14 minute read

ELECTRONEX

Electronics Expo returns to Sydney in April Melbourne Park F unction Centr e 11-12 September 2016www.electronex.com.au

By Claire Moffat

Advertisement

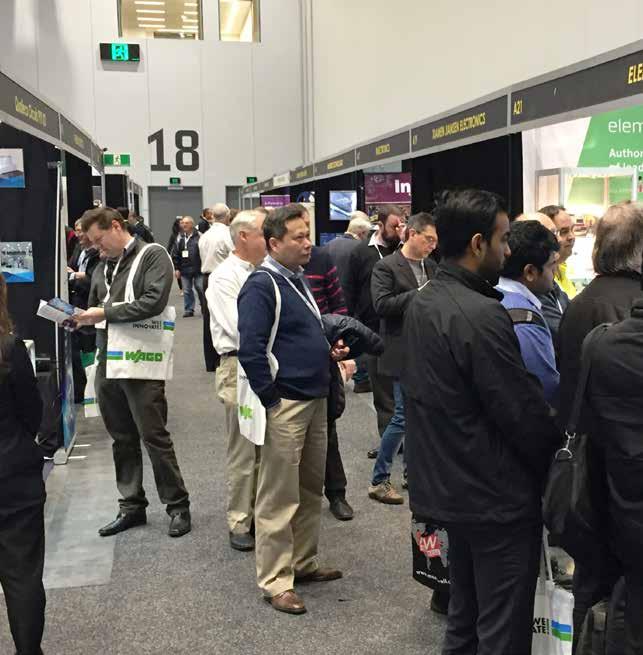

Australia’s only dedicated trade event for the electronics industry will be held in Sydney in April after a four year absence. Electronex – The Electronics Design and Assembly Expo and Conference will be staged from 5-6 April at Rosehill Gardens Event Centre.

The event is in its 12th year and alternates annually between Sydney and Melbourne, the Expo was postponed in 2020 due to COVID and according to the organisers, exhibitors and trade visitors have been eagerly awaiting the Sydney event.

“With Australia on a path to learning to live with COVID there is pent up demand from visitors to return to face to face discussions with companies to discuss their manufacturing requirements. The increased focus on hi-tech manufacturing in Australia is expected to boost attendance and Electronex brings together Australia’s leading suppliers with the latest technology and solutions.

“In a visitor survey at the 2019 Expo in Melbourne, 98% of attendees said that a dedicated industry exhibition such as Electronex was beneficial for their industry,” Australasian Exhibitions and Events managing director Noel Gray said.

Ninety companies onboard

In addition to featuring a wide range of electronic components, surface mount and inspection equipment, test and measurement products and other ancillary products and services, companies can also discuss their specific requirements with contract manufacturers that can design and produce turnkey solutions for specific applications. Around 90 companies will be represented at the Expo which Gray described as “a must see event” for designers, engineers, managers, and other decision makers who are involved in designing or manufacturing products that utilise electronics. A large number of companies will also be launching and demonstrating new products and technology at the event.

Visitors to the Expo can register for free at www.electronex.com.au. Visitors are asked to pre-register and their badge will be emailed to them to avoid crowding and queuing at the entrance. IU

Electronex +613 9676 2133 www.electronex.com.au

This is the 12th year that the Electronex industry trade event has been staged

Since 1988, the Surface Mount & Circuit Board Association (SMCBA) has conducted Australia’s only conference dedicated to electronics design and manufacture. The 2022 conference is again being held in conjunction with ElectroneX at Rydges Parramatta, NSW.

The registration desk is open from 7:00am for 8:00am start with workshops and presentations being held over two days:

The keynote address will be live streamed from the US by IEEE Fellow, Dongkai Shangguan presenting on Key Topics in Electronics Manufacturing: From Semiconductor Packaging to System Assembly.

This will be followed by Future Electronics Australia and New Zealand general manager Matt Wild presenting Supply Chain Challenges and Strategies. This will look at current issues and their causes with the resulting change in supply trends and costs. It will also focus on recommended practices to mitigate impact and how future supply will be ensured..

UK based trainer and industry consultant business Bob Wallis is also a member of the SMART Group Technical Committee. He is conducting as series of Electronics Manufacturing workshops which will be live streamed: • Printed Circuit Board Inspection and Field

Failures – Causes and Cures: a half-day workshop highlighting test methods to understand how

PCBs can fail and how to eliminate many of the common causes. This session also includes a free set of 25 training wall charts covering PCB failures and surface finish inspection for registered delegates to use. • Counterfeit Component Avoidance, Inspection and Failures – Causes and Cures: a half-day workshop that will not only illustrate the problems raised by counterfeit components within the electronics industry but it will also demonstrate some of the different test methods that can be used to confirm the integrity of the components.

Failure analysis techniques are now frequently being used to see if components are what they say they are rather than finding failure modes.

This session also includes a free set of 28 training wall charts covering testing and counterfeit avoidance procedures for registered delegates to use.

Senior PCB Designer at Design Science PCB Susy Webb will conduct PCB Design workshops: • Best DFM Practices for Board Engineers: a halfday class. In this class, Webb will discuss good practices for building footprints, how parts might be placed for manufacturability, routing practices that are helpful, trace widths and spacings that are producible and a stackup structure that can realistically get the impedance and signal return needed. She will also look at documentation for the manufacturer that is complete and understandable. This presentation is about the practical things a board engineer can do to help make fabrication and assembly easier and therefore increase yields and lower the cost. • HDI Routing Solutions is a half-day class. With the pitch of the parts getting tighter and the pin count of BGAs going up, there is a need to get as much routing, on as few layers as possible, into very dense areas of the board. HDI will help to accomplish this, but the technology requires some setup and thought as to what is needed and how to accomplish it from a design perspective. • This class will begin with the structure of the HDI traces and vias, through the different possible stackup types, ways to get signals from layer to layer in the board and possible patterns and grids to maximize fanout and routing opportunities.

All the while keeping routing return, power distribution, and layer paired routing in mind.

Lastly, it will address the benefits for other parts on the board that HDI can provide, and information about the unique manufacturing needs of these types of boards. • Designing the Signal Return Path is also a halfday class. The signal routing and its return are critical to the circuit working properly; however, while great care is usually given to routing the signals, often the return portion is the last thing considered, or sometimes it is forgotten.This presentation will talk about the importance of designing that return path, with a discussion of the physics involved, where the energy flows, the interference caused when it is not controlled, and the planes and stackup needed.

Senior technical advisor at Nihon Superior, Japan, Keith Sweatman is presenting Low Temperature Soldering – A new challenge in electronics assembly. Just as the electronics industry is getting settled into the use of the current generation of lead-free solders, new issues are forcing consideration of a change to lead-free solders that can be used at process temperatures even lower than those that were used with tin-lead solder. This move is being driven by several factors and presents potential benefits, but with these advantages come complications. This presentation will review the emerging low temperature soldering technology and identify the challenges to be addressed. IU

Melbourne Park Function Centre 11-12 September 2016 Melbourne Park Function Centre 11-12 September 2016

Design, Develop, Manufacture with Smart Solutions

Powering New Technologies in Electronics & Hi-Tech Manufacturing

Free Registration Online www.electronex.com.au

In association with

Rosehill Gardens - Sydney 5 - 6 April 2022

Organised by

Strong year predicted for electronics innovation Cables respond to safety & environmental standards

Continued from page 32

6. Printing technologies The most effective method for reducing the overall cost of PCB assembly is to print electronic components on semiconductor substrates. As a result, manufacturers continuously look for new technologies and upgrade conventional printing methods to conquer this challenge.

Printed electronics rely on conductive inks and flexible films rather than traditional semiconductors, which use tiny wires to form circuits. They can also be printed anywhere. In addition, advances in printing technologies also contributed to the momentum of the flexible hybrid electronics field. Accordingly, startups and scaleups are working on solutions for advanced printing.

7. Advances in IC packaging With chip design and packaging becoming hot topics in recent years, chip packaging is no exception. Moore's law - an old method of scaling a device - has its limitations nowadays.

Alternatively, multiple complex devices can be packaged in an advanced package to create the benefits of scaling. To provide greater silicon integration in increasingly miniaturised packages, semiconductor companies develop advanced IC packaging technologies. Additionally, vertically stacked modular components enable manufacturers to offer customization and improve yields. Furthermore, advanced IC packaging optimises manufacturing processes to balance customer needs with overall costs.

8. The miniaturisation of electronics The miniaturisation of electronics has opened up several new application areas. Due to space constraints, specific devices cannot be implemented in the healthcare and automotive industries.

There was a limit to miniaturisation due to their practical handling, display, and battery, rather than electronics built-in. Innovations are being made to reduce the size of electronic components while maintaining speed, reliability, and efficiency. As miniaturisation advances, more features are integrated into one compact unit. Some recent developments in miniaturised electronic components include Nanonet sensors and Forksheet FETs. 9. Added value with additive manufacturing With 3D Printing, flat circuit boards are no longer necessary in electronics manufacturing. Through it, it is possible to create new and innovative designs and shapes that would have been unattainable otherwise. 3D printers also create electronic components as a continuous, single piece, allowing them to manufacture fully functional electronics that require minimal assembly. Because of the implementation of this electronics manufacturing trend, prototyping processes are sped up, mass customization is possible, and parts can be produced decentralised.

A general benefit of 3D printing technology is that electronic components can now be produced in three dimensions, rather than just two, and circuits can now be stacked in new ways.

10. Technologies that rely on immersion During different stages of the PCB assembly process, humans play a significant role. Human error is a possibility in manufacturing, and it impedes overall efficiency. An effective solution to these challenges is the adoption of immersive technologies. Using such solutions, all possible scales of design objects are inspected, eliminating product defects at the design stage.

A circuit quality check identifies design problems in the circuitry and common manufacturing problems like slivers, missing solder pads, and starved terminals before fabrication begins. Moreover, it facilitates personnel training, prototype development, and assembly maintenance and enables operators to visualise production workflows before changing their lines.

Despite another challenging year for manufacturing, 2021 provided an opportunity to improve risk management programs, manufacturing operations, and supply chain management. Organisations will be better prepared for 2022 if they embrace environmental issues instead of fighting against them.

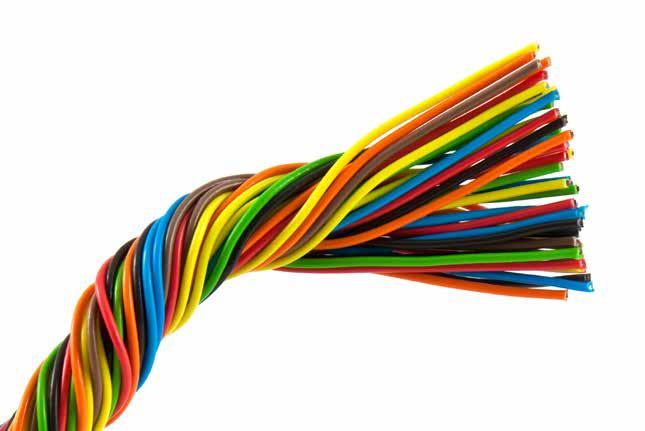

Manufacturers can build more dynamic and flexible supply chain structures and operations by embracing these changes. The new year will be successful if this mindset is applied, as it reduces risks, streamlines processes, and creates a clear path for success. IU L app Australia’s Low Smoke Zero Halogen (LSZH) 110 Degree Tinned Appliance Wire is suitable for wiring of switchboards, control, general wiring, instrumentation, and communication systems.

Available in a full rainbow of colour options, the new chemical, oil and

UV-resistant cables are designed for a nominal voltage of 600-1000V and are tested to 3000V. They are constructed of flexible tinned copper wire stranding class 5 or 6, according to IEC 60228 and AS/NZS 1125.

Common applications of the wire include:

• Underground Railway • Stadiums • Airports • Shopping malls • Data Centres • Ships • Power Plants and Nuclear Facilities • Control Cabinets • Switchgear Cabinets • Distribution Boxes

Lapp Australia managing director, Simon Pullinger said that the product is part of a Lapp’s comprehensive range of LSZH cables and wires, which are recommended (and in some cases required) for environments where the protection of people and equipment is paramount.

“In the event of a fire, the sheaths used on this type of cable will release far less smoke and no harmful halogen gases when burning compared to nonLSZH wiring,” Pullinger said.

He added that the LSZH cables are recommended for Green Star rated building projects due to the low toxicity and low smoke design. The cables don’t require PVC Best Practice certification as there are no PVC elements in the cable construction.

“Lapp has the widest range of LSZH cables stocked in Australia, and our team can offer technical advice to building managers and electrical contracts seeking compliance with all building regulations,” Pullinger added.

Safety first halogen-free cables Since halogen-free wires and cables don’t produce toxic corrosive gases in fires, they help minimise damage to electronic equipment and aren’t threatening to workers in surrounding areas.

“There are some situations where halogenated cables are the right choice. Adding halogens to compounds gives wire and cable the ability to perform well during flame testing. Also, halogens provide a cost-effective, highly efficient flame retardant component mechanism to compounds. However, keep in mind that while it sometimes makes sense to use halogenated cables, ingesting their fumes can be harmful to human life,” Pullinger explained.

“So, the choice typically comes down to where the cables will be used, and whether workers are likely to come into contact with the fumes in the event of an emergency. If you’re looking for a cable that’s safer for your workers and machinery, you’ll want to go with a halogen-free cable.”

LAPP Australia 1800 931 559 lappaustralia.com.au

The high-speed doors provided by Sydney-based DMF International are designed to offer temperature and sound insulation. They are useful to lower air conditioning power costs, protect stock from the effects of varying temperatures and increase employee comfort.

DMF International supplies and install locally manufactured high speed roll doors and the premium Efaflex high speed doors from Germany. Also called rapid roller doors, these products are designed for a high frequency of use with opening and closing speeds suitable to protect against the loss of costly conditioned or chilled air through doorways.

Insulated door blade The locally manufactured RL3000Coldsaver door comes with an insulated door blade that is 15 mm thick flexible PVC with insulate core, providing a temperature insulation of 0.91 W/m2K or sound insulation of R=22.

For the Efaflex spiral doors, the door blade is made from aluminium, core filled with a PU foam, available in thicknesses from 40mm to 80mm depending on the model selected. The temperature insulation provided is from 0.6 W/m2K or sound insulation from R=25.

The Eflaflex spiral doors offer a quiet operation at up to 2.0m/sec depending on their size. They operate by rolling over a spiral design at turbo speed with minimal wear.

Suitable for many applications Suitable for a wide variety of applications, these doors can accommodate openings up to 8m high and 8m wide and can be exposed to high winds.

Suitable applications include warehouses, processing areas, distribution centres, mining stores or sites requiring security, high speed action and insulation. Additional componentry can be used to configure these doors for bulk chiller and freezer applications.

www.dmf.com.au

Applications for DMF Doors include warehouses, processing areas, distribution centres, mining stores or sites requiring security.

DOORS DOORS DOORS

pvc strip doors swingflex doors traffic doors impact doors hygienic doors hospital doors cleanroom doors high speed doors efaflex doors coldsaver doors insulated doors security doors carpark doors foldup doors mining doors hangar doors

www.dmf.com.au

sales@dmf.com.au

Aust wide 1800 281170

DMF International Pty Ltd is a fully Australian owned family business, with over 50 years of supplying specialty doors. Our focus is in climate control and high speed security door solutions, and flexible PVC door products. With Australia wide service and export to over 10 countries, our experienced approach ensures the best design solution for any application. Call us today for free design assistance . . . . .