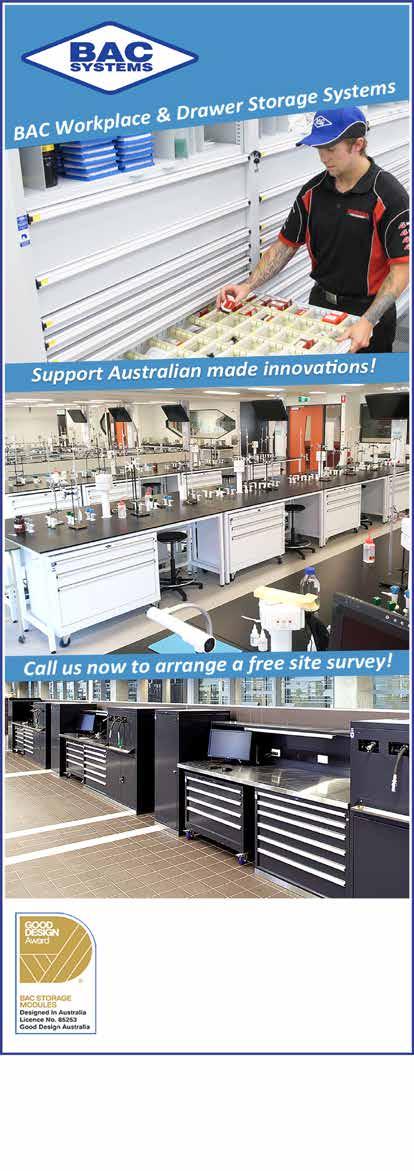

Australian Made 30

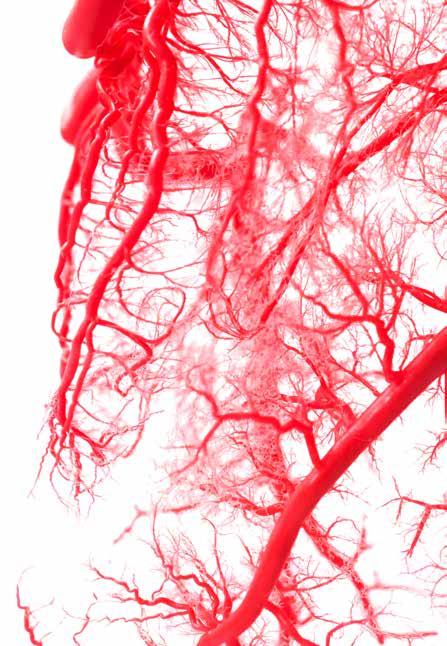

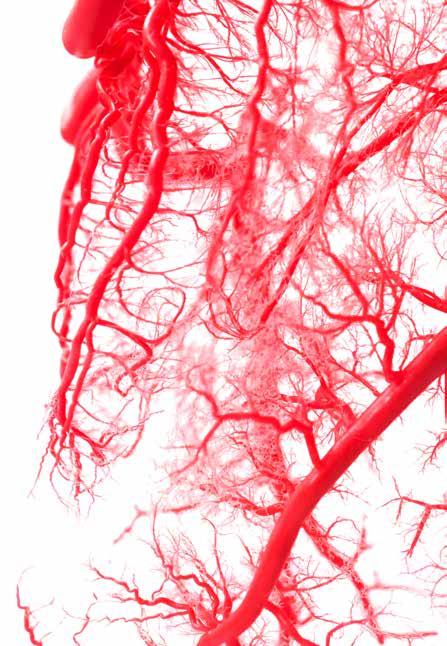

Cyber crime is an almost invisible pandemic that has been infecting the world, and manufacturers need to be on high alert.

According to IBM’s 2022 X-Force Intelligence Report, manufacturing became the most attacked industry globally in 2021 – replacing financial services. Manufacturing is less of a target here says the Australian Cyber Security Centre (ACSC) — but for how long?

Cyber attacks worldwide are estimated to have stripped companies of US$8.4 trillion last year, according to Statista. com, and it’s only going to get more expensive. Industry estimates put the cost of attacks by 2025 between $10-$20 trillion (for context, nominal GDP for the US was $23 trillion last year).

Several of Australia’s biggest, hightech firms were shocked by last year’s breaches and data theft, despite a cascade of warnings over the years. Although

manufacturers are less likely to store consumer data than recent high-profile victims, they too will be shocked when their systems are breached, held hostage and production crippled.

There’s a bucketful of reasons manufacturers are increasingly targeted by cyber criminals. Yet many are complacent and some oblivious as to just how vulnerable their systems are – making them even more attractive.

It’s sometimes been assumed industrial operations are less likely to be targeted because they don’t hold consumers’ personal data, but that’s no longer the case. The misconception is partly because most reported breaches are by public-facing firms which have had consumer data stolen and they have been compelled to tell people their data has been stolen.

Incidents reported, however, are just the tip of the iceberg: most often, victims

by Christine Powis

do not talk about it unless they have to.

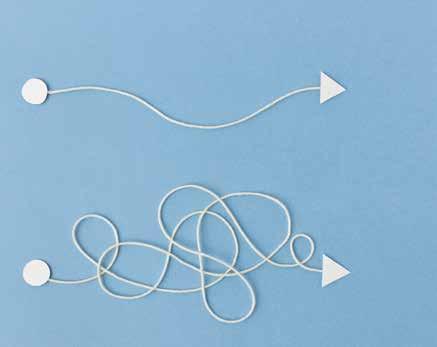

Smart factories are busy enhancing production and supply chain performance by combining information tech (IT) and operational tech (OT) into reliable, interconnected factories which proactively analyse data for ongoing improvement. This integration can boost cross-functional collaboration, help plan and optimise processes, remediate quality defects and generally deliver better products faster and more cheaply.

Along with all these advantages, greater interconnectedness brings greater risk: each interconnection enlarges the attack surface. Yet the trend to more connectivity and more smart devices in the Internet of Things (IoT) is not slowing, and 5G networks’ next-level connectivity will accelerate it.

The risks are huge: around 60% of SMEs in the US which had a cyber Continues on page 14

AUSTRALIA'S LARGEST CIRCULATING MANUFACTURING MAGAZINE Issue 130 Feb/Mar 2023 $12.00 inc. GST 18 20 48 Logi-Tech partners with Aria Cybersecurity to protect older legacy OT systems Industry maverick hands over company - but isn’t ready to retire yet Tailor-made measurement with A&D Australasia Manufacturing’s

industry ACCESS OVER 25,000 L APP CABLES, CABLE GL ANDS & CONNECTORS ONLINE. Make the right connection with L APP Australia. lappaustralia.com.au sales@lappaustralia.com.au 1800 931 559 LEADER IN CABLE AND CONNECTIVIT Y SOLUTIONS

cyber status: most attacked

AUSTRALIA’S PREMIER MANUFACTURING SOLUTIONS EVENT 9TH – 12TH MAY 2023, MELBOURNE • MCEC SCAN HERE TO REGISTER NOW! 1699AMWMEL23INDUPDATE

60

Manufacturing trends for 2023

Getting Territorial about manufacturing

By Margie Smithurst

It’s an ambitious goal for an economy that’s underpinned by primary resources and raw materials.

By 2030, the Northern Territory government wants its economy to be worth $40 billion, requiring a sustained annual GSP (Gross State Product) growth rate of 3.9%.

With current forecasts sitting at $35.2bn, there’s considerable ground to make up – an extra $1.4 billion per year worth of output, according to the Territory Economic Reconstruction Commission report.

markets,” says the AMGC’s NT Director, Charmaine Phillips, “and there are good existing capabilities here already. The pandemic showed how cut off the NT was from a lot of suppliers, and forced local businesses to strengthen the region’s manufacturing ecosystem.”

Money for manufacturers

Phillips says the AMGC is looking to invest in NT manufacturers to support them in adopting advanced manufacturing technology and processes in order to make more products locally, to work smarter and become more competitive.

But there are challenges, admits Charmaine Phillips, including businesses not understanding what advanced

Manufacturing Ecosystem Fund

(AMEF) is administering $7.5 million of NT Government money, and has supported six local manufacturing projects since opening in 2021.

Slated as a five year program, the AMEF has already committed $2.2m, with another 30 applications in various stages of the pipeline.

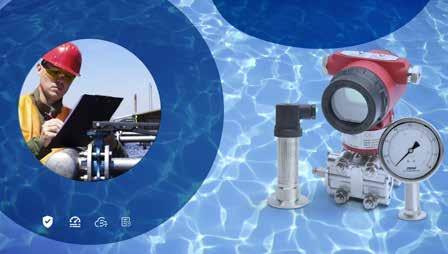

The first co-investment was with Palmerston-based company Corrosion Instruments (CI), which is also first off the rank with a new product.

First NT electronics production

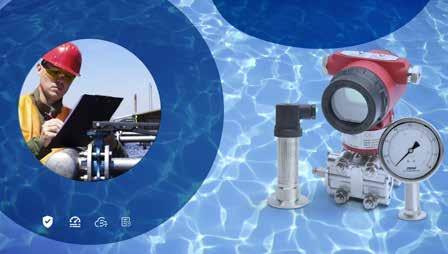

After three years of development, Corrosion Instruments has launched CI-Tx, a system that remotely monitors and

electronics production manufacturing facility. And Pattemore is hoping to eventually hire out their in-house equipment to other local businesses to build local capabilities.

It’s about capability

Fundamentally, the AMGC believes manufacturing needs to be looked at as a capability rather than an end product.

The AMGC’s Tyson Bowen cites the example of how they encouraged the only wristwatch manufacturer in Australia, Nicholas Hacko Watchmakers, based in Sydney, to pivot to producing space components.

Wristwatch making is a process that requires difficult precision engineering, with techniques, knowledge and machining equipment similar to the capabilities required to manufacture space componen-

To get there, the NT is hoping to bolster its underdeveloped manufacturing sector, which currently accounts for only 3.6% ($1.1bn) of the Territory’s GSP and employs around 3,400 people.

Leveraging the NT’s considerable resources base to add value is one way forward. The growing opportunities in the defence, maritime and space sectors are another, as is expanding on manufacturers’ current capabilities.

This is where the AMGC, the Advanced Manufacturing Growth Centre, comes in. In partnership with the NT Government, it is identifying opportunities in all regional centres, and says the NT is uniquely placed for manufacturing expansion.

“Darwin is well positioned for export

manufacturing can be, and not being aware of the technology that’s available, nor having access to it.

controls the cathodic protection on pipelines, wharves, storage tanks and tunnels.

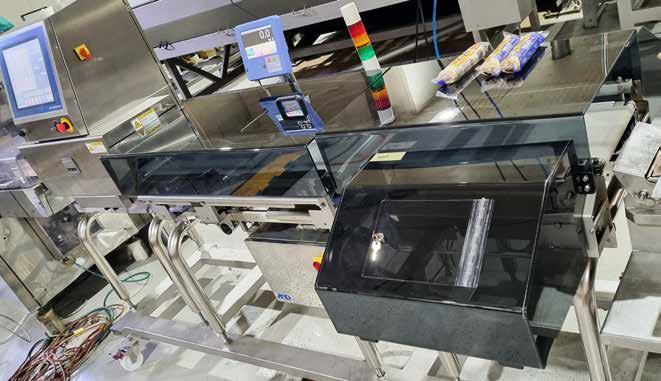

Previously, monitoring corrosion on such large metal infrastructure was an onerous task that had to be done manually, says founder and Managing Director, Sam Pattemore.

Pattemore says they sought co-investment largely because global supply chain issues for electronics meant a local prototype and testing facility was urgently needed.

“One of my initiatives this year will be to take the NT delegation to the Australian Manufacturing Week in Melbourne (in May) so they can build relationships, increase their knowledge of what’s being used elsewhere, and start thinking about how they can incorporate that into their organisations.”

The AMGC’s Advanced

With $110,000 from the NT-Government (via the AMEF fund), matched by their own $110,000 in funding, the company has been able to buy machinery and tools, including a PCB prototype printer.

This allows them to manufacture prototypes in-house, meaning they can commercialise products much more quickly.

Critically, it’s also the NT’s first

try - for micro satellites, for example.

The company now has an offshoot, NH Micro, which offers precision contract manufacturing not just for the space sector, but for scientific instruments and the semiconductor industry.

In the NT, the AMGC’s Charmaine Phillips is cautiously optimistic.

“I’ve lived here for 16 years and worked with industry for a long time. I’m very supportive of local businesses here in the NT.

“But we do have a perception challenge to get over in these early days, which is why having this five year program is great.

“That allows me to work with manufacturers to get a change of thinking happening, so that they can look at their

strategic goals for the next 3-5 years, and hopefully put processes in place to adopt advanced manufacturing technologies, which is where AMGC can then support them in further developing increased local manufacturing capabilities.”

INDUSTRY NEWS

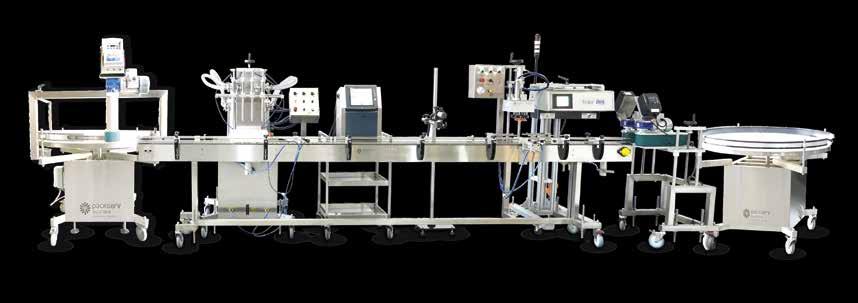

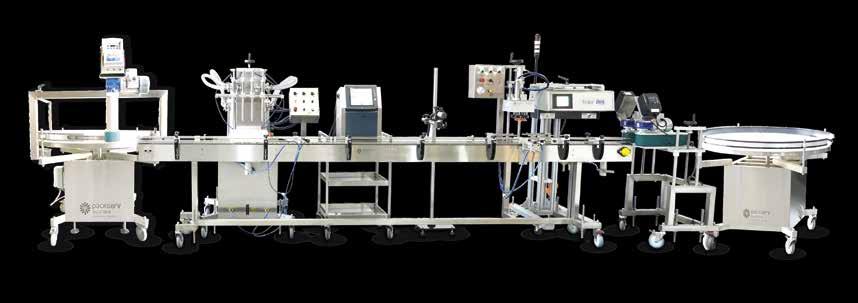

Corrosion Instrument’s CI-Tx hardware in production

“Darwin is well positioned for export markets”

“The NT’s first electronics production manufacturing facility”

“The AMGC believes manufacturing needs to be looked at as a capability rather than an end product.”

Corrosion Instrument’s CI-Tx system

Charmaine Phillips, AMGC’s NT Director

4 | Industry Update Issue 130 Feb/Mar 2023 industryupdate.com.au

Corrosion Instruments’ team, with Sam Pattemore 4th from left

CONTENTS

www.greasemax.au

MANUFACTURING MAGAZINE

Industry Update Media Pty Ltd ABN 25 083 502 783 Suite 403, Level 4, 116-118 Christie Street, St. Leonards NSW 2065 +61 2 9439 1288 / sales@industryupdate.com.au

Circulation 17,754

Readership 71,016 as at September 2022

All material in this publication is copyright to the publisher and/or its contributors. No material may be reproduced in part or in whole without the written consent from the Publisher. It is a condition of purchase or acceptance of this magazine that the Publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission on this publication or from the use of the information in this publication or from the use of the information and illustrations contained herein and the Publisher makes no warranties, express or implied, with respect to any of the material contained herein. © Copyright Industry Update Media Pty Ltd 2023

Publisher SCOTT FILBY scott@industryupdate.com.au

Editor CHRISTINE POWIS editor@industryupdate.com.au

Writer MARGIE SMITHURST writer@industryupdate.com.au

Universities & Collaboration Editor DAVID SLIGAR unieditor@industryupdate.com.au

Sub Editor WILLIAM POOLE subeditor@industryupdate.com.au

Advertising Sales Director SCOTT FILBY scott@industryupdate.com.au

Marketing Manager DUMI UDESHIKA marketing@industryupdate.com.au

Creative Director EDWIN KWONG production@industryupdate.com.au

Production Manager DUMI UDESHIKA copy@industryupdate.com.au

Video Editor & Producer CHARLIE LOUGHLIN video@industryupdate.com.au

Office Manager NICOLE CHARLES nicole@industryupdate.com.au

Finance & Accounts MICHELLE ALCOCK michelle@industryupdate.com.au

Consultant TRACY FILBY tracy@industryupdate.com.au

Accounts Receivable LYN SLIGAR lyn@industryupdate.com.au

Subscription Assistant SAM HICKS info@industryupdate.com.au

Circulation Assistant JERIN BURZACOTT circ@industryupdate.com.au

Printer

Developer

M

SPOTPRESS Web

JINI

R

simply superior! single point lubrication WHAT’S POOR LUBRICATION COSTING YOU? MEDIAKIT2023 MANUFACTURING MEDIA AUSTRALIA’S NO.1 MANUFACTURING & INDUSTRIAL EQUIPMENT MAGAZINE & DIRECTORY DOWNLOAD MEDIA KIT Industry News 4 From the Publisher 8 From the Minister 10 From the Shadow Minister 12 Cyber Security 14 Manufacturing Trends 20 Business, Finance & Accounting 22 Australian Made 30 Automation 34 Machinery 44 Materials Handling 45 Focus on South Australia 58 Workplace Health & Safety 64 Women in Manufacturing 69 Energy, Waste & Recycling 72 Doors 76 Products 79 Events 82 Treotham Automation supplies an extensive range of high-quality flexible cables, cable glands and accessories. Each state office has a full range of products in stock ensuring fast turnaround for all orders. Our highly experienced technical engineers provide thorough and reliable ser vice to custom-build solutions for projects of any size or application. 100 Australian Owned and Managed Celeb ating 30 years -1992-2022 Contac t Treotham Automation 1300 65 75 64 info@treotham.com.au Treotham has a full range of VSD cables and cable glands in stock now. 6 | Industry Update Issue 130 Feb/Mar 2023 industryupdate.com.au

Deakin’s ManuFutures hub opens doors to more businesses

More Victorian businesses are set to benefit from Deakin University’s expanded $20 million ManuFutures hub – its advanced manufacturing innovation facility.

Having doubled in size, the now complete and new-look ManuFutures building at Deakin’s Waurn Ponds campus is partnering with 14 successful and emerging businesses to grow advanced manufacturing capability in regional Victoria and Australia.

It can now deliver an increased number of tenancy opportunities, new manufacturing incubator programs, training, and product engineering services.

The expansion was funded by the Victorian Government ($10 million) and Deakin University ($10 million) as part of the Government’s $350 million Victorian Higher Education State Investment Fund launched post-COVID.

Deakin Research Innovations Regional Manufacturing Director Mark Curnow said the completion of ManuFutures2 puts Deakin University at the forefront of manufacturing innovation for entrepreneurs, start-ups and existing businesses.

“Our new ManuFutures2 building includes collaborative working spaces, further rental tenancy bays for manufacturing businesses, and an Innoveering Centre that includes product engineering and development capability, and opportunities for research collaboration and integration,” Mr Curnow said.

“Four new manufacturing businesses

have already moved into the new spaces as tenants, with room for two more. A total of 14 successful and emerging global manufacturing businesses now call Deakin’s ManuFutures home.”

Deakin University Deputy ViceChancellor and Research Professor Julie Owens said ManuFutures demonstrated Deakin’s leadership and success in real world research and commercialisation, in partnership with industry.

“Since opening in 2018, ManuFutures has a successful track record of helping entrepreneurs and start-ups take ideas from paper, to prototype, to emerging global businesses,” Professor Owens said.

“ManuFutures has helped create more than $1 billion in company value, incubated more than 17 advanced manufacturing start-ups, helped companies establish export markets in more than 35 countries, hosted 500 student placements, and created more than 120 advanced manufacturing jobs.”

Victoria’s Minister for Training and Skills, Higher Education, and Agriculture, Gayle Tierney, said that the Victorian Government’s investment in ManuFutures as part of the Victorian Higher Education State Investment Fund is helping to strengthen innovation, training, and industry collaboration in regional Victoria.

“Deakin’s new advanced manufacturing hub provides a space for higher education and industry to collaborate on complex challenges, ensuring opportunities in emerging industries and future jobs for Victoria’s regional communities,” Minister Tierney said.

To learn more about ManuFutures tenancies, training and services visit: deakin.edu.au/manufutures

The

to

...for all your linear motion needs 54-58 Arkwright Drive, Dandenong South Vic. 3175 Tel: 03 9706 7888 info@lineartechnik.com.au www.lineartechnik.com.au LINEAR BEARINGS LINEAR SETS ALUMINIUM PROFILES PROFILE RAIL GUIDES • Expert Product Knowledge • Huge Stock Holdings • Fast Access to all Brands • 24/7 Breakdown Service • Fully equipped Workshop facilities • Same Day Despatch to all States on Stocked Products With over 50 years of combined experience, Linear Technik has gained an enviable reputation as Australia‘s leaders in Linear Motion Technology. Our product and industry knowledge is second to none and our range covers all aspects of Linear Motion Technology. Linear Technik has a solution for all Linear applications!

name

remember

ManuFutures deakin.edu.au/manufutures INDUSTRY NEWS Industry Update Issue 130 Feb/Mar 2023 | 7 industryupdate.com.au

Deakin

Industry Update’s first bumper edition for 2023 is our biggest in four years and it covers a lot of ground: from vital cybersecurity information (the first of a two-part series) to the manufacturing trends ahead and developments in the renewable energy sector.

As well, drawing from the lessons of Covid, many manufacturers are looking to the challenge of supply chain sovereignty. The Federal Government considers its proposed $15bn National Reconstruction Fund, yet to pass parliament, as a key driver for this shift, with what it says is a vital new approach to industry investment.

Meanwhile, industry collaborations and co-investments, both at the R&D and the more mature stage, are proving productive and profitable. The IMCRC recently closed shop, saying it leaves a $6 billion legacy from its 70-plus project collaborations with companies, universities and CSIRO. The AMGC continues to look for funding opportunities in the sector, and we highlight one of its first product launches in the Northern Territory

- a remote corrosion management system that has enabled the NT’s first advanced electronics facility. Workplace health and safety continues to be a priority. For a number of years, Industry Update has drawn attention to the dangers of silicosis and recently wrote about the CFMEU’s call to ban working with the ‘killer stone’, the engineered stone in benchtops and other work surfaces that’s behind the life-threatening lung disease. It’s good to see Sixty Minutes focus on the issue recently, which has led to governments doing the same.

And finally, 2023 is filled with unmissable manufacturing expos, including Australian Manufacturing Week in Melbourne in May, and in the same month, the WHS Show will be held in Brisbane for the first time. Also look out for an innovative new food expo, thinkfood LIVE in Sydney in October. Here at Industry Update we’re preparing for another invigorating year in manufacturing, and we look forward to you joining us.

No-one could have missed last year’s explosive news about data security — or some companies’ lack of it — and government was on the front foot in response.

Even when launching its principles for cyber security to members in late October (perhaps in response to Medibank and Optus breaches), the Australian Institute of Company Directors (AICD) had its launch event hijacked by hackers. As the Sydney Morning Herald reported at the time, a fake Eventbrite link – which unsuspecting AICD members clicked on – was posted in LinkedIn’s chat function asking for credit card details. The AICD then had to urgently ask participating members not to use any links posted there and pretty much stop the event in its tracks.

If organisations advising members on security and high-tech data experts at Optus and Medibank were caught out by hackers, Industry Update wondered how manufacturers are challenged by cyber security issues. In our cover story this issue we found manufacturers have much to grapple with.

Not least is the global trajectory of manufacturing in criminals’ crosshairs. If Australia is to follow world trends, by all reports our manufacturers are about to become the top target for cyber criminals as they have elsewhere.

So it’s vital manufacturers protect their intellectual property, all records of staff, customers and business partners — and importantly all their interconnections. Connecting digital systems with external parties means that, no matter how well protected your system is, it is vulnerable if any of your connected partners have weaknesses. You need to secure your back yard but know that your external connections have equally protected theirs.

Our cyber feature this issue outlines the challenges and how to think about cyber security. Next issue we run a manual from cyber and risk expert, Ashwin Pal of RSM Australia, for securing your operational tech (OT) specifically. The OT side of the manufacturing house is the least understood tech and faces the most challenges.

FROM THE PUBLISHER

Publisher Scott Filby

UNIT 3/64 HASSALL STREET SMITHFIELD 2164 PH: (02) 9757 4367 SALES@LMFASTENERS.COM.AU LM FASTENERS PTY. LTD. TYPE 17 WASHER HEAD LMFASTENERS.COM.AU

Editor Christine Powis

8 | Industry Update Issue 130 Feb/Mar 2023 industryupdate.com.au

Minister for Industry and Science Ed Husic

This year is critical for Australian industry as it recovers from challenges either caused or highlighted by Covid. Onshore capacity to safeguard against future supply chain threats will be key.

Local manufacturers’ commitment to greater self-reliance is in no doubt yet many companies continue to be impacted by political, economic and climatic change — made more complex by tightening credit markets here and overseas.

Against this background, the rollout of the $15 billion National Reconstruction Fund (NRF) has assumed even more importance and greater urgency.

The Albanese Government was elected last year with a mandate to revive this country’s ability to make world-class products.

Australia has long been over-reliant on manufactured imports. That trend started well before Covid struck but the pandemic underlined the need to diversify and rejuvenate Australia’s local industries.

By enabling complex value-added manufacturing, we’ll lessen our dependence on overseas supply chains, create more secure, well-paid jobs for Australians, and put the economy on a more sustainable footing.

To help deliver this goal, we’re working to have the NRF up and running as soon as possible this year. The legislation to establish the NRF was introduced into Parliament late in November and I expect it will pass into law soon.

In the meantime, we’re consulting with industry and the community on other elements of the NRF such as its investment mandate, its management structure, and its operational objectives.

The NRF represents a new approach to industry investment in Australia, and a vital new approach to creating real, well-paid jobs.

It will invest strategically in industries that play to Australia’s natural and competitive strengths, that have good growth prospects, and help us address climate change and other national challenges.

Investment decisions will be made by an independent board. The fund’s goal is to achieve a positive return on

investment, as does the Clean Energy Finance Corporation.

The NRF will not provide grants nor duplicate existing government grant initiatives that support early-stage research and development or commercialisation.

NRF will provide finance, including through loans, guarantees and equity, across seven priority areas:

• Renewables and low-emission technologies

• Medical science

• Transport

• Value-adding in the resources, agriculture, forestry and fisheries sectors

• Defence capability

• Enabling capabilities

The NRF will complement other investors to help create the widest possible range of financing options for up-and-coming manufacturers to ensure our most innovative manufacturers and start-ups can grow and be competitive.

We’re under no illusions about the challenges of putting our industry on a more advanced footing. In the 1980s, large parts of Australia’s manufacturing base were uncompetitive after years sheltered behind high tariff walls.

The costs of this protection were unsustainable – and the Hawke/Keating government responded with industry restructuring plans and reduced tariffs. The resulting plans – led by then Industry Minister John Button – helped vulnerable sectors of manufacturing to modernise, innovate and find new markets.

Forty years on, we need similarly transformative strategies to broaden and advance Australia’s industrial base.

The NRF is central to our plans to nurture a new generation of innovative companies — supported by a strong STEM-skilled workforce — to form a competitive, sophisticated industrial sector. It needs to function efficiently. To that end, I urge you to keep submitting feedback around implementation of the NRF.

FROM THE MINISTER

NRF consult.industry.gov.au/ national-reconstruction-fund 10 | Industry Update Issue 130 Feb/Mar 2023 industryupdate.com.au

Fiber Lasers • Tube Lasers • Turret Punch Presses • Pressbrakes • Guillotines • Automation Call: Email: Visit: 03 9706 8066 sales@appliedmachinery.com.au appliedmachinery.com.au GROW YOUR BUSINESS WITH YAWEI. THAT’S APPLIED THINKING. Precision sheetmetal processing solutions.

FROM THE SHADOW MINISTER

Deputy Leader of the Opposition and Shadow Minister for Industry

Sussan Ley

Time and time again, I’ve heard a phrase which really frustrates me. You have probably heard it too — “We need to become a nation that makes things again”.

Whenever I hear it, I want to shout back, “Australians do make things here, and we are bloody good at it too”.

That phrase talks down one of the most vital parts of our economy.

Australia has a diverse and dynamic manufacturing sector which gets on with the job, even when government gets in the way, which is all too often.

The job of any government is to facilitate conditions for growth, innovation and further investment.

The LNP’s Modern Manufacturing Strategy, developed in close consultation with industry, set a solid foundation to build up our industrial base.

Take manufacturing complementary medicines for example — in Australia we are world leaders. We are known for great produce, innovation and our

quality-assured products — this is doubly so in medicine and preventative health. It was clear to me as Minister for Health that there’s incredible opportunities in this booming sector.

We have a significant opportunity to take medical manufacturing to the next level through the 2020s and beyond. As the booming populations of south and south-east-Asian middle classes grow, Australian-made medical products should be their first port of call.

Yet there is work to do to get that right. Making medical products and medicines requires state-of-the-art, skilled, advanced manufacturing processes. Governments and industry have to work hand in hand to make the most of the opportunities.

government procurement must function well so that SMEs have the opportunity to provide services and products.

It’s a sector that needs to hit the highest of benchmarks for quality and safety, and rightly so — that is why our products are so sought after.

Take Blackmores, which last year celebrated its 90th year in Australia. This second-generation family business still acts on the founder’s vision and is a household name.

We need to celebrate these success stories. Not play down our national potential.

Complementary medicine manufacturing is a high-demand and high-growth industry. The medical products and medicines sector today supports 30,000 workers across the supply chain, and more than 2,500 manufacturing workers.

The Coalition’s Modern Manufacturing Strategy provided a long-term vision to support the scale and competitiveness of medical manufacturing. It outlined opportunities for Australian businesses based on strengths, emerging industry trends and market potential. We also laid out how industry and government, together, could capture opportunities and address barriers to scale.

And we backed it with investment to support companies that want to grow their manufacturing here.

Building up our medical products and medicines manufacturing requires specific things from governments: they must ensure they build a skilled workforce so the sector can commercialise technologies and advanced manufacturing capabilities.

Governments are the main customers for many medical products so

But regulation needs to balance safety and trust with market access. Government must support businesses as they navigate new markets so they can compete globally. We mustn’t let Australia’s potential success be hobbled by obstacles such as an over-priced energy market.

When the LNP was in government, we backed the medical and medicine manufacturing sector as a national manufacturing priority. We need to see that approach continue.

While we are at it, we need to recognise the good work being done across the manufacturing sector. That starts by acknowledging that we do build stuff here, and we are good at it too.

Attention forklift operators - show off your skills!

The inaugural Australian Forklift Championship powered by CeMAT Australia is searching for the best of the best in forklift operators around the country. With prizes and bragging rights on the line, the competition will be fierce. Split into three separate events, Male 21+, Female 21+ and Junior, the competition will begin with a self-assessment portion, running from February to May. This will be the opportunity for

competitors to prove themselves against their co-workers in a familiar environment and will be used to choose the competitors for the semi-finals, to be held in Sydney, Melbourne, Perth, and Brisbane.

The semi-finals will be a competition between the top forklift drivers in each state, where competitors will be judged on safety, knowledge, accuracy and speed for the honour of entering the Australian

Forklift Championship finals. Held at CeMAT Australia 2023, the finalists will compete in two competition categories, counterbalance and reach truck. The winners in each category will earn amazing prizes, and the overall winner will become the first ever Australian Forklift Champion, earning the Bill Henman Trophy and industry publicity. Register as either an individual or company. All registration proceeds

will go to the CeMAT Australia Charity Partner, Healthy Heads. CeMAT would like to thank the Australian Forklift Championship Sponsor, Hyundai Forklifts Australia.

“We do build stuff here, and we are good at it too”

“The medical products and medicines sector today supports 30,000 workers”

CEMAT

12 | Industry Update Issue 130 Feb/Mar 2023 industryupdate.com.au

Australia cemat.com.au

First critical minerals plant

An Australian-first critical minerals demonstration facility originally slated to process vanadium will be expanded to process cobalt and rare earth elements in Townsville.

The Queensland government believes the new facility will unlock Queensland’s next mining and manufacturing boom.

“Queensland has the sunshine and wind above the ground combined with the critical minerals below the ground to make batteries and renewables with renewable energy,” said Premier Annastacia Palaszczuk.

Yet to be built, the $75 million facility will cost more than seven times the original planned vanadium processing facility and is expected to commence operations by the first half of 2025. The just-secured site for the facility is at Cleveland Bay Industrial Park, sitting between the Sun Metals (Korea Zinc) zinc refinery and Glencore Copper refinery and is within a few hours’ drive of some of the mines which would use the facility for testing the quality of raw materials which could include alumina and molybdenum.

batteries and advanced materials in Queensland with minerals mined from Queensland.

The facility is a key action in the Queensland Resources Industry Development Plan, and supports the delivery of the $62 billion Queensland Energy and Jobs Plan and the transformation of Queensland’s energy system to deliver clean, reliable, affordable energy to provide power for generations.

The Premier made the announcement while visiting the Sun Metals green industrial precinct.

“Sun Metals is not just the largest private employer in Townsville, it is a world-leading green industrial precinct processing the zinc needed for wind towers and batteries with renewable energy and using hydrogen to store and transport renewable energy,” the Premier said.

Minister for Resources Scott Stewart said there was enormous potential for vanadium mining and production in North Queensland.

“North Queensland provided copper during the second industrial revolution to transport electricity and now stands at the centre of the clean energy industrial revolution,” said the Premier.

“After working with prospective users [miners], universities, and research centres, the facility will not only be able to process vanadium, a key component of large-scale batteries, but it will be expanded for a range of critical minerals like cobalt and rare earth elements to be processed.“

“This facility will prove up the commerciality of critical minerals in Queensland, creating jobs not just in mining but in processing and manufacturing.

“Critical minerals are needed to build the SuperGrid, batteries and the wind and solar farms under the Queensland Energy and Jobs Plan.

The facility is part of a $150 million commitment announced in December 2022 for common user infrastructure to support the development, extraction and production of critical minerals.

The $100 million Critical Minerals Investment Fund managed by Queensland Investment Corporation will further support Australian businesses to compete globally and make

“Global demand for vanadium in batteries and high-quality steel is expected to outpace supply before the end of the decade. Queensland has world-class, highly economic deposits of vanadium in accessible marine shale.

“Because they hold their charge in a liquid form, vanadium redox batteries can be built to a much bigger scale, powering larger communities for longer,” he said.

“Vanadium has the potential to be the ‘Eureka’ moment for North Queensland.”

“There is already interest from companies in using the facility and once the market sees the quality of Queensland’s valuable resources for themselves, they will have confidence to invest in commercial scale facilities and downstream manufacturing infrastructure — creating thousands of good, skilled jobs for Queenslanders.”

The Premier said that Sun Metals and Ark Energy had paved the way for future critical minerals processing plants in North Queensland.

“The opportunities in North Queensland include mining and processing the minerals for vanadium, zinc bromine and iron flow batteries, cobalt and nickel used in lithium-ion batteries, high-purity alumina for LEDs, batteries and semiconductors, rare earth elements used in electronics and silicon for solar panels and semiconductors.”

“Already we have seen Queensland

INDUSTRY NEWS

See more at www.business.gov.au

Pacific Metals secure an agreement with General Motors to supply minerals for electric vehicle batteries.

Queensland Premier Annastacia Palaszczuk Photo: Griffith University

ENCLOSURE CABINET PRECISION COOLING Designed to keep your electronics cool and operating at optimum performance - Cooling capacities range from 30W to 6kW - IP Ratings – IP54 (Indoor), IP56 (Outdoor) & IP66 (Harsh) - Mild Steel Powder Coat and Stainless Steel - Seifert also offer Peltier Coolers, Heat Exchangers Fan Systems, Heaters and accessories – Complete Thermal Solutions KEEP COOL 03 9801 1906 e info@seifertsystems.com.au w seifertsystems.com.au Industry Update Issue 130 Feb/Mar 2023 | 13 industryupdate.com.au

“North Queensland ... now stands at the centre of the clean energy industrial revolution.”

Manufacturing’s cyber status: most attacked industry

by Christine Powis

Greater connectivity brings greater risks as well as efficiencies. Smart factories need to get smart with security on both sides of the manufacturing house – in information technology (IT) and operations technology (OT). This month, we publish the first of Industry Update’s two-part feature on cyber security.*

security breach went out of business, the US Securities and Exchange Commission reported in 2022.

Low-hanging fruit

The speed at which manufacturers are integrating systems to catch up with the rest of the business world means little or no focus on security which makes them easy pickings. Digitisation and systems integration is a new phase for most manufacturers so rookie mistakes are likely and hackers know this.

As manufacturing has digitised, it has experienced more cyber-related incidents, often through interfaces and OT control systems managing industrial operations. OT includes programmable logic controllers and distributed control systems, embedded systems and industrial IoT devices. The latter includes interconnected sensors, measuring instruments, and other smart devices networked with industrial applications, including manufacturing and energy management.

Application Programming Interfaces (APIs) allow different systems to talk and share data. Every time a once-discrete system needs to talk to another, it uses an API and, without the right precautions, increases the attack surface. And, without adequate security, the convergence of OT and IT enables vulnerabilities in one area to be used by hackers to traverse to the other.

operational risks, such as cyber security, were the greatest danger to smart factory initiatives.

Deloitte and MAPI found a significant share of manufacturers which are getting smarter in the production area have yet to build cyber capabilities to secure their new critical systems. While 90% of surveyed manufacturers said they could detect cyber events, very few proactively monitored their OT environments, and less than half had run security assessments in the last six months. Almost one quarter surveyed do not even run annual risk assessments.

Faced with a cyber threat, the report said, these IT and OT leaders are not ready to respond. This is also true when new technologies go online in periods between risk assessments.

Low priority

Industry experts say manufacturers’ attention to security suffers from many factors, not least workplace culture, including security awareness and different teams’ priorities:

• Inadequate training: last year the World Economic Forum’s (WEF) Global Risks Report 2022 declared 95% of cyber security issues can be traced to human error and that insider threats, accidental or intentional, create 43% of breaches across all sectors

insurance than think about the issues. Beware: prices for cyber insurance in the US are skyrocketing: up by 96% in Q3, 2021 alone, and a 204% jump on the previous year, says the WEF.

• Not all IT teams are as security-savvy as they should be, and perhaps too ready to try a work-around that creates a weak spot

• Factory floors’ fear of downtime means systems have not been patched to latest versions so they’re vulnerable

• Old factory equipment that’s impossible to update to work with more secure OT

• Smaller businesses looking for security services can face an unexpected constraint: security providers too busy for ‘smaller’ $100,000 jobs

“Outdated infrastructure and lack of visibility into the OT environment provides attackers with an easy way in,” says John Shier, senior security advisor at IT security company Sophos.

“The convergence of IT and OT is increasing the attack surface and exacerbating an already complex threat environment,” says Shier, referring to gaps between security for production systems and front-office IT.

Patching does mean downtime but it’s vital: most of the significant incidents responded to by the Australian Cyber Security Centre (ACSC) in 2021-22 were due to inadequate patching.

of a patch release or technical write-up. But security measures don’t always mean downtime according to Ashwin Pal, Partner at Cyber Security and Privacy Risk Services with RSM Australia — in fact, most of his recommended OT security measures do not (as outlined in the next issue).

“Even encryption shouldn’t slow things down noticeably for users,” says Pal. “People say it does but it’s usually network configuration and capacity that slows things.”

Observers say every company will experience a security breach that affects its continuity, yet they also say that most SMEs — which typify Australian manufacturing — don’t have a disaster recovery plan.

Complacency

Reports of complacency include one security provider’s survey of manufacturers’ knowledge of their systems and their APIs: it showed manufacturers’ confidence in their system security to be badly misplaced.

Noname Security’s survey found that while 71% of respondents were comfortable and confident in API security, 76% had experienced a security incident and yet 74% didn’t know how many APIs were involved in their systems! Noname had surveyed 600 cyber security professionals in the UK and US in six markets including manufacturing.

“When we go out to an organisation to build an inventory of their systems, we find they’re not aware of 20% to 30% of their APIs – so they can’t secure them,” says Filip Verloy, a Technical Evangelist with Noname.

Deloitte and the US’ Manufacturers Alliance for Productivity and Innovation (MAPI) studied cyber security and risks for manufacturing. Almost half the manufacturers (48%) of 600 IT execs with global firms surveyed by the 2019 Deloitte and MAPI Smart Factory Study said

• OT teams naturally focus on physical machinery, tangible products and maximising production. often wary of ‘interference’, there’s a reluctance to give IT oversight and a tendency for OT to integrate systems ad hoc.

• Business leaders not being IT savvy, not unlike their OT teams! IT advisors struggle to get points on cyber security through to leaders. The C-suite has been criticised for preferring to pay cyber

The ACSC warns that criminals persistently scan networks for unpatched systems offering entry points for higher value targets. Most breaches observed by the ACSC used simple tools and techniques including phishing, targeting third-party service providers and exploiting unpatched or badly configured systems using public vulnerabilities. These methods are low cost and scalable, and exploits can be deployed within hours

External-facing connections are exposed to the world and therefore a greater risk but a rise in phishing has bumped internal APIs onto the risk list too.

“Because phishing is now prevalent and gives hackers valid user credentials, they then log in ‘internally’ as that user, so internal security must be a priority too,” says Pal.

“Security is about securing all layers, not just the main ones. The way networks are now designed means the lines between

CYBER SECURITY

“60% of SMEs in the US which had a cyber security breach went out of business”

“Systems integration is a new phase for most manufacturers so rookie mistakes are likely and hackers know this.”

14 | Industry Update Issue 130 Feb/Mar 2023 industryupdate.com.au

Continued from front page

internal and external are very blurred.”

Pal recommends all APIs be controlled with strong authentication, authorisation, and logging controls, and be backed by regular penetration testing to detect any vulnerable APIs.

Broken rules

Experts say the ‘triple-A’ rule of security — authentication, authorisation, and accounting — has not failed.

“The problem is it’s often not applied properly, as in last year’s Optus and Medibank cases,” says Pal.

“Big companies often outsource development and testing new developments to other countries but, with outsourcing, rules are more likely to get broken.”

successful, highly sophisticated supply chain hack. SolarWinds made what seemed a routine software update available for its network management software, Orion, but it had been planted with malicious code, which was far-reaching because as network management software, Orion is in contact with entire networks.

The technique was so advanced, it is believed Russia was behind the action: they found a way to infiltrate Orion’s sealed code and to create a system that used domain names to select targets and mimicked Orion’s communication protocols so they could hide “in plain sight”, as radio NPR put it.

Naturally, many of Orion’s subscribers downloaded and deployed the malicious updates. Even by the conservative, best estimate of the SolarWinds’ CEO, Sudhakar Ramakrishna, 18,000 customers were affected, numbering about a dozen government agencies including the Pentagon, Treasury, Justice and Energy Departments and 100 companies such as Microsoft, Intel and Cisco. Understandably, the government went into overdrive with sanctions and executive orders.

Government policy

Industry observers believe Optus had a test system set up by an outsourcer with an API open to the Internet so anyone on the Internet could access the test system, and the test system had production data — actual customers’ data.

This view sees the hacker accessing Optus data without authentication, without authorisation, and without any accounting because no logs were generated for what was done so no one knew what was accessed, and importantly, that the data was not masked or otherwise represented.

Optus claims this was not the case.

CIO Mark Potter says criminals made concerted efforts to bypass Optus defences to steal data, that it was a malicious and persistent attack, and not at all like data being accidentally left out in the open, as Home Affairs Minister, Clare O’Neil suggested.

Third-party threats

As the Optus breach shows, your security is only as good as your business partner’s. This is crucial for manufacturers connecting with third-party suppliers, customers, developers and, some suggest, even security service providers.

Connections with partners multiply weaknesses and enhance the attraction for hackers. As US cyber security consultancy Mandiant says in its M-Trends 2022 report, “the supply chain is as attractive a target as ever, providing a potential entry point into multiple vendors.”

The attack on US software company SolarWinds in 2020 was a frighteningly

More recently, in July 2021, supermarkets in Sweden closed after a cyber attack on its IT services provider based in Florida. Then in February, 2022, an attack on satellite services in Ukraine forced electricity-generating wind farms to shut down across central Europe.

Whether on the cloud or on premises, businesses must be confident of the security of any externals with which they connect. Potential business partners can offer their bona fides but a manufacturer needs to diligently discover their true security posture, all their precautions and if they’re vulnerable. Any manufacturer should want to know if its potential business partner has suffered breaches, how these happened, the outcomes and how future breaches are being prevented.

If a manufacturer is considering links with big companies, even a Google search can find mentions of breaches in an annual report or media reports. A manufacturer can give a potential partner a questionnaire to investigate what access is required, why they need it, who in their organisation would have access, and all protocols observed to get access and during access.

Vetting potential third parties is a business in itself: companies such as Upguard specialise in risk management of the attack surface and connections

Following the Optus and Medicare breaches last year, Home Affairs and Cyber Security Minister, Clare O’Neil announced Australia was “punching back” with a new team of 100 cyber crime experts to proactively hunt down cyber criminals. The team is being put together by Australian Signals Directorate and Australian Federal Police.

Businesses’ obligations

Under the Privacy Act, data breaches are when personal information is accessed without authorisation, is stolen or lost, including employee records.

Companies with revenues of $3 million or more must take reasonable steps to protect personal information and must report breaches both to the Australian Privacy Commissioner and to people whose data has been affected within a reasonable, practical timeframe.

The Labor government reacted to last year’s high-profile breaches by hiking fines for companies failing to adequately protect data or report

with partners including ongoing monitoring of partners and automating security questionnaires. Many manufacturers hire security consultancies to thoroughly vet potential partners.

The WEF found that 39% of respondents to its survey had been affected by an incident originating with a third party, reporting that “They were ‘collateral damage’ after their operations were disrupted by attacks on companies

breaches, up from $2.2 million up to either:

• $50 million or more

• thrice the benefit obtained from misuse of data, or

• 30% of a company’s turnover for the relevant period

Penalties will be decided caseby-case by the Australian Privacy Commissioner. See www.oaic.gov.au Company directors were this year also put on notice that they can be scrutinised by corporate regulator ASIC if they failed to prioritise cyber security and their businesses are hacked by cyber criminals.

The government has advised companies not to pay ransoms to hackers and is considering further policy reform including whether to make paying ransom illegal.

For firms managing critical infrastructure and essential goods or services (groceries, transport, health), more strict obligations include timeframes for reporting to Australian Cyber Security Centre. See www.cisc.gov.au

from whom they bought or to whom they sold.”

Almost all respondents to the WEF (90%) were concerned about the cyber resilience of third parties which had access to their systems, and businesses are reacting to rising threats by strengthening controls for connected third parties and re-evaluating countries with which they do business.

“76% had experienced a security incident and yet 74% didn’t know how many APIs were involved in their systems!”

CYBER SECURITY

Industry Update Issue 130 Feb/Mar 2023 | 15 industryupdate.com.au

Ashwin Pal, Partner Cyber Security and Privacy Risk Services, RSM Australia

Top target

Manufacturers made up 23% of the attacks that IBM’s X-Force team of responders, hackers, researchers and analysts remediated in 2021.

In Asia, manufacturing was targeted almost as much as financial services (29% vs 30%).

Ransomware

The ACSC is not alone in pointing at ransomware as the most destructive cyber crime.

While cyber crime is diverse and huge in scale, ransomware is a threat on multiple levels. Ransomware’s impacts include business disruption from locked away or encrypted data. Despite a good backup system which can get a business running again, manufacturers’ intellectual property can be abused and they also face reputational damage if stolen data is released or sold on. Even when ransom is paid, a business cannot trust a thief to not continue to abuse stolen data. And then there’s the clean-up and reconstruction of more secure systems.

Ransomware has a good success rate for hackers, it’s easily spread and cheap to deploy. ACSC responses to ransomware incidents in 2020-21 went up more than 75% compared with 2019-20, racing ahead of growth of total number of reports, up by only 13%.

Ransomware attacks occur because:

1. An employee clicks on a phishing link that downloads ransomware

2. Hackers pick up credentials from remote access users, often individuals using their own device. A hacker can intercept staff member’s remote access either by phishing or details bought on the dark web

3. Hybrid working has increased both attack surface and attack numbers. Companies with remote users expose many applications and their internal system structures to the world.

The ACSC’s and government’s advice is not to pay ransoms to hackers, and Home Affairs this year said it is considering making ransom payments illegal. See the ACSC’s Ransomware Prevention and Protection Guide.

Ransomware was the most common type of attack on manufacturers, making up almost a quarter of attempts.

While malware increased by 358% in 2020, ransomware increased faster, by 435%, the WEF report in 2022. It also noted a four-fold rise in the known collective value of cryptocurrency received as ransomware in 2020 over 2019.

Australian manufacturers seem to have dodged a storm of cyber bullets so far.

In mid-2022 the Australian Cyber Security Centre (ACSC) reported that only 4% of Australian incidents to which it responded attacked manufacturing, and financial services was similarly affected. Meanwhile the federal government copped most of the attacks — at 24% and state governments 10%, with the health sector experiencing 9% of incidents involving the ACSC.

Although sophisticated, the financial sector was an obvious target so it advanced its security further, and now thieves look elsewhere.

While the highest profile breaches in Australia have been public-facing organisations, bad actors are attracted to manufacturers because they’d be decimated by loss of intellectual property or downtime. Not only that, low tolerance for downtime can also mean manufacturers might not have adequately patched and protected their systems.

As Sophos’ senior security advisor John Shier says, “Manufacturing is attractive for cyber criminals due to the privileged position it occupies in the supply chain.”

That was clearly flagged by the mid2021 ransomware attack on big meat processor JBS when its US network stopped for several days — leading to disruption across the US, literally piles of dead animals at its door, a $14 million ransom and more in losses and system clean-up costs for JBS.

Sophos’ 2022 report State of Ransomware in Manufacturing and Production found that cyber incidents demanding ransom are increasing for manufacturers, up by nearly 20% on 2021 but it still saw what it called a “low” attack rate: 55% of surveyed manufacturers reported ransomware attacks. Sophos surveyed 5,600 IT professionals in mid-sized firms across 31 countries,

including 420 in manufacturing and production.

Sophos’ also found manufacturing and production paid the highest average ransom of any business type at more than US$2m, far higher than the cross-sector average of US$800,000. In Australia ACSC’s much lower count on the average cost per cyber crime reported to it here was $39,000 for small businesses and $88,000 for medium-sized businesses.

Interestingly, Sophos reported that of those manufacturers breached and held to ransom, most did not pay the ransom: 36% paid compared with payments by 46% average across sectors.

Original sin

Insecurely designed equipment can create a problem from the start. Integration aside, risk can be inherent in products a manufacturer uses: the US Cybersecurity and Infrastructure Security Agency lists more than 1,200 known OT system-related cyber security issues as Common Vulnerabilities and Exposures (CVEs) that arise from more than 300 OEMs and system providers.

In the first half of last year, the agency found 560 CVEs, most of which were new. Of those CVEs reported, 131 affected multiple sectors but manufacturing was the most directly affected sector: it suffered 109 reported system CVEs.

RSM’s Pal says OT devices are often made by industrial equipment manufacturers and although their devices have computing code, they are not designed with cyber security in mind so they are inherently vulnerable.

“It could be robotic arms in car manufacturing or extruders of aluminium cans run by computer code – made by machine makers that are not cyber security experts. I know manufacturers of large systems that have had vulnerabilities come up when there’s a cyber breach when the equipment’s on the factory floor.”

Evolution

While many cyber crimes are becoming more sophisticated, they’re also being tried out by less skilled actors through ‘cybercrime-as-a-service’ (CaaS) on the black-market.

ACSC reports that CaaS’s ever-increasing range includes provision of server infrastructure used to host cyber crime campaigns, the sale of access to compromised victim networks, money laundering, and development and obfuscation of malware.

Ransomware-as-a-service (RaaS) provides technically unskilled bad actors with ability to launch highly profitable attacks. In addition, the CaaS industry allows actors to monetise their

“Leading to literally piles of dead animals at its door, a $14 million ransom and more in losses”

“They were ‘collateral damage’ after their operations were disrupted”

CYBER

16 | Industry Update Issue 130 Feb/Mar 2023 industryupdate.com.au

SECURITY

Resources

The Australian Cyber Security Centre offers guidelines on security focus areas at cyber.gov.au/acsc/view-all-content/ ism/cyber-security-guidelines

That same page can link you through to specific guides for SMEs, bigger firms and infrastructure organisations including security for small business assets on the cloud and how to report a breach. The ACSC offers Essential Eight mitigation strategies for MS Windows-based networks, Strategies to Mitigate Cyber Security Incidents and an Information Security Manual.

• There is advice on ransomware, Business Email Compromise and other threats.

• If you suspect a cyber security crime and need advice, call the Australian Cyber Security Hotline on 1300 292 371

• IBM X-Force Threat Intelligence Report 2022 is at ibm.com/downloads/cas/ ADLMYLAZ

initiatives, Deloitte found the value delivered to be worth the risks. What is urgently needed, Deloitte says, is a holistic approach to the OT and IT environments and prevention and mitigation plans that focus on secu

SOCIAL SPOTLIGHT

CYBER SECURITY

The Cybercrime as a Service (CaaS) ecosystem offers functions to malicious actors who can then outsource the skills they lack

Industry Update Issue 130 Feb/Mar 2023 | 17 industryupdate.com.au

Cyber security for manufacturers’ legacy OT

by Christine Powis

by Christine Powis

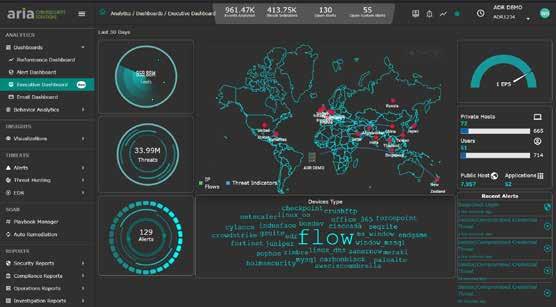

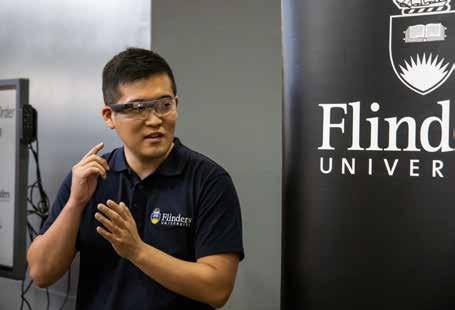

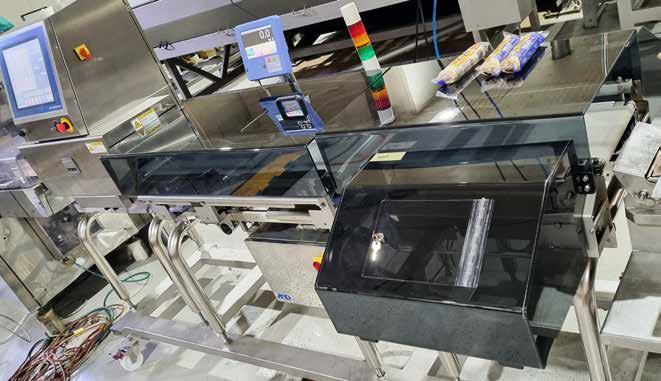

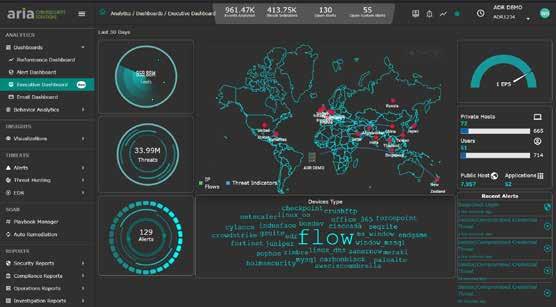

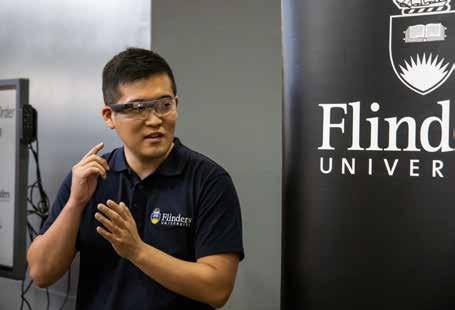

Cyber security firm LogiTech is partnering with Aria Cybersecurity in the US to set up a local 24/7 security operations team in Adelaide to support Australian clients using Aria products - including a new release designed to protect older, legacy systems on which manufacturers’ operational technology often relies.

Logi-Tech’s Managing Director Peter Moore has worked for the Australian Defence Department (ADF) and his Australian cyber security customers include critical infrastructure, energy and state and federal government agencies, as well as the ADF and companies aligned with it.

data in March when the new AZT PROTECT for older OT environments will also be available.

The Adelaide SOC will be trained by Aria’s US team and initially rely on the experience of Aria’s US SOC for interpreting data about any unusual behaviour which could flag a cyber threat.

Aria’s ADR offers automated threat detection, isolation and containment within seconds, thanks to its data engine’s use of artificial intelligence (AI), machine learning and behavioural models developed by Aria.

Logi-Tech has 37 years’ ICT and security experience and already distributes Aria’s Advanced Detection and Response (ADR) system and will distribute and support Aria’s new AZT PROTECT which stops threats to legacy industrial systems.

“Competitor products offer detection and sometimes containment within one to three hours,” said Aria’s Vice President and General Manager, Gary Southwell, who has found manufacturers’ and heavy industries’ attitude to cyber security has changed in the last four to five years.

“Industry attitudes have changed since intrusions by Dark Side,” said Southwell, referring to the notorious network of cyber criminals who, for example, in 2021 paralysed major US fuel distributor Colonial Pipeline, halting half the US east coast’s supply of diesel, petrol and jet fuels.

solve those problems for industry.”

Aria’s ADR can be run remotely from anywhere by one staff member, hence its moniker ‘SOC in a box’. However 80% of Aria clients prefer to use Aria’s SOC team to interpret the data and scope of a threat, contain it and then advise the client on action to be taken.

Moore expects that, within a few months, it will be supporting local clients as the US team does – monitoring and investigating threats, managing alerts and containment then advising the client on immediate action and ways to prevent the problem in future. The client’s IT team

Aria is a division of 68-year-old, publicly listed CSP Inc and originally built radars for US defence agencies. It has since worked with the world’s foremost defence intelligence agencies in the US, the UK, Australia and Canada on special projects.

Moore believes that keeping the data and security operations centre (SOC) in Australia maintains data sovereignty compliance, and keeps businesses and their data safer.

“Setting up Aria’s customers’ data here in Logi-Tech’s Adelaide data centre makes sure data doesn’t go out of the country — this reinforces not only an organisation’s security but also its sovereignty of data and governance — unlike other cyber security platforms where data goes to engines to be analysed in, say, Germany or India.”

Logi-Tech’s data centre will be running and supporting local customers’

“Bigger manufacturers have gotten smarter — they now know what the ramifications are — no one wants to explain in their quarterly report why their revenue dropped suddenly because they didn’t take cybersecurity seriously.”

“If companies’ processes go down, they know it could lose them a million dollars a day — those companies we don’t have to convince,” said Southwell. “They need not just detection but immediate containment to happen within minutes when critical systems may be a target – this is what we built our ADR solution to achieve. We can offer them SLAs which commit to detection, isolation and containment in minutes, not multiple hours or days to stop an attack.”

“Then you’ve got manufacturers with OT environments and old systems that are not constructed to take traditional IT-level products and can’t be updated — so they struggle with security. That’s why we’ve come in with Aria AZT PROTECT to

Aria ADR stops many types of attacks including intrusions, ransomware, insider threats, brute force, distributed-denial-of-service attacks, data exfiltration, malware, compromised credentials, and policy violations. Its detection speed is possible because it takes in data from all connected network packets, devices, event logs – the lot –which goes into an engine that uses AI to detect attacks and machine learning to understand normal versus unusual behaviour. The analytics engine then filters, correlates and identifies actual threat behaviour and its scope.

It does not rely on teams of people to weed out false positives. Detecting unusual and actual threat behaviour is key: the product’s designers developed 60 models of threat behaviour and its SOC team is highly experienced in interpreting these.

Many companies get thousands of threats every day; local bank NAB reports 50 million attempted attacks a month. Without AI, machine learning and expertly framed behaviour models, even just a few thousand threats a day would take a team of about 100 experts to filter out false threats from the actual and raise an alarm.

Initially Logi-Tech’s SOC in Adelaide will rely on training and support from Aria’s US SOC when Logi-Tech runs trials with its Australian customers in March.

Peter Moore,

Managing Director

can then take on the project.

“The beauty of Aria compared to the rest is that it deploys so easily, and in a format which enables users to have visibility into the system and work with it if they want to either manage it themselves or simply gain insights,” said Moore.

Southwell says Aria is unlike “other big security guys who say ‘we’ll call you when there’s a problem’ — but then give clients no access or visibility into the system.

“We’re an open book as far as clients go: they can look in and see that we’re ticketing alerts as we’re watching new behaviours and they can ask us about what’s going on.”

CYBER

SECURITY

Gary Southwell, Aria Cybersecurity’s Vice President and General Manager

Logi-Tech’s

“Industry attitudes have changed since intrusions by Dark Side.”

“Logi-Tech will support Aria’s AZT PROTECT to stop threats to legacy industrial systems.”

Logi-Tech logitech.com.au 18 | Industry Update Issue 130 Feb/Mar 2023 industryupdate.com.au

Aria ADR’s top-evel user interface dashboard.

#CeMATAus cemat.com.au Innovation & Industry 4.0, the Future of Intralogistics, Warehousing , Automation, Materials Handling and Supply Chain Management R E G I ST R AT I O N S O P E N N OW Including: 25 – 27 July 2023 The Dome, Sydney Olympic Park

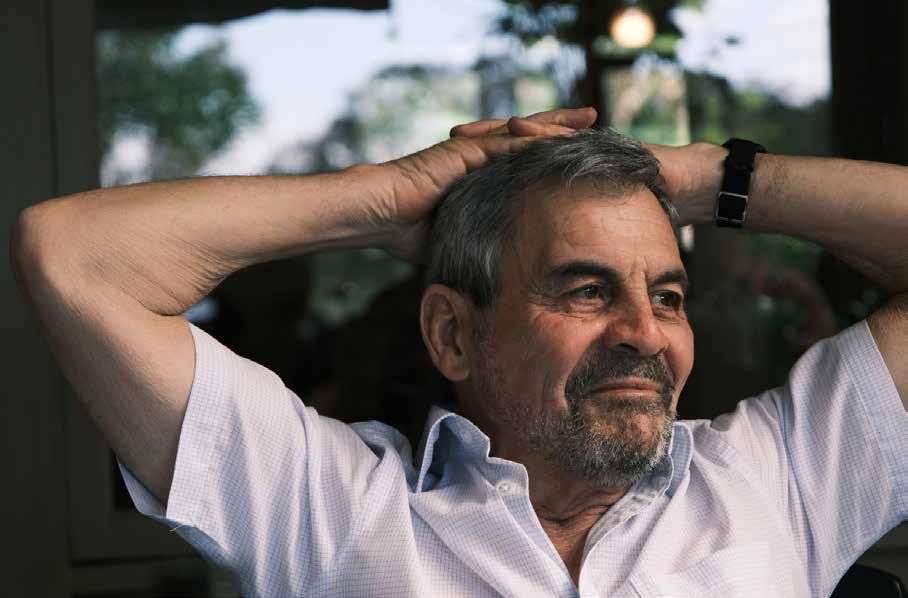

Australian manufacturing trends in 2023: more automation, micro-training and a focus on energy

By Margie Smithurst

By Margie Smithurst

While Australian manufacturing continues to be affected by the pandemic’s challenges, geo-political factors and clouds of global recession, it faces new trials as well as potential opportunities. With that in mind, what sort of trends can we expect in the sector in 2023?

Industry Update sat down with Ben Kitcher, the Executive Director of Research and Technology at Western Parkland City Authority, who is leading the development of the Advanced Manufacturing Research Facility (AMRF) opening in Western Sydney this year.

Industry Update: First of all, tell us a bit about yourself, and why you’re a good person to talk to regarding manufacturing trends.

Ben Kitcher: I’ve been involved in manufacturing technology since 2006. I was incredibly fortunate to join a very new team working on advanced manufacturing in the UK [the Sheffield Advanced Manufacturing Research Centre]. I didn’t quite realise at the time the opportunities that lay ahead in terms of being able to work on advanced manufacturing technology for high value applications, and the way in which those technologies would take off. So I was in the right place at the right time, able to join a really visionary team of people who had a large impact on the UK manufacturing sector. And today, I’m working to bring some of those insights and understandings on how to apply manufacturing technologies to our project, the AMRF which will be in Bradfield, in Western Sydney.

Automation value

Industry Update: Which brings us to what you see as some of the key trends across Australian manufacturing in 2023.

Ben Kitcher: The first is a continuation of something, but I think we’ll see a greater uptake in terms of automation technologies. And within automation, I include digital technologies - automation back office processes related to manufacturing. Automation goes hand in hand with greater productivity and profitability of the manufacturing business, so that’s fantastic. It also goes hand in hand with increasing the value added per worker per job, and that’s something that both the business and the individual have a keen interest in demonstrating.

The NSW Productivity Commission recently released a report titled Adaptive NSW, in which they highlight a potential “productivity dividend” of $27,400 per household by 2034-35 in today’s dollars. The basis of these benefits are in the adoption of new technology, including automation.

Automation also addresses a longterm deficiency in market availability for skills - it’s a key part in addressing the skills gap. We keep looking for the same skills that we were looking for a decade ago in machinery operators and technicians. And I think the opportunity to look forward and say that automation is key to resolving some of those skills gaps, is one that industry is coming to. Automation technologies are becoming more commoditised and more affordable, and the vendors and suppliers of the automation tools are also understanding

that accessibility is key.

Lowering the barrier to entry for automation technologies is a huge objective of theirs, and therefore greater implementation or at least spotting the opportunity and making inroads into implementing automation technologies will continue to be a big trend of 2023.

Micro-training shift

Ben Kitcher: I also think our training mechanisms are a key point of differentiation. We’ll continue to see the change from credentialism to micro-training, and picking up the vocational skills necessary to implement multiple automation technologies.

It’s about working with vendors of technologies and tertiary education providers to run very short courses that give just enough to implement a technology which is right for you and your business. And that’s how we can respond quickly to the needs of increased automation.

That’s what we’re trying to do with the New Education and Training Model (the NSW government program rolled out in March 2022, also offered in other states and federally). We have a number of micro-credentials up and running through that.

The first cohorts have been through that and the feedback we’ve had from learners and their employers has been outstanding. So they’re really valuable, tangible and actionable skills that they’ve

Western Parkland City Authority’s Ben Kitcher is leading the development of the Advanced Manufacturing Research Facility (AMRF)

learned in a very short amount of time and can take straight back into the business. This isn’t a full degree’s worth of content which may or may not get used, and from personal experience and my engineering degree, that’s exactly what happens - you may or may not use it. Micro-credentialing really seems to address the needs of what industry wants.

MANUFACTURING TRENDS 20 | Industry Update Issue 130 Feb/Mar 2023 industryupdate.com.au

Focus on energy Industry Update: What other trends do you foresee?

Ben Kitcher: The other one that I think is an increasing trend, and one that we’ve not necessarily been consciously moving towards, is energy efficiency and energy diversification. And 2023 will be a year where this really starts to take hold.

I’m sure there are businesses and

necessarily been successful in deepening Australian supply chain participation.

There are many areas of supply chain capability that warrant a greater focus – valve assemblies, lightweight aero structures, and actuators, amongst others. These types of sub-systems and their components are product specific, but widely applicable to various defence products.

We also know that there are very capable manufacturers of these types of components in Australia, and that with support and the right opportunity, these valuable products could be sourced domestically. There is an opportunity to significantly increase Australian content in defence contracts, and to broaden that impact from hotspots of activity where projects are integrated to widespread value creation.

companies who are very conscious of energy and do make big efforts to reduce their use, but on an industry wide basis, I think there’s a very long way to go from an efficiency and energy source diversification point of view.

Australian manufacturing hasn’t had the same pressures that manufacturers elsewhere in the world have had, particularly from an energy price point of view, and in some cases, stability of supply. That’s been a massive, massive factor in places such as Germany and the UK. We should prepare for those types of shocks to come through the system in Australia, and understand that the risk profile that comes with high energy intensity operations will be a trend for 2023.

I think it’s something which will be at least a decade-long focus for the manufacturing industry, and every decision we take henceforth, energy will be a very key consideration. Whereas at the moment, we are still looking at power availability as an absolute limit in what operations we can implement.

Today, we rarely consider how many units of energy per annum we’re working through, where we’re sourcing those, what the potential price fluctuations could be, and what their security is. I think these factors will become more commonly considered throughout next year and beyond.

Eyeing the defence pie Industry Update: It’s interesting how much Australian manufacturing seems to be positioning itself towards the defence sector. Do you see that as a trend?

Ben Kitcher: Yes, definitely. When you’ve got a confirmed market of $270 billion, plus export potential, it makes perfect sense. And I think we ought to support Australian industry in accessing as much of that as possible.

I’ve looked at the very much project-based focus for securing Australian content into various defence contracts in the past, I can see that it hasn’t

The barrier to making this happen is legacy and the practical aspects of managing an unfamiliar supply chain. Because we don’t have the aggregated and defence-proven capabilities in Australia that you do elsewhere, i.e., you don’t have very large companies managing sub-tiers of supply chains, we must work with many smaller companies representing a large manufacturing industry. So that’s a challenge that we need to address – not by changing the industry, but how the supply chain becomes established and functions.

capable. The level of innovation that is repeatedly released by our labs in photonic devices, transceivers, RF devices, and more recently, quantum is genuinely world class. Organisations such as the Australian Nano Fabrication Facility [ANFF] have been supporting this development for many years. But we don’t yet have a really solid, sensible, or competitive pathway for those technologies to be industrialised, or productionised here in Australia. And we should! They’re critical to our security and highly exportable, so not tied to our domestic market or consumption. So that’s what we’re working on, we can see a long-term plan.

I think the second half of this decade is our opportunity to really see an at-scale presence in the semiconductor industry, but we must start building on the foundations now.

Industry Update: Although we may be about 20 years behind the UK in establishing facilities like the Tonsley ‘Factory of the Future’ in SA, and the AMRF in Bradfield, which you will be running and which will provide technology trialling and testing for Western Sydney businesses, the fact that it’s happening at all is extremely promising, isn’t it?

Ben Kitcher: The main attractor to the AMRF and Western Parkland City project for me was coordination. The fact that governments are really getting involved, not just in the central funding of the centre and leaving someone else to do it, the government is taking this on and doing it.

In the case of the AMRF it’s part of a multibillion-dollar project to build the city of Bradfield, including public transport, city infrastructure, education, with investment attraction, the whole thing. The potential here for Australia to be more successful, in a shorter timeframe than the UK has done, I think is great. And that genuinely is the reason I wanted to join the project.

Certainly, the implementation of digital manufacturing technologies will help. The ability to manage the supply chain more effectively using those technologies is something that over the long term will help integrate more smaller businesses in such high value contracts.

Semiconductor groundwork

Industry Update: With the geo-political shifts in advanced chip manufacturing, there’s now talk of the need for an Australian semiconductor and advanced electronics manufacturing sector. The AMRF intends to focus on this in its second facility, which will come online in 2026, but what do you see in the immediate years ahead?

Ben Kitcher: From an industrial and production point of view, 2023 won’t be when Australia takes a significant share of the global semiconductor industry, but lots of groundwork is being done. Our existing semiconductor industry will continue to manufacture but they’ll be in relatively small volumes, and in terms of the overall makeup of the Australian industry, still small. Our opportunity is looking further down the track. Our laboratories and businesses in Australia are unbelievably

MANUFACTURING TRENDS

“2023 won’t be when Australia takes a significant share of the global semiconductor industry, but lots of groundwork is being done.”

“Every

PROTECT WHAT MATTERS PROTECTIVE COATINGS DESIGNED TO LAST. MAXIMISING PROTECTION & PERFORMANCE [02] 9603 1888 info@deco.net.au deco.net.au/protective-coatings A N ODIS I N G HARD A N O DI S IN G SPE CIA LT Y F IN I S H E S Sustain your components and add longer life and durability to your equipment with DECO’s range of protective coatings. With a wide variety of finishes offering superior corrosion, chemical, abrasion and wear resistance, DECO can help find a solution for your project requirements, and protect your components in the toughest of applications. Contact our team to discuss your project today Industry Update Issue 130 Feb/Mar 2023 | 21 industryupdate.com.au

“Very short courses that give just enough to implement a technology which is right for you and your business.”

decision we take henceforth, energy will be a very key consideration.”

Review: what’s working and what’s not

By John Spender, Director, William Buck

As we dive into a new calendar year, industry leaders are asking themselves “what’s the future of the manufacturing industry? And what position does my business occupy?”

In this four-part series, William Buck Accountants and Advisors share strategies that manufacturing leaders can employ to adopt new ways of thinking and cement their positions in the market.

These strategies fall into 4 key areas

• Revive: Immediate actions for restarting

• Review: What’s working and what’s not

• Refocus: Strategy and planning

• Thrive: Growth and opportunities

The new year is the perfect time to undertake an objective review of your operations and procedures. Take this time to identify the areas that are driving value in your business and any key issues that could be impeding your strategic goals. Five key areas to review include:

Review your operating model

Has it changed during the last two years and how will it be impacted as the economy kicks off? Is your organisational structure still appropriate? Are you happy with how your functional areas are organised?