6 minute read

ENVIRONMENT, ENERGY & WASTE MANAGEMENT

THIS YAWEI LASER IS DESIGNED TO CUT NOW THAT’S APPLIED Good for the environment – even better for your bottom line. Now that’s Applied thinking. THIS YAWEI LASER IS NOW THAT’S APPLIED THIS YAWEI LASER IS DESIGNED TO CUT ABOVE THE REST. NOW THAT’S APPLIED We’ve shredded the price, not the quality. Now that’s Applied Thinking.

V A L U E F O R M O N E Y H E A V Y D U T Y C O N S T R U C T I O N R E D U C E S W A S T E

Advertisement

PACKAGING PLANT SOLVES WASTEWATER-PUMPING PROBLEMS

With its extreme accuracy, speed and consistency of cut, combined with very low operating costs, the new Yawei HLF fiber laser is the perfect way to take your business to the next level. Dollar for dollar, the new HLF is in a league of its own, opening up possibilities for companies all across the laser cutting sector; from start-ups through to full production, 3-shift With a quality German built Precitec auto-focus cutting head, IPG laser source, Siemens 840DSL controller and a fabricated, stress-relieved fully annealed frame it really is a cut above • Hot melt processing achieves a 90:1 densification ratio • Huge volumetric savings on your waste bins • Create a new revenue stream with your densified EPS • Keep EPS out of landfill, and contribute to the true circular economy • Simple, cost effective, safe operation With its extreme accuracy, speed and consistency of cut, combined with very low operating costs, the new Yawei HLF fiber laser is the perfect way to take your business to the next level. Dollar for dollar, the new HLF is in a league of its own, opening up possibilities for companies all across the laser cutting sector; from start-ups through to full production, 3-shift With a quality German built Precitec auto-focus cutting head, IPG laser source, Siemens 840DSL controller and a fabricated, stress-relieved fully annealed frame it really is a cut above With its extreme accuracy, speed and consistency of cut, combined with very low operating costs, the new Yawei HLF fiber laser is the perfect way to take your business to the next level. Dollar for dollar, the new HLF is in a league of its own, opening up possibilities for companies all across the laser cutting sector; from start-ups through to full production, 3-shift With a quality German built Precitec auto-focus cutting head, IPG laser source, Siemens 840DSL controller and a fabricated, stress-relieved fully annealed frame it really is a cut above Heavy duty, reliable, cost effective recycling solutions Australia’s favourite solution for all kinds of waste/ materials reduction applications Extensive range available: • Vision Series Shredders • Gran-Calibur Series Granulators • Complete recycling lines; tyres, e-waste, cable, plastic washing & drying.

Connect with us socially Connect with us socially

appliedmachinery.com.au

22/12/16 9:27 am 22/12/16 9:27 am

Visy Packaging operates a state-of the-art drink-can manufacturing plant in Stapylton, Queensland. The plant employs more than 50 people and produces export-quality cans for local and overseas markets.

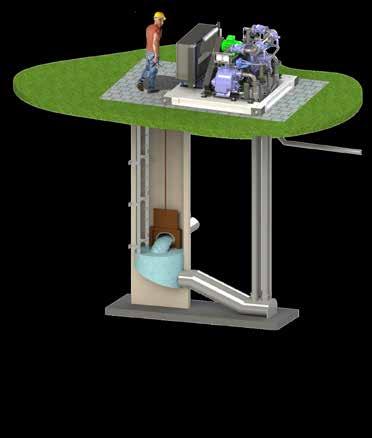

The company was however having chronic reliability issues with its submersible wastewater pumps. Engineers had been trying to solve this issue for seven years when Paul Carter, Engineering Manager – Beverage and Food Can, spoke to one of his contractors. This contractor suggested he look at Gorman-Rupp self-priming wastewater pumps, which had been successfully installed at the Pacific Fair shopping centre on the Gold Coast.

Carter instantly saw the benefit of this style of pumping equipment and the maintenance and reliability benefits that they offered. Being surface mounted meant they would be easier to access for monitoring and service. Gorman Rupp units have allowed us to achieve that, and we now have no issues with our system.”

The most suitable pump for the Visy application was the Gorman-Rupp T2A65-B. This is a 50mm self-priming trash pump, which is capable of selfpriming to depths of 7.5 metres, and can handle solid particles up to 38mm diameter and also stringy materials such as rags.

If anything too big does get into the pump, there is a large inspection coverplate for operators to access the pump interior.

The Gorman-Rupp T2 is able to deliver flows up to 10L/s, but larger pumps in the range are capable of flows up to 200L/s. Pumps also come in various materials of construction to cope with abrasive and/or corrosive wastewater.

HOLISTIC APPROACH TO ENERGY MANAGEMENT AND EFFICIENCY PAYS OFF FOR MANUFACTURERS

Replas will save $2.8 million over the next 25 years across its two sites

It’s no secret that as Australia’s largest energy users, in recent years the nation’s manufacturers have suffered “bill shock” of a massive magnitude when their time came to negotiate their latest round of energy contracts.

However, there are always alternatives, whether it be changing energy supplier, introducing a degree of on-site generation with rooftop solar (bearing in mind that manufacturing plants are not exactly short of roof space), or looking in greater depth of the energy efficiency of the manufacturing process.

Increasingly, manufacturers are turning to energy consultants such as Choice Energy that can provide a balanced view of the problem, addressing all sides of the energy equation.

One such manufacturer is Ballaratbased Replas, Australia’s leading manufacturer turning plastic waste into sustainable products.

Recognising the irony of producing sustainable products in a factory running 24/7 with very energy-intensive processes, the company approached Choice Energy to carry out a solar feasibility study.

Not only did Choice Energy enable significant savings for Replas by adding solar energy to its mix, the company also identified significant energy wastage throughout the plant due to the poor power factor caused by the nature of the loads within the factory.

The addition of a power factor correction unit restored the power factor and removed this energy wastage.

Replas went on to commission a further solar installation at its Recycling Education Centre in Carrum Downs. And between the two sites, the company calculates that it will save $2.8 million over the next 25 years.

One case that illustrates that solar is not the only solution is Ryan & McNulty Sawmillers, a company that makes high-quality timber products for flooring, cladding and decking based in Benalla in NE Victoria.

After reviewing the company’s energy bills, Choice Energy helped procure new retail electricity contracts, securing forward pricing well before huge market increases. This alone, saved Ryan & McNulty $186,000 over a three-year period.

Ryan & McNulty also signed up for Choice Energy’s metering and monitoring service, which not only validates the company’s monthly energy bills, it also records all consumption and the allimportant load profile.

This soon proved its worth when Choice Energy switched Ryan & McNulty to a different network tariff, saving a further $6500 per year.

Eventually, though, Ryan & McNulty did invest in a 320kW solar system, which is by far the largest solar installation in Benalla, generating 1MWh of solar energy per day.

Sometimes, it is a combination of measures that produces the desired effect. So, when Lago Quality Smallgoods called on Choice Energy for solutions to its rising power bills.

The company’s timing was good, because Choice Energy was able to lock in new electricity retail contracts before a significant rate increase.

Then, having built a consumption and load profile of the energy Lago was using and submitting this as an evidence-based application, Choice Energy was able to renegotiate a better tariff from Lago’s network provider, saving some $19,000 a year.

Choice Energy also installed a power factor correction unit for the business, in an effort to reduce the demand from its network provider, and this has proved to save a further $16,300 a year.

What these case studies illustrate is that the Choice Energy energy management team continues to identify new ways to help manufacturers take charge of their energy bills and secure their vital energy supplies.

At the same time, the company is committed to providing high-quality, safe and effective PV solar solutions that it will support long into the future.