03 Welcome

IMechE chief executive

Alice Bunn on maximising the impact of engineers

42 The big interview

Clive Hickman OBE talks about the challenges that lie ahead for him as IMechE president

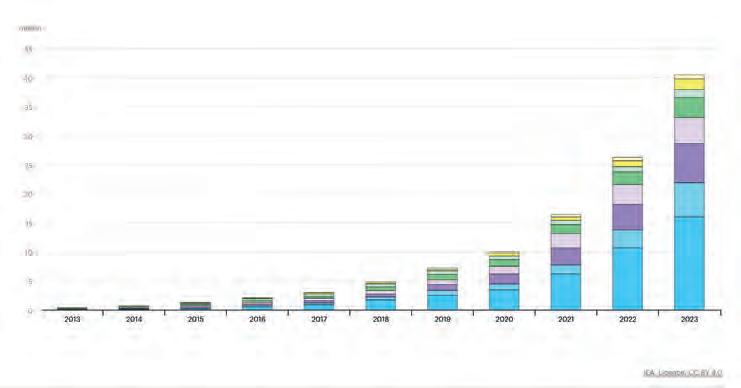

46 EV batteries

Developing cleaner and more efficient alternatives to today’s batteries for electric vehicles

52 Artemis explained

How the technology used by NASA for its Artemis missions to the Moon compares to that employed in the past

58 Climate change

How massive geoengineering projects could help to halt the pace of climate change

64 Weird engineering

How mayonnaise, of all things, could influence the design of nuclear fusion reactors

05 Opener

The world’s biggest aeroplane could be used to transport parts for giant wind turbines

06 Picture story

A synthetic active model of the heart could improve patient care

09 Five for the future

Meet the engineers and researchers who are coming up with ground-breaking innovations

11 Blueprint

How businesses can harness the potential of artificial intelligence

13 In the spotlight

Our series on IMechE members who are having a big impact profiles Laura Kershaw

19 HQ update

How members will have their say on the future of the IMechE headquarters

21 Boosting diversity

The work of the IMechE diversity and inclusion committee is explained

22 Competitions

The latest news from Formula Student and the UAV Challenge

25 Your Voice

Readers have their say on key issues of the day

27 Heritage

Celebrating the paddle steamerWaverley

29 Skills training

IMechE’s education policy adviser explains how the Institution plans to work with the new government to boost education and skills training

33 Driving down risk

How businesses must balance costs and legal compliance to ensure that their operations are always kept safe for employees and the public

39 Hot stuff

Useful advice for operators of heat recovery steam generators on how to keep their technology up to date

s a global community of engineers, we’re not just solving problems, we’re shaping the future. Our mission is clear: to improve the world through engineering, and showcase the role engineers play in addressing the world’s pressing challenges. To achieve this, we’ve set two clear goals in our IMechE 2030 strategy:

l Membership development: Develop, register and support our members and the engineering community to be at their best for a more inclusive and sustainable world. l Impact: Maximise the impact of our community to promote engineering, inform opinion and stimulate innovation for the benefit of society.

Lifelong learning

We’re dedicated to helping engineers expand their skills. Our Expertise division is growing rapidly, and aims train 17,000 engineers this year alone. We’re collaborating with up to 500 companies globally to deliver the events and training courses needed to meet future challenges. We’re excited to offer new programmes in AI and predictive technology, and expanded offerings for the power sector. That's alongside events on key industry challenges and advancements, presented by leaders in the field. See the enclosed 2025 training and events calendar for opportunities that reflect your career goals.

Influencing policy

Highlighting the importance of engineering and the role of our community in meeting future challenges is a key strategic goal. As demand for our expertise grows, so

PROFESSIONAL ENGINEERING

is published by Think on behalf of the Institution of Mechanical Engineers.

PE, 65 Riding House Street, London W1W 7EH 020 3771 7200

EDITORIAL profeng@thinkpublishing.co.uk

Editor: Amit Katwala

Deputy editor: Joseph Flaig

Chief sub-editor: John Moore

Group art director: Jes Stanfield

Executive director: Jackie Scully

Client engagement director: Kieran Paul

does the opportunity for engineers to shape policy, and we’re working to maximise our members’ opportunity to advise government. We recently published our ‘asks’ for the new government – priorities for the profession that we'll be discussing with policymakers. These align with manifesto pledges, including making the UK a cleanenergy superpower, designing a mission-driven industrial strategy, modernising transport, and education reform. We're calling on members to put forward their expertise and advice when appropriate, and not just in the UK. Many countries face similar challenges and our community can provide valuable technical and policy comparators.

We have much to learn about best practice, and one of the areas we can reflect on is vocational training and learning (see page 29). Countries such as Germany and Switzerland offer excellent models. In England, the introduction of Technical Levels as a post-16 alternative provides a pathway to apprenticeships and further or higher education. More is needed to support T-level graduates as they transition into technical roles or further courses. This begins with enhancing the understanding of what T-levels are and the depth of learning these students have achieved.

The Institution's financial stability is key to the success of the 2030 strategy. A membervote on the future of our Birdcage Walk HQ is imminent and is an important component towards ensuring that we continue to operate on a solid, sustainable financial footing.

ADVERTISING 020 3771 7232

Commercial director: Michael Coulsey michael.coulsey@thinkpublishing.co.uk

Group commercial manager: Matt Hall matt.hall@thinkpublishing.co.uk

Senior commercial partnerships manager: Chris Barnard chris.barnard@thinkpublishing.co.uk

Commercial partnerships manager: Leanne Rowley

leanne.rowley@thinkpublishing.co.uk

Printed by: Acorn Web, Yorkshire

Copyright: Think Publishing 2024

SUBSCRIPTIONS

ABOUT IMECHE

The Institution of Mechanical Engineers is the professional body overseeing the qualification and development of mechanical engineers. It has 115,000 members in 140 countries. Visit imeche.org for more information about membership and its benefits, or email membership@imeche.org.uk

Views expressed in Professional Engineering are not necessarily those of the Institution or its publishers.

Chief executive: Dr Alice Bunn OBE FIMechE

President: Clive Hickman OBE FIMechE IMechE is a registered charity in England and Wales number 206882 @ProfEng tinyurl.com/PEmagazine

For address changes, phone 01952 214050 or email subscriptions@imeche.org

''We have an agenda and a list of companies we want to see depending on the equipment we want to buy for the next 5 years. For us, it is about having a one-stop shop where you can find the supplier you need. It is all about networking and finding contacts for the future. Roy Higginbotham, Procurement Contract Specialist, Leonardo Helicopters Association partners

2da s 400+ of networking leading suppliers

5free 9000+ to attend engineering forums professionals 1000s of innovative solutions

To get giant turbine parts to their final destination, you need the world’s biggest plane

Transporting wind-turbine blades by road is no easy task. Stretching for 50m or more, they make driving round even the slightest of bends in a narrow rural road a complex logistical challenge.

This means that current deployments are in “the most cherry-picked locations,” said Paul Hanna, marketing executive at energy company Radia. “You can’t turn corners. You can’t get them under bridges – and, for those that you can, it literally takes a year-anda-half to plan to move, by ground, one blade from the manufacturing facility or the port to the windfarm.”

Blades on future turbines will be even longer – maybe 100m or more, which Radia claims is much too long to travel by road. But what if disruption could be avoided by transporting blades by aircraft, landing close to the windfarm site?

The Colorado firm aims to provide that with WindRunner,

which will be the world’s largest aircraft if the project is successful. Aerospace multinational Leonardo will develop the fuselage, Radia announced at Farnborough, while Spanish company Aernnova will partner on development of the aircraft’s wing and engine pylons, and New York consultancy AFuzion will provide safety and certification consulting.

The aircraft is designed to fly turbine blades as long as a football pitch direct to windfarm sites, landing on ‘semi-prepared’ dirt runways as short as 1,800m.

“The innovation that we’re bringing to this aircraft is how we’re bringing together the existing product catalogue of things that have already been certified and are flying on Airbus and Boeing planes today,” said Hanna. “In some respects, there’s no new technology.”

Illustrations of the aircraft

123m

length of the 54-tonne blades on the world’s biggest wind turbine at the Zhangpu Liuao Phase 2 offshore windfarm in China

nonetheless reveal a distinctive airframe, including a tall – and extremely long – unpressurised fuselage. Radia is using the philosophy of ‘minimal viable aircraft design,’ said Hanna. He was unable to provide a specific number of planes the company aims to build, but it will be in the dozens. The company aims to triple the acreage available for onshore wind deployment, driving down the cost by 30%.

At Massachusetts Institute of Technlogy, biomedical engineer Ellen Roche is developing the medical devices of the future. She directs the Therapeutic Technology Design and Development Lab, which uses soft robotics, advanced manufacturing techniques and computational analysis to develop new therapies. Here she’s holding a synthetic active heart model of the left atrium and ventricle – these could be personalised to help doctors gain an insight into a specific patient. “We can look at various devices and tune the heart, depending on what we’re trying to test,” said Roche.

The only company that does IT ALL and does IT globally

Astheonlymanufacturer of everyretainingring style(circlip,snapringandspiral),R.otorClip ensuresyouhavethebestringsolutionforyour application.Standardorcustom,coiledorstamped, wearecommittedto producingthehighestquality ringswithunparalleledengineeringsupport.

Meet the scientists and researchers improving the world through engineering. For more, head to imeche.org/news

Massachusetts Institute of Technology engineers have developed a more accurate model of the airflow around windfarm rotors, which are currently worked out using inaccurate century-old science. It could improve the way turbines are designed, and how windfarms are laid out.

01 02 05 04 03

US engineers have developed a tiny battery for cell-sized autonomous robots that could deliver drugs inside the human body. The battery is 0.1mm long and as thin as a human hair. It captures oxygen from the air and uses it to oxidise zinc, creating a current of up to 1V, say the Massachusetts Institute of Technology researchers.

Researchers in Hong Kong have developed an artificial compound eye that aims to mimic the benefits of insect vision, providing a wide field of view and advanced motion-tracking capabilities. Potential applications include close-formation flying of drone swarms.

Georgia Tech researchers are using AI to search for the next generation of polymers –substances such as Kevlar and Teflon that can add functionality to products. They’ve developed algorithms that can predict the properties of a new polymer before it’s actually been physically made.

Oxford University spinout OXCCU has built a demonstration plant that can convert CO2 into aviation fuel in a single-step process that could cut the cost of developing ‘power-toliquid’ fuels for sustainable aviation. There are plans for commercial plants in the future.

Alan King, author of a new IMechE report on artificial intelligence, gives his recommendations for how businesses can grasp its potential.

01 Stay informed about the latest AI developments, tools and trends, and engage in discussions with AI experts and thought leaders to gain insights into emerging technologies and their potential applications.

implementing data management systems, or adopting cloud-based solutions, ensuring a robust foundation for AI adoption.

05

02 Collaborate with industry partners, academic institutions and other organisations to share knowledge related to AI implementation. Joint research projects and partnerships can lead to valuable insights and innovations, while fostering a sense of community and collective progress in the AI domain.

03

Establish a dedicated AI team or appoint AI champions within the organisation to drive AI initiatives, promote innovation and support the integration of AI technologies. These individuals should have a strong understanding of AI applications and their impact, as well as the ability to communicate the benefits and challenges of AI adoption to various stakeholders.

04

Assess the organisation’s technological infrastructure and capabilities to identify areas for improvement. This may include upgrading hardware, investing in new software tools,

Develop a comprehensive AI strategy that outlines clear objectives, timelines and performance metrics to track progress and measure the success of AI implementation. This strategy should consider the ethical implications of AI adoption and include guidelines for responsible AI usage.

06

61% of engineers feel positive about the use of AI, according to our AI survey.

Ensure that data privacy and security adhere to regulations and industry standards while utilising AI technologies. Implement robust data protection practices to safeguard sensitive information and maintain customer trust.

07 Develop ethical guidelines for AI usage within the organisation, addressing issues such as transparency, accountability and fairness in AI decision-making processes. These guidelines should be communicated to all employees and stakeholders and regularly reviewed to ensure ongoing compliance.

08 Foster a culture of learning and professional development, providing employees with the resources and training to adapt to the changing landscape driven by AI advances. Encourage collaboration so that everyone can contribute to the AI journey.

09

Monitor the impact of AI initiatives on the organisation’s performance, customer satisfaction and other key indicators. This will ensure that the organisation is leveraging AI technologies effectively to drive growth and innovation.

For more context and information, read the full report Harnessing the Potential of AI in Organisations at imeche.org

In our latest article showing the tremendous impact made by IMechE members, we speak to Laura Kershaw, who fell in love with engineering while making movies

Laura Kershaw boarded a London-bound train with big plans to break into the film industry. She was 17 and had never stepped onto a movie set. But she had permission to skip a school day and was convinced that her creativity would find a home behind the cameras.

And it did. She ended up working with Tom Cruise and Benedict Cumberbatch. She got to travel and helped to build towering sets, including a life-sized submarine designed to rise up on its side (they don’t call it Mission Impossible for nothing).

passionate about. She’s just started a year-long stint as the chair of Women’s Engineering Society’s Apprentice Board. Laura speaks at charity events and documents her own engineering adventures on YouTube and TikTok (Laura Kershaw Workshop) – hoping to inspire young women.

“When I was growing, I wish I could have seen someone who looks like me welding or working in a workshop,” she explains. “But all I saw was three men on Top Gear.”

Laura discovered the specialeffects department and put her skills to good use at different studios, from Paramount to Netflix and from Marvel to Disney.

But when, earlier this year, she took her seat on the stage where actors receive BAFTA awards, Laura wasn’t there to talk films. She was there to talk engineering. A career she’d found while making movies.

Inspiring others, one frame at a time

The event at the BAFTA venue was hosted by SheCanEngineer, a charity that promotes women in engineering. It’s a cause that Laura, a 24-year-old apprentice at an international engineering consultancy business, is

Discovering her superpower

The message she wanted to share most from that BAFTA stage was that careers don’t have to be linear. They can be “squiggly”.

“You can dream about what you’d like to happen,” she explains. “And it probably will. But not necessarily in the way you planned it.”

Laura’s first life squiggle came when she was just four. Growing up in Guildford, Surrey, she was a

‘You can dream about what you’d like to happen. And it probably will. But not necessarily in the way you planned it’

bright, creative child. She could pick up new skills quickly, whether she was playing guitar or painting hyper-realistic portraits. But at school she was struggling to keep up. Tests revealed she was dyslexic. And, while they brought some relief and a plan to tackle the learning difficulty, they also shook Laura’s confidence.

“My parents told me it was a superpower, not a disability,” she says. “They drilled into me the idea that I could do anything I put my mind to. That nothing is impossible.”

Take two: from movies to engineering

With some extra lessons and extra hours, Laura finished school with distinctions. She’d settled on the film industry but knew no one who could open a door for her. So she started to email and call companies, looking for a way in. There were a lot of rejections. Many just ignored her. She was young and had no experience. Finally, Laura decided to try a new approach: to be at the right place at the right time.

Her breakthrough came at an expo in London – the one she was catching a train to. She met someone who got her a gig as a stand-in on a movie set. Set design led to prop building, prop building led to special effects, and special effects led to an explosion of interest in engineering. She saw how ideas went from being designed on a computer to being welded together in workshops.

“The more I learnt, the more I fell in love with it,” she remembers. Laura changed direction. A little over two years ago, she applied for and landed an engineering apprenticeship. She’s loved the chance to explore powertrain systems development from all angles. She’s spent time in departments building engines,

to restore vehicles

‘When I started I was nervous there would be no one like me in engineering and no one would believe I could do it. It’s a good thing to be creative in this field. That’s where the ideas come from’

researching hydrogen fuel cells and testing emissions.

“It’s really interesting how the brain adapts to things,” she says, referring to living with dyslexia.

“I’ve learnt how my brain works and how to cope with different scenarios. I encourage others to make people aware of how they learn and think.”

Embrace your creativity

Laura’s been using her “superpower” in all kinds of ways. Having never touched a spanner, she decided to restore a 1983 Super Dream Honda motorcycle, which had spent more than a decade rusting in a barn. Learning along the way, she stripped the bike back to its frame and rebuilt it. While she was at it, she decided to learn how to ride motorcycles.

More recently, Laura found a workshop, bought welding

machines and is now restoring an old classic Mini car. You can watch her progress on YouTube. She also does photography, paints, enjoys the gym and hikes with her friends.

When she speaks to young engineers, she tells them not to be daunted.

“Don’t be intimidated by your differences,” she says. “When I started I was nervous there would be no one like me in engineering and no one would believe I could do it. It’s a good thing to be creative in this field. That’s where the ideas come from.”

To nominate an IMechE member making a difference, email profeng@ thinkpublishing.co.uk

AWE Nuclear Security Technologies is the only nuclear defence laboratory in the UK; no one else can do what we do.

Our unique mission is to deliver warheads for the UK’s nuclear deterrent and to use our expertise to support national safety and security. Our engineers support a wide range of activities delivered in high hazard environments: from warhead engineering and anti-terrorism to nuclear forensics, building services, plant and construction.

If you thrive under the challenges of a high hazard production and assets environment and would like your job to make a real difference, we’d love to hear from you.

If this has sparked your interest in AWE Nuclear Security Technologies, please see our current vacancies.

We are extremely proud of what we do and there has never been a more exciting time to join our mission. THIS COULD BE YOU AT AWE.

At AWE Nuclear Security Technologies our unique mission is to deliver warheads for the UK’s nuclear deterrent and to use our expertise to support national safety and security. For over 70 years, we have been a centre of scientific, engineering, and technological excellence, and we’re proud to call some of the world’s greatest minds in engineering and science members of our team.

The rapidly changing skyline at our Aldermaston and Burghfield sites gives an indication of the transformational change now underway to meet the future challenges of a changing world. We and our partners are delivering a cutting-edge, sustainable environment for the future, while maintaining our existing 1,000-acreplus estate that already includes many unique facilities.

Yet the impressive infrastructure programme tells only part of the story. We’re in the early stages of a significant programme to design and produce a replacement warhead for the UK’s continuous at sea deterrent, ensuring the safety and security of us all for many decades to come.

Truly extraordinary engineering

Our work can involve working with fissile, explosive and toxic materials in complex facilities. To overcome the challenges this poses and thrive in this environment requires a very specific mix of skills, experience and behaviours. We would love to hear from talented, dedicated engineers who have worked in high hazard production and who would like to supercharge their career in our unique environment.

Manufacturing is at the heart of what we do at AWE. Our manufacturing and production engineers create amazing components, with ultra-precise tolerances and extreme reliability, that are assembled into our products.

Our work ranges from the traditional to the highly unusual in terms of the materials used and the manufacturing processes employed. The scope of work undertaken by our facility and asset engineers is huge.

Our products remain in service for decades with stringent monitoring and maintenance schedules. This includes the continued, reliable use of ‘legacy’ facilities and assets –condition monitoring, reliability and preventative maintenance are key – in some cases extending the safe and effective working life of equipment beyond its originally-planned lifespan. Elsewhere, we are commissioning some of the most cutting-edge facilities and equipment on the planet in preparation for new products.

Quality, safety and security are central to our success. Our engineers must be at the top of their game every day. Continuous professional development and career progression are key to our professional approach. We take registration as EngTech and CEng very seriously, with a

comprehensive mentoring and support framework to help our people achieve these. Our engineers secure top national accolades such as Whitworth Scholarship Awards and Fellowship of professional institutions.

Today, AWE’s workforce stands at over 8,000 exceptional, diverse people. We’re consistently named as one of the UK’s top 25 best big companies to work for, recognising our commitment to our people and demonstrating that we prioritise employee engagement as a vital part of our success.

If this has sparked your interest in AWE and the opportunities we offer to progress your career, please see our current vacancies.

l For further information visit www.awe.co.uk/careers/

By IMechE president Clive Hickman OBE

Iam delighted to share some exciting updates about our headquarters building in central London. For over a century, the building has been our home, but it now needs extensive refurbishment and modernisation.

We have made significant progress in our review of alternatives for our headquarters and plan to hold a member vote by the end of the year.

Work has accelerated in recent months, and we have now entered a new phase led by the HQ Programme Sponsor Board (HQSB). The board, chaired by trustee Chris O’Boyle, will oversee the process of evaluating options for the building and consult with members through the voting process, with the goal of seeking member support for a recommended way forward.

There has been extensive work by members over more than a decade to agree a decision about the future of our HQ. We’re now ready to take this next step thanks to the work of those earlier groups and to extensive consultation and engagement with members in recent months over how to deliver a solution that will achieve widespread backing.

This decision is one of the most important in the Institution’s history and will be crucial to ensuring our long-term financial sustainability. HQSB will be working closely with the trustees, council and the executive to ensure members are involved throughout the decision-making process.

Failing to take action now will have serious consequences for

the future of our Institution and our members. These could include diverting more income from member subscriptions to cover building costs, to the detriment of other services. Parts of the building needing major repairs may have to be mothballed.

Given our headquarters’ heritage and unique location in Westminster, determining its true value is challenging and our professional property advisers have recommended marketing the building.

Bearing this in mind, the trustee board has decided to hold a two-step voting process to go to market to understand the true value of the building and evaluate options, before proposing a recommended solution to members.

l First vote (Q4 2024) – members will be asked to approve marketing the building and the process for evaluating options. l Second vote (Spring 2025) – members will be asked to approve the trustees’ recommendation for the building.

This approach, which has received input from council, ensures that members have a say at key stages.

All options identified in previous reviews of the building will be fully considered in the evaluation process.

Chris and the members of the HQSB have extensive real estate, commercial and asset management expertise, and the Institution is fortunate to benefit from their skills and experience.

The board will be tasked with overseeing the marketing and evaluating options to determine the most sustainable long-term solution, and the delivery of the recommended proposal.

Each option will be developed to the same level of detail and evaluated using predefined criteria, enabling HQSB to make a transparent recommendation to trustees of its preferred solution. Council will be asked for its advice on the recommended option before a decision is made by the trustees.

Your voice will be crucial in deciding the future of our headquarters building and ensuring the Institution remains strong and successful for generations to come.

We are committed to transparency and will be holding webinars which will be open to members to ask questions and find out more details.

l For more information, visit imeche.org/HQprogramme or contact us at hqprogramme@ imeche.org.

Holley Reece-Barkell speaks about her role as IMechE’s new Diversity and Inclusion Committee chair

What motivated you to apply to be D&I chair?

As a chartered mechanical engineer and fellow of IMechE, I’ve always felt a sense of responsibility to give back to the engineering community that has shaped my career. I previously volunteered as a Professional Review Interviewer and, when I saw the D&I chair role advertised, I thought it was a great match for my skillset. I chair the Frazer-Nash D&I committee and also lead a number of D&I initiatives within Frazer-Nash and with our clients. I was particularly attracted by the idea of bringing an industry-focused perspective to IMechE’s D&I efforts. Equally, there is best practice from IMechE, such as the Inclusion Moments, which I have used in other settings to initiate D&I discussions.

What are your priorities as chair?

I would like employees and members to feel a positive shift in the representation and behaviours towards minority groups, and I want IMechE to be recognised as leading the way in D&I across the engineering community.

To achieve this, my goals include improving the data that informs our D&I decisions and launching the Culture Ambassador network to support our work. We will build on the results of these activities to refresh our D&I strategy for the next five years (2026-31).

Most of our diversity data relates to gender and so this is

where many of our actions have focused to date. To drive the organisation towards a more inclusive culture, we first need a clear understanding of our current baseline. This requires the collection and assessment of data so we can identify priority areas from a diversity, equity and inclusion (DEI) perspective which will influence our next D&I strategy.

I would encourage members to complete the diversity monitoring form under the ‘My Profile’ section of their IMechE account profile if they feel comfortable to do so. We take security of this data very seriously and we would never share data that could be attributed to an individual. Sharing this data can truly make a difference to the future of the Institution.

Tell us more about the new Culture Ambassador network

The Culture Ambassador network will play a pivotal role in shaping the inclusive culture across our professional institution and

engineering community. We have appointed Emma Bould as Culture Ambassador Lead for members and global relationship manager Farah Baksh to represent employees. They will guide our efforts to build a network that reflects the diversity of our community. We are inviting members and staff to apply to be Cultural Ambassadors. This is a volunteer role designed to attract individuals who are passionate about working together to foster an environment where everyone feels welcomed, valued and empowered to contribute, especially if you haven’t previously found the right opportunity to do so.

This is an excellent way to engage in the Institution’s D&I work and an opportunity to make a real difference. If you are interested in taking part in the network, I encourage you to apply. l More details can be found on our D&I webpage at www.imeche.org

Would you recommend volunteering to others?

Absolutely. Volunteering has helped me to raise my professional profile, expand my professional network and have a positive impact. The members and employees I met have been incredibly welcoming, supportive and curious to learn more.

I would like to encourage members from all backgrounds to get involved, whether by taking part in IMechE committees and events, through attendance and also participation as a speaker, organiser or chair. These opportunities are invaluable for professional development and for becoming visible role models within the engineering community.

The Silverstone paddock is always a hive of activity before a weekend of Formula Student track events, with the noise and bustle of cars being taken apart and reassembled. But those sounds were replaced with the tapping of keyboards and clicks of mouses in some garages this year, as more teams than ever took part in the IMechE competition’s autonomous FS AI element.

The increased focus on selfdriving cars at this year’s event (17-21 July) was enabled by a grant from the Centre for Connected Autonomous Vehicles (CCAV), which funded two more shared driverless cars, and re-engineering of two existing ‘dedicated vehicles’. The four IMechE cars were controlled by autonomous navigation and driving systems developed by the students.

The 20 FS AI teams this year needed to “think a different way” to the groups building humandriven internal combustion (IC) cars and electric vehicles (EVs), said engineering design judge Willem Toet at the event. “You have to think about computer programming and analysing pictorial data.”

The AI element is a good way for universities that do not have big budgets to get involved, Toet said, because they do not have to build their own cars.

“It actually opens things up to students with good brains, who don’t have the budgets or the facilities to build a complete car –that I love,” he said to Professional Engineering. “The programming experience that the students have will land them great jobs.”

Techniques honed at the competition are useful for features

including adaptive braking, cruise control and lane assist, he said, as well as in fully autonomous cars in future.

‘Higher playing field’

Oxford Brookes Racing is one of FS AI’s most successful teams, and came second in the category this year. “Each year we compare ourselves to the competitors, people who are ahead of us, and see what changes we can make to cross that level,” said team leader Mihir Gohad.

This year, that involved development of a new sensor plate, with a GPS accurate to 2cm. “We also have a thing that we call a magic box, which gives us wireless telemetry access while the car is running. We can monitor critical systems, like a mission control. Because in dynamic events we get 15 minutes, so we need to know, do we need to abort the current run, reset, or do we let the car go?”

The high level of communication and data collection allows the team to maximise their use of the available time. “If you do a fast run and there’s some behaviour that is undesirable, you can change your system to correct or change the behaviour. Sometimes you might have multiple strategies, based on the event, so you can switch strategies to get a better result.”

Taking part in the AI element “is like a higher playing field,” he added. “It sets you up for a good

career path, because autonomous vehicles will happen some day. If you get in early, you will be in a good position down the road.”

Optimised performance

Innovation at the event was not limited to autonomous teams. Grand champions Edith Cowan Racing, who travelled all the way from Perth in Western Australia, used a new rear suspension system known as the integrated powertrain suspension (IPS). The axle of a micro sprint car is mounted to a triangular mechanism, which also holds the engine. With two tie rods at the sides and two suspension pick-ups, the entire rear suspension can unbolt from five bolts.

Team leader Ashley Ure explained how the design allows for easy disassembly and reassembly, and how it improves performance on tight Australian tracks.

‘It actually opens things up to students with good brains... The programming experience that the students have will land them great jobs’

“We are really looking to optimise our performance on track,” she said. “They run really tight tracks, even in comparison to the UK track. It’s actually quite a lot faster over here. So what we want to do is make sure that our vehicle can rotate… our drivers find that it’s actually really predictable.”

The approach paid off, with the team winning the sprint and

The 10th UAS Challenge competition was a great success

More aircraft flew than ever before at this year’s UAS Challenge thanks to increasingly enthusiastic and engaged participants.

The event’s 10th anniversary was “the best we’ve had”, said chief scrutineer Rod Williams, despite some challenging weather at BMFA Buckminster in rural Leicestershire in early July. Twentyfour teams took part, with 16 successfully flying their unmanned aerial systems (UAS) in simulated humanitarian missions.

endurance track events, as well as the engineering design trophy.

After a trial last year, all IC teams were provided with 95 Ron E10 and E85 sustainable fuels, which offer an 80% reduction in greenhouse gas emissions compared to fossil fuel equivalents.

The new options provided a “bit more power” compared to petrol, said Staffordshire University team leader Angel Dong. The fuels can run on the same engines, saving extra engineering work.

The team, which came fourth overall, was able to instead focus on aerodynamics, developing a full aero package for the first time. “It was a lot of innovating, a lot of learning composites.”

Williams said the drones, designed and built by student teams from British and international universities, were in better shape than ever. More support from universities, which are increasingly building it into degree schedules, and IMechE – which ran webinars explaining each phase of the project –explains why teams are better prepared, Williams said. There is also more enthusiasm from students, he added. “From every aspect there’s more engagement, we’re much more used to it and they’re much more engaged, and joining in greater numbers,” he said.

Increasing focus on the competition’s endurance

element is driving teams towards more fixed-wing bases, Williams said, which involve more technical design than simple quad- or hexacopters.

Seventeen designs were pure fixed-wing, one was a helicopter, and six were VTOL (vertical take-off and landing) tilt-wings or hybrid aircraft. The team from the Estonian Aviation Academy even had a Flying V blended-wing design.

Innovation is “nice to have” but effective operation is the paramount concern, said Williams. “It’s putting things together well that are simple, that makes it more effective, and makes it deployable to an NGO (non-governmental organisation) somewhere out there… can they put it together in the simplest way and get it flying as soon as possible?”

Teams put some good thought into that this year, he said, including a focus on maintainability.

The winning team from Beihang University in China was “very organised,” Williams said. “When they were putting it together there were nine of them, but they were coordinated, controlled, with someone doing quality checks.”

He added: “It was two-prop, V-tail, high-wing… it wasn’t just botched together, the quality of what they did was very good, and they scored, clearly, very highly on the missions.”

For more information, visit imeche.org/events/formula-student and imeche.org/events/challenges/aac-challenge

Got something to share with the IMechE community? Write to us at profeng@thinkpublishing.co.uk, using the subject line ‘Your Voice’

Self-charging at a standstill

A couple of months ago I bought a relatively new Toyota Yaris selfcharging hybrid in an attempt to get onto the eco trail.

Within weeks I discovered that ‘self-charging’ is not entirely accurate!

I quickly experienced several events where the battery did not have enough power to start the car, putting hospital appointments in jeopardy and requiring the dealer’s mechanics to start the car.

Whilst I looked for a solution, I bought a jump-starter power pack for peace of mind.

The final advice from the dealer is to connect a trickle charger every time I garage the car.

It turns out that I don’t drive far enough to charge the self-charger’s battery, as it is not a priority to charge the battery to have enough charge to restart the car.

Being a mechanical engineer, I thought it would be an easy programme modification to test the state of the battery and give priority to restore that battery first, but no.

So effectively I have a selfcharging hybrid which does not charge itself.

Am I alone in thinking the model needs a name change?

Brian Burgess

Pioneering nuclear design

In your article about nuclear decommissioning, it was stated that the designers of the Dounreay fast reactor did not incorporate a method of draining the sodium/ potassium coolant (“Powering down,” Professional Engineering No 1, 2024).

In fact the fill/dump line, which terminates at the base of the reactor in a flattened nozzle, was used in 1967 to drain the coolant so that

National effort needed to source biofuel

With reference to Tom Austin-Morgan's comprehensive summary of the options for decarbonising aviation, I believe he was somewhat too pessimistic on one small point (“Decarbonising aviation,” Professional Engineering No 1, 2024). That is that the supply of potential feedstock for biofuel production is limited. If any waste organic material can be considered as potential feedstock, there would seem to be a virtually unlimited supply. The problem is collecting it. Perhaps a national collection scheme run in parallel with current recycling systems could be arranged.

If every available source of organic waste, from agriculture, forestry, domestic, fishing, food processing and even sewage, were included, with suitable financial incentives, I suggest that more than enough for both aviation and road transport could be collected. The only limitations would then be the supply of renewable and nuclear electricity and the finance to design and build the manufacturing plant. Its use in both existing and new aircraft would accelerate progress to net zero compared with all the other, new-design-only, alternatives which are unlikely to make a significant impact as a proportion of the total aircraft fleet until the 2040s. This option would also have the effect of reducing disposal of waste to landfill.

John Hardaker

the primary circuit leak could be repaired, and again in more recent times to finally drain the system as part of the decommissioning programme. This operated on a simple pressure differential.

My memory is a bit sketchy on the prototype fast reactor which followed, but it also had an installed drainage system for the sodium coolant. This was of a more complicated eductor type, I believe because of the greater height of the reactor. This was not used to ultimately drain the system –instead a main pump was installed in place of one of the coolant circulators, and later a smaller pump was installed through the

fuel carousel to remove the dregs at the base of the primary tank. Robin Herrick

Due to climate change we are now being subjected to major floods regularly and the economic and human suffering cost is escalating. I wonder if it would be possible to pressurise houses to say 1.5psi, thereby holding back 3ft of water. It would mean sealing air vents, drains, toilet etc, and shutters to protect windows. A diesel/electricdriven air compressor would do the pressurising. Is a trial of this idea worthwhile?

Phil E Lambley, Hinckley, Leics

After a chequered history, paddle steamer Waverley is still plying the waves, and won an IMechE award

In 1940, the paddle steamer PS Waverley was sunk while ferrying British troops back from Dunkirk. Its replacement, also called the PS Waverley, was built in Glasgow in 1946 and like its predecessor takes its name from Sir Walter Scott’s first novel. It was built for the London & North Eastern Railway for the Firth of Clyde steamer route, which ran from Craigendoran Pier near Helensburgh up Loch Long to Arrochar.

The ship was withdrawn from service in 1973, but between 2000 and 2003 it underwent a substantial rebuild at Great

Yarmouth, with new boilers installed with the help of funding from the Heritage Lottery Fund. It then returned to service as a passenger ferry – the last seagoing passenger-carrying paddle steamer in the world, with room for up to 800 passengers. It has a displacement of 693 tons and a Rankin & Blackmore tripleexpansion steam engine producing 2,100hp at 58rpm. In acceptance

trials it has achieved 18 knots. The ship resumed passenger excursions from Bournemouth, Glasgow, Southampton and London. In 2011, the ship was awarded an Engineering Heritage Award by IMechE, but in 2019 it was withdrawn from service owing to boiler problems. A fundraising appeal secured £2.3m, and by August 2020 the PS Waverley was back on the water.

Find out more about the Institution’s history at www.imeche.org/engineering-heritage-awards

Southern Manufacturing & Electronics, the UK’s largest annual industrial exhibition, returns to Farnborough International Exhibition & Conference Centre from 4th to 6th February 2025, now under the ownership of Easyfairs, a European leader in events. Since its debut in 1997, the show has been a key platform for showcasing new engineering and manufacturing technology.

Attendees can explore the latest in mechanical, electrical, and electronics manufacturing, along with ancillary products like labelling, freight forwarding, and training. The event attracts professionals from design, production, procurement, and management who are looking to stay updated on advancements in

machine tools, automation, robotics, and more.

Easyfairs aims to expand the event while maintaining its collaborative atmosphere, which has drawn both large manufacturers and small to medium-sized enterprises for nearly

three decades. The open-access policy fosters a vibrant, inclusive environment, encouraging crossdisciplinary interaction.

The 2025 show will also feature a technical seminar program, which Easyfairs plans to grow, emphasizing education and sustainability.

Including AutoAero as an integrated zone, the event will highlight key developments in automotive and aerospace engineering, sectors vital to the UK economy.

Visitors can enjoy free admission and parking, along with complimentary shuttle services between Farnborough’s railway stations and the exhibition.

l Register now at www.southernmanufacturing-electronics.com/

This has been absolutely fantastic—far beyond our expectations! The turnout has been incredible, with more visitors than we ever anticipated. We’ve attended other shows across Europe in recent months, and this one is by far the largest. The energy has been amazing right from day one, with a constant flow of enthusiastic visitors. We’re thrilled with the outcome!

Agnieszka Radecka Regional sales manager, TME

With a new government, there is a fresh opportunity for engagement with policymakers on key issues. Lydia Amarquaye, IMechE”s education policy lead, examines the policy shift in education and skills

The Labour Party’s manifesto and the king’s speech outline a policy agenda to address skills shortages and overhaul the provision of education and skills in the UK. Central to this renovated vision is the establishment of Skills England, an initiative that resonates with IMechE’s commitment to fostering engineering excellence and supporting the growth of the engineering workforce.

The government’s announcement of the creation of Skills England marks a significant step towards integrating

training with the country’s labour market needs. This new body aims to incorporate businesses, training providers, unions and government entities to create a cohesive and dynamic skills system. By placing employers at the heart of skills development, this new government body aligns with IMechE’s vision of ensuring that engineering education meets industry demands and that stakeholders collaborate towards common goals. With Skills England assuming some functions from the Institute for Apprenticeships and Technical Education, we will continue

to ensure that employer engagement is maintained, and vocational qualifications remain relevant to sector needs.

The apprenticeship levy reform is part of the government’s plan to introduce a growth and skills levy to address the skills shortage and align training with the country’s needs. The reform will provide businesses with greater flexibility to invest in a broader range of training programmes, including non-apprenticeship courses, which is crucial for the engineering sector,

Boost your savings. IMechE members receive up to 20% off on top technology.

Laptops & Desktops

SAVE 5% OFF

Get your discount on Latitude and Optiplex business laptops and desktops.

Accessories

SAVE 20% OFF

Get your discount on wide range of products (excluding Alienware accessories).

Access your exclusive member discounts by scanning/clicking the QR code and using the unique password 'IMECHE' © 2024 Dell Inc. All rights reserved. All offers valid until 2nd August 2024. Offers apply to 'Small Business Partnership' members only. Small Business Partnership discount coupons can be used in conjunction with other offers or discounts. Coupon codes applied in basket at check-out. Subject to availability while stocks last. Maximum 5 units per customer during promotional period. Prices and specifications are correct at date of publication but subject to availability or change without notice. Purchases from Dell.co.uk only (excludes Outlet store). Terms and Conditions of Sale and Service apply, see dell.co.uk/terms. Photos for illustrative purposes only -actual items may differ from photo. Dell is not responsible for errors in typography (including pricing errors) or photography. Not valid for resellers and/or online auctions. Dell Corporation Limited. Registered in England. No. 02081369. Office address: 1st and 2nd Floor, One Creechurch Place, London EC3A 5AF. Dell Services do not affect customers' statutory rights.

SAVE 6% OFF

Get your discount on all PowerEdge Servers.

Building partnerships between schools, colleges and employers will equip young people with work-ready skills

Above: Young people will be offered two weeks‘ worth of work experience

where diverse skill sets are required to meet the challenges of modern industry. Lifelong learning is a core value of the work of the Institution, and this could play a major part in how businesses choose to upskill their employees.

The Labour government plans to devolve adult skills funding to combined authorities, empowering local leaders to tailor skills development to regional needs. This approach echoes IMechE’s advocacy for localised solutions that address industry challenges by fostering innovation and growth in engineering communities across the UK.

Labour plans to recruit 6,500 teachers to address the teacher recruitment crisis, particularly in shortage subjects. IMechE has been working with the government to encourage engineers to become physics teachers, and it is recognised that there is a shortage of STEM teachers overall. We hope IMechE can

complement this work by supporting educators in delivering top-tier engineering education.

and assessment

The government will launch a curriculum and assessment review that aims to create a curriculum that enhances school standards and prepares young people for life and work. This initiative seeks to address challenges in educational attainment and remove barriers that hinder opportunities for socioeconomically disadvantaged children and those with special educational needs or disabilities. The desired outcome is that people aged 16-19 will have access to rigorous and high-value qualifications and training, preparing them for the evolving workplace. It will also evaluate the current assessment system to explore potential improvements, maintaining the essential role of examinations while considering the impact on

students and staff. IMechE will support this review by providing evidence, highlighting the importance of adding real engineering examples across the curriculum, showcasing careers and role models.

As part of the government’s plans to partner with business, it has announced a new commitment to two weeks’ worth of quality work experience for every young person and to recruit more than 1,000 new careers advisers, building partnerships between schools, colleges and local employers to equip young people with work-ready skills. This is an important development, especially for engineering, as discussed widely in a review led by EngineeringUK. IMechE already provides virtual work experience, and we hope companies represented by IMechE will also see the importance of providing this work experience, both for them and the wider sector.

l IMechE remains committed to supporting its members and the government in delivering policies that ensure that the UK remains a leader in engineering innovation and development.

Impact

The Tinius Olsen IT impact range can be configured for Charpy and/or lzod tests, for manual or automated specimen feed, from O.SJto SOJ.

Impact Accessories

Available from Tinius Olsen; Test specimen notch er and notch verification stations.

Tinius Olsen offers solutions for testing the strength and performance of plastics through tensile, flexural, compression, folding endurance, impact, head distortion, vicat, melt flow, tear and puncture tests. Our versatile benchtop polymertesting machines can perform tests in accordance with ASTM, ISO and other international standards from test configuration through to reporting and generating results immediately for your processes.

Contact us now for information on our full range and help with enquiries.

The Tinius Olsen MP1200 model is configurable from a standard procedure A format through procedure B and on with automatic motorized weight application capability, post test polymer purge and cleaning.

A step change in extensometer technology capable of replacing multiple contacting and non-contacting sensors with a single, industry specific instrument. Integrating adaptive Al capabilities with optical hardware, Vector reduces test throughput times and complexity, automating the process of capturing strain, improving measurement accuracy, data consistency and operator safety.

Firms must balance costs and legal compliance when deciding how to ensure safe operations

ngineering firms have a duty to take reasonable measures to ensure that everybody who comes into contact with their operations is unharmed by them. This has a cost, and those in charge of health and safety must decide what to spend.

The law says these costs should be As Low As Reasonably Practicable (ALARP). This is intended to ensure that, while operations are safe, the costs do not render companies financially incapable of operating.

The ALARP principle was enshrined in UK law in 1949, and in the Health and Safety at Work Act 1974, which requires “provision and maintenance of plant and systems of work that are, as far as reasonably practicable, safe and without risks to health”.

This is interpreted to mean that risks must be reduced to an ALARP level. In short, duty holders must reduce risks unless the cost of doing so is grossly disproportionate to the benefits. The law assumes that safety measures are implemented unless they are ruled out due to being disproportionately costly.

Duty holders need to ensure that all reasonably foreseeable hazards have been identified, and that all “reasonably practicable” control measures are implemented unless they are “grossly disproportionate”.

This requires the costs and benefits of a control measure to be compared. The Health and Safety Executive (HSE) provides guidance “to spend £1m on preventing five staff suffering bruised knees is grossly disproportionate, but to spend £1m on preventing an explosion that would kill 150 people is obviously proportionate”.

ALARP applies to everything from daily costs of supervising employees through to the management of rare but extreme events. It puts the

obligation on the duty holder to determine the appropriate level of risk mitigation. It can be difficult to interpret and implement this vital law, particularly as an assessment of the balance of cost and benefit relies on an understanding of the likelihood of a hazard which can be specifically challenging when assessing complex engineering systems.

The IMechE Safety and Reliability Group have produced guidance to help engineers understand and discharge their responsibilities, as well

‘To spend £1m on preventing an explosion that would kill 150 people is obviously proportionate’

as deliver robust safety engineering. A key element of this is the concept of the ‘Well-Reasoned Argument’ which is the rational explanation of how ALARP has been achieved, and where risk quantification is used to support the argument that it is based on sound statistics and robust data. There’s also a ‘proportionality matrix’ that provides a framework to help engineers understand the level and depth of analysis they should undertake based on the worst reasonably foreseeable consequence. For example, ensuring compliance with recognised practice and standards may be sufficient for

situations with limited potential for severity, but not for complex systems with potential for multiple fatalities.

ALARP is not static as the nature of the hazard, the mitigation costs and available risk mitigation technology change over time. Regular structured reviews are therefore required to ensure that risks remain ALARP.

Duty holders must be able to satisfy themselves that they have taken all reasonable measures to reduce the risk profile and also demonstrate that further measures do not pass the disproportionate test. Assessments and decisions relating to gross disproportion are rarely obvious and can be very subjective in nature. Organisations need to understand these difficulties and develop robust processes, that are appropriate given their specific context, to ensure that the risks associated with their products and operations are ALARP.

The IMechE report ALARP for Engineers: A Technical Safety Guide has been updated for 2024. Read it at imeche.org/policyand-press/reports/detail/alarpfor-engineers-a-technical-safetyguide

Throughout the decades, Support Network has always been there to help and connect with members.

11a small monthly allowance to a member 72 years old, without work, savings or means"

Last year marked the 110th anniversary of Support Network. Since 1913 we have assisted members of the IMechE and their families, helping them to face and overcome unexpected circumstances in their lives. Established long before the creation of the welfare state, Support Network, originally known as The Benevolent Fund, then (and until recent times) was undoubtedly a significant safety net for members who were injured in conflict. developed chronic health conditions or who passed away, leaving widows and children otherwise without support.

Extracts from our early case records -written long hand with a fountain pen into a leather-bound tomeshine a light on the social conditions of the time, and The Benevolent Fund's response. It provided "a small monthly allowance to a member 72 years old, without work, savings or means". It supported another member, who was physically impaired

due to rheumatism, by helping him move into a medical home and paying his maintenance fees, plus the "occasional provision of small comforts".

Support Network continues to care in an holistic way, by providing services and specialist support in addition to grants and loans. The past decade in particular has seen the development of new services including counselling

(on line, telephone and face to face); dyslexia, ADHD and autism support; employment coaching; a parenting helpline to improve our mental health interventions; enabling engineering careers, with particular reference to students, newly qualified and STEM returners; establishing a foundation funding activity to improve lives through engineering; and placing diversity and inclusion at the heart of all that we do.

In 2023 we were increasingly aware of our global membership, with most of our student assistance being to those members who were studying outside of the UK, plus the expansion of our lunchtime webinar offerings to include wellbeing, financial, and family themes further increased our reach and brought members closer to our work, utilising technology that was far beyond the imaginings of our founders.

I've got a lot more freedom now - this bike and your support has been truly liberating"

Mr Fry, an IMechE member, contacted us for assistance to help purchase a bespoke recumbent bicycle for his wife. Following health difficulties she was no longer able to use her regular bicycle and very much missed being able to join her husband and children on family outings. She also wanted to be able to accompany the younger children on their journey to and from school. She said that not being able to fully participate in these family times had left her feeling excluded and very low. As Support Network also assists the close relatives of members, we were able to respond, and worked to ensure that the bicycle was available in time for the Easter holidays, so that it could be of maximum impact in the shortest time.

During the personal visit to understand more about her needs, it became clear that Mrs Fry had started to wonder whether she

might be autistic, as that would explain many of the challenges she had faced as a consequence of the family needing to relocate several times for work and to keep starting over. As Support Network helps in a variety of ways, we were able to offer a referral assessment for Mrs Fry and access to specialist peer groups. This also inspired us to expand the neurodiversity support that we provide, and we introduced a more in-depth service to support autism, ADHD and dyslexia needs in 2023. This was a good example of how spending time, and especially talking face to face, can often lead to identifying issues other than those that were first presented. Support Network is one of the few organisations in our sector to use this model, and we do so as we feel that membership matters. Mr and Mrs Fry have kindly given their permission for us to write this article.

11 1 don't know how I would've managed without your help"

When Rachel's partner was diagnosed with a serious health condition (thankfully now resolved), her world suddenly "turned upside down". Her family faced an uncertain future as she tried to manage bills on a single income, maintain school routines, and keep up with work, all while worrying about what might happen next. Support Network provided a 'breathing space' grant, offered additional help during the school holidays and was there to lend a listening ear. We also intervened to

ensure that overdue heating repairs were finally undertaken by her landlord: "When everything fell apart and it was so overwhelming there was always the contact from the volunteer Visitor, telephone calls, texts,just

Why did I join the board?

I have been a Support Network volunteer since 2010, undertaking visits and helping with case requests. The organisation is managed by a small and dedicated team, who deserve all the support I can offer. The Trustee Board is similar -a diverse group of very committed individuals -currently representing many aspects of the IMechE membership. Hence it was an easy decision to say 'yes' when the opportunity to join the Board arose in 2023, and there have been no regrets.

Impressions to date?

All the people involved are very approachable. Similarly, the processes and procedures used to make decisions on who and how to support are very considered and logical, with room to shape to the individual; it's all very inspiring.

Future activities for Support Network?

The challenges facing the organisation are all positive -how and where to develop our services and foundation funding reachin short, how to do more of our needed work and share more of our resources doing so?! Effective communication is key. We aim to be globally inclusive and prioritise reaching those starting their posteducation IMechE membership.We anticipate Africa and Asia leading the way, continuing to help improve mental and physical wellbeing and ideally investing in engineering innovation for social good.

knowing that there was someone there for us. It wasn't just the practical help and grants that made such a difference, it was how you did this that mattered so much; you made kindness so very meaningful. I don't know how I would've managed without your help and your caring interest in me and my family-we will never forget that."

Support Network continues to be proud of the foundation funding work that we began in 2020. This stream of our work enables us to reach and have a positive impact on many more people and their potential engineering futures.

After three complete years of operation, Support Network has made 13 awards to organisations working

in a STEM related way in the areas of international development. education and/or engineering innovation -areas which also align with the objectives of the IMechE-with the amount granted being almost £400K. The impact of this has been significant and rewarding.

The foundation funding project activity undertaken in 2023 included the construction of a suspended trail bridge in Nyacyonga, Rwanda. Support Network partnered with Bridges to Prosperity and local residents to install a bridge that would serve five communities in the Kicukiro District by connecting them to health care, government services and markets, as well as primary and secondary schools.

Due to the river often flooding in the rainy season, or the force of the water weakening the previous log bridge, children and adults alike were either putting their lives in jeopardy

11When it rained the children could not go to school and we could not leave our home until the sun came out"

through attempting unsafe crossings or were simply going without access to education or medical assistance. As a consequence, many community members were injured or sadly lost their lives. The certainty of the crossing has started to lead to social and economic stability, with improved incomes, lives and futures.

"Before the bridge we used to cross in a very unsafe place. When it rained the children could not go to school and we could not leave our home until the sun came out and dried the path. Now

Support Network plays an integral role in assisting student members not only to complete their studies but also to progress into their mechanical engineering careers. We provide hardship grants to IMechE members who are undergraduates, Masters students or Apprentices, and prioritise those in their final year or stage.

Help is available on a global basis, and in 2023 we received many applications from students in Nigeria. We are indebted to our international Trustee, Chukwumaoge Onunkwo (right}, himself Nigerian,

who was able to provide an in-country assessment of the differing needs and to offer suggestions about the best way to help individuals.

As a result we developed a new model of working directly with the academic institutions in order to ensure that our help reaches those who most need it. Our Newly Qualified fund assists members in the first three years of their careers to meet transitional costs of relocating, setting up home and taking their first steps.

thanks to the bridge, no one will have to worry about crossing the river, plus the hospital and the market can be reached. Thank you so much!"

Through this work and partnership, Support Network has been able to add contributions in two more of the United Nations Sustainable Development Goals (see below) than we were previously working in.

11I'm so proud of all that I've achieved, I didn't think graduating was within reach and now I have a degree and my first job in engineering! I am so very grateful for your belief in me"

assistance included:

10 Newly Qualified grants to help with first steps in STEM careers

200 Student and Apprentice grants, awarded to international and UK based mechanical engineering students (vs 21 grants in 2022)

145 'Breathing space' grants to help members pay essential bills in times of transition or unanticipated circumstances

183 Fuel and Winter Warmth grants given to either those on fixed incomes or households with disabled and/or vulnerable members

Wellbeing support included:

19 respite breaks for carers and other care costs grants

74 counselling grants to help manage mental health difficulties or past traumas

115 social visits, calls and on line contact made by our volunteers

Practical help included:

7 health, disability, autism and dyslexia related costs or access to specialist support

18 sleep support programmes provided to tackle the underlying causes of poor sleep

39 employment coaching and CV specialist referrals to help members get back into work

160 callers used the legal helpline and downloadable factsheets for advice on tax, probate and housing matters

International grants included:

1 plastic additive machine purchased to help recycle retrieved beach plastic into goods (Kenya)

63 young people participating in small business start ups in tuk-tuk repair and micro finance (Uganda)

350 pupils receiving enhanced STEM lessons through ENTHUSE partnerships (UK)

11Reaching out for help was the hardest part, but I'm so glad that I did. Thank you for everything."

Colin contacted us when he was made redundant after working for the same engineering company for 25 years. Whilst losing his job was a shock, it was nothing compared to the mental impact that developed over the following months of unemployment. He found the recruitment process to be very different to when he had last applied for a position and he found his lack of purpose was difficult to manage.

We referred him to our employment coaching specialists who provided technical help on how to navigate the digital job market, and also identified the need for talking therapies to help address impaired self esteem, which Support Network was able to source. Through his counselling, Colin realised that although his redundancy was not fault based, it had nevertheless triggered deep feelings from his younger years which were hampering his best attempts to move forward. Colin persisted with this therapy and

employment coaching and now has a new position. He has joined the running club at his new employment and is "in a much better place. I've come a long way since those early difficult days. Reaching out for help was the hardest part, but I'm so glad that I did. Thank you for everything."

To discuss how we might be able to help you, or for more about us, email supportnetwork@imeche.org or text/Whatsapp/call/leave a voicemail on 07552 669160 www.imeche.org/supportnetwork

To view the full 2023 financial accounts and activities report visit www.imeche.org/support-network/governance

Plastic INylon ICarbonIWax IRubberIPeek IUltemTM

• SLA

• SLS

• MJP

• DLP

• CJP

• BJP

Stereolithography SLS300. Sinterit

Pro jet 2500+ W IC Figure 4

Pro jet 660 Pro Concr3de

• FFF Omni. Fusion

• FFF-HT Funmat Pro 610 HT

For a quotation please send your STL file to:

rep1ik8@cdg.uk.com 01420556755

Make sure your CV is perfectly aligned to the job description. Support Network can provide one-to-one career coaching to you or a member of your family. Support is available \ on an international basis. And it's free.

Good advice is on offer to enable operators of heat recovery steam generators to keep their technology up to date

To most people, the age of steam is in the past. It conjures up images of mighty locomotives thundering through viaduct-strewn landscapes; beam engines powering mine pumps and factories; huge ships with heavy chains, designed by gentlemen in stovepipe hats.

Engineers know different. Most of our electricity is generated by turbines spun by steam at high pressure. The energy that boils the water comes from a variety of sources but effectively we can still be said to be in the age of steam.

So it’s vital to ensure that as little as possible of the energy that generates that steam is wasted. In particular, if a fuel is burned to generate steam by boiling water, then the gases given off from burning the fuel will be hot, and that heat can be used to boil more water. The equipment used to do this is called a heat recovery steam generator (HRSG), and these are standard and vital components, not only in power stations but in most industrial plants that have boilers, as the steam they generate can also be used as process steam (for example to heat chemical reactions), or as part of a heating system.

HRSGs are a specialised branch of engineering. They share commonalities with process engineering, especially where it overlaps with power engineering, as they are effectively a subcategory of heat exchanger, where hot gases flow past tubes containing a cooler circulating fluid, arranged so that the hottest flue gases are brought against the coolest circulating fluid.

There are several different types of HRSG. One classification derives

from the direction of flow of the flue gases that enter the equipment. This can be horizontal, in which case the water that the gases are heating flows in vertical tubes; or vertical, in which case the water flows in horizontal tubes. Apart from the orientation, the main difference between the two is that, in a horizontal HRSG, fluid flow is powered by the higher density

Heat recovery steam generators are vital components, not only in power stations but in most plants that have boilers

of cold fluids than a hot mixture of water and steam; these are therefore also sometimes known as natural circulation systems. This can’t be the case in a vertical HRSG, so their horizontal fluid flow is assisted by pumps: these are sometimes known as forced circulation systems. Vertical HRSGs tend to occupy less space

Above: ‘Effectively we can still be said to be in the age of steam’

than horizontal systems and are faster to start up.

Another classification for HRSGs derives from how the steam raised by the system is handled. In one type, steam is stored in a drum and sent for further heat exchange with hot flue gases in a section called a superheater, while liquid water is recirculated; the pressure in the drum builds up over time, so it must be made from thick metal to withstand its maximum pressure level. Another type is the “oncethrough” HRSG – as the name implies, water is not recirculated and is only heated by the hot flue gases once. Other classifications refer to whether the steam generated is at a single pressure or at multiple pressure levels; power plants tend to use multiple pressure level systems, with several steam drums at different pressures.

Enjoy peer-reviewed technical presentations and learning opportunities at this year's HRSG User Group meeting on 6-7 November at the Holiday Inn, Coventry. Attend to understand how to keep your technology up to date, enhance its operational lifespan and remain competitive in the market. Hear successful strategies and

new technologies to enhance the efficiency and operational lifespan of your heat recovery steam generator assets. Share expertise and guidance with manufacturers, owners, operators, engineering thought leaders and maintenance contractors.

Find out more at imeche.org/ events

Engineering can solve some of humanity’s most pressing challenges, says the new IMechE president Clive Hickman OBE

By Joseph Flaig

For Clive Hickman OBE, home and vocation are as closely related as the pistons and valves inside an engine. “The Black Country is the heart of manufacturing in the UK –always has been, always will be,” says the new IMechE president. “Other places have tried to emulate us, but it’s still the core, it’s where the industrial revolution started.” Manufacturing is in his blood – and, half a century into a richly rewarding career, he says his passion for it is only growing.

Born and raised in Dudley, Hickman realised he wanted to work in engineering as a young teenager, when he spent his time messing around with cars. “Trying to keep them on the road most of the time,” working on the “old bangers” was much more accessible than it is now, he says. “In those days, with a spanner set and a little bit of an idea of what you’re doing, you could work on most things on vehicles.”

It seemed like a natural progression to go into engineering. After O-levels, he took a job working for a fire detection company, which put him on an apprenticeship. This resulted in an ONC (Ordinary National Certificate) qualification, after which he studied and received a first-class honours degree in mechanical engineering from Wolverhampton Polytechnic. A PhD in engine-driven heat pumps at Aston University followed a few years later.

His career went from the graduate development programme at GKN to a powertrain development job

‘How can we influence government to take a greater interest in what we do in manufacturing in the UK?’

at Longbridge after his PhD. From there he went to the Motor Industry Research Association (Mira), where he worked his way up to director of engineering.

He joined the business development group at Ricardo, going on to become managing director of Ricardo UK, where he was head of projects including powertrain development for the Bentley that was presented to the late Queen on her Golden Jubilee, the transmission for the Bugatti Veyron, and the first homegrown engine for JCB. He was then headhunted by Tata Motors, working on the low-cost Tata Nano as head of engineering in India.

In 2010, he returned to the UK and set up the Manufacturing Technology Centre (MTC) in Coventry, which had previously been “a bit of an idea, rather than

anything that was real”. Hickman, the centre’s first employee, has grown it to a £120m turnover business with almost 1,000 employees. He became chairman in March 2023.

Also chairman of clean transport company TRL, Hickman received his OBE in the 2022 New Year Honours List for services to engineering, manufacturing and technology development. His work at IMechE has included time on the boards of the automobile division, the manufacturing division, the trustee board award committee and the qualifications group. He has chaired the technology strategy board, the commercial and finance board, and became president in May. We asked him about the challenges ahead.