5 minute read

Ingredients of technological success AZO

AZO is a global market leader in the automated handling of raw materials. Philip Yorke reports on a company that offers unique tailor-made solutions for manufacturing companies involved in the production of pet foods, confectionary, pharmaceuticals and baking, among many others.

INGREDIENTS OF TECHNOLOGICAL SUCCESS

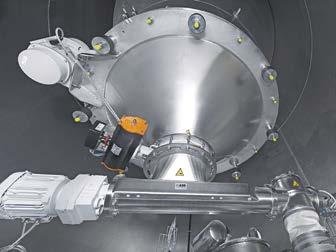

The AZO Group of Germany is a true global leader when it comes to the automated handling of raw materials with its network of high-tech partners and agents worldwide. Its workforce of more than 1,000 people is able to draw on an unrivalled wealth of experience in plant engineering and construction that has been accumulated over a period of more than 70 years. Inventiveness and innovation go hand-inhand at AZO, which began when its founders invented the revolutionary cyclone screener back in 1949. This breakthrough has been followed with countless other innovations in bulk materials handling that offer long-term benefits and unique prospects for growth for manufacturers.

Today the company’s broad range of engineering services range from the design and supply of individual components, to the construction of complete turnkey plants, advanced automation systems, installation, commissioning, and complete after-sales service. All AZO services are available from a single source as well as never being far away from customer’s location anywhere in the world.

Better by design

When it comes to engineering, no one project is the same as a customer’s requirements dictate the specifications, whilst thorough groundwork forms the basis of the final customised solution. The company offers total support in pre-engineering and the planning of new plants, as well as for the expansion and refurbishment of existing plants. It conducts feasibility studies and works on viable proofs of concept until it arrives at the optimum solution for a project that satisfies all its client’s various requirements.

Fully automated production processes in the fields of foods, pharmaceuticals, cosmetics, chemicals and plastics are the company’s core activities. Everything is available from a single source, from individual components for storage, discharge, screening, conveying, dosing and the weighing of raw materials, to the development of unique, innovative systems. These technologies can involve dispersion, mixing and the homogenisation of liquid and semi-solid products, right through to turnkey solutions. The company’s role is not over until the new production line is running to a customer’s complete satisfaction.

When it comes to control engineering and automation, from the latest sensor technology to the commercial production and planning phase, the company provides tailor-made, solutions at every stage. This ensures that plant engineering, process engineering and automation can dovetail seamlessly, with no interfaces.

Pioneering solutions

With its unrivalled knowledge and many years of experience in an ever-widening range of bulk handling sectors, the company will transform and upgrade any existing plant control technology. It makes no difference whether controls are required for the baking business, spice mix production or to manufacture tablets. As a competent partner to the food and pharmaceutical industries, the

company is acknowledged for its ground-breaking, pioneering solutions that can be relied upon at every stage of the handling process.

In the bulk handling of raw materials, AZO is the global leader in automated controls for the entire value chain: from efficient materials management in the supply and replenishment of raw materials, to conveying, detailed recipe control, and the weighing and mixing processes.

This is in addition to container handling, support for cleaning intervals, temporary storage and feeding to the subsequent packaging processes, and with end-to-end chronological documentation for use in batch tracing, all rooted in proven practical applications. Flexible plant controls with the option of rapid recipe change, are also available with absolute product and production safety together with support in complying with regular cleaning and inspection cycles. Today, intelligent plant controls are the perfect supplement to any company’s plant technology systems. Together they represent the best possible solutions, thus helping to increase a customer’s competitive edge, both in the long and the short term.

Eliminating batch contamination

The automated handling of raw materials in the manufacture of pet foods involves a large number of different components, such as flavourings and colourings. This makes automation of the raw materials used in producing mixed batches with absolute minimum contamination essential. Bulk components, which are used in almost every recipe, are usually handled using outdoor silos for storage and vacuum conveyors for transfer to scale hoppers in the mixing area that are able to withstand a powerful vacuum. Dosing and screening are usually done by type-DA cyclone screeners that provide highly accurate weighing parameters throughout the process.

In order to meet the requirements for a high number of batches, partial batches are produced while the mixing process is ongoing. These are conveyed with careful handling to the mixer provision level. These partial batches can be produced for the different product groups using several AZO Componentors® in a circular configuration. These special devices are often employed when there are less changeovers of products and the products or the partial batches are allocated onto individual mixer lines.

In such cases, indoor silos are frequently used to store raw materials. If there is a larger number of medium and minor components, entailing a greater need for flexibility when changing over raw materials, the components are dosed and weighed by the company’s patented ‘Componentor’ system and supplied to the mixing process. In addition, the company’s Dosinentor® offers an affordable solution for automating these components and provides a high level of flexibility when changing over individual raw materials. n

For more details of AZO’s latest pioneering, automated bulk handing systems visit: www.azo.com