41 minute read

BUSINESS & FINANCE

Only 30% of manufacturing workers optimistic about future – well below national average of 80%

Advertisement

A survey has found that while four out of five of Australian workers feel optimistic about the next five years, only 30% of those in manufacturing feel the same way. It also found that 10% of Australian manufacturing workers reported losing their jobs last year.

The findings were based on a global survey of more than 32,000 workers by the ADP Research Institute in November and December last year. They were reported in The People at Work 2021: A Global Workforce View.

The survey, which included 1,902 Australians from all industries, explored whether the effects of the pandemic affected employees’ attitudes towards the current world of work and what they expect and hope for in the workplace of the future.

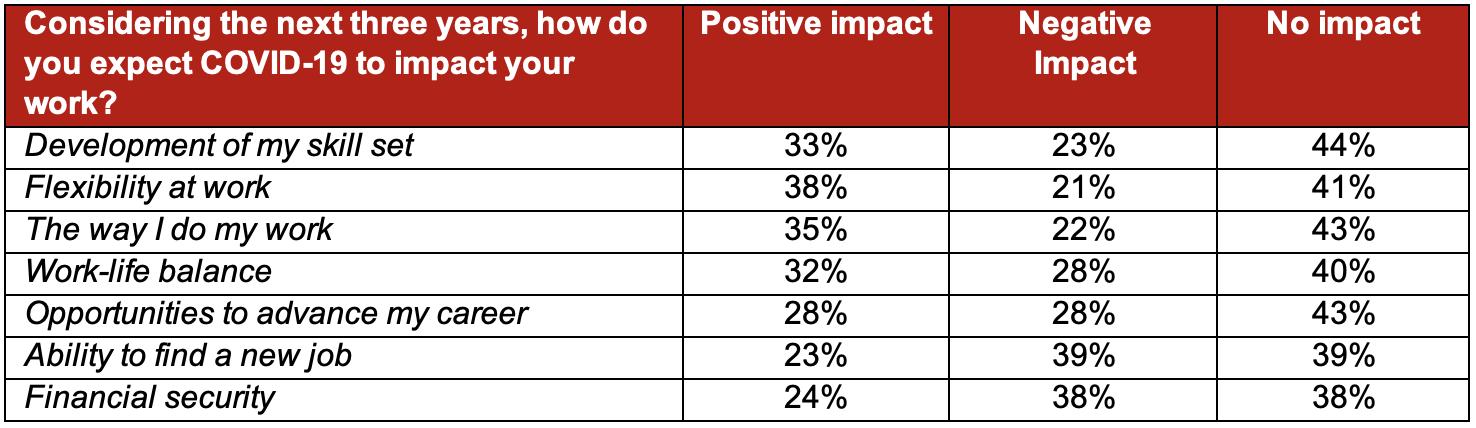

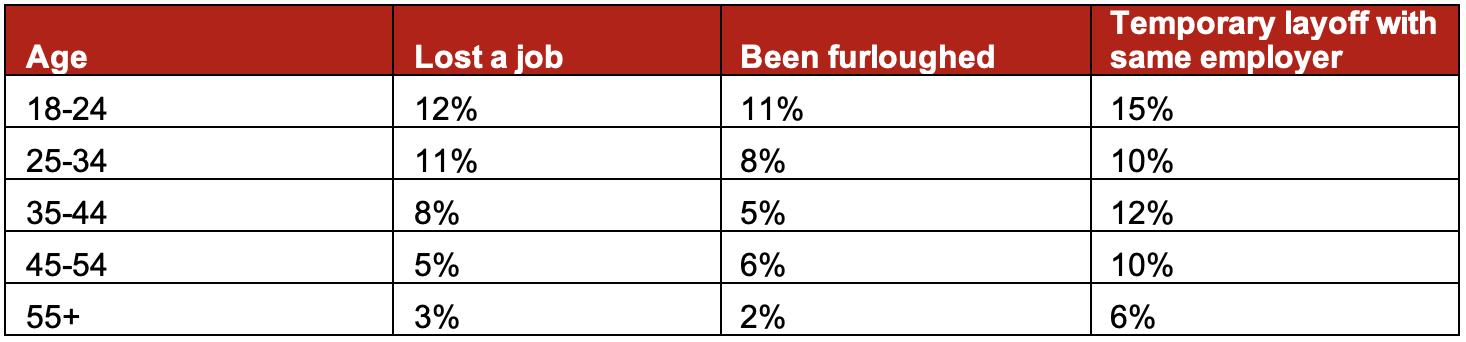

According to the report, three quarters of working Australians felt uncertainty over their job security during the pandemic and more than half were affected professionally by Covid. A quarter of all respondents were laid off (8%), furloughed (6%) or temporarily laid off (11%) by the same employer. In respect of manufacturing, the figures were • Lost a job – 10% • Furloughed – 3% • Temporarily laid off by same employer – 11%.

Of those people who lost their jobs, 17% were in the leisure and hospitality industry, followed by IT/telecoms (11%) and manufacturing. Workers in transportation and warehousing were the most secure, with only 4% being laid off, followed by 5% working in construction and 6% in education and healthcare.

When it came to furlough, real estate workers were the hardest hit, with 13% in this industry saying they were “sent home” at some point last year. This was followed by 9% in IT/telecoms and 8% in hospitality and leisure.

Hospitality and leisure workers were most impacted by temporary layoffs from their employers, with 19% affected, followed by 14% of construction workers and 12% of finance workers.

Industries which feel most hopeful for the next five years in the workplace are IT/ telecoms, construction and finance, with 85%, 85% and 83% respectively saying they feel quite or very optimistic for the next five years in the workplace.

Workers in the real estate, media and manufacturing industries were the most pessimistic for the future, with only 42%, 36% and 30% respectively saying they feel optimistic for the next five years in the workplace.

Those living in Tasmania and Northern Territory are the least optimistic for the five years ahead, with almost a third (31% and 27% respectively) saying they’re not feeling optimistic for the next five years in the workplace, compared to the national average of 21%.

When asked about the affects of Covid-19 on their work in the next three years, more respondents said they expected it to have a positive impact in the areas of skill development, flexibility at work, the way they do their work and worklife balance. Only in their ability to find a job or financial security, did they expect it to have a negative impact.

Peter Hadley, President - APAC at ADP, commented: “This new data from ADP tells us that Australians really felt the pressures falling out from the Covid-19 pandemic.

“Although many people have been hard hit professionally, there’s a sense that what has been a dark could have a silver lining in various ways when it comes to the world of work. Particularly in terms of accelerating the shift towards flexible working patterns, with two in five Australians saying they believe Covid-19 has had a positive impact here.”

He said that understandably, job or financial security was front of mind for many, and these concerns unfortunately reflected reality.

“In a year when many businesses have had to shut temporarily or permanently, or significantly alter their operations, the effects of the disruption and uncertainty on the workforce have been profound,” said Mr Hadley.

“The challenge now for employers and HR teams is to find ways to harness the positives while, as far as possible, alleviating the negatives to ensure that staff stay upbeat, motivated and empowered to do well moving forward.”

Selling conversations, the key to the future

by Justin Roff-Marsh

Assuming that a business has a compelling product (or service), and the ability to execute flawlessly, then growth should be simple. All that business must do is out-communicate its competitors!

Now, some communication can be automated. Advertising, online activities and the like. But once mass communication hits diminishing returns, direct outreach is often required.

Salespeople, in other words.

Once a business reaches that point, it will maximise growth by ensuring that its sales team participates in more selling conversations than its competitors’ teams do, when adjusted for market share.

Note, what moves the needle here is selling conversations. Not salespeople.

If a business wants to participate in more than its fair share of selling conversations, it has two choices. Hire more salespeople. Or, figure out how to get its existing sales team to perform more selling conversations.

The latter is where the true potential is. A typical salesperson spends only a tiny percentage (single digits) of their time engaged in selling conversations. The balance of their time is dedicated to customer service, administration, prospecting, project management, and the like.

The key to get salespeople selling then, is to remove ALL responsibilities other than selling conversations. This requires upgrades to other organisational functions to take over these responsibilities from sales: customer service, marketing and engineering.

The good news it turns out that customers want to communicate online and by phone to the maximum possible extent. Even where major deals are concerned, video conferences are almost always a better alternative than face-to-face visits.

Of course, a few critical activities do still need to occur in the field: and that’s fine.

This fundamental change in market dynamics requires that we make an ideological shift. The salesperson’s pragmatism won’t cut it. We need to embrace this change and recognise that, today, sales is essentially an inside activity supported by discrete field activities on an as-needed basis.

The good news is that this new, insideout approach to sales enables you to exploit economies of scale.

Running a large field sales team is incredibly expensive (on a per-sellingconversation basis) relative to inside sales. An inside salesperson can have up to 30 meaningful selling conversations a day, where a field salesperson will work hard to average 4 meetings.

Moreover, if you insist all sales interactions are held with a field salesperson, you are turning your back on selling conversations that you could have had but will not have if you insist that each prospect accepts a field visit.

This is a critical point!

It’s easy for sales managers to argue (as they do) that field meetings are more effective than phone conversations. However, this argument ignores the fact that, an insistence on field meetings results in salespeople having fewer selling conversations overall.

Justin Roff-Marsh, Founder of Ballistix

Justin Roff-Marsh is the author of the book, The Machine: A Radical Approach to the Design of the Sales Function. You can get the first 4 chapters of this book absolutely free here. https://info.ballistix.com/ sampler-request-industryupdate

Wage rise stimulus arguments 'don’t add up'

The peak national employer organisation representing business has rejected arguments that an increase in the minimum wage would have a similar positive effect on the economy as government stimulus payments. "This argument has substantial flaws and should not be accepted by the Expert Panel of the Fair Work Commission,” said Innes Willox, Group Chief Executive of the Ai Group.

Mr Willox made these comments in his organisation’s second submission to this year’s Annual Wage Review, in which he also argued for a delay in the operative date for any potential pay increase for employers in distressed sectors "Unlike stimulus payments, rises in minimum wages are paid by businesses and other employers and therefore involve a diversion of money from employers to those households which receive higher wages because of the minimum wage decision,” continued Mr Willox. "Because there is no additional money injected into the economy from an increase in minimum wages, there is no comparability between stimulus payments made by governments and rises in minimum wages. One is stimulus; the other is a transfer within the economy. They are chalk and cheese. "We also propose a delayed operative date of 1 September 2021 for any wage increase in Group 2 awards. Last year, the minimum wage increase for these awards was delayed by four months. This year, we propose a delay of two months. This would facilitate a smooth transition to a 1 July operative date for any minimum wage increase next year, if there are no ongoing 'exceptional circumstances'.”

KEEP COOL

ENCLOSURE CABINET PRECISION COOLING

Designed to keep your electronics cool and operating at optimum performance.

- Cooling capacities range from 200W to 6kW. - IP Ratings – IP54 & IP56. - Mild Steel and Stainless Steel finishes. - Seifert also offer Heat Exchangers, Peltier Coolers and Fan Systems - complete Thermal Solutions.

info@seifertsystems.com.au / +61 3 9801 1906 seifertsystems.com.au

CSIRO leads top Aussie researchers in global partnership for low-emissions power

The CSIRO is drawing together leading energy research organisations as part of a global research push to decarbonise electricity systems. The partnership brings CSIRO and the Australian Energy Market Operator (AEMO) together with University of Melbourne, RMIT University and global consultancy Stratagen.

The partnership will comprise the Australian contingent of the Global Power System Transformation (G-PST) consortium, an international group of electricity system operators collaborating with leading researchers to speed up the shift to low-emission, cost-effective and reliable power systems.

The assembly of these researchers and electricity system operators marks an important step towards permanently reducing emissions trajectories, while at the same time improving the reliability, resilience and security of the grid.

Dr John Ward, Research Director of CSIRO’s Energy Systems Research Program, said that the energy sector is “a central tenant of our net zero future”. He said that CSIRO and AEMO would draw on their experience in research-industry collaborations to lead the Australian contribution to the global effort.

The energy sector “accounts for 54 per cent of Australia’s emissions,” said Dr Ward. He also said it “has the most mature range of low emission technology options for immediate and long-term opportunities”.

“The cost of renewable energy is no longer our major challenge – integrating this energy efficiently into our electricity systems is what we need to solve.”

The challenges facing industry are broad. They include solving technical issues, enhancing workforce training and developing new real-time operational tools. Collaboration is the best way to deal with these issues.

CSIRO will act as the Australian research coordinator, as well as contribute directly to the research. The agency will ensure that Australian universities work hand-in-hand with industry, so that research is targeted to our country’s practical needs. Australian industry also stands to gain from the research contributions of other countries shared under G-PST, while our researchers will benefit from global exposure.

The CSIRO-led partnership will commence with a focus on developing Australian research plans in line with the G-PST research agenda. Target themes include quantifying technical requirements of future power systems for reliability and cost-efficiency, and investigating opportunities relating to Australia’s rooftop solar uptake – which is near the global frontier.

Research plans will include a focus on inverter designs and power system stability tools, as well as the restoration of electricity systems with 100 per cent renewable energy.

The collaboration is expected to expand to include more top Australian research organisations.

Australia has critical advantages in developing power systems thanks its world-leading uptake of renewables, said AEMO Chief Operations Officer Michael Gatt.

“Australia is at the forefront of the global energy switch to inverter-based renewable energy, allowing us to provide a unique perspective to develop the power systems of the future,” Mr Gatt said.

“We’re looking forward to collaborating with Australia’s leading science agency, CSIRO, and researchers to address emerging challenges as we transition to a low emissions future energy system."

Business and Health Thoughts The lost opportunity of a millennium

By Frank Ferrara Entrepreneur / Director of Cornick Pty Ltd

Global leaders have missed the rare opportunity to vastly improve the health of people all over the world. The pandemic has grabbed the attention of the global population and provided authorities with the platform to communicate preventative health information to as many people as possible. Unfortunately, they have overlooked this opportunity to communicate knowledge and potentially save lives.

In this crazy age of Covid-19, we are told to wash our hands, maintain social distancing, and wear masks. We are required to record our presence in public areas, shops, restaurants and at sporting events. These are important measures, but they do not provide any advice for healthier living.

Unfortunately, the things being promoted are mask-wearing and selfisolation – far from pro-active solutions. Apart from vaccinations, which have proven difficult to roll out and track, no clear and certain plan for combating Covid-19 has been put forward by world experts.

This is why, as a business owner of 44 years, I say I have never seen a greater marketing opportunity lost, than that surrounding Covid-19. When everybody is listening to what you have got to say, say something useful. The useful message to be heard by everybody is simple; live better.

As business owner in the technology industry and distributor of Italian food and beverages, I find that nothing has been achieved to improve the health and wellbeing habits of the general public. No authority – scientific, medical or government – has put forward the case of healthy living to minimise the possibility of being affected by Covid-19.

Ask yourself:

• Has anyone in the past 15 months given me advice on how I can stay healthy? • Has anyone given me simple advice on how to eat and drink well or how much alcohol is safe to drink? • Has there been any discussion of how to get a great night’s sleep? Or what exercises are best for my body?

Have you heard any of this lifestyle advice that you can use, so if you are unlucky enough to contract Covid-19, you can easily overcome it?

Here are things you can do to improve your health:

Stop smoking

This is a no-brainer, but it is one of the most important things you can do to safeguard yourself against Covid-19. Smoking reduces the availability of vitamin C in the body. Vitamin C is usually involved in the body’s immune response, but when smoking, it is instead utilised for tissue repair, collagen synthesis and wound healing.

To alleviate this, you must eat foods high in vitamin C and possibly take supplemental vitamin C to counteract the effects. High vitamin C intake and cutting out smoking will improve your immune response immeasurably.

Practice moderation

The worst part about drinking alcohol is its impact on sleep. The two do not mix and just because alcohol may be able to put you to sleep, it certainly does not mean you get a good night’s rest. So cut it out. If you must drink, do not drink after dark. This impacts your circadian rhythm and prevents your body from recovering properly, leaving you open to infection.

While drinking alcohol in the daytime is not ideal, it has less chance of affecting your sleep. People that do drink frequently are far more likely to get pneumonia or respiratory syndromes, as well as cancers and liver diseases.

Eat a Mediterranean diet

There is compelling evidence that the Mediterranean diet is best to keep you healthy. This diet typically involves increased consumption of vegetables, legumes, fruits, nuts, extra virgin olive oil, fish and low consumption of red meat and dairy products that are high in saturated fats.

Research has shown that the traditional Mediterranean diet can help you live longer, with reduced incidence of many diseases, reduced inflammation and reduced overall frailty as you age. This is because the Mediterranean diet is full of foods containing high concentrations of compounds called polyphenols (pronounced ‘Poh-Lee-Feh-Nuhls’).

Polyphenols are micronutrients that have antioxidant and, in some cases, anti-inflammatory properties. These properties help them absorb oxygen free radicals, which can otherwise cause degenerative diseases that are the major killers in Western society – such as cancer and cardiovascular disease. In addition to protecting from diseases, polyphenols also help protect your skin from ultraviolet radiation, reduce brain degeneration and reduce the signs of aging.

Stay healthy and be great.

Hydraulink Jim Read Racing dragster wins Nitro Thunder event with ‘best under pressure’ race

The Hydraulink-sponsored Jim Read Racing team has added another trophy to its cabinet with a dramatic win at the 2021 Gulf Western Oil Nitro Thunder event.

The Hydraulink top fuel dragster, driven by Jim Read’s son Phil, came up against experienced drag racer Peter Xiberras in the final. Xiberras had consecutively beaten two personal bests in the lead-up to the final, achieving 3.797/315MPH (about 507 km/h) and was looking unstoppable.

In a last-minute twist, both cars rattled the tyres out of the gate and had to frantically pedal to the finish line, with Read getting the upper hand, in what he described as a “Stephen Bradbury style victory”.

The event was the penultimate round of the 400 Thunder championship for all brackets ahead of next month’s Winternationals, and after a tough year full of Covid disruptions, Phil Read was delighted to be back out on the track.

“It’s been a great weekend with such an awesome crowd in attendance. I really wanted to win this event for the Hydraulink franchisees who are here today. They’ve been so supportive of us whilst racing was suspended over the last year due to Covid. If you want to finish first, first you have to finish. The last race with Peter Xibberas just showed how much both of us wanted the win, and I’m glad I could do it for the Hydraulink franchisees,” he said.

Hydraulink Australian National Franchise Manager Wayne Abbott said: “Hydraulink had 40 people, including franchisees and customers, witness Jim Read Racing’s dramatic win. They learnt a lot about how the Hydraulink Top Fuel Dragster team works together. The Jim Read Racing team performed ‘Best Under Pressure’, just like the Hydraulink franchisees do when it comes to fast and reliable 24/7 mobile hydraulic hose and fitting repairs.

The event spectators included mechanics from the automotive, diesel and heavy plant industries who typically make outstanding franchisees within the Hydraulink network.

Hydraulink is expanding its network of more than 400 service points throughout Australia, New Zealand, Pacific Islands and the Western United States, drawing interest from areas as diverse as Kalgoorlie in the goldfields of Western Australia, the Marlborough vineyards of New Zealand, and the rapidly expanding site of Sydney’s second new airport at Badgery’s Creek, which, by itself, will create tens of thousands of jobs and involve massive infrastructure, earthworks, roads, transport and heavy machinery demand.

Covid has made many people think more about securing their future financial independence. “Owning a franchise where you can be your own boss, and where you’re backed by the resources and support of the Hydraulink network is highly appealing to people with mechanical aptitude and ambition for success,” says Mr Abbott.

“Familiarity with a broad range of machinery, from agricultural to earthmoving to road and civil, to forestry and more is certainly an advantage, but we’re looking particularly for motivated, ambitious individuals with strong ethics. We can always teach the right people the right skills,” he said.

Hydraulic service specialist Hydraulink supplies hydraulic hoses, fittings, adaptors and accessories to major industrial markets in Australia and New Zealand, including construction and infrastructure, roads and earthworks, civil engineering, mining, energy, oil and gas, agriculture, materials handling, manufacturing, rental industry, transport and machinery servicing, handling machinery, waste management recycling machinery, and safety.

For further information about franchise opportunities, please contact Wayne Abbott, National Franchise Manager, Hydraulink Australia Pty Ltd, 61-2-8785 4600 61 455 478 699 wayne@ hydraulink.com.au

For further information on Hydraulink, please contact Daniella Laurenzi, Group Marketing Manager, Australia and New Zealand, Hydraulink, 123 Long St, Smithfield NSW 2164, ph 61-2-8785 4600, Daniella.L@hydraulink.com.au

The winning team (from left): Jim Read, 16 times Top Fuel Champion and International Hall of Fame Legend; Phil Read three-times Top Fuel Champion and winner of the event; Bruce Read, Team Principal; and Guss Ussia, Car Chief.

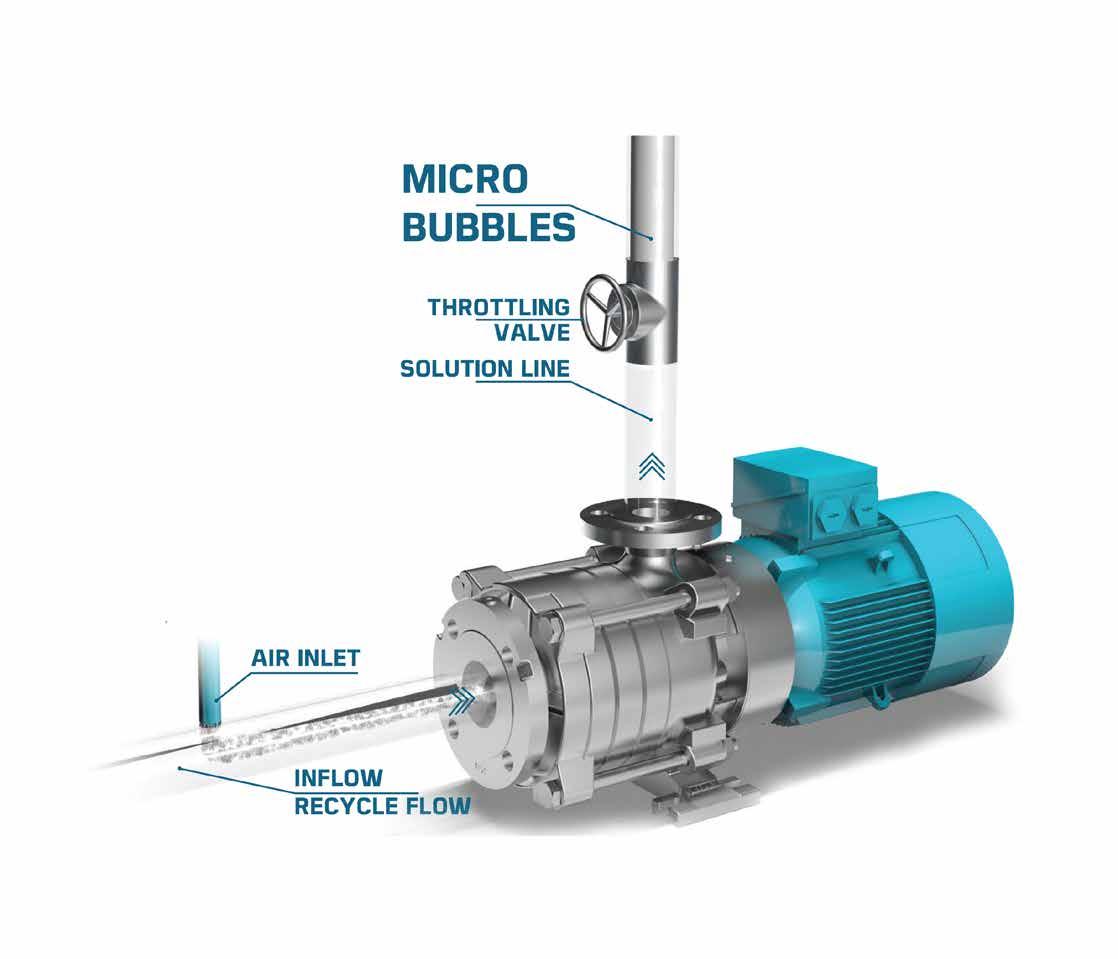

DAF PUMP

Hydraulink Australia 1300 36 37 34 www.hydraulink.com

Velisha Farms sews the seeds of safety

By David Sligar A leading grower and producer of premium vegetables in Australia, Velisha Farms has long been a class act in business and the community. It should come as no surprise then that Managing Director, Catherine Velisha, has stepped up to become a safety ambassador for Worksafe Victoria.

Ms Velisha follows in a long family tradition. Her grandfather and his brothers set up in the industry in 1949, starting as dairy farmers. After moving into horticulture, they became one of Australia’s first exporters of cauliflower and broccoli.

Ms Velisha is well placed to advise on a broad range of safety matters as the business spans both packaging and agriculture, which she describes as one of the “most dangerous industries.”

At its Werribee South headquarters, Velisha Farms runs a large packaging facility, co-located with a farm for broccoli, cauliflower and iceberg lettuce. The firm also grows zucchini, brassicas, kale, coriander, parsley and celery at other locations around Australia.

“We obviously have a packing facility which is lots of machinery, of moving parts, lots of people,” Ms Velisha said. “On a farm, you’ve obviously got really dangerous equipment like tractors and harvesters.”

One of Ms Velisha’s strong beliefs is that “good safety is good business”.

“It’s a benefit to productivity because when you’re constantly looking at your processes and your people, what it does is make sure you’re running as effectively and efficiently as you can. So we see it as a benefit to our business, not a cost.”

And Ms Velisha should know. She has been surrounded by farming her whole life, even before entering the family business at 19. There has been tremendous change in farming, she said, particularly in terms of professionalisation and safety.

But Velisha lists “fear” as one of the factors that can slow the evolution. It’s human nature to stick to existing ways of doing things. However, she believes that peer education between businesses at different stages of the journey can play a crucial role.

“What we need to do is help other businesses have access to people who will help then, and meet them where they are,” she said.

“It’s education, it’s giving that approachable, understandable, real life knowledge to people so they can implement.”

To this end, Ms Velisha has united with Worksafe Victoria, which aims to promote high standards of safety and to provide insurance protection to businesses for workers.

“There’s people out there that want to help you; make sure you educate yourself and your people to help build capacity.”

Her safety promotion comes on top of a busy schedule. Velisha Farms employs around 70 people and sells to wholesalers, supermarkets and major retailers, while exporting to Indonesia, Singapore, Philippines and Malaysia.

Acoustic moving walls for luxury gymnasium in Port Melbourne

Bildspec recently completed another quality installation of its Series 100 Double Glazed Operable Acoustic Walls at the PM Gym, part of PM Port Melbourne at 320 Plummer Street - luxurious high-rise apartment living at its finest.

PM includes two residential towers and a luxury apartment hotel as part of a grand renewal plan for the area. Located in the new suburb of Fisherman’s Bend, PM is changing the street scene with the evolution of the sleepy industrial estate into a bustling, vibrant suburb to accommodate 40,000 new residents, with access to eight new green spaces, walking trails, bicycle lanes, an extended tram line into the city, three new schools, and within walking distance of the beach and waterfront cafes and bars.

Designed by Elenberg Fraser, the complex is as luxurious in its exterior as it is inside. Luxurious amenities include a health and wellness retreat with state-ofthe-art gymnasium.

Bildspec was engaged to supply and install bespoke double glazed acoustic moving walls intended to provide an acoustic separation between the main workout room and weights gym. This uniquely designed project required three off-pivot panels requiring precision alignment between the inset display windows and the archway above them. The top track has been concealed in the arched window mullion to ensure a seamless connect between the different bottom sections and overhead panels.

The "Navurban Clifton Hill" Veneer (by New Aged Veneers) coupled with the Electro Dark Bronze frame colour contributes to a clean, relaxed and natural finish befitting such a luxurious wellness centre.

For further information, visit Bildspec's website at www.bildspec.com.au or contact the office on 1300 967 672 or send an email to sales@bildspec.com.au.

Australian Trellis Door Companys 1800 657 435 www.trellisdoors.com.au

ATDC installs old-style expanding door at Adelaide Station

The Australian Trellis Door Company (ATDC) has recently installed its S06 commercial expanding door to secure the front entry to Adelaide Railway Station, which is part of the Adelaide Festival Plaza Upgrade.

Specified by Adelaide based ARM Architecture and project managed by construction firm Hansen Yuncken, the 7000mm wide x 4500mm high black satin, powdercoated, expanding door has been fitted with intermediate up/down locking mechanisms for seamless lockup.

The open grille old-style appearance of these scissor action doors produced by ATDC means they are frequently specified on heritage buildings and are often installed at railway stations such as Wynyard Station, St James, North Sydney and Central Station in Sydney.

For further information on ATDC’s range of commercial expanding doors please visit its website at https://www.trellisdoors. com.au/products/commercial-security

Australian Trellis Door Companys 1800 657 435 www.trellisdoors.com.au

Oxygen Analysers, Relative PRODUCTS U.V Absorption Humidity Sensors and Meters, Conductivity Thermal flow switch helps keep AMS Instrumentation & Calibration Pty Ltd pH / ORP ColourDewpoint Measurement tunnels safely ventilated Analytical Process Division

Powerful fans are used to ventilate rail and road tunnels, but which direction should they be blowing in and how strong should the airflow be? That’s where a thermal flow switch such as the FLT93S from Fluid Components International (FCI) comes into the picture.

Supplied by AMS Instrumentation & Calibration, it helps manufacturers of powerful industrial fans and blowers used in the transportation industry to obtain accurate airflow control data under variable vehicle traffic conditions.

Proper tunnel ventilation is critical to maintain tunnel temperatures within acceptable limits and to help control the flow of fresh air to prevent unhealthy toxic carbon monoxide (CO) exposure, as well as smoke or gas in the case of fire or other emergencies.

Depending upon a tunnel ventilation system’s design, the airflow fans must operate in either a forward or reverse airflow configuration. For example, during emergencies requiring air, gas or smoke evacuation, a flow switch such as the FCI Model FLT93S needs to detect forward or reverse fan airflow to prove air is blown into or extracted from a tunnel where vehicle drivers and emergency responders can be either trapped or at work.

The versatile FLT93S Thermal Flow Switch can be configured with a uni-directional shroud to help verify the airflow direction of each tunnel fan. FCI developed this special shroud for the FLT93S Switch, which allows the detection of airflow from a single direction. By installing two flow switches per fan, engineers and operating technicians are able to verify with confidence the direction of airflow for each fan in a tunnel.

The FLT93S Thermal Flow Switch is suitable for placement in tunnel ducts or fan casings up to 2.4 metres in diameter. It can detect airflow ranges from 0.08 to 37 NMPS with flow accuracy as precise as ±2% of the setpoint velocity over a ±28°C temperature range; repeatability is ±0.5% reading. Flow elements are available for operation and survival (in the case of adverse conditions) for process Oxygen Analysers, Thermal Conductivity Analysers, NDIR require virtually no maintenance. There is Industrial Water Analysers and Liquid Analytical Products (pH, Conductivity, The FLT93S from Fluid Components International temperatures up to either 260°C or Analysers, Multigas nothing to break, clog or foul that requires ORP, Dissolved 454°C.Analysers, OEM Analysers continuous maintenance technician Oxygen, etc)

Based on FCI’s thermal dispersion attention. They are available with a choice expertise, the unique sensor technology of materials: 316 L stainless steel, Hastelloy NSW Ph: 02 9911 6615Head Office: of the FLT93S Switches, combined with FlexSwitch temperature-compensation circuitry, introduces unparalleled or exotic materials. In addition, these switches offer an exceptionally long life and a low lifecycle cost. WA Ph: 08 9201 0984 QLD Ph: 07 3387 7706 SA Ph: 08 7221 2205 Unit 20, 51 Kalman Drv Boronia VIC 3155 Ph: 03 9017 8225 performance capabilities for a wide range Fax: 03 9729 9604 of heavy-duty industrial applications. AMS Instrumentation &

Featuring an all-welded, no-moving Calibration www.ams-ic.com.au parts design, the FLT93S Switches www.ams-ic.com.ausales@ams-ic.com.au

Custom-made ladder rung covers provide much-needed safety

Along with the pain suffered and the lost time due to the seriousness of the injury, worn out, shiny, oily and greasy metal ladder rungs are among the main reasons why slipping and falling down ladders have become major concerns. Paints and tapes have been tried in the past but offer little long-term protection, and can become a regular and costly maintenance job.

Floorsafe Australia is sensitive to cost considerations, and is always looking for better ways to easily fix and solve a problem. The company now custommakes round and square Safety Tread metal ladder rung covers that will fit snuggly over the old and unsafe metal rung.

Manufactured from a 1.6mm metal, the metal is cut to length and shaped to fit over any size diameter rung. A special primer process is applied before applying three coats of a high-quality two-part polyurethane. A fine grade carborundum oxide grit is incorporated into the final coating, which increases the hardness and provides a high slip rating that meets the Australian slip standards. The product is of the highest quality and comes with a five-year wear warranty.

The company also supplies costeffective round Fibreglass ladder rung covers. Available in standard 20mm, 25mm and 30mm diameters, they are supplied cut to any length.

Installation is quite simple once the existing rung has been cleaned. Just apply an adhesive bead inside the new ladder rung cover and place over the existing rung. Floorsafe can also provide the 11FC fast-curing construction adhesive, which is available in cartridge and sausage form.

As a national supplier of aluminium and Fibreglass stair nosings, tactile indicators, skateboard deterrents, wheel stops and safety tapes, why buy any product when you can have a quality Floorsafe product?

Floorsafe is a five-star company that offers a complete range of quality products that get delivered on time.

Floorsafe Australia 1300 717 769 www.floorsafe.com.au

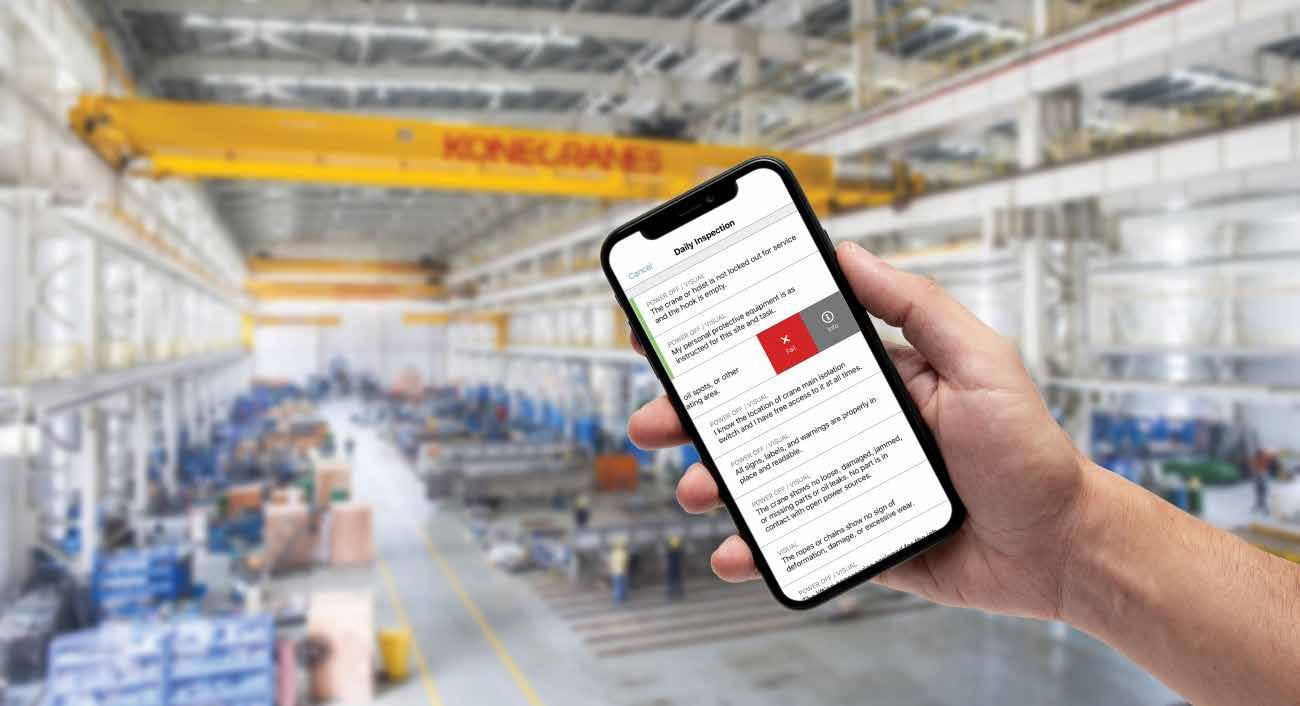

Konecranes' new app to help crane operators

Konecranes is launching an app to help crane operators with their daily pre-shift and pre-lift inspections.

CheckApp has been designed to help crane users quickly and easily record their findings. These pre-start inspections are part of the owners’ manual documentation of every crane and hoist, but Konecranes realised that thick paper manuals were not the most efficient way to conduct daily inspections.

A lot of countries also require these pre-start inspections to be done as a matter of code compliance.

“CheckApp was conceived as a great way to deliver an effective inspection format direct to any crane operator. Being electronic, it also becomes an accessible permanent record, unlike paper, which can be lost or misplaced,” said Mr John Jackman, Modernisation and Light Lifting Sales Manager, Konecranes and Demag.

Mr Jackman was part of a team that developed the idea for CheckApp. The idea for this clever new app was the winning submission from a Konecranes global innovation contest.

Inspection template

“Almost everyone has a mobile device of some kind. Using electronic technology allows us to not only provide a quality, convenient inspection template, but also allows us to build in additional reference for those learning to do inspections properly,” he said.

“In a practical sense, one of the most important functions the CheckApp achieves is that it improves the communication between a person identifying a fault and the repair of that fault by maintenance,” says Mr Jackman. “No one wants an operator using a crane with a potentially dangerous fault condition.”

“I’m delighted to see the app ready for release. It’s a cost-effective way for customers to record and retrieve daily inspection data that can be used for internal auditing and compliance,” said Mr Jackman.

“The app supports Konecranes Service’s mission to provide smart technology and a digitally-enabled customer experience to improve the safety, productivity and sustainability of our customers’ operations,” he said.

The app can be downloaded for free from the Apple AppStore and from Google Play for Android devices.

Daily Inspections

A daily inspection is a user’s – or crane operator’s – own assessment of the condition of an asset and environment for safe use. It is not an expert’s examination of the condition of an asset or component. Konecranes CheckApp for Daily Inspections follows the guidance set in the ISO 9927 standard and in applicable statutory regulations.

Daily inspection records are accessible on the yourKONECRANES customer portal where, combined with maintenance history and condition data collected from selected components with TRUCONNECT Remote Monitoring, customers get a comprehensive view of the condition of their assets in one easily accessible place. This data assists in planning maintenance actions and provides an audit trail of performed daily inspections.

Deficiencies

The Daily Inspection view in yourKONECRANES shows daily inspection details as well as useful summary views. Daily inspection details – revealing who performed the inspection, when it was performed, what deficiencies were reported – are accessible through the activity, overview and asset fleet views. A detailed summary for the selected timeframe is provided in the Business Review tab.

Benefits include:

· Satisfies regulatory requirements helping businesses stay compliant · Allows for easy and reliable auditing of performed daily inspections · Easy-to-use mobile app can help motivate users to perform daily inspections on a regular basis · Assists with timely recognition of potential asset-specific safety or production risk issues · Assists in identifying workplace improvement opportunities · Assists in identifying needs for operator training as well as deviations in following local safety and other site rules

Konecranes 1300 937637 www.konecranes.com.au

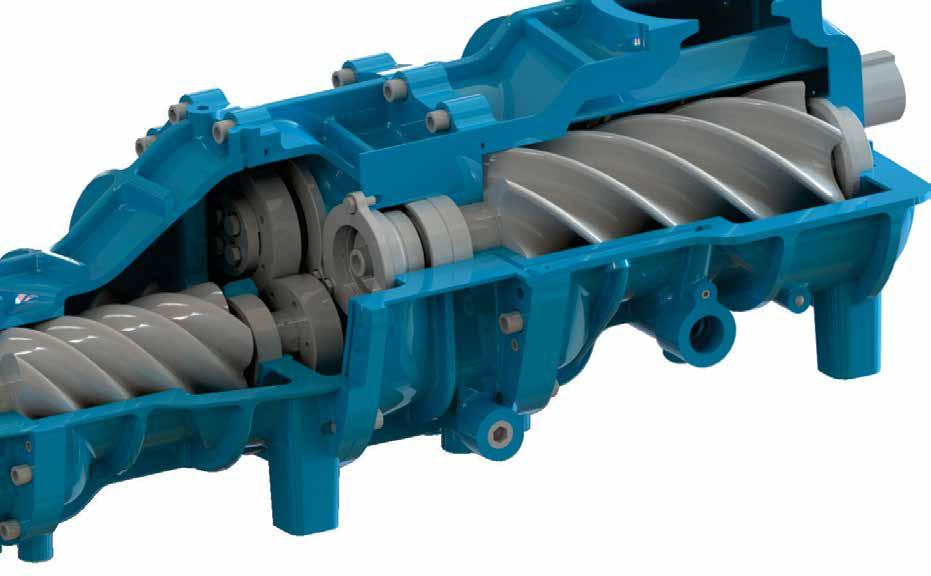

PRODUCTS High efficiency grit removal showcased at water conference

Independently tested grit removal technology that achieves 95% efficiency down to 105 microns over 10:1 turndown was introduced to the annual conference of the Queensland branch of the Water Industry Operators Association in Toowoomba on June 2-3.

CST Wastewater Solutions installation and service specialist Peter Bambridge introduced WIOA delegates to the Smith & Loveless PISTA VIO grit removal system, for which it is exclusive Australian distributor.

Smith & Loveless says most grit removal systems are designed only to remove grit in the 200-300 micron range, but typically 40-80% of grit in wastewater is in the 105-200 micron size range. These findings motivated the company to develop a superior grit removal system down to 105 microns.

“With so much of Queensland and Australia’s population living near the coast and in often remote sandy areas, such markedly superior grit removal offers immediate and long-term benefits in helping to prevent common grit problems in municipal and industrial water and wastewater systems,” said Mr Bambridge.

Left unchecked, grit build-ups create trouble throughout the entire wastewater process, he said. They expose plants to wear, blockages, breakdowns, flooding and hazardous recovery operations by public and private wastewater operations staff. They are on the front line of defence against such issues causing downtime and service interruptions in municipal and private industrial applications, including food and beverage.

“The Smith & Loveless technology provides clear benefits to municipal and industrial organisations plagued with grit issues. And now we’ve had the system independently tested to confirm its performance, and it reached the 95% benchmark it was designed to achieve,”

Smith & Loveless’ PISTA technology sets a new benchmark in grit removal, with 95% efficiency down to 105 microns over 10:1 turndown.

said Mr Bambridge.

The latest PISTA VIO grit removal system features full variability of inlet and outlet channels. It also features a hydraulic vortex grit chamber design that utilises a new baffle system. This type of grit removal system – one of the first of its kind in the industry – provides the ability to design the inlet and outlet channels at any variable angle up to the full 360° of the chamber. Designers can arrange the system to fit existing sites, or maximise space during construction on new sites.

KDS liquid-to-solid separator

This highly efficient, low-maintenance technology – also available in a skid mounted version for easy transportation via truck or trailer, including to remote sites – requires no washwater, while capturing up to 95% of solids. KDS technology removes more than 50% of the water from wastewater sludge to provide a 50% reduction in transportation costs (which are typically $150 per tonne or higher).

“The new skid-mounted KDS technology offers potential users a highly effective plug-and-play solution to waste processing needs,” says Mr Bambridge. Measuring only 3.8 by 2m, it offers the type of low-maintenance high efficiency that is so important where agribusiness, industrial and municipal operations don’t have the resources to place engineering staff on close standby.

Fine Screening

CST’s locally manufactured screens provide a first line of defence in wastewater or waste management plants.

CST provides fine screening down to 3mm to safeguard later parts of the treatment plant from larger bulkier waste that could clog systems and cause unwanted downtime.

In addition to supplying quality product, CST’s Services Division also maintains and services screens to optimise their performance and ensure they can cope with varying loads.

Clarifiers

With more than 120 installations throughout Australia, CST has the experience, resources and capability for clarifier projects of diverse types, says Mr Bambridge. CST – as an authorised Australian representative of Smith & Loveless – provides a complete range of Clarifier designs and systems for all municipal and industrial water and wastewater treatment applications. The CST range presented at the WIOA conference incorporates circular and rectangular Clarifiers, CLAR-I-VATOR solids contact clarifiers and high rate lamella and tube settler systems.

Design Features & Options:

• Centre & Peripheral Drive Systems • Flat Floor-Suction Arm Systems • Concrete & Steel Tank Designs • Launder Covers & Cleaning Systems • Thickeners & High Solids Systems • EDI & Floc Well Design Options • Retrofit & Upgrade Designs

FOODPRO 25-28 July 2021 Sydney Showground Sydney Olympic Park https://foodproexh.com/

WORKPLACE HEALTH & SAFETY SHOW 7 & 8 September 2021 Sydney Showground Sydney Olympic Park www.whsshow.com.au/sydney

MODERN MANUFACTURING EXPO 7 & 8 September 2021 Sydney Showground Sydney Olympic Park

WORKPLACE HEALTH AND SAFETY SHOW 25 & 26 May 2022 Melbourne Convention & Exhibition Centre

SAFETYSCAPE 25 & 26 May 2022 Melbourne Convention & Exhibition Centre

ELECTRONEX 15-16 September 2021 Rosehill Gardens Sydney https://www.electronex.com.au/?ref=tradefest. io&utm_campaign=tradefest.io&utm_ source=tradefest.io&utm_medium=tradefest.io

AUSTRALIAN MANUFACTURING WEEK 2022 8-11 March 2022 Australian Manufacturing Technology Institute Ltd Co-located with AUSTECH Melbourne Convention and Exhibition Centre https://australianmanufacturingweek.com.au INTERNATIONAL CONFERENCE ON MANUFACTURING ENGINEERING AND TECHNOLOGY

WORLD ACADEMY OF SCIENCE, ENGINEERING AND TECHNOLOGY ICMET 2021

2-3 December 2021 Sydney NSW https://waset.org/manufacturing-engineeringand-technology-conference-in-december-2021in-sydney

ENERGY NEXT IN PARTNERSHIP WITH THE CLEAN ENERGY COUNCIL 13 & 14 July 2021 ICC Sydney Energynext.com.au

ALL-ENERGY AUSTRALIA 2021 IN PARTNERSHIP WITH THE CLEAN ENERGY COUNCIL 27 & 28 October 2021 Melbourne Convention and Exhibition Centre all-energy.com.au

WASTE EXPO AUSTRALIA 27 & 28 October 2021 Melbourne Convention and Exhibition Centre wasteexpoaustralia.com.au

ENERGY EFFICIENCY EXPO AUSTRALIA 27 & 28 October 2021 Melbourne Convention and Exhibition Centre

energyefficiencyexpo.com.au

They said it..

The best industry and political quotes of the past and present:

“Most of the important things in the world have been accomplished by people who have kept on trying when there seemed to be no hope at all.” Dale Carnegie, American writer and lecturer

“It's OK to have your eggs in one basket as long as you control what happens to that basket.” Elon Musk, entrepreneur

“Meetings are indispensable when you don't want to do anything.” John Kenneth Galbraith, CanadianAmerican economist

“Do not compromise on the quality and your customers will not negotiate on the price." Amit Kalantri, author “Most of what we call management consists of making it difficult for people to get their work done.” Peter Drucker, Austrian consultant, educator, and author

“If you could get all the people in the organisation rowing in the same direction, you could dominate any industry, in any market, against any competition, at any time.” Patrick Lencioni, American business author

“The way we look at manufacturing is this: the US's strategy should be to skate where the puck is going, not where it is.” Tim Cook, Apple CEO

“If I have over a thousand ideas and only one turns out to be good, I’m satisfied.” Alfred Nobel, Swedish chemist, engineer, inventor, businessman and philanthropist

1. How can you throw a ball as hard as you can and have it come back to you, even if it doesn't hit anything, there is nothing attached to it, and no one else catches or throws it? 2. A man stands on one side of a river, his dog on the other. The man calls his dog, who immediately crosses the river without getting wet and without using a bridge or a boat.

How did the dog do it? 3. You’re escaping a maze, and there are three doors in front of you. The door on the left leads to a pit of lava. The door in the centre leads to a room filled with deadly gas. The door on the right leads to a lion that hasn’t eaten in three months. Which door do you choose? 4. Four cars come to a four-way stop, all coming from a different direction. They can’t decide who got there first, so they all go forward at the same time. They do not crash into each other, but all four cars go. How is this possible?

hasn’t eaten in three months would be dead. 4. They all made right-hand turns. ANSWERS: 1. Throw the ball straight up in the air. 2. The river was frozen. 3. The door on the right. A lion that

Make a clean start on the road to prosperity

Our focus on industrial cleaning products in the August/September edition of Industry Update is timely, given the recent Covid-19 outbreak in Melbourne.

While we now have an array of risk management tools under our belts to help us navigate our way through the pandemic, cleanliness, in all its forms, remains one of the strongest weapons in our arsenal.

In the next edition, we will also explore the ebb and flow in the world of compressors and pneumatics, fluid control, pumps, pipes and valves.

We’ll have our ears to the ground for stories from the world of industrial flooring and our measuring tapes out to size up what’s happening in test and measurement, handle sensors, and weighing and instrumentation.

If you’re interested in 3D technology, we’ve also got you covered.

You can expect our usual coverage of topics such as Workplace Health and Safety, Business and Finance, Education and Training, Security, Environment and Waste Management, Machinery, and Metalworking and Machine Tooling.

Don’t miss out.

Call Scott or Dominic about your advertising needs on 02 9439 1288, and send your editorial to editor@industryupdate. com.au before 21 July 2021.

PBE-Roboplas' Yizumi 5 offers 'excellent value proposition'

By David Sligar Sydney-based PBE-Roboplas provides a versatile range of plastics machinery and ancillary equipment. This includes injection moulding, blow moulding, loading, drying, temperature control and dosing systems.

Francis Frutschi, father of current part owner Gerald, has been in the plastics business for more than 40 years. After immigrating to Australia from Switzerland in 1970, he began working for a machine agent where he was importing high speed injection moulding machines from Switzerland.

“That agency did well at the time because the industry was in a growth stage as plastics became wildly recognised as an economical packaging and engineering material solution,” said Gerald.

Francis Frutschi went on to found Roboplas in 1985, which in 1997 merged with Paul Blunschi Electrics (PBE).

“My father’s been in this industry for a long time,” said Gerald. “That’s his life.”

Today the bulk of their business comes from injection and blow moulders, who use the machines and equipment for diverse purposes.

“Their machines need to be very flexible and universal,” he said. “A lot of the moulding is based on an engineered component or a storage solution such as food and beverage as an example.”

PBE-Roboplas, which employs eight people, saw an upturn in orders during the pandemic. “It has been good for us,” he said. “With significant offshore outsourcing, businesses suddenly had to find alternatives, returning focus to Australian manufacturing. With recent government depreciation incentives and very limited good quality used equipment available, we have seen an increase in sales.”

PBE-Roboplas is the exclusive distributor of Yizumi in Australia.

The most popular model in the Yizumi range is the Yizumi A5. This range offers “an excellent value proposition”. It is precise and stable, has a wide range of capabilities, is energy efficient and is very user friendly.

The all-electric range from Yizumi is also gaining popularity. These machines have electric drives instead of a hydraulic system. The solution provides further process accuracy, speed, improved power efficiencies over the A5 range. “The real benefit of the electric machines is a tighter process control”.

The Yizumi range also includes large capacity 2 platen and high speed packaging injection moulding machines.

Other brands offered by the

High precision six-axis robots, with repetitive accuracy of +/- 0.03mm. These feature end-of-arm loads from 3-550kg.

company include Sinco, Tool Temp, Ferlin, Crizaf, Wemo, and Enmair.

Repairs and maintenance are an important part of the PBE-Roboplas business. The firm can help with hydraulic, mechanical, and electric aspects of the machines.

“We have a service group who are all are technically knowledgeable. As a maintenance crew, we’re very competent and skilled,” said Gerald.

“There’s sometimes small niggling problems, where it might be a 1 in 100 cycle fault. They can be very difficult to find, a bad electrical connection for instance. But we usually find it.”

Gerald believes there are genuine environmental concerns with plastic disposal and recycling. “Plastics are falling out of favour because of environmental issues, however we are still a long way from large-scale transition out of plastics.

“There have been positive movements in alternative and natural materials, recycling processes and recycled products, but the problem is so large scale because plastics by themselves have been such an effective and broad solution.

“There needs to be a novel solution where we can quickly, easily and cheaply remove plastic from the environment at the same rate as its introduction,” concluded Gerald.

PBE-Roboplas (02) 9674 6511 www.pbe-roboplas.com.au

The SpecialiSTS in elecTronic DriveS for over 30 yearS

• Repairing of complex electronic boards, including obsolete boards that are no longer supported by vendors • Design and construction of multi-drive systems • Professional Control Systems Integrators • Repairing/retrofitting of electronic AC, DC and servo drives • Laboratory & Clean Room • Large Stocks of Spare Parts • Australia wide 24 hour service Datafactory

Contact us for a free

no obligation quote today

INDUSTRIAL & COMMERCIAL

DOORS & GATES

24/7 Emergency Breakdowns Preventative Maintenance New Installations

Over 12 years experience

0432 127 279

service@vulcandoors.com.au