September

6 Cover Story

The Role of Hydraulic Wrenches in Industrial Applications

Hydraulic wrenches have become indispensable due to their accuracy and simple operation.

10 Manufacturing Quality Parts

While Protecting Workers’ Lives

In all things hydraulics, assuring safety of workers is of utmost importance.

12 Proper Filtration is Critical to Your Operation

Often in hydraulic system design filtration is not properly calculated for.

20 Growth & Knowledge

Touted as the best of the best, the Utility Expo is a platform for new products and technologies.

24 Test Your Skills

Ensure Component Compatibility

How to select components for hydraulic systems.

28 Case Study

Hyundai Drives Ahead with Flexible and Efficient Control Valve Platform

The Korean off-highway manufacturer is standardizing the working hydraulics of wheeled loaders, excavators, and forklifts.

Publisher’s Note: The information provided in this publication is for informational purposes only. While all efforts have been taken to ensure the technical accuracy of the material enclosed, Fluid Power Journal is not responsible for the availability, accuracy, currency, or reliability of any information, statement, opinion, or advice contained in a third party’s material. Fluid Power Journal will not be liable for any loss or damage caused by reliance on information obtained in this publication.

algorithms, and computer programming developed by engineers – just another machine designed and built by people. Fortunately, we forget things we learned over time and it makes the new technology seem more impressive. AI can process larger volumes of data and answer more complex questions.

I remember starting my engineering career conducting validation testing on hydraulic components and having a very expensive pressure transducer capable of 140 MPa (20,000 PSI) readings and would only utilize it sparingly. Today, transducers are available that are capable of higher pressures and cost less, making it economical to have the transducers provide continuous readings and data. Another change in recent

Each has a vested interest in the collection and evaluation of the data. This information will lead to better predictive maintenance, shorter lead times, and fewer unscheduled repairs.

RECENTLY MY SON and I discussed his potential obsolescence as Artificial Intelligence (AI) eliminates some jobs when he attempts to join the workforce. We discussed that many of the mathematical concepts he is learning in middle school math – coordinate dimensions, trend analysis, and basic probability are at the core of the programming driving AI. Forty years ago, computerized spreadsheets augmented engineers’ abilities to analyze data, and the AI of today will evolve into Augmented Intelligence (AgI) allowing for deeper analysis of data.

My son quoted his Opa (Grandpa) as telling him, “You don’t use everything you learn in school.” ChatGPT’s response “The purpose of education is to provide a broad foundation of knowledge and skills that can be approved in various contexts”. This answer takes much of the mystique out of the fantastic powers of Artificial Intelligence. At its core, AI is trained on data sets of human interactions, using mathematics,

years is the reduction in wiring needed as sensors utilize the wireless spectrum. The ability to place sensors in more locations without hindering the motion of the mechanisms allows the collection of greater amounts of data. Combined with the reduced costs, combination sensors, and new feedback technologies, engineers can have volumes of data telling them in real time how the fluid power system is functioning and its relation to the machine’s movements.

The accumulation and sharing of data will be a critical component in the future successes of equipment manufacturers, users, and suppliers.

Data is wonderful, but actionable information based on data delivers results. We asked ChatGPT to rank two major league catchers that played for the same team and both later went on to manage the same team. Its answer was to provide us with a summary and links for us to investigate; like going to the encyclopedia for the answer and then being redirected to the library. My perception is that ChatGPT and other AI is most valuable in analyzing multiple data sets for patterns and trends. In the future, a construction equipment manufacturer will be collecting vast amounts of data on the hydraulic system, engine performance, and using GPS location and weather conditions during operations. What could you ask from this data? Could the aftermarket team analyze the data and make changes in components or settings during a service call to improve efficiencies and/or outputs of the machine? Could the inventory from component suppliers be moved to service centers strategically by AI analysis to reduce logistics?

Artificial intelligence is a misnomer. Augmented Intelligence is more reflective of the technology. Humans develop and program the initial code and datasets. While AI can provide answers and identify new patterns or trends, it will be important for people to review and understand how to turn all this into actionable information. AI is simply a new and improving tool that allows us to answer the age-old engineer’s question – is there a better way to do this?

(Logan Fluegel, aged 10, will be starting middle school in the fall and will be continuing in advanced Math where he will pursue his interest in engineering.)

Data is wonderful, but actionable information based on data delivers results.

p U b LISH er

Innovative Designs & Publishing, Inc.

3245 Freemansburg Avenue, Palmer, PA 18045-7118 Tel: 800-730-5904 or 610-923-0380

Fax: 610-923-0390 • Email: Art@FluidPowerJournal.com www.FluidPowerJournal.com

Founders: Paul and Lisa Prass

Associate Publisher: Bob McKinney

Editor: Janis Adams

Technical Editor: Dan Helgerson, CFPAI/AJPP, CFPS, CFPECS, CFPSD, CFPMT, CFPCC

Marketing and

Social Media Consultant: Kristy Jones

Graphic Designer: Nicholas Reeder

Accounting: Donna Bachman, Sarah Varano

Circulation Manager: Andrea Karges

IN ter NAt IONAL FLUID p OW er SOCI et Y 1930 East Marlton Pike, Suite A-2, Cherry Hill, NJ 08003-2141 Tel: 856-424-8998 • Fax: 856-424-9248 Email: AskUs@ifps.org • Web: www.ifps.org

2023 b OA r D OF DI re C t O r S

President: Scott Sardina, PE, CFPAI, CFPHSWaterclock Engineering

Immediate Past President: Denis Poirier Jr. CFPAI/AJPP, CFPHS, CFPIHM, CFPCCDanfoss Power Solutions

First Vice President: Jeff Hodges, CFPAI/AJPP, CFPMHM- Altec Industries

Treasurer: Lisa DeBenedetto, CFPSGS Global Resources

Vice President Certification: James O’Halek, CFPAI/AJPP, CFPMIP, CMPMM - The Boeing Company

Vice President Marketing: Chauntelle Baughman, CFPHS - OneHydraulics

Vice President Education: Daniel Fernandes, CFPECS, CFPSSun Hydraulics

Vice President Membership: Garrett Hoisington, CFPAI/AJPP, CFPS, CFPMHM - Open Loop Energy

DI re C t O r S-At-LA r G e

Stephen Blazer, CFPE, CFPS, CFPMHM, CFPIHT, CFPMHTAltec Industries

Cary Boozer, PE, CFPE - Motion Industries

Bruce Bowe, CFPAI/AJPP - Altec Industries

Bradlee Dittmer, CFPPS - Norgren/IMI Precision Engineering

Brian Kenoyer, CFPHS - Cemen Tech

Wade Lowe, CFPS - Hydraquip Distribution

Jon Rhodes, CFPAI, CFPS, CFPECS - CFC Industrial Training

Mohaned Shahin, CFPS - Parker Hannifin

Randy Smith, CFPHS - Northrop Grumman

Ethan Stuart, CFPS, CFPECS - Quadrogen

Bradley Wagner, CFPAI/AJPP - Manitowoc Crane Group

Brian Wheeler, CFPAI/AJPP, CFPMM, CFPMIPThe Boeing Company

CHI e F e X e CU t IV e OFFIC er (e X-OFFICIO) Donna Pollander, ACA

HONO r A rY DI re C t O r (e X-OFFICIO)

Ernie Parker, CFPAI/AJPP - Hydra Tech

IF p S S tAFF

Chief Executive Officer: Donna Pollander, ACA

Communications Coordinator: Victoria Piro

Technical Director: Thomas Blansett, CFPS, CFPAI

Assistant Director: Jenna Mort

Certification Logistics Manager: Kyle Pollander

Bookkeeper: Diane McMahon

Administrative Assistant: Beth Borodziuk

Instructional Designer and Layout: Chalie Clair

Fluid Power Journal (ISSN# 1073-7898) is the official publication of the International Fluid Power Society published monthly with four supplemental issues, including a Systems Integrator Directory, Off-Highway Suppliers Directory, Tech Directory, and Manufacturers Directory, by Innovative Designs & Publishing, Inc., 3245 Freemansburg Avenue, Palmer, PA 18045-7118. All Rights Reserved. Reproduction in whole or in part of any material in this publication is acceptable with credit. Publishers assume no liability for any information published. We reserve the right to accept or reject all advertising material and will not guarantee the return or safety of unsolicited art, photographs, or manuscripts.

»A COMPANY THAT makes carbon fiber leaf springs for the GM Corvette had to replace the main pilot operated directional valve that was scarred badly by a broken spring from the load check that failed. They replaced both the check valve and directional valve from their stores room and after cycling the press several times to remove the air, maintenance turned it over to production. The production group reported back that all was working fine other than the

press would slowly drift down when they would break for lunch or when they would do a die change. Maintenance replaced the pilot operated check and the directly operated relief. But the press would still drift down. They then blocked the rod side outlet of the cylinder and determined the cylinder piston was not leaking since the drift stopped.

Any idea what could be causing the ram to drift down?

For the solution, see page 31.

Robert Sheaf has more than 45 years troubleshooting, training, and consulting in the fluid power field. Email rjsheaf@cfc-solar.com or visit his website at www.cfcindustrialtraining.com. Visit fluidpowerjournal.com/figure-it-out to view previous problems.

Hydraulic torque wrenches are devices used to supply a specific amount of torque to tighten or loosen nuts and bolts. This hydraulic set up consists of two main components: the hydraulic pump, which is typically either electrically or pneumatically driven, and a hydraulic wrench that actually delivers the torque directly onto the bolt. These wrenches typically come in two different styles, a square drive style and a low-clearance style. Hydraulic wrenches have become indispensable in various industries due to their accuracy and easy operation compared to other tools. They are used for tasks such as tightening large nuts and bolts, when installing machinery components, structure-steal joints, flanges in the water, oil and gas sectors along with applications in many other industries.

In this article, we’ll explore the role of a hydraulic torque wrench and its application across industries.

The versatility of hydraulic torque wrenches makes them a worthwhile investment for any industry that requires precision when working with multiple sized fasteners and bolts. The ability to accurately apply the desired torque and cope with the most demanding applications makes hydraulic wrenches an indispensable tool across industries. The design of hydraulic wrenches also means they can provide a high torque output when compared to traditional hand tools, such as spanners, ratchets or standard torque wrenches.

Hydraulic torque wrenches are available in a range of sizes depending on the application requirements, from small handheld units suitable for light-duty jobs right up to large, high-powered wrenches for heavy-duty tasks. The torque setting

and amount of force applied are easily adjustable via a control dial located either on the hydraulic pump, allowing operators greater precision when dealing with delicate components.

As well as offering precise accuracy and great durability options, hydraulic torque wrenches provide controlled tightening and also offer increased safety, as once employees have been efficiently trained on the job, even those who may not have much experience handling hydraulic equipment should be comfortable using the tool.

Hydraulic torque wrenches are used to tighten or loosen bolts and nuts with high precision and efficiency. They utilize hydraulic pressure to apply controlled torque to fasteners, offering several advantages over traditional manual wrenches or pneumatic tools. Let's explore the technology and applications of hydraulic torque wrenches in more detail:

Hydraulic torque wrenches consist of a hydraulic power pack and a torque wrench. The power pack generates hydraulic pressure using an electric or pneumatic motor, which is then transmitted through hydraulic hoses to the torque wrench. The torque wrench typically features a reaction arm or reaction pad, a drive mechanism, and a socket or ratchet link to engage with the bolt or nut.

Hydraulic Power Pack: This unit includes the hydraulic pump, which generates the pressure up to 70 MPa (10,000 psi) required for torque application. It also contains a reservoir for hydraulic fluid, valves for controlling pressure and flow, and safety features such as pressure relief valves. It is at the hydraulic power pack where you make all your

pressure adjustments to achieve the proper torque.

Hydraulic Hose: The flexible hose transmits the hydraulic pressure from the power pack to the torque wrench. It is designed to withstand high pressure and ensure efficient power transmission.

Torque Wrench: The torque wrench is available in various configurations, such as square drive or low-profile, to suit different applications. It incorporates a mechanism that converts hydraulic pressure into rotational force to tighten or loosen bolts.

Reaction Arm or Pad: To counteract the torque reaction and provide stability during operation, a reaction arm or pad is used. It rests against a sturdy surface to absorb the reactive forces generated when torque is applied.

The different types of hydraulic torque wrenches include:

1. Low profile hydraulic torque wrenchesLow profile wrenches provide the ideal solution for tight, hard-to-reach areas in various industries. These torque wrenches are ideal for tight spaces, where there is limited “above the nut / axial” clearance. They provide an accurate high torque output where other standard tools could not fit. This style tool is made to be able accommodate all different size fasteners from 20 mm – 195 mm (⅞” - 7-⅝”), and times even larger. This makes an ideal tool for any fastening jobs or applications where you are located in very compact spaces.

2. Square drive hydraulic wrench - A versatile device used for tightening or loosening bolts and nuts. It features a square drive mechanism where a socket or interchangeable socket heads can be attached. This type of bolting tool allows for efficient and secure torque application, making it a popular choice in construction, manufacturing, and automotive. The square drive design enables easy interchangeability of sockets and an adjustable reaction arm which allows the tool to have multiple reaction points, facilitating adaptability to different fastener sizes and applications while achieving precise torque control.

The applications of a hydraulic torque wrench are numerous, as they provide a safe and efficient way to perform complex tasks with precision. From automotive manufacturing plants to petrochemical refineries, these devices can be used in many industries for

fastening bolts or tightening nuts. The range of sizes available makes them suitable for lightduty use right through to heavy-duty bolting applications, making them an invaluable tool across a wide variety of industries.

In automotive manufacturing plants and general manufacturing processes, hydraulic torque wrenches are used for precise bolt tightening on engines, chassis, and machinery. They help achieve consistent torque values, ensuring product quality and safety.

In automotive production lines, a hydraulic wrench can provide excellent levels of speed and accuracy when assembling components such as engines or gearboxes — ensuring that each component is correctly fitted with minimal effort from operators. This helps reduce assembly time while also mitigating any potential safety risks associated with incorrect torque being applied due to over-tightening or under-tightening bolts etc.

Hydraulic torque wrenches are used in the construction of buildings, bridges, and large structures that require heavy-duty bolting. They

ensure proper tightening of critical connections, such as steel beams and foundation bolts.

Hydraulic torque wrenches are also widely utilized in construction equipment manufacturing - allowing engineers precise control when installing large machinery parts onto vehicles like excavators or bulldozers etc., minimizing the risk of damage occurring if forces aren’t precisely controlled every step along the way! What’s more, their portability means they can easily be moved around sites whenever needed, with only the very large units requiring lift assistance with a hoist or something equivalent when being placed in position.

Petrochemical plants utilize hydraulic torque wrench technology greatly too — since oftentimes pipes and pressure vessels must join together perfectly to prevent leaks from occurring once the system is fully operational. Hydraulic wrenches are commonly used for routine maintenance, planned turnarounds and even in emergency situations when there is a torque requirement on any of the bolted assemblies.

continued on page 8

www.otto-controls.com

In the oil and gas sector, hydraulic torque wrenches are employed for pipeline construction, equipment installation, and maintenance tasks. They are crucial for achieving proper sealing and torquing of flanges and other connections in pipelines and refineries. Low clearance wrenches are commonly used in these industries due to the compact placement of flanges and valves on top of each other.

Hydraulic torque wrenches are utilized during the assembly and maintenance of wind turbines, generators, and other power plant equipment. They help ensure the secure fastening of critical components, minimizing the risk of failures and downtime.

Hydraulic torque wrenches play a vital role in the assembly and maintenance of mining

equipment, earthmoving machinery, and heavy industrial machinery. They assist in achieving proper torque on bolts and ensure safe and efficient operation.

Hydraulic torque wrenches may also be used for heavy duty applications to tighten nuts and large-size bolts in other industries, such as:

• Shipbuilding

• Hydropower, Wind & Thermal Power

• Heavy Equipment & Machinery

• Steel Mills

• Rubber

• Pipelines

• Maintenance and Emergency Repairs.

• Crane Erecting

• Aerospace

Selecting the right hydraulic torque wrench depends on various parameters such as application, spatial limitations and torque range. Additionally, the working environment needs to be taken into account to identify the correct type of hydraulic wrench and pump combination. This selection often comes down to making the choice of having to run a pneumatically driven pump vs. an electrically driven pump in case the environment you are working in is required to run a “spark-free” work zone. Hydraulic torque wrenches can be divided into two categories: square drive & low-clearance. Overall, the choice between a square drive hydraulic wrench and a low-clearance hydraulic wrench will come down to the spatial limitations of your application. The square drive wrench is the most versatile and economical as you can add any size socket to the square drive and the adjustable reaction arm gives the user multiple areas to provide the reaction forces, but there are times where the low-clearance wrench will be the only feasible option.

The use of hydraulic torque wrenches provides several benefits, including safer operation compared to older methods of striking or manual application of torque, reduced labour costs, improved accuracy and repeatability, enhanced operator safety, and increased productivity. They are versatile tools suitable for a wide range of bolting applications, enabling efficient and reliable fastening in var ious industries.

25 years ago, Murrelekronik developed and produced the first pre-wired and molded valve connector. It was revolutionary and just the beginning of our quest to make

Murrelektronik valve plugs are available in all common forms (A, B, BI, C and CI) as well as a variety of styles including field wirable or fully molded with open ended cable, M8 or M12 connection, DEUTSCH and junior timers. Our valve plugs are easily recognizable with the wiring

With their short lead times, they are ready to become a part of your line up (or maybe your value add assembly?).

murrinc.com

contact us or visit our website today.

By Michele Baker Thomas, Ph.D., Business Manager, York Precision Machining & Hydraulics

By Michele Baker Thomas, Ph.D., Business Manager, York Precision Machining & Hydraulics

Many of the parts in the vehicles we drive are made using molds in stamping, forming, and injection-molding presses. Any movement of the mold during the forming operation could result in a damaged or ruined part. Concern for operator safety is also a major concern when designing or implementing these machines. In this article, we will address both the performance and safety issues.

Why is zero movement important in producing a good part? Movement at the outset of the forming process may leave excess material along the edge of the molded part that must be removed, adding time and cost to the manufacturing process. Likewise, movement at any time during the forming process can ruin the part. Most load-holding devices in forming presses cannot achieve zero movement.

An automotive stamping or forming press is a massive machine with forces in the range of 13,300 kN (1,500 tons). Devices that depend on hydraulic pressure to remain locked are at high risk because there is always the potential for loss of hydraulic pressure. It could be the result of power failure, operator error, or component failure. If a press brake relies on hydraulic pressure to remain locked, loss of pressure represents a life-threatening danger. In addition to the incalculable loss of human limb or life, failure to provide proper safety features can result in costly fines or even the closing of operations.

Whether pressure is lost on command or by accident, the Bear-Loc system engages automatically and instantly without delay or movement. It will hold the load without movement until hydraulic pressure is applied. When

hydraulic pressure is removed, workers can safely operate and maintain presses.

Another Bear-Loc distinctive: infinite position. The rod can be engaged by the lock in any position along its stroke. That’s perfect for many applications. For presses, platen adjustment requires infinite position mechanical locking under heavy load cycling.

One of our automotive customers has five Bear-Locs placed on each corner and in the center of a press that stamps automotive bumpers, five at a time. The Bear-Locs hold the platen in place without any backlash. (Backlash, sometimes called “lash” or “play” is clearance or motion in a mechanism caused by gaps between the parts.) Hydraulic cylinders lacking zero backlash capability could move and potentially ruin the part or cause costly rework.

If your processes require locking with zero backlash, make sure the components you choose are qualified for the job. These products feature zero backlash. They deliver no-motion reliability in any direction when engaged and operated within their rated capacity.

Injection molding machines, also known as injection presses, make plastic and vinyl products we use daily. Generally consisting of three parts, an injection unit, mold, and a clamping unit, these machines produce parts for a variety of industries such as automotive, packaging, electronics, toys, appliances, and medical devices.

Hydraulic clamps are often used, particularly when fast tool changes are required. The clamp cylinder can be oriented horizontally

(HCIMMs) or vertically (VCIMMs) and holds the mold closed so that the injected material can be accurately formed. The injected material exerts a tremendous force that acts to separate the parts of the mold. The Bear-Loc holds the mold together, ensuring a quality part.

A positive locking capability means that the device will not move or shake loose when locked. This patented design is based on the principle of the elastic expansion of metal under pressure. Simply put, the unit locks when hydraulic pressure is intentionally removed or accidentally lost.

In addition to infinite position capability, device also has bi-directional locking power. The rod can be engaged by the lock in any position along its stroke, and motion is impossible in any direction when the lock is engaged and operated within its rated capacity. •

Additional features included for both new and existing equipment:

Design simplicity. Does not depend on moving parts, valves, or other components to obtain its positive mechanical lock.

Wide range of configurations. Are available in a wide range of configurations such as linear actuators, linear units, and rotary units, all available in both tie rod and mill type constructions. Engineering design. Designed specifically for the customer’s application. Every system is tested and certified to meet the customer’s application requirements.

Proper filtration in hydraulic system design is a critical, yet often overlooked, component. Many times, filtration is inadequately and improperly planned for the system. However, in order to maintain a system that is operating smoothly and efficiently, adequate filtration must be designed into it. Simply said, if the filtration breaks down, the system will break down. According to Mark Redmond, a hydraulic systems engineer for Michigan-based MFP Automation Engineering (www.mifp.com), “over 75 percent of all failures in a hydraulic system are caused by contamination. If you can control the introduction of contaminants into the system, you will experience greater uptime and much lower expenditure for repairs and replacements down the road.”

When selecting filters, consider operating pressure, fluid compatibility, level of filtration required for the specific locations in the system where they are being installed, filter media and strength, and capacity. Where are the filters being installed? Suction line? Pressure line? Return line? For a smooth and efficient operating system, filter placement is critical. If you are not sure where the target critical locations are, you should contact a filter specialist.

MFP manufactures over 1,000 hydraulic power units a year and always includes specs for replacing components. According to Redmond, “it’s critical for OEMs and end users to follow our recommendations when replacing filters to ensure proper system operations.”

Proper filtration is necessary if you want peak performance from your hydraulic system. There are a series of considerations to consider before filters are installed. Know and understand hydraulics and the application, as well as the requirements of its performance. Filter sizing can be a problem if you aren’t sure of the system operation and what its primary function is. The point is, you shouldn’t just remove a filter and install a new one in its place without making sure you have the correct filter to get the job done efficiently and effectively.

Here are some considerations when trying to ensure proper filtration. First, there are many different systems, performing many different applications, with many different requirements.

Sizing a filter to a system is critical and could be the difference between a smooth-running operation and a poor one. Here are a series of questions that should be considered:

1. What is the flow rate of the pump? The first consideration is knowing the rate of flow of the process fluid. This would tell you how large or small the surface area of the filter media should be (sq. in.). See chart 1 below for an approximation of the size of the filter media and the corresponding flow rates. Most

common suction strainers are made from 100 mesh (149 micron) stainless steel screens and operate at around 100° F.

2. What is the pipe size? Flow rate and pipe size go hand in hand. If you have a flow rate of 50 gpm, the filter must be the correct size to keep the pressure drop in check. A pump creating flow of 50 gpm, for example, will have a lower pressure drop flowing through a 3” npt line, than it will a 1” npt line. Knowing the pipe size will narrow the options you have to adequately determine the correct filter size. A general reference, chart 2, follows for flow rate/ pipe size sizing. “Typically,” velocity in fluid

conductors should be flowing adequately to have the system running smoothly and efficiently. Chart 3 below shows what the velocity of the process fluid should be in various lines.

3. What is the working system pressure? Consider selection based on the question, “Can this filter handle the pressure it will experience?” If a filter collapses in use, not only will it lose its integrity and break down, but it will cause

continued on page 14

the system to become damaged or break down. When a filter collapses, fragments of epoxy or filter media will get into the flow stream and cause damage to downstream equipment.

4. What is the fluid? Is it standard hydraulic fluid? Is it a petroleum-based product where fluid and equipment will work in harmony? It is extremely important to have all system components, not only filters, compatible with the fluid. Otherwise, you are asking for serious system damage or destruction. Damage could be caused to equipment and seals, creating leaks, and allowing serious contamination problems to occur.

5. What is the viscosity of the fluid? The viscosity of standard hydraulic fluid is 150200 SUS, simply stated. However, what if there was a process fluid in the system of 250-300 SUS? System designers should recommend the proper fluid for the application. A fluid with higher viscosity is thicker than standard hydraulic fluid. This must be taken into consideration because the fluid that has a higher viscosity will create a higher-pressure drop flowing through the system, especially during cold weather start-ups. When passing through filters it is necessary to have them strong enough to be able to handle higher pressure drops or filter collapse and destruction may occur.

6. What type of pump is being used? Is it a piston, gear, vane, or other type of pump? This would be important when installing a new or replacement suction strainer. Different pumps sometimes require more critical protection. If the pump fails, the system fails. Suction strainers protect the pump.

7. What type of filter is required? In-tank or in-line, when referring to suction straining? Do you need a replacement filter for an existing housing only? Or a replacement filter with a replacement cartridge in the housing? It is important to visually get this in your mind if you

are unsure of what the requirement may be. Is filter media wire cloth, cellulose or a synthetic? If so, what is the synthetic material and has it been performing properly?

8. Will the system be operating continuously, intermittently, or infrequently? If a system is in operation continuously, selection may be one that can withstand the rigors of the constant operation. Is it a filter made with wire cloth media instead of cellulose or microglass media? If the filter is used in a system that only operates occasionally, a less costly one may be installed. The important decision is to install a filter that is best for the operation. The worst possible occurrence is a machine breaking down because the filter installed couldn’t withstand the operation.

fall in the reservoir, air enters and is expelled from the reservoir. It carries both particles and moisture contaminants. A hygroscopic breather may be warranted. Sizing of this component is as critical as any other system filter. Air intake is measured in cubic feet per minute (CFM or SCFM). Sizing is important but it is permissible to oversize your air filter. A “general” rule of thumb to follow when sizing a tank breather is to use the following formula: Gallons per Minute, divided by 7.5 = CFM (GPM/7.5 = CFM).

9. What is the system operating temperature? Hydraulic system standard operating temperature is “usually” around 100°F. If the temperature runs hotter than standard, it must be kept in check. Too hot a system can destroy seals and cause leakage, as well as breakdown of the fluid. Either a fluid cooler should be installed or the proper seals, for example, Buna, Teflon, Viton, etc, must be used to be compatible with the operation.

10. Is the system indoors or outdoors? Moisture is the second most damaging contaminant in any system. An outside environment will most likely allow moisture into the system. Hygroscopic breathers may be necessary to prevent moisture from entering the system. Even in some indoor systems, depending on the geographical region, moisture can play havoc with a system, too. It may be necessary to use stainless steel filters with housings to prevent corrosion from occurring. If you are not sure if the metal “details” of a filter require stainless steel or plated steel, ask yourself the question, “What are the other components in the system made of?” Therein may answer your question of which type of filter to use.

11. What about the air that gets into the reservoir? The tank breather is one area which seems to be neglected and not serviced as often as it should be. As fluid levels rise and

12. What mesh or micron should be used? To completely size a filter, the level of filtration is critical. This could make or break an efficient operation. Suction lines should be no finer than 200 mesh (74 micron). Having too fine of filtration on the suction side may cause pump cavitation. Follow a few general rules above in the chart in Item #6. Protecting the pump in an effective manner is critical. “Typically,” the pressure line has the finest filtration in the system. It could be as fine as being in the sub-micron area depending on the application. The return line should be anywhere from 74 microns to 5 microns, depending on the application. This is an area that should be looked at closely because there are so many different applications with so many different requirements and with so many various scenarios. Know your equipment. These are points to consider when sizing a filter to a system to keep it running in a smooth and efficient manner. To protect the entire system, you want adequate filtration in all lines; suction, pressure, return, and tank breather. To reduce the downtown of your system, reduce the contamination in it.

The first step in reducing downtime is to size filters correctly, along with a properly scheduled maintenance program. Hydraulic equipment is a valuable and expensive capital investment, and the use cost is very high. Remember that to better reflect the economic benefits, make it a goal to strengthen the maintenance program to keep equipment operating as efficiently as possible.

Whether you are designing a new fluid power system or maintaining an existing one, your operation requires proper filtration to protect its critical parts. Selection of proper filtering components and establishing a regular maintenance program will ensure your system operates at peak efficiency with limited downtime. MFP’s Redmond says that all their hydraulic power units ship with a list of recommended spare parts including replacement filters. Sticking to the manufacturer’s recommendations is your best bet in maintaining your equipment. •

Raw Index Data, Index: 2018=100

The table above is expressed in terms of cumulative percent changes. These changes refer to the percent difference between the relevant cumulative total for 2023 and the total for the same months in 2022. For example, May 2023 pneumatic shipments figure of 8.3 means that for the calendar year through May 2023, pneumatic shipments increased 8.3% compared to the same time-period in 2022.

Each point on this graph represents the most recent 12 months of orders compared to the previous 12 months of orders. Each point can be read as a percentage. For example, 111.2 (the May 2023 level of the industrial hydraulic series) indicates that industrial hydraulic orders received from June 2022 to May 2023 were 111.2% of the orders received from June 2021 to May 2022.

(Base Year 2018 = 100)

Each point in this graph represents the average index for the 12 most recent months of shipments. Moving averages help clearly identify trends. The latest data shows total fluid power, total pneumatic, and total hydraulic shipment indexes continue to grow. (Base Year 2018 = 100)

Data published by the National Fluid Power Association shows the 12 month moving average of shipments for pneumatics, hydraulics, and total fluid power continues to grow. The year-to-date % change for shipments in May 2023 is 10.7%. Mobile hydraulic orders received from June 2022 to May 2023 are currently 95.8% of the orders received from June 2021 to May 2022. When looking at raw index data, pneumatic, mobile hydraulic, and industrial hydraulic shipments increased when compared to last month. These charts are drawn from data collected from over 70 manufacturers of fluid power products by NFPA’s Confidential Shipment Statistics (CSS) program.

This graph of raw index data is generated by the total dollar volume reported to NFPA by CSS participants and compared to the average monthly dollar volume in 2018. For example, the May 2023 total dollar volume for pneumatic shipments is 125.4% of the average monthly dollar volume in 2018. (Base Year 2018 = 100)

Why should you consider conducting a presentation?

• You’ll receive recertification points.

• You’ll receive a free thank you golf shirt.

• It's great promotion for you and for your company.

• We'll email you a template to use.

• We’ll rehearse before going live.

Simply email Victoria Piro at vpiro@ifps.org with your topic and a short description and she will contact you to set up the presentation. It’s that easy!

» THE IFPS ANNUAL Meeting will be held in-person and virtually September 25-28, 2023. The in-person meeting will take place at the Pfister Hotel, Milwaukee, WI. Why attend? You’ll meet a dedicated (and fun) group of professionals who exchange ideas and technologies, on ways to improve and educate the fluid power workforce. Our board members have diverse backgrounds and work in many different segments of the industry. So, the discussion is lively and informative. Imagine the things you’ll learn!

Each of our committees, Education, Certification, Membership, Marketing and Finance, follows a mission statement and each team works together on projects to meet those goals. Our members’ input is vitally important, so if you can’t attend in person, consider joining one of our committees. Contact Jenna Mort at jmort@ifps.org.

In addition to committee meetings, tours, and networking, a Technical Workshop, Hydraulic Fluid - The “Life Blood” of Hydraulic Systems – Purpose, Performance Characteristics, Maintenance & Monitoring, will be held on Monday, September 25th.

Register by visiting ifps.org

June 2023

Engineer (E)

Hiteshkumar Patel, Plasser American Corporation

System Designer (SD)

Ashwin Shridhar, Applied Industrial Technologies

Specialist (S)

Garrett Reichart, Airline Hydrualics

Thomas Miklos, Galland Henning Nopak

Donald Steinhart, Gulf Controls Company

Mark Suber, Triad Technologies

Olaf Pippel

Richard Haas

Hydraulic Specialist (HS)

John Duehlmeyer, Harsco Rail

Daniel Pelletier, Hydro Air

Shirish Gurav, TEchmahindra

Carson Depew, TPE Midstream, LLC

John Pereira, Western Hydraulics Ltd.

Connector and Conductor (CC)

Nathan Sweitzer, Airline Hydraulics

Electronic Controls Specialist (ECS)

Ian Klein, GCC

Julian Gardner

Dharmesh Vadgama, Parker Hannifin Corporation

Industrial Hydraulic Mechanic (IHM)

Clancy Vaughn, Coastal Hydraulics

Aaron Alston, Coastal Hydraulics Inc

Parker Willms, D.A.S. Services, Inc.

Guy Roberts, The Boeing Company

Travis Medberry, The Boeing Company

Victor Diep, The Boeing Company

Mobile Hydraulic Mechanic (MHM)

Adam Wilfong, Altec Industries, Inc.

Dwight Smith, Altec Industries, Inc.

Jesse Brant-Maracle, Altec Industries, Inc.

John Robinette, Altec Industries, Inc.

Kasyn Judd, Altec Industries, Inc.

Kyle Hendrickson, Altec Industries, Inc.

Mario Turrubiates, Altec Industries, Inc.

George Merrill, Altec Industries, Inc.

Travis Sheldon, Altec Industries, Inc.

Gideon Williamson, Cannon Mining

Joshua Powers, J.H. Fletcher & Co

Adam Powers, Versant Power

Maxwell Lipphardt

Mobile Hydraulic Technician (MHT)

Logan Furnish

Pneumatic Specialist (PS)

Garrett Reichart, Airline Hydrualics

Thomas Miklos, Galland Henning Nopak

Donald Steinhart, Gulf Controls Company

Mark Suber, Triad Technologies

Chad Beyer, Triad Technologies

Kevin Gerros, Triad Technologies

Olaf Pippel

Richard Haas

THE IFPS RELEASED a new and upgraded Connector and Conductor Certification and is now available to order! The new release includes an enhanced study manual and test.

In addition to the study manual, and tests, a companion PowerPoint presentation has been released, and Interactive Training Modules are coming soon!

• Both the written and Job Performance portions are included in one study manual.

For more information, visit www.ifps.org/web-seminars.

UPCOMING WEB SEMINARS

Conductor Identification

When: Oct. 5, 12 p.m. [ET]

Calculating the Useable Amount of Oil from a Pneumatic Accumulator

When: Nov. 2, 12 p.m. [ET]

• Additional Safety Information, including over 25 Safety tips!

• Pages and pages of full-color photos and graphics are available to download!

• Additional information on measuring implements.

• Added additional Fluid Compatibility information.

• Updated/added pressure rating and pipe tubing information.

• Added metric units throughout.

• Standards updated/added to conform with the latest:

› ISO 1219

› SAE J517

› ISO 8572

› ISO 6149-1

› ISO 9974-1

› Code 61 & 62 Flanges

• Improved graphics throughout and many real-life photos to assist in visualization.

ALAbAm A

Auburn, AL

Birmingham, AL

Individuals wishing to take any IFpS written certification tests can select from convenient locations across the United States and Canada. IFpS is able to offer these locations through its affiliation with the Consortium of College testing Centers provided by National College testing Association.

Contact Kyle pollander at Kpollander@ifps.org if you do not see a location near you. Every effort will be made to accommodate your needs.

Calera, AL

Decatur, AL

Huntsville, AL

Jacksonville, AL

Mobile, AL

Montgomery, AL

Normal, AL

Tuscaloosa, AL

ALASKA

Anchorage, AK

Fairbanks, AK

ArIZONA

Flagstaff, AZ

Glendale, AZ

Mesa, AZ

Phoenix, AZ

Prescott, AZ

Scottsdale, AZ

Sierra Vista, AZ

Tempe, AZ

Thatcher, AZ

Tucson, AZ

Yuma, AZ

ArKANSAS

Bentonville, AR

Hot Springs, AR

Little Rock, AR

CALIFOrNIA

Aptos, CA

Arcata, CA

te N tAtIV e te S tING DAte S FO r ALL LOCAtIONS:

September 2023

Tuesday 9/12 • Thursday 9/21

October 2023

Monday 10/2 • Thursday 10/26

November 2023

Tuesday 11/7 • Thursday 11/30

December 2023

Tuesday 12/5 • Thursday 12/14

Bakersfield, CA

Dixon, CA

Encinitas, CA

Fresno, CA

Irvine, CA

Marysville, CA

Riverside, CA

Salinas, CA

San Diego, CA

San Jose, CA

San Luis Obispo, CA

Santa Ana, CA

Santa Maria, CA

Santa Rosa, CA

Tustin, CA

Yucaipa, CA

COLOrADO

Aurora, CO

Boulder, CO

Springs, CO

Denver, CO

Durango, CO

Ft. Collins, CO

Greeley, CO

Lakewood, CO

Littleton, CO

Pueblo, CO

DeLAWAre

Tallahassee, FL

Tampa, FL

West Palm Beach, FL

Wildwood, FL

Winter Haven, FL

GeOrGIA

Albany, GA

Athens, GA

Atlanta, GA

Carrollton, GA

Columbus, GA

Dahlonega, GA

Dublin, GA

Dunwoody, GA

Forest Park, GA

Lawrenceville, GA

Morrow, GA

Oakwood, GA

Savannah, GA

Statesboro, GA

Tifton, GA

Valdosta, GA

HAWAII

Laie, HI

IDAHO

Boise, ID

Coeur d ‘Alene, ID

Idaho Falls, ID

Lewiston, ID

Moscow, ID

Nampa, ID

Rexburg, ID

Twin Falls, ID

ILLINOIS

Carbondale, IL

Carterville, IL

Champaign, IL

Decatur, IL

Edwardsville, IL

Glen Ellyn, IL

Joliet, IL

Malta, IL

Normal, IL

Peoria, IL

Schaumburg, IL

Springfield, IL

University Park, IL

INDIANA

Bloomington, IN

Columbus, IN

Evansville, IN

Fort Wayne, IN

Gary, IN

Indianapolis, IN

Kokomo, IN

Lafayette, IN

Lawrenceburg, IN

Madison, IN

Muncie, IN

New Albany, IN

Richmond, IN

Sellersburg, IN

JO

Arizona

California

Colorado

Florida

Georgia

Maine Michigan Minnesota Montana New Jersey

Nova Scotia Pennsylvania Texas Washington Wyoming Western Australia

Dover, DE

Georgetown, DE

Newark, DE

FLOrIDA

Avon Park, FL

Boca Raton, FL

Cocoa, FL

Davie, FL

Daytona Beach, FL

Fort Pierce, FL

Ft. Myers, FL

Gainesville, FL

Jacksonville, FL

Miami Gardens, FL

Milton, FL

New Port Richey, FL

Ocala, FL

Orlando, FL

Panama City, FL

Pembroke Pines, FL

Pensacola, FL

Plant City, FL

Riviera Beach, FL

Sanford, FL

LOUISIANA

Bossier City, LA

Lafayette, LA

Monroe, LA

Natchitoches, LA

New Orleans, LA

Shreveport, LA

Thibodaux, LA

m ArYLAND

Arnold, MD

Bel Air, MD

College Park, MD

Frederick, MD

Hagerstown, MD

La Plata, MD

Westminster, MD

Woodlawn, MD

Wye Mills, MD

mASSACHUSettS

Boston, MA

Bridgewater, MA

Danvers, MA

Haverhill, MA

Holyoke, MA

Shrewsbury, MA

mICHIGAN

Ann Arbor, MI

Big Rapids, MI

Chesterfield, MI

Dearborn, MI

Dowagiac, MI

East Lansing, MI

Flint, MI

Grand Rapids, MI

Kalamazoo, MI

Lansing, MI

Livonia, MI

Mount Pleasant, MI

Sault Ste. Marie, M

Troy, MI

University Center, MI

Warren, MI

mINNeSOtA

Alexandria, MN

Brooklyn Park, MN

Duluth, MN

Eden Prairie, MN

Granite Falls, MN

Mankato, MN

mISSISSIppI

Goodman, MS

Jackson, MS

Mississippi State, MS

Raymond, MS

University, MS

mISSOUrI

Berkley, MO

Cape Girardeau, MO

Columbia, MO

Cottleville, MO

Joplin, MO

Kansas City, MO

South Bend, IN

Terre Haute, IN

IOWA

Ames, IA

Cedar Rapids, IA

Iowa City, IA

Ottumwa, IA

Sioux City, IA

Waterloo, IA

KANSAS

Kansas City, KS

Lawrence, KS

Manhattan, KS

Wichita, KS

KeNtUCKY

Ashland, KY

Bowling Green, KY

Erlanger, KY

Highland Heights, KY

Louisville, KY

Morehead, KY

NeW JerSeY

Branchburg, NJ

Cherry Hill, NJ

Lincroft, NJ

Sewell, NJ

Toms River, NJ

West Windsor, NJ

NeW meXICO

Albuquerque, NM

Clovis, NM

Farmington, NM

Portales, NM

Santa Fe, NM

NeW YOrK

Alfred, NY

Brooklyn, NY

Buffalo, NY

Garden City, NY

New York, NY

Rochester, NY

Syracuse, NY

NOrtH CArOLINA

Apex, NC

Asheville, NC

Boone, NC

Charlotte, NC

China Grove, NC

Durham, NC

Fayetteville, NC

Greenville, NC

Jamestown, NC

Misenheimer, NC

Mount Airy, NC

Pembroke, NC

Raleigh, NC

Wilmington, NC

NOrtH DAKOtA

Bismarck, ND

OHIO

Akron, OH

Cincinnati, OH

Cleveland, OH

Columbus, OH

Fairfield, OH

Findlay, OH

Kirtland, OH

Lima, OH

Maumee, OH

Newark, OH

North Royalton, OH

Rio Grande, OH

Toledo, OH

Warren, OH

Youngstown, OH

OKLAHOm A

Altus, OK

Bethany, OK

Edmond, OK

Norman, OK

Oklahoma City, OK

Tonkawa, OK

Tulsa, OK

Beaufort, SC

Charleston, SC

Columbia, SC

Conway, SC

Graniteville, SC

Greenville, SC

Greenwood, SC

Orangeburg, SC

Rock Hill, SC

Spartanburg, SC

teNNeSSee

Blountville, TN

Clarksville, TN

Collegedale, TN

Gallatin, TN

Johnson City, TN

Knoxville, TN

Memphis, TN

Morristown, TN

Murfreesboro, TN

Nashville, TN

teXAS

Abilene, TX

Arlington, TX

Austin, TX

Beaumont, TX

Brownsville, TX

Commerce, TX

Corpus Christi, TX

Dallas, TX

Denison, TX

El Paso, TX

Houston, TX

Huntsville, TX

Laredo, TX

Lubbock, TX

Lufkin, TX

Mesquite, TX

San Antonio, TX

Victoria, TX

Waxahachie, TX

Weatherford, TX

Wichita Falls, TX

UtAH

Cedar City, UT

Kaysville, UT

Logan, UT

Ogden, UT

Orem, UT

Salt Lake City, UT

VIrGINIA

Daleville, VA

Fredericksburg, VA

Lynchburg, VA

Manassas, VA

Norfolk, VA

Roanoke, VA

Salem, VA

Staunton, VA

Suffolk, VA

Virginia Beach, VA

Wytheville, VA

WYOmING

Casper, WY

Laramie, WY

Torrington, WY

CANADA

ALbertA

Calgary, AB

Edmonton, AB

Fort McMurray, AB

Lethbridge, AB

Lloydminster, AB

Olds, AB

Red Deer, AB

brItISH

COLUmbIA

Abbotsford, BC

Burnaby, BC

Castlegar, BC

Delta, BC

Kamloops, BC

Nanaimo, BC

Prince George, BC

Richmond, BC

Surrey, BC

Vancouver, BC

Victoria, BC

m ANItObA

Brandon, MB

Winnipeg, MB

NeW brUNSWICK

Bathurst, NB

Moncton, NB

NeWFOUNDLAND AND LAbrADOr

St. John’s, NL

NOVA SCOtIA

Halifax, NS

ONtArIO

Brockville, ON

Hamilton, ON

London, ON

Milton, ON

Mississauga, ON

Niagara-on-the-Lake, ON

North Bay, ON

North York, ON

Ottawa, ON

Toronto, ON

Welland, ON

Windsor, ON

QUebeC

Côte Saint-Luc, QB

Montreal, QB

SASKAtCHeWAN

Melfort, SK

Moose Jaw, SK

Nipawin, SK

Prince Albert, SK

Saskatoon, SK

Kirksville, MO

Park Hills, MO

Poplar Bluff, MO

Rolla, MO

Sedalia, MO

Springfield, MO

St. Joseph, MO

St. Louis, MO

Warrensburg, MO

mONtANA

Bozeman, MT

Missoula, MT

NebrASKA

Lincoln, NE

North Platte, NE

Omaha, NE

NeVADA

Henderson, NV

Las Vegas, NV

North Las Vegas, NV

Winnemucca, NV

OreGON

Bend, OR

Coos Bay, OR

Eugene, OR

Gresham, OR

Klamath Falls, OR

Medford, OR

Oregon City, OR

Portland, OR

White City, OR

peNNSYLVANIA

Bloomsburg, PA

Blue Bell, PA

Gettysburg, PA

Harrisburg, PA

Lancaster, PA

Newtown, PA

Philadelphia, PA

Pittsburgh, PA

Wilkes-Barre, PA

York, PA

WASHINGtON

Auburn, WA

Bellingham, WA

Bremerton, WA

Ellensburg, WA

Ephrata, WA

Olympia, WA

Pasco, WA

Rockingham, WA

Seattle, WA

Shoreline, WA

Spokane, WA

WeSt VIrGINIA

Ona, WV

WISCONSIN

La Crosse, WI

Milwaukee, WI

Mukwonago, WI

YUKON terrItOrY

Whitehorse, YU

UNIteD KINGDOm

Elgin, UK

GHAZNI

Kingdom of Bahrain, GHA

Thomasville, GHA

eGYpt

Cairo, EG

JOrDAN

Amman, JOR

NeW ZeALAND

Taradale, NZ

CFpmmH

Certified Fluid Power

Master of Mobile Hydraulics

(Must Obtain CFPMHM, CFPMHT, & CFPCC)

CFpmIp

Certified Fluid Power

Master of Industrial Pneumatics (Must Obtain CFPPM, CFPPT, & CFPCC)

CFpCC

Certified Fluid Power Connector & Conductor

CFpSD

Fluid Power System Designer

IFPS offers onsite review training for small groups of at least 10 persons. An IFPS accredited instructor visits your company to conduct the review. Contact kpollander@ifps.org for details of the scheduled onsite reviews listed below.

HYDrAULIC SpeCIALISt

Aug. 14-17, Fairfield, OH, CFC Industrial Training,

Written test: Aug. 18.

Dec. 4-7, 2023, Fairfield, OH, CFC Industrial Training. Written test: Dec. 8, 2023.

eLeCtrONIC CONtrOLS SpeCIALISt

For dates, call CFC Industrial Training at (513) 874-3225 or visit www.cfcindustrialtraining.com.

pNeUmAtIC SpeCIALISt

Nov. 13-16, Fairfield, OH, CFC Industrial Training.

Written test: Nov. 17.

CONNeCtOr & CONDUCtOr

Nov. 15-16, Fairfield, OH, CFC Industrial Training. Written and JP test: Nov. 17.

mObILe HYDrAULIC meCHANIC

Oct. 23-26, Fairfield, OH, CFC Industrial Training. Written and JP test: Oct. 27.

Online Mobile Hydraulic Mechanic certification review for written test is offered through CFC Industrial Training. This course surveys the MHM Study Manual (6.5 hours) and every outcome to prepare you for the written test. Members may e-mail for a 20% coupon code off the list price. Test fees are not included.

INDUStrIAL HYDrAULIC meCHANIC

For dates, call CFC Industrial Training at (513) 874-3225 or visit www.cfcindustrialtraining.com.

INDUStrIAL HYDrAULIC teCHNICIAN

For dates, call CFC Industrial Training at (513) 874-3225 or visit www.cfcindustrialtraining.com.

mObILe HYDrAULIC teCHNICIAN

Sept. 18-21, Fairfield, OH, CFC Industrial Training. Written and JP test: Sept. 22. pNeUmAtIC teCHNICIAN and pNeUmAtIC meCHANIC

For dates, call CFC Industrial Training at (513) 874-3225 or visit www.cfcindustrialtraining.com.

JOb perFOrmANCe trAINING

CFC Industrial Training offers an online Job Performance Review that includes stations 1-6 of the mechanic and technician Job Performance tests. Members may e-mail IFPS for a 20% coupon code off the list price. Test fees are not included. CFC also offers live distance learning Job Performance Station Reviews. To register or purchase, contact CFC Industrial Training at (513) 874-3225 or visit www.cfcindustrialtraining.com.

By the numbers, with more than 19,000 attendees, 900 exhibitors displaying their equipment and services and 1.4 million square feet or approximately 32 acres of exhibits, THE UTILITY EXPO is touted as the largest and fastest growing trade show in the utility industry.

The Expo has been ranked the #1 Trade show in the utility industry, and this comes as no surprise with an understanding of all that is offered at the event held September 26th through the 28th in Louisville, Kentucky.

Keeping with the times, the Expo addresses the transformation of the utility industry. The Infrastructure Law, new regulations, sustainable approaches, and incredible new innovations have opened up a world of potential possibilities within the business in the utility industry.

For attendees, the Expo offers a platform for new products and technologies to be showcased. New approaches for employers to establish positive work outcomes, maximizing time and speed in accomplishing and exceeding goals are highlighted. Insight into market trends and educational opportunities will be focused upon.

Past attendees and those looking forward to the Expo experience both conclude that one of the greatest payouts for being on-hand at the event is the peer-to-peer education and faceto-face networking that occurs.

The utility infrastructure takes a great stride into the future as it splays out a host of possibilities in growth and knowledge. •

Fix & Stabilizer

turns unusable, milky, emulsified hydraulic oil into usable oil. It encapsulates water, DEF and stabilizes oil:

• FIX and PREVENT water contamination in hydraulic fluid

• FLUSH and CLEAN the entire hydraulic system (including hard to reach, intricate locations)

• For PREVENTATIVE maintenance

And it’s plant-based and biodegradable!

Product details and video demo: www.b3cfuel.com/product/ hydraulic-oil-fix-fixes

b3C Fuel & Oil Solutions

843.347.0482

B3CFuel.com

108 Daytona St, Conway, SC 29526

We're hydraulic filter experts. We've been doing it for over 30 years. We're very competitive and happy to serve your needs. If you need hydraulic filter application help, we know the right questions, and we can give you the right answers.

J/t Hydraulics & Service Co. Inc. 1601 W. 25th Street • Houston, tX 77008

Local: 713.984.9727 • toll Free: 800.591.8280

Fax: 713.861.2250 • www.jthydraulics.com

The compact footprint coupled with the long life, and exceptional leak resistance make the ES line suited to improve reliability in a wide range of applications including biomedical, dental, test equipment, oxygen control, textile, packaging, pressure control, automation and portable systems.

• Over 1 billion cycles (under ideal conditions)

• 0.01 atm sccm leak rate

• No threads in flow path

• Fast response - 5 to 10 ms (nominal)

• Close mounting - 7/8” on center. Overall height less than 1”

• Ideal for ultra-low leak applications

World Wide Metric offers a wide selection of DIN 2353 compression fittings. These fittings are a high quality product used for fluid power systems joining tubes together. Available in carbon steel and stainless steel with sizes ranging from 4mm–42mm.

Contact

Keep your oil clean and dry with Xtract Filter Carts from Lubrication Engineers. These portable filtration systems make it easy to pull oil samples, clean the oil, and maintain oil cleanliness in multiple applications using the same fluid. They enable you to both screen oil to remove large particulates and clean oil to remove small particulates.

www.lelubricants.com

info@le-inc.com

800-537-7683

Skip counting teeth and join the revolution. By measuring the gear’s rotation, we can double your resolution and accuracy across all your process flows. From 1 cc/min to 240 liters/ min, Max Gear Meters provide 0.3% accuracy and data up to 500 pulses/cc. See what flow you’re missing and how to improve your process by using a Max Precision Gear Meter.

Precision Flow Meters

max machinery, Inc.

33A Healdsburg Ave.

Healdsburg, CA 95448

707-433-2662

www.maxmachinery.com

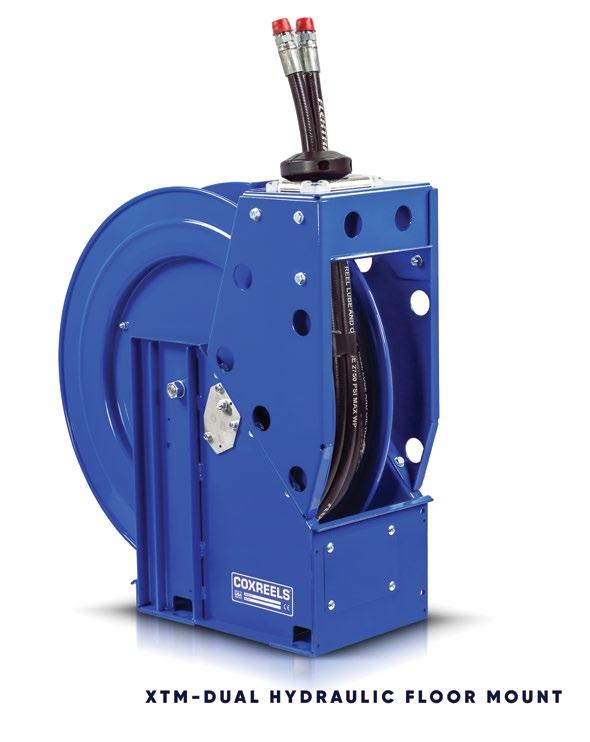

Coxreels is proud to introduce the Dual Hydraulic X tm-Dmp-450 reel.

Coxreels’ single-sided, dual-bodied hydraulic swivel is unique in the industry and is featured on this reel allowing for the inlet connections to both be on the same side of the reel. It is rated to 2500 PSI and combines the ultimate features into the world’s most robust reel solution.

www.coxreels.com

MP Filtri MYclean filter series is a market innovation breakthrough for mobile and industrial equipment OEM’s. Our patented polygon endcap interface feature ensures only original filter elements are used guaranteeing maximum performance and safety throughout the machine's design lifespan.

mp Filtri USA, Inc.

1181 Richland Commerce Drive

Quakertown, PA 18951

Toll free: 888-263-0090

sales@mpfiltriusa.com

www.mpfiltriusa.com

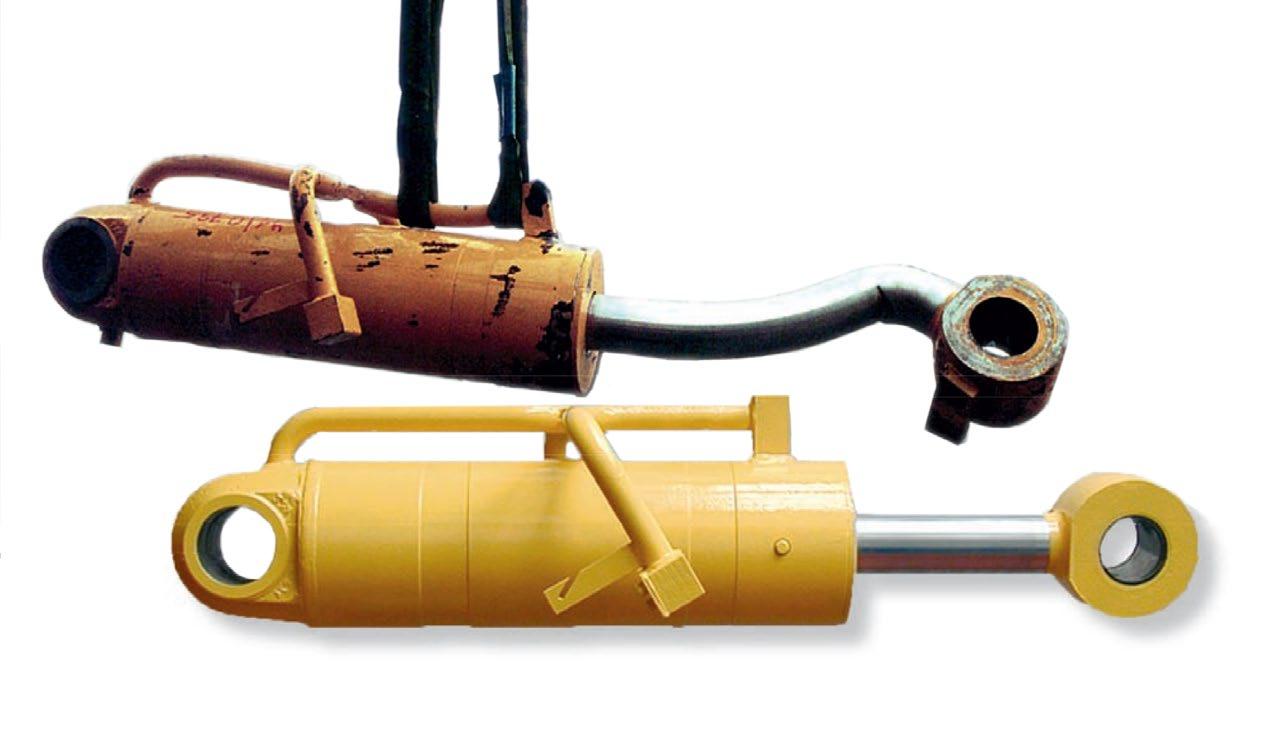

Custom Welded Cylinders:

• 1.5” up to 50” bore, with strokes exceeding 300”

Heavy Duty Mill Cylinders:

• 1.5” up to 50” bore, with strokes exceeding 300”

NFPA/JIC Tie Rod Cylinders:

• 1.5” up to 24” bore; interchangeable with all brands

Yates Industries (HQ) 586.778.7680

Yates Cylinders Alabama 256.351.8081

Yates Cylinders Georgia 678.355.2240

Yates Cylinders Ohio 513.217.6777

Some fluids with very good lubricity and viscosity characteristics may prove caustic to the material in pumps, actuators or valves, especially when hot.

There are three areas of component compatibility that the designer needs to consider. The first is within the circuit, the second is chemical reaction, and the third is temperature. Chemical compatibility is an important consideration when choosing the hydraulic fluid for the system. The inner tube of the hydraulic hose must not react chemically with the fluid. The same can be said of the seals within the components. Water is a chemical that can adversely affect the seals, so special seals must be applied where HWCF is used. Water-glycol fluids attack zinc, cadmium and aluminum, so these elements must not be located anywhere in the circuit in order to prevent contamination and deterioration of the hydraulic system. It is important that the designer be aware of the composition of the parts that make-up the system components.

Many seals are manufactured in a process that includes heat to cure the product in the mold. This process is very specific and provides the Duron® rating of the seal. Exposing seals to heat beyond their rating will result in continued curing, making the seals brittle and without proper elasticity.

The designer must be familiar with the chemical and temperature compatibility charts for both seals and metal parts (Fig. 3-41) so that proper choices can be made.

Seals prevent internal and external leakage in a hydraulic system. Static seals are used for pump housings, valve bodies, and reservoir covers, and between cylinder ends and the cylinder tube, where there is not any relative movement between the parts to be sealed. Dynamic seals are used between moving parts, for example, between the piston and cylinder bore and between the cylinder rod and the rod bearing. About 80% of seal applications use static seals.

The starting and operating temperatures of the machine are also used to select hydraulic seals that retain their sealing properties in ambient and hot conditions. Neoprene, a general use sealing material, has a temperature range of -65°F to 225°F (-54°C to 149°C). Neoprene is satisfactory for static gasket seals and O-rings with petroleum base fluids, but is not as well suited as Nitrile rubber (Buna N™), urethane, and even leather, for dynamic applications. Extremely cold and hot conditions require a sealing material that is more tolerant of heat. Viton™ and silicone compounds are the sealing material of choice for applications with temperature extremes.

The ability of a sealing material to prevent leakage is tested by measuring the durometer (indentation hardness), creep, and compression set after deformation. The sealing compound must be hard enough to resist wear and extrusion, for the clearance gap and pressure that will be encountered, yet still be soft enough to maintain a seal during continued use. Seals have a tendency to swell in the presence of hydraulic fluid. Some swelling is permissible, and even somewhat desirable, in maintaining a fluid tight seal, but excessive swelling and accompanying softness of dynamic seals will increase friction and the tendency to abrade. Twenty percent swelling is considered to be the maximum allowable swell; swelling by a factor of 40% to 50% is allowable for confined static seals. •

1. Referring to Fig. 3.41 , which seal material has the widest temperature range?

a. Polyurethane.

b. Leather.

c. Neoprene.

d. Silicone rubber.

e. Fluoro-elastomer.

2. What is the reason for knowing the chemical compatibility?

a. Avoiding bad chemical reactions.

b. Choosing the correct seals.

c. Matching the fluid to the pump and/or motor.

d. Applying appropriate components.

e. All of the above.

See page 31 for the solution.

Seal Material Compatible Fluids Temperature Range

1. Metallic piston rings Petroleum base and synthetic fluids, phosphate esters - for highpressure and severe conditions

2. Leather Petroleum base and some synthetics, phosphate esters - for medium to high-pressure

3. Neoprene rubber General purpose industrial use, Freon™ 12; weather and salt water resistant

4. Nitrile rubber (Buna N™) Petroleum base fluids and mineral oils - used for some rotating seals, extrusion resistant

5. Silicone rubber Water and petroleum base fluids, phosphate esters; low tensile strength and tear resistance recommended for static seals only

Petroleum base, synthetic, diester, silicate ester, and halogenated hydrocarbon fluids - for high temperature fluid applications

Low to 500°F (260°C)

-65°F

Fig. 3-41 Common Sealing Materials and Their Applications

to 149°C

to 107°C

Screw plugs to avoid wasteful loss of compressed air. For connection dimension comply with ISO 16030. With assembled o-ring, available from M 3 and up. Developed especially for the requirements in the field of pneumatics.

mail@heinrichs-usa.com | +1 859 371-4999

to 400°F

to 200°F

HN P | SCREW PLUG

Diamond Hydraulics provides fast, accurate repair of hydraulic components by industry experts. With state-ofthe-art test equipment, we ensure that your products are in the absolute best condition before leaving our facility. We are committed to providing excellent customer service and strive to consistently meet and exceed the needs and expectations of every customer.

Diamond Hydraulics, Inc.

6776 FM 2004 Rd Hitchcock, Tx 77563 409-986-3957

www.diamondhydraulics.com

sales@diamondhydraulicsinc.com

HED’s product lineup includes Controls, Displays, Keypads, and Telematics. Visit HED online to view our product lineup and options. View product options along with customized features, data sheets, and request demos of desired products.

HeD, Inc.

Hartford, Wisconsin

262.673.9450

800.398.2224

HEDcontrols.com/FP23

Brochure offers a comprehensive overview of the company’s complete line of compressed air filtration products. Highlighted is the patented family of Extractor/Dryers. These two-stage, point of use filters remove contaminates to a 5-micron rating with flow ranges of 15 to 2,000 scfm. Additional products available include the SuperStar Membrane Dryer, .01 Micron Filter, Refrigerated Extractor/Dryer, and much more.

La-man Corporation

800.348.2463

www.laman.com

Our Genuine Metaris MHDV20 & MHDV35 series directional control valves are engineered specifically for the Truck Equipment market providing an interchange solution to common valves already on the market. They’re functional interchange replacements for: Parker®/Commercial® DVA/ DVG20, DVA/DVG35, VA/VG20, VA/VG35, A20, V40, V42 and 25P Series, and Muncie® 60V Series.

Hydraulex Toll Free: 800.422.4279

Tel: 586.949.4240

Email: sales@hydraulex.com

www.hydraulex.com

New 120 page catalog includes popular styles of MAIN Manufacturing’s extensive offering of carbon and stainless Hydraulic Flanges and Components – ready for immediate shipment. Metric ordering information, weld specs, and dimensional information included. The “Quick Reference Guide” helps specify less popular items often stocked or quickly manufactured (generally 3-4 days) at our US plant.

mAIN manufacturing products, Inc.

Grand Blanc, MI

800.521.7918; FAX: 810.953.1385

E-mail: info@mainmfg.com

www.mainmfg.com

25 years ago, Murrelekronik developed and produced the first pre-wired, molded valve connector. It was the beginning of our quest to make connectivity easier!

Murrelektronik valve plugs are available in all common forms as well as a variety of styles. Our valve plugs are easily recognizable with the wiring diagram printed on the side, a captive gasket, integrated LED and suppression.

murrelektronik, Inc.

1327 Northbrook Parkway

Suite 460

Suwanee, GA 30024

P: 770-497-9292

Email: 2info@murrinc.com

OTTO Controls designs and manufactures precision switches, grips, joysticks and other operator controls solutions, and its Product Summary highlights products applicable to various markets. Check out U.S.-made controls solutions for military/aerospace, industrial, material handling, medical and additional applications.

Visit www.otto-controls.com.

World Wide Metric's updated CAST catalog features 358 pages of their fittings product line, along with technical information and drawings. Their wide selection includes DIN metric compression, JIC flared, BSP adaptors, coversion adaptors, ORFS, hose and hose fittings. Catalog can be downloaded on their website with print version available upon request.

www.worldwidemetric.com

sales@worldwidemetric.com

732-247-2300

manufacturers and distributors trust OFCO’s flexibility, product quality and unparalleled delivery times.

Our central-Ohio manufacturing facility and veteran workforce deliver solutions that consistently meet critical specifications and exceed customer delivery expectations. OFCO has been the manufacturer of choice for strainers, breathers, screens and filtration solutions since 1945. We offer a wide variety of ready-to-ship products or work with your engineering team to create custom filtration solutions for your specific need.

Contact info:

888-354-0291

info@ohfab.com

www.ohfab.com

Inline and 90° hydraulic live swivels. Available in sizes from 1/8" to 2-1/2", rated to 10,000 PSI, heat treated, superior quality alloy steel, chrome or stainless steel ball bearings, withstands heavy side loads, burnished (micro smooth) barrel bores, Viton®, Aflas® , or Teflon® encapsulated seals, zinc or nickel plated, available in 304 and 440 stainless steel, full flow - low pressure drop, rebuilding kits available.

Super Swivels

Phone: 763.784.5531

Fax: 763.784.7423

Email: sales@superswivels.com

Website: www.superswivels.com

From 0.733 CIR to 73 CIR. Radial piston motors, From 1.2 CIR to 700 CIR, axial piston motors from 0.855 to 4.15 CIR and assemblies with gear Reducer with torque up to 1.200.000 LB-FT

Find your product: Young Powertech Inc. 3060 Plaza Dr. Garnet Valley PA 19060

610-558-0760

info@youngpowertech.com

www.youngpowertech.com

By Edwin Harnischfeger, Senior

Engineer

By Edwin Harnischfeger, Senior

Engineer

The decision to use the modular RS valve platform with similar equipment brings many advantages. The same modular technology for all machine types and performance classes not only simplifies engineering, but also documentation and service. At the same time, Hyundai benefits from even more precise design and design freedom in the course of standardization. For example, the electric pilot valves with their uniform characteristics simplify software creation. At the same time, the amount of piping required in production is reduced.

“Bosch Rexroth’s modular solution approach enables us to combine the market requirements of flexibility and standardization in the interests of our customers,” explains Kangjun Sim. “In doing so, we achieve noticeable time and cost savings over the entire life cycle, which strengthens our overall competitive position.”

In the operating phase, the RS platform reduces energy requirements and thus diesel consumption. For example, the load-sensing controlled priority valve realizes energy benefits compared with conventional priority valves, as only the oil volume dedicated for steering flows via the LS priority valve, thus reducing previous flow losses. A further customer benefit results from the electrohydraulic control, which makes operation significantly quieter and enables so-called “hydraulics-free cabs.”

By switching to the RS modular valve platform, Hyundai has taken a further step toward future viability. “For us, the partnership with Bosch Rexroth is a competitive factor,” sums up Kangjun Sim. “The quality of support and solutions is excellent, response times are short, and the innovative strength reinforces the future viability of our vehicles - in terms of design and cost efficiency as well as functionality and sustainability.”

Before the introduction of the modular valve platform, the working hydraulics of the mobile off-highway machines varied greatly by type and model. After all, excavators, wheeled loaders and forklifts require different types and numbers of functions. In addition, different performance classes require larger or smaller control blocks, whose control axes must in turn be adapted to the required functions.

CASE STUDY Application Construction Machinery, Bosch RexrothMonolithic control blocks cannot map this cross-vehicle spectrum of requirements, as they realize the desired functions with a model-specific manufactured component. In contrast, the modular RS platform enables Hyundai Engineering to flexibly configure and standardize individual control blocks with flow-sharing (LUDV) to meet specific requirements.

Kangjun Sim, Team Manager Hydraulic Components at Hyundai Construction Equipment stated, “With the introduction of the RS platform, we are not only simplifying engineering and assembly, but also setting the course for the digital future at the same time.”

Hyundai laid the foundation for the switch to today’s RS solution back in 2009. In just two years, the manufacturer equipped ten wheeled loader models with the Rexroth Monoblock M6 with flow-sharing technology (LUDV). At the same time, the Monoblock M7 LUDV went into series production in the forklift product range (larger than 18 ton). Both innovations represented an important step for Hyundai in the direction of energy efficiency and functionality. With this step, the previous fixed displacement pumps were replaced by variable displacement pumps and the hydraulic architecture was changed to closed center. This led to energy savings of ten percent and more, depending on the model. In functional terms, both vehicle types also benefited from the flow-sharing, as it distributes a brief undersupply evenly to all (non-safety-related) consumers and functions, thus avoiding the abrupt shutdown of just one function.

Hyundai took an even bigger evolutionary step from 2019 with the introduction of the RS valve platform as a flexible replacement for the two monoblocks M6 and M7. On the one hand, this allows individual control blocks to be assembled from standardized slice and function modules, and on the other hand, both worlds of flow-sharing (LUDV) and load-sensing (LS) can be combined. For example, prioritized functions such as steering can be implemented with the aid of the RBM priority module. With further integrated functions, Hyundai implements, for example, a vibration damping system (boom suspension) as well as anti-drift valves, variable or fixed tank preload valves and a control oil supply system.

Excavators and wheeled loaders have different functions, but with the RS modules from Bosch Rexroth they have a uniform valve platform for the working hydraulics – including the option of electronic control.

The modular valve platform not only gives engineering a high degree of freedom in design, but at the same time lays the foundation for the gradual electronification of the working hydraulics. This is because in addition to hydraulic control, the internal channeling also enables electrohydraulic (EH) control, which Hyundai is successively expanding. The eOC software modules (electronic Open Circuit), for example, gives operators a feel for the payload even without load sensing by finely controlling the variables of flow and pressure at the start of the movement. In the course of increasing electronification, a number of new assistance and logic functions have already been implemented, such as a floating position for planning, anti-drift, or return-to-dig. More are to follow.

In the meantime, the RS platform with its characteristic slice modules has proven itself in four vehicle types at Hyundai. The first to go into series production with them were seven machine sizes in the HL wheeled loader series.

While the smaller HL930 and HL940 models use size 15 modules, the larger machines from HL955 to HL970 are based on size 20. Thanks to the slice design, modules of both sizes can also be combined to meet different flow requirements or to combine several functions that could not previously be integrated in just one block. This saves installation space, weight and expense. Following the successful series launch of the wheeled loaders, Hyundai also introduced the new platform in wheeled excavators and mini-excavators in the HW and HX model series.

Hyundai is thus extending flow-sharing technology to smaller trucks and now benefits from a uniform platform for the complete model range from 110D to 250D. Here, too, different valve blocks are designed in line with flow rate requirements by combining modules of different nominal sizes. For example, the lift function can be represented by the RS20, the tilt function realized with the RS15 and the steering backed up by the RBM priority module. •

Did