5 minute read

Forging ahead Böhler Schmiedetechnik

FORGING AHEAD

Leading manufacturer of forged components for turbines and the aerospace industry, Böhler Schmiedetechnik GmbH & Co KG, a subsidiary of the listed voestalpine Group, is committed to utilising its extensive knowhow to deliver high quality parts to high tech industries. Emma-Jane Batey spoke to the managing directors, Thomas Kornfeld and Martin Reicher, to find out how this is being achieved.

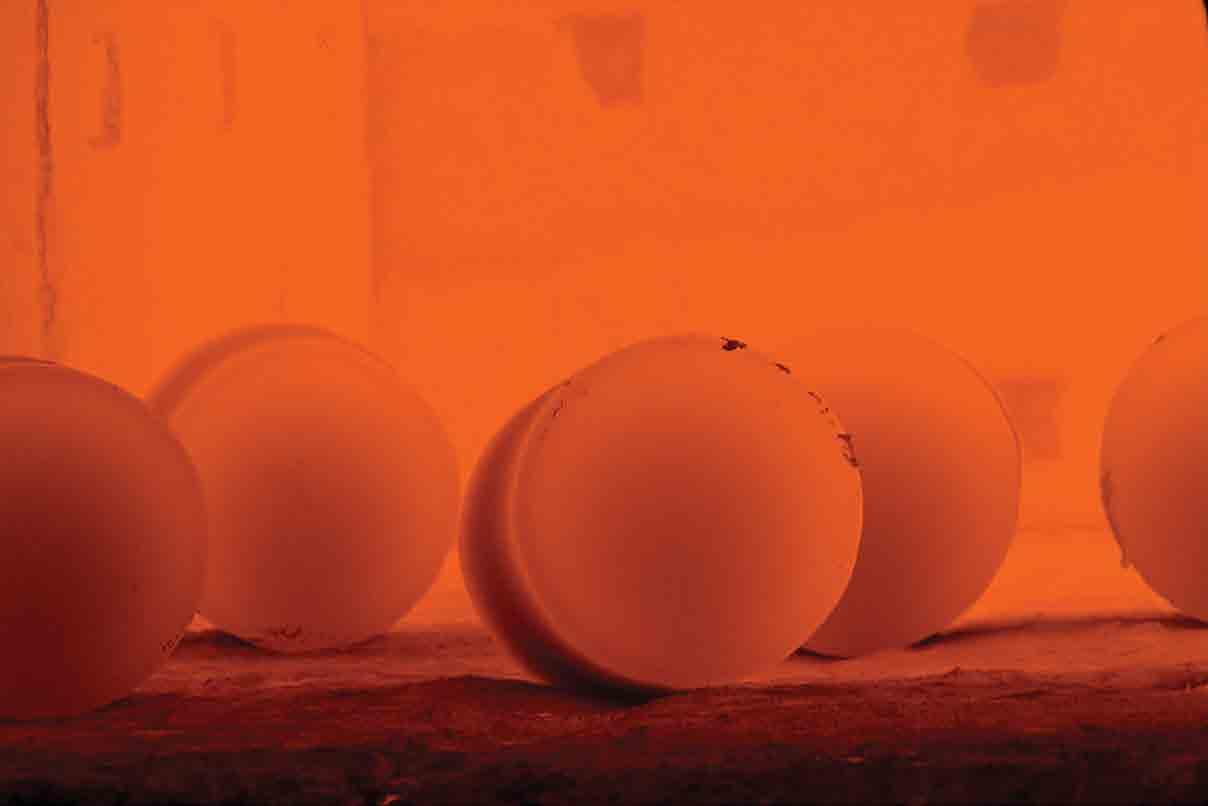

Founded in Austria in 1991, specialist forging company Böhler Schmiedetechnik GmbH & Co KG is a part of the wellrespected voestalpine Special Steel Division. Designing, manufacturing and delivering high quality forged components for turbines, the aerospace industry, power generation applications and other high tech industries, Böhler is highly regarded as a technically advanced partner by its customers worldwide.

Commercial managing director of Böhler Schmiedetechnik GmbH & Co KG, Thomas Kornfeld, told Industry Europe how the company’s reputation for excellence has long allowed it to stay at the top of its game. He said, “We have focused on continual investment in people and equipment since 1991, which has proved to be a solid business development strategy that benefits both us and our customers. Our impressive forging capabilities are perfectly complemented by the state-of-the-art forging presses we own which let us get extremely close to the final shape of the part. This skill, coupled with excellent raw material usage and knowledge, is what sets us apart from the competition.”

Highly skilled, highly successful

Located in the Austrian city of Kapfenberg, Böhler has two plants employing more than 550 employees and generating an annual turnover of around €158 million in 2010. Supplying over 200 technically advanced customers worldwide, Böhler’s approach is to be that of a partner rather than a supplier.

Mr Reicher, technical managing director of Böhler Schmiedetechnik GmbH & Co KG for production, explained, “We offer considerable benefits to our customers worldwide. We are able to comprehensively support them wherever they are in the world and we have a carefully selected network of approved sub contractors. We have approval from all the major companies across the aerospace industry in particular, such as Airbus and Boeing, so we can support contracts with tier one suppliers, including the increasing number of new orders arriving from Asia.”

The high level of service and customer relations provided by Böhler is certainly appreciated by its customers, who are increasingly active across Asia. Mr Kornfeld pointed out that more and more activity, particularly subcontracting, in the global aerospace industry is now conducted across the region, and with manufacturers such as Airbus obliged to offset some contracts where the aircraft is destined to be sold, the fact that Böhler has approval in China, India and other Asian countries makes it a very attractive partner.

He added, “We are highly regarded for our ability to support the subcontractors wherever they are based as we have the correct approvals. With our added-value approach to designing, manufacturing and supplying high quality forged components, we have found that globally operating clients are keen to work with us as they appreciate our attention to detail and reliability as well as our international approvals.”

Continuous investment

In order to maintain such high levels of achievement, Böhler is keen to continue its investment in machinery and equipment. Its dedication to advanced design and development sees concurrent engineering and material expertise working alongside microstructure modelling, ensuring that all client expectations are exceeded and high performance is guaran-

teed. Böhler’s latest investment includes screw presses capable of up to 35,500 tonnes.

Mr Reicher said, “As we work so closely with such technically advanced customers, it is imperative that we can meet their very specific expectations, both in terms of products and services. Our ongoing investment in machinery means that our forging presses and related equipment is more than capable of manufacturing everything our clients request, which adds to our reliability. As a proven partner for our customers, our forged components have excellence as standard. All of our precise forging is as a result of our state-of-the-art equipment and the exceptional know-how and skill of our workforce.”

Such skill means that actually very little additional machining is required as the Böhler equipment and employees are able to get very close to the final shape of the part just with forging. Not only does this mean the product is of a superior quality and strength, but it also considerably reduces the costly raw material usage and wastage, which in turn represents a cost-effective solution for the customer. With this efficient input-to-output ratio of raw material to finished product a perfect illustration of Böhler’s continued success, it is no surprise that Mr Kornfeld is feeling positive about the company’s future.

He concluded, “With a broad range of customers in high tech industries, forging capabilities that are second-to-none and a worldwide coverage of approvals, Böhler is ready for the challenges of 2012. As around 75 per cent of our company’s turnover is dependent on the global aerospace industry, the fact that this sector is still positive these days, with both a huge order backlog and a strong-looking order book for the coming years, means that we are well-positioned for good results for 2012 and beyond. We appreciate that our network of customers and extensive forging skill makes us a very appealing prospect as an approved international partner, so we are keen to exploit that potential both with new customers and our existing partners.” n