8 minute read

Investing to meet growing demand

Nitrogénművek Zrt is a well-established and respected producer of nitrogen fertiliser. The company was foundated in 1931, and is still at the forefront of the industry 82 years later. With the world population rapidly increasing and the demand for fertiliser growing, Nitrogénművek Zrt is keen to meet the challenge. Edina Beale reports.

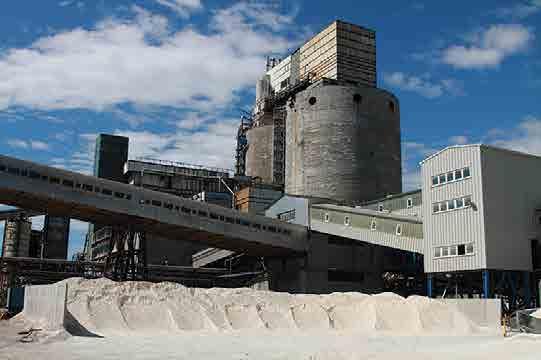

Pétfürdő in Hungary is home to the headquarters of Nitrogénművek Zrt. Established in 1931, the company has faced a great many challenges over the years – war, changing political environments, new technologies, ever more demanding controls and regulations for production and of course the current financial crisis in Europe. Despite these obstacles the company has maintained its domestic dominance with a 70 per cent share of the Hungarian fertiliser market, and has continued to develop trade with surrounding countries including Austria, the Czech Republic, Germany and Romania.

The success of Nitrogénművek Zrt has ensured that it is one of the largest employers in Pétfürdő; the company and its subsidiaries provide employment for approximately 700 people. In 2011–2012 these people played an important part in enabling the company to work at 95 per cent capacity, producing 1 million tonnes output. This production led to a significant milestone of HUF 100 billion turnover. Growing capacities

Nitrogénművek Zrt understand the importance and value of investment, even in these financially challenging times. In the past two years the company has made considerable capital investments. The need for quality products produced using energy-efficient processes and reducing the environmental impact have been the main drivers for these investments.

In 2011, it was identified that the storage system for bulk fertiliser was in need of modernisation. An injection of €5 million to

www.ins.pulawy.pl

Good reputation and well known trade mark

Instytut Nawozów Sztucznych (INS) seated in Puławy is a state research centre with a long tradition. Its beginnings as a Research Laboratory at United Factories of Nitrogen Compounds date back to 1935. It has been operating under the present name since 1958 and in 1968 its registered office was moved to Puławy.

INS is one of the best Polish research centres. It is a company with good reputation and a well known trade mark both in Poland and abroad.

The principal aim of INS activity is work for chemical industry, mainly for its fertilizer and inorganic branches what leads to innovations and improvement of competitiveness of companies operating in chemistry and chemical technology areas.

Close to industry

INS carries out research and development work in close partnership with industry, employing high qualified staff and maintaining best standards applying to research methods and procedures. It cooperates with all nitrogen works in Poland and numerous companies abroad. It has a unique advantage of carrying research works in pilot plants and directly in industrial plants.

More than 50 years of experience

Many years of research and experimental work in close cooperation with industry resulted in broad experience, mainly in the fi eld of chemical technology and applied catalysis. INS offer covers:

• modernization processes for ammonia and nitric acid plants including syngas processing (HP purification of process condensates, synthesis gas drying, revamping of carbon dioxide removal system (Benfield/Carsol), carbon dioxide purity improvement in Benfield/ Carsol unit, natural gas saturation), energy saving ammonia process, revamping of ammonia synthesis converters, modern technology for nitric acid plants; • catalysts and sorbents for syngas production (natural gas purification, HDS, removal of sulphur and chlorine compounds), hydrogen and syngases production (steam reforming, sweet and sour WGS, methanation), synthesis (ammonia, methanol, DME), hydrogenation (benzene to cyclohexane, edible oils and fats), environment protection (nitrous oxide decomposition, de-NOx, SCR, Claus process, processing of coal and biomass gasification products).

Over 20 years of INS and Nitrogénművek Zrt. successful cooperation

INS was involved in the following revamping projects implemented by Nitrogénművek Zrt. in its Kellogg’s ammonia plant: • carbon dioxide purity improvement, • Carsol unit upgrading, • natural gas saturation system, • HP purification of process condensate.

At present, INS is involved in the project of ammonia plant upgrading which would lead to increase of the ammonia plant capacity up to 1650 MTPD.

INS is a traditional supplier of catalysts being applied in Kellogg’s ammonia plant.

New leadership: plant extracts

Since 2000 INS has been conducting extraction of plant materials with carbon dioxide in supercritical conditions and has become a Polish and European leader in the fi eld of this process. Extraction technology belongs to the “green chemistry” and enables production of pure plant extracts, sterile and free from impurities.

INS portfolio covers:

• research: supercritical extraction of natural raw materials (plants), fractionation of supercritically extracted products, primary processing of materials used for extraction (drying and granulation of plant materials in inert gases), new technologies with the use of supercritical fl uids (SCF). • plant extracts (hop extract, sweet red paprika extract, strawberry seed oil, raspberry seed oil, blackcurrant seed oil) for brewery, food, pharmaceutical and cosmetic industries.

Aleja Tysiąclecia Państwa Polskiego 13A 24-110 Puławy, Poland Phone: +48 81 473 14 00, Fax: +48 81 473 14 10

improve the storage system has had a substantial impact on this area of business. Storage capacity has been increased by 85000 tonnes and the daily distribution capability is now 10,000 tonnes. These changes have additional positive attributes – the improved systems allow for improved quality of the products and significant reduction in harm to the environment.

Another goal is to increase production capacities for producing ammonia, nitric acid and Pétisó (CAN) by 15–25 per cent within the next five years. All this investment is taking place at a time when other companies are struggling to manage; perhaps this is the reason for Nitrogénművek Zrt’s continuing success. Another reason could be the effect that the investment is having on product safety and quality, two key areas for the company and the customer. Since the investments, both the quality and the safety of products has improved.

Fuel and energy costs are a major consideration for any business and Nitrogénművek Zrt is no exception. In 2012 work commenced to reduce the energy consumption in their base factories. This undertaking again required substantial investment. To date €10 million has been used to improve the energy efficiency of the ammonia plant alone.

Establishing firm roots

The production achievements are commendable, but production is only one side of the story, in any business you need to retain your existing customers and seek out new customers. The company is focusing on strengthening its position in its existing markets. With a 10 per cent increase in the share in the domestic market being achieved in the

past two years alone, it is now seeking to strengthen its position in the countries where it already has a substantial foothold. Germany, Austria, the Czech Republic, Poland, Slovakia and Romania all have large agricultural industries, and in many areas these businesses are constantly looking to develop and improve the way they farm.

Due to the findings of recent research, the company is striving to ensure that it has the quality, capacity and products to meet the expected demand. “In the central European region – in our dominant markets – Fertilizers Europe indicated that the use of our core products, nitrogen fertilisers will be expanding in the future,” says Mr István Blazsek, CEO of Nitrogénművek Zrt. “In order to prepare for this, we have been making investments to increase our capacity and to reduce our energy consumptions in our base factories since the middle of 2012. In the short term we aim to increase our capacity by 15 per cent whilst reducing our energy consumption by 10 per cent.

In the longer term the objective is to increase our present capacity by 25 per cent. This investment will strengthen our competitiveness over the next 3–5 years.”

Nitrogénművek Zrt is determined to improve on its success, to overcome the hurdles and barriers that face any business venture and to invest time and money researching markets and improving its facilities to meet the expected demand. With all the other initiatives to improve product quality and safety and to operate efficiently, the company is in a good position to build on its existing success and improve its business in the surrounding markets. n

Main contracting Diagnostic

Turbine & Compressor maintenance services

www.tlw.hu

Trans Lex Work Kft. - Hungary, 1075 Budapest, Asbóth u. 19.

Trans Lex Work Kft.

Established in 1992 Trans Lex Work Kft. (TLW) has been a key supplier for NZrt. and has provided various activities ranging from maintenance work to taking significant role in large developments since 1995. Headquartered in Budapest, the Hungarian limited company was chosen to be the main contractor for carrying out the reconstruction of the cooling towers for the fertilizer manufacturing company; part of the redevelopment of one of their warehouses; the construction of three 2000m3 acid container tanks and the demolishment of 2C and 3C obsolete acid plants. TLW has always been given a main role in the maintenance of turning machines with key importance as well as in the maintenance and assembly of the ammonia and the previous acid plant turbine-compressor machinery. In their most recent and significant project, Trans Lex Work Kft took part in the intensification of the primer wrecking furnace, where the full replacement of the fireproof walls and pipe system was completed within 29 days.