15 minute read

MATERIALS HANDLING

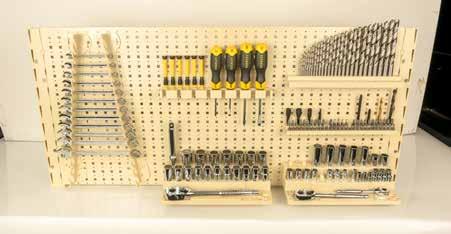

WALL STORAGE SYSTEM AVAILABLE ONLINE

BAC Systems has added a new e-commerce section to its website to allow speedy access to its highly acclaimed BAC Wall Rack wall-mounted toolboard system.

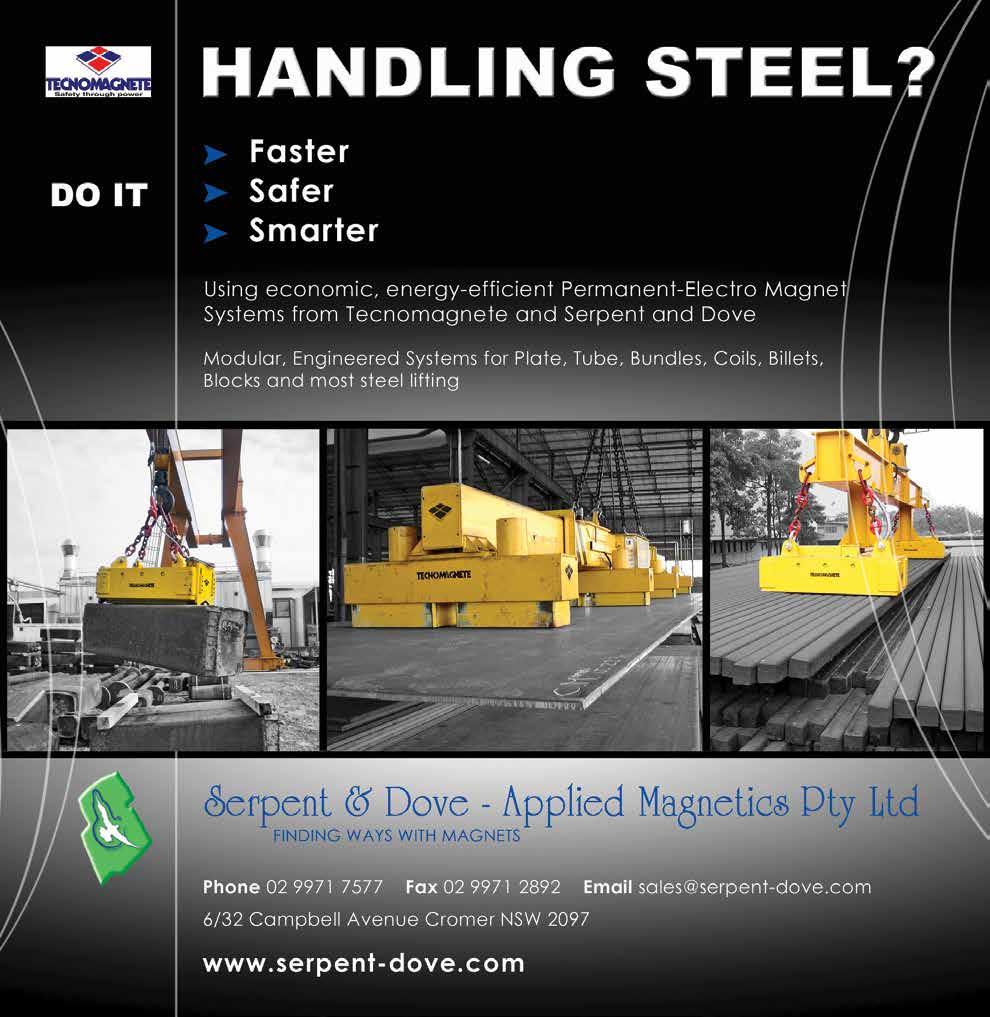

Advertisement

Billed as the ideal way to organise a workshop, the basic BAC Wall Rack system comes with hooks and brackets for hanging tools, but it also accommodates a wide range of accessories, including plug-in toolbars for socket sets, drill bits and the like. All the addons are securely mounted on the BAC Wall Rack using the system’s novel combination of square holes and round holes.

There are five basic types of steel panels, all locally made from Australian steel, and all plastic mouldings are made from ABS recyclable plastics.

BAC Systems has put together a number of cost-effective BAC Wall Rack starter kits to help users get their workshops organised. These kits combine the basic panels and supports with a selection of toolholders – in fact everything needed to organise a workshop.

Individual panels, partitions and accessories are also available to enable custom installations that provide highdensity bespoke storage on any wall. Full installation instructions are provided on the BAC Systems website.

“Whether it’s for your workplace or your garage, this product - though small and simple - can transform your tool storage,” says Bob Griffin of BAC Systems.

“We wanted to make it easy for the customer to purchase this product, because we think it’s a real winner – hence, the e-commerce system was made available.”

The BAC Wall Rack kits and components are available now from the BAC Systems website, with free delivery Australia-wide (subject to a minimum order of $30).

BAC Systems 02 9832 2777 www.bacsystems.com.au

Solve your space problem with an Altrac gantry crane

N EED M ORE LI FT? I N VERTED GAN TRY LOW CEI LI N GS? LOW H EADROOM GAN TRY CORN ERS? CU RVED GAN TRY

An inverted gantry crane allows safe lifting and changeover of tractor implements by just one person.

A low-headroom gantry maximises the very limited space inside a shipping container.

A curved gantry allows safe work flow moving heavy stone items in a circular building.

Contact us or visit our website for a free quote

COGGED V-BELT IN DRIVE FOR MACHINERY DUTIES

Available now from Optibelt Australia, the Super XE-Power Pro is a revolutionary range of EPDM cogged V-belts for use in a wide range of machinery from compressors and pumps to lathes and CNC machine tools.

The design of the belt features a novel moulded cogged profile that greatly improves durability, flexibility and power transmission over previous generations of belts.

And the high-modulus polyester cords used in the construction of the belt resist stretching, making the V-belt fully maintenance free. This reduces downtime, improves drive efficiency, and increases belt power capacity by up to 20% over other high-performance cogged V-belts.

The new tooth shape allows the Super XE-Power Pro to be used on pulleys with extremely small diameters, making it suitable use in smaller machines. And, unlike competing products, the belt is also suitable for back bend idlers, which enables its use in ultra-compact drive units.

The combination of the lowstretch cords used in conjunction with a tooth form optimised for dynamic loads gives the Super XE-Power Pro extremely high power handling capabilities. And the inclusion of an innovative red cushion compound gives a perfect adhesion for tension cords and high load capacity.

The EPDM transverse-fibre-laden compound gives the belt a wide operational temperature range from -40 to +120°C, and it runs extremely quietly and smoothly - even at high speeds.

Optibelt Australia 03 8791 2700 www.optibelt.com

A fully integrated system or a basic component –YOU choose from a single supplier.

Adept has been supplying the materials handling industry with innovative and Bespoke designs for many years.

Warehouse order fulfilment systems. Freight and courier parcel handling systems. E-commerce - Scope and range to satisfy and support most e-commerce companies. Faster Deliveries - Not subject to long lead times. Faster deliveries than all industry peers. Systems can be up and running before others get theirs off the boat. Flexibility - We provide solutions from a basic component to full system analysis, design and implementation. Long Term Support - Will always have availability of spares no matter how old the design may be. Local Manufacturer Not an importer, we use components from our own exclusive European partners and build all conveyor products HERE.

European Quality Partnered with affiliates from all over Europe for specialised products.

Sydney (02) 9771 4655

Melbourne (03) 9357 8814

sales@adeptconveyor.com.au adeptconveyor.com.au

GETTING TO GRIPS WITH BULK BAGS

TENTE E-DRIVE FLEX STARTING ASSISTANCE SYSTEM

As more companies look to reduce their packaging and transportation costs, bulk bags are becoming widely used as a cost effective, efficient and eco-friendly solution for storing, transporting and discharging bulk materials.

When fully loaded, the size and weight of these bulk bags create a problem for safe and productive handling in the workplace. The issue is finding cost effective equipment that is safe and practical for basic handling applications.

East West Engineering has now extended its range of bulk bag handling equipment to include a range of bulk bag stands, each suiting a variety of applications. The extensive range allows greater use of bulk bags in the workplace for general-purpose waste collection, as well as storing, filling and dispensing of bulk materials.

SKB bulk bag stands safely hook open bulk bags for filling, saving time and costs. There are three basic models. The SKB50 is a lightweight unit for easy relocation. The SKB100 is perfect for general site and excavation waste on building sites. And the SKB150 is ideal for manufacturing sites that require complete manoeuvrability, with its sheet-metal base, fork pockets, crane lugs and optional wheels.

The multipurpose SKX100 bulk bag frame has been designed to not only hold a bulk bag open, but when combined with the SKH100 bulk bag hopper with slide gate, it can be used as a bulk bag filling or dispensing station. Additionally, this model can be stacked two high when full or three high empty, saving valuable warehouse space.

East West Engineering 1800 061 998 www.eastwesteng.com.au Extended Position

Retracted Position

Demonstration Unit Available Contact Tente Castors & Wheels for further information 1300 836 831

- E-Drive Flex system can be retro tted to most trolleys - Increase manpower e ciency by saving e ort - Used a a 5th wheel to improve direction stability - Retractable wheel system ensures easy manouverability - Reduces potential injuries for sta – neck, back, shoulder and wrist pain - In nite speed control (forward and reverse) - Egonomic handle design with system and battery charge LED indicators

SILENCE IS GOLDEN IN PALLET HANDLING

The humble pallet truck is one of the great workhorses of the materials handling sector, and its design has remained unchanged for decades. It is, however, a little “clunky”.

With its solid plastic or metal wheels and rigid construction, the basic pallet truck is both noisy and prone to shock and vibration. And while the noise is undesirable in many applications, such as retail spaces, the shock and vibration can be hazardous to users in any application.

Enter the Panther Silent, a new breed of pallet trucks designed and manufactured in Denmark by Logitrans, and available in Australia exclusively from Maverick Equipment.

The Panther Silent is almost exactly what it claims to be – producing no more than 60dBa in use on any surface. And it produces this low noise level due to two key design innovations.

First, it has special soft rubber wheels (both for steering and on the forks). These not only deal with any uneven surface without raising the noise level, they are particularly low in friction, which makes the Panther Silent particularly easy to manoeuvre.

Secondly, all the metal components of the pallet truck are manufactured to extremely tight tolerances and assembled with nylon caps on all the joints to avoid metal-on-metal contact. This removes that “clunky” noise associated with the old-style pallet truck.

The overall design is particularly easy to manoeuvre, with a 210-degree turning angle made easy by the larger than normal 200mm low-friction steering wheels that also reduce the

operator effort required to move the load. And the lifting operation is particularly easy on the operator, with fewer pumps of the handle required to raise the load.

“But so quiet and smooth is the Panther Silent that it would be an improvement for many logistics operations – particularly those that operate near residential areas,” he adds.

MAVERick Equipment 1800 500 411 www.maverickequipment. com.au

ELECTRICAL AND MECHANICAL ENGINEERING PRODUCTS ELECTRICAL AND MECHANICAL ENGINEERING PRODUCTS

ONE SOURCE TOTAL SOLUTIONS ONE SOURCE TOTAL SOLUTIONS

MS300 Compact High Performance Drive • 40% reduction in size • 0.02kW to 22kW • High starting torque 200% at 0.5Hz • Fast response to load changes • Removable keypad • Side by side installation • C2 filter • Wide range of option cards including EtherNet, EtherCat and CANopen Industrial Sirens & Beacons • Electronic Sounders • Sounder – Beacon combinations • Motor Sirens • Electric and Air Operated Horns • Bells and Buzzers • Xenon and LED Beacons • Rotating Beacons • Voice and Tone Sounders

Clifford & Snell

ADXL Soft Starters • 15 to160kW • From power up to start up in 4 easy steps • Motor protection built in • Built in bypass relay • Default set up for fire pumps • Remote control and monitoring with • Set up in the box with NFC technology and Wide Area Signalling • 1ph and 3ph Motor Sirens • High Power electronic Sounders • Customised tones • Voice messages • Battery backup option • Radio control • Customised solutions

TRUCK AND TROLLEY COME TOGETHER

Available exclusively in Australia and New Zealand from Tente Castors & Wheels, the Convert-A-Trolley is a novel rethink on some of the most basic materials handling operations, combining the functions of a hand truck and a platform trolley. What’s more, the lightweight unit can be converted between the two roles even while loaded.

The European-made ConvertA-Trolley was originally conceived to overcome unsafe manual handling practices at a well-known global beverages brand.

The result is a patented ergonomic design that is easy to manoeuvre in a busy warehouse or in tight spaces and on variable floor surfaces both indoors and out.

It converts from a hand truck to a platform trolley with a single latch and lever mechanism. And the whole structure folds flat for space-saving

storage and transport.

As a result, the Convert-A-Trolley is equally at home in the warehouse and operating from the back of a delivery vehicle.

Ruggedly made from powdercoated steel or stainless steel, the Australian version of the trolley is made using high-quality Tente castors and pneumatic wheels.

Weighing in at just 22kg itself, the Convert-A-Trolley is rated for loads up to 150kg as a hand truck and 350kg as a trolley.

The V2 model is made fully from 304-grade stainless steel (including the wheels and castors), and so is fully specified for use in heavy washdown areas in food and beverage and pharmaceutical facilities.

The Convert-A-Trolley is available now from Tente Castors & Wheels in both powder-coated and stainless steel. Customised versions can be created to special order.

Tente Castors & Wheels 1300 836 831 www.tente.com.au

PRECISION ENGINEERING & LOCAL EXPERTISE mrtaustralia.com.au JOINT AUSTRALIAN / GERMAN OWNERSHIP EXCLUSIVE DISTRIBUTION RIGHTS

CONVEYOR COMPONENTS

Range unmatched from any other Australian supplier. Performance and reliability unmatched and backed. No comparable products on the local market that can match it for quality and performance. Hard to beat price on any other European products. Solutions to most hard to source replacements. Complete roller range offered and assembled here.

CONTAINER LOADING SYSTEM FILLS TO WITHIN 0.1% OF TARGET WEIGHT

way. That clarity and understanding the special arrangement made the project much simpler to put forward, justify and ultimately deliver.”

The entire pre-feeder and pivoted weigh screw conveyor installation is contained on an existing mezzanine situated above the truck loading position. This location has the additional benefit of providing workers with easy access to carry out routine maintenance.

The CAD modelling and attention paid by Active Weighing Solutions engineers to careful measurement also aided easy installation of the upgrade to the container loading system.

In the haulage business, having your trucks sent back from the weighbridge because of over-weight or under-weight containers is a costly exercise.

A new loading system installed at Malteurop Australia now fills 25-tonne containers to within 20kg of the target weight. This equates to less than ±0.1% variation from the target payload, and is significantly better than the requested performance.

Malteurop Australia needed to resolve a weighing issue when filling 40ft containers with malt. When fully loaded and check weighed at the weighbridge, a 40ft container could be found to be overweight. At this point in the supply chain, rectifying an overweight container means there will be obvious double handling and additional production costs.

Overweight trucks were being returned from the weighbridge so that excess product could be removed. This process could mean vacuuming the product out or piercing the plastic liner. The outcome of this also adds the risk of poor container presentation to the customer.

Double handling and increased production costs are also an issue where underfilled containers occur. Underfilling means trucks return to the filling station to receive additional product to meet the specification for the load.

Malteurop Australia approached Active Weighing Solutions for a weighing solution that would enable containers to be loaded within ±0.5% of the total batch. The specification also required the loading system to run at 90t/h (taking about 15-16min to load a nominal 25t batch).

Custom design and 3D modelling

Active Weighing Solutions proposed a pivoted weigh screw conveyor (PWS-C) as a solution to improve outloading weighing accuracy. Pivoted weigh screw feeders and conveyors fully enclose the product stream and are particularly useful where weighing accuracy is important, the product flow is consistent, and the material is dusty or hazardous. This weighing solution is also suited to restricted space situations. (And in this case there was very limited room available in the plant to retrofit more equipment into the loading system.)

Active Weighing Solution’s engineers visited the site and measured up the existing plant. They created a CAD 3D model of the proposed solution. The model showed the existing plant constraints and the location of a custom designed screw pre-feeder and a pivoted weigh screw conveyor.

This visual representation helped plant management to truly understand how the finished weighing equipment would fit into the available space. The operations manager said that “being able to view a 3D model of the finished product assisted in presenting the concept in a graphic and transparent

Engineered for accuracy

Applying a constant weight model design approach to a pivoted weigh screw application ensures the highest possible accuracy. This is achieved through matching screw diameter, pitch, fill capacity and speed, and considering these parameters along with flow rate and material bulk density.

The accuracy that can be achieved in each situation depends a great deal on accommodating these design criteria and parameters, and the real-world applications. Pivoted weigh screws perform at their optimum when operating at a constant weight, delivering the same accuracy across the whole operating range.

The configuration required for Malteurop Australia called for a pivoted weigh screw with pre-feeder. The prefeeder controls the rate of feed into the pivoted weigh screw and allows the screw to run at a constant weight, and therefore with the highest possible accuracy.

Better than expectation

According to Active Weighing Solutions Director Nigel Saul: “The pivoted weigh screw is a great alternative for dusty and toxic products or applications where there is very little height available. We can reliably get within less than ±0.5% if material testing can be performed or ±2% using static weights.”

industry update ad.indd 1

30/08/2011 5:25:30 PM