6 minute read

350 years of progress Saint-Gobain

350 YEARS OF PROGRESS

Saint-Gobain is a clear world leader in the habitat and construction market. It designs, manufactures and distributes high-performance building materials and provides innovative solutions in the fields of energy efficiency and environmental protection. This year sees the company’s 350th anniversary, which will be celebrated by its customers and employees alike. In 2014 Saint-Gobain recorded sales of more than €41 billion, is operational in 64 countries and employs over 180,000 people worldwide. Philip Yorke reports.

TO celebrate the landmark of 350 years of technological progress and achievement, the Saint-Gobain Group’s anniversary pavilions are travelling the world. Following stop-overs in Shanghai, China, in January and Sao Paulo Brazil in April the exhibition continues to travel throughout the USA. These specially designed pavilions promote the group’s exceptional expertise in the fields of materials and in particular building materials, and are a tribute to the company’s expertise and its dedication to protecting the environment. The next and final stopover for the ‘Four Sensations’ pavilions will be in Paris, France from 14th–31st October.

Four sensations

Saint-Gobain celebrations feature four pavilions and each covers a key sector of the company’s business activities. They are known as the ‘Future Sensations’ pavilions and are titled, ‘The Look’, ‘The Listen’, ‘The Colour’ and ‘The Create’.

The ‘Look’ pavilion features Saint-Gobain’s time-honoured tradition of glassmaking and is comprised of numerous mirrors encrusted with LEDs. This first pavilion provides disorientating sensations and perspectives. By day its exterior aspect reacts to the changing skies above and by night it becomes a perpetually changing cube of light. Once inside, visitors are plunged into a whirlwind voyage to the heart of new materials and advanced technology through its numerous light displays with cascading images and special sound-effects.

The ‘Listen’ Pavillion offers a completely different experience and is naturally associated with the company’s acoustic performance materials. This ‘padded’ cube is perfectly sound insulated and takes visitors on an interactive trip through sound specialisation technology in which they are confronted with a temporary disorientation of their senses. By contrast the ‘Colour’ pavilion is a carousel made of two glazed mobile concentric rings and multicoloured textures. This is a kaleidoscope on a human scale that demonstrates the convergence between the light, colours and textures of glass. By day and by night it transports visitors to a dreamlike multi-coloured and multi-faceted world.

Finally, the ‘Create ‘ pavilion is an impressive spiral staircase that evokes an upward movement to the spectator. An architectural feat, this pavilion pays homage to the technical content and performance of Saint-Gobain’s diverse range of materials. By night its sharp edges lined with LEDs blur its structure to reveal a futuristic movement, whist inside squares of fibre optic and laser beams create a constantly changing space.

In addition to the travelling pavilions, Saint-Gobain also offers a virtual online exhibition in six languages and provides the viewer with the opportunity to explore and rediscover the company’s unique history. There is also an anniversary book connected to the virtual exhibition with QR codes that provide viewers with an opportunity to learn more about Saint-Gobain in a different way.

INGTOP

Apart from having their 350-year-anniversary, Saint-Gobain also has another little jubilée – 20 years of cooperation with INGTOP, s.r.o. Czech Republic.

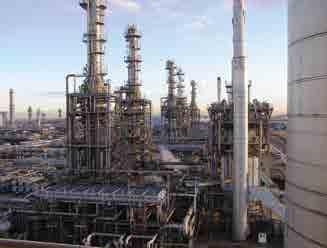

INGTOP, as a certified company (ISO-9001, 14001, 3834-2, OHSAS-18001, EN-1090, EcoVadis etc.) and approved contractor of Saint-Gobain group, supplies parts of production lines for SAINT-GOBAIN production plants worldwide, especially in the European Union and Russia.

INGTOP is specialized in designing, manufacturing and installation of “hot end“ machinery for production lines – cupolas (furnaces), fiberizing machines, binder plants, forming sections, crimping machines, curing ovens, cooling zones, and its accessories as edge-trim recycling, cooling systems, pipe distribution systems, pressure tanks, steel structures, conveyers etc.

INGTOP´s installations can be seen in Genouillac, Orange, Chemille, Chalon s.S., Auvelais, Bergish Gladbach, Lubz, Stockerau, Gliwice, Dabrowa-Gornica, Billesholm, Castolovice, Ploiesti, Chelyabinsk, Gomzovo, Yanbu and dozens of others.

We produce such fi lms as: • Stretch hood • Orientated fi lms • Flexo prints up to 2000mm wide phone: +48 (65) 512 86 86 fax: +48 (65) 512 79 01 e-mail: biuro@folplast.com.pl

Our high quality and reliable service is also well known to major polyethylene users in Europe.

Wytwórnia Wyrobów Foliowych “Folplast” is a leading producer of various LDPE fi lms in Poland.

www.folplast.com.pl

There is a ‘World 350 game’, which is available as a free download for smartphones or tablets and enables players to test their digital skills. Here the task is to build houses on planet World 350. Finally an anniversary day is to be held which will be celebrated by all the group’s employees worldwide on October 15th this year.

Pushing back the barriers

Across the broad spectrum of innovative business activities at SaintGobain, ground-breaking technology continues to emerge. A recent example of the company’s dedication to innovation and the environment can be found in its recent partnership with Renault to launch the ‘Super Alma’ co-development project. Its purpose is to push back the barriers when it comes to making car glass sets lighter by reducing 30–50 per cent of their mass, whist still guaranteeing their acoustic and mechanical performance.

This challenge has been taken up by the Eolab prototype exhibited by Renault at the World Motor Show last October. This advanced prototype is equipped with a significantly thinner windshield, which is only 3mm thick compared to the usual 4.5mm. The next step is to reduce the thickness of sidelights to 3mm using thinner laminated glass instead of the traditional 3.5mm tempered glass. It will also have an aerodynamic backlight made of organic materials, which in this case is varnished polymer, which is also replacing tempered glass.

The ambition is to develop a vehicle that consumes only 2L/100km and in doing so reduce CO2 emissions fixed by the EU authorities at 95g/km by the year 2012. This project aims to contribute significantly to the automotive industry’s strategic commitments and also meets the recommendations laid down in a strategic white-paper inspired by the works of PREDIT on lightweight, aerodynamic and advanced vehicle architecture. n

For further details of Saint Gobain’s 350 year anniversary celebrations and for information about their latest innovative products and services visit: www. Saint-gobain.com