11 minute read

INDUSTRY POLITICS

It has only been a few months since I commenced as Minister for Industry, Science and Technology, but a lot has happened in that time.

The Morrison Government invested more than $475 million in the May Budget for initiatives that will drive industry growth and scientific development, building on our $1.5 billion Modern Manufacturing Strategy (MMS) announced in the previous Budget.

Advertisement

Manufacturing industries in Australia have shown themselves to be incredibly resilient and adaptable in meeting the challenges of Covid-19. With the support of the government, employment in the manufacturing sector is almost at pre-Covid levels and is on the rise.

The Ai Group’s Australian Performance of Manufacturing Index shows that manufacturing is now a flourishing sector. That is an impressive performance after severe disruptions.

Funding from the May Budget includes $387 million towards building the Square Kilometre Array (SKA), which will be at the cutting-edge of scientific discovery.

The SKA has been called the world’s largest radio telescope, but it actually will consist of two telescopes – one in South Africa, and one in the Murchison region of Western Australia. I am very pleased that this investment in my home state will create hundreds of jobs. In fact, expressions of interest have

just opened for the first SKA related construction contract.

Our investment in this project highlights that science and advanced manufacturing are at the heart of the Government’s National Economic Recovery Plan from the Covid-19 recession.

The Hon Christian Porter MP – Parliament of Australia, Minister for Industry, Science, and Technology

Budget initiatives will drive industry growth

Other Budget initiatives:

• Investing $124.1 million over the next six years to deliver Australia’s first Artificial Intelligence (AI) Action Plan, which will support business to adopt and develop AI.

The investment will unlock highskilled jobs, enable industry wide transformation and improve lives. AI is playing an increasingly important role in modern manufacturing. • $116.7 million over four years for

the Australian Nuclear Science and Technology Organisation (ANSTO). That builds on the $238 million committed over four years in last year's budget to ensure the long-term safety, quality and reliability of ANSTO’s core operations, including nuclear medicine production. (About 7580% of nuclear medicine isotopes used in Australia come from

ANSTO’s Lucas Heights campus in

Sydney, which I recently visited.) • $66.4 million over six years to increase Australia’s workforce skills in cyber security and emerging technologies, including funding for at least 234 scholarships that support emerging technologies areas, such as those identified through the

Modern Manufacturing Strategy. • Advancing Australia’s manufacturing capacity by developing onshore mRNA vaccine capability, through continued negotiations and an approach to the Australian market.

Prior to the Budget, funding was opened for all six of our National Manufacturing Priorities under the Modern Manufacturing Strategy – Defence, Space, Recycling and Clean Energy, Resources Technology and Critical Minerals Processing, Food and Beverage, and Medical Products.

This funding will help manufacturers to scale-up production, commercialise their products and operations, and integrate into domestic and global supply chains.

The government will also accelerate the creation of a $1 billion Sovereign Guided Weapons Enterprise, boosting skilled jobs and helping secure Australia’s sovereign defence capabilities. The Enterprise will support missile and guided weapons manufacturing in Australia for use across the Australian Defence Force.

This strong commitment to manufacturing will continue. As Minister I will work with industry stakeholders to increase the strength and vibrancy of the sector, keeping it at the heart of our economic recovery, as we work to create more well-paid jobs for Australians.

For more information on our industry road maps and available grant funding visit industry.gov.au/manufacturing.

Smart thinking in motion

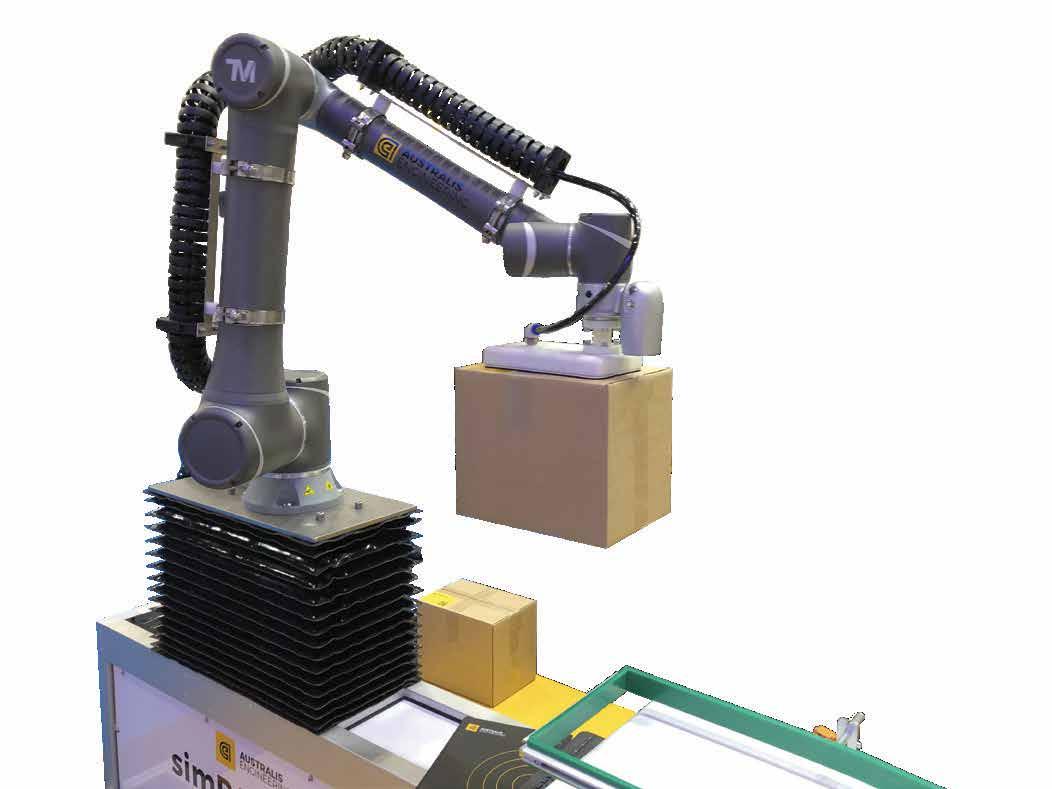

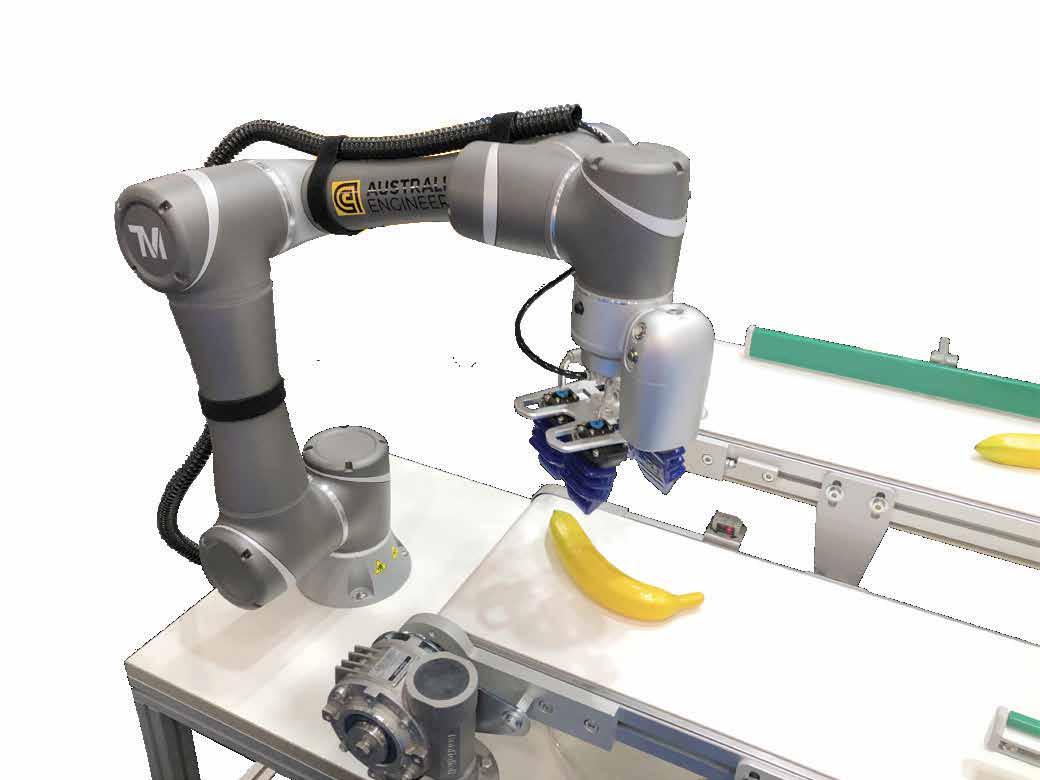

australiseng.com.au FLEXIBLE AUTOMATION FOR A WIDE VARIETY OF APPLICATIONS

TM ROBOT

Stand-Alone Cobot Solutions Smart

Intelligent Vision System Simple

Intuitive Teaching Safe

Human Friendly Robotics

With much flourish, the Coalition announced its plan for a $1.5bn Modern Manufacturing Strategy (MMS), but red flags are already emerging around the future integrity of the program.

Despite the fanfare, MMS has not recorded the creation of a single job, despite Scott Morrison promising to create 80,000 direct jobs in manufacturing.

Senate Estimates hearings at the beginning of June have triggered concerns within the Opposition that existing successful industry initiatives like the Industry Growth Centres (IGCs) may be hollowed out and siphoned off to pay for the MMS – paving the way for another Coalition electioneering slush fund.

Prior to Senate Estimates I had been hearing anxious whispers that the government was getting ready to pull funding for IGCs.

IGCs have a proven track record around the world and have had a positive impact here. It was recently reported that the Federal Government is refusing to release a report into the IGCs that says as much.

They help support collaboration between manufacturers and research organisations, and help assist SMEs to

diversify into new high value products and services.

In Germany, there are 71 Fraunhofer institutes that receive 2.8 billion Euros of public funds annually, compared to the $50 million a year received by growth centres in Australia.

The UK’s Catapult program has seen very good results using a one-third model which draws in funding from the public purse, competitive government grant programs and contract research.

The government’s belief that these local centres can become self-sufficient

doesn’t stack up due to an overall poor program design and lack of funding compared to overseas models – issues made clear in a secret $400,000 taxpayer-funded consultant’s report, as referred to above.

It is claimed the previous minister, Karen Andrews, didn’t see it. I personally find that hard to fathom. Why would a government refuse to acknowledge a report that spoke glowingly of its own work?

Unless that same government found the findings running counter to their determination to kill off the growth centres.

Given the challenges monopolising the attention of the current Industry Minister, I wouldn’t be surprised if he is yet to see it too. But the reports I’ve seen suggest that IGCs are proving effective and could be more impactful with increased government funding.

A fundamental aspect of growth centres succeeding is because they dispense grants based on their deep knowledge of the sectors in which they operate and provide valuable support to businesses.

This seems to be a much more productive pathway for future industry support as opposed to the establishment of a grants program where a government minister makes a final say about funding support, regardless of departmental advice.

This politically venal model has generated all the worst headlines in other areas: sports rorts, road rorts and regional funding rorts. We cannot have industry funding subjected to the same treatment.

For the sake of our economy and future jobs, we need an industry policy and funding model we can genuinely believe in.

The Hon Ed Husic MP – Shadow Minister for Industry and Innovation

Industry Growth Centres could be even more effective with increased funding

THE DEATH OF FIELD SALES

This book shows a better way to grow sales significantly faster than expenses, as we return to business as usual. Get the first four chapters FREE:

deathoffieldsales.com

The days of large field-based sales teams are numbered. Most customers don’t want it and most businesses simply can’t afford it! The Machine presents a radically different approach to sales where salespeople just sell.

11x more selling

It shows how to generate up to 11x more selling conversations for salespeople compared to what your competitors are doing—without adding significant expenses. Yours FREE

GET IT NOW:

deathoffieldsales.com

By Barry O’Hagan Simple, high-quality coffee is revered in Italy. So when an Australian of Italian heritage, who has been involved in the coffee business most of his life and visits Italy regularly, tells you that Australian roasted coffee is the world’s best, you sit up and take notice. And when he goes on to tell you that his business will soon launch one of the country’s first Australian grown and roasted coffees, then you really take notice.

The man we are talking about is Ross Schinella, co-founder of the Schibello Coffee Group. He and business partner Tony Sorbello have come a long way since their business venture’s humble beginnings in a Gladesville garage in 1999.

At the time, there were just 22 coffee roasters in Australia, says Ross. By providing old-fashioned service and building relationships, Schibello Coffee Group has grown to now have national and international presence.

Schibello’s latest goal is to launch its own fully fledged Australian-made product in a market shared by nearly 1,100 roasters. This new blend will be grown in Australia, harvested by Australians, roasted on Schibello’s premises in Sydney and Brisbane, and sold in Australian-made packaging. It may even be bundled with an Australian-made coffee machine.

Why is this so significant? The majority of the Australian coffee market imports raw coffee from countries such as Brazil, India and Colombia to then roast here, as locally grown coffee is rare and also far more expensive. However, Australiangrown coffee is a growing space and Schibello wants to bring visibility and support to local farmers through this new project, as well as explore the unique flavours of our local crop.

“In Australia, we’ve got amazing coffee. Not just great coffee,” Ross told Industry Update. “Worldwide, we are the leaders in coffee. I can tell you, I’ve travelled all around the world and been to every single corner that has coffee, and nobody does coffee like Australia. It’s because we’re dedicated to bringing to life amazing experiences, and we’re educating the rest of the world,” said Ross.

In addition to its Sydney and Brisbane roasteries, Schibello is also looking at expanding its facilities to Melbourne. It also has roasting rooms in Singapore, and exports to Fiji.

“Fiji is our biggest-growing market at the moment. We’re lucky to have some great partners there, and we are probably among the top two brands in Fiji. We also sell coffee in the US; it’s a lengthy process but we’ll slowly educate them on quality and better experiences,” said Ross.

Ross and Tony took their business to another level in 2014 when they acquired the boutique brands Arte Coffee Roasters and Cleanskin Coffee Co. Ross says the latter is not for everyone but is featured in a selection of specialty coffee outlets, where the focus is to create unique coffee experiences. Arte Coffee is targeted at the conscious consumer market, with a portion of all sales donated to the International Women in Coffee Association.

Like good coffee, there’s more to Schibello than meets the eye. Its offering to café partners includes barista training, equipment and merchandise support, business advisory and even design consulting.

What are Schibello’s biggest challenges? Ross says that the closing of Australia’s international borders has created a shortage of hospitality workers and skilled labour from overseas. “There are so many businesses out there chasing chefs, baristas and floor staff. Operators are going back on the tools because they have been forced to. They can’t work on their business while working in the business.”

Ross is the first to admit that the business could not have grown to where it’s at today were it not for a helping hand along the way from St.George Bank. He partnered with the bank from day one, back in 1999. While the loans have grown since then, so too has the relationship.

“That’s the nice thing about St.George. They’ve always had key personnel who are accessible and that’s important. Sometimes you have to make calls and decisions and you don’t need the red tape. The current team at Parramatta are awesome,” said Ross.

“Industry people are also key in this relationship. The best thing St.George Bank did was introduce the industry division, because they have people in there who actually know their stuff. They’re always helpful and always ready to lend a hand.

“We’ve probably stayed so tight because they get us. Guys like Matt (Kelly, Head of Manufacturing and Wholesale) and Pete (Crabtree, Relationship Director) have always been readily available to give us the best advice. The industry experience is important because they obviously know trends. ”If anyone asks me who are the best out there, I always say St.George.”

St.George Bank’s services to Schibello don’t stop at loans either. The bank has been able to help the roaster with advice on currencies and provide access to experts outside the industry on topics such as assets, insurance and superannuation.

Matt, who has known Ross nearly as long as Schibello has been in business, said: “Our relationship has grown over a number of years. We’re proud to have been able to assist them in their acquisitions and growth strategy to help them achieve their goals. We look forward to doing that for many years into the future and using our contacts to help them grow and take advantage of whatever opportunities are out there, such as government grants or R&D opportunities.”

Schibello Coffee gets a latte love from St.George Bank

Schibello Coffee Group CEO Ross Schinella is flanked by St.George Bank’s Head of Manufacturing and Wholesale, Matthew Kelly (left), and Relationship Manager Peter Crabtree, in front of a 120kg roasting unit in Rhodes, Sydney.

Schibello Coffee (02) 9807 6033 www.schibellocaffe.com

St.George Bank 0412 265 197 www.stgeorge.com.au/ manufacturing