8 minute read

INDUSTRY NEWS

Brigitte Stavar is the new President of the Australian Manufacturing Technology Institute Limited (AMTIL). Having served on the AMTIL Board for the past 6 years, Stavar has spent more than 16 years as General Manager at Sheetmetal Machinery Australia. She succeeds Paul Fowler, Managing Director of Dimac Tooling, who has served as President since 2013.

“I look forward to continuing the great work AMTIL is involved with, representing our members interests and supporting the current initiatives such as the AM Hub, Export Hub and the Entrepreneurs Programme,” said Stavar.

Advertisement

“The Australian manufacturing industry is undergoing change and to remain competitive we need to become innovative, adaptive and flexible; embrace the latest technologies; and improve efficiencies, training and education to be the best we can be in the global economy. The AMTIL Board will focus on developing and supporting strong networks in helping businesses grow within the manufacturing sector.”

Stavar is joined on the AMTIL Board by Peter Sutton, Managing Director of Sutton Tools, who replaces Philip Xuereb, also of Sutton Tools, who is also standing down.

AMTIL CEO Shane Infanti welcomed Stavar to her new role, saying: “She is a highly respected figure within the industry, with a wealth of experience and insight that will be of enormous benefit to AMTIL and to our members.

“In addition I must thank Paul for the enormous contribution he has made over the last six years. AMTIL has made huge advances under his leadership. And I would like to also thank Philip, and welcome Peter onto the Board. I feel confident with Brigitte and the Board we have in place, we are in safe hands for the coming new decade.”

RAISING THE ROOF ON NEW YORK’S NEW TRANSPORT HUB

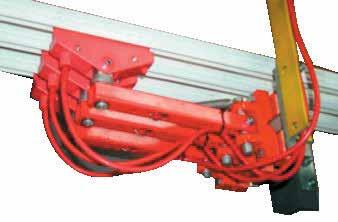

RACK ARMOUR PALLET RACKING PROTECTION

RACK ARMOUR IS THE SIMPLE SUPERIOR SOLUTION TO PALLET RACKING DAMAGE CAUSED BY FORKLIFTS.

RACK ARMOUR IS A PATENTED PRODUCT, LOCALLY MANUFACTURED AND INTERNATIONALLY RECOGNISED.

German manufactured Winkel bearings and profiles have been used in the construction of the newly opened World Trade Center Transportation Hub in New York.

The US$3 billion Transportation Hub and four new skyscrapers occupy the site of the former World Trade Center that was destroyed in 2001.

The Transportation Hub was designed by star Spanish architect Santiago Calatrava and provides transit connections to train and subway lines and ferries as well as linking the various buildings of the emerging World Trade Center Complex.

The most striking feature of the building is its futuristic roof: it is made of glazed steel ribs soaring upwards in the shape of a V for more than 50m, and is modelled on the wings of a bird taking flight, according to Calatrava.

To let in sunlight, the entire roof can be opened up to 10m in the middle so the bird is seemingly flapping its wings – an effect made possible by the Winkel bearings and U-profiles.

Built into the roof of the Transportation Hub, these components make up a robust and durable guide track system that handles the extreme loads during the opening and closing of the rib structure.

Winkel delivered a total of 224 bearings with flange plates and 445m of U-profiles for the project. The bearings have a special anti-corrosion coating to protect them from the elements.

“Of course we are proud to play our part in such a historic and innovative project,” says Winkel’s Bernd Rudolph. “The Winkel bearings in conjunction with the U-profiles are the ideal solution for this difficult task. They can withstand enormous static and dynamic loads, have a long service life and are easy to install and replace.”

Winkel bearings are available in Australia from TEA Transmissions.

REDUCE MAINTENANCE COSTS ON OVERHEAD CRANES

LOAD LIMITERS ROPE AND CHAIN CRANES AND HOISTS • Helps reduce the risk of accidents • Protects against overloading of crane and supporting structures • Quick and easy installation and available for all capacity cranes • Available preset or easily calibrated on site • Helps reduce maintenance costs • Minimises down time • Automatic reset by reducing the load

CONDUCTOR BAR

• Available in steel & copper • Quickly and easily installed • Supports required only every 1.5m • Also available in a compact cluster range

Liftco Industrial Supplies Pty Ltd (02) 9829 4411

SIDE PULL PREVENTERS / ROPE GUIDE PROTECTOR

Prevents side pulling and protects rope guides and drums on most multi-fall cranes & hoist • Prevent dragging of loads • Easily fitted to any crane/hoist • Helps reduce down time

optibelt SUPER XE-POWER PRO M=S

THE MOST ADVANCED COGGED V-BELT IN THE INDUSTRY

9 TOTALLY MAINTENANCE FREE 9 WIDE TEMPERATURE RESISTANCE 9 HIGH POWER RATING 9 SUITABLE FOR BACK BEND IDLER

+130°C

–40°C

FLEMING TAKES ON MANAGEMENT ROLE ON THE COAST

(L to R) Jon Fleming and Jason Stenning

NSW Central Coast native Jon Fleming has joined Industree Group as General Manager and Equity Shareholder. The appointment continues the company’s focus on employing high-quality Central Coast locals for the West Gosford business. Industree Group expertise in growing and improving our PPE based business.

currently employs 22 Central Coast based employees.

According to Managing Director, Jason Stenning: “Industree Group prides itself on the high quality of our Central Coast team and Jon’s appointment adds significant business experience and

“Jon has a strong focus on establishing business partnerships and fostering customer relationships. He has a long history of creating highly engaged teams, which makes him a perfect fit with Industree Group’s people-centred culture.

“With over 30 years’ experience and the majority of time spent in senior level national and international roles in the PPE industry, Jon will help guide Industree Group through our next growth and development phase.

“I am personally very pleased that we have been able to attract someone of Jon’s calibre and look forward to working with him and our Executive Team as we continue the exceptional growth of our carbon neutral Central Coast business operations,” Stenning concluded.

Industree Group 1800 276 872 www.industree.com.au

OPTIBELT AUSTRALIA E: sales @ optibelt.com.au T: 03 8791 2700

www.optibelt.com

ELECTRONICS SHOW SWINGS BACK TO SYDNEY IN SEPTEMBER

Electronex – The Electronics Design & Assembly Expo and Conference will return to Rosehill Gardens in Sydney on 9th and 10th September 2020.

The 2019 event was hailed as an outstanding success at the Melbourne Conference and Exhibition Centre, with attendance increased by more than 12% and a record number of exhibitors. In a visitors and exhibitors with several regular exhibitors commenting that it was the best Electronex show they had ever been involved in.

further endorsement for the growth of the electronics sector and the success of the event, 53% of visitors had not attended Electronex previously and over 90% were engineers, managers or involved in production or purchasing.

Electronex was first held in 2010 and has grown to become the pre-eminent trade event for companies that use electronics in manufacturing, assembly or servicing.

Reflecting the growth of high-tech niche manufacturing in Australia, at the recent Melbourne Expo more 87% of visitors said that they had met new companies and 81% discovered new products and technologies they were not aware of, reinforcing the important role of exhibitions in sourcing new technology and solutions in a rapidly changing marketplace.

The Sydney Expo is now open for bookings, and the organiser reports that around 60% of the space had already been booked by late December 2019.

Australasian Exhibitions & Events 03 9676 2133 www.electronex.com.au

Cutting the ribbon are Lynn Johnson (Senior Manager Process Engineering APAC), Geoff Boshell (Senior Director, Supply Chain APAC), Shayne Bennett (Derrimut Service Centre Manager) and Jake Weragoda (Senior Manager, Technical and Strategic Operations)

CHEP Australia has unveiled its “Plant of the Future” concept with the opening of its newly upgraded Derrimut Service Centre, one of four Australian service centres to be upgraded as part of a global plant automation strategy.

Speaking at the opening, Phillip Austin, President, CHEP Asia Pacific, said: “This is the first site of its kind for our region, and I am proud of the work our team has done to bring this together. This not only creates more local jobs, we’re also ready to further support the growing needs of our customers sustainably with more capability and greater efficiency.

“As the industry gears up to meet the Australian Government’s 2025 Sustainable Packaging Targets, customers are increasingly looking to make their supply chains more sustainable and more resilient.

“The first ‘plant of the future’ site,Derrimut allow growers, producers and food manufacturers within the region to deliver life’s essentials more sustainably,” Austin concluded.

Pallet equipment has been added to the multi-platform site, which now includes timber pallets, plastic pallets, bins, containers, crates and automotive platforms. The new pallet equipment has the capability to condition up to 3 million pallets per year and was built locally in Bendigo, Victoria.

Geoff Boshell, Senior Director Supply Chain, CHEP Asia Pacific, said: “Benefits of a multi-platform site, include it’s a one-stop-shop for CHEP customers. We have also expanded the size of our site to house more platforms onsite, ready for when our customers need it.”

The 24,000m 2 facility includes renewable energy technologies, including solar, which has already saved 220 tonnes of carbon emissions. There is also a new automated bin washer and

an upgraded crate washer, both using 100% recycled water.

All CHEP sites achieved zero product waste targets for timber and plastics in FY19, showcasing best practice product stewardship as part of the company’s circular, share and reuse model.