL LOCATIONS: December 2022 Tuesday 12/6 • Thursday 12/15 January 2023 Tuesday 1/10 • Thursday 1/26 February 2023 Tuesday 2/7 • Thursday 2/23 March 2023 Tuesday 3/7 • Tuesday 3/28 Cer tification Empowers Opportunity.

IFPS CERTIFICATIONS

CFPAI

Certified Fluid Power Accredited Instructor

CFPAJPP

Certified Fluid Power Authorized Job Performance Proctor

CFPAJPPCC

Certified Fluid Power Authorized Job Performance Proctor Connector & Conductor

CFPE

Certified Fluid Power Engineer

CFPS

Certified Fluid Power Specialist (Must Obtain CFPHS & CFPPS)

CFPHS

Certified Fluid Power Hydraulic Specialist

CFPPS

Certified Fluid Power Pneumatic Specialist

CFPECS

Certified Fluid Power Electronic Controls Specialist

CFPMT

Certified Fluid Power Master Technician (Must Obtain CFPIHT, CFPMHT, & CFPPT)

CFPIHT

Certified Fluid Power Industrial Hydraulic Technician

CFPMHT

Certified Fluid Power Mobile Hydraulic Technician

CFPPT Certified Fluid Power Pneumatic Technician

CFPMM

Certified Fluid Power Master Mechanic (Must Obtain CFPIHM, CFPMHM, & CFPPM)

CFPIHM

Certified Fluid Power Industrial Hydraulic Mechanic

CFPMHM

Certified Fluid Power Mobile Hydraulic Mechanic

CFPPM

Certified Fluid Power Pneumatic Mechanic

CFPMIH

Certified Fluid Power Master of Industrial Hydraulics (Must Obtain CFPIHM, CFPIHT, & CFPCC)

CFPMMH

Certified Fluid Power Master of Mobile Hydraulics (Must Obtain CFPMHM, CFPMHT, & CFPCC)

CFPMIP Certified Fluid Power Master of Industrial Pneumatics (Must Obtain CFPPM, CFPPT, & CFPCC)

CFPCC

Certified Fluid Power Connector & Conductor

CFPSD

Fluid Power System Designer

CFPMEC (In Development)

Mobile Electronic Controls

CFPIEC (In Development) Industrial Electronic Controls

Tentative Certification Review Training

IFPS offers onsite review training for small groups of at least 10 persons. An IFPS accredited instructor visits your company to conduct the review. Contact kpollander@ifps.org for details of the scheduled onsite reviews listed below.

HYDRAULIC SPECIALIST

Onsite review training for small groups. Contact IFPS for details.

Nov. 28-Dec. 1, Fairfield, OH. CFC Industrial Training. Written test: Dec. 2. Contact info@cfcindustrialtraining.com for more information and to register. May 1-3, 2023, Mukwonago, WI, MSOE. Written test: May 4, 2023

PNEUMATIC SPECIALIST

Onsite review training for small groups. Contact IFPS for details. Dec. 12-16, Fairfield, OH, CFC Industrial Training. Written test: Dec. 16.

CONNECTOR & CONDUCTOR

Onsite review training for small groups. Contact IFPS for details Nov. 15-16, Fairfield, OH, CFC Industrial Training. Written and JP test: Nov. 17.

ELECTRONIC CONTROLS SPECIALIST

Onsite review training for small groups. Contact IFPS for details.

INDUSTRIAL HYDRAULIC MECHANIC

Onsite review training for small groups. Contact IFPS for details.

INDUSTRIAL HYDRAULIC TECHNICIAN

Onsite review training for small groups. Contact IFPS for details.

MOBILE HYDRAULIC TECHNICIAN

Onsite review training for small groups. Contact IFPS for details. Call CFC Industrial Training, Fairfield, OH, for dates: (513) 874-3225.

PNEUMATIC TECHNICIAN and PNEUMATIC MECHANIC Onsite review training for small groups – contact IFPS for details Call CFC Industrial Training, Fairfield, OH, for dates: (513) 874-3225.

JOB PERFORMANCE TRAINING

Online Job Performance review. CFC Industrial Training offers online JP Reviews that include stations 1-6 of the IFPS mechanic and technician job performance tests. Members may e-mail askus@IFPS. org for a 20% coupon code off the list price. Test fees are not included. For more information, contact info@cfcindustrialtraining.com.

LIVE DISTANCE LEARNING JOB PERFORMANCE STATION REVIEW

For more information, contact info@cfcindustrialtraining.com.

WWW.IFPS.ORG • WWW.FLUIDPOWERJOURNAL.COM NOVEMBER 2022 17 AVAILABLE

IFPS UPDATE

All Around the World Circular Sustainability for Fluid Power

By Michael Cook, Global Segment Director for Off-Highway & Segment Manager Fluid Power in the Americas, Trelleborg Sealing Solutions

In today’s environmental and economic landscape, it is critical for fluid power component manufacturers and seal suppliers to incorpo rate sustainable methods into design, manufacturing, and production practices through design thinking for circularity and circular products.

For a long time, our economy had been a linear concept. This meant taking the needed resources, making a product, using it, and then, at the end of its life, sending it to a landfill or to be recycled. Until recently, sustainability focused on recycling and energy usage.

At the forefront of sustainability is the concept of product circularity and a circular economy. Circularity is more than developing a product that can be recycled; it is about designing extended value into a product, for the customer, for their customer, and for the first, second, and even third users of the product. It is not a step-by-step linear process with a clear end but a continuous cycle.

The circular economy

Seal suppliers and OEMs should consider the circular economy in the design phase of their products, materials, and solutions instead of using the traditional linear economy approach to manufacturing – taking a raw material, making it into something, and at the end of its life disposing of it. Creating circular products that last longer and use less energy, can be repaired, refurbished, or recycled, and have a useful second life supports the circular economy and sustainability. In a circular economy, OEMs aim to reduce waste through the reuse, recycling, and repurposing of a product. Leading component manufacturers do this through design thinking for circularity.

CIRCULAR ECONOMY

As opposed to a disposable design that has no consideration of what happens to the product at the end of its life, design thinking for circu larity shifts the way products are developed. It is thinking about product design from the very start, with a desire to develop solutions that are part of the circular economy and designed with the environment and sustainability in mind.

Design thinking for circularity at Trelleborg Sealing Solutions is not about designing a product for recycling; it’s about designing seals that last longer, use less energy, and support easy repair and replacement.

It’s critical that seal manufacturers create high-performance seals with a long life so that customers replace them less often, resulting in less waste, reduced raw material use, and a greater return on investment.

High performance starts at the design phase. Seal manufacturers like Trelleborg model seal performance through finite element analysis and simulations across a range of application conditions and materials. This allows manufacturers to modify designs prior to testing, reducing the number of prototype loops, lowering development costs, reducing material waste, and speeding up the time to market. The extensive testing ensures seals perform as expected in an application.

Design for the environment

When possible, raw materials should come from sustainable and renewable sources. Regrinding production waste into a material blend for noncritical components such as wipers and wear rings gives this material a second life, reducing material sent to landfills.

Manufacture

Raw Material

Sustainable sourcing from renewable sources is the best-case scenario.

Recycle

Recycling is a great way to reduce dependence on raw materials. Recycled material becomes the new raw material.

Minimal Waste

Eco-friendly compostable materials.

Minimizing energy usage, minimizing waste, and maintaining quality are core to a sustainable future.

Reuse

Equipment and products are too often replaced long before the useful life has expired. Use it longer, sell it, donate it.

Remanufacture

Make it new again significantly reduces waste and carbon usage compared to making it new from scratch.

18 NOVEMBER 2022 WWW.FLUIDPOWERJOURNAL.COM • WWW.IFPS.ORG

Circular Products

By creating virtually leak-free seal designs, fluid power seal manufac turers minimize the risk of contamination to ground and water resources, protecting the environment from contaminants.

The extended product life of seals has a clear impact on sustainability. Fewer parts to replace means using fewer consumables and raw materials. The transport and logistics involved in moving parts and people to remote locations also have a massive impact on the environment. Extending product life reduces CO2 emissions in the supply chain.

When seal manufacturers provide robust lubrication management programs and technology, it reduces friction, wear, and heat generation in linear tandem sealing applications by allowing just the right amount of fluid film to reach the secondary seal and prevent dry running conditions. This reduces the energy needed to power the system and can support the downsizing of drive components, in turn reducing the overall amount of energy the equipment uses.

In rotary applications, Trelleborg uses Turcon Varilip PDR, a single-acting low friction seal with no stick-slip. The seal provides long-last ing seal efficiency and can withstand dry running conditions. When compared to a standard radial oil seal, the low friction characteristics mean the seal uses less energy and lowers the risk of environmental con tamination as a result of premature failure.

Modularity

Utilizing industry-standard design profiles and sizes ensures that designers and end users can easily specify sealing components, allowing the reuse of hardware designs. Standardization supports ease of repair, refurbishment, and reuse with readily available replacement parts, to give the hardware a second or third life.

During the design phase of a seal, seal manufacturers work with cus tomers to design solutions that can be easily disassembled to enable repair of parts. Seals that are easy to remove and replace minimize damage to equipment and reduce downtime.

The less material we put into landfills, the better. Methane gas that releases as waste decomposes in landfills creates a greenhouse gas that contributes to global warming and climate change.

When seals for fluid power applications are designed to last as long as possible, it reduces the need for replacement parts and the waste that gets placed in landfills. •

FACTS ABOUT THE CIRCULAR ECONOMY

The earth takes almost 1.5 years to regenerate what we use in a year.

After burning, 80% of waste from consumer goods goes to a landfill because of poor design or lack of end-of-life collection options.

Over 80% of a product’s environmental impact is determined at the design stage.

Currently, only 9% of our world economy is circular.

Sixty to 70% of the world’s ecosystems are degrading faster than they can recover.

We recycle less than 20% of electronic waste.

Recycling electronics uses less energy in production and conserves resources like copper and aluminum.

TRELLEBORG CIRCULAR PRODUCT DESIGNS

Here are two examples of circular product designs from Trelleborg.

Lightweight advanced composite materials. Trelleborg’s Automated Fiber Placement (AFP) technology is part of a special continuous-fiber manufacturing process that produces strong, lightweight components for a wide range of applications. This technology uses thermoplastic composite materials that are recyclable and suitable for repurposing at the end of life, unlike traditional thermoset composites.

Organically sourced materials. The development of bio-friendly materials using renewable plant-based compounds such as sugar cane and natural oils is something we are looking to explore in the future. These materials could allow Trelleborg to create sealing solutions that not only provide high-performance sealing with a long life but also use less energy and have a significantly reduced carbon footprint during manufacturing.

WWW.IFPS.ORG • WWW.FLUIDPOWERJOURNAL.COM NOVEMBER 2022 19

New Partnership Makes for Easier Access to ISO Pneumatic Rod Cylinders

Don’t Compromise – that hydraulic flange you want maybe at MAIN

J518 Code

DIN,

flange

and

6162, ISO 6164, and specials with

butt-weld, ORB, BSPP, etc.; all geometries, flange

in carbon, stainless,

GEMELS IS THE WORLD'S LEADING

OF HIGH PRESSURE VALVES & QUICK COUPLINGS.

Contact us to showcase your products and services in the Product Spotlight. This special section is a high-profile area offering product-specific advertising. Visit www.fluidpowerjournal.com for more information or to view our media guide. SPECIAL AD SECTION WWW.IFPS.ORG • WWW.FLUIDPOWERJOURNAL.COM NOVEMBER 2022 21 Go ahead. Push me. Ordinary heavy duty not heavy enough? Heavy-Duty Mill Cylinders for: • Induction-Hardened, Chrome-Plated Rods • Heavy Wall Tubing • Replaceable Glands & Retainer Rings • High-Load Piston Design Think indestructible and call Yates. www.yatesind.com Yates Industries (HQ) 586.778.7680 Yates Cylinders Alabama 256.351.8081 Yates Cylinders Georgia 678.355.2240 Yates Cylinders Ohio 513.217.6777

MAIN stocks 10,000+ hydraulic flanges and manufactures components in 4-7 days in the USA. SAE

61

J518 Code 62, JIS,

ISO

socket-weld,

heads,

adapters;

cupro-nickel, ductile, aluminum, etc. Sixty years’ experience plus SAE and ISO technical committee experience. MAIN Manufacturing Products, Inc. 800.521.7918 https://mainmanufacturing.com/block-categories

MANUFACTURER

GEMELS NORTH AMERICA INC. northamerica@gemels.com gemels.com

W.C. Branham teams up with Artec SRL in the U.S. and Canada. Artec is a leading 40-year Italian rod cylinder manufacturer with ISO9001:2015 certification. Cylinders are their passion! 715.426.2000 AskWCB@WCBranham.com www.WCBranham.com High Quality Art On The Inside. Standard and Stainless Steel Cylinders ISO 6432 Micro Round | ISO 15552 ISO 21287 | UNITOP | Compact | Guided Compact | Short Stroke | Cartridge We at Branham Listen, Let Us Help You Today

www.flangelock.com

The FlangeLock™ Tool is the ultimate contamination control tool for protecting your hydraulic systems. It allows for the simple sealing of open SAE code 61, 62 & CAT-Style hydraulic flanges without tools. Constructed from lightweight aluminum. Easy on, easy off. Offers a leakproof solution to hydraulic system and environmental cleanliness. FlangeLock™ Tools stop the mess!

www.mainmanufacturing.com

Main's website provides quick access to the 120 page catalog that includes popular styles of MAIN Manufacturing’s extensive offering of carbon and stainless Hydraulic Flanges and Components – ready for immediate shipment. Metric ordering information, weld specs, and dimensional information included. The “Quick Reference Guide” helps specify less popular items often stocked or quickly manufactured (generally 3-4 days) at our US plant. “Create-AFlange” offers more parts than the catalog — by picture. If it’s not here, or for questions, E-mails may be sent to get your answer quickly.

Have a Purchase Order? Please email to sales@flangelock.com or fax to 203-622-1238

Corporation is a leading manufacturer of compressed air filtration products. With over 30 years of experience, we truly understand the importance of protecting valuable machinery, tools, and finished products from dirty, wet, contaminated air. La-Man’s line of products include the patented Extractor Dryer, .01 micron filter, as well as, LA-MAN-Air Breathing Systems™, SuperStar™ Membrane Dryers, and the Refrigerated Extractor/Dryer.

At Texcel, our cutting-edge line of hydraulic hose and fittings is not just a product division. It’s a promise of superior service, quality, technical support and availability. We’ve built our company on impeccable customer service. Let us know how we can make a difference for your business. 4444 Homestead Road • Houston, Texas 77028 (800) 231-7116 • sales@texcelrubber.com

22 NOVEMBER 2022 WWW.FLUIDPOWERJOURNAL.COM • WWW.IFPS.ORG SPECIAL AD SECTION Web MARKETPLACE

www.texcelhydraulics.com

1-800-521-7918 info@mainmfg.com www.laman.com La-Man

PO BOX 328 • Mazeppa, MN 55956 800-348-2463

COMPONENT SHOWCASE

ES SERIES MINIATURE ELECTRONIC VALVES

Spider technology is renowned worldwide for exceptional leak resistance and long life. Clippard developed, patented and perfected this spider technology. Ideal applications have exceeded 1,000,000,000 cycles with this technology which utilizes one moving part that travels a mere 0.007” during operation. This single moving part with a short stroke enables the ES series to operate with exceptional reliability.

The ES series features large cross sectional o-rings, minimal leak points, and proven poppet designs. All mounting hardware is outside of the flow path for the ES, and no internal parts are threaded during assembly to reduce the possibility of contamination. The ES has the best performance-to-price ratio for low leak valves.

The compact footprint coupled with the long life, and exceptional leak resistance make the ES line suited to improve reliability in a wide range of applications including biomedical, dental, test equipment, oxygen control, textile, packaging, pressure control, automation and portable systems.

Over 1 billion cycles (under ideal conditions)

0.01 sccm leak rate

No threads in flow path

Fast response - 5 to 10 ms (nominal)

Close mounting - 7/8” on center.

Overall height less than 1”

No anaerobic sealant

Ideal for ultra-low leak applications

Made in USA

MINIATURE, DOUBLE ACTING, PNEUMATIC ACTUATORS

Small solutions to big problems. We carry the smallest pneumatic double acting actuator on the market.

Our miniature pneumatic actuators are manufactured to tight tolerances with premium quality and variations for travel, mounting, porting, and piston rods. The components are hard anodized aluminum with other materials available upon request. OD sizes from 1″ 2.50″and up to 2″ of travel is standard in 1/8″ increments.

Miniature pneumatic actuators are often used in testing or production of; electronic components, medical devices, and high-end composite materials.

AUTOMATIC (RETURN) VACUUM CYLINDER

Pick up with ease!

Our automatic vacuum cylinders are non-rotating with a stable z axis actuation and automatic stroke compensation. The cylinder piston extends when vacuum is applied, and it automatically retracts when the rod end is sealed against the surface of the load. When vacuum is turned off, the load is released.

Be free of maintenance and lubrication through our hard anodize and Teflon coating on materials. Say yes to fast production and have our vacuum cylinders speed things up for you with rapid cycle rates.

WWW.IFPS.ORG • WWW.FLUIDPOWERJOURNAL.COM NOVEMBER 2022 23 SPECIAL AD SECTION