6 minute read

Modern technology for energy Rafako

MODERN TECHNOLOGY FOR ENERGY

Rafako SA, a company based in Raciborz, Poland, is the largest European manufacturer of boilers. It also offers complete power generation units including units for supercritical steam parameters. The company offers design and manufacturing of a wide range of boilers, including PC boilers and fluidized bed boilers.

Established in 1949, Rafako SA has always served the power generation industry offering design and manufacture of boilers and environment protection plants. Since 1993 Rafako SA has been a joint stock company whose shares are quoted on the Warsaw stock exchange. The company is a leader in Poland’s power generation equipment market and the biggest boiler producer in Europe. It is based in Raciborz, where its headquarters and main production facilities include five production workshops and design offices. During the past few years new production workshops in Radomsko and Wyry have been established as well as design offices in Rybnik, Czestochowa and Belgrade. In 2009 a new division was created in Pszczyna, offering design and delivery of dust removal equipment.

Wide range of products and services

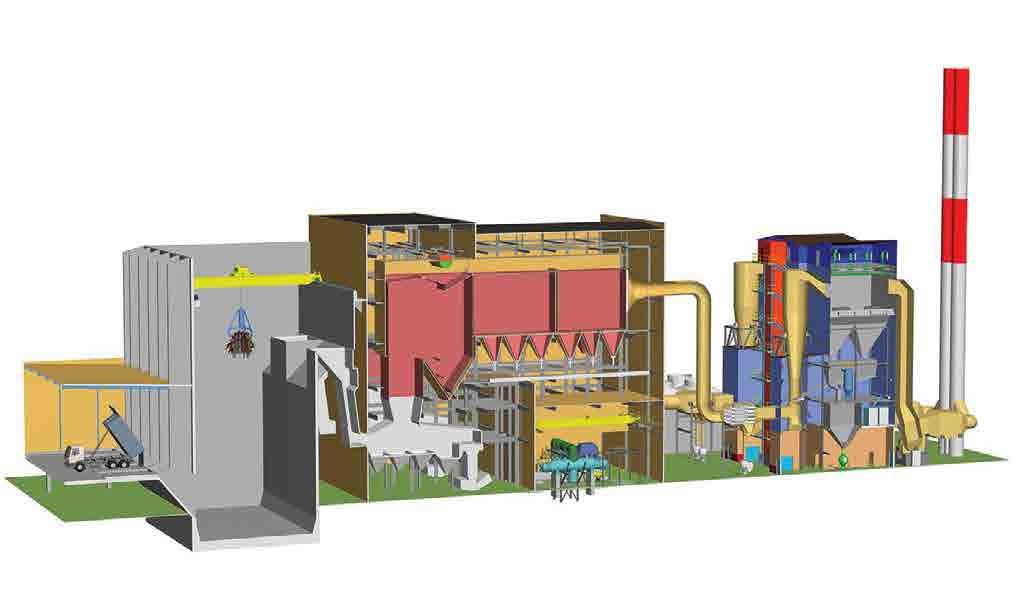

Rafako offers general contracting within the scope of fossil-fired power generation units, boiler islands in particular, including PC boilers for sub- and supercritical steam parameters, CFB boilers, HRSG and stoker-fired boilers as well as flue gas cleaning plants and equipment. The company also offers boilers for waste incineration and biomass combustion. Up to 80 per cent of the boilers operated by Polish utilities have been been delivered by Rafako. The company is also a leader within the field of flue gas desulfurisation plants based on wet lime and semi-dry methods.

Rafako SA is the largest European manufacturer of boilers and environmental protection equipment for the power industry. It offers complete power generation units fired with coal, oil, gas or biomass and

based on various boiler systems including sub- and supercritical PC boilers, CFB boilers and stoker fired boilers. Rafako is able to design and deliver equipment and plants for so called ‘boiler islands’ including boiler and flue gas cleaning systems. Moreover, for years it has provided boilers for thermal treatment of waste, biomass combustion and heat recovery steam generators. This offer is complemented by a variety of maintenance services, from diagnosis through repairs, maintenance, supply of spare parts to the comprehensive modernisation of boilers and associated equipment. In the field of environmental protection the company designs, manufactures and implements turnkey flue gas desulfurisation systems, systems to reduce nitrogen oxides and dust extraction equipment.

Furthermore, Rafako SA is a leading global manufacturer of boiler components. FPM SA, a company from Mikolow, which belongs to the Rafako group, makes mill installations and chain grate stokers, while a new division in Pszczyna offers complete dust collection equipment, including highperformance electrostatic precipitators.

The leader in Poland and in Europe

Rafako SA employs more than 2000 people. Net revenues from sales of products, goods and materials reached in 2011 a level of more then €270 million. Net profit for the period was estimated as €14.4 million. After three quarters of 2012 (latest available data) the company’s sales reached €190 million, and net profit – nearly €4.4 million.

The company has supplied boilers for almost all domestic power plants, and hundreds of units in the energy industry in Poland. It has references from a number of countries in Europe and Asia, including China, Turkey, India, Yugoslavia, Germany, France, Switzerland, Belgium, the Czech Republic and Scandinavia.

The turn of 2013 is an intense period of activity for Rafako SA. In December 2012, a consortium of Rafako and PBG signed a contract with EDF worth net €188 million for implementation of the flue gas desulphurisation in power plants in Krakow, Wroclaw, Gdansk and Gdynia. These installations will operate with the Rafako flue gas desulphurisation technology, and completion of the order is scheduled for 2015. At the beginning of March, 2013 the company signed a contract worth €54 million with Mostostal Warszawa for the construction of the boiler island for the Department of Waste Management in Szczecin. Under the agreement, Rafako SA will supply all the technological parts of the project, from the burning grate, boiler, through the exhaust gas cleaning system for desulfurisation and denitrification dust. Also in March, Rafako SA signed a contract with Enea for the replacement of electrostatic filters on block No. 8. The contract net value is €6.44 million.

Fuelled by its partners’ strength

The recognition which the company enjoys in Poland and all over the world is not only a result of the years of experience. It is also the result of selecting the most valuable partners for the tasks that Rafako SA is to accomplish. ELWRO-SYSTEM of Wroclaw, Poland is one such reliable partner of Rafako S.A. The essential group of the ELWRO-SYSTEM engineering staff has derived from the former ELWRO Electronic Plant’s Department of Automation in Wroclaw (manufacturer of equipment and systems for automation). It has more than 40 years of experience in the design, production, programming and implementation of systems for industrial process control and telemetry systems in the automation and electrical industry.

Multiserwis of Krapkowice, is another excellent example of cooperation with Rafako SA Multiserwis specialises in insulation techniques for power, chemical, oil, cement, food and building industry. The company is part of Bilfinger, one of the largest companies operating in the field of industry service.

The implementation of contracts between RAFAKO – KOTTEX / DAUME is very highly rated, including with far reaching satisfaction on the side of RAFAKO and the Investor.

DAUME, the manufacturer of control valves with headquarters in Germany, is very actively and professionally represented by its sole distributor on the Polish market, the company KOTTEX, operating since 1990.

Control valves designated for specialist applications and including more strategic use is aimed at the energy industry:Power plants, power stations, waste incineration plants, boilers for biomass. It is important to note that the largest customer for control valves in Poland is RAFAKO Racibórz. Only in the recent period, from 2012 up till now, a complete boiler control valve system has been supplied for new investments carried out by RAFAKO: are Jaworzno Power Plant, Połaniec Power Plant, Roskilde (Denmark) Project, Cleveland (UK) Project, India Project.

Ambitious plans

Strategic goals of Rafako SA for the coming years include strengthening its position as general supplier of power plants for complete power generation units, or so-called boiler islands, including supercritical technology based on the company’s know-how; complete installation of municipal waste incineration; complete installation of flue gas desulphurisation by the wet, semi-dry and dry technology; installations of catalytic denitrification, and the modernisation of boilers and power equipment.

The other long-term goal of Rafako SA is to strengthen its market position in the supply of conventional fuel-fired boilers (coal, lignite, oil, gas) and in the supply of power equipment, such as rotary air heaters and coal mills and of pressure components for supercritical boilers and other boilers. Rafako SA also intends to take part in the construction of nuclear power plants, particularly through the supply of pressure equipment. n