Circular Economy

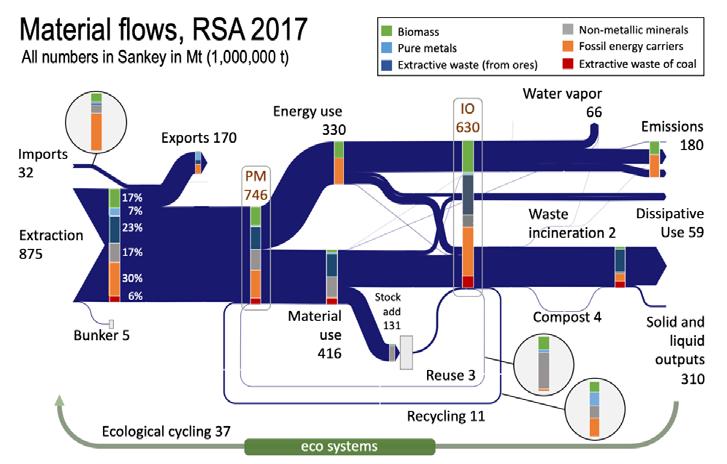

How circular is the South African economy?

Landfills

How can landfills be extended sustainably?

Waste Pickers

No reclaimers, no recycling!

Legislative

foils recycling potential

How circular is the South African economy?

How can landfills be extended sustainably?

Waste Pickers

No reclaimers, no recycling!

Legislative

foils recycling potential

Vertical single-stage submersible motor pump for wet installation, with free-flow impeller (F-max), stationary or transportable version. Electrical submersible Motor sizes ranging from 1.1 kW to 10.2 kW.

- Pumping station

- Waste water containing long fibre

- Waste water treatment (Including sludge and solid substances treatment and recirculation)

- Municipal and industrial waste water

- Fluids containing gas

- River water transport

- Storm water transport

- Service water

- Grey water

waste is the single largest waste stream generated in South Africa, accounting for 87.7% of all waste generated in the county, yet a quagmire of uncertainty holds back its recycling potential. P6

This Women’s Month we celebrate the women who work tirelessly in support of the NCPC-SA’s mission to promote resource efficient and cleaner production in industry. Join the ranks of these powerful agents of change by signing up for the NCPC-SA assessment or our training programs.

We are currently not all in the office so please email us on ncpc@csir.co.za. For more information, visit www.ncpc.co.za.

The NCPC-SA is a programme that promotes the uptake and implementation of resource efficient and cleaner production (RECP), funded by the dtic and hoisted by the CSIR.

Editor Nombulelo Manyana

Managing editor Alastair Currie

Head of design Beren Bauermeister

Chief sub-editor Tristan Snijders

Contributors Willem de Lange, Benita de Wet, Thurman Ezikiel, Lorren Haywood, Mishqah Hussain, Brendon Jewaskiewitz, Logan Moodley, Lerato Molefi, Suzan Oelofse, Garyn Rapson, Hugh Tyrrell, Eckart Zollner

Production & client liaison manager

Antois-Leigh Nepgen

Production coordinator Jacqueline Modise

Group sales manager Chilomia Van Wijk

Distribution manager Nomsa Masina

Distribution coordinator Asha Pursotham

Printers Novus Print Montague Gardens

Tel +27 (0)21 550 2300

Advertising sales Joanne Lawrie

Cell +27 (0)82 346 5338 joanne@3smedia.co.za

Publisher Jacques Breytenbach

3S Media

46 Milkyway Avenue, Frankenwald, 2090 PO Box 92026, Norwood 2117

Tel +27 (0)11 233 2600

Fax +27 (0)11 234 7274/5 www.3smedia.co.za

Annual subscription subs@3smedia.co.za

R200.00 (incl VAT) South Africa

ISSN 1680-4902

Institute of Waste Management of Southern Africa

Tel +27 (0)11 675 3462 Email iwmsa@iwmsa.co.za

All material herein is copyright protected and may not be reproduced either in whole or in part without the prior written permission of the publisher. The views and opinions of authors expressed in the magazine do not necessarily reflect those of the publisher, editor or the Institute of Waste Management of Southern Africa.

© Copyright 2021. All rights reserved.

Novus Holdings is a Level 2 Broad-Based Black Economic Empowerment (BBBEE) Contributor, with 125% recognised procurement recognition. View our BBBEE scorecard here: https://novus.holdings/sustainability/ transformation

We’ve all heard the classic trio: reduce, reuse, recycle. But very few people are aware that there are other steps you must take to reduce your impact on the environment – before ultimately recycling.

According to a report released by the UN Environment Programme and the CSIR in 2018, Africa recycles only 4% of the waste it generates. This is a far cry from the African Union’s vision that African cities will be recycling at least 50% of the waste they generate by 2023.

We must start thinking differently about not only where our waste goes but rather what we can do to reduce our environmental footprint. Within the waste hierarchy, there are six principles of sustainability, namely: rethink, refuse, reduce, reuse, repair and recycle.

Not only do these six principles of sustainability force us to think about our waste generation habits but they further the efforts of moving towards a circular economy.

Let’s take a look at these pillars:

Do I really need that? According to this principle of sustainability, this is the first question you should be asking yourself. It implores consumers to question and understand that their consumption habits have an impact on the environment – and decide whether they want it to be negative or positive.

This might be the most important of the six principles. We need to be reducing the amount of waste we generate by making smarter decisions. The idea is to consume less, so we waste less.

This one basically implores consumers to refrain from buying products that are not environmentally friendly and rather buy those that lend themselves to being recycled. With the gazetted extended producer responsibility regulations, this will be an easy consideration.

Before throwing it away, repurpose that product in another way. Reinvent it by upcycling it. One of the articles in this issue looks at how the tyre industry is reusing and repurposing waste tyres (see page 26). Always look for alternative ways to use your products.

Before you recycle, think to yourself: ‘Can I fix this?’ This part asks us to explore the different ways we can expand the shelf life of the product and/or make better use out of whatever we buy.

Lastly, if you cannot reuse the product, then recycle it. Practise separation at source and buy recyclable goods. With the regulations government has put in place and continues to implement, consumers have no excuse not to recycle.

We must start thinking beyond simply recycling and rather about implementing sustainable practices within our daily activities.

through regular interaction with like-minded individuals who are working towards a sustainable environment

by attending events discounted exclusively for IWMSA members

through education and training in the realm of effective and efficient waste management is also a key focus for us

as we contribute to the improvement of waste management standards and legislation, support international, national and regional trends in best environmental practices

through adhering to the IWMSA code of ETHICS trusted by clients in the waste environment

“We don’t make reality. We evade it. By looting natural capital and hiding the costs. But the bill is coming, and we won’t be able to pay.” – Richard Powers, The Overstory

As I pen this note, in the midst of the devastating third wave of the Covid-19 pandemic and the worst civil unrest democratic South Africa has seen, I cannot help but reflect on our recent past with dismay and genuine wonder as to what the future might hold.

At the moment, with the shocking visuals of widespread destruction, looting, and loss of life and livelihoods being broadcast across the world, it is hard to remain positive about creating a viable and prosperous future for all, never mind getting on top of our waste management problems.

The images of municipal waste collection trucks dumping their loads on our national roads, and the mess left behind by looters and arsonists are hard to erase from one’s mind. The damage to physical property, our status as an investment destination and national psyche is staggering. As events unfold, it is becoming clear that – if we are ever to emerge from this quagmire – the role and level of commitment of civil society are going to be the deciding factors.

This is also directly applicable to the waste management sector – while many of our national and local government officials have good intentions and the best interests of society at heart, they just don’t seem to be winning the war.

This is exemplified by the recent victory in the matter of the South African Human Rights Commission vs Msunduzi Municipality, regarding the mismanagement of the New England Landfill in Pietermaritzburg, in which the municipality was found guilty of breaching a number of environmental laws, including section 24 of the Constitution, which upholds everyone’s right to a healthy environment, protected from pollution. It is a sad day when the resolution of matters on which we have an abundance of expertise – but a lack of political will and leadership –requires civil society to approach the courts for help. This is going to happen more and more, particularly as aggrieved parties become emboldened by such judgments. One may ask where are the established authorities, who are clearly mandated to deal with such matters, including enforcement?

Speaking of looting, this edition of ReSource, featuring recycling and resource efficiency, is one with a relevant theme in our current waste management predicament. We simply cannot continue on the current path of resource exploitation and waste accumulation indefinitely, living permanently in a state of crisis. However,

we cannot think that recycling on its own will solve our problems.

Much more attention needs to be paid to the upstream elements of resource utilisation, starting with the design and manufacture of components and products to enable costeffective and efficient recycling, and the reuse of materials down the line, while still performing the job for which they were intended. This is clearly part of the ongoing circular economy discussion, and will present many interesting and exciting challenges for years to come.

Please don’t forget to take a look at our website and support the IWMSA by registering for ‘Landfill and Waste Treatment 2021’ – our first virtual seminar and exhibition of its kind – to be held from 3 to 5 November. Plans are taking shape and we look forward to seeing you online. I wish all of you and your loved ones the best of health during these trying times. Please be safe and well.

Brendon Jewaskiewitz, President, IWMSA

Mine waste is the single largest waste stream generated in South Africa, accounting for 87.7% of all waste generated in the country.

By Lorren Haywood, Benita de Wet, Willem de Lange & Suzan Oelofse*

The magnitude of environmental damage associated with acid mine drainage and leaching from mine waste dumps globally is rated by the European Environmental Bureau as “second only to global warming and stratospheric ozone depletion.”

Merely addressing the environmental damage is not enough to mitigate the impacts. A more proactive approach is required. Avoiding waste generation by using smarter mining techniques, as

well as the reuse of mine waste in other applications, would bring about alignment with the waste management hierarchy and support South Africa’s transition to a circular economy.

Numerous uses of mine waste have been documented globally, including aggregate and fill material for construction, structural additives to concrete, topsoil for agricultural activities, backfill, landscaping material, and aggregate in roadbuilding. Mine water is often used for dust suppression and in mineral processing, industrial cooling, and

– with proper treatment – even for irrigation and domestic use.

The mine water purification plant supplying water of drinking water quality to eMalahleni Municipality in Mpumalanga is an example; however, uptake of the reuse of mine waste in South Africa has been slow.

The CSIR investigated the main reasons for the slow uptake of the reuse of mine waste in the South African economy and discovered that legislative and governance issues are the primary reason. The

research findings were first published in the journal The Extractive Industries and Society in 2019, which highlighted the following key issues hampering mine waste reuse in South Africa:

The lack of a clear definition of mine waste

Mine waste is not defined in South African law. The Mineral and Petroleum Resources Development Act (No. 28 of 2002; MPRDA) defines ‘residue deposits’ and ‘residue stockpiles’. These definitions are carried forward into Category A: Hazardous Waste of schedule 3 in the amended National Environmental Management: Waste Act (No. 59 of 2008) in 2014.

In the MPRDA, residue deposits and residue stockpiles are considered to be resources with reuse potential, whereas the same residue deposits and stockpiles are defined as waste streams in the Waste Act, schedule 3. This contradiction creates confusion on the legal status of the material and consequently hampers the development of any business case for the reuse of mining waste, or associated markets.

Mine waste is classified as hazardous waste

Listing residue deposits and stockpiles as Category A: Hazardous Waste in schedule 3 significantly impedes the reuse and recycling of mine waste. Even though the reuse of hazardous waste is technically and legally possible, the bureaucratic processes and legal requirements for obtaining the required environmental authorisations for reuse are challenging.

Another, perhaps less obvious, issue is that current legislation is aligned with a ‘cradle-tograve’ environmental management approach, despite the national government imperative towards creating a circular economy, which calls for a ‘cradle-to-cradle’ approach.

Consequently, all materials considered to be waste from the mining process are only addressed in terms of environmental management requirements and reuse is not a major consideration of that management process. The cradle-to-cradle approach not only focuses on reducing, minimising and mitigating environmental impacts, but also encourages the uptake and reuse of mine waste as inputs into other industries. It is, therefore, not enforced and, consequently, closing the loop on mine waste is not possible.

The responsibility for the regulation of mining activities and their environmental impacts is split between two departments to avoid conflicts of interest in the regulatory mandates.

However, mine waste remains a contentious issue by virtue of the fact that one department views this material as a resource for future mining, while the other department is concerned about potential environmental damage from a waste management perspective.

Reusing mine waste as an input into the secondary resources economy, as envisaged from a waste management perspective, permanently locks all future opportunity for remining from a mineral extraction perspective. Therefore, tension remains, and the conflict is not conducive to promoting the recovery and reuse of mine waste. In fact, it traps the residue between being a byproduct with economic value and being an environmental hazard.

In the study, the importance of suitable, well-aligned legislation, clear unambiguous

definitions, and appropriate classification of waste streams were identified as necessary to enable and drive the development of a secondary resources economy – including industries supporting the repurposing of mine residue and waste. Failing to fulfil these requirements first will make it impossible for anyone to build a business in reusing mine waste.

Furthermore, the benefits to be realised if the largest waste stream in South Africa is reused or repurposed far outweighs the cost associated with the clean-up and mitigation of environmental damage caused by mining.

The environmental benefits will be complemented by socio-economic benefits, including increased employment and improved living conditions for those living in currently and formerly mined areas.

*Lorren Haywood, Benita de Wet, Willem de Lange and Suzan Oelofse form part of the Sustainability, Economics and Waste Research Group at the CSIR.

Colgate’s first recyclable toothpaste tube is now available in South Africa.

The oral care brand has launched its new Naturals toothpaste range, with packaging comprising a recyclable plastic tube inside a recycled carton box.

Most of today’s toothpaste tubes are made from sheets of plastic laminate – usually a combination of different plastics – sandwiched around a thin layer of aluminium. The mix of materials makes it impossible to recycle through conventional methods.

The Colgate Naturals range changes this in South Africa by using high-density polyethylene (HDPE) – the plastic used to make milk jugs and other plastic bottles already widely recycled.

The tube has received recognition from APR (Association of Plastic Recyclers) and RecyClass (an initiative that works on improving recyclability of packaging), which set recyclability standards for North America and Europe respectively.

The Colgate Naturals range is available now at all major retailers in South Africa. The three variants include Charcoal, Hemp Seed Oil and Aloe Vera, which contain ingredients that are 99.7% of natural origin to make the paste optimal for everyday protection.

Consol has launched a multifaceted campaign to raise awareness around the pollution of oceans and encourage a switch from single-use to reusable packaging.

Scientists assert that, unless we act soon to remedy the pollution of oceans, there will be more plastic in our oceans than fish by the year 2050.

“By making better choices today, we can create a better tomorrow,” says Dale Carolin, senior executive: Marketing and Commercial, Consol. “By choosing sustainable packaging such as glass, we can be part of this important change and give our oceans a chance to recover. It’s a simple choice that can lead to oceans of change.”

Consol will be joining hands with several organisations to raise awareness and encourage action against pollution of our oceans. Initiatives will include working with credible organisations to initiate monthly beach clean-ups on South Africa’s coastline. In an average beach clean-up, dozens of plastic bottles are collected, and these can be recycled and reused.

A key element of the ‘I Changed 2050’ campaign is the launch of Consol’s 2050 Sleek Bottle, which is not only stylish but promises to be endlessly refillable and easily recycled.

As June marked National Environment Month, protecting the ecosystems fell firmly in the spotlight. Of particular importance was ensuring that hazardous waste does not pollute the natural environment.

Used lubricating oil is a hazardous waste that, if irresponsibly dumped, can severely contaminate our water resources. One litre of used oil can contaminate a million litres of water. Used oil contains harmful compounds such as iron, tin, copper, zinc, as well as many other hazardous organic molecules.

The Recycling Oil Saves the Environment (ROSE) Foundation – an industry body that has been championing the responsible collection and recycling of used oil for 27 years – is calling on businesses that generate used motor lubricant oil, to become agents of change and ensure that they do their part to protect the environment by responsibly collecting, storing and recycling the used oil they generate.

The foundation says the safe disposal of hazardous waste is a critical issue and the legislation in place means that responsible waste management is no longer merely a good thing to do – it is a necessity.

Joburg-based digital recycling platform Kudoti was announced as one of five winners of Nestlé’s 2021 Creating Shared Value (CSV) Prize –winning a cash prize of US$40 000 (about R568 000).

Nestlé says the winning teams were selected for their innovative recycling impact through technology.

Kudoti, which is Zulu for ‘in the trash’, provides a digital platform to help waste management and recycling companies optimise their operations through the use of data collection tools.

The cloud-based platform digitises and automates waste management operations from start to finish through SMS interactions and webbased interfaces.

A groundbreaking trial that renders plastic bottles with selfadhesive labels fully recyclable promises positive spin-offs for the environment and plastic producers who have until November to comply with section 18 of the National Environmental Management: Waste Act (No. 59 of 2008).

Until now, polyethylene terephthalate (PET) plastic bottles with adhesive labels have hampered South African recycling processes, because the glue from the labelling has discoloured the recyclate.

This has meant that discoloured recycled PET (rPET) from those bottles could not be repurposed into high-quality, clear plastic beverage bottles, and could only be used to produce a limited range of products.

Post-consumer PET bottle recycler Extrupet trialled a new wash-off label adhesive in April in conjunction with PETCO – which showed more than satisfactory results. Plastic producers are set to benefit from the new technology as it would help them comply with new government legislation on extended producer responsibility.

As each country pledges its own targets to reduce the production of traditional fuels and turn to ‘greener’ energy sources, how much does each country currently rely on fossil fuel, renewable and nuclear energy sources?

Research has found South Africa relies on coal more than any other country in the world, while generating only 7% from renewable sources.

A study by energy tariff comparison platform

Utility Bidder revealed that Singapore relies on fossil fuels more than any other country.

While being the third most reliant nation on fossil fuels, South Africa also uses the highest proportion of coal in the world – standing at 73% of its total supply.

In Saldanha Bay Municipality, a new initiative encourages residents in lower-income areas to participate in recycling by feeding hungry schoolchildren in return. By Hugh

Tyrrell*

Since it began in 2016, the kerbside recycling collection service operated by Saldanha Bay Local Municipality has been running well in middleand upper-income suburbs. Each week, householders put out their recyclable materials in a clear bag (provided free by the

is below 15%. Many of those who do not participate, however, would understand the value of recyclable packaging materials, as they form part of the purchase price of groceries and other items they buy. There is reasonable reluctance to part with their recyclables without some form of compensation in return.

As a retailer with thousands of suppliers and millions of customers, Pick n Pay is mindful of its broad reach and the environmental impact across the value chain. It is committed to reducing its impact – enabling its customers to play their part in protecting the environment – and working with its suppliers and partners to innovate for a healthy planet. In supporting circular economy principles, Pick n Pay’s progress is underpinned by promoting the ‘avoid, reduce, reuse and recycle’ waste management hierarchy. The retailer’s efforts include working towards ambitious commitments to reduce food waste across its value chain and to increase the renewability of packaging, with a focus on transforming the plastics system.

The company assumes a leadership role in local and international collaborative efforts that bring retailers, brand owners, industry bodies and the government together to sit and work towards long-term common targets for the plastics value chain. This will drive positive change for its customers on a much larger scale.

Pick n Pay is a founding member of the SA Plastics Pact, which was launched in January 2020. In 2019, Pick n Pay became a signatory to the Ellen MacArthur Foundation’s Global Commitment to develop a circular economy for plastic. Pick n Pay is also a member of the South African Alliance to End Plastic Pollution in the Environment.

GreenEdge Communications, the recycling behaviour change subcontractor to the municipality, then researched various approaches to providing an incentive, with this in mind.

A low-income suburb was selected as the pilot site, where a coupon incentive, exchangeable for food at a nearby shop, was initially offered to those who participated. However, this met with opposition from some parts of a neighbouring informal settlement community, which was not on the municipal recycling collection route and therefore unable to benefit.

The ‘Recycling Enterprise and Education Project’ GreenEdge then came up with an alternative concept as an incentive. Entitled the ‘Recycling Enterprise and Education Project’ (REEP), it encourages residents to participate in recycling, which helps to feed a schoolchild at the same time. In exchange for a bag of recyclables given by a resident to the roving mobile recycling collector, a donation will be made to the nearby Masiphathisane Primary School feeding fund.

The donations are generously made as part of a sponsorship by Pick n Pay’s ‘People and Planet’ sustainability programme. PETCO came on board as a co-sponsor, kindly contributing the specially made recycling street carts and uniform.

The recycling collector, Busiswe Madlaliso, lives in the suburb herself, thereby providing a community job creation component to the project. Thandokazi Mdungwana – the local

environmental coordinator for the national Department of Forestry, Fisheries and the Environment – is providing environmental education, linked to responsible recycling and environmental care, to the school as well.

The pilot has achieved a fivefold increase in recycling collections, though off a low base. The project will run for three months and then be reviewed. If successful, the aim is to continue it and expand to other areas of the municipality.

The REEP project aligns with the circular economy – diverting valuable waste materials from landfill into the recycling industry, reducing energy and resource use, and creating employment – while also helping to feed young learners at school.

*Hugh Tyrrell is the founder of GreenEdge Communications.

Environmental solutions for post-consumer PET plastic PETCO, the PET Recycling Company, represents the South African PET plastics industry’s joint effort to self-regulate post-consumer polyethylene terephthalate (PET) recycling. The PET plastics industry acknowledges that aside from the convenience and life-saving qualities of plastics, a solution for post-consumer plastic packaging is critical in order to minimise its impact on the environment.

To achieve this, everyone is involved – from the raw material producers, converters, brand owners and retailers, to consumers and recyclers, all are playing their part in the solution, with PETCO fulfilling the PET industry’s role of extended producer responsibility (EPR).

EPR promotes the integration of the environmental costs associated with PET products throughout their life cycles into the marketing costs of the products, and shifts responsibility for dealing with the used container from government and the public to private industry.

Operating throughout South Africa, PETCO has been financed by a voluntary recycling levy paid by converters on PET resin purchased. PETCO also receives grants from brand owners, resin producers and retailers. This goes into supporting PET recycling efforts and ensures an ongoing monetary value for postconsumer PET.

PETCO’s ongoing public education, awareness activities and support for recycling entrepreneurs and projects promote environmental responsibility and encourage greater recycling of PET plastics.

The global increase in population, over-consumption and urbanisation has directly influenced the waste generation rates in recent years.

By Logan Moodley, PrEng, Mishqah Hussain & Thurman Ezikiel

In 2016, a study conducted by the World Bank reported an estimated worldwide waste generation rate of 2.01 billion tonnes – equivalent to 0.74 kg of waste generated a day per person (World Bank, 2019). This is expected to increase to 3.40 billion tonnes by 2050 – weighing approximately 500 times more than the Great Pyramid of Giza!

Similarly, eThekwini Municipality is challenged with an ever-increasing amount of waste being generated, with the current option for disposal being landfilling. Landfilling, despite being at the bottom of the waste hierarchy, is key in the effective management of waste within South Africa. It is the primary and most costeffective means of disposal for residential and commercial waste within eThekwini.

Despite its convenience and cost-effective nature, landfilling does pose environmental implications over and above the natural resources being wasted. These include the contamination of surface water and groundwater by leachate, pollution of soil by direct contact with wastes or leachate percolation, air pollution, and the uncontrolled release of

methane by the anaerobic decomposition of waste. Hence, the management of waste produced within the municipality is of economic, environmental and social importance.

As such, the design, construction and operation of landfills should be conducted in a sustainable manner while encapsulating these three aspects. In addition, consideration should be taken to move away from landfilling as the only option for waste treatment, while embracing waste diversion aspirations.

Within the management of solid waste, the idea of zero waste (although technically not zero, as there will always be residual waste needing final safe disposal) is an effective way to solve issues. Following the concept set out by the waste hierarchy, the aim is to landfill only waste that cannot be processed by diversion – i.e. recycling or reusing.

While undeniably an ambitious goal, business leaders and policymakers must recognise the importance of initiating the adoption of

strategies and processes that move South Africa closer to a sustainable landfill. However, strategic waste management planning cannot be fully capitalised on without having a clear understanding of the waste stream in question.

As such, the need for waste characterisation becomes a priority, begging the question: “How can landfills be extended in a sustainable manner?”

The waste generated within eThekwini Municipality is heterogeneous in nature, arising from varying income groups – which contributes to the different waste streams. Hence, precise and reliable data regarding the composition of domestic waste generated is critical for the planning of future waste management strategies. Consider this as a basic recipe for a ‘good bake’.

As such, Cleansing and Solid Waste (CSW) has designed, and is in the process of implementing, a tailored waste characterisation study to suit the current operation. The data obtained – and subsequent analysis thereof – will allow for city

decision-makers, within the waste management sector, to pursue innovations and technologies that offer economic, environmental and social benefits (the triple-bottom-line assessment).

The study seeks to fulfil the vision outlined by the National Waste Management Strategy (2011) in reducing waste generation rates and their respective impacts on the environment, and aims to contribute to the vaguely existing knowledge regarding the composition and generation of municipal solid solid waste (MSW) within the eThekwini region.

These findings will guide CSW into exploring alternate sustainable waste management solutions that aim to divert a large fraction of the MSW from landfills. In addition, the diversion of waste from landfill and maximising its potential can help CSW to reduce operating costs and increase process efficiency.

In light of the waste characterisation study, CSW has recognised the need to act on opportunities within the business that can result in quick wins

(i.e. do the easiest things first). Culture change and education towards reusing and recycling are part of a long-term strategy and addressed within the strategic development and planning of the 2022-2027 Integrated Waste Management Plan. However, short-term goals have been identified as the following:

i. The shredding of green waste

In the eThekwini Municipal Area, green waste constitutes 4% to 7% of the waste stream received at landfills. The current method of disposal for this waste stream is landfilling. As a long-term solution, this option poses many challenges – one of them being a significant impact on landfill airspace, as it does not compact easily. In addition, hardy green waste takes a considerable time to decompose in the present anaerobic conditions.

As a proposed solution, green waste has been targeted as the first step in saving landfill airspace, thereby extending the life of the landfill sustainably. Pilot-scale studies conducted on the mechanical treatment of green waste have demonstrated a 60% to 70% reduction in size (Moodley, 2011). The processed green waste, referred to as mulch, can be used for the following applications within the landfill operations:

1 Soil amelioration: The heavy earthworks machinery tends to leave the surface soil in a compacted state. This is unfavourable for plant growth due to a poor porosity and low oxygen content of the soil. Physical soil amelioration, a method used to directly improve the air and water balance of the soil, can be used to cultivate the compacted soil (Rollins & Kim, 2010). Thereafter, the processed mulch can be used to produce compost, which can be used to induce optimum plant growth on the surface layer.

2 Cover material: The need to properly manage exposure to solid waste in the landfill to the surrounding community is the

primary objective of the landfill operation. As such, cover material is key in achieving this. Successful implementation of the green waste project will result in a steady production of cover material from green waste.

3 Compost: The produced compost can be used to rehabilitate the Bisasar Road Landfill in the decommissioning stage by assisting in suitable plant growth on the site. A social benefit is the inception of vegetable gardens for the local community.

ii. Rubble crushing

Builder’s rubble constitutes a significant portion of the total waste stream received at landfills within eThekwini. Due to the limited availability of suitable land for new landfill development, alternate waste management solutions, such as the mechanical crushing of rubble/concrete, are being considered. The crushing of builder’s rubble was identified as a quick win as part of CSW’s Integrated Waste Management Plan. Possible applications for the processed rubble include alternate construction materials, as well as cover material.

iii. Separation-at-source programme

The strategic direction set in place by the National Environmental Management: Waste Act (No. 59 of 2008; NEMWA) requires municipalities to implement programmes aimed at diverting waste from landfill. To achieve this goal, CSW initially developed buyback centres, community recycling and drop-off centres, waste exchange centres, materials recycling facilities, and onestop recycling processes within commercial and industrial regions to promote recycling within the surrounding communities.

While these initiatives did encourage recycling, the quality and volume of the recycled materials did not meet the required objectives, hence calling for an improved strategy to tackle waste diversion – separation at source.

CSW has, in the recent years, implemented a separation-at-source programme in certain

regions within eThekwini Municipality. Orange bags are supplied to households for the recyclable stream within municipal solid waste, including newspapers, magazines, cereal cartons, cardboard, plastics, plastic bottles, and Tetrapak materials. These bags are collected on the same day as the black refuse bags. With this initiative, CSW hopes to achieve waste minimisation by supporting households and businesses to separate recyclables from their waste, thereby promoting a community-driven approach to waste management.

An alternate waste management solution of interest to CSW is anaerobic digestion. This is due to the large portion of organic waste present in municipal solid waste, which can be utilised as a suitable feedstock for anaerobic digestion (AD), provided separation at source is effective. Furthermore, studies suggest that AD may be the most adequate and environmentally sustainable technology to tackle the challenge of food waste, as it is a relatively easy and natural way of turning a broad variety of complex waste into fuel gas and digestate. Currently, this initiative is in Phase 1 – the inception and planning phase within CSW. Technical support for Phase 2 to work has been triggered with CSW engineers.

1. CSW is currently in the process of implementing a waste characterisation study that will inform decision-making on alternate waste solutions, hence diverting waste from the landfill and aiding in the move towards a circular economy as outlined in the NEMWA. 2. The separation-at-source programme, shredding of green waste, and rubble crushing have been sighted as short-term goals in diverting waste away from landfill, making progress in moving towards the vision of zero waste.

References:

Marcin K. Widomski, P. G. (2017). Sustainable Landfilling as Final Step of Municipal Waste Management System. Problems of Sustainable Development, 147-155.

Novella, P. (2014). Sustainable Landfills – Can These Be Achieved? Proceedings of the 20th WasteCon Conference. Cape Town. R Cossu, H. v. (2013). Sustainable Landfilling. The World Bank, I. (2019, September 23). Solid Waste Management. Retrieved from The World Bank IBRD IDA: https://www.worldbank.org/en/topic/ urbandevelopment/brief/solid-waste-management

Timothy G. Townsend, J. P. (2015). Sustainable Practices for Landfill Design and Operation. Springer.

Taking practical or financial responsibility for the disposal of one’s products is no longer a nice-to-have or a tick-box exercise.

Extended producer responsibility (EPR) of producers and importers in the electrical, lighting, and paper and packaging sectors has now been made mandatory by the South African government. On 5 May 2021, the Department of Forestry, Fisheries and the Environment (DFFE) gazetted the amended EPR regulations under section 18 of the National Environmental Management: Waste Act (No. 59 of 2008).

These regulations aim to provide the framework for the development, implementation, monitoring and evaluation of EPR schemes. This will promote the effective life-cycle management of the identified

products and enable the implementation of circular economy initiatives.

The regulations also make the producer (or group of producers) responsible for: the establishment of an EPR scheme, the development and implementation of an EPR plan, and compliance against annual recovery and recycling targets.

According to Francois Marais, manager of Fibre Circle – the producer responsibility organisation (PRO) for the paper and paper packaging sector – EPR will foster collaborative investment in material recovery infrastructure, such as convenient recycling facilities for consumers and collection at the pre-consumer phase.

Fibre Circle is calling on obliged paper producers – which could encompass manufacturers and importers of paper and paper packaging, as well as brand owners and retailers – to join its ranks.

Any South African company or brand that makes or imports paper or paper packaging (whether primary or secondary) for distribution in South Africa is required to belong to an approved EPR scheme and to pay an EPR fee per sales tonne of product.

In collaboration with its members, Fibre Circle will manage the EPR schemes for newspapers; magazines; office, graphic, mixed and other papers; corrugated cases and kraft paper; liquid board packaging; labels; and paper sacks.

“By joining Fibre Circle and doing so before 5 November, your paper and paper packaging interests can be collectively represented and you will be compliant with EPR regulations,” says Marais.

He adds that Fibre Circle will identify shared problems and opportunities for collaboration among member companies, municipalities, other PROs and the informal sector – all in support of a thriving circular economy.

While businesses only need to calculate their liability and submit their carbon tax return once a year, compliance with the Carbon Tax Act (No. 15 of 2019) itself is not a once-off accomplishment.

By Eckart Zollner*

Carbon tax compliance is not as difficult to achieve as some organisations think. Rather, by using the right monitoring tools, such as a cloud-based carbon tax calculator, along with practical strategies like pollution prevention plans and carbon budgets, organisations can track compliance and determine liability in an ongoing manner.

With a clear view of emissions across the organisational value chain provided by carbon analytics tools, businesses can monitor their outputs and measure the effectiveness of their carbon reduction efforts in line with their goals in real time.

Calculating emissions to determine tax liability on an annual basis is not what the Act intended. Instead, it aims to use carbon tax as a tool to bring about environmental awareness and urge behavioural change in the industry. It has been an effective tool in other countries, with Sweden reducing its greenhouse gas emissions by 26% while growing the economy by 78% between 1990 and 2017.

In the same time frame, France cut emissions by 13% and grew its economy by 51%. As South Africans, meaningful change in both business

mindset and operational processes is required to play our part in averting climate change and preserve our planet for future generations.

South Africa has committed to achieving netzero emissions by 2050. The Act was introduced in 2019 and is being rolled out in three distinct phases. While the first phase, lasting until 31 December 2022, has been introduced as a ‘soft phase’, subsequent phases are expected to have more stringent continuous requirements towards significant reductions in CO2 emissions.

To make a meaningful contribution to achieving a carbon-neutral economy, organisations need to take seriously their obligation to reduce emissions and examine greener approaches in their business. How can they do this when compliance seems like an abstract concept and the target of 2050 seems so far away? The type of change required for meaningful compliance starts with quantification.

Once the output is measured and tracked across the organisation’s value chain, it becomes possible to determine the carbon budget and to identify the necessary starting point for pollution prevention plans. A carbon budget evaluates the tolerable quantity of output that can be emitted over a specified period, while a pollution prevention plan details practical measures

and processes that require change to reduce emissions over time.

To do this, organisations must analyse their emissions continuously, set real-time goals and reduce emissions intensity at the required pace in order to stay within budget and achieve the desired results.

Such tracking and analysis are easier these days, thanks to technological advancements. Designed for local conditions, cloud-based carbon analytics tools give businesses the power to visualise emissions across the entire operational chain for the primary purpose of cleaning up their operations while calculating tax liability at the same time, considering offsets and allowances in the Act.

The pressure is mounting for industries to meet their carbon tax obligations and reduce their environmental impact but saving the planet does not have to feel like an unattainable goal. With the ability to monitor their carbon footprint, businesses will find it much easier to make meaningful changes required to achieve environmental goals and tax compliance.

*Eckart Zollner is head of Business Development at Energy and Densification Systems.

Arguably one of the most critical and far-reaching infrastructure decisions, secondary only to the selection and preparation of the landfill site, is the choice of liner and capping system to be put in place.

Karlo Wentzel Sales Manager: Geomembranes, AKS

Modern landfill best practice favours geomembranes as effective, durable barriers against liquid and gas leaching. To assure landfill owners and operators of a continuous, enduring seal across the entire area of the site, polyethylene geomembranes such as AKS Geoliner are specified as both lining and capping solutions.

It’s tough in a landfill

Because of the demanding, often aggressive and hazardous environments of landfills, the installed lining should comply with various manufacturing standards and pass numerous pre-installation and in situ tests to ensure it will withstand a lifetime of harsh surroundings. Factors considered when designing and manufacturing AKS Geoliner include the on-site physical stresses likely to be encountered, the types of waste material, the expected depth of fill, the compaction methods envisaged, and the geophysical characteristics of the site. Making allowances for these factors determines the type of resin used, the thickness, and the asperity height of textured or smooth geomembranes.

In AKS’s state-of-the-art laboratory, the company follows strict testing protocols, adhering to and usually exceeding international standards. For example, the US Geosynthetic Research Institute’s GRI-GM13 Standard Specification requires textured liner to elongate only 100% before break, where AKS’ textured liners will

elongate to over 300% under the same test conditions. In fact, all Geoliner produced by AKS meets or exceeds international standards such as GRI-GM13 (HDPE), GRI-GM17 (LLDPE) and the local SANS 1526.

Testing during production is done as a matter of course; continued pinhole detection is applied across the entire width of the sheet. For added peace of mind, AKS invites customers to a plant visit to familiarise themselves with the integrity and quality standards at work in the company’s modern, easily accessible plant in Brackenfell.

Along with its excellent impermeability, AKS Geoliner is characterised by its exceptional durability, high chemical resistance, UV protection and superior weldability.

The material’s excellent tensile properties and high elongation characteristics, combined with flexibility, make for a tough barrier that is highly resistant to tearing and puncturing. At the same time, AKS Geoliner is flexible enough to allow for ease of installation without compromising its integrity.

Geoliner is manufactured using the calendered ‘flat-die’ extrusion process, in 7 m widths with thickness ranging from 1 mm to 3 mm.

It is available in HDPE and LLDPE, with a smooth or textured finish, or a combination of smooth and textured, either on one or both sides of the sheet. AKS Megatextured Geoliner is available

in HDPE, with the same texture options of either single- or double-side.

To ensure a consistent product with the highest level of accuracy, AKS liners are manufactured using European-made precision extruders.

Geoliner can be custom-made to suit specific project requirements, taking into account installation needs, roll lengths, and truck or container loading configurations. When it comes to handling – to facilitate offloading and moving the product on-site – each roll is fitted with two certified lifting slings.

An inline marking system ensures on-site quality control and traceability. Instead of relying on a mere sticker or label to identify the brand and batch, a line indicating the wedge weld overlap width – 150 mm from the edge – is printed every linear metre together with the roll number. The number is linked to the AKS quality control system and provides manufacturing information. In large installations, the number is entered in a panel layout to provide a record of every square metre of lining used on the site.

AKS Geoliner is manufactured at the company’s modern plant based in Brackenfell, Cape Town. A large yard with ample storage provides the shortest possible lead times to customers.

For further information, please visit aks.co.za, email info@aks.co.za or call +27 (0)21 983 2700.

Waste in South Africa is currently governed by means of a number of pieces of legislation. This can make understanding your responsibility as a generator, disposer, or transporter of waste challenging.

By Garyn Rapson & Lerato Molefi*

Waste management is complex and is embedded in various pieces of environmental legislation, including the National Environmental Management Act (No. 107 of 1998; NEMA), the National Environmental Management: Waste Act (No. 59 of 2008; the ‘Waste Act’), and the National Water Act (No. 36 of 1998; NWA).

Waste is defined in the law as any substance, material or object that is (or is intended to be) unwanted, rejected, abandoned, discarded or disposed of by the holder, whether it can be reused, recycled or recovered, and includes all wastes as defined in the Waste Act.

However, waste ceases to be waste in these cases:

• once an application for its reuse, recycling or recovery has been approved or, after such approval, once it is, or has been, reused, recycled or recovered

• where approval is not required, once a waste is, or has been, reused, recycled or recovered

• where the Minister of Forestry, Fisheries and the Environment (‘the Minister’) has exempted any waste, or a portion of waste generated by a particular process from the definition of waste

• where the Minister has excluded any waste stream or a portion of a waste stream from the definition of waste.

A key legal principle of waste management is the ‘cradle to grave’ principle, the effect of which is that the generator of waste bears responsibility for the environmental, health and safety consequences of its waste throughout its life cycle – i.e. from generation to disposal.

It is worthy to note that the Waste Act defines a ‘holder of waste’ as any person who imports, generates, stores, accumulates, transports, processes, treats, exports, or disposes of waste.

Therefore, companies that generate waste and temporarily store it, as well as companies contracted to transport, treat and/or dispose of such waste, i.e. waste management contractors, are classified as ‘holders of waste’ in terms of the Waste Act. Understanding the definition of a holder of waste plays an important role in understanding how responsibility is divided between the generator of waste and the disposer/transporter of that waste, as well as compliance necessary for both parties. To assist with legal compliance, we have produced the checklist table to the right.

*Garyn Rapson and Lerato Molefi are both environmental law experts at Webber Wentzel.

SPECIFIC OBLIGATIONS

CLASSIFICATION & ASSESSMENT

WASTE MANAGEMENT LICENCES

STORAGE OF WASTE

REMOVAL OF WASTE

TRANSPORT OF WASTE

DISPOSAL OF WASTE

POLLUTION

COMPLIANCE

The classification and assessment of waste is regulated by the Waste Act and, as such, compliance with the Waste Classification and Management Regulations GNR735 of GG 36784 of 23 August 2013 and the National Norms and Standard for Assessment of Waste for Landfill Disposal – GNR 635 of GG 36784 of 23 August 2013.

All waste must be classified under these laws.

Section 19 of the Waste Act provides that no person may commence, undertake or conduct a waste management activity without a waste management licence issued in respect of that activity. A list of waste management activities has been published in terms of Government Notice 718 of 3 July 2009 – these include Category A and Category B activities.

Should a generator of waste and a company contracted to manage, treat and/or dispose of that waste trigger any of the listed waste management activities, the necessary waste management licences must be obtained by the respective parties.

In terms of section 21 of the Waste Act, a person storing waste must at least take steps to ensure that:

• the containers in which any waste is stored are intact and not corroded, or in any other way rendered unfit for the safe storage of waste

• adequate measures are taken to prevent accidental spillage or leaking

• the waste cannot be blown away

• nuisances such as odour, visual impacts and breeding of vectors do not arise

• pollution of the environment and harm to health are prevented.

The person storing waste will also need to comply with the provisions of the National Norms and Standards for the Storage of Waste (GNR 926 of GG 37088 of 29 November 2013) and the Regulations Regarding National Norms and Standards for the Sorting, Shredding, Grinding, Crushing, Screening or Bailing of General Waste (GNR 1093 GG 41175 of 11 October 2017), if applicable.

In terms of section 24 of the Waste Act, no person may collect waste for removal from premises unless such person is:

• a municipality or municipal service provider

• authorised by law to collect that waste, where authorisation is required

• not prohibited from collecting that waste.

Holders of waste must be appropriately authorised to collect and remove waste. Registration is typically required for these activities in terms of local by-laws.

Transporters of waste for gain may be required to register with the relevant waste management officer in the Department of Forestry, Fisheries and the Environment (DFFE), province or municipality as applicable and to furnish such information as may be required.

Transporters must also take all reasonable steps to prevent any spillage of waste or littering from a vehicle used to transport waste.

Transporters of waste must be authorised to transport waste. Registration is again typically required in terms of local by-laws.

In addition, transporters of waste must comply with Chapter 8 of the National Road Traffic Act (No. 93 of 1996), which sets out very specific obligations on the transportation of dangerous goods.

Transporters of waste must, before offloading, ensure that the facility to which the waste is being transported is authorised to accept the waste. When hazardous waste is being transported, the transporter must ensure that the facility or place to which the waste is transported is authorised to accept such waste and must obtain written confirmation that the waste has been accepted.

Section 26 goes on to provide that no person may dispose of waste, or knowingly or negligently cause or permit waste to be disposed of, in or on any land, waterbody or at any facility, unless the disposal of that waste is authorised by law.

Regulation 15 of the Hazardous Chemical Substances Regulations (GNR 1179 of 25 August 1995), as published in terms of the Occupational Health and Safety Act (No. 85 of 1993), also provides that an employer shall as far as is reasonably practicable ensure that hazardous chemical substance wastes that can cause exposure are disposed of only on sites specifically designated for this purpose in terms of the Waste Act, in such a manner that it does not cause a hazard inside or outside the site concerned.

It is crucial that holders of waste who have contracted the services of a transporter of waste ensure that such transporter is disposing of its waste on landfills that are appropriately authorised to accept the waste. This is a vital in terms of complying with the cradle-to-grave principle of environmental law.

Section 26 of the Waste Act provides that no person may dispose of waste in a manner that is likely to cause pollution of the environment or harm to health and well-being.

A key environmental principle commonly referred to as the ‘polluter pays’ principle is encapsulated in the NEMA, which says: “The costs of remedying pollution, environmental degradation and consequent adverse health effects and of preventing, controlling or minimising further pollution, environmental damage or adverse health effects must be paid for by those responsible for harming the environment.”

This polluter-pays principle is incorporated in the NWA by section 19 and is fleshed out in section 28 of the NEMA, which places a duty of care on every person who causes, has caused, or may cause significant pollution or degradation of the environment to take responsible measures to prevent such pollution or degradation from occurring, continuing or recurring.

The reference to a person generally refers to the owner of the land or premises, a person in control of land or premises, or a person who has a right to use the land or premises on which or in which an activity is performed or a situation exists that causes, has caused, or is likely to cause the pollution or degradation. Such persons will generally be held liable for the costs of remedying the pollution or degradation caused to the environment.

WASTE INFORMATION Sections 60 to 64 of the Waste Act provide that the Minister must establish and incrementally implement a national waste information system for the recording, collection, management and analysis of data and information. Provincial waste information systems may also be established.

Any person may be required, by notice in the Government Gazette or in writing, to provide within a reasonable time or on a regular basis, any data, information, documents, samples or materials that are reasonably required for the purposes of the waste information systems.

The National Waste Information Regulations GNR 625 GG 35583 of 13 August 2012 came into force on 1 January 2013. The purpose of the regulations is to regulate the collection of data and information to fulfil the objectives of the national waste information system.

Regulation 5 requires any person conducting an existing activity listed in Annexure 1 to apply to the DFFE to be registered on the South African Waste Information System (www.sawic.org.za) within 90 days of the promulgation of the regulations (i.e. by 1 April 2013) or within 30 days of commencing such an activity after the regulations come into force. Different activities must be registered individually.

Once registered, quarterly reports must be submitted in terms of regulation 8 and appropriate records must be kept in terms of regulation 9 for five years.

As part of Stellenbosch Municipality’s commitment to becoming a greener and more sustainable valley, the local authority launched a brand-new waste materials recovery facility (MRF).

Landfills across the country are filling up, including the Stellenbosch Municipality site, which reached capacity in 2019. Building new landfill sites is not sustainable, nor is it environmentally feasible, as there simply isn’t enough land available to develop new landfills.

Although Stellenbosch Municipality is currently investing in the expansion of its landfill site, it has also shifted its focus to minimising waste to landfill by reducing, reusing and recycling.

Thus, the launch of the advanced recycling facility, commonly known as an MRF, is part of the process of taking the minimisation of waste to the next level. This runs in conjunction with other waste minimisation initiatives.

“The municipality is looking at various waste minimisation initiatives, which include the separation of green waste – which is shredded and beneficiated. We also divert all clean builder’s rubble away from the landfill and are planning to crush this material to G5 aggregate to use in other construction projects,” says Stuart Grobbelaar, communications manager at Stellenbosch Municipality.

The municipality has obtained an environmental authorisation and is busy with detail designs to construct an organic waste transfer station. The diversion of organic waste and recyclable material entails waste streams that have been identified in the National Waste Management Strategy as those that need to be diverted from landfill. The MRF allows for recyclables to be handled

and processed in Stellenbosch, allowing for faster turnaround times by eliminating the need to travel to Cape Town. At the same time, it will provide jobs to residents registered on the unemployment database, which also includes waste pickers.

This is how it works at the MRF:

• Mixed recyclables are transferred to the MRF and offloaded at the northern end of the building.

• Bags are moved to the infeed conveyor by a loader or by hand, and are broken open by hand.

• Glass bottles are removed and placed in a glass recycling container, while all other mixed recyclable material is placed on the infeed conveyor at an incline and feeds into the elevated sorting conveyor, where the sorters will extract the recyclables.

• The 30 m sorting conveyor has place for 36 sorters, who extract the various recyclable materials and drop them into a separate container via a chute at each of their respective stations.

• The containers that hold recyclables that could be baled are then moved to the baler, where they are baled and stored at the western side of the building ready for collection.

• The equipment was sized to handle 450 tonnes per month.

This state-of-the-art facility basically serves as a place where recyclables are taken to, grouped, and baled. They then will be provided to companies for use as raw material in the manufacturing of new products. The sorted recyclables have a much higher value than mixed recyclables and will be easily accepted into the booming recycling market.

“The municipality has awarded a tender to a company that is experienced in the recycling market. Part of the scope of works for this tender is to ensure that the recyclable material is sold off and new markets are found to recover more recyclable material,” states Grobbelaar.

The facility also features a public dropoff area, which will allow for residents to bring garage and recyclable waste to dispose of responsibly.

Grobbelaar says that although local residents are very positive about the facility, the municipality plans to engage with more awareness and marketing initiates to get all residents’ support.

“The activating of the MRF is a significant step in preserving our environment and maximising landfill airspace for future generations.”

Construction of the facility began in August 2019 and the total budget for the project was R29 million. The project was funded partly in terms of the Integrated Urban Development Grant and through own capital funding.

The MRF currently has the capacity to process 450 tonnes of recyclable material per month and, although still in its early days, Grobbelaar says the recycling capacity has already been increased from 80 tonnes of recyclables to 100 tonnes within the first two months. “The aim is to reach maximum capacity soon.”

Grobbelaar asserts that with the country’s move towards a more circular economy, investing in alternative waste disposal sites like this will help to realise this momentous shift.

“We have to look at different opportunities to reduce the amount of waste that ends up at landfill and apply the hierarchy of waste, which entails: avoid waste from being generated, reduce waste, reuse waste, recycle, treat waste, and finally dispose of waste.

“Recycling will also result in less waste being landfilled and less raw materials being produced. Recycling will also reduce the need to develop or expand landfills in the future. Recycling creates employment and business opportunities for small and medium enterprises – and provides a source of income for many unemployed individuals. In the era of climate change, we need to reduce our dependency on raw materials, and recycling provides the opportunity to reuse and recycle material,” Grobbelaar concludes.

South Africa’s waste pickers are critical to the recycling economy and green future yet, for the most part, are still marginalised and discarded. According to research, reclaimers collect up to 90% of all post-consumer packaging and paper left behind; if they stopped today, there would be no recycling industry in South Africa.

Over the past several years, Dr Melanie Samson – senior lecturer: Human Geography in the School of Geography, Archaeology and Environmental Studies at Wits – has been leading initiatives to ensure that waste pickers are recognised and valued.

Samson recently completed a three-year research project on ‘waste picker integration’ funded by South Africa’s Department of Science and Innovation’s Waste Research, Development and Innovation Roadmap and the current Department of Forestry, Fisheries and the Environment (DFFE). She also facilitated the DFFE’s national stakeholder process to develop the Waste Picker Integration Guideline for South Africa (‘the Guideline’) and is its primary author.

Samson previously worked for the National Union of Metalworkers of South Africa, and led a research and education project on gender and waste privatisation for the South African Municipal Workers Union. Her research focuses on how reclaimers forge value out of waste, reclaimer dispossession and ‘integration’,

According to the CSIR, informal waste pickers (also known as reclaimers) recycle roughly 90% of the recyclables collected from households in South Africa –saving municipalities up to R750 million in landfill space every year.

working in the informal waste economy. A major challenge has been that people don’t really understand the value that reclaimers bring to the South African recycling economy, Samson notes.

“Each party [municipality, department] has a different understanding of the existing recycling system. It’s therefore essential to develop a common understanding about what reclaimers do – with reclaimers sharing their experiences,” she adds.

They are prevented from access to landfills in some municipalities, stigmatised by government and the public, exposed to unhealthy working conditions, and vulnerable to volatile price changes on the scrap market.

the political ecology of waste, and informal worker organising. Her research on reclaimers arose out of her activist work accompanying reclaimer movements.

Prior to joining Wits, she was the African waste sector specialist for Women in Informal Employment: Globalizing and Organizing, where she worked with reclaimer (waste picker) organisations across Africa, Asia and Latin America.

This, she says, is where she learned about the many challenges that reclaimers face

Samson believes that the only way to overcome the challenges with regard to integrating waste pickers into the formal waste management sector is first to demystify the sector.

From her work with Latin American reclaimer organisations, Samson has been able to see what element makes those integration models successful, in comparison to the South African context.

“In countries like Brazil, Colombia and Argentina, you have well-developed models where cities pay for their service,” she says.

“When a municipality contracts private companies to recycle, they pay the company a collection fee, while waste pickers [in South Africa] are not paid for the collection services they provide.

“In South Africa, we always looked at integration as us doing waste pickers a favour by including them into the national waste management system, but we don’t see that waste pickers have been doing us the favour all along – boosting our economy and helping to make South Africa’s recycling rate equivalent to that of some Western European countries.”

According to the 2020 National Waste Management Strategy, this is the timeline for integration:

• 2020: Guidelines adopted and implemented

• 2021: All metros have integration programmes in place

• 2024: All secondary cities have integration programmes in place

• 2024: 500 jobs/decent livelihoods created in collecting recyclables.

According to Samson, a vital part of waste picker integration is their participation in decision-making within the waste management process and recognition of the public service they supply. It also requires what Samson refers to as ‘social integration’.

She says government and industry need to transform how waste pickers are seen, appreciated and valued – by residents, industry and government officials.

“There is not enough focus on reclaimers as people. People with unique histories, knowledge, expertise, ideas, passions – they are not given the same rights and dignity as everyone else.”

Second, there is a need to understand what already exists – and this is where Samson coined the term ‘separation outside source’ (SoS), which helps with understanding the role of waste pickers.

“Waste pickers created a wellfunctioning SoS system long before government interest in the 3Rs.”

According to the CSIR, SoS saves municipalities up to R748 million per year in landfill airspace. It also saves them transport and labour costs.

“Municipalities and industry benefit, but don’t pay for the collection service. Waste pickers only earn very low prices from sale,” assert Samson.

In contrast to the existing separation-atsource (S@S) system, SoS doesn’t allow for the ‘disintegration’ of reclaimers. Samson’s research has shown that, through S@S, companies or community coops were being paid to collect recyclables – meaning reclaimers were pushed out by the company but still had to keep working to survive. Only, this time, they access fewer materials and, unlike the contractors, are not being compensated for collection.

“This means reclaimers’ incomes, working conditions and relationships with some residents deteriorated. Waste pickers are criminalised, their dignity is compromised, and local street reclaimers are simply not included,” she adds.

Building on the SoS model (instead of importing companies into the sector) can ensure that waste pickers are prioritised and empowered though systemic integration, Sampson states. “The simple truth is we need reclaimers as much as they need us.”

Through the development of the Guideline, Samson argues that we need to ask ourselves the following key questions: “Who is being integrated into what, when, why, how, by whom, and in whose interests?”

She insists, “Reclaimers are the experts, and they know best what they do, how recycling works in the city, and how they want to be integrated.”

Samson adds that engagement and collaboration are part of the definition of integration; if reclaimers are not involved in planning and implementation, it will fail.

The Guideline provides a clear and important definition of waste picker integration. “Waste picker integration is the creation of a formally planned recycling system that values and improves the present role of waste pickers, builds on the strengths of their informal system to collect and revalue materials, and includes waste pickers as key partners in its design, implementation, evaluation and revision. It includes the integration of waste pickers’ work, as well as the political, economic, social, legal and environmental integration of waste pickers,” Samson concludes.

1. Recognition, respect and redress

2. Waste pickers know best what they want

3. Meaningful engagement

4. Build on what exists

5. Cost-effective, increased diversion

6. Evidence-based

7. Enabling environment

8. Improved conditions and income

9. Payment for services and savings

10. Holistic integration

It is estimated that millions of waste tyres are lying in South African dumps, as stockpiles, or simply scattered across residential, industrial and rural areas.

South Africa’s recycling rate for vehicle tyres increased from 4% to 60% in the space of three years after the implementation of the Waste Tyre Management Plan. The strategy was developed where used tyres were collected from dealers, brought to dedicated depots, and then transported to processing plants for recycling.

All activities were funded by introducing a tax instrument that placed a levy on all new tyres. The environmental tyre levy, which is implemented through the Customs and Excise Act (No. 91 of 1964), allows for:

• the tyre manufacturing industry to pay the levy directly to the South African Revenue Service, for depositing into the National Revenue Fund, as with all other environmentalrelated taxes.

Bridgestone has introduced the new Ecopia tyres, which are environmentfriendly and fuel-efficient

• the revenue raised through the levy to be appropriated to the Department of Forestry, Fisheries and the Environment (DFFE) via the national budgeting and appropriations process, for funding the implementation of the tyre waste management programme to contribute to reducing waste tyre disposal on landfills and to build a viable circular economy from the recycling of endof-life tyres.

A fee of R2.30/kg is levied on all new tyre rubber. The proceeds are used to establish infrastructure for tyre collecting and downcycling, and pay for its administration. The DFFE is the current custodian of the industrywide plan.

Nduduzo Chala, managing executive at the South African Tyre Manufacturers Conference (SATMC), says local tyre manufacturers have always supported the implementation of the levy to fund the proper treatment and disposal of waste tyres.

“It is critical for the tyre industry to ensure that waste tyres are disposed of correctly in order to limit the impact on the environment and ensure that they do not find a way back into the market,” he says.

Waste tyres that are resold are not only illegal, but pose a safety risk for consumers, Chala emphasises.

The SATMC is the official industry body and trade association of the four local tyre manufacturers – Bridgestone, Continental, Goodyear and Sumitomo. They are the voice of the local tyre manufacturers and represent them on trade, economic and environmental policies, and tyre sector regulations.

They are currently focusing on four main areas of improvement – the proper mutilation and disposal of waste tyres, a reduction of materials used in manufacturing tyres, the sustainable sourcing of materials, and a reduction in carbon emissions.

Environmentally friendly tyre

Bridgestone has introduced the new Ecopia tyres, which are environment-friendly and fuel-efficient. This tyre reduces fuel consumption and boasts a quieter ride and improved roadholding, while reducing carbon dioxide emissions.

Sustainable sourcing of materials

Goodyear’s overall corporate responsibility includes the sustainable sourcing of materials. The company is exploring using a soybean oil tread compound in four of its tyre lines to create more sustainable rubber with added traction benefits. It

also uses rice husk ash silicate, which helps to deliver similar performance to traditional sand-based silica with less environmental impact and waste to landfills.

Sumitomo Rubber SA has installed a 1 MW solar system on its truck and bus radial production facility roof in order to reduce its emissions from electricity consumption. Additionally, Continental Tyre South Africa won the Industrial Corporate Project of the Year award for innovative industrial energy management projects and outstanding contributions to the energy industry. Continental received this award for a heat recovery project that saved 4.5 million kWh of energy and over R1 million in 2019.

However, the Bureau has been challenged with processing capacity since it started managing waste tyre operations. Its processing performance was further affected in 2020/21 due to Covid-19.

Chala emphasises that although the industry has been diligently paying the levy, these issues with the collection and disposal of waste tyres have impacted the tyre recycling industry negatively. “We need to put in place a sustainable recycling mechanism, so that tyres do not end up at landfills but are utilised effectively through recycling.”

The SATMC and other players in the tyre sector are currently working with the DFFE to finalise the details of an updated/new draft industrywide plan.

The Waste Bureau was appointed by the DFFE with the responsibility for tyre waste management since October 2017, after the withdrawal of the Recycling and Economic Development Initiative of South Africa (Redisa) plan.

“As the local tyre manufacturers, we will continue to be responsible and work with government to ensure we comply with regulations and put in place measures that limit impact on the environment; however, the DFFE, as the custodian, needs to take more ownership of the plan and implement proper measures to dispose of waste tyres, seeing as the industry is funding it,” Chala concludes.

• Waste Collection Optimisation

• Waste Transfer Station design

• General Waste Landfill design

• Hazardous Waste Landfill design

• Landfill Rehabilitation

• Landfill Auditing and Monitoring

Contact Numbers

Telephone:+27 (0)21 982 6570

Fax:+27 (0)21 981 0868

• Landfill Closure

• Leachate Treatment

• Regional Waste Studies

• PPP Involvement in Waste Management

• Alternative Technologies for Waste Reduction

• Integrated Waste Management Plans

Physical Address

60 Bracken Street, Protea Heights South Africa, 7560

Postal Address

P.O. Box 931, Brackenfell South Africa, 7561

Lay’s has launched a new global programme that will use empty chip packets and the power of football to bring joy to communities around the world.

During June 2021, Lay’s announced that it has partnered with the UEFA Foundation for Children and streetfootballworld on a new global initiative, Lay’s RePlay. The goal of this initiative is to reuse empty chip packs to help create sustainable soccer pitches.

Lay’s also partnered with local organisation Amandla, the South African Football Association, and the City of Ekurhuleni.

Up to five Lay’s RePlay football pitches are set to open throughout the world in 2021, with the first being in Thembisa, and Russia, Brazil, Turkey and the UK following suit.

With the potential to benefit over 16 000 members of the community through more than 3 600 hours of play and educational-sporting programmes in the first year alone, Lay’s RePlay places a strong emphasis on involving community members and local organisations throughout the planning, construction, and maintenance phases of each pitch.

In South Africa, the local programme, managed by NPO partner Amandla, looks to empower the youth, promote inclusivity, and share key life skills and prosocial behaviours with EduFootball sessions.

Lay’s RePlay pitches maximise social value while minimising environmental impact. From the