Water & Sanitation Africa

Complete water resource and wastewater management

Complete water resource and wastewater management

The ideal low-pressure solution INDUSTRY 4.0

Embracing the digital utility

WATER SECURITY

Large-scale greywater reuse

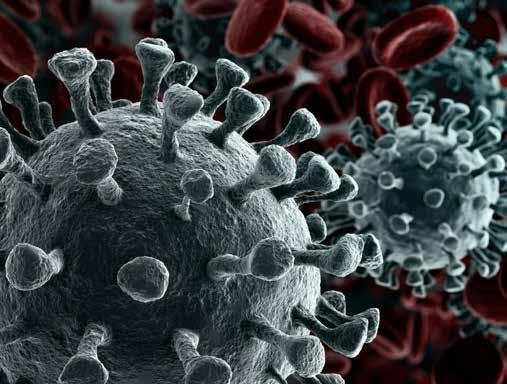

COVID-19

Responding to a pandemic

Unmet efficiency with up to 10%-20% energy cost reduction

Super high flow rate

Designed for superior cavitation resistance

High regulation capabilities

An increasing focus on environmental protection and energy savings means that water supply and distribution systems need to become more efficient and operate optimally at minimum pressures. P4

Multi Parameter Digital Level Sensor CTD (Conductivity, Temperature, Depth)

• Accuracy / Range of Conductivity Sensor:

± 1 % max. / 0,2...200 mS/cm

• Accuracy / Range of Temperature Sensor Pt1000:

± 0,1 °C / -10…40 °C

• Accuracy / Pressure Range of Depth:

± 0,02 %FS max. / 5…200 m

• Applications:

Monitoring of Water Quality and Level

• For wireless tank content measurements, optionally with conductivity measurement

• KOLIBRI Cloud compatible

• LoRa™ ready

Remote Data Transmission Solutions

• ARC-1: 3G Multi parameter modem logger or ADT-1: LoRa modem

• Data transmission via LoRa, E-Mail, FTP or SMS

• Battery life up to 10 years

• Easy to install

• Free software

• LoRa™ ready

• KOLIBRI Cloud compatible

Level and Temperature Logger Solutions

• Autonomous

• Easy to use

• Battery life up to 10 years

• Applications:

· Fresh Water

· Salt Water

· Dirt Water

• Available in stainless steel, hastelloy or titanium

Editor Danielle Petterson

danielle.petterson@3smedia.co.za

Managing editor Alastair Currie

Head of design Beren Bauermeister

Designer Jaclyn Dollenberg

Chief sub-editor Tristan Snijders

Contributors Raeesa Bhikhoo, Jo Burgess, Jacky Burke, Lester Goldman, Niel Ramsay Louw, Ashton Busani Mpofu, Peter Prevos, Serigne Mbaye Thiam, Peter Townshend, Annejan Visser, Swen Weiner, Achim Wurster

Operations & production manager Antois-Leigh Botma

Production coordinator Jacqueline Modise

Distribution manager Nomsa Masina

Distribution coordinator Asha Pursotham

Group sales manager Chilomia Van Wijk

Financial manager Andrew Lobban

Bookkeeper Tonya Hebenton

Printers Novus Print KZN

Advertising sales Hanlie Fintelman

t +27 (0)11 467 6223 | c +27 (0)82 338 2266

Hanlie.Fintelman@3smedia.co.za

Publisher Jacques Breytenbach

3S Media

46 Milkyway Avenue, Frankenwald, 2090 PO Box 92026, Norwood 2117

Tel: +27 (0)11 233 2600 Fax: +27 (0)11 234 7274/5 www.3smedia.co.za

ISSN: 1990 - 8857

Annual subscription: R330 (SA rate) subs@3smedia.co.za

Copyright

WISA Contacts:

HEAD OFFICE

Tel: 086 111 9472(WISA)

Fax: +27 (0)11 315 1258

WISA’s Vision Inspiring passion for water

Physical address: 1st Floor, Building 5, Constantia Park, 546 16th Road, Randjiespark Ext 7, Midrand

Website: www.wisa.org.za

BRANCHES

Central Branch (Free State, Northern Cape, North West)

Chairperson: Dr Leana Esterhuizen

Company: Central University of Technology

Tel: +27 (0)51 507 3850

Email: lesterhu@cut.ac.za

Eastern Cape:

Branch Contact: Dan Abrahams

Company: Aurecon

Tel: +27 (0)41 503 3929

Cell: +27 (0) 81 289 1624

Email: Dan.Abraham@aurecongroup.com

Gauteng

Branch Lead: Zoe Gebhardt

Cell: +27 (0)82 3580876

Email: zoe.gebhardt@gmail.com

KwaZulu-Natal

Chairperson: Lindelani Sibiya

Company: Umgeni Water

Cell: +27 (0)82 928 1081

Email: lindelani.sibiya@umgeni.co.za

Limpopo

Chairperson: Mpho Chokolo

Company: Lepelle Northern Water

Cell: +27 (0)72 310 7576

Email: mphoc@lepelle.co.za

Mpumalanga

Chairperson: Lihle Mbatha (Acting)

Company: Inkomati-Usuthu Catchment Management Agency

Tel: +27 (0)13 753 9000

Email: mbathat@iucma.co.za

Western Cape

Chairperson: Natasia van Binsbergen

Company: AL Abbott & Associates

Tel: +27 (0)21 448 6340

Cell: +27 (0)83 326 3887

Email: natasia@alabbott.co.za

Namibia

Please contact the WISA Head Office on admin@wisa.org.za for more information

With more than 5.6 million people infected across the globe, as at the time of writing, Covid-19 has dominated the headlines for the better part of 2020. We have all been made aware of the importance of hygiene and handwashing. But turning on the tap and simply washing your hands is not a luxury afforded to all South Africans.

One of the major shortcomings the novel coronavirus outbreak has highlighted is just how far South Africa and many other African countries still have to go to ensure equitable access to water.

Don’t waste a crisis

There’s nothing like a crisis to unite people towards a common goal – Cape Town’s near miss with Day Zero is a perfect example of this. Covid-19 has highlighted just how important access to clean water and adequate sanitation is. In South Africa, we’ve seen trucks loaded with water tanks being transported to communities across the country to ensure people can wash their hands regularly in an effort to curb the spread.

Although it may not be under the best circumstances, the pandemic has forced governments to act decisively in bringing these essential services to communities.

But the concern is that once the pandemic is over and compulsive handwashing is no longer at the forefront of our minds, will those communities who have received water during this time be forgotten? Will the delivery of water stop? Or will we see our government step up and roll out more sustainable, long-term solutions?

Salga has highlighted the fact that, with three million people without access to water, the challenge is too big to be resolved

purely through the provision of water tanks and tankers. This approach is logistically difficult and expensive, costing in the region of R100 million per month and several MPs have complained that tanks in their constituencies have not been serviced or even connected.

One of the messages that emerged following Day Zero in Cape Town was the importance of suspending party politics during a crisis. The novel coronavirus pandemic offers us an opportunity to rebalance party politics with technical expertise and the needs of the country. Corruption appears to almost have become the norm for South Africa. But this is not the time to give in to the wants of politicians. Instead, we should focus on the needs of the people. Now is the time to let the technical experts guide our response as we work to rebuild a capable state. Let’s look at decentralised water treatment solutions for off-grid communities. Let’s develop attractive alternative sanitation solutions. Let’s ensure equitable water and sanitation for all. These are not luxuries – these are basic human necessities.

Thank you to our water professionals who continue to work during lockdown to provide these essential services and to ensure that our communities have access to safe water and sanitation. These are, after all, essential to protecting human life during this time.

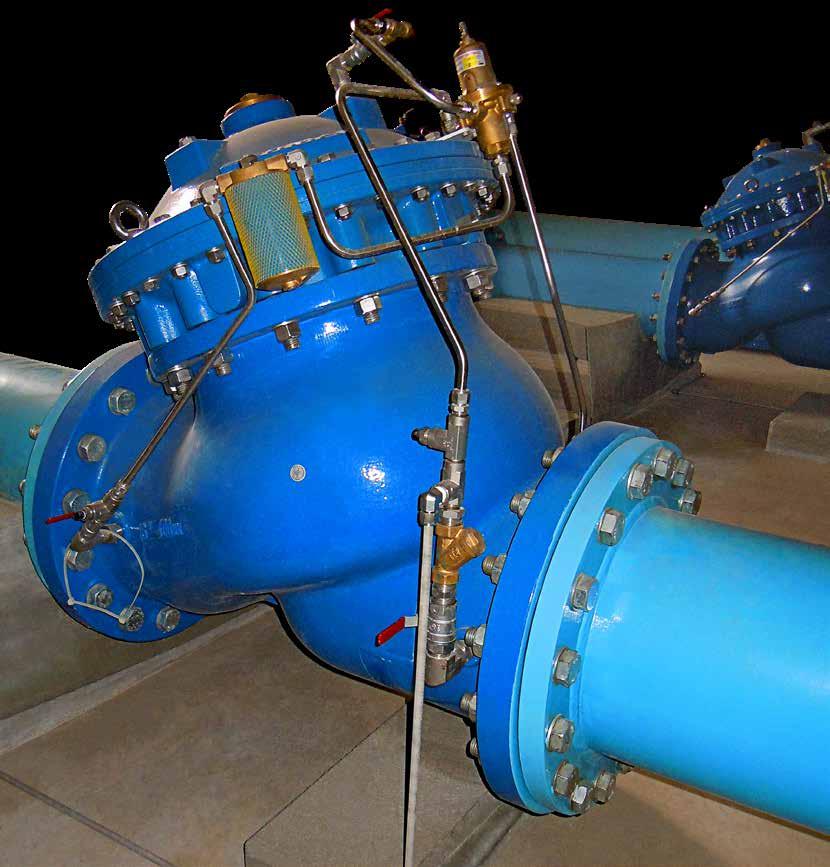

An increasing focus on environmental protection and energy savings means that water supply and distribution systems need to become more efficient and operate optimally at minimum pressures.

Single-chamber control valves are traditionally used in water supply and distribution systems due to their cost-efficiency; however, their functionality is limited in such low-pressure conditions.

To address this, Bermad has developed its 700 Sigma Series double-chamber control valves. These valves have a unique design only available in this series and are the same size as their single-chamber counterparts, explains Rowan Blomquist, CEO, Macsteel Fluid Control. Macsteel Fluid Control is the sole franchise holder for Bermad in Southern Africa.

These are also the only valves on the market that enable water system designers and owners to easily convert their single-chamber valves into doublechamber valves, and thus optimise their systems for smooth, accurate, secured,

stable, and efficient operations under low-pressure conditions.

Immediate response and regulating

In the case of low-pressure conditions in the network, a double-chamber valve with a three-way pilot can completely vent the control chamber, enabling the valve to open fully. This means that the valve is transparent in terms of head loss. In addition, the valve resistance becomes minor and the valve supplies sufficient pressure to consumers without creating a negligible pressure drop.

Fast, powerful, smooth

In Bermad’s 700 Sigma Series doublechamber valves, the diaphragm is isolated from the downstream pressure, which applies the valve opening force in singlechamber valves. When a double-chamber

valve is opened, the closing and opening forces on the seal disc neutralise each other.

To start the closing process, the upstream pressure water is diverted to the upper control chamber. Since there are no opposing opening forces, the diaphragm assembly and shaft move the seal disc quickly, in a linear direction and with high force, towards the seat.

When the valve is almost closed and head loss is starting to build up, the downstream pressure starts to diminish. The balance of forces on the seal disc changes and the upstream pressure causes the closing process to slow down. As a result, the end of the closing process is smooth and soft. This built-in feature is essential to modern water supply and distribution systems, as it protects them against potentially damaging scenarios such as water hammer due to valve closure.

The concept of CLAM networks has become more common and is now widely used in water utilities. This has led to increasing awareness about the slamming of pressure-reducing valves (PRVs) and is exactly where non-slam, double-chamber valves offer a vital advantage.

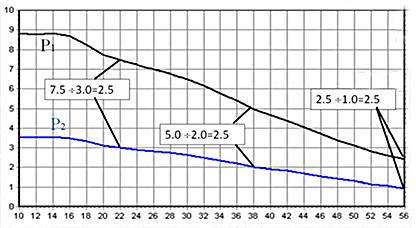

Double- vs single-chamber valve – closing speed

Opening Rate %

Double-chambered

Pressure (bar)

Proportional pressure reducing with the Bermad 720-PD Sigma

Quick reminder

Time (sec.)

macsteel.co.za

WASTEWATER NETWORKS:

MAXIMISED RELIABILITY

EASY OPERATION REDUCED OVERFLOW RISK

GRUNDFOS iSOLUTIONS A SMART SOLUTION FOR YOU

INTELLIGENT SOLUTIONS FOR WASTEWATER NETWORKS

Grundfos iSOLUTIONS can reduce the risk of clogging and overflow in your wastewater network. The solution monitors actual flow in sewers and sends a warning in advance of high water with an indication of where the pumping system could fail. This empowers you to do maintenance before a potential overflow situation occurs, saving labour, energy and possible extensive damages to the system and the environment.

Find out how Grundfos iSOLUTIONS can optimise your wastewater network with intelligence at www.grundfos.za

As we navigate our nation’s lockdown response to the Covid-19 pandemic, we at WISA would like to take a moment to salute the entire water sector.

We have been encouraged by the spirit of ubuntu displayed by our members. Politics and differences have been set aside and we have all worked together to ensure that all aspects of the water system are kept running smoothly. This period has not been easy for any of us, but you have stepped up to the plate and continued to provide an excellent essential service.

The race is not yet over. The strains on our economy and our families are not lessening. Businesses are failing and many people face food insecurity. But thanks to you, water has been the least of our worries. Those of us with access to running water in or near to our homes have had the assurance that the water that comes out of our taps is clean and safe to drink. You have also provided safe, clean water to many

I am proud of the way the WISA office team members have shown their commitment to the sector by performing their work with the same commitment to excellence they show each day when we are all sitting under one roof

thousands of people under the most trying of conditions. And your work is not over. As the government steps up the provision of water to schools across the country, you will be there playing your part.

I am proud of the way the WISA office team members have shown their commitment to the sector by performing their work with the same commitment to excellence they show

Dr Lester Goldman, CEO, WISA

each day when we are all sitting under one roof. We have remained in touch with our stakeholders throughout the lockdown and meet virtually to discuss concerns and plan for the times ahead.

As you know, the pandemic has meant that #WISA2020 has had to be postponed to 6 to 9 December 2020. We have been encouraged by the positive feedback we have received from speakers and delegates, and are pleased to say that registrations are continuing to grow. We are confident that the meeting will be a success and are exploring new and innovative ways of meeting that will allow for top quality virtual sessions if necessary.

We would like to encourage our members and the general public even further to share some of your stories of life and work in the water sector at this time. Please let us know if you have a story to tell, and we will be in contact. Email us on admin@wisa.org.za.

Stay strong. Stay safe.

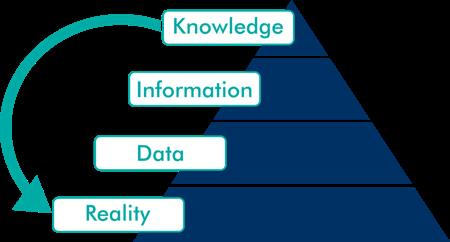

The world is in turmoil due to the combined impacts of the Covid-19 pandemic and the lockdown-induced economic crisis on people’s health and quality of life.

By Achim Wurster

The existing challenges regarding water governance and funding, together with their impacts on water security and drought resilience in the face of climate change, remain. These will be exacerbated by even greater funding challenges in future. How can the water sector address these challenges to ensure the best possible positive outcome for society?

We regularly see well-meaning attempts to address a problem causing unintended, negative side effects. Examples are present across all spheres of life:

• Covid-19: Lockdowns reduce the rate of spread of the disease. Lockdowns also destroy people’s ability to sustain themselves, as a lack of income and confinement result in overall poorer health, making people more susceptible to disease and potentially leading to higher mortality rates. Lockdowns also interrupt the supply chains required to keep essential services such as water supply operational.

• General health: The excessive use of antibiotics accelerates antibiotic resistance, which is now one of the biggest threats to global health. Healthcare errors and adverse reactions between medicines are now a leading

cause of death in developed nations.

• Economy: Governments implement excessively strict laws to regulate economic activity. As a result, the competitiveness of the economy reduces, businesses close and jobs are lost, increasing dependence on imports and, in the long term, lowering the quality of life for citizens as prices rise and income drops. To counter that, prices are fixed but, as input costs rise, products are no longer financially viable and shelves run empty.

• Environment: The removal or reintroduction of apex predators or significant grazing herds from/to ecosystems results in fundamental changes to those ecosystems. Wolves being reintroduced into the Yellowstone National Park is one well known example, while a lack of grazing and overgrazing by ruminant herds both lead to degraded grasslands.

• Water: The provision of free water to poor communities results in standpipes being left to run continuously, as there is no incentive for individuals to close the tap after use, depleting the resource and reducing the reliability of supply. In suburbs, people are told to reduce municipal water consumption; yet in many municipalities, it is illegal to use rainwater or borehole water in the home, as charges for wastewater treatment are linked to the municipal water meter reading. Building more dams in upper catchments resolves a water shortage in the upper catchment but results in shortages lower down in the catchment.

for problem-solving

A do-nothing approach is also not viable. While it prevents unintended negative consequences, the primary problem is not mitigated. We must recognise that there are almost always multiple factors at play and the optimal solution balances mitigating the problem against

any subsequent negative consequences.

In addressing problems, I have found the following principles useful:

• Every challenge is also an opportunity to innovate.

• Approach challenges like chess or Go: every decision you make has immediate and long-term strategic implications. The more options you evaluate and the further ahead you think, the better your decision is likely to be. But this must be balanced against taking too long to decide.

• There is usually no single ideal solution. All systems are interlinked, and everything is a compromise. The goal is to optimise the solution for the most positive result, using limited available resources.

• It helps to get inputs from specialists covering a wide range of disciplines, as well as from people on the ground that have experience or are living with the problem or are impacted by the proposed solution. The only way to get effective input is to have open discussions, listen to and understand other’s inputs. While doing so, we have to set aside our preconceived ideas, our egos, our various dogma and especially the outcomes that we want to see.

• We must consider all the relevant data. Since we can only manage what we measure, we need to identify and fill data

Achim Wurster, chair, WISA

gaps. We also need to recognise that we must measure not only the problem we want to address but also the impacts and side effects. Only then, can we develop balanced and optimised solutions that are supported by data.

• Then, we have to work together as a team, pulling in the same direction, using all available tools in our toolbox to achieve a win-win outcome for everyone.

The challenges the water sector faces are numerous and largely complex. To ensure the best outcome for society, we need to constantly improve our technical, problemsolving and complex system management skills. This will ensure that the water sector is effective and efficient at addressing the challenges we face. To borrow from the WISA 2020 Conference theme, this once again requires #AllHandsOnDeck.

Quantity and quality. These are the cornerstones of any definition of water security: a reliable quantity and quality of water must always be available for all sectors of the country for it to be considered ‘water secure’.

By Niel Ramsay Louw, Raeesa Bhikhoo and Ashton Busani Mpofu*

For anyone who lived under the constant threat of a ‘Day Zero’ in Cape Town, or in the many other parts of South Africa that suffered equally terrible fates due to the severe 2015/16 El niño drought, it is no secret that the country’s ability to provide a reliable quantity of water and, by extension, water security has come under threat in recent years.

In February 2020, the government declared yet another national state of disaster due to recurrent droughts in multiple parts of the country, particularly the Eastern, Northern and Western Cape provinces. This coincided with nationwide power cuts as Eskom’s generation capacity dwindled. The impact of water security on the South African economy is continuously exacerbated by the recurrent energy shortages. Water and energy security are integrally linked to the country’s sustainable economy growth.

In 2019, the World Economic Forum identified the country’s water crisis as the second highest risk for doing business, further contributing to reduced levels of future investment in the economy. The recent droughts have already taken a toll on the key economic sectors of the economy such as manufacturing and agricultural, as their annualised growth rates dwindled in the last quarter of 2019 by 1.8% and 7.6% respectively (Stats SA, 2020). This was severe on the agricultural sector,

as it is the largest water user nationally, with a 62% share. The economy has been further weakened by the global Covid-19 pandemic. Water security stands out as an unprecedented important resource to stop the contraction caused by the pandemic.

South Africa’s water supply

Multiple factors have contributed to the lack of reliable water quantity in some parts of the country in recent years. Most notable is an increasing water demand due to population growth and the increase in economic activity rapidly surpassing water supply.

The country’s water supply is affected by climatic variations, saturation of water-supplementing opportunities, massive water losses due to ageing and deteriorating reticulation systems, and a lack of investment. Population and economic growth projections show that South Africa could have a 17% gap between supply and demand by 2030.

The National Water and Sanitation Master Plan: Vol 2 (2018) specifies that groundwater, wastewater reuse and desalination should increasingly contribute to the national water supply mix. But sadly, due to cost and energy inefficiencies, the potential potable panacea of technologies such as desalination is still many years away and cannot yet be considered a viable solution to the problem.

So too has the reliable assurance of raw water quality been threatened in

past years, as pollution in the vital river ways, dams and wetlands of the country has spread seemingly unmitigated. The ability to adequately treat this polluted water has waned in many areas across the country and will require investment in advanced treatment technologies. Simply stated, it is apparent that there is a substantial battle ahead of the country in ensuring a reliable quantity and quality of water – one of the most valuable resources for any country’s sustainable economic development.

The role of YWPs

However, there is one resource – often overlooked, yet equally valuable – that South Africa has no shortage of in terms of both quantity and quality: its citizens, especially the youth (ages 18 to 35 years), which forms a third of the population (Stats SA, 2019). The most affected population groups are women and the youth (Unesco, 2017). Every step towards a solution is fundamentally derived from understanding the problem. To solve our water woes, any viable solution must involve young citizens and would need broad public support – notwithstanding the fact that human influence has significantly contributed to our water crisis.

The lack of public acceptance and support of various water and sanitation solutions and/or technologies designed to improve access to water and sanitation such as dry sanitation technologies has been a major

drawback to their full utilisation. Cases of vandalism and theft of water and sanitation infrastructure cost the country billions of rand and place significant strain on the already limited budget. Municipalities struggle to normalise reduced water use among most of the population largely due to stubborn perceptions that there is ample water supply.

The implementation of water reuse is largely affected by public perception, known as the ‘yuck factor’. These perceptions and wasteful tendencies become more set as people age and are likely to be taught to the future custodians. Raising public awareness on water conservation at all levels of society to cope with its scarcity and ensure sustainability is a vital and practical approach that must precede every other solution. In 2018, the City of Cape Town succeeded in reducing its daily water usage by more than half, through public campaigns that resulted in conservative consumption by its water users.

YWPs can be instrumental in transforming societies and in addressing their own challenges, such as a lack of access to water and sanitation, unemployment and poverty. Their involvement creates a deeper, active sense of ownership, builds trust, and contributes to sustaining solutions and social capital in the community.

Furthermore, YWPs can play an active role in helping communities to learn about water security, activate their water stewardship and global citizenship. They possess youthful energy and a unique potential of connecting with their peers – the future citizens. Creating awareness among today’s youth on water conservation

and the concept of integrated water resources management will be an investment towards a water-secure future that will enhance sustainable economic development.

Today’s youth is more technologically acquainted than any previous generation and can play an active role in the transition of the South African water sector to the Fourth Industrial Revolution (4IR), which promises to revolutionise water sectors across the world. They can bridge the knowledge gap in innovation and education to build a culture of water resilience at all levels of society.

There are many methods, including: employing blockchain-based technology to improve water resources management, using the internet of things and artificial intelligence to effectively and efficiently operate and manage water and wastewater treatment utilities, creating smart cities, or making improvements in advanced materials and energy consumption that will revolutionise the desalination and air-to-water markets.

Youth empowerment and engagement as equal partners in inclusive sustainable development can fundamentally improve South African societies. However, the full realisation of an inclusive and sustainable societal development approach that involves the youth requires the provision of an enabling environment that they can thrive in.

We must do away with our notion of treating YWPs as inexperienced and immature individuals whose future we

can decide without their involvement. It is our role as a country to create an enabling environment where their voices will not only be heard but where they will be afforded an active, integral role to shape a water-secure South Africa.

In recognition of this need, WISA, under the inclusive conference theme #AllHandsOnDeck, has afforded its YWP empowerment platform an opportunity in the upcoming conference to convene and discuss the country’s water issues. This YWP forum will provide a platform for YWPs across the world to discuss and bring about innovative solutions that will feature in WISA’s position paper.

It is apparent that there is still great work ahead of the South African water sector in ensuring water security for economic development. However, as the ones who will not only inherit a possibly water-insecure future, but who will also be tasked with managing and mitigating it, it is critical that YWPs be included and allowed to play an active role in improving the country’s water security.

*The authors are all members of the YWP-ZA National Committee. NielRamsayLouwistheGautenglead, Raeesa Bhikhoo is the North West lead,andAshtonBusaniMpofu is the national lead.

Covid-19 has highlighted the serious water challenges facing many African nations. Despite frequent handwashing being the most common advice for combating the virus, many do not have access to clean water.

Free water to beat back Covid-19

Governments failing on SDG 6

A new Afrobarometer analysis shows that there has been little progress in recent years towards Sustainable Development Goal (SDG) 6: ensure availability and sustainable management of water and sanitation for all.

In 20 out of 34 countries, majorities say their government is doing a poor job of providing water and sanitation services.

Water tankers bring water

One in five Africans who tried to obtain utility services from government during the previous year report they had to pay a bribe.

On average, more than half of Africans have to leave their compounds to access water, and only 25% have access to sewage infrastructure – a particular concern considering the importance of proper hygiene for preventing the spread of coronavirus and other infectious diseases.

The governor of Angola’s capital, Luanda, has promised the delivery of water tankers to communities.

Governor Sérgio Rescova guaranteed this during a recent visit to municipalities where he assessed the provision of free water, within the framework of the contingency plan to contain the Covid-19 pandemic.

He stated that, in partnership with the Provincial Water Company of Luanda, the provincial executive will make efforts to continue to assist the population and increase distribution in areas of where access is difficult.

As regular handwashing is a key tool in combating Covid-19, the UN and its partners are taking steps to ensure people living in informal settlements in Kenya have access to running water.

UN-Habitat said the impacts of the novel coronavirus disease could be considerably higher on the urban poor living in slums, where overcrowding also makes it difficult to follow other recommended measures such as social distancing and self-isolation.

A panel of experts from UN Human Rights Council added that it is essential for people in poverty to receive free water cost for the duration, and that public and private service providers must be enforced to comply with these fundamental measures.

Currently, a coalition of UN agencies under the banner of UN-Water is working with national and local governments, as well as civil society organisations, women, youth groups and community leaders. They are supporting a UNHabitat-led global network of smallscale water and sanitation service providers, utilities and authorities.

Word from around Africa – including the latest industry, project and development news.

Word from around Africa – including the latest industry, project and development news.

Award-winning Covid-19 project

The Integrated Urban Water and Sanitation Project for Mzimba Town, helping to curb the spread of Covid-19 in Malawi, has won the prestigious Prince Talal International Prize for Human Development.

The project is rapidly expanding access to water and sanitation to communities, while promoting good hygiene practices

such as handwashing with soap. It has increased the community’s access to potable water from 65% to 95%, raised access to improved sanitation from 45% to 97%, and created around 1 000 jobs.

Components of the project, including a community-led ‘Total Sanitation’ initiative, have helped to reduce diarrhoeal cases from 35% to 3%.

Some 10 potable water kiosks were established in nearby rural villages,

Response to Covid-19, floods and drought

Somalia has received a US$137.5 million (R2.4 billion) International Development Association (IDA) grant to respond to and recover from multiple, ongoing, and overlapping crises.

With repeated cycles of flooding and drought over many years, swarms of desert locusts threatening food security, as well as the Covid-19 pandemic, Somalia is in the grip of a climate and public health emergency.

The Somalia Crisis Response Project (SCRP) will provide immediate support to the areas hardest hit by these crises by supporting the recovery of livelihoods and infrastructure in flood- and droughtaffected areas, and will also strengthen the government’s systems and capacity

for disaster preparedness. The SCRP’s immediate response will benefit up to 1.7 million Somalis – particularly the most vulnerable populations, farming communities, internally displaced peoples, rural and urban communities, and host communities with a strong focus on female-headed households –affected by locusts and flooding.

In addressing medium-term flood recovery, the project will rehabilitate water and sanitation systems, broken or non-functioning flood control systems, health facilities, bridges, and smaller roads. Responding to the government’s urgent request for additional financing, the SCRP also includes a $20.5 million (R368 million) emergency investment for Covid-19 response.

helping to curb attacks on women trekking for water, often at night. Primary school sanitation facilities, including secured toilets, were also constructed.

The prize money of US$200 000 (R3.6 million) will go to a project implemented by government agencies, public institutions or social businesses approved by the Mzimba Town scheme.

Unsafe water raises Covid-19 risks

Long before the novel coronavirus pandemic, much of Zimbabwe suffered a severe water and sanitation crisis.

Over the last three decades, Zimbabwe has experienced a gradual decline in access to clean and safe water. From 2000 to 2017, the percentage of people with access to safe water and basic water services decreased from 72% to 64%, and basic sanitation decreased from 46% to 36%.

Over two million people in the capital city of Harare and the greater metropolitan area have no household access to safe drinking water or adequate waste and wastewater disposal services.

“Covid-19 has made an already dire and dangerous water crisis even more urgent in Zimbabwe,” said Dewa Mavhinga, director: Southern Africa at Human Rights Watch. “Failure to provide sufficient safe water would severely undermine the Zimbabwe government’s efforts to fight the virus and protect people’s lives.”

In Mutare, the court has ordered the city council to provide regular supply of potable water to its residents during the Covid-19 lockdown period, following an appeal by residents.

New research suggests that the SARS-CoV-2 virus can be tracked in wastewater where it may provide an early warning of the spread of Covid-19.

According to current knowledge, the SARS-CoV-2 virus, which causes Covid-19, is shed in stools. Sewage research being conducted by the Dutch KWR Water Research Institute suggests that studying wastewater may serve as an early-warning system, signalling the appearance or the return of the novel coronavirus.

The team at KWR refers to sewage as the ‘mirror of society’ because it can provide a great deal of information about the population.

Many countries, including the Netherlands, are collecting samples from their sewer networks to detect hereditary material of the virus causing Covid-19 in wastewater at treatment plants. In doing so, the entire city can be screened with one sample.

Dutch project

A study conducted by the KWR laboratory using sewage samples from seven cities and an airport in the Netherlands was able to detect SARS-CoV-2 in sewage, even when the Covid-19 prevalence is low. This indicates that sewage surveillance could be a sensitive tool to monitor the circulation of the virus in the population.

Sewage research can, for example, help determine how much Covid-19 occurs in the population and whether it is increasing or decreasing.

The initial study sought to establish a reproducible method for concentrating the virus from sewage and the isolation of RNA from the concentrate. While KWR has not yet been able to monitor the concentration of the SARS-CoV-2 M protein, this should be possible and future studies aim to improve the detection method for SARS-CoV-2, mainly for reasons of quantification.

This project aims for further screening on SARS-CoV-2 presence in sewage wastewater within a selection of large communal wastewater treatment plants in the Netherlands, in order to provide:

• trends of SARS-CoV-2 spread of the 2020 pandemic in the Netherlands

• supportive information for evaluation of quarantine/mitigation measures

• an early warning system for when Covid-19 may be on the rise again in the Netherlands

• a realistic estimate of the percentage of mild Covid-19 presence.

KWR also hopes to study other aspects, such as the density at which virus particles remain active in sewage at certain temperatures and residence times. Although studies with related viruses previously indicated that this is unlikely, this needs similar verification for Covid-19.

A new study conducted by Arizona State University researchers Rolf Halden and Olga Hart analyses what can and cannot be measured when tracking SARS-CoV-2 in wastewater. According to Halden, the population-wide screening of wastewater

makes the task of testing for the virus far more manageable, as exclusive reliance on testing of individuals is too slow, cost-prohibitive and, in most places, impractical given current testing capacity.

In the current study, researchers modelled wastewater samples in Tempe, Arizona, for the presence of the SARS-CoV-2 virus. Their work draws on computational analysis and modelling, and projections of past, present and future epidemic hotspots.

By pinpointing viral hotspots, researchers will be able to better direct resources to protect vulnerable populations through social distancing measures, while easing restrictions in virus-free regions.

A research team from the University of Michigan and Stanford University is also exploring the tracking of Covid-19 through wastewater. One of the key areas they’re exploring is whether SARS-CoV-2 can be detected in a community’s wastewater before it is known to be circulating there. The team believes the research could provide a clearer picture of how broadly the disease is spreading because it could pick up evidence of upticks in more mild cases or those that bring no symptoms at all.

Drinking water safe

Currently, there is no evidence that water is a transmission route for the SARS-CoV-2 virus. While RNA fragments of the virus have been detected in sewage water, they have a low probability of being infectious particles.

With current treatment methods, there is no evidence that Covid-19 could pose a risk via drinking water.

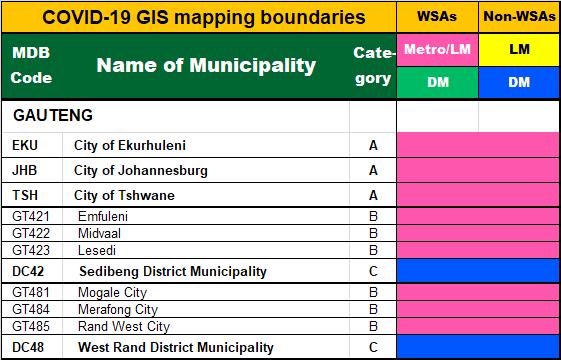

In the fight against the Covid-19 pandemic, a South African water services specialist has developed a GIS tool to better facilitate communication between tiers of government.

Professional water services consultant Derek Hazelton explains that the purpose of the simple, userfriendly Covid-19 GIS mapping and communications enabling tool is to allow for easier communication, in any direction, between national departments and all tiers of government, as they respond to the Covid-19 pandemic, and plan their interventions to fight and overcome it.

Facilitating closer cooperation Hazelton argues that close cooperation between National Treasury, CoGTA, the Department of Health (DoH), Department of Human Settlements, Water and Sanitation, Salga, health services at every level, water boards, CSIR, provincial and local government is essential in addressing the crisis.

“An essential piece in the jigsaw of cooperation is outstanding communication and transparency,”

says Hazelton. He believes that the DoH leads in achieving transparency but does face weaknesses in broad cooperation and formal communication. “Otherwise, communication, both formal and informal, and transparency are seriously lacking, especially as to how the command councils function, what their challenges are, and what their successes have been,” he says.

Hazelton’s goal is therefore for the tool to be used for basic visual GIS mapping by all the provincial and district command councils, and local municipalities of South Africa, so that they have a common communication language, except, perhaps, the eight metros, which are probably already using GIS mapping.

The boundaries of South Africa’s nine provinces, eight metros, 44 district municipalities (DMs) and 205 local municipalities (LMs) have been plotted

Derek G Hazelton, Pr Eng., FWISA, founder and manager of TSE Water Services

using Google Earth Pro. Thus, the records of the Covid-19 cases and the hotspots will be visibly located in each of the 257 municipalities. Ward boundaries, the boundaries of Stat SA’s main places, sub-places and any other boundaries or names that users wish to add can be included.

Hazelton chose Google Earth as the vehicle to launch the tool because it is freely available and easy to use. This makes it an ideal communication tool for all tiers of government, but especially for poorer municipalities.

The tool has been designed to plot the location of hotspots and to receive and update data on these hotspots, from any source. It can also receive and update data on the location of Covid-19 cases, and other information such as deaths.

Hazelton also sees the tool as being useful in other areas after the pandemic. Prior to the novel coronavirus outbreak, he was at an advanced stage of assembling a small team to respond to the National Water and Sanitation Master Plan’s Call to Action.

“We planned to facilitate and coordinate the implementation of water services authority (WSA) turnaround programmes. The programmes encompass WSA capacity building, community employment creation, improved wastewater management, reduced water leakage from water systems, and the financial strengthening of WSAs.

“The implementation of the proposed mapping and communications enabling tool, apart from supporting government’s Covid-19 response efforts, will also build a useful foundation for implementing the WSA

turnaround programmes, once South Africa and the world return to a new normal,” he says.

Commenting on water supply interventions during the pandemic, Hazelton expresses concern that interventions appear to be limited to the installation of water tanks, which are subsequently being filled by water tankers. Tankering, he says, “is costly and therefore not sustainable”.

He draws on his experiences as the Water Supply Task Force Coordinator for the National Consultative Forum on Drought in 1992/93. During the 1992/93 drought, efforts quickly moved from tankering to refurbishing old boreholes and drilling new ones. Today, with many more households having piped water, fixing visible leaks on distribution systems and from fixtures on private property also needs to proceed immediately, so that downstream users, without water, receive a supply. “Fixing these leaks will create employment – another

aim of the 1992/93 Consultative Forum on Drought, which is still indispensable today. Under these circumstances, none of the 15 000 young graduates of War on Leaks programme should be without a job,” says Hazelton.

While the 1992/93 interventions were highly beneficial to all stakeholders, they did not lead to sustainable supplies, because there was no follow-up, he explains. “The same situation is likely to apply today, in 2020.

A very comprehensive follow-up in line with the National Water and Sanitation Master Plan’s Call to Action will be required to turn around the current water services crisis that already existed before Covid-19.”

KwaZulu-Natal’s WSAs, illustrating how Covid-19 cases and hotspots will be captured and displayed

Formoreinformation,contact DerekHazeltonontsewater@icon.co.za.

Water usage patterns have changed all round the world due to populations in lockdown spending more time at home.

By Dr Jo Burgess*

The morning ablution peak has shifted to late morning, and domestic water consumption has increased by 15% to 25%, while non-domestic has decreased by 30% to 50%. In Africa, this is a critical issue because there are fewer domestic customers on metered water connections than elsewhere in the world, which means that a much higher proportion of the water that water service providers are supplying is not being paid for. The result is depressed revenue at exactly the time when utilities desperately need income to extend water and sanitation services to unserved communities.

Covid-19 response challenges

Africa has issues of managing Covid-19 in communities that do not have access to running water, and do not have the ability to self-isolate. Consider the minimum requirements for a lockdown to be effective: access to safe drinking water in the home; access to adequate sanitation in the home; a source of reliable energy; access to information or communications technology; and having

a permanent source of income or savings.

If the first three requirements are not met, then almost all household members will need to make multiple daily trips to places where other people congregate, such as communal taps and communal ablution blocks (CABs). Seemingly simple steps to battle the spread of Covid-19, like regularly washing hands with soap and water, present fundamental challenges.

While facing the global issues of sourcing personal protective equipment, social distancing and operating with a scaled-back workforce, the African water industry has mobilised to assist the poorest customers, both domestic and commercial, with access to a supply of safe water. In South Africa, organisations have banded together to provide resources like multilingual advice for people using CABs. The Department of Human Settlements, Water and Sanitation has procured 41 000 water tanks and is providing them to small or rural municipalities to enable them to supply potable water to unserved communities.

Most utilities, for example in Ghana, South Africa, Malawi and Uganda, are supporting the vulnerable and are trying to remobilise their capital programmes.

Research-wise, the monitoring of genetic material from the inactive virus found in sewerage systems could provide a rapid early detection method to identify its presence in communities and lead to targeted lockdowns.

This approach, often termed wastewater-based epidemiology (WBE), has some potential advantages over case-by-case tracking, including improved throughput at the community level and tracking asymptomatic cases. This is a hot research topic right now, with universities, utilities and

Dr Jo Burgess

A WhatsApp group intended for a handful of utilities to share learnings and experiences of the Covid-19 pandemic has quickly scaled to involve over 260 organisations.

Dr Piers Clark, founder and chairman of Isle Utilities, started the chat group in March when lockdowns required utilities to respond rapidly to multiple unprecedented challenges. The group includes 41 African organisations – 21 municipalities, 17 water boards and water and sewerage companies, two water service provider associations, and a national water authority – from eight countries, with 68 individual members. To help curate the rich stream of information shared in the WhatsApp group, Clark hosts a weekly webinar on Thursdays at 08:30 and 17:30 (SAST) to accommodate global time differences.

Clark says issues on the technical side have been around the contamination and reuse of personal protective equipment, asset management and the impact of changes in demand on models for water network management. More recently, people are asking about modelling of the financial impacts on organisations and changes in the way rates are charged and collected.

“Covid-19 is affecting everyone, and if ever there was a time for collaboration, this is it. The ability to communicate between colleagues within utilities has always been quite good, but what we are seeing now is that walls between utilities have crumbled,” says Clark. To register, visit www.isleutilities.com/events or email piers.clark@isleutilities.com.

research centres in Australia, Egypt, France, Mexico, the Netherlands, South Africa, the UK, the USA and others collaborating in the race against time to develop a reliable WBE programme.

It is critical to note that these detections do not represent a culturable virus in the wastewater that would be necessary to cause infection. Separate research is being conducted to assess the presence and persistence of the severe acute respiratory syndrome coronavirus-2 (SARS-CoV-2), which causes Covid-19 disease, in wastewater and any disinfection required.

*DrJoBurgess isatechnicalconsultant atIsleUtilities.

South Africa’s ailing wastewater treatment works are becoming a significant concern for public health and safety.

By Danielle Petterson

Approximately 56% of the more than 1 150 municipal wastewater treatment works (WWTWs) in South Africa are in a poor or critical condition and in need of urgent rehabilitation as well as skilled, registered process controllers.

According to the National Water and Sanitation Master Plan (NW&SMP), approximately 44% of the country’s 962 water purification works are in a similar position, and 11% of all treatment infrastructure is completely dysfunctional.

The NW&SMP explains that the failure of some municipalities to provide reliable water and sanitation services is largely due to the lack of technical skills, institutional capacity and funding to operate, maintain and manage water and wastewater infrastructure assets.

Ayesha Laher, director, AHL Water, identifies several of the major problems she sees facing our WWTWs. The first is a lack of motivation to change the current status quo due in the absence of punitive measures in response to legislative noncompliance. Another is a lack of leadership with the necessary technical skills to implement sustainable solutions, along with insufficient operational resources. Like the NW&SMP, Laher also identifies a lack of maintenance programmes, as well as incident reporting to ensure effective asset management.

Marlene van der Merwe-Botha, director, Water Group Holdings, cautions against generalising the problems or singling out a particular problem. Each plant has its own specific risks and set of challenges that contribute to noncompliance. These can range from limited plant capacity to a lack of capital for upgrades or renewals, a lack of operational budget or human resources, ageing or non-functional assets, a lack of performance management, and inadequate or inappropriate design and technology.

Van der Merwe-Botha does, however, concur that the one problem underlying most of the challenges at WWTWs can be reduced to skill, experience, competency and caring.

While Van der Merwe-Botha believes that appropriate technologies are predominantly employed at most WWTWs, she argues that the skills do not always complement the technology and, subsequently, the technology underperforms against its initial design expectations. In cases where inappropriate technologies are used, this is usually due to

project managers and municipal officials lacking the know-how to specify and/or implement the appropriate technology.

She calls for a back-to-basics approach. “Many plants are just battling with the basics, and telemetry, Scada and other automation technologies are often defunct or unused – and not of direct benefit to the daily operations. Having observed this, we note that automation is well applied at capacitated municipalities with knowledgeable and well-trained technical staff, to the benefit of operational control and meeting compliance targets.”

Laher also sees room for automation to enhance water and wastewater management, in particular the operational control of collection and supply systems. This can allow for quicker reaction problems and improved performance. However, she cautions that while new technologies must be embraced, one must ensure the technology is appropriate for local conditions.

One way to address some of these challenges is through focused skills development. “We need academic and theoretical knowledge to be translated into practical know-how. Universities and colleges need to bridge the gap from tertiary level into the workplace and the workplace needs to employ experienced, capable plant managers to mentor, guide and teach process controllers on the job,” says Van der Merwe-Botha.

She stresses that professional wastewater practitioners need to be appointed on merit, irrespective of other criteria, and calls for young professionals and students to be brought back into learnerships under capable mentors.

Laher adds that while there are many skilled process controllers in South Africa, they need to be capacitated by management to do their work. “We need skills development of senior management including project management units, technical directors, procurement and councillors so they can make the right decisions and understand the consequences of their inaction.”

Upon launching the NW&SMP, Minister of Human Settlements, Water and Sanitation (DHSWS) Lindiwe Sisulu announced that her department would revitalise the Blue, Green and No Drop monitoring programmes. The master plan states, “To date, one of the more successful and informative regulatory programmes

was the Blue Drop and Green Drop certification.” Unfortunately, no Green Drop reports have been released since 2014, leaving a significant gap in the industry. Van der Merwe-Botha reiterates that this gap encompasses many areas, which include the availability of credible data, self-motivation and self-regulation by municipalities to perform and comply, secondary industries and economies such as laboratory analysis, research and application of disruptive technologies, and collaboration and sharing between government departments with shared wastewater services quality objectives.

“Since Green Drop certification was suspended, the vast majority of municipalities have failed to conduct and submit monthly compliance data to the DHSWS as per section 62 of the Water Services Act (No. 108 of 1997),” says Laher. The Green Drop system was replaced by the IRIS system for submission of compliance data to the DHSWS. However, the IRIS system only reports on effluent quality compliance data submitted and does not allow for trend analysis over time.

Laher and Van der Merwe-Botha both agree that the Green Drop (as well as the Blue Drop) programme should be reintroduced. The award-winning Green Drop programme – which provides legislative and best practice guidelines for the operations and management of WWTWs – received international praise.

Citing the Green Drop results from 2009 to 2014, Van der Merwe-Botha says, “Never had we (South Africa) seen such a drastic influx and improvement in know-how, compliance, caring, budget, skills and positive attitudes flooding a single sector as during this time. The positivity, energy and drive for progressive improvement by municipalities made this one of the most exciting and progressive periods in the history of South African water and wastewater and the people serving in this industry.”

According to Laher, this can largely be attributed to the incentive-based approach of the Green Drop, which appealed to a sense of pride among municipal officials, leading to a top-down, proactive approach to ensure Green Drop compliance – which translates directly into efficient WWTWs and good-quality effluent.

The programme stimulated a healthy competitive environment in which municipalities not only competed for the best scores, but also assisted and supported each other to achieve higher

scores through knowledge-sharing and peer exchange.

“The secret of the ‘Drops’ lies in its design and implementation, which ensured nationwide buy-in and desire to participate. It comprises a well-designed audit scorecard, implemented by highly competent and trained inspectors through a process of consultative auditing, thereby allowing inspectors to guide and transfer knowledge to municipal teams during the audit process,” says Van der MerweBotha, adding, “We cannot afford not to reintroduce the Green Drop.”

Ultimately, if the problems at many of the country’s WWTWs are not addressed, it is the health of the public and environment that will suffer. The cost of water and health will likely escalate, and negative impacts will be felt by the economy.

“Our water treatment plants are not designed to treat wastewater. If we do not repair our WWTWs, our WTWs will fail and the health of our citizens will be negatively

impacted, especially vulnerable groups,” stresses Laher.

Van der Merwe-Botha concludes: “If we carry on as is, and the regulators continue to delay their regulatory duties (such as reintroducing the Green Drop), we will not be having debates about whether South Africa is facing a crisis. Instead, we will be living that crisis in the same way that we live with Covid-19 now.”

Concrete is the structural material of choice for pipes, bunds and reservoirs in wastewater treatment plants. The addition of HDPE liners can protect concrete, ensuring greater longevity.

Concrete, a versatile and age-old material, presents one serious and costly drawback: it is susceptible to degradation in modern, aggressive environments.

Concrete corrosion due to chemical attack can significantly reduce the lifespan of unprotected concrete structures, such as pipes used in wastewater treatment works. This often necessitates disruptive and costly replacement operations for municipalities and facility operators.

Sophisticated cast-in corrosion protection liners (CPL), such as those manufactured by AKS Lining Systems, effectively prolong the lifespan of new pipes, bund areas and reservoirs, dramatically reducing the lifetime cost of water treatment infrastructure.

AKS Lining Systems has taken the cast-in liner concept and perfected its design through the development of Anchor Knob Sheet (AKS™) technology. The concept surpasses all concrete protection alternatives both in cost saving and performance.

AKS CPL, manufactured from HDPE, was designed specifically for the conveyance of sewage and is supplied in wide sheets, tubes or rolls to suit the project requirements. In the case of concrete piping, the concrete pipe manufacturer

integrates the tube with the concrete during the casting process. The unique anchors are embedded into the concrete, so that the tube forms an integral part throughout the length of pipe.

In this way, AKS CPL enhances the robust qualities of HDPE linings through the close matrix of anchors. These anchors permanently secure the sheeting to the structure.

AKS CPL is unique in its design. A total of 1 230 anchors per square metre ensure the lining is locked firmly into the concrete structure. Supplied in thicknesses from 1.65 mm up to 10 mm, the liner is used in a diverse range of chemically aggressive applications such as mining, water treatment and sewage conveyance.

Once anchored firmly into the structure, AKS CPL offers a chemically inert, flexible skin. The liner offers high abrasion resistance, is acid-proof and offers long life expectancy in the harshest environments. Its superior crack-bridging ability allows for movement in the concrete structure, without delamination.

The use of HDPE AKS CPL in conventional concrete pipes enables these pipes to be used in applications where only GRP, PVC or solid wall HDPE pipes would have been

considered previously.

An AKS-lined concrete pipe offers numerous benefits: chemical resistance to nearly all aggressive environments; no limit to the size or diameter of the pipe; the smooth HDPE internal surface offers far higher friction values for additional carrying capacity; high abrasion resistance ensures minimal damage or wear and tear; and the overall cost of large-diameter AKSlined pipe is greatly reduced compared to alternatives.

AKS CPL is manufactured at AKS Lining Systems’ large production plant in Brackenfell, Cape Town. A yard with ample storage provides the shortest possible lead times to customers.

For further information, email info@aks.co.za or call +27 (0)21 983 2700. AKS invites its customers to a plant visit to familiarise themselves with the integrity and quality standards at work at the company.

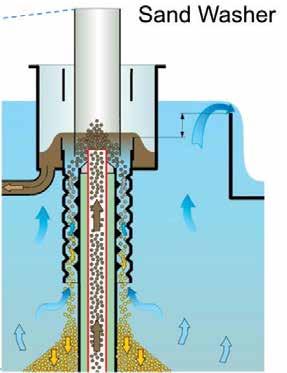

As Southern Africa faces a growing wastewater crisis, engineers and representatives from KSB Group companies have committed to finding workable solutions.

Governments and municipalities across Africa are grappling with ways of dealing with growing wastewater requirements, and it has become increasingly evident that a onesize-fits-all approach does not work. Differing conditions – such as sand content, water quality and existing infrastructure – play a large role in the specification of future pumping infrastructure requirements. This has prompted the KSB Group to play a more active role in assisting wastewater entities and to lend its technical expertise through its extensive network of regional companies, branches and dealers that are well established in every country in sub-Saharan Africa.

Strategic training

Preparations to support the intensive new wastewater drive got under way at the regional office of KSB Pumps and Valves in Johannesburg recently, when global expert Ben Harrison – regional application manager: MEAI KSB Global Corporate Water Department, from Germany Halle (Saale) – led a two-day workshop aimed at sharing countryspecific information and devising ways of working with authorities to provide wastewater solutions.

“As one of the largest pump companies in the world and a major role player in Africa, we are listening to the needs of the market and taking info from our representatives in each region to our technical department to find pumping solutions for each district,” he says.

“We want to bring international standards to local solutions and provide the kind of wastewater solutions that are affordable, durable and appropriate for the kind of maintenance and support available in that particular area.”

KSB is well entrenched as a main supplier of potable water and other

fluid transfer solutions to governments and utilities in many African countries. It therefore makes sense to expand support and solutions for wastewater applications.

“KSB has the support and expertise to support plans to deal with future wastewater requirements. We understand that expectations don’t differ by country and we assure customers that the knowledge required for engineers in KSB is the same in every country,” says Harrison.

KSB sales engineers are able to discuss requirements on equal terms with engineering teams and can call upon local and international expertise to find the right pumping solutions for the right job.

Now that the company has assembled its internal staff and put in simplified structures to support wastewater pumps in each region, it can be expected that it will hit the ground running and make significant inroads in a market that currently does not enjoy the attention of other large pump manufacturers. In South Africa, KSB also has the advantage of being a Level 1 BBBEE contributor.

The Kouga Local Municipality is proactively providing infrastructure for future economic growth in the area. In line with this, the St Francis Bay Wastewater Treatment Works (WWTW) has been upgraded from 750 m3/day up to 2 000 m3/day. The upgrade also ensures that the effluent discharged from the WWTW complies with relevant standards.

The plant serves the growing communities of St Francis Bay, Cape St Francis and Sea Vista, and will cater for future development in the area. It was originally built by Prentec in 1995 and has undergone two subsequent capacity upgrades of 250 m3/day, each in 2000 and 2007.

The upgrade

Prentec was appointed as the main contractor on the upgrade project and SRK Consulting as the consulting engineer. The plant upgrade included the refurbishment of the existing works, covering civils, mechanical and electrical.

Local labour was used as much as possible, with a total of 44 639 worker hours completed by local labour on the project. In addition, local subcontractors and suppliers for services and materials

PROJECT TEAM

Client: Kouga Local Municipality

Main contractor: Prentec

Consulting engineer: SRK Consulting

SUBCONTRACTORS

Civil earthworks: SP Excel

Electrical installations: Servelec

were sourced and employed. The project took place over two years – from February 2018 to February 2020. In order to manage the client’s budget, this spanned three financial year periods. “The project was split into three portions, each to be completed within the respective financial period. Portion 1 was the refurbishment of the existing works; Portion 2 was the construction and commissioning of the new plant equipment; Portion 3 was the construction of the wetland area for the plant discharge, including fencing and landscaping of the area,” explains Duncan Klinkert, project manager, Prentec.

The hydraulic loading on the treatment works is extremely seasonal. The town has a permanent population of approximately 10% of the peak holiday population, and therefore experiences peak loading over the Christmas holiday in December and January, and over the Easter holiday in April.

Tiaan Claassen, principal engineering technologist, SRK Consulting, says that various technologies were investigated for the upgrade, but it was concluded that it would be in the best interest of municipality to use the cost-effective technology currently used – namely sequential batch reactors (SBRs), which may be classified as extended aeration activated sludge technology. This technology was also considered favourable, as the plant operators were already accustomed to the existing plant’s operational processes and procedure.

The Prentec SBR process treatment is based on total oxidation by the extended

The capacity of the newly upgraded St Francis Bay Wastewater Treatment Works has been significantly increased, allowing for future growth and ensuring effluent compliance.

aeration principle of the activated sludge process and may be described as a controlled biological process where the aeration of the mixed liquor, as well as the settling and decanting of the treated effluent take place in a single reactor.

This technology offers many advantages, including: being more environmentally friendly; reduced capital costs; improved plant reliability, performance and operational control; reduced sludge volumes; and reduced labour and maintenance needs. Batch plants are also constructed in a modular fashion, allowing for easy and costeffective plant extensions.

The Kouga Local Municipality has been operating the plant since its inception in 1995, and the original plant operator is still working at the plant. The upgrade employs the same principles and technology that enable an ease of operation by the client.

The addition of new technology and automation systems through a computerised Scada system and mechanically operated inlet works screens allows for a larger plant to be more readily controlled. Prentec provided training to five plant operators, including theoretical and practical training.

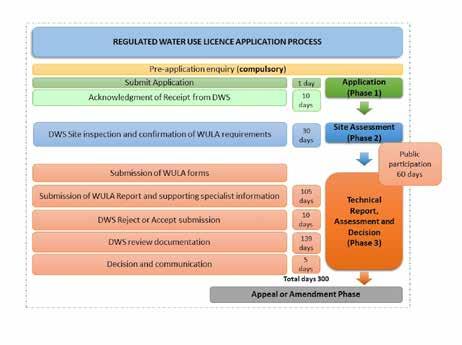

The stricter regulation of water use has become both a social and environmental imperative for South Africa, and the country is gradually coming to grips with what this means in practical terms – with the processing of water use licence (WUL) applications showing both progress and challenges. By Jacky Burke*

Following the governmentissued regulations on WUL applications in 2017, one of the initiatives by the Department of Human Settlements, Water and Sanitation (DHSWS) to streamline the WUL application process has been the department’s launch of its Electronic Water Use Licence Application and Authorisation System (Ewulaas), which has certainly been an improvement over the previous paperbased system.

There is still some way to go, however, in establishing a smooth and wellresourced system for managing the scale of WUL applications, and stakeholders are, at this stage, trying to collaborate as closely as possible to ensure that application timeframes are met.

One of the most important contributions of the 2017 regulations was to put in

place a clear process and timeframe that stakeholders could understand and to which parties (both the applicant as well as the authorities) could be held accountable. The aim is to complete a WUL application in a structured 300-day process, which is spilt between 146 days for applicant processes and 154 days for the DHSWS’s review and decision process.

The capacity constraints are reflected in various delays still evident in the system, such as the lags that may occur in the issuing of the department’s letter of acceptance of an application. This problem results, for instance, in time being lost between the applicant’s allowed time and the department’s allowed time. Specialists in the DHSWS – based mainly at national level – are also under extreme pressure from the sheer number of applications coming from regions, and this can often create a bottleneck in the process.

The Ewulaas system has streamlined efforts considerably, providing a userfriendly platform to walk applicants through the submission process and allow for the digital uploading of all necessary documents. There remain various technical challenges from time to time, however, where the system’s functionality is not always optimal – creating difficulties for both the department’s officials and the WUL applicants.

What is apparent at this stage is that the process still requires vigilance and careful monitoring to keep WUL applications on track. Applicants and their consultants need to establish and maintain strong communication channels with the relevant DHSWS officials – including case officers where possible – to track progress in applications and to iron out problems where these occur. This is a natural

part of evolving a functional and efficient system. There is clearly still scope, however, to build the capacity within the department itself – including the sheer numbers of qualified professionals required.

Part of the continuous improvement of the Ewulaas system could also include simplifying the data requirements at upload stage. The length of application forms – running to multiple pages per water use, for example – imposes considerable investment in time and costs that could be avoided. These costs are raised significantly when the online system fails, and data cannot be uploaded or is lost. This requires frequent reworking on the part of applicants or consultants. The department has demonstrated that it is committed to improving the system; and as consultants, we offer regular and constructive comment.

The close contact between consultants, their clients and the DHSWS is in part necessitated by the intrinsic complexity of water management – and hence of the data required in a WUL application. Where officials have queries or require gaps to be filled, it is vital for these matters to be taken up promptly and addressed; this way, the projects that depend on the WULs will not be unduly affected or delayed. Here, consultants play a valuable role in ensuring speedy responses, especially where the applicant’s own resources are stretched. It is worth mentioning, however, that while some officials are happy to work with

consultants on the client’s behalf, others prefer dealing with the applicant directly. As the application process becomes stricter, the DHSWS is requiring more detailed information on project design in the WUL application. This is placing increasing demands on the applicant, and we advise clients to advance their project planning to a certain level of detail to ensure greater completeness in their WUL applications. This ensures that the application is made only once the scope of the project is fully defined; by ‘freezing’ the project scope, there is less chance that design changes made at a later stage might force the application to be reconsidered from scratch. If that happens, the intended efficiency advantage of submitting an application early is lost.

Recent weeks, following the outbreak of the Covid-19 pandemic, have shown that the country has much work to

do in addressing the risk of infectious diseases. Part of this response will include government measures to allow civil servants to work in isolated environments, while still delivering the services that the country requires. The DHSWS will be no exception, and the WUL application system – enhanced by Ewulaas – will need to be further adapted to meet this challenge.

*JackyBurkeisa principalscientist atSRKConsulting withover 30yearsof experience inthefields ofwateruse authorisation andintegrated waterquality management.

Climate change will bring hydrological changes that challenge the sustainable management of water resources and affect the availability, quality and quantity of water for basic human needs. And the impacts on Africa’s water resources are already acute.

Water use has increased sixfold over the past century and is rising by about 1% a year. However, it is estimated that climate change, along with the increasing frequency and intensity of extreme events – storms, floods and droughts – will aggravate the situation in countries already currently experiencing water stress and generate similar problems in areas that have not been severely affected.

According to the newly released United NationsWorldWaterDevelopment Report2020:WaterandClimateChange , a deterioration of water availability, quality and quantity as a result of climate change will hinder the achievement of Sustainable

Development Goal (SDG) 6, which calls for access to safe drinking water and sanitation for all by 2030. This will be a considerable challenge considering that 2.2 billion people currently do not have access to safely managed drinking water, and 4.2 billion – or 55% of the world's population – are without safely managed sanitation.

According to the report, the impacts of climate variability on Africa’s water resources are already acute, with several studies finding that rainfall in Southern Africa has decreased recently, likely as a result of climate change.

Climate-related impacts are also expected to increasingly interact with non-climaterelated drivers of water scarcity and water pollution, such as a growing population, economic development, and conflict and fragility. On the African continent, where the population is predicted to grow by more than a half billion by 2050, the increasing water stress will be particularly pronounced. The report also states that water-related

impacts of climate change on human health are expected, through vector- and waterborne diseases (including by further challenging access to safe drinking water, sanitation and hygiene) and via malnutrition, given the expected impacts on food security. In agricultural systems, especially in semi-arid areas, conventional livelihood-based approaches do not appear robust enough to deal with the long-term impacts of climate change.

The report indicates that the experience of water-related impacts of climate change in sub-Saharan Africa is exacerbated by policy contexts that suffer from challenges in coordination as well as gaps in monitoring and research.

In the face of these threats, the report highlights the two complementary strategies to be implemented – adaptation and mitigation:

• Adaptation encompasses a combination of natural, technical and technological options, as well as social and institutional measures to mitigate damage and exploit the few positive consequences of climate change. It is likely to have very rapid benefits, mainly at the local level.

• Mitigation consists of the human actions needed to reduce greenhouse gas (GHG) emissions while exploiting carbon sinks to reduce the amount of CO2 and other GHGs in the atmosphere. It can involve large geographical areas, but with gains that may be spread over decades. However, the possibilities

for mitigation in water management remain largely unrecognised.

The authors note that while the need to combat climate change through better management of the water cycle is well recognised, it is not being translated into reality. “The word ‘water’ rarely appears in international climate agreements,” observes Audrey Azoulay, director-general, Unesco.

The ‘nationally determined contributions’ submitted by states under the Paris Agreement remain general in nature, without proposing specific plans for water. While most countries recognise water in their portfolio of actions, few of them have actually calculated the costs of these actions and even fewer have put forward specific projects. Meanwhile, the possibilities for synergies between adaptation and mitigation measures are often neglected.

Wastewater treatment contributes to climate change, as it generates GHGs through the energy it requires and the decomposition of organic matter, accounting for an estimated 3% to 7% of all emissions.

It is estimated that, worldwide, between 80% and 90% of wastewater is discharged into the environment without any form of treatment. Left untreated, wastewater is a major source of methane. Wastewater harbours more energy than is needed for its treatment, provided that it is harnessed. In concrete terms, the optimal management of water resources means investing in modern treatment techniques that allow for the extraction of methane from organic matter to generate the energy needed to run the process. Where these techniques have been successfully implemented, public utilities have reduced emissions by thousands of tonnes of CO2, while making financial savings and improving the quality of the service.

The question of finance is crucial. The authors point out that water resources management and water supply and sanitation services are underfunded and require greater attention from countries. There are increasing opportunities to systematically integrate adaptation and mitigation planning into water-related investments, in order to make them more

attractive to donors. A good example of this is a Green Climate Fund project in Sri Lanka, which aims to improve irrigation systems in vulnerable village communities and promote climate-smart agricultural practices in three river basins, offering both climate adaptation and mitigation benefits, while conserving water and protecting drinking water sources.

Various water and climate change initiatives can also bring co-benefits such as job creation, improved public health, poverty reduction, the promotion of gender equality and improved livelihoods, further enhancing their attractiveness to donors.

The adoption of integrated adaptation and mitigation measures is a win-win proposition. They are clearly beneficial for the sustainable management of water resources and the human right to safe drinking water and sanitation. They also directly address the causes and consequences of climate change, including in terms of the response to extreme weather events. Finally, they contribute to the achievement of several of the SDGs.