14 minute read

ROBOTICS & AUTOMATION

ROBOTICS AND AUTOMATION

SMARTER CLEANING WITH ROBOTICS

Advertisement

Robotic cleaning machines offer many practical advantages from increasing productivity, to improving the consistency of cleaning, with lower maintenance costs from minimal human operator error.

Tennant ANZ is ready to lead the way locally with its T7AMR solution that has already sold more than 1000 units in North America and Japan.

Robots have a major role to play a role in making work environments safer by reducing accidents and mistakes due to human error. Overnight cleaning crews, for example, can get tired and make errors of judgment or lose focus. This can lead to accidents and damaged equipment, structures, or products. Some of these mistakes can be costly.

Robotic cleaning machines, on the other hand, are programmed to be reliable and consistent. Many have built-in safety features that protect against accidents, whether they’re used independently of, or collaboratively with, human workers.

Today’s robotic cleaning machines also offer the latest in sustainable cleaning solutions, technologies, and equipment. Tennant’s machines, for example, minimise environmental impact in seven key categories including energy, CO2 emissions, ozone, smog, acid, eutrophication, and particulates.

These machines require less water and fewer chemicals - saving money on supplies while reducing downtime, thereby making cleaning crews more productive.

What about the workers?

Robotic cleaners also offer benefits that can help retain and attract employees. First, robotics can aid employee retention by improving job satisfaction, performance, and overall work quality. The high-tech equipment training involved enhances workers’ skills, which can make them feel more valued and help them become more desirable employees (while expanding their career opportunities).

Robotic cleaning machines can also help companies repurpose existing workers. With less time spent doing repetitive tasks, employees have more time to focus on other cleaning tasks that require a human to perform.

For companies having trouble filling positions, robotic cleaning machines can help by enabling current employees to accomplish more in less time, allowing fewer workers to accomplish the work of a larger crew. And when it comes to attracting prospective employees, robotics brings a leadingedge perception that’s attractive to those interested in working for a forward-thinking company.

All about the data

Data tracking is increasingly important and widespread across business, technology, and life in general – from sales data, to financial data, to GPS data, to health data, and much more.

Choosing robotic cleaning machines with data reporting technology gives fleet

managers greater insight into cleaning performance, enabling them to optimise their cleaning performance and track key performance indicators with dashboard reporting and alerts. This can help companies increase efficiency, reduce expenses, maximise operation time, ensure health and safety, make fewer errors, and identify areas for improvement.

Last year US-based retail giant Walmart became the first major retailer to introduce Tennant’s robotic solution, the T7AMR, equipped with Brain Corp’s self-driving operating system, BrainOS, to deliver operational efficiency, cleaning performance and customer value.

Following the success of the initial partnership, which saw 360 robotic floor cleaners, powered by BrainOS, deployed in Walmart stores, the fleet has increased by an additional 1500 machines.

The robots operate collaboratively alongside Walmart associates by using a “teach and repeat” approach that allows associates to easily deploy the machine and adjust cleaning routes as the environment changes.

In Australia, the T7AMR will be available from the first quarter of 2020, with local support to be provided by Tennant Australia and New Zealand. “We’re winning with [the T7AMR] globally in retail and building service cleaners,” explains Tennant Australia and New Zealand General Manager, Chad Angeli.

“The advantage for ANZ is that we have our direct service organisation and customer care centre team for support. We can set it up as Tennant, service as Tennant, connect with BrainCorp and channel back to customers with anything they may need.

“We believe having a strong, local direct service and customer care team will give customers a better experience with robotics. They can always deal with us from the initial set up and teaching their machine routes, to after-market support conducted by Tennant, and also representatives to help with getting them the data usage reports.

“Robotics is not for all customers, so we need to make sure we continue to invest in a variety of value propositions. However, we know we will have robotics across more machine platforms in the future with an even more advanced technology.

Tennant Australia 1800 226 843 au.tennantco.com

BE THE CONTROLLER OF YOUR AGV SYSTEMS

Now you can, with the newly arrived state-of-the-art MAX AGV & warehouse management system. All system configuration tasks are done visually with the windows-based MAX Editor, enabling you to configure all aspects, from the location & operation of a pick up or storage position.

MAX Editor is really easy to use & learn for operators. Ask us for a demonstration.

Key benefits are:

> Runs on a modern client server Windows ®

environment, utilising Microsoft ® products

> Ability to edit your own AGV track & functions

> Easy to create future expansions & edit modifications.

With over 3,000+ installations & more than 30 years expertise, Robotic Automation P/L is your Trusted Supplier. Contact us on:

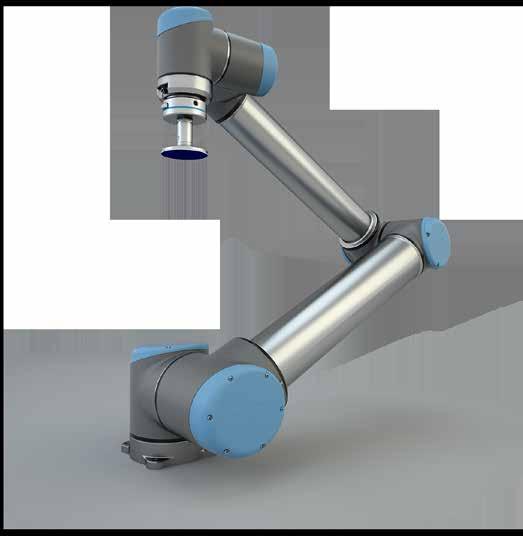

LEASING PROGRAMME CUTS THE COST OF STARTING WITH COBOTS

Universal Robots has teamed up with global vendor finance company DLL to launch a cobot leasing programme that will enable any manufacturer to reap the benefits of automation without worrying about cashflow or seasonal fluctuations.

The global programme is expected to appeal to the market in Australia and New Zealand, allowing manufacturers to start automating with cobots immediately.

According to Darrell Adams, Head of SEAO at Universal Robots: “Locally, systems are in place and this service is available to Australian and New Zealand manufacturers.

“The equipment starts generating income before you have made your first payment. It helps the business acquire the cobot it needs now without significant down payment. Leasing also ensures you are never stuck with outdated equipment and there are further tax advantages too.

“With automation and Industry 4.0 becoming more and more of a hot conversation topic in the local market, the move could not have come at a better time. Accelerated automation is required, and the UR Leasing Programme will go a long way towards making this a reality for many small to medium enterprises,” says Adams.

DLL is offering UR’s customers tailor-made financing and leasing programmes designed to meet the needs of the modern manufacturing business, while enabling growth. As business needs change, customers will have the option to schedule payments to fit fluctuations in cash flow, upgrade to new equipment, or add cobots anytime during the contract term.

At the end of the finance term, customers will have the option to buy the equipment for a fraction of the original cost, upgrade to newer technology, extend the finance term or simply return the equipment.

“We are delighted to establish a global partnership with Universal Robots,” said Neal Garnett, President of Construction, Transportation & Industrial (CT&I) Global Business Unit at DLL. “The market we operate in is evolving rapidly. Through this partnership we can now offer financial solutions for a wide variety of automation equipment.

“Cobots are transforming the industry and UR is clearly the market leader. Our tailored financial solutions give

Darrell Adams, Head of SEAO at Universal Robots

UR’s end users an easy way to reduce the risk of deploying cobots by shifting from ownership to flexible, usage-based financing. Manufacturers can build the operations they need to compete and thrive, while people work on strategic tasks.”

The UR distributor network is working directly with DLL’s dedicated finance experts in each country to provide new payment and leasing options for interested customers. In the ANZ region, customers can contact UR directly or go via their local UR distributor for more information.

“Universal Robots is looking forward to removing the last barrier to automation!” concludes Adams.

Universal Robots +65 6635 7270 www.universal-robots.com

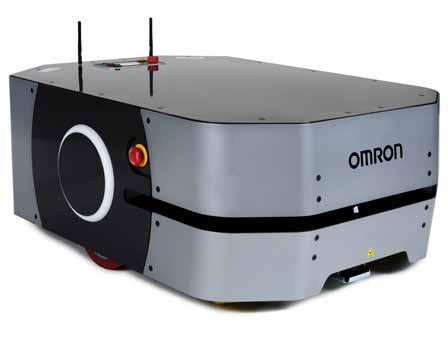

MOBILE ROBOT FAMILY GAINS BIG DADDY

The latest addition to Omron’s LD autonomous mobile robot (AMR) range is the strongest yet. The LD-250 has a payload capacity of 250kg, a maximum

speed of 1.2m/s and can run for 13 hours before it needs recharging.

The LD-250 is based on the same tested-and-proven technology used in the industry-leading LD-90, with a higher payload capacity and tougher metal skins.

Working seamlessly into an integrated Omron mobile fleet, the LD-250 can allow customers to optimise their traffic management, battery management, and routing of vehicles with a more diverse fleet.

Unlike AGVs, Omron AMRs can safely navigate without the use of floor magnets or wall-mounted beacons.

An AMR will first create a baseline map of a facility using built-in sensors, then will constantly detect its surroundings. When processes change, AMRs can easily change as well, creating networks of new routes or being reassigned to new tasks.

So although AGVs allow modifications to production lines, facilities will need to install new equipment every time the AGV path is changed, leading to downtime and extra costs.

And AGVs will stop at obstacles indefinitely, AMRs avoid stationary or moving obstacles and automatically reroute themselves when necessary. AMR paths automatically change without human intervention, making operations more flexible and decreasing total cost of ownership.

Safety is a key focus with the LD-250. The robot complies with ISO EN1525, JIS D6802 and ANSI B56.5 safety standards and works safely around people.

SELF-ADHESIVE GRIPPER IS AT HOME ON COMPACT ROBOTS

OnRobot has launched a compact, single-pad version of its Gecko nomark adhesive gripper designed for applications with small footprints and lower payloads. The Gecko SP is available for payloads of 1, 3 and 5kg.

The award-winning Gecko gripper design uses millions of micro-scaled fibrillar stalks that adhere to a surface using van der Waals forces – as used by the lizard of the same name. The grippers need no compressed air or external power, and can be implemented quickly and easily on any major collaborative or light industrial robot arm.

Because the technology doesn’t mark even high-shine surfaces, it eliminates the need for a cleaning step in manufacturing processes, saving time and improving output. And it can grip even perforated workpieces such as printed circuit boards or aluminium mesh. According to Enrico Krog Iversen, CEO of OnRobot: “Our unique Gecko technology automates processes that no other gripper can accomplish, and now it’s available in a compact, flexible format that offers our customers even more options.

“This is a true plug-and-play gripper that fulfils our promise of a full range of easy, cost-effective, flexible robotic tooling that lets customers focus on their application rather than the robot.”

OnRobot is supported in Australia through six distributor partners: Mobile Electrics, Scott Automation and Robotics, Collaborative Robots Australia, Auto Controls Systems, Australis Engineering, and Diverseco.

OnRobot onrobot.com

Input

EtherNet/IP

Logic

Output

Safety over GuardLink™

Safety over EtherNet/IP™

NHP’s Smart Safety enables smarter machines and equipment

NHP delivers a Smart Safety solution that improves access to real-time data including diagnostic information, enabling end users to gain efficiencies, minimise downtime, improve product quality and make operations more responsive. With the broadest range of safety products, NHP promises seamless integration by bringing these together to provide a complete Smart Safety solution to meet safety requirements. NHP and Rockwell Automation’s Smart Safety solution enables better visibility into safety-system performance and stoppages, transforming the way you monitor and manage safety.

Australia really needs to lift a gear in the field of industrial automation to avoid falling further behind. But it’s just not happening. Why?

Personally, I think there are a number of factors, such as the lack of continuity of staff across the board from end users to suppliers. There is a lack of direction of manufacturers to adopt continuing improvement. And often the decision to go ahead is not made in Australia.

If you look at the differences between the Australian industrial automation market and that of say Europe, it is what I call the “continuity factor” that really stands out.

This is glaringly obvious if you attend the same international exhibitions over the years and you find you are still talking to the same people from most of the automation suppliers - particularly if they are from Northern Europe.

The “continuity factor” really helps in the continuance of development and knowledge in a vein of a particular technology.

As an example, if a manufacturer anywhere in the world has a high turnover of its key engineering staff then the probability of that manufacturer being able to conceive, procure and implement an appropriate automation project is severely hampered, and probably will not happen - thus falling further behind.

Over the years it’s not uncommon for an automation systems integrator (ASI) in Australia to be asked to look at solving the same automation problem for the third time, with the manufacturing staff completely unaware that the problem has been “doing the rounds” for some years but with no result.

The effect on this manufacturer is disastrous as it will continue to fall behind in productivity - possibly to the point of no return as the cost to upgrade may have now gone past the tipping point and has become an unviable option.

This “continuity factor” not only plagues the manufacturers it’s also a problem for the ASI as it appears that millennials (in particular) simply don’t want to stay anywhere long enough

THE CONTINUITY FACTOR

to actually really get to grips with the role and the technology as depth of knowledge is not high on the agenda .

This particularly exasperating as the technology depth in automation is continuously increasing to the extent that companies need more exposure to it in order to cope and fully absorb the issues.

My extensive experience in interviewing many candidates and listening to the tales of woe they have brought on themselves in a series of jobs that actually all started by them leaving a perfectly good job for a seemingly better one that did not turn out so well is significant. The only winners it appears are the recruitment consultants.

As a result, in some manufacturers, the ASI is one of the few “continuity factors” they have and while this is not ideal, at least there is some continuance of knowledge.

It’s also worth noting that many solid automation projects just don’t go ahead because the decision-making process is now overseas and no longer in Australian hands. This is another reason why automation projects simply don’t happen or die through lack of continuity.

I would also point out that the continuity factor is considerably less of a problem in rural or far-flung locations, where it is refreshing to engage with people that really know how their plant works and have done so for many years.

So what’s the answer? There’s no single answer.

However, procrastination from CFOs and senior management in manufacturing companies can lead to key staff moving on as there’s not enough actually happening, as already mentioned some don’t need much to move on .

On average it takes about 6 to 9 months for an ASI to get to the point of having a solid proposal to fit a solution. Then it can be anything up to a year to fully implement the system. Senior management will complain that this is way too long. And they are right.

But these long timescales are generally caused by a lack of engagement from the client, leaving the ASI with a shortage of key information. This will be made worse by continuing staff changes, and worse still by the need for overseas approval.

You can see how so many projects are never completed.

I guess if a manufacturer believes it has a valid project then the company should do the due diligence in picking the ASI that’s right for the job. This doesn’t mean inviting eight different ASI’s to “have a go”. That leads to all sorts of differing specs that will create confusion for the manufacturer and ensure that project will go nowhere.

Experienced ASIs will know this is a shambles from the start and will allocate resources accordingly or not bother at all.

Australian manufacturing industry needs to wake up to what’s happening in the world and get cracking on doing what it can now. Start with the low-hanging fruit – the easy projects. There are generally plenty of these in many plants we visit. But do get on with it.

If I sound concerned, it’s because I’m not sure how many years Australian manufacturing has left if it does not wake up and start actually doing it instead of talking about it.