Water & Sanitation

Complete water resource and wastewater management

Complete water resource and wastewater management

SLUDGE MANAGEMENT

Unmet efficiency with up to 10%-20% energy cost reduction

Super high flow rate

Designed for superior cavitation resistance

High regulation capabilities

air flotation is one of the most

versatile and widely used unit operations in the treatment of water worldwide. Johan Bieseman, managing director, AquaPlan, speaks about the benefits of this

technology. P4

Multi Parameter Digital Level Sensor CTD (Conductivity, Temperature, Depth)

• Accuracy / Range of Conductivity Sensor:

± 1 % max. / 0,2...200 mS/cm

• Accuracy / Range of Temperature Sensor Pt1000:

± 0,1 °C / -10…40 °C

• Accuracy / Pressure Range of Depth:

± 0,02 %FS max. / 5…200 m

• Applications:

Monitoring of Water Quality and Level

• For wireless tank content measurements, optionally with conductivity measurement

• KOLIBRI Cloud compatible

• LoRa™ ready

Remote Data Transmission Solutions

• ARC-1: 3G Multi parameter modem logger or ADT-1: LoRa modem

• Data transmission via LoRa, E-Mail, FTP or SMS

• Battery life up to 10 years

• Easy to install

• Free software

• LoRa™ ready

• KOLIBRI Cloud compatible

Level and Temperature Logger Solutions

• Autonomous

• Easy to use

• Battery life up to 10 years

• Applications:

· Fresh Water

· Salt Water

· Dirt Water

• Available in stainless steel, hastelloy or titanium

Editor Danielle Petterson

danielle.petterson@3smedia.co.za

Managing editor Alastair Currie

Head of design Beren Bauermeister

Designer Janine Schacherl

Chief sub-editor Tristan Snijders

Contributors Neil Armitage, Jay Bhagwan, Lester Goldman, Sudhir Pillay, Anthony Turton, Achim Wurster

Operations & production manager Antois-Leigh Botma

Production coordinator Jacqueline Modise

Distribution manager Nomsa Masina

Distribution coordinator Asha Pursotham

Group sales manager Chilomia Van Wijk

Financial manager Andrew Lobban

Bookkeeper Tonya Hebenton

Printers Novus Print KZN

Advertising sales Hanlie Fintelman

t +27 (0)11 467 6223 | c +27 (0)82 338 2266

Hanlie.Fintelman@3smedia.co.za

Publisher Jacques Breytenbach

3S Media

46 Milkyway Avenue, Frankenwald, 2090 PO Box 92026, Norwood 2117

Tel: +27 (0)11 233 2600 Fax: +27 (0)11 234 7274/5 www.3smedia.co.za

ISSN: 1990 - 8857

Annual subscription: R330 (SA rate) subs@3smedia.co.za

Copyright 2020. All rights reserved. All articles herein are copyright protected and may not be reproduced either in whole or in part without the prior written permission of the publishers. The views of contributors do not necessarily reflect those of the Water Institute of Southern Africa or the publishers.

WISA Contacts:

HEAD OFFICE

Tel: 086 111 9472(WISA)

Fax: +27 (0)11 315 1258

WISA’s Vision Inspiring passion for water

Physical address: 1st Floor, Building 5, Constantia Park, 546 16th Road, Randjiespark Ext 7, Midrand

Website: www.wisa.org.za

BRANCHES

Central Branch (Free State, Northern Cape, North West)

Chairperson: Dr Leana Esterhuizen

Company: Central University of Technology

Tel: +27 (0)51 507 3850

Email: lesterhu@cut.ac.za

Eastern Cape:

Branch Contact: Dan Abrahams

Company: Aurecon

Tel: +27 (0)41 503 3929

Cell: +27 (0) 81 289 1624

Email: Dan.Abraham@aurecongroup.com

Gauteng

Branch Lead: Zoe Gebhardt

Cell: +27 (0)82 3580876

Email: zoe.gebhardt@gmail.com

KwaZulu-Natal

Chairperson: Lindelani Sibiya

Company: Umgeni Water

Cell: +27 (0)82 928 1081

Email: lindelani.sibiya@umgeni.co.za

Limpopo

Chairperson: Mpho Chokolo

Company: Lepelle Northern Water

Cell: +27 (0)72 310 7576

Email: mphoc@lepelle.co.za

Mpumalanga

Chairperson: Lihle Mbatha (Acting)

Company: Inkomati-Usuthu Catchment Management Agency

Tel: +27 (0)13 753 9000

Email: mbathat@iucma.co.za

Western Cape

Chairperson: Natasia van Binsbergen

Company: AL Abbott & Associates

Tel: +27 (0)21 448 6340

Cell: +27 (0)83 326 3887

Email: natasia@alabbott.co.za

Namibia

Please contact the WISA Head Office on admin@wisa.org.za for more information

The GDP figures for the fourth quarter of 2019 show a 1.4% contraction in the economy, plunging South Africa into its third recession since 1994 in the second half of 2019. Construction was the third worst affected sector, with a decline of 5.9%, followed by electricity, gas and water, which saw a 4% decline.

This poor growth is of great concern considering that South Africa will also be negatively affected by global trade wars and the impacts of the Covid-19 outbreak.

Budget speech

Minister Tito Mboweni’s 2020 Budget Speech received mixed reactions. While many were relieved to see no major tax increases, labour unions were quick to denounce the minister’s plans to cut the public sector wage bill by R160.2 billion over three years. This substantial cut comes in light of South Africa’s growing financial deficit. In fact, servicing debt is now our third biggest budget expense.

We are now highly reliant on government to successfully negotiate with labour unions to ensure the necessary cut in the wage bill.

Dr Azar Jammine, director and chief economist at Econometrix, has warned that if South Africa does not manage to control its growing public debt, the country could soon end up in a very similar situation to Greece’s sovereign debt crisis, which saw it require bailout loans in 2010, 2012 and 2015 from the International Monetary Fund, Eurogroup and European Central Bank.

As the economy continues to contract, it is the poorest communities who suffer most. Unfortunately, the country has seen a rise in poverty levels in recent years, and progress that was made in eradicating poverty is being undone.

In March, we celebrate World Water Day, which forces us to consider SDG 6: water

and sanitation for all by 2030. Over 3 million South Africans still do not have access to a basic water supply service and 14.1 million people do not have access to safe sanitation.

Unfortunately, it is these poor, sometimes forgotten, communities who are likely to continue to suffer without the basic necessity of water and the dignity of sanitation, as the country grapples with a potentially looming financial crisis.

President Cyril Ramaphosa has highlighted the haemorrhaging of skills in the public sector, which undermines planning, asset management and the creation of a credible pipeline of infrastructure projects.

In response, industry associations such as WISA and CESA have begun to call on the private sector to offer skills and support to the public sector. According to a recent CESA survey, one in five people in all consulting firms is not gainfully employed. The capacity therefore exists for a short- to medium-term measure to utilise private sector skills to capacitate the state.

WISA recently put out a request for skilled unemployed or under-employed members who would like to offer their services to the Department of Human Settlements, Water and Sanitation to add their names to a skills database.

It is encouraging to see the private sector working to collaborate with government. If initiatives like these can succeed, we may well see a turnaround in service delivery and, hopefully, the economy.

Hanlie.Fintelman@3smedia.co.za

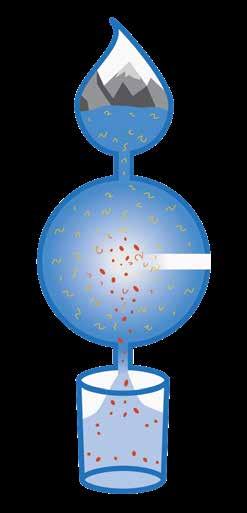

Dissolved air flotation is one of the most robust, versatile and widely used unit operations in the treatment of water worldwide.

Johan Bieseman, managing director, AquaPlan, speaks to Water&Sanitation Africa about the benefits of this

treatment technology.

Why is dissolved air flotation (DAF) an increasingly popular option for clients/ end users?

JB In the past, DAF systems were often a wish list item. Today, DAF systems have become an intrinsic part of the process of treating water due to their very efficient and cost-effective removal of, among others, suspended solids, chemical oxygen demand and phosphorus in wastewater.

This trend has picked up over the past few years, as more pressure is mounting on industries and governments alike to consider the reuse of water in various applications.

In which cases can DAF be considered the best available technology?

DAF systems have been utilised in the water treatment processes for industrial effluents from steel mills, oil refineries, chemical plants, paper mills, and effluents from food and beverage processes.

The implementation of a skid-mounted, modular, cost-effective DAF system as part of the process to produce clear,

treated water from industrial effluent from almost any source of water – including wastewaters with high organic content, suspended solids and colour – cannot be over-emphasised.

A well-placed, well-designed DAF system offers unprecedented advantages for both up- and downstream processes as part of both the removal of pollutants in the water, as well as the protection of membrane processes downstream of the DAF. Our three most recent installations serve as pre-treatment in the preparation of drinking water from the polluted effluent in food and beverage processes.

How does DAF measure up in terms of lead time and cost?

AquaPlan has developed a robust, simple, easy-to-operate and versatile range of DAF systems that encompass the dissolving of air, recirculation of white water, as well as the distribution and separation of particles in one simple, skid-mounted system. The material of construction ranges from epoxy-coated carbon steel to 316 stainless steel as the material of choice in food and beverage as well as papermaking applications. All the materials utilised in the manufacturing of a complete DAF system are readily available in the local South African market.

Our skid-mounted systems are well suited to be installed into current processes as a pre-treatment to both ultrafiltration and reverse osmosis systems, as well as a post-treatment step for biological processes such as MBR, MBBR and SBR systems. Coupled to welldesigned biological systems, the removal and carry-over of suspended and organic matter to post-treatment processes pose a direct threat to the longevity and sustainability of membrane processes. The DAF system is very cost-effective in removing oils, fats, greases, organic compounds, and very fine colloidal suspended solids in one easy process, which effectively removes these unwanted particles from the chain. The process is extremely energy efficient and the float collection mechanism has no moving parts; the waste floats can be lifted off with a simple and automatic hydraulic jump. The equipment is placed on a simple and cost-effective concrete slab, or plinth, by merely lifting the complete system into position. Quick, simple and efficient, the DAF system can be installed and commissioned within two to three days.

The low maintenance costs associated with the system, as well as the costeffective spare parts that are readily available, are welcomed in the industry.

What makes AquaPlan particularly suited to supply DAFs?

AquaPlan has successfully designed, manufactured, installed and commissioned many DAF applications and a wide variety of effluent water and applications over the past 25 years. Our specific in-house experiences in different applications have necessitated optimisation changes to each process, best suited for the application.

The current AquaPlan DAF system comprises a fully integrated air saturation and recirculation pump system, flotation basin, lamella-pack integrated settler tubes, scum flotation system, and conical sludge removal underflow, all on to one integrated skid-mounted frame, ready for installation. Our range of systems are simple and quick to install, and cover a very small footprint for large flow rates when compared to conventional clarification systems.

Is DAF particularly suited to the South African water sector or is it simply a generalapplication technology?

The biggest driver of recycling water, or reusing any treated effluent, is believed to be the sustainability of water securities, as the availability of both groundwater and surface water resources is rapidly diminishing. The reuse of wastewater will be an absolute necessity when the normal sources run dry or are contaminated. This holds true as a worldwide application and not specifically only in the South African context.

South Africa is an arid country with a low average rainfall, where reservoirs and water storage capacities are often extremely low. With the projected population growth over the next 10 years, coupled to the effects of global warming and shifting weather patterns, the use and reuse of water in South Africa as a water source to augment natural sources is a great opportunity to drive sustainability. It is projected that large wastewater works in South Africa that are well established and near city metropoles will adjust their way of treatment through the inclusion of DAF systems. This will provide sources of drinking water to communities who currently simply do not have a sustainable source of drinking water.

the shift to utilise industrial effluent water or wastewater for drinking water will grow exponentially. The technology already exists to produce drinking water from a wide range of non-potable sources such as acid mine drainage, seawater and raw sewage at city outfall points. As responsible citizens, we each have a vested interest in not only minimising waste, but utilising our waste streams in environmentally responsible ways, reducing our carbon footprint and conserving energy. Drinking our own treated waste is slowly gained traction and is indeed our future.

Industrial effluent and human wastewater comprise all the unwanted and toxic elements a design engineer in water treatment can be confronted with. These include organic matter, viruses, bacteria, as well as suspended mater, oils and fats that need to be removed. To this effect, a well-positioned DAF is critical in removing most of these constituents. One of the biggest challenges to this process is the protection of the equipment against fouling, blocking and to guard against high energy and maintenance costs within the system.

Is there work to be done in terms of changing people’s attitudes towards effluent and wastewater treated for potable use – even with using DAF as pre-treatment?

There is indeed a lot of work to be done. While more pristine natural resources diminish, and the environmental degradation of sustainable habitats is more and more evident as a direct result of industrial activity,

www.aquaplansa.co.za

ENERGY REDUCTION

Try Grundfos SP Pumps if you’re looking for the most energy efficient solution.

GRUNDFOS SUBMERSIBLE SOLUTIONS – DELIVERING PUMP SYSTEMS WITH NO SURPRISES

Our complete system combines a stainless-steel SP submersible pump, an MS/MMS motor made to match the pump, a dedicated electronic motor protection unit or variable speed drive, plus a remote management system. One of the biggest benefits of applying this complete SP system is significant savings potential.

As we get ready to observe World Water Day in March, we are reminded that our WISA 2020 Conference is fast approaching.

We all know that we are facing increasing water demands to meet the needs of a rapidly growing and urbanising society, economic growth and changing lifestyles. With only 10 more years to achieve our SDGs, we need #AllHandsOnDeck to address the water challenges we are faced with.

South Africa is facing a water crisis as a result of insufficient water infrastructure maintenance and investment, recurrent droughts and

floods driven by climatic variation, inequities in access to services, deteriorating water quality, and a lack of skilled water practitioners.

The country’s National Water and Sanitation Master Plan warns that the impacts of the growing water crisis will be exacerbated if not addressed and could lead to a 17% water deficit by 2030. If this becomes a reality, South Africa’s chances of achieving SDG 6: clean water and sanitation for all by 2030 will fall by the wayside.

The master plan, like the WISA 2020 Conference, seeks to rally all water sector stakeholders in South Africa to work together in order to ensure that the country gets ahead of the curve in relation to both current and future challenges.

The WISA 2020 Biennial Conference and Exhibition, being held in Sandton from 31 May to 4 June, provides a platform for these issues to be discussed, solutions shared, and decisions taken.

It is imperative that the country embraces a few fundamental shifts around water. Our water resources are limited, and we have to start doing more with less. In a country such as South Africa, the work done by the water sector has a major influence on the sustainability and success of our communities and our economy. For WISA, our biennial conference is a reflection of the vital role that we have to play as we adapt to the new, water-constrained, normal.

WISA 2020 therefore aims to speed up delivery and bring purposeful feedback to the leadership of South Africa. The six thematic streams promise to provide enough platforms for you to interact and suggest solutions to the challenges we face. You will have the opportunity to listen to local and global experts and challenge them to define the solutions we need.

Sector leaders will mingle with sector experts, and the layman, to address such challenges.

Continuous professional development should also be about applying learning, and the conference is the perfect opportunity to see this in action.

For more information about the conference, please visit our website: www.wisa2020.org.za.

We hope you will join us at WISA 2020 and help us get #AllHandsOnDeck for a sustainable water future.

As South Africans, we have what is considered by many as some of the most progressive water-related legislation. On paper, the legislation and structures put in place to give effect to the rights enshrined in the Constitution seem ideally suited to ensure that all South Africans experience the benefits. Scanning the news reports, however, paints a different picture, with regular reports of protest action due to lack of water services delivery or reports of water outages due to infrastructure failure. So, what are the underlying causes that prevent us from ensuring the rights are not just a nice-sounding idea but are a lived experience? The following is a list of just some of the reasons that come to mind:

• Commercial operations including industry, farming and mining often use water outside of their licence conditions, abstracting and using too much water or discharging poorly treated wastewater.

• Water boards and state-owned entities are responsible for our bulk water supply infrastructure.

We will be celebrating National Water Week and World Water Day in March. What does this mean to you? The right to access sufficient clean water to sustain life is enshrined in our Constitution; however, this alone neither gives effect to nor ensures that the right to water is realised.

By Achim Wurster, chair, WISA

There are often news reports of corruption and mismanagement of large sums of money in the associated infrastructure projects. At times, the level of infrastructure maintenance is inadequate. National Treasury funding is under pressure and the end users are reluctant to pay more for water services.

• Municipal budgets for water-related infrastructure and services are always under pressure from competing interests and glamour projects designed to get politicians re-elected. This applies especially to sewage treatment infrastructure, resulting in many municipalities discharging partially treated or untreated sewage. Corruption and mismanagement of the already inadequate funds that are directed to water infrastructure make the situation worse. Many municipalities also do not pay their bills, placing excessive financial strain on the water boards. Municipal infrastructure is intentionally vandalised by criminal elements who sell parts as scrap or to ensure that a connected individual benefits from a contract for the provision of water tanker services.

• Individuals that are either unaware, selfish, or simply don’t care about their fellow citizens, misuse water services by illegally connecting to water services, not paying for services received or by illegally discharging toxic waste into sewers or the environment.

• The regulator and law enforcement bodies are not effective at ensuring that our otherwise good laws are enforced. The regulator may be conflicted, as it is also acting as an implementing agent and regulating yourself is not always easy. The law enforcement agencies are typically overwhelmed trying to enforce other more serious crimes, or they are at times also susceptible to corruption. Often, the only thing that commercial entities, water boards, municipalities and individuals alike have that prevents them from operating outside of the law are the moral standards of the individuals in the various organisations.

For you and every other South African citizen, the result of the above is that

we are paying more for a water supply that is less reliable and for water that is of a lower quality. This is also why South Africa has not managed to give effect to the water rights enshrined in our Constitution to each and every citizen. So, what now?

I propose that we approach the matter from the other side; instead of focusing on our rights, let us focus on our responsibilities. If each individual in our society would ask, “What is my responsibility?” and act accordingly, then we would live in a utopia. While this is not realistic, we could – as a

society and individuals – decide to think bigger and longer term, as well as change our values to at least not cause harm or shift burdens to others. Therefore, it is up to you to:

• Make choices that show a regard for the law and the rest of society, whether in your capacity as an employee in industry, farming, mining, water board, municipality or regulator, as well as in your private capacity at home and when interacting with the rest of society.

• Speak up and be an agent for changing values in the rest of society: to educate

and inform the rest of society on the benefits to all if we work together because our individual interest and the common interest are intertwined when it comes to water.

• Hold politicians, the regulator and law enforcement agencies accountable for the policies they make and decisions they take.

Focusing on our responsibilities is the only feasible way for South Africa to achieve the right to clean water for all as our Constitution intends. To borrow from the WISA 2020 Conference theme, this once again requires #AllHandsOnDeck.

The #AllHandsOnDeck WISA 2020 Conference will take place from 31 May to 4 June 2020 at the Sandton Convention Centre in Johannesburg.

As part of the #AllHandsOnDeck movement, the Young Water Professionals (YWP) empowerment platform of WISA will be coordinating a number of events and sessions during the conference. We invite you to familiarise yourself with the sessions and please volunteer your name to participate in any of these sessions.

Rapporteur programme

A rapporteur programme, coordinated by YWP, will run for the duration of the WISA conference. Volunteers to this programme will be expected to participate in planning meetings leading up to the conference, attend sessions representative of the conference sub-themes to capture key messages, work with teams to summarise the key messages from the sessions and report back at the YWP Forum. The objective of the rapporteur programme is to ensure that the emerging messages from the various conference sessions and sub-themes are represented and debated upon during the YWP Forum.

For the rapporteur programme, we will bring YWPs together to debate on key issues from the conference. An almost week-long programme of working together with other YWPs promotes relationship building and trust – the foundation of a growing network in the South African water and sanitation sector.

The YWP Forum will take place on Day 3 of the conference and will run

as an interactive session. It is open for everyone to attend. The objective of the forum is to debate on the key messages emerging from the conference that will be presented by the rapporteurs. The debate will include a brainstorming session on what we think may be solutions/improvements to challenges and current practices and how YWPs could contribute to these solutions or improvements.

The YWP Forum will be the flagship event for YWP at the WISA Conference. The outcomes from the forum session will be consolidated and integrated into the conference feedback.

The YWP Forum 2020 is therefore a unique opportunity for all YWPs attending the conference to have their voices heard, contribute to the future thinking of the South African water sector, and to be part of a community of young people set to make a difference. YWP-ZA would like to invite all YWPs interested in having #AllHandsOnDeck and their voices heard to volunteer

themselves to be part of the rapporteur programme and the YWP Forum. You can reach out to us on ywpzaconf@gmail.com.

YWP will be involved in several other sessions:

• Opening and closing plenaries on Day 3 (June 3) of the conference.

• YWP meet and network social – more information on the date, venue and time will be posted from the @YWPZA Facebook account closer to the conference. Please check our Facebook account for the latest information.

• Wetskills South Africa Programme & Awards –participants will work together in mixed teams on water challenges provided by organisations of the local and international water sector. This edition of Wetskills will take the participants to the Gauteng region, with Johannesburg and Pretoria, and its magnificent and interesting surroundings. They will get a two-week programme with workshops and teamwork, visiting interesting water-related locations, and having the finals and awarding ceremony at the bi-annual WISA 2020 Conference. On Day 1 of the WISA 2020 Conference (1 June), the Wetskills participants will present their concepts, followed by an awards ceremony (award ceremony date and time still to be confirmed). To get the latest updates on this programme, please access https:// wetskills.com/event/ wetskills-south-africa-2020, and follow @Wetskills on Facebook and Twitter.

Multi-Parameter Testing device combines all of the key water testing parameters & testing ranges

Highest accuracy due to interference filters

More than 120 pre-programmed methods

Portable instrument for use in the lab, plant or out in the field

User interface is intuitive & easy to navigate

GERD meetings show promise Representatives from Sudan, Egypt and Ethiopia met in Washington, DC early this year for a round of talks on the Grand Ethiopian Renaissance Dam (GERD).

The US-sponsored talks between the three nations seek to resolve a dispute over the GERD being constructed on the Blue Nile, a tributary of the Nile River.

The US, with technical support from the World Bank, has agreed to facilitate preparations of the final deal to be studied by the three countries.

Egypt has opposed the project over fears that it will stem the flow of the Nile, on which it depends for around 90% of its water supply.

Construction of the dam is well under way and expected to be completed

A sanitation crisis

A recently released census report has revealed that only 9.7% of Kenya’s national population use sewered sanitation.

Data from the Kenya National Bureau of Statistics reveals that most Kenyan households are not connected to the main sewer grid and must use alternative sanitation options. More than half of the country’s 12 million households use covered pit latrines –more than 61% in rural areas and 34% in urban areas.

A significant number of households also use uncovered pit latrines or defecate in the open; 12.5% of rural households and 4.4% in urban areas use uncovered pit latrines, while 11.5% of those in rural areas and 0.8%

by 2023. The hydroelectric dam will produce 6 475 MW for Ethiopia’s domestic and industrial use, as well as for export to neighbouring countries.

The three countries have reportedly reaffirmed the importance of transboundary cooperation in the development of the Blue Nile to improve the lives of the people of Egypt, Ethiopia and Sudan.

in urban areas practise open defecation.

Urban areas such as Nairobi, Mombasa and Kisumu boast higher connectivity to the main sewer line. Currently, Nairobi is the best connected, with more than 54% of households using sewered sanitation. In Mombasa and Kisumu, the proportions of the population connected to sewers are 16.6% and 4.8%, respectively.

Unfortunately, the improvement of Kenya’s sanitation infrastructure has been slow over the last 20 years, showing little change despite other infrastructure development. Kenya has long struggled with this problem and was among the countries that did not achieve the Millennium Development Goal for increasing access to water and sanitation.

Expanding WASH services

Water security for farmers

USAID’s new Water for Agriculture project will boost the livelihoods of farmers in the conflict-affected states of Borno, Adamawa and Yobe by improving the water supply in crisisaffected zones in north-east Nigeria.

The three-year project will reach at least 4 000 smallholder farmers and 50 000 livestock herders by constructing new earth dams and systems for crop production and livestock watering, strengthening water governance and management, improving production, and helping mitigate conflict between farmers and herders.

The West Africa Municipal Water, Sanitation, and Hygiene (MuniWASH) activity is providing support to city governments in West Africa to improve and expand water and sanitation services to meet critical needs.

Urbanisation in the region is challenging municipalities’ ability to deliver consistent and quality water and sanitation services as well as make improvements towards the water and sanitation Sustainable Development Goals (SDGs). In both Benin and Ivory Coast, for example, millions of people lack access to basic or safely managed drinking water and sanitation services.

MuniWASH’s focus is on helping government to improve financial viability and sustainability, technical and operational performance, and governance and management oversight to bridge the gap between country national priorities and the SDGs.

Currently, MuniWASH is supporting city governments, national directorates and agencies, utilities, and service providers in Benin and Ivory Coast to sustain and expand city-wide WASH services to fill critical needs that reach poor and underserved community members in priority municipalities.

Safe water sources needed

A recently released Unicef report states that almost 60% of the Zimbabwe’s water sources do not provide access to safe water, leaving many families to depend on unsafe or contaminated sources, increasing the risk of diarrhoeal disease outbreaks.

The Zimbabwe Humanitarian Situation Report indicates that 1.9 million people are in need of safe drinking water, sanitation and good hygiene. However, it acknowledges that this figure may need to be revised given the growing economic challenges facing Zimbabwe and the late onset of rains.

During 2019, Unicef provided WASH responses to Zimbabwe’s cholera,

Water for Agriculture will also improve the capacity of local governments and communities to govern and manage water infrastructure and resources in the region.

“Water for Agriculture will play a critical role in USAID’s strategy to develop new sustainable water sources in rural communities where displaced populations are returning,” says Stephen Haykin, mission director, USAID. “It will contribute to our promotion of agriculture-led economic growth to improve resilience and nutrition, and stronger governance of the water and sanitation sector.”

typhoid, Cyclone Idai and drought emergencies. Around 1.3 million people were reached with a safe water supply, and 158 638 people were reached with basic sanitation in emergency settings.

A recent sector review of cholera, typhoid and cyclone responses highlighted the importance of expanding rapid response teams that delivered a comprehensive WASH response to cholera and contributed to faster control of the outbreak.

Unicef also supported the development of a diarrhoea, typhoid and cholera outbreak emergency preparedness and response plan for the City of Harare as well as developing its own internal contingency plan to deal with the growing challenges facing the WASH sector in Zimbabwe.

To support the achievement of Sustainable Development Goal 6 – water and sanitation for all by 2030 – World Water Day raises awareness of the 2.2 billion people living without access to safe water. Climate change must be taken into consideration as variable climates increasingly affect global water sources.

As climate change increases variability in the water cycle, it induces extreme weather events, reduces the predictability of water availability, affects water quality, and threatens sustainable development, biodiversity and the right to water and sanitation worldwide.

According to the UN-Water Policy Brief on Climate Change and Water, growing demand for water increases the need for energy-intensive water pumping, transportation and treatment, and has contributed to the degradation of critical water-dependent carbon sinks such as peatlands. And, some climate change mitigation measures, such as the expanded use of biofuels, can further exacerbate water scarcity.

The UN has therefore called for an integrated approach to climate change and water management in climate policy and planning, both at a national and regional scale. A business-as-usual approach is no longer an option. Instead, water management must be scrutinised through a climate resilience lens.

The

global climate crisis is inextricably linked to water. This year, World Water Day highlights how climate change is already impacting on global water supplies.

The policy brief calls for more investment in improved hydrological data, institutions and governance, education and capacity development, risk assessment, and knowledge sharing. Policies need to ensure the representation, participation, behavioural change and accountability of all stakeholders.

The argument is that significant co-benefits exist to managing both climate and water in a more coordinated, sustainable manner. And solutions for addressing these integrated challenges are available. However, meeting the climate challenge means:

1. Acting now

2. Considering water as part of the solution

3. Improving water management practices

4. Ensuring transboundary cooperation in adaptation

5. Rethinking financing.

SA acknowledges climate threat

The recently released National Water and Sanitation Master Plan (NW&SMP) acknowledges that climate change will result in there being less water available at a time when the country is dealing with increasing water demands.

Climate change is projected to increase the variability of rainfall throughout South Africa and to reduce average rainfall, particularly in the western part of the country. Climate change will result in more

intense floods and droughts, and may also increase the agricultural demand for water due to higher temperatures and a reduced ability to rely on rain-fed agriculture.

The plan calls for a new normal to achieve water security in South Africa. This requires a significant paradigm shift that:

• recognises the limitations of water availability

• addresses the real value of water

• ensures equitable access to limited water resources

• delivers reliable water and sanitation services to all

• focuses on demand management and alternative sources of water

• considers the impacts of climate change

• addresses declining raw water quality.

The NW&SMP states, “The implementation of this plan will enable South Africa to become more resilient to climate change

Wetlands are the most effective carbon sinks on earth, but are declining three times faster than natural forests.

and the increasing intensity of droughts and floods, while meeting the water needs of a growing population and economy.”

The master plan goes on to acknowledge that strong regulation is critical to achieve water security in South Africa, which includes being resilient to climate change impacts. It also calls for ongoing research, modelling and planning around climate change and its impacts on water security and water infrastructure, as well as the need to initiate a hydrological monitoring centre to re-establish a robust data, monitoring and information capability for more effective water resources planning and climate change forecasting.

This year, the South African Department of Environment, Forestry and Fisheries has announced that it will assist municipalities to implement their climate change response strategies. The South African Weather Service will also ramp up efforts to educate local communities so they can better understand climate change and respond appropriately.

Through the department’s environmental programmes, R1.9 billion is to be spent in 2020 to restore wetlands, estuaries and coastal dunes to better protect built infrastructure and human settlements from storms, floods and rising sea levels.

South Africa will also continue to lobby developed countries to provide for an adequate, reliable and predictable source of international funding for both mitigation and adaptation.

If demand continues to grow at current levels, the deficit between water supply and demand in South Africa could be between 2.7 and 3.8 billion m3/annum by 2030 – a gap of about 17% of available surface water and groundwater.

If we limit global warming to 1.5˚C, we could cut climate-induced water stress by 50% 50%

Climate-resilient water supply and sanitation could save more than infants annually

360 000

64 ℓ/day

South Africans use more than the global average

5.7 billion

South Africa is facing a projected water deficit by 2030

17%

2.2 billion

Consistent load-sheddingrelated or other major electricity disruptions can have severe consequences for the continuous treatment and supply of water services, writes Jay Bhagwan*.

Systems across the municipal and water board sector remain vulnerable, as per a recently completed Water Research Commission (WRC) study. The study found that, until recently, the high assurance of electricity supply did not warrant municipalities to have backup plans on its key water services infrastructure.

It is a huge concern that many large metros and municipalities have no preparedness to deal with outages, especially extended ones. The consequences of electricity outages for potable water supply can be severe, disrupting supply completely in extreme cases. This is especially true of much of the Gauteng water supply area, which straddles the continental divide, with most of the water supply having to be pumped and raised before it can be distributed to users. The water sector is highly vulnerable and there is no regulation that ensures the continuity of supply due to energy.

Historically, the risk of electricity supply failure did not play a significant role in the design and operation of water supply and distribution systems. In 2010, the introduction of load-shedding prompted the WRC to initiate a high-level study on the effect of electricity interruptions on water supply. A follow-up study, which was recently concluded, explored the implications of this in greater detail and took account of new concerns that have arisen.

The study was based on the preparedness of the City of Tshwane, which makes up a significant portion of

the Rand Water supply area. Some 80% of the municipality’s water supply is derived from Rand Water and Magalies Water, while the remaining portion is derived from the city’s own sources at Rietvlei Dam, Roodeplaat Dam, along with various dolomitic springs and wells. The study made use of risk analysis methods, the selection was based on a quantitative approach, and the duration and likelihood of the various hazards identified were estimated based on the available information.

The likelihood of the worst-case scenario (total blackout for 30 days) was found to be highly improbable (1:155-year probability). However, the other scenarios highlighted that there is a lack of or no preparedness of key water supply infrastructure points at the municipal level. Water will stop flowing if there is an extended loss of electricity. Further, the scenario analyses provided the following insights:

• For short-term electricity disruption events, it is crucial to first ensure that reservoirs and elevated towers are large enough to be able to supply at least two days’ annual average daily demand. Second, reservoir and tower operating rules should be adhered to in order to ensure that water levels are maintained within the fluctuation volume of the reservoirs/towers.

• For medium- to long-term electricity disruption events, the volume of water stored is less important, since the water stored in reservoirs will almost certainly run out if water is not supplied into the reservoir.

• Backup power generation (both mobile and permanent) will require

ongoing servicing and maintenance – this will have to be incorporated into the city’s water department’s operational and maintenance schedules.

• Providing emergency storage capacity for sewage inflow in wastewater treatment works is more expensive than providing backup power generation at wastewater treatment works. Emergency storage will not be practical for medium- to long-term duration electricity disruption events.

• The supply and delivery of fuel to the city’s water and sewer pump stations and its water and wastewater treatment works will have to be planned.

• Alternate energy and power generation at wastewater treatment and works can reduce, if not eliminate, the costs associated with standby power.

*Jay Bhagwan is the executive manager: Water Use and Waste Management at the Water Research Commission.

Criticism from within the ruling party suggested that internal communication was flawed, and accusations were made that suggest deep internal cleavages. The controversy itself betrays the existence of internal dynamics at work within the ANC.

The real headline-grabbing issue is the growing public resentment, with some cashing in on the anti-government bandwagon by suggesting that water services have deteriorated to a point where they are currently worse than existed in 1994. If true, then this is an indictment on the way water has been managed during our quarter century of democracy.

The reality sandwich

FDI value of 5% and it established the background for regime change in 1994. We, therefore, ought to be very concerned at the trajectory post 2014 because it is fast approaching net negative 30%. This is a serious matter, because it tells us that the economy is in tatters, so the first big question that arises is who will fund the R1 trillion being so glibly touted?

Companies are in dire straits, so profits are down, with a direct impact on revenues to the fiscus. The hostility created by the Bell Pottinger campaign against ‘white monopoly capital’ has done something that we never saw in the past. While the net negative 5% FDI in the decade from 1985 to 1995 was driven by institutional capital outflows, the current net negative 25% is driven by the flight of individual savings.

Trust has been lost in the government and the economy, so it is no longer investible. This means that the fiscus is simply unable to pay for the infrastructure needs touted by the NW&SMP. On the

The National Water and Sanitation Master Plan (NW&SMP) was recently announced, and immediately became embroiled in controversy.

By Anthony Turton

To assess the implications, let us take a bite out of the reality sandwich. The most glaring aspect of the NW&SMP is that it mostly reflects the same old thinking that has dominated the last two decades. The usual noises are made about the need to manage demand better, with some scant reference to new sources of water such as desalination and wastewater recovery. As usual, blame is shifted to the consumer for ‘using too much water’ and a call is made to reduce consumption. The attention-grabbing aspect is the cost – around R1 trillion, give or take a few rounding errors.

Therefore, the first bite of the reality sandwich arises from that fact that South Africa has been cash constrained since 2014. Foreign direct investment (FDI) expressed as a percentage of GDP became net negative at the time of the Marikana Massacre and has consistently dropped off the cliff. Of historic reference, we saw the same thing happen between 1985 and 1998. That period saw a net negative

contrary, the fiscal cliff – that moment when civil servants can no longer be paid because of insufficient revenues to the state – will become a very real issue in the short- to medium-term future. Every civil servant ought to become aware of this issue, as it will affect them personally when 40% needs to be lopped off the total government salary and benefits bill.

The minister’s advisor

This brings me to the second key element of the analysis. Minister Sisulu has come under considerable fire because of the appointment of Mo Shaik as a personal advisor. I hold a different view on this matter, because if anyone understands water as a national security risk – the sort of thing that becomes central to regime change when FDI values continue to plummet – then it is Shaik.

I worked with him during the amalgamation of the statutory and nonstatutory intelligence structures in 1994/95, where I developed a respect for his insight into national security skills. I have worked closely with him on some strategic matters and can attest to his abilities in that sphere. His appointment is thus an important one in my view, because it signals the fact that government is now beginning to realise the national security risks arising from the collapse of water and sanitation infrastructure.

Shaik’s immediate deployment into an area of festering unrest in the Free State is consistent with this realisation. Knowing him as I do, pubic perceptions aside, if anyone can do what needs to be done, then it’s probably Mo Shaik. We ought to support him, not decry his appointment and bay for his blood.

Water as an economic enabler

This takes us to the second element of the analysis. Toyota has reached out to government with a simple message that, as a company, they understand how to help rebuild a shattered economy. Their experience is rooted in the rebuilding of Japan after the destruction of the Hiroshima and Nagasaki nuclear bombs

that ended the Second World War. The vision they offered is one of economic prosperity for a rejuvenated South Africa, which has now been given a name – the Public Private Growth Initiative (PPGI).

Central to the PPGI is the recognition that water is an economic enabler, so the instruction was given by senior government officials to create a business chamber for those entities involved in the business of water services provision. Believe it or not, the commercial players in the water sector have never been organised into one coherent body that can bring funders, technology providers and bankable projects together.

This has now been created and is working closely with the National Planning Commission to prioritise a set of key interventions that will kickstart the economy. This is where the NW&SMP comes in. To this end, existing impediments are being removed with the intention of making the water sector investable once again to enable this master plan.

There is no shortage of capital or technology, so, frankly, the R1 trillion is an attainable target, provided that

bankable projects are generated and trust is restored.

This is not the privatisation of water, as some might suggest, but merely the emergence of a new partnership between business, as creators of jobs and generators of taxes, and government that provides the enabling environment for job creation and human development. The lead agency is the Development Bank of Southern Africa, with the full support of the SA Business Water Chamber.

In my professional opinion, this is the game changer that will create an investment platform into the water sector focusing on the rehabilitation of all existing wastewater treatment works, and the emergence of utility-scale seawater desalination projects for all the coastal cities with water-constrained economies. Implementation will be through a series of special-purpose vehicles designed to protect capital from theft, but also to provide the skills needed to make service delivery sustainable in an invigorated national economy.

This is what I believe will make the National Water and Sanitation Master Plan succeed. Water is an economic enabler and the Business Water Chamber will work with all existing parties to make this happen.

A newly upgraded desalination plant in the Eastern Cape has brought welcome relief to parts of the droughtstricken region.

Amatola Water contracted Quality Filtration Systems (QFS) to upgrade the Albany Coast reverse osmosis plant at Ndlambe in the Eastern Cape. Completed in eight weeks, Phase 1 of the upgrade increased the plant’s capacity by 1.4 million litres to a total of 3.5 million litres, serving a population of over 11 000 people.

The desalination plant, located between Bushman’s River and Kenton-on-Sea, was opened by Minister of Human Settlements, Water and Sanitation Lindiwe Sisulu in December 2019.

Officials from Ndlambe Municipality, Amatola Water, the local business forum, the ratepayers’ associations and the Kenton Development Forum joined forces to implement a plan that included maintenance and repairing leaks and the Amatola-funded upgrade of the treatment works.

With many rivers in the region running dry, the upgrade of the Albany Coast reverse osmosis plant brought welcome

relief to holidaymakers and residents impacted by water shortages.

“This is the oldest and one of the few facilities in the Eastern Cape that draws water from the ocean via reverse osmosis and converts that water to drinkable World Health Organization-standard water,” said Herman Smit, managing director, QFS.

“As one of the most experienced membrane technology suppliers in South Africa, we were extremely proud to be selected by Amatola Water to provide the much-needed water for this area in the Eastern Cape,” he added.

The plant was originally built in 1982 and became the first desalination plant in South Africa. Amatola Water has allocated R80 million for the plant to be upgraded.

Smit believes that small- to medium-sized membranebased plants delivering up to 5 million litres per day will play a major role

in emergency drought alleviation for cities and towns.

Along the coast, this will take the form of desalination, while inland users can take advantage of wastewater reuse. Both these applications require speciality membrane plants including ultrafiltration and reverse osmosis.

TOXIC BYPRODUCTS

When phenols mix with chlorine, hundreds of unknown, potentially toxic by-products are formed

Credit: Marissa Lanterman/Johns Hopkins University

Researchers from Johns Hopkins University, in collaboration with the University of California, Berkeley and Switzerland, have published new findings that show that the chlorine treatment of drinking water may unintentionally be causing harm.

Phenols – chemical compounds that occur naturally in the environment and are abundant in personal care products and pharmaceuticals – are commonly found in drinking water. The research, published in EnvironmentalScience&Technology, shows that the mixing of phenols and chlorine creates numerous by-products.

Unfortunately, current analytical chemistry methods are unable to detect and identify all these by-products, some of which may be harmful and have long-term health consequences. “There’s no doubt

One of the most common methods of treating drinking water – chlorination – has been found to produce toxic by-products when mixed with phenols.

that chlorine is beneficial; chlorination has saved millions of lives worldwide from diseases such as typhoid and cholera since its arrival in the early 20th century,” says Carsten Prasse, an assistant professor of environmental health and engineering at Johns Hopkins University and the paper’s lead author.

“But that process of killing potentially fatal bacteria and viruses comes with unintended consequences. The discovery of these previously unknown, highly toxic by-products raises the question of how much chlorination is really necessary.”

In this study, Prasse and his colleagues employed a technique commonly used in the field of toxicology to identify compounds based on their reaction with biomolecules like DNA and proteins. They added N-alpha-acetyl-L-lysine, which is almost identical to the amino acid lysine that makes up many proteins in our bodies, to detect reactive electrophiles. Previous studies show that electrophiles are harmful compounds that have been linked to a variety of diseases.

The researchers first chlorinated water using the same methods used commercially for drinking water; this included adding excess chlorine, which ensures sufficient disinfection but also eliminates harmless smell and taste compounds that consumers often complain about. After that, the team added the aforementioned amino acid, let the water incubate for one day and used mass spectrometry analysis to detect the electrophiles that reacted with the amino acid.

The experiment found the compounds 2-butene-1,4-dial (BDA) and chloro-2butene-1,4-dial (or BDA with chlorine attached). BDA is a very toxic compound

and a known carcinogen that, until this study, scientists had not detected in chlorinated water before, says Prasse.

Alternative treatment methods

While Prasse stresses that this is a labbased study and the presence of these novel by-products in real drinking water has not been evaluated, the findings also raise the question about the use of alternative methods to disinfect drinking water, including the use of ozone, UV treatment or simple filtration.

“In other countries, especially in Europe, chlorination is not used as frequently, and the water is still safe from waterborne illnesses. In my opinion, we need to evaluate when chlorination is really necessary for the protection of human health and when alternative approaches might be better,” says Prasse.

“Our study also clearly emphasises the need for the development of new analytical techniques that allow us to evaluate the formation of toxic disinfection by-products when chlorine or other disinfectants are being used. One reason regulators and utilities are not monitoring these compounds is that they don’t have the tools to find them.”

Other authors on this study include Urs von Gunten of the Swiss Federal Institute of Aquatic Science and Technology and David L Sedlak of the University of California, Berkeley.

“The discovery of these previously unknown, highly toxic by-products raises the question of how much chlorination is really necessary.” Carsten Prasse

We offer process application expertise through our products, solutions and services.

You optimize your process for maximum safety, reliability and e�ciency, with minimum impact on the environment.

Customers around the world trust us when it comes to process automation. Our shared goal is plant safety, availability and e�ciency. We are with you every day, everywhere.

Contact us:

Email: info.za.sc@endress.com

Tel: +27 11 262 8000

Web: www.endress.com

When wastewater sludge is incinerated or disposed of at landfill, we are are both wasting a valuable resource that could be recycled for use on agricultural lands and potentially polluting the air and groundwater.

By Danielle Petterson

As all aspects of society are being pushed to move from a linear to a circular economy, it is important to consider how the wastewater treatment process can follow a similar approach. Professor Eyob Tesfamariam, University of Pretoria, argues that treated wastewater sludge can serve as a source of organic matter to reclaim degraded lands and a source of macroand micronutrients to agricultural lands, boosting food production while providing a sustainable solution for sludge management.

In doing so, Tesfamariam believes we can address multiple Sustainable Development Goals (SDGs), including:

• SDG 2 (zero hunger) – by boosting crop production

• SDG 3 (good health and well-being) – by adding micronutrients back into our food

• SDG 6 (clean water and sanitation) – by improving raw water quality

• SDG 12 (responsible consumption and production) – by restoring degraded land

• SDG 15 (life on land) – by sequestering more carbon into the soil.

For decades, most commercial famers have been adding only three macronutrients to their soils: nitrogen, potassium and phosphorus. Little attention was given to the status of soil micronutrients, which have been exploited for decades or even centuries. As a result, most cultivated crops are deficient in micronutrients and need fortification for human consumption. Treated wastewater sludge is rich in micronutrients and could serve as a source of micronutrients as well as the most commonly applied macronutrients, explains Tesfamariam.

The use of sludge in agriculture

Sludge has been used in agriculture in South Africa for many years, and South Africa has developed very strict guidelines in this regard. Sludge may only be used on agricultural lands if the pollutant concentration, sludge stability and status of pathogens all fall within acceptable limits.

The current South African Sludge Guideline states that sludge that qualifies for agricultural use should be applied according to crop nutrient requirements at a maximum application rate of 10 t/ha/year. However, Tesfamariam questions whether we should stick to the maximum application guidelines. This is because different sludge

has different release rates, and different crops require varying amounts of nutrients within different ecological zones. This has been proven by a study that Tesfamariam has been working on for the past 15 years.

“We’ve done a lot of field work and laboratory studies and found that activated sludge has got the highest nitrogen release rate, while anaerobically digested paddy-dried sludge has much lower release rates. This means the amount of nitrogen that will be available to the plants will be completely different. It is clear that you

cannot apply the same rate for different sludge types,” he explains.

Another study by Tesfamariam and his colleagues also looked at sludge degradation and nutrient release rates across South Africa’s six different agro-ecological zones and found that the amount of nitrogen released differs between zones. The release rate is far lower in arid zones than in humid zones.

Taking into account the interaction between the soil type, the sludge release rate and crop nutrient requirements, Tesfamariam and his team have developed the SARA (sludge application rate advisor) platform, which integrates these factors to provide site- and cropspecific recommendations.

To do this, the platform requires the user to input a variety of data points, including:

1. Sludge classification parameters (faecal coliforms, helminth ova,

pollutant concentration and stability class) to determine whether it is fit for agricultural use

2. Sludge parameters (nutrient content such as N, P, K, water content , etc.) to determine the fertiliser value of the sludge

3. Farm parameters (location, soil type, nutrient composition of the soil, crop to grow, etc.).

Using this data and the Fertilizer Handbook (which is built into the model), the model predicts the nutrient requirements for the specific crop in the specific area. It also predicts the amount of nitrogen likely to be released in that agro-ecological zone based on the type of sludge. Taking all of this into account, it provides a recommendation rate for sludge application.

Importantly, the model takes into account the nutrients already in the soil in order to maximise your sludge application rate per field and minimise environmental impacts through nitrate leaching.

It also informs you how much potassium fertiliser you need to add, as sludge is not a good source of potassium.

Based on input data, the model will determine the period after which you should expect a heavy metal buildup and the type of heavy metals that will reach a threshold level. Lastly, a cost-benefit analyser determines the economic feasibility of using sludge based on transportation and spreading costs, using commercial fertiliser as a benchmark.

Although the SARA platform is still a work in progress, Tesfamariam plans to make it freely available through the Water Research Commission once complete.

The by-product of wastewater treatment

– sludge – is considered a problem for most utilities. However, partnership opportunities can be developed that allow private companies to turn that sludge into valuable fertiliser, saving municipalities time and money.

In most instances, sewage sludge is seen purely as waste which is to be disposed of at the lowest possible cost.

Conventional disposal by landfill or crude agricultural application incurs significant and increasing costs and represents serious ecological hazards. Today, as rapid urbanisation increases wastewater volumes, financially strained utilities often follow such unsustainable disposal strategies with minimum compliance.

As a result, utilities often seek to dispose of sludge in land applications at the highest possible application rate, as close as possible to the point of generation, complying with the minimum level of compliance possible.

Sludge for agriculture

If correctly treated to A1a requirements, sludge can be hugely beneficial to agricultural land. Biosolids from the wastewater treatment processes consist almost entirely of dead and decomposed microorganisms. Once stabilised and processed, the resultant product is rich in humus and humic substances,as well as plant macroand micronutrients.

The organic fertiliser that can be produced offers many measurable,

positive effects on crucial soil processes. It improves soil structure through the formation of aggregates, thereby also improving gas exchange and soil permeability. The material retains up to 20 times its own mass in water, preventing drying and shrinking of soils, while also dramatically increasing cation exchange capacity and the formation of chelates.

However, from a nutrient perspective, excessive amounts of biosolids are often applied when municipalities opt for the highest possible application rate as a means of lowering costs. According to Francois Burger, managing director, Agriman, biosolids have far more value if applied at the right rate, in the appropriate relation to other nutrients, and in the right physical format.

“Unfortunately for sludge producing authorities, the agricultural industry has developed into a highly scientific environment with the current trend of precision farming practices, which requires any new entrants to the market to provide all the services in the value chain,” says Burger. This includes agronomical advice, evaluation of chemical soil analyses, prescription of fertiliser programmes, formulation and blending of prescribed mixes, aftersales service and problem-solving. Producers of fertiliser products to be used in agriculture need to comply with legislation (Fertilizers, Farm Feeds, Seeds and Remedies Act (No. 36 of 1947)) as well as standards regarding physical properties – e.g. density,

particle size, hardness, chemical stability and flow. To compete in the conventional fertiliser market, the product must be fit to be applied by conventional equipment and implements.

Although sludge is often considered a burden, companies like Agriman partner with municipalities to transform their sludge into fertiliser for the agricultural industry. The products and services developed by Agriman for the beneficial utilisation of wastewater sludge cover the entire value chain, from sludge dewatering right through the process of fertiliser manufacturing and sales, up to aftersales service to the farmer in his fields.

The benefit to the local authority is that they bear no responsibility for the ‘waste’ product once it leaves the gate, as the product becomes a registered fertiliser. They do not incur any transport costs and, due to the value proposition, the distribution radius of the product exceeds the borders of our country. This, says Burger, is a true example of a viable circular economy.

“Municipalities should focus on producing a top-quality sludge, investing in proper on-site dewatering and drying facilities. Then they can pass their sludge on to organisations like Agriman to produce fertiliser products, without incurring the everincreasing cost of off-site disposal,” he concludes.

The Western Cape has called for a total ban on organic waste to landfill by 2027, with a target of 50% by 2022. As other municipalities follow suit, the case for codigestion with wastewater sludge is worth considering.

By Danielle Petterson

South Africa produces around 10 million tonnes of food waste per year.

According to a 2017 WWF report, titled Food loss and waste: Facts and futures , the cost of energy embedded in this food waste is approximately R1 billion per annum. The energy wasted every year for producing food that is never consumed is estimated to be able to power Johannesburg for roughly 16 weeks. But what if that food waste were turned into energy?

The opportunity exists to significantly increase energy production at wastewater treatment plants through co-digestion with food waste.

Creating efficiencies

Many of the large wastewater treatment plants in South Africa’s metros contain anaerobic digesters. They form part of the process to treat sewage sludge and generate biogas, which can in turn be used to generate combined heat and power (CHP). Significant opportunities exist to boost CHP production at these

plants by adding organic waste to the anaerobic digesters. Organic waste with a high organic fraction can significantly increase biogas production, says Karl Juncker, owner, WEC Projects. This has been proven at the Northern Wastewater Treatment Works in Johannesburg, where ice cream waste was added to the digesters and more than doubled biogas production with the same digesters.

The key is to have consistent sources of organic waste, as big changes in consistency can be problematic. If municipalities were to approach surrounding businesses, regular sources of consistent organic waste could be secured. “Wastewater sludge is relatively low in organics. Adding 20% volume of high organic sludge would be fantastic in a wastewater digester. With consistent organic addition, you can double or even triple your biogas production,” says Juncker. He uses Johannesburg Water as an example. The utility requires 17.18 MWe to run its treatment plants with the potential of generating 9.58 MWe from biogas produced in the

anaerobic digestion process. If the utility were to incorporate organic waste, it has the potential to meet and even exceed its energy requirements.

Prohibitively expensive?

Organic waste-to-energy has often been touted as too expensive, largely because landfilling is considered ‘prohibitively cheap’. However, as municipalities are faced with diminishing landfill airspace and organic diversion targets, organic waste-to-energy may present an attractive alternative. In terms of alternative energy production, waste-to-energy is typically labelled as far more expensive than solar or wind power. However, Juncker points out that wind and solar have limitations. Although solar may appear cheaper per kW produced, there are only four to five hours a day for peak solar energy production. It is also difficult to store this energy and bad weather affects its productiveness. Wind power has similar limitations. Large-scale wind and solar are also typically limited to decentralised locations far from where the energy requirements are.

Biogas, on the other hand, can be easily stored in gas holders and its peaks manipulated to suit requirements, allowing for continuous energy production. As a result, Juncker believes that, per hour, the costs work out to be similar.

The infrastructure costs are the largest expense when it comes to waste-to-energy. By utilising existing infrastructure at wastewater treatment plants in a co-digestion facility and simply adding engines, costs can be significantly reduced, making it far more economically viable.

Such partnerships could also be used to reduce the overall costs of wastewater sludge treatment and improve environmental compliance for municipalities.

Other advantages

By converting organic waste to biogas for energy production, municipalities can help contribute to the circular economy. The power generated can be used to run the wastewater treatment plant while the heat can be used in the biodigesters or sold back to industry for heating requirements. There also exists the opportunity for nutrient removal. The digested sludge and organic

210 kg per person of food waste is generated per year of SA’s water is used for food that is wasted 1/5th

which can be sold to the agriculture sector as fertiliser. Biofuels and biogases could also be created for use in vehicles.

Water is another by-product that can be treated and reused. Industries that generate organic waste are typically high water users and could be supplied with water in exchange for their waste. Abattoirs are perfect operations for partnerships, says Juncker. They generate a large amount of organic waste, which can be fed into digesters, and require heat, power and water for their operations, which can be produced through the biodigestion process.

The process also creates an inherent reduction in emissions, offsetting what would be created if that organic waste were sent to landfill or composted. This opens opportunities for carbon credits.

“There is a big benefit to adding high organic waste to stimulate biogas production. If your digesters operate correctly, you are guaranteed a good product,” concludes Juncker.

When Cape Town was faced with the possibility of running out of water, attention turned to rainwater harvesting. Now studies are under way to determine the viability of urban stormwater ponds as water resources for the city.

By Neil Armitage*

The 2000 edition of the ‘Red Book’ – i.e. the CSIR Guidelines for Human Settlement Planning & Design – defines stormwater as mere “run-off”’ and describes it as “the common enemy that each property owner may fight... or control” essentially by any means available, as long as there are not obviously detrimental consequences to the neighbours.

Nothing could be further from the truth. The revised ‘Red Book’ (CSIR, 2019) more accurately defines stormwater as: “rainwater or melted snow that runs off

streets, lawns and other sites... [and it] should be regarded as a resource.” Like any other resource, it can be used or abused.

The Day Zero crisis in Cape Town that came to a head in 2018, where the city came perilously close to running out of potable water, heavily underlined the fact that the days of considering stormwater as ‘the common enemy’ are now past. Even in the driest of years, the metro receives far more water in the form of rainfall than it ever supplies to its residents. However, almost all

water supply comes from the ‘Big Six’ reservoirs situated in the Hottentot Holland Mountains east of the city. Meanwhile, the run-off in the city – increased in recent years by the relentless development that seals the surface – is largely discharged into the sea, taking along with it all sorts of pollutants including nutrients, heavy metals, trash and even sewage.

The threat of dry taps rapidly changed attitudes towards rainwater in Cape Town. Purveyors of rainwater tanks did roaring business, as the more affluent citizens in the leafy suburbs queued up to have them installed in their properties – at great expense – so at least they could secure some additional supply. They quickly found that even the largest tanks cannot hold enough roof water to see most properties through Cape Town’s long, hot, dry summer. In most instances, drilling well-points/ boreholes gave a better return – but, even then, the water table began to drop owing to excessive withdrawal. There are several lessons to be learnt here: rainwater is hard to store in quantity at household level; groundwater needs to be replenished, if it is to serve as a reliable water resource; and stormwater should not be abused (through urban pollution) and ignored – except when it is a threat to property.

Cape Town (UCT), entitled ‘The viability of urban stormwater ponds as water resources in Cape Town’.

The study looked at the Zeekoe Catchment that lies between Cape Town International Airport and False Bay, which conveniently overlies a large unconfined sandy aquifer. The objective was to see whether stormwater could provide a reliable supply of reasonably cheap water in enough quantity to make a difference to Cape Town’s water supply needs.

Key was the idea of repurposing some of Cape Town’s 800-odd stormwater

detention ponds for the sole purpose of reducing downstream flood levels. Two

to potable standards and distribute through the existing water reticulation system?

The study, which was completed in 2018, showed categorically that, for the study site at any rate, it was better to store the water in the aquifer and, when required, treat to potable for distribution through the existing water reticulation system. The estimated cost was comparable to that of groundwater extraction – something the City of Cape Town is beginning to do in the area in any case – and not that much more than the cost of

bringing water in from the reservoirs in the mountains.

Stormwater harvesting in this one catchment alone, which only covers some 4% of the metro, could realise approximately 3% of the city’s current potable water demand – on top of the 6% potentially available from the natural recharge of the aquifer.

Questions still, however, remain regarding the practicalities of turning dry detention ponds into periodically wet infiltration ponds – particularly in low-income areas where the water quality is poor, and safety and security are major issues.

Thankfully, Future Water at UCT has been awarded funding from the Danish government through Danida to, inter alia, study this in conjunction with colleagues from the University of Copenhagen. This is a three-year study that will be complete in 2022.

*ProfessorNeilArmitage is the deputydirectorandco-founderof the Future Water Institute at the UniversityofCapeTown.

With the transition to smart cities, opportunities arise to harness smart technologies to reduce water losses and better manage all aspects of the water network.

With the rise of the Fourth Industrial Revolution, engineers are turning their attention to smart cities: areas that harness the internet of things (IoT), making use of electronic sensors to collect data that can be used to manage assets, resources and services efficiently.

Smart cities will feature a range of disruptive technologies, including smart metering, automated meter reading (AMR), advanced metering infrastructure (AMI), cloud computing, real-time hydraulic modelling, artificial intelligence (AI) and more.

When it comes to water, smart cities should at least feature AMI, says Dr Alexander Sinske, senior executive, GLS Consulting. AMI offers numerous benefits by supporting strategies to address water scarcity and water conservation. It allows municipalities to better understand water consumption and

demand patterns, while reducing non-revenue water by detecting water losses and improving the management of water production, storage and distribution. It also enhances customer service by facilitating more accurate billing and efficient administration.

The use of digital twins is also growing in the infrastructure space. A digital twin is a digital replica of a physical entity. Digital twins integrate elements including IoT, AI, machine learning and more to develop models that can be continuously updated and maintained to be truly representative of the real world.

Achieving this in the water field requires having extensive monitored network data available for calibration and validation, together with high-quality information, such as customer demands and weather forecasts. In turn, the digital twin can provide a very good picture of what has happened, what is happening now, and what will happen in the future, explains Sinske.

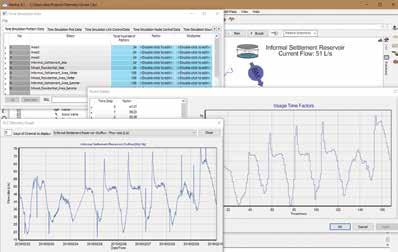

Building a smart city using Wadiso

GLS recently undertook a pilot project incorporating AMI and other smart city elements with the view of creating a water digital twin that would assist with reducing water losses.

This pilot system integrates diverse systems including time series data from several web services, as well as extended period hydraulic models using GLS’s own Wadiso™ software. The base functionality of the system is to highlight and summarise key information, such as showing critical meter status and historic graphs as well as highlighting sensors that have stale information. It also links data from hydraulic models or system schematics based on GIS and performs advanced post-processing.