4 minute read

Safety on railways DAKO-CZ

safety on raiLways

DAKO-CZ is a manufacturer of pneumatic, electro mechanic and hydraulic brake systems for rail vehicles with a proven track record reaching back two centuries. As in previous years, the company is looking at increased financial performance in 2018.

The company, with a planned annual turnover of around €40 million, 70 per cent of which is generated in the export markets, is based in Třemošnice in eastern Bohemia. The majority owner of the company is CZECHOSLOVAK GROUP. The second shareholder is Tatravagónka a.s. Poprad, a leading European manufacturer of freight wagons.

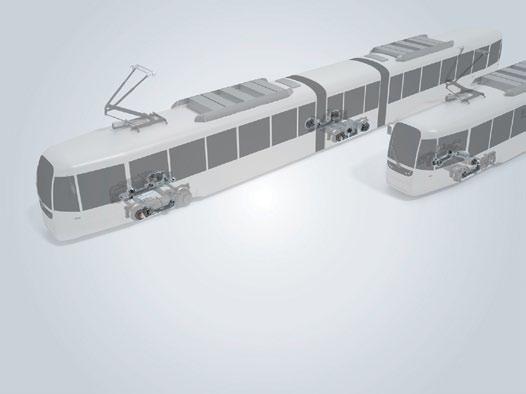

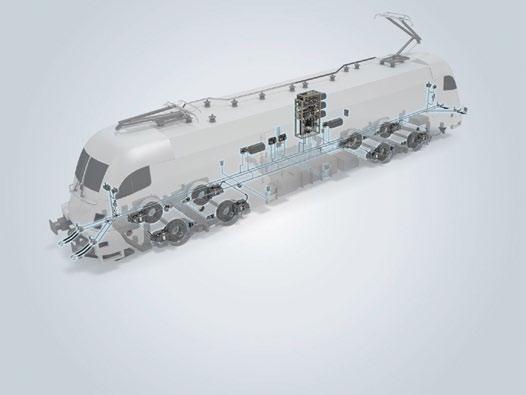

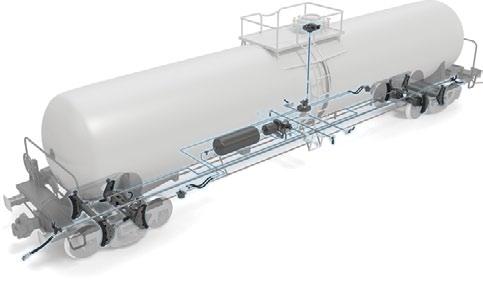

DAKO CZ supplies brake systems and components for freight and passenger cars, suburban units, locomotives, metro vehicles and trams. Rail vehicles equipped with DAKO brakes can be seen not only in Europe but also in China, India, Malaysia, Indonesia and Algeria, where the company cooperates with leading rolling stock manufacturers and operators of mass rail transport. The company has its own research and development centre, a proprietary testing laboratory and a design centre.

DAKO’s unique know-how is based on a strong tradition – its history goes back to 1816, when a casting and mechanical engineering factory was founded in Třemošnice. After 1920, the company’s core business was expanded to include products for the railway industry. In the 1950s DAKO started to manufacture and assemble brake systems of its own design. But progress did not stop there. International success was achieved with CV1 and CV2 distributors for international railway and in 1995 the first brake systems for trams were designed and made.

“Last year we achieved around €30 million in sales and plan to continue to grow,” says general director Dagmar Matúšová. “It is very positive to see our people’s commitment to achieving this strategic goal. The increase in financial indicator has been boosted by our efforts to find the optimum production, logistics, purchasing and sales channels as well as by a continuous production process improvement.”

New products

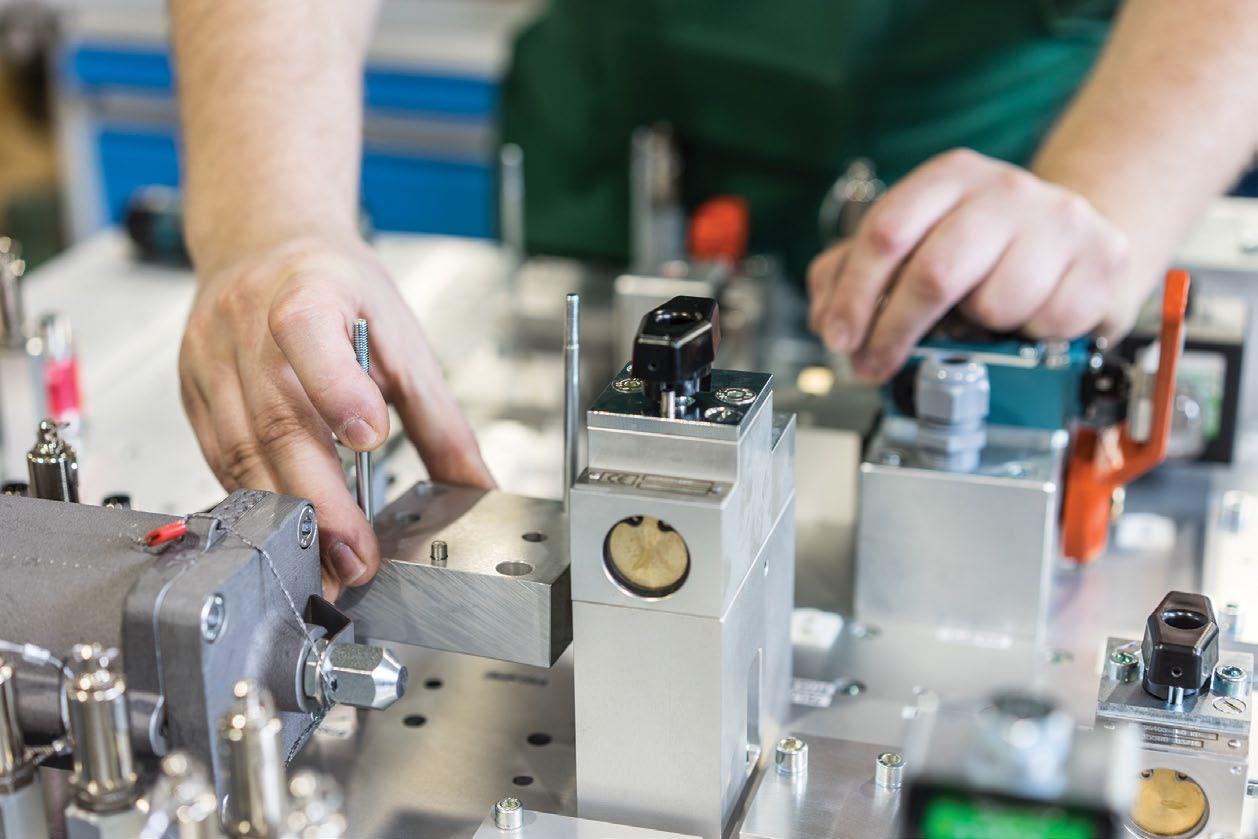

The fully modernised plant in Třemošnice makes products with the DAKO-CZ logo, currently ranking among the best in the domestic and global markets. The reliability of DAKO-CZ’s brake design has been confirmed by a number of patents and licences. The products comply with all applicable UIC and TSI standards and regulations. The company strives to support the professional development of its staff, as well as to improve their working conditions, as it is the people who are the most important factor contributing to the quality of DAKO brake systems. As a result of the expertise and hard work of its designers and project managers, supported by continued investment in product research and development, the company can regularly introduce new products to global markets.

In-house research and development is the company’s major asset. Also, thanks to the state-of-the-art testing and prototype workshop, the company has introduced new products including a new electromechanical brake unit, designed for rolling stock, and the iRB series control units, designed for hydraulic and electromechanical braking systems.

The new DAKO-CZ electromechanical braking system has become a modern BRAKE BY WIRE technical innovation that meets the most demanding environmental requirements. Also new in development is the compact brake valve MEMU, designed for controlling the metro (M) and suburban (EMU) unit brake systems. MEMU represents a new generation of compact brake valves, integrating all the necessary functions including the SIL 2 control electronics into a single unit. The new brake valve will be presented at InnoTrans 2018.

Prospective future

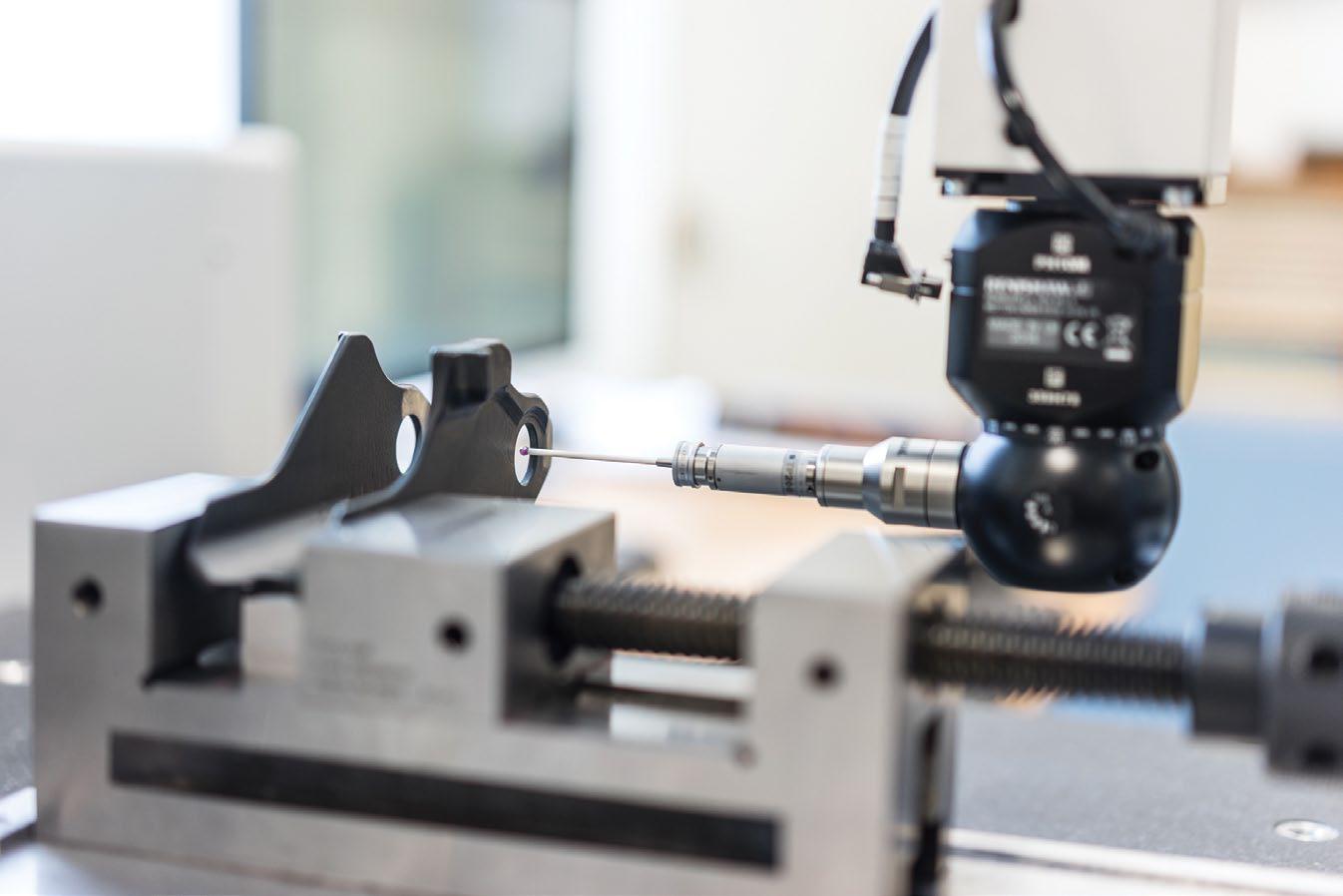

The company plans to invest in new machines in 2018, aiming to reduce production and logistics times and improve production quality. Investments planned for 2018 will also include buildings. At the moment, preparations are under way to extend the repair shop, to create a comprehensive repair workstation that would cover dismantling, cleaning and assembly. The company also plans to modernise its measuring stations and to upgrade the bench for dynamic testing of high-speed brake units and brake discs so that high-speed brakes may also be tested (i.e. EMB, EVO).

In February 2018, DAKO-CZ was certified by the RDSO Certification Authority as a supplier of systems for LHB coaches for the Indian Railways. By the end of next year, the company will have delivered brake systems for 600 passenger coaches. Siemens is another longterm partner for whom DAKO-CZ has realised a number of successful projects. This year, the company will deliver brake components for the metro systems in Munich, Sofia, Nuremberg and Bangkok. Until 2019, the Třemošnice plant will be producing new electromechanical brake units and control units for new trams for the Polish city of Poznan. The new electromechanical units will be installed in the Moderus Gamma trams, supplied by Modertrans Poznań.

“In general, the passenger and freight transport market is growing, with increasing demand for the new generation of brakes for passenger coaches and metro vehicles, with reduced cost of brake lifecycle and higher utility value for the vehicle operator,” says Mrs Matúšová, confirming that DAKO-CZ will develop products in line with these trends. “We will present our new products for both passenger and cargo rolling stock at InnoTrans in Berlin in September.”

We lARGelY CoNTRIBuTe To SAFeTY oN RAIlWAYS.