Complete water resource and wastewater management

Water & Sanitation Africa

Increasing dam storage capacity through the NatSilt Programme

INDUSTRY INSIGHT

APE Pumps

New mechanical/electrical installation at Verulam and La Mercy Pump Station

Blue Drop and Green Drop programme revitalised

Water Warriors

The water crisis: it’s not a supply issue, it’s a demand one

Holistic approach to industrial effluent and mine water treatment

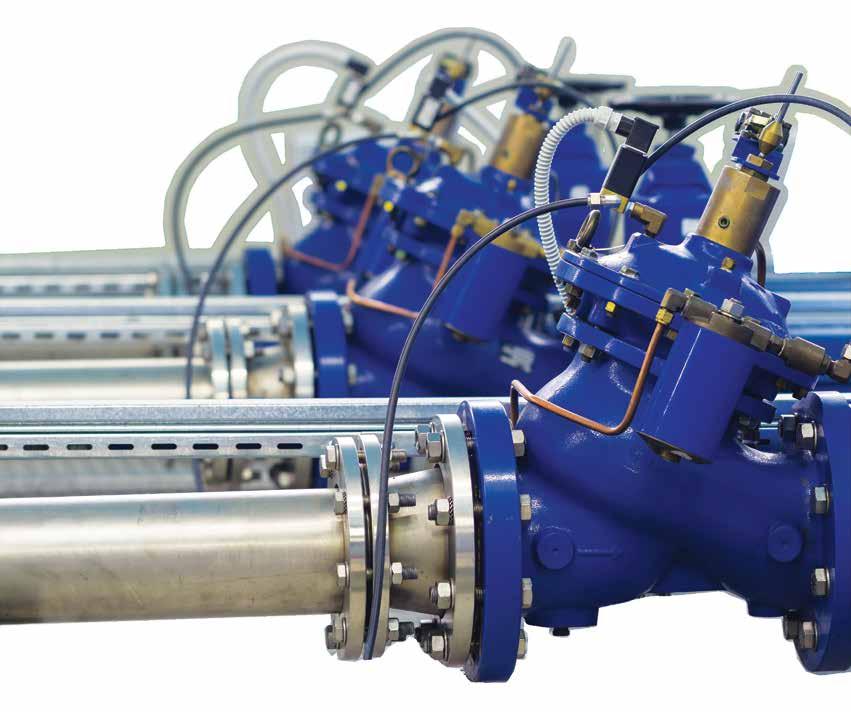

Low or High, Bermad can handle the Pressure

Whether your needs are to reduce, relieve, or sustain, we have the right valves to handle any pressure and keep your business going. Our partnership with Bermad is long-standing and has been one of the ways we keep reinventing ourselves.

Scan the QR Code to get in touch with us and find out more about Macsteel Fluid Control

THE FLOW MUST GO ON.

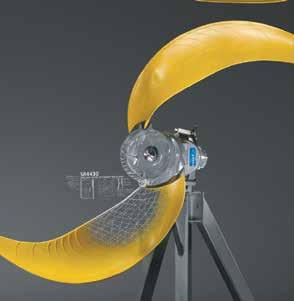

AMAREX - Dual performance submersible pump

Vertical single-stage submersible motor pump for wet installation, with free-flow impeller (F-max), stationary or transportable version. Electrical submersible Motor sizes ranging from 1.1 kW to 10.2 kW.

Applications

- Pumping station

Fluids handled

- Waste water containing long fibre

- Waste water treatment (Including sludge and solid substances treatment and recirculation)

- Municipal and industrial waste water

- Fluids containing gas

- River water transport

- Storm water transport

KSB Pumps and Valves (Pty) Ltd

Tel: +27-11-876-5600

www.ksb.com/ksb-za

Your B-BBEE Partner

- Service water

- Grey water

Editor Kirsten Kelly kirsten.kelly@3smedia.co.za

Managing Editor Alastair Currie

Head of Design Beren Bauermeister

Chief Sub-editor Tristan Snijders

Contributors Xanthe Adams, Lester Goldman, Thandeka Jwara, Chetan Mistry, Kagiso More, Dan Naidoo, Christian Wolkersdorfer

Production & Client Liaison Manager Antois-Leigh Nepgen

Production Coordinator Jacqueline Modise

Distribution Manager Nomsa Masina

Distribution Coordinator Asha Pursotham

Group Sales Manager Chilomia Van Wijk

Bookkeeper Tonya Hebenton

Advertising Sales Hanlie Fintelman

c +27 (0)67 756 3132

Hanlie.Fintelman@3smedia.co.za

Publisher Jacques Breytenbach

3S Media

46 Milkyway Avenue, Frankenwald, 2090 PO Box 92026, Norwood 2117

Tel: +27 (0)11 233 2600 Fax: +27 (0)11 234 7274/5

www.3smedia.co.za

ISSN: 1990 - 8857

Annual subscription: R330 (SA rate)

subs@3smedia.co.za

Copyright 2021. All rights reserved. All articles herein are copyright protected and may not be reproduced either in whole or in part without the prior written permission of the publishers. The views of contributors do not necessarily reflect those of the Water Institute of Southern Africa or the publishers.

WISA Contacts:

HEAD OFFICE

Tel: 086 111 9472(WISA)

Fax: +27 (0)11 315 1258

WISA’s Vision Inspiring passion for water

Physical address: 1st Floor, Building 5, Constantia Park, 546 16th Road, Randjiespark Ext 7, Midrand Website: www.wisa.org.za

BRANCHES

Central Branch

(Free State, Northern Cape, North West)

Chairperson: Dr Leana Esterhuizen

Company: Central University of Technology

Tel: +27 (0)51 507 3850

Email: lesterhu@cut.ac.za

Eastern Cape:

Branch Contact: Dan Abrahams

Company: Aurecon

Tel: +27 (0)41 503 3929

Cell: +27 (0) 81 289 1624

Email: Dan.Abraham@aurecongroup.com

Gauteng Branch Lead: Zoe Gebhardt

Cell: +27 (0)82 3580876

Email: zoe.gebhardt@gmail.com

KwaZulu-Natal

Chairperson: Lindelani Sibiya

Company: Umgeni Water

Cell: +27 (0)82 928 1081

Email: lindelani.sibiya@umgeni.co.za

Limpopo

Chairperson: Mpho Chokolo

Company: Lepelle Northern Water

Cell: +27 (0)72 310 7576

Email: mphoc@lepelle.co.za

Mpumalanga

Chairperson: Lihle Mbatha (Acting)

Company: Inkomati-Usuthu Catchment Management Agency

Tel: +27 (0)13 753 9000

Email: mbathat@iucma.co.za

Western Cape

Chairperson: Natasia van Binsbergen

Company: AL Abbott & Associates

Tel: +27 (0)21 448 6340

Cell: +27 (0)83 326 3887

Email: natasia@alabbott.co.za

Namibia

Please contact the WISA Head Office on admin@wisa.org.za for more information

Great news about energy reform – but what about water?

Although I am an optimist, my optimism is often put to the test when writing about the water industry.

But I remain optimistic, and devour any good news story that comes my way.

When President Ramaphosa announced an energy reform, where the government will amend the Electricity Regulation Act (No. 4 of 2006) to raise the exemption threshold from 1 MW to 100 MW, I did a happy dance. And then my heart dropped when I read his statement: “Our ability to address the energy crisis swiftly and comprehensively will determine the pace of our economic recovery. Resolving the energy supply shortfall and reducing the risk of loadshedding is our single most important objective in reviving economic growth.”

What about water?

Water use and energy supply are inextricably linked. The provision of energy requires water, and energy is often needed to pump, treat or transport water. The need to protect water quality and supply – and the need to ensure a stable and growing energy supply – should hold equal weight. However, the water situation is more dire than the energy situation. Water supply is mostly fixed by nature whereas energy supply is by design. We cannot create water.

Water Warrior

But back to optimism – WASA has created a new permanent feature called Water Warriors. This is an individual/ business that addresses South Africa’s water challenges through corporate stewardship.

The profile will demonstrate how the individual/corporate identifies and reduces critical water risks to their businesses, seize water-related opportunities, and contribute to water security and the UN’s SDGs. I could not have hoped for a better Water Warrior in Gerrie Brink, his company – AQUAffection – and the #SurplusWater2025 movement that they

started. #SurplusWater2025 has saved over one billion litres of water to date! Gerrie is calling on companies to collaborate and work together in tackling the water crisis. Read the story on page 16 and please do join the #SurplusWater2025 movement.

Blue and Green Drop

And then there is more good news: the much-needed Blue Drop and Green Drop certification programme has been resuscitated.

Established in 2009, the incentive-based Blue Drop and Green Drop programmes aimed to raise the awareness of municipalities of good practice in water supply and wastewater treatment. They led directly to many municipalities investing in their water and sanitation staff and infrastructure, and thereby improving their performance. The programmes also generated a wealth of data that enabled the water sector at large to plan and manage the water value chain more effectively. Read more about this on page 52.

Mine water and industrial effluent

We also delve into the very complex and interesting world of mine water and industrial effluent where key players like Knight Piésold, Aquamat and WaterIcon talk about trends and issues facing the industry.

Covid-19

Currently, I am writing this column in my five-year-old son’s room as he is home from school after his teacher tested positive for Covid-19. He has made surprise appearances in my Teams meetings, and taken over my office space by playing drums on my desk. But that inconvenience is small, considering the loss suffered by families and businesses. Please look after yourselves, be kind to each other and stay safe.

COVER OPPORTUNITY

You said it in WASA

The

opinions and

statements

shared by thought leaders in the water industry to Water&Sanitation Africa

“Managers have pushed the pause button on training and capacity building during Covid-19, assuming we can return to a sense of past normality. But organisations cannot afford to put this on hold, as employees need capacity building now more than ever.” Lester Goldman, CEO of WISA

“We have established our whole economy and livelihood around these majestic dam structures, but we can so easily lose them if we don’t apply proper management procedures to keep them in that state.” Leonard Manus, acting deputy director-general: Regulations, Compliance and Enforcement at the Department of Water and Sanitation

18

“We have the president who is lobbying for investment on one side and municipalities that cannot deliver a basket of basic services on the other. Delivering water services is a building block for the reconstruction and development of our country. This is not about building new infrastructure only – it is also about fixing some very basic issues that can make an immediate and significant impact.” Dan Naidoo, chairman of WISA

“Technology has evolved, and the prices of smart devices have decreased. Ripping out all the existing hardware is probably not the best approach. Utilities need to start with a clear strategic plan to create a full ecosystem.” Joyce Moganedi, sales manager: Power and Water at ABB Energy Industries Division

21

“The impacts of climate change are all around us, especially when it comes to water quality and water scarcity. Unless all sectors of society take collective responsibility, we run the major risk of polluting the few resources we have left. That will in turn push up the cost of water purification treatment and compliance, with a resulting financial knock-on effect for industry, mines and their neighbouring municipalities. That’s why it’s critical that mines and industry take full responsibility for their water cycle – from abstraction to treatment and eventual discharge.” Chris Braybrooke, GM: Marketing, Veolia Services Southern Africa

“Everybody is focusing on alternative water sources, building dams, desalination and wastewater treatment. A lot of money is spent on treating water that is then directed into a system that is 80% inefficient. We need to create an efficient system before investing in backup or alternative water sources.” Gerrie Brink, owner and founder of AQUAffection

“Water treatment can be a complex process and requires constant water testing and specialised skills. For example, phosphates found in wastewater can affect some industrial processes, while it will not affect others. A lot of mines can use treated wastewater but need to use better quality water in certain processes. If mines can use wastewater, they often find that they need bigger quantities than those available. Every mine and factory is faced with its own unique challenges with regard to water security and creating zero discharge at a feasible cost.” Leon Naude, section manager: Water Division, Knight Piésold 08

“Individuals and companies are starting to take ownership of their own water security by using tanks provided by Rainbow Reservoirs. We can no longer rely upon rainfall or local authorities for consistent or reliable water supply. Businesses are realising that they need a bulk water reserve for the continued running of their operations during municipal water outages or restrictions. It is imperative that we all do everything we can to save and conserve water.” Quinton Coetzee, director of marketing and business operations at Rainbow Reservoirs

“There is no silver bullet that can fix all your water treatment problems. I have personally seen many ‘white elephants’ where millions have been spent on a plant that is simply not fit for purpose. Every industry is different, and every factory generates different wastewater. Make sure that you have a plant that will work on a bench scale.” Chris Ashmore, general manager, Watericon

“The mining industry is confronted with challenges such as low commodity prices, the increasing cost of electricity and production, and pressures from non-governmental organisations to provide fast and useful monitoring data. These issues are driving the mining sector to Industry 4.0, which leads to industrial transformation. However, the implementation of digital technologies drives an increase in skills demand –resulting in high-quality job creation.” Christian Wolkersdorfer – part of the South African Research Chair Initiative for mine water management at Tshwane University of Technology

“Whether a company is looking to meet stricter limits or improve the quality of its discharge, one of the first decisions it will need to make is usually related to possible treatment options for the water it discharges. This is where a broader approach is valuable, because few water treatment options are completely free of environmental impact.” Xanthe Adams, principal engineer, SRK Consulting

“Effluent seldom remains consistent and its quality should, therefore, be consistently analysed and changes implemented to address any fluctuations. Some clients will have their own laboratories and quality systems in place, while others will contract Aquamat to do all the testing.”

Gavin Mwanza, head: Engineering, Aquamat

“Traditionally, septic tanks are used in rural areas that are far from the metros. A septic tank will break down solids, but it cannot treat water. With septic tanks, there is a high probability that impurities will pollute groundwater. While the National Water Act does not prevent septic tanks from being built, it does specify a level of water quality that has to be reached before discharge, and a septic tank cannot reach that level of water quality. Furthermore, honey suckers are needed to remove wastewater from septic tanks and transport the wastewater to municipal WWTPs. This is costly and often inconvenient. Therefore, many municipalities no longer approve the installation of septic tanks.” Gerhard Cronje, owner and founder, Maskam Water

“Women, children and the elderly dominate rural populations. Many rural communities draw water from undeveloped local sources, creating ample opportunities for crime and intercommunity conflict. Collecting water is also a tremendous time burden, reducing the community's effectiveness. Addressing rural water issues is a direct win for women and children, making them safer and more productive.”

Chetan Mistry, strategy and marketing manager, Xylem Africa

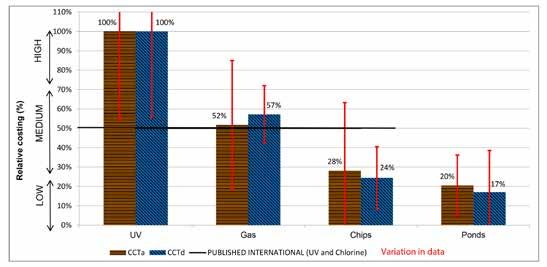

“Everybody knows that bleach is cheap and chlorine gas is cheaper. But is it really? There is a long-held assumption that the cost of a chlorination programme can be determined by comparing the relative cost of the chemical (R/kg), but recent extensive studies have invalidated this perspective.” Peter Buchan, CEO of Control Chemicals

“Typically, we find groundwater in abundance where we don’t need it; and where we need groundwater, we don’t have it. This is due to the complexity of the geology, hydrogeology and variability in rainfall.” Yazeed van Wyk, national treasurer, Ground Water Division

A leader in fluid control solutions, APE Pumps was appointed by Umgeni Water to manufacture, supply, deliver and commission Pump 4 at Verulam Pump Station.

New mechanical/ electrical installation at Verulam and La Mercy Pump Station

Located in La Mercy, the Verulam Pump Station lies within eThekwini Municipality about 27 km north of Durban, close to King Shaka International Airport.

The Verulam and La Mercy Pump Station is part of the Hazelmere Water Treatment Works and has six pumps – four pumps dedicated to the La Mercy area and two pumps for the Verulam area. Water from

the Verulam side of the pump station is pumped to a holding tank at Grange that distributes to surrounding areas. The La Mercy side of the pump station also acts as a backup to the Avondale Pump Station that supplies Ballito. Water from the Verulam side services a population of 70 000 people.

“APE Pumps replaced a split-case pump with a new vertical turbine pump (APE

18 HC) – complete with piping, auxiliaries, valves, instrumentation and a motor. The pump was specifically designed to fit into the footprint of the old pump,” says Peter Robinson, a director at APE Pumps who managed the entire project.

Variable-speed drive (VSD)

Pump 4 was fitted with a 650 kW VSD, where, instead of running two pumps in line, only one pump would be used. This is because Pump 4 can deliver in excess of what the two pumps could currently achieve.

“The VSD will help to minimise life-cycle costs because the pumps will not be switched on and off repeatedly. By reducing the pump speed, the water flow is reduced and the reservoir level is maintained. The pump will therefore run for longer at lower speeds and heads. Then as water demand increases, the pumps will run at increased speeds to meet the demand,” explains Robinson.

ABOVE Pump suction and delivery lines, manufactured by APE

FAR LEFT Peter Robinson, director at APE Pumps

LEFT Kelwyn Davidson, project manager at OBS

Additional work

After problems were experienced with the switchgear and induction motors, APE Pumps was further tasked with replacing the medium-voltage switchgear from the 6.6 kV, 2.2 kV transformer. Six 500 kW soft starters were installed – an extra one was included for future expansion plans.

The 490 kW motor was replaced with a 650 kW motor and the pumps can run from 1 200 rpm to 1 650 rpm. Auxiliaries and pipe work to Pump 4 were supplied new, as was the instrumentation.

It was important to keep a flow of water to both Verulam and La Mercy. The pump station had to remain functional while the work took place, so APE Pumps worked around the parameters of Umgeni Water.

Avondale Pump Station had operational issues and shutdowns, with La Mercy pumps acting as backup supply.

“Shutting down the La Mercy pumps was not possible, and this required flexibility on the part of all players, with strict adherence to windows of opportunity for shutdowns. These very tight timelines were set to prevent any shortages of water supply to any of the systems and reservoirs.

“We could not shut off the pump station; it is a large system and the taps have to have water in them at all time. We had to carefully plan our work. APE Pumps would cut off a panel and work on one side of an incomer, and transfer cables from one side to the other, so that everything was running on one system. The La Mercy and Verulam areas would be fed by one pump while we worked on the other pump.

We had to take the transformer and the available kilowatts into consideration,” says Robinson.

APE Pumps was responsible for the transportation and offloading of equipment on-site. It was found that the existing crane could not accommodate the weight of the existing and new equipment, so we had to replace it.

During the project, various outside factors influenced the programme of works – the obvious being Covid-19 and the strict protocols in place. Access was restricted at times to the plant at Hazelmere.

Ageing infrastructure and equipment made the transition from the old to new equipment a challenge at times. Two existing Verulam pumps were removed and refurbished, with new valve spools on the delivery lines supplied to eliminate or minimise potential problems in the foreseeable future. A split-case pump was sent to APE Pumps for refurbishment, and the motor was serviced at LHM in Durban. Furthermore, a brand-new APE 18 HC pump and motor was supplied, to ensure a backup pump is always ready to replace Waterloo Pump 2 in the event of any mechanical failures of the refurbished pump.

damage to the pumps and assists with preventative maintenance.

The new La Mercy Pump 4 now produces between 600 m3/h and 1 100 m3/h, and 24.6 Mℓ/day, working on the VSD.

Contract Participation Goals

“APE Pumps has been fortunate enough to work with OBS Mechanical Electrical Turnkey Projects, a Level 1 BBBEE company, for transformation purposes. We trained a number of young people during the manufacture, installation and commissioning of Pump 4,” says Robinson.

Kelwyn Davidson, project manager at OBS, says APE Pumps and OBS have developed a seamless partnership.

“Furthermore, Umgeni Water was fantastic to work with – they embraced suggestions to improve the basic day-to-day running of the systems and methodology to safeguard the ageing equipment. Everyone worked as a team. I look forward to future projects with both APE Pumps and Umgeni Water.”

OBS has already partnered with APE Pumps on a number of Umgeni Water projects. The company has expertise in many areas of engineering, along with water movement and treatment.

Instrumentation was installed on all pumps to evaluate pressure, vibration and temperature, as well as a humanmachine interface (HMI). The pumps will automatically be turned off when their pressure, vibration and temperature move outside set parameters. This prevents serious www.apepumps.co.za

APE VERTICAL TURBINE PUMPS

Manufactured locally, APE vertical turbine pumps have the following features:

• Civil work is easier and cheaper

• Installation is easier

• There is no suction valve, with consequent cost and pressure-loss savings

• Efficiencies are good

• Net positive suction head (NPSH) problems are eliminated

• Space is saved and, by using weatherproof motors, no need for a building to be erected

• There is no danger of flooding the electrics

• By adding stages, a very wide range of duties can be covered with standard parts, thus making for cheap and readily available spares

• The pumps generally have a non-overloading kW characteristic, and a steep head quantity curve

• There are no radical loads on the bearings or glands, so they last longer and maintenance is reduced

• In dirty water, grit tends to fall vertically out of the wear areas and so does less damage

Do not put training on hold

Managers appear to have put training on hold during this pandemic – stunting organisational resilience and capacity building. By Dr Lester Goldman

Covid-19 has had a devastating impact on our sector and communities. Thrust into a third wave currently, we pray that we are able to overcome, and that lives are spared. During this Covid-19 phase, many have managed to become tech-savvy, and adept at Zoom, Teams and so forth. Lockdown and working from home have become second nature to some, and even improved the efficiency rate of many.

Unfortunately, we have seen one area lagging – and that is training and development. Managers seemingly have pushed the pause button on training and capacity building, while assuming we can return to a sense of past normality. However, organisations cannot afford to put this on hold, as employees need capacity building now more than ever.

Digital technology, resilience, coping skills and other soft skills may be the

very crutch your staff need, and now they may not be able to access it due to working remotely. Strategically, this period could be a valuable one spent developing and improving staff capacity and developing organisational resilience. Capacity building in areas like learning responsiveness, adapting delivery, exploring digital strategies, and multiple outcomes development can improve your business and competitiveness, for an eventual postCovid-19 world.

Evolution of capacity building History shows that training and capacity development have evolved through decades. From the Industrial Revolution of the early 1900s, where the fundamentals of on-the-job training were developed and are still practised, to post-war booms where efficiencies were emphasised. The 1960s brought new a civil focus globally, which also changed development focus to

Dr Lester Goldman, CEO, WISA

leadership and personal development. The 1980s brought an IT revolution, with many of us having to learn new skills, just to be able to communicate effectively in the workplace, and the 1990s introduced widespread internet – ensuring we became global players to remain relevant. The 2010s brought about social media and learning, and development focused on marketing and communications in a whole new way.

Covid-19 will probably be the stimulus for a whole new way and focus of doing business, and capacity building during the 2020s. Almost certainly, it will be virtual, as platforms developed are expanded and improved, and the time benefits are integrated into business. Hence, lockdown becomes a period of opportunity for early adopters and adapters of virtual training.

Gaining a head start for your organisation and employees, in this undoubtedly new stage of capacity development, brings huge strategic opportunity. I hope that this can be leveraged, to ensure that post-Covid, you leap from lockdown, even more empowered and capacitated than ever. If you need any assistance in this regard, please do contact us at WISA (training @wisa.org.za). We can assist in crafting online capacity building for your organisation, professionals and employees.

Please stay safe, practise collective responsibility in fighting the effects of this virus, and I wish you continued health and blessings!

TIME TO ACKNOWLEDGE THE ECONOMIC IMPACT OF WATER

According to the latest local government audit outcomes report, 27% of South Africa’s municipalities say they don’t know if they can continue – and almost one in four councils, or 57, failed to deliver any kind of financial statement by the statutory audit deadline.

By now, we all know the story about how a small local municipality (Emfuleni) posed a significant threat to the Vaal River System – one of the most strategic water assets in the country and on the African continent.

After a damning ruling by the South African Human Rights Commission (SAHRC) and a consequent R8 billion intervention by the Department of Water and Sanitation (DWS), there is a chance that the Vaal River System situation will be improved.

Holding authorities to account

Then there is a story about how a poultry producer, Astral Foods, took Lekwa Local Municipality to court over the non-delivery of basic services – and won. Government will be required to intervene in Lekwa and, together with National Treasury, prepare a financial recovery plan. The order also provides for Astral to approach the court again for further relief, if it is of the view that the financial recovery plan is not being implemented.

Another story features dairy group Clover, and the fact that it is shutting down its factory in Lichtenburg over similar service delivery failures – and opting to shift its operations to Durban instead. This showcases the economic impact that a lack of water delivery has on surrounding areas.

The problem is, if all businesses move to areas with better service delivery, there is an additional burden placed on already water stressed areas, while negatively impacting on the local economy it leaves behind. It is not a sustainable solution for all affected parties.

The current situation is dire and there is little doubt that our municipalities are failing to deliver water.

We have the President who is lobbying for investment on one side and municipalities that cannot deliver a basket of basic services on the other. Delivering water services is a building block for the reconstruction and development of our country. This is not about building new infrastructure only – it is also about fixing some very basic issues that can make an immediate and significant impact.

Immediate action

Our industry requires a high level of intervention and immediate action. There are brilliant professionals in the sector and I firmly believe that solutions to the water crisis lie within the membership of WISA and our other professional bodies.

By Dan Naidoo, chair, WISA

We need to understand how to elevate the discussion around water at its most basic and impactful level. How do we communicate this risk better, with our stakeholders and citizenry? How do we start to do things differently to avert the major crisis we know is looming?

We all need to get our hands dirty and start to fix the problems facing our industry, but only if we are allowed to do what we are good at in a multidisciplinary team effort in a compact with our communities and citizens.

Meet some of YWP’s water change-makers

We would like to introduce you to a few young professionals contributing to the present and future needs of the water sector in South Africa.

NKOSINATHI BUTHELEZI

Nkosinathi grew up in rural KwaZulu-Natal and has been an active professional in the water sector since 2012. He holds a chemical engineering degree, an honours degree in water utilisation, and a master’s degree in commerce and leadership studies. Nkosinathi has worked for eThekwini Municipality, where he started his career in the R&D Department, as well as Mhlathuze Water Board, working as an engineer. He is currently employed by the Department of Water and Sanitation as a chief engineer and area manager for the Tugela Vaal Government Water Scheme. He is a registered professional with the Engineering Council of South Africa and a project management professional with the Professional Management Institute. Goals: To work towards ensuring that more and more of our rural communities get

access to water for various uses – especially agricultural and domestic uses. This is particularly important to him as he grew up in the same environment. Working to make sure that water benefits our most vulnerable communities is a huge motivation for Nkosinathi. Message to young professionals: “The ball is in our court. Young professionals need to be professionally active in our societies in order to make a meaningful impact on the socio-economic landscape of this country. I believe there is scope and opportunity for young professionals to play a more direct role in the betterment of our communities.”

ODWA NTSIKA MTEMBU

Born and raised in rural Eastern Cape, Odwa is a climate change activist, social entrepreneur and a young professional practising in the field of climate, water and applied geomorphology. He has obtained a BSc Hons Environmental and Geographical Science and BSc Geology, Environmental and Geographical Science. Odwa is passionate about working towards inclusive and innovative sustainable solutions to build smart and self-sustainable cities. He is the founder of World Merit SA and, through his volunteer work in this platform, has managed to link community development and connect young people

MBALI SIBAYA

Mbali hails from the south of Durban where she grew up and went to school. She is an employee of Umgeni Water and has 10 years’ experience in the water sector. With a BTech Chemical Engineering (Environment), Mbali was selected in a group of 20 women to be part of an Executive Development Programme: Women in Leadership at Wits University. She is a mother to four children and an active young water professional, where she now serves as the YWP-ZA Transformation Lead. Mbali is a member of the WISA Process Controllers Division, where she advocates for the transformation of water treatment processes and inclusivity of process controllers in the sector. Mbali has presented her work at international and national conferences in the sector, is a member of the Water Youth network, as well as the Women in Water and Sanitation Network. She is an advocate for women rights and the SDG 6 agenda.

Goals: To play an active role in ensuring water for all by 2030. To be impactful in society in encouraging and inspiring youth involvement in a transformed South Africa in governance, ethics and sustainable life for all.

Message to young professionals: “This year marks 45 years since the 1976 student uprising in Soweto. A significant year of transformation change and great challenge to leadership in our country. We must challenge ourselves to be transformational and impactful leaders in all spheres of our world. Let us be beacons of hope and life in our communities and form progress partnerships that will enable us to be instrumental in growing youth employment for an inclusive and transformed society. As the struggle for equal education was the battle that the youth of 1976 had to fight for an die, let us continue the struggle for economic emancipation in their honour.”

to opportunities from around the world. Odwa is a registered scientist with SACNASP and is employed by the Department of Water and Sanitation. Goals: His passion and purpose are rooted in his ethical duty to serve his community.

Message to young professionals: “Young professionals in the sector have the skills, experience and knowledge to tackle local to global issues and connect everyone to opportunities through our networks with the resources we have in our communities and organisations. As we continue to lead, research, innovate, implement, monitor and

evaluate our work in the sector, let us not forget to ensure transformation, transparency, progress, accountability and sustainability.”

DR LLOYD FISHER-JEFFES

Dr Lloyd Fisher-Jeffes is a graduate from the University of Cape Town and currently working as a registered, professional civil engineer with a specific interest in the design, management and planning of water resources. A member of WISA, South African Institution of Civil Engineers (SAICE) and International Water Association (IWA), Lloyd is a co-winner of the CESA Young Engineer Award in 2020.

Goals: To play a role in developing and improving the practice of sustainable urban engineering, with a specific focus on the management of water resources in Southern Africa.

Message to young professionals: “The water sector offers young professionals the opportunity to make a huge positive impact on people’s lives. Be one of the diverse, energetic and exciting people to make a water sector that South Africa can depend upon.”

YWP holds webinar between South African and Japanese water sectors

Protecting and maintaining water distribution systems is crucial to ensuring high-quality drinking water. By

Thandeka Jwara

Distribution systems consist of pipes, pumps, valves, storage tanks, reservoirs, meters, fittings, and other hydraulic appurtenances that carry drinking water from a centralised treatment plant to consumers’ taps. Therefore, distribution is an important part of the value chain and requires adequate monitoring and management to ensure sustained access to water and customer relations.

Webinar

The YWP recently held a webinar between eThekwini’s Water and

Sanitation Department, Umgeni Water and the Yokohama Waterworks Bureau in Japan.

Presentations were kicked off by an Umgeni Water and eThekwini Water and Sanitation representative who gave an overview of the organisation, the water distribution management strategy, as well as its water supply services. South Africa – and KwaZulu-Natal in particular –faces challenges with non-revenue water through illegal connections or unregistered customers.

Customers in rural areas where the service level is such that they consume 6 kℓ of free basic water tend to tamper with infrastructure in order to gain full pressure supply. Other consumers bypass meters to avoid billing,

while some reconnect their supply (illegally so) after being disconnected for non-payment.

Japan representatives, however, claimed that they do not have such challenges, as most of their customers are billed. They alluded to the fact that their effective system performance is due to the integration of technology for most, if not all, of their distribution and demand management infrastructure. This was a key highlight, as KZN has ageing infrastructure and faced an estimated 45% of non-revenue water in the 2018/19 financial year.

The session remains available on YouTube for live-streaming and more conversations of a similar nature are envisaged for the future.

Population growth, rising per capita water consumption, and increasing environmental protection efforts have increased pressure on the world’s freshwater resources.

Why social data matters

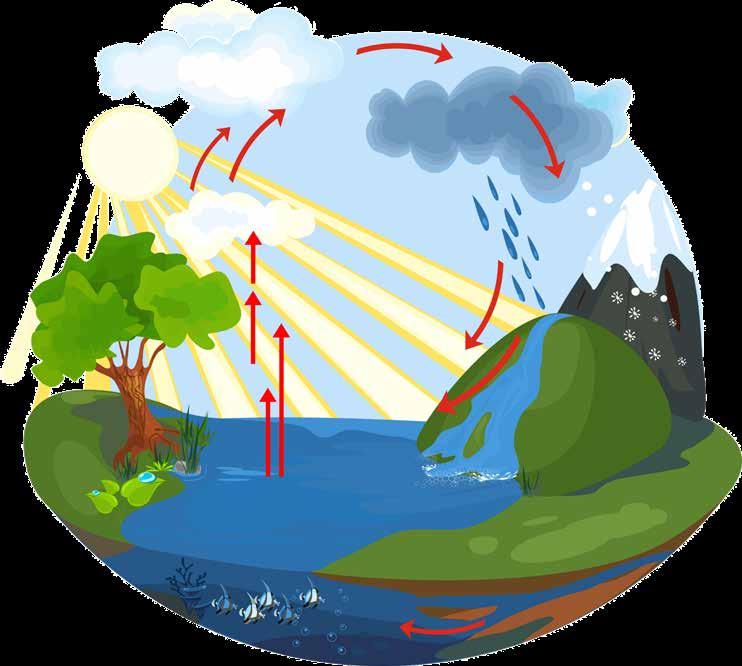

The hydro-social cycle, rather than the traditional hydrological cycle, identifies social power and structures, inequality in water provision, and institutions and governance processes that shape the outcomes of water management

While water management has been framed predominantly as a technical field informed by natural science and engineering expertise – and addressed through infrastructure provision – it also has a social and political dimension that involves power relations, human values, behaviour and attitudes, providing a broader context for water management and governance.

The hydro-social cycle promotes a critical analysis of water-society relationships, positioning humans within the hydrologic cycle, where society and water outcomes are shaped by complex interactions between social, political, historical, economic and hydrological factors.

“The hydro-social cycle, rather than the traditional hydrological cycle, identifies social power and structures, inequality in water provision, and institutions and governance processes that shape the outcomes of water management. Social data relating to the hydro-social cycle helps to create just and transformative sustainability in our water and sanitation systems,” explains Cathy Sutherland, associate professor from the University of KwaZulu-Natal, who has recently joined WISA’s new Modelling and Data (MAD) Division to support the production and use of social and governance data.

How is social data used?

The Blue Diversion Autarky toilet, developed by Eawag in Switzerland, is a sanitation system that does not rely on water and wastewater infrastructure. It was tested as part of the Bill and Melinda Gates Foundation’s Reinvent the Toilet Challenge in a single peri-urban household in Durban, as the only form of sanitation for three months. The effectiveness of the toilet was measured from both a technical and social perspective. The social acceptability of the toilet, which is key to its success, was determined by ensuring that household members played a central role in the coproduction of knowledge around the functioning and social acceptability of this innovative sanitation system.

In another project, the Blue Diversion Autarky handwashing station, developed by Eawag and EOOS in Austria, was tested in an informal settlement in Durban for three months. The water treatment system recycles handwashing water,

which means the station can operate independently off the grid.

Residents of the informal settlement, who had been trained by researchers from KwaZulu-Natal, collected data on the use of the system, to determine the community response to and acceptability of the system. This local knowledge (social data) assists scientists and government officials in developing a better understanding of the effectiveness of innovative water systems that address water scarcity and the lack of access to largescale infrastructure.

Social data has also been collected on water and sanitation services across different informal settlements in Durban, including surveys on the satisfaction of informal settlement residents of communal sanitation facilities. The results of the surveys reveal high use of the communal ablution blocks (CABs) – the multiple ways in which they are used, including for sanitation, water collection, showering and laundry – but also the significant challenges of the system in providing dignified and safe sanitation.

Within the Palmiet Catchment Rehabilitation Project, river rehabilitation is being supported through a community-based partnership where ‘EnviroChamps’ report sewage outflows on a smartphone app that provides data to the municipality. Community members, through their collection and transfer of data have become social agents of change.

Big data platforms

Expert and experiential knowledge is therefore informing more sustainable water management. “This localised data needs to be brought into big data platforms so that it can make a difference. We are currently working with Dublin City University, in association with the European Space Agency, to develop a big data platform to monitor the functioning of CABs so as to manage risk,” says Sutherland.

Dublin City University aims to use technical data from satellites, sensors in rivers to detect pathogens, sensors on CABs and waste treatment plants, weather data, clinical data, and apps that track service vehicles in order to build an integrated data platform to monitor sanitation provision and safety. These researchers are working with the WASH R&D Centre at the University of KwaZulu-Natal, which Sutherland and her team are a part of, to bring social data (like a user’s perception of CABs, attitude to using CABs and civic science) into the new big data platform.

“It is new work that we are involved in. I am excited to learn from this and contribute to other social data projects in the water and sanitation space,” adds Sutherland.

Social science in water Sutherland states that social science brings different kinds of approaches and methodologies, as well as different forms of data. “It is critical to integrate engineering data, natural science data, and social science data for improved water governance and management – to ensure the provision of safe, accessible, dignified, and affordable water and sanitation services for all.”

Cathy

www.veolia.co.za

Generous donation makes breathing easier for South African asthma patients

There are thousands of examples of kindness and empathy displayed by ordinary South Africans during the Covid-19 pandemic. WISA and Grundfos were among the corporates and non-profit organisations that used their resources and expertise to mitigate the devastating impact of the pandemic.

At the height of lockdown in 2020, there was a dire shortage of personal protective equipment. N95 masks, in particular, were in short supply.

Jaco Seaman, marketing and events manager at WISA, is a 3D printing hobbyist and belongs to a 3D printing hobbyist group. He says that through a coordinated effort, the 3D printing community members used their expertise, their time, filament and skills to print the N95 masks.

“The idea was to stretch resources. So instead of wearing an N95 mask for one day, we designed an N95 mask that could be worn for nine days. We printed thousands of these masks. Emergency Management Services picked up these masks from our houses (as they were the only people who could drive around at all times during hard lockdown) and distributed them wherever needed,” he says.

Eventually, the 3D printers ran out of filament and the group was unable to import anything. A local company, AMS, offered to locally manufacture the

printing filament at cost; however, many of the people in the group could not afford to keep buying filament at these huge quantities.

“Our group started to ask for donations; however, no one wanted to take responsibility for the money, as we were not a registered company. WISA stepped in to handle donations and the Grundfos Foundation in Denmark allocated an amount of R270 000. But, by then, the need for the 3D printed masks had run its course, so WISA and Grundfos set out to find another life-giving project into which the money could be channelled.

AfriSpacer

“We assessed a number of projects, and the one that we decided to support is the AfriSpacer – a simple, low-cost attachment for a plastic bottle that can be used with a traditional asthma inhaler to increase its effectiveness,” says Peter Mashaba, facilities supervisor: SSA for Grundfos South Africa. “It ties in with the intent of the donation – providing funds

that will save lives, particularly during the Covid-19 pandemic.”

The need is huge – at 15 000 lives lost each year, South Africa has one of the highest asthma death rates in the world. As many as 80% of these deaths could be prevented with better treatment and access to medicine.

The AfriSpacer attaches to one end of a plastic bottle, with the patient’s inhaler attached to the other. Medication is pumped from the inhaler into the empty chamber of the bottle and the patient breathes it in, allowing the medication to reach the lungs without spraying micro droplets into the air. A key feature of the AfriSpacer is its one-way valve system –the AfriValve – which can be washed and reused, making it a safe, effective and durable product on a par with more costly commercial asthma spacers.

The AfriSpacers are being distributed by the Allergy Foundation South Africa (AFSA), whose CEO, Professor Michael Levin, is head: Allergy at the Red Cross War Memorial Children’s Hospital in Cape Town.

“We’ve been using the spacers for more than 20 years, but it was only recently that an affordable and scalable solution was developed,” Levin says. “Then the challenge became finding the funds to produce them at the scale we need – which is where the very generous donation from Grundfos is going to make such a difference.”

A key feature of the AfriSpacer is its one-way valve system – the AfriValve – which can be washed and reused, making it a safe, effective and durable product on a par with more costly commercial asthma spacers

WARRIORS

Our very first Water Warriors feature introduces Gerrie Brink, his company –AQUAffection – and the #SurplusWater2025 movement that they started.

The water crisis: it’s not a supply issue – it’s a demand one

With a growing global population, the demand for potable water increases daily. South Africa has moved from a water-stressed country to a water-scarce one. It is predicted that South Africa will form part of the ‘extreme scarcity’ category by 2025.

When I heard this prediction, I started to think about what could be done to turn South Africa’s water situation around. We cannot simply sit around and accept that South Africa will fall into the ‘extreme scarcity’ category. We have to do something now,” says Gerrie Brink, managing director of AQUAffection.

Over one billion litres of water saved #SurplusWater2025 is an initiative born out of Brink’s vision to effect positive change in South Africa’s water industry. To date, 31 companies have joined the movement, 473 meters have been installed, and over a billion litres of water have been saved. The current daily savings are running at close to two million litres, with this number growing as more companies join the movement.

“The movement is about collaboration. It is about pooling resources together. I believe that if everyone focuses on their core expertise, we can make a far bigger impact in a shorter amount of time. We need to stop competing with each other and start complementing one another. #SurplusWater2025 is about sharing knowledge,” explains Brink.

Monitoring

“It all starts with monitoring – you cannot manage what you cannot measure. Water meters are a form of measurement, but they are a snapshot where a reading is taken at the beginning and the end of a month –giving a total consumption of water in a month. It does not give insight into what makes up the water consumption (toilets, irrigation, water coolers, etc.) or when there are peak flows, or how much water is used during a particular period in the day.”

AQUAffection researched a number of monitoring tools. “There are many hardware and software options, but they seldom integrate seamlessly with each other. We then found WRP Consulting’s Zednet water demand management solution. It can show different parameters (tank levels, rainfall, flow patterns, borehole water, quality monitoring, electricity consumption) on the same display. It is customised to the needs of our corporate clients,” adds Brink. By using the monitoring tool, all water savings are easily reported daily, and

SOME OF THE COMPANIES TAKING PART IN THE #SURPLUSWATER2025 MOVEMENT

• Atterbury

• Attacq

• ADvTECH

• Emira

• Steenberg

• Fortress

• OUTsurance

• We Buy Cars

• SBS Tanks • WRP Consulting • Rainbow Reservoirs • Moolman Group

a cumulative number displays savings since the start of the project. This assists corporates in calculating money saved versus money spent on water saving initiatives. The water savings contribute towards the #SurplusWater2025 initiative.

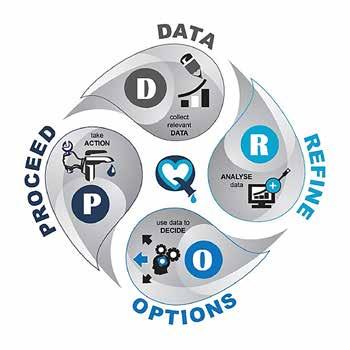

The DROP Approach

AQUAffection uses the ‘DROP Approach’ when tackling a water problem.

1) Data: Collect all relevant information/ data to determine historic daily demand of the site. Understand history of water demand from water bills and meter readings. AQUAffection determines if the site can save water. This also establishes the baseline against which future demand will be measured to calculate savings.

2) Refine: Install electronic monitoring devices – also called automatic meter reading devices – to refine and better understand the site’s water demand profile; monitor site consumption to determine flow profiles and demand.

3) Options: Determine the options to lower demand (leaks, efficiency devices, system optimisation), as well as options for backup systems and alternative sources.

4) Proceed: Proceed with the implementation of the identified options.

“DROP forms a continuous loop to reduce the water footprint. For example, once a leak is repaired, then data is collected and the whole process starts again. We aim to achieve the biggest impact with the lowest capital outlay and without impacting on anyone’s comfort levels.”

AQUAffection first works towards reducing the client’s water demand before

setting up backup or alternative water sources. This ensures a lower-cost backup system, as it is always smaller than initially estimated – corporates therefore save money, mitigate risk and are more sustainable.

“Everybody is focusing on alternative water sources, building dams, desalination and wastewater treatment. A lot of money is spent on treating water that is then directed into a system that is 80% inefficient. We need to create an efficient system before investing in backup or alternative water sources,” adds Brink.

Training

“We offer training because the water crisis is not a technical problem; it is caused by human behaviour and a lack of knowledge – you don’t know what you don’t know. There needs to be greater awareness around water and more education on the topic. AQUAffection provides training on the extent of the water problem in South Africa and gives information on what each person can do to address it,” explains Brink. Security guards, cleaning and maintenance staff, as well as facilities managers and operational and administrative employees, all receive different types of training so that everybody is working towards reducing water consumption. They are taught to identify and fix malfunctioning toilets and leaking taps. Often, corporates use their skills development budget to fund the training component. There is also a focused training for top management on designing a sustainable water strategy.

Patented flushing mechanism

Brink did an MBA at the University of Stellenbosch Business School with a research paper on ‘Factors influencing water demand in commercial buildings’. “If there are no cooling towers or water irrigation, 90% of water consumption is from toilets. And if a mechanism gets stuck in a toilet, it can flush over 700 litres an hour. This is why AQUAffection has developed a patented outlet valve mechanism together with Dutton Plastics Engineering, which is available at various outlets like Plumblink and Chamberlains.”

Tests have shown that, by changing the outlet valves on all of the toilets, one can

reduce water in commercial buildings by up to 80%.

“This is what I mean about collaboration – if AQUAffection decided to manufacture the outlet valve ourselves, it would have taken years to bring it to market. But by working with Dutton Plastics Engineering, we can readily use the outlet valve now while focusing on our core business – reducing water consumption in commercial buildings,” says Brink.

With the calculated water savings and available data, AQUAffection is influencing greenfield projects too. It has a dedicated Wet Services Department that takes everything learned from AQUAffection’s retrofit projects and assist developers and architects with water-efficient buildings.

Ifyouwanttojointhe #2025SurplusWatermovement,visit: https://surpluswater2025.com.

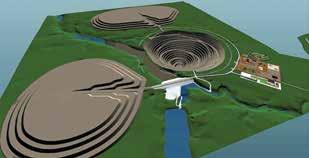

Increasing dam storage capacity through the NatSilt Programme

South Africa has a history of building dams to address water security needs and to provide essential bulk water supply to its population. Several large dams are steadily losing storage capacity each year due to soil erosion and land clearance, with many smaller farm dams now full to the brim with silt.

Dams disrupt normal surface water and sediment flow, leading to sediment being trapped and unavailable for essential downstream ecosystem functioning. This can lead to erosion and ultimately reduce a dam’s water storage capacity over time. Sedimentation rates in South Africa are extremely high. One of the country’s worst-hit large reservoirs is the Welbedacht Dam on the Caledon River in the Free State – which has lost more than 90% of its storage capacity due to siltation. In 2016, the CSIR estimated that South African national dam storage capacity loss due to siltation was 10%. This reduction threatens water security, which threatens food security,

ecosystems, and economic progress in the country.

National Siltation Management Strategy

In response to this, the Department of Water and Sanitation (DWS) has appointed the Water Research Commission (WRC) to develop the National Siltation Management Strategy for Large Dams (NatSilt Programme). This will represent a collaborative, transdisciplinary approach to tackle the wide spectrum of dam sedimentation and storage capacity challenges in South Africa.

The NatSilt Programme is initiated and funded by the DWS through its Infrastructure Build, Operate and Maintenance (IBOM) branch, which is responsible for the asset management and infrastructure maintenance of 276 government water schemes across the country, including 320 large state dams that make up more than 90% of the country’s total storage capacity.

Occurring in three phases over three years, the NatSilt Programme is expected to be concluded in 2023.

The WRC will be developing a package of siltation management solutions that include relevant tools, models, frameworks, protocols, guides and plans in order to assist with the implementation and monitoring of the strategy. This will help the DWS in ensuring sustained supply to domestic, industrial and agricultural bulk water users, as well as save scarce financial resources by extending the life cycle of existing dams. Among the vital insights that have been gleaned so far include the role municipalities play in the maintenance

of the catchment areas and how crucial it is that there is cooperation between the various government departments in ensuring the programme’s success.

“We have established our whole economy and livelihood around these majestic dam structures, but we can so easily lose them if we don’t apply proper management procedures to keep them in that state,” says Leonardo Manus, acting deputy director-general: Regulations, Compliance, and Enforcement at the DWS. Manus adds that the NatSilt Programme will provide the department with the tools and intelligence to make appropriate, site-specific decisions regarding each dam, instead of using a blanket approach. “Where sedimentation occurs to such an extent that it has to be dealt with, we will create a business model that will not be to the detriment of those who are dependent on the dam. To minimise costs to the downstream users in that specific catchment, we need to find alternatives to expensive methodologies and dredging models deployed to keep any dam operating.”

A coordinated approach

For dam siltation management to be successful, the efforts need to

The release of large volumes of muddy water can inundate riverbeds and drastically effect downstream ecosystems if not properly planned

We have established our whole economy and livelihood around these majestic dam structures, but we can so easily lose them if we don’t apply proper management procedures to keep them in that state.”

address the state of the existing dams, how they should be operated and the activities within their respective catchments. While addressing dam engineering components of dam siltation management, it is equally important to address the socio-ecological systems aspects of it.

Among the components of dam siltation highlighted by the programme implemented by the WRC is the development of a dam classification framework and dam operations model. The classification framework aims to classify dams from exhausted to sustainable and subsequently inform the development of the operations model. The dam operations model will recommend strategies suitable for operating specific dams.

Dam engineering has an important role to play in safeguarding water security.

However, the design and construction of these dams need to consider their impacts on society and ecological systems. The way in which this has been done in South Africa has resulted in dam siltation not being managed adequately. This can be attributed to the inconsistent monitoring efforts and lack of holistic approaches when dams are being designed and constructed. This negatively affects the lifespan of the dams.

At a global level, concern is growing about declining dam storage levels due to siltation, increased human populations, urbanisation, as well as exacerbated storm erosion linked to climate change. “By 2050, roughly 64% of the world’s current reservoir storage capacity could be filled with sediment.” says Professor Gerrit Basson, who is head: Hydraulic Engineering at Stellenbosch

THE KEY DELIVERABLES OF THE NATSILT PROGRAMME ARE TO DEVELOP:

• A dam basin siItation management operations model

• A sustainable dredging business model/s

• A dam basin classification decision-making tool

• Capacity-building

• A step-by-step comprehensive implementation plan and piloting of the draft strategy, models and tools

• A pilot plan potentially rolled out in three government water schemes – Welbedacht Dam in the Free State, Hazelmere Dam in Kwazulu-Natal, and Darlington Dam/Orange-Fish GWS in the Eastern Cape

WATCH

A VIDEO SUMMARY OF THE NATSILT PROGRAMME HERE:

https://www.youtube.com/watch?v=7BOtiQlMm6o

For additional information or programme enquiries, contact:

• Lesego Gaegane, senior project manager: National Dam Siltation Programme, WRC: lesegog@wrc.org.za

• Vuyokazi Matiwana, project officer: National Dam Siltation Programme, WRC: vuyokazim@wrc.org.za

Because of the massive cost of building new dams, the problem of siltation has to be tackled swiftly to extend the lifespan and capacity of existing infrastructure

University’s Civil Engineering Department, former chairperson of the reservoir sedimentation committee of the International Commission on Large Dams (ICOLD), and a current member of the World Bank-Unesco Task Group on reservoir sedimentation management. ICOLD assessments suggest that several countries – almost a third of them in Africa – could therefore experience critical sedimentation volumes by 2050.

Management strategies

Several management strategies to combat and prevent siltation have been explored and implemented – including extensive catchment management strategies focusing on land-use practices and restoration, in an attempt to minimise soil erosion – effectively treating the problem at the source that often contributes the majority of sediments. Other management options include the construction of upstream ‘check-dams’ to aid in trapping sediments during flood events, by-passing schemes via tunnels or off-stream dams, as well as flushing or sluicing techniques. These strategies provide alternatives to the traditional approaches of simply raising dam walls or constructing completely new reservoirs, which are both often extremely expensive.

Locally, less emphasis should be placed on strategies in reservoirs that rely heavily on water, such as flushing and sluicing, and more on alternative measures. This is because South Africa is largely an arid environment, so most dams do not have the excess water

available to carry out these operations. There are also potential problems downstream because of the release of large volumes of muddy water that can inundate river beds and have drastic effects on downstream ecosystems if they are not properly planned.

Sediment research

Sediment research and the daily suspended sediment sampling of rivers in South Africa started in the 1920s. By the 1970s, with many new dams constructed, most of the river sampling programmes were stopped and replaced by reservoir surveys by the DWS, which are recorded in the so-called ‘Dam List’. These early sediment yield maps for South Africa were updated in 2010. Earlier this year, the WRC developed a shortlist of 20 dams believed to contain among the highest silt levels.

Some of the dams of concern include the Lake Arthur Dam on the Tarka River (52% silted), Darlington, Nqweba, Lubisi, Grassridge and Bospoort (all above 40%). In KwaZulu-Natal, the Hluhluwe Dam is estimated to be 25% silted up, while the Gariep Dam on the Orange River (South Africa’s largest dam) is nearly 20% silted up. Looking to the future, other feasible options to manage siltation should be pursued, such as sediment by-passing, which is not new in South Africa. Many dams were designed in KwaZulu-Natal – such as the Nagle, Henley and Shongweni dams – more than 70 years ago, with sediment bypass facilities. Experts have recommended that such facilities be incorporated in the proposed Smithfield

Dam in KwaZulu-Natal to also help limit further coastal erosion.

The NatSilt Programme is essential in aiding the decision-making behind which strategies to employ for current and future dams, and is “absolutely critical to the country’s water security”, as emphasised by Dhesigen Naidoo, CEO at the WRC. Jurgen Kogl, a ministerial advisor for the DWS, pointed out at the recent NatSilt virtual symposium, held in May 2021, that dealing with siltation was sometimes viewed as a grudge purchase – in a similar way to how consumers often viewed buying life insurance. However, because of the massive cost of building new dams, the problem of siltation has to be tackled swiftly and head on, in order to extend the lifespan and capacity of existing infrastructure to supply water to South Africa’s fast developing and growing population.

FOR MORE INFORMATION:

Visit: https://wrcnatsilt.org.za

Digital water management solution

Joyce Moganedi, sales manager: Power and Water at ABB Energy Industries Division, speaks to Water&Sanitation Africa about ABB’s automation and control solutions within the water and wastewater industry.

ABB’s digital, electrical and automation solutions can help upgrade South Africa’s ageing infrastructure. These solutions cover all types of water processes: desalination, water pump stations, industrial water treatment and wastewater treatment.

Moganedi believes that the local water sector is aware of the benefits of digitalisation, and that there has been some positive movement towards implementing these technologies, but there should be more pilot projects and adoption. “Technology has evolved, and the prices of smart devices have decreased. Ripping out all the existing hardware is probably not the best approach. Utilities need to start with a clear strategic plan to create a full ecosystem. This can start by dividing the water network into discrete zones and identifying what is needed to address the specific challenges in each. Effectively, it is best to start small by adding to existing technology. In this sense, smart sensors are the perfect starting point, as they can be placed on a motor, pump, bearings or gearing. They are easy to connect and use, without having to invest in new, expensive systems.”

The next step would be to use a PLC (programmable logic controller) solution or Scada (supervisory control and data acquisition) monitoring software that would receive information from connected sensors or input devices, process the data, and trigger outputs based on pre-programmed parameters. “The digital part is the top of the pyramid. The bottom of the pyramid is the plant assets and then a Scada or PLC solution; only afterwards can further digital solutions be implemented. Digitalisation can be implemented on a gradual basis,” says Moganedi.

Unlocking value

Moganedi believes that many municipalities and end users make the mistake of viewing an ABB solution as a commodity and do not consider the value behind the solution. “They seldom factor in the money saved by creating greater energy efficiencies or minimising leakages. They do not consider the value our solutions provide or the after-sales support. In order to overcome this obstacle, I have started to mention key performance indicators (KPIs) instead of features and benefits. For instance, I now

talk about how much our solutions can reduce non-revenue water or improve water quality.”

This can be achieved via ABB’s digital water management system that has user-friendly and KPI-oriented dashboards to provide an overview of the condition of a distribution network to operators, maintenance teams and managers. It offers real-time detection and localisation of water leakages, pipe bursts, faulty meters and equipment faults. This solution can help improve water supply quality, as well as drive operational and maintenance efficiency.

Global presence

ABB Energy Industries has a global presence and has worked with the water and wastewater industry in numerous countries. ABB contributed towards Botswana’s North-South Carrier water project by supplying a power and automation solution for a new water pipeline and pump station.

“Worldwide, water is far more than a mere commodity and is no longer taken for granted. If there’s no water, there’s no development. The availability of water and economic development are closely linked on numerous levels. There are decent jobs linked to water management in both the developed and developing world; moreover, access to safe drinking water and sanitation protects people from disease and allows them to attend school or work without disruption, leading to higher education and employment, which are foundational for growth. Problems like ageing infrastructure, urbanisation putting extra pressure on water supply, and limited water resources are experienced globally. While we have a local presence, we also have international experience in the water sector,” concludes Moganedi.

Water storage tank manufacturer expands range

What do St Helena, Madagascar, Mauritius and Seychelles have in common? Apart from being islands, they’re all home to Rainbow Tanks.

Quinton Coetzee, director of marketing and business operations at Rainbow Reservoirs, explains why:

“These islands do not manufacture water tanks. They have to import them. With air freight and sea freight, cargo is charged by volume. A single 10 000 ℓ plastic tank occupies a huge equivalent volume – you are basically paying to ship air. Islands therefore prefer Rainbow Tanks that can be flat-packed and then assembled onsite – the holding capacity of the modular Rainbow Tanks that can fit into a container is much greater, by orders of magnitude, than that of the plastic water tanks.”

Used in over 30 countries around the world, like Peru, the Philippines

and Panama, Rainbow Tanks can be transported to any place with minimal difficulty. “Concrete reservoirs require stone, cement and concrete mixers to be transported to site by road. Our tanks with

a capacity below 400 000 ℓ do not need a concrete slab – they are simply erected on levelled ground on a sand pad and can be transported by a 4x4 vehicle. Where other reservoirs may take months to build, it takes a few days to install our tanks,” says Coetzee.

Premium tanks for remote sites

Rainbow Reservoirs manufactures its tanks’ walls and roofs from premium aluzinc steel. The aluminium zinc coating is six times more anti-corrosive than a regular galvanised coating. All the tank’s fittings – like roof trusses, nuts, bolts and ladders – are galvanised for durability and long lifespan.

“Many tanks have to be installed remotely – in the middle of the Kalahari Desert, on top of a mountain or on a beach – and it’s a huge inconvenience if the nuts do not thread properly or wall panels do not fit perfectly. We therefore have modern, automated machinery that manufactures precision components to ensure everything fits 100% correctly,” adds Coetzee.

These premium-quality reservoirs are manufactured in varying sizes – from 5 000 ℓ capacity to over 4 Mℓ capacity –and can be fabricated in any requested

diameter and height. Included with each tank is a ladder, inspection hatch, in-/ outlet and overflow, while a scour drain, gutter system, level indicator or wind turbine ventilation fans are optional extras. They are also fitted with different tank liners suited to various applications.

The company supplies tanks to municipalities, townships, residential estates, agriculture, the food and beverage industry, the hospitality sector, and mines.

“With a new mine, tanks for potable water are usually installed before anything else, as only then can people move on-site to build infrastructure. Tanks are also essential for a mine’s processing needs,” explains Coetzee.

Rainbow Reservoirs is a specialist in firefighting and hydrant tanks. Accredited by the Automated Sprinkler Inspection

Oasis Tanks

2 3 4

1 The construction of Rainbow Tanks in the Philippines

2 Oasis Tanks has stuck to the tried-and-tested corrugatediron profile that for decades has defined farm tanks on our agricultural landscape

3 Tanks can be manufactured in varying sizes – from 500 ℓ capacity to over 4 Mℓ capacity – and can be fabricated in any requested diameter and height

4 Accredited by the Automated Sprinkler Inspection Bureau, these firefighting tanks adhere to strict regulations for the proper design and installation of fire protection tanks

Bureau, they adhere to strict regulations for the proper design and installation of fire protection tanks.

However, not all markets require a topof-the-range Rainbow Tank; therefore, Rainbow Reservoirs has applied its expertise in the manufacture of sectional steel water tanks to create the new Oasis Tanks product.

While the Rainbow Tank range is used in some of the biggest shopping malls as high-tech firefighting tanks, sprinkler and fire hydrant tanks, Coetzee explains: “A farmer may not require a tank of those rigid specifications to water crops. Consequently, we have developed a range of cost-effective, agricultural tanks adapted to the landscape, our harsh climate and specifically to the needs of our farmers.”

Rainbow Reservoirs retained the traditional corrugated aesthetic of farm tanks and make use of modern technology. “Farmers are ever more conscious of water conservation and recycling. Furthermore, water used in micro-sprinkler systems must be free of impurities that may clog up irrigation systems. Our settling and filtration tanks are pivotal in this function.”

“Individuals and companies are starting to take ownership of their own water security by using tanks provided by Rainbow Reservoirs. We can no longer rely upon rainfall or local authorities for consistent or reliable water supply. Businesses are realising that they need a bulk water reserve for the continued running of their operations during municipal water outages or restrictions. It is imperative that we all do everything we can to save and conserve water,” he concludes.

Profitability and resource conservation can co-exist. WASA speaks to Chris Braybrooke, GM: Marketing, Veolia Services Southern Africa, about intervention and management strategies.

Why is water stewardship so important?

CB The impacts of climate change are all around us, especially when it comes to water quality and water scarcity. Unless all sectors of society take collective responsibility, we run the major risk of polluting the few resources we have left. That will in turn push up the cost of water purification treatment and compliance, with a resulting financial knock-on effect for industry, mines and their neighbouring municipalities. That’s why it’s critical that mines and industry take full responsibility for their water cycle – from abstraction to treatment and eventual discharge.

How does Veolia help mines and general industry remain compliant?

The cost of non-compliance is not an option, whether from an environmental, reputational or operational perspective.

Determining the true cost of water

Mining and industrial operations run 24/7 and they cannot afford to shut down even for a few days. Were this to happen due to a non-compliance issue, the repercussions could result in the withdrawal of investor support, punitive fines and even business closure.

Our focus at Veolia is multifaceted across our three core business areas, namely water, energy and waste. We work with our mining and industrial clients to shift these elements from a potential risk to a business opportunity.

In this respect, Veolia has more than 350 proprietary technologies that we can draw from to develop tailored solutions. That’s important because mining and industrial wastewater streams tend to require complex process techniques. Within the mix, there are also energy opportunities. Examples include biogas plants used to fuel boilers and/or as a heat source. Although essential, investment in water

and wastewater treatment plants is capital intensive, and the cost doesn’t contribute positively to the mine’s bottom line. However, not having adequate treatment facilities in place also means that mines cannot legally operate. So, it’s about finding the optimum financial and environmentally compliant balance.

What is Veolia’s SHEQ policy?

Across the board, Veolia has strict safety, health, environment and quality (SHEQ) systems in place. As a company, we have a zero-tolerance approach to noncompliance across all our operating sites. The Veolia Group is further governed by its Impact 2023 programme.

Impact 2023 aligns Veolia’s multifaceted performance model with the UN’s Sustainable Development Goals, against which all Veolia business units are measured in terms of agreed-on key performance indicators.

The five elements of the Impact 2023 wheel are environmental, commercial, economic and financial, human resources, and social performance.

It’s a two-way model, where we apply Impact 2023 to empower our employees to optimise client efficiencies, skills and profit margins.

What are the key steps to bringing down costs and improving efficiencies?

The ideal for any mining or industrial operation is to aim for zero liquid discharge (ZLD) and/or zero effluent discharge.

We start by providing a full risk assessment of the mining or industrial site. This entails a water cycle audit and technical study. Veolia refers to this exercise as determining the true cost of water.

Factors to consider within the process circuit include incoming raw water, process water, wastewater generated, plus the effect that seasonal rainfall patterns have for that region. Since mines and industry tend to be major water users, water scarcity is an operational risk factor.

Once this report has been completed, we then dissect, model and map out a mitigation strategy for the client. This could include changing process steps and/or introducing further Veolia technologies, like wastewater reuse. We also recommend pilot trials, followed by a phased approach.

The modern way is to build scalable, modular plants that reduce the footprint. Clients also prefer this approach, as it ties in with their carbon reduction strategies. Locally, our modular units are manufactured in Sebenza, Gauteng, either as skidmounted or containerised plants.

Is there a proven cost benefit in outsourcing operations and maintenance (O&M)? Globally, mines and industry have

recognised the benefits of outsourcing non-core operations like water purification and wastewater treatment. This is a field where Veolia has vast experience, working on hundreds of customer sites worldwide.

We’ve been able to pass on significant operational benefits, bring down energy consumption costs and, in many cases, turn a hazardous waste stream into a financially viable by-product.

We have a steadily growing client base in South Africa, ranging from food and beverage producers to automotive manufacturers and deep-level gold mines.

A prime example of a large-scale client is our O&M contract for South Africa’s largest steel producer. On this customer site, there are around 32 process areas that require some form of water or wastewater treatment. They have a ZED programme in place, which includes a highly successful water reduction strategy. All recovered and treated water is recycled back into the process engineering cycle.

Examples of Veolia innovations employed are HPD® evaporation and crystallisation technologies. Key benefits include the recovery of by-products from waste streams, and volume reduction and water recovery. The objective wherever possible is to manage and reduce waste generation on-site to reduce the cost of disposal.

Has Veolia secured any new O&M contracts recently?

We were recently awarded a major O&M contract for one of South Africa’s deep-level gold producers. This is an exciting and broad-ranging project. We’re treating water from depths of 4 000 m and producing potable water for the mining operation. We are also responsible for the optimisation of the mine’s cooling and ventilation plants. These tend to absorb large volumes of water and are essential for regulating

underground temperatures at workable levels for miners.

What is Veolia’s local strategy for its waste business?

An exciting development is the acquisition of Dolphin Coast Landfill Management (DCLM) in KwaZulu-Natal. This is a hazardous landfill that serves some 400 clients from diverse industries. We’ve invested in new technologies like HPD to maximise opportunities for saleable byproducts that include ammonium sulfate, which can be used as a fertiliser.