Water & Sanitation Africa

Complete water resource and wastewater management

George Diliyannis

Senior Technical Service and Development Engineer, Safripol

Industry Ins I ght

World-class plastic solutions

The advantages of PVC-O pipelines

Water S ecurity

Building resilience

Pla S tic P i P e S

Developments in PVC-O

Sanitation

Managing school toilets

Wa S te W ater

Changing reuse perceptions

Proce SS control The power of dashboarding

Treat your water-energy like gold

Unmet efficiency with up to 10%-20% energy cost reduction

Super high flow rate

Designed for superior cavitation resistance

High regulation capabilities

Lightweight and requiring no specialised skills to install, sizabantu’s tom® 500 PVC- o is ideally suited for community projects in addition to providing longer-term savings for water utilities. P6

HDPe pipe has a proven history of high performance in water transportation. Leading southern African polymer producer safripol supplies versatile, quality plastic material that is Iso compliant. P10

DeVeLoPIng PVC- o PIPes AnD FIttIngs

BUILT TO MEET THE NEEDS OF ALL COMMUNITIES

STORAGE TANKS AND WATER SOLUTIONS

SBS Tanks®, a proudly South African company based in Pinetown, Kwazulu Natal, specialises in liquid storage solutions within the South African market servicing a multitude of industry sectors including Mining, Fire Protection, Municipal, Water Conservation, Food and Beverage, and Agriculture.

The SBS Tanks® range has been designed, developed and engineered with expertise gained from over 20 years of experience within the international water storage industry. SBS Tanks® offers a broad product range of liquid storage tanks for multiple applications, from 12 kilolitres in capacity to the largest single storage solution of it’s kind, the impressive 3,3 megalitre capacity water storage tank. Manufactured from pre-fabricated Zincalume® steel panels, and fitted with an approved liner, SBS Tanks® are highly resistant to corrosion and proven to be an effective and reliable product offering.

As a company, SBS Tanks® operates on a shared set of corporate values and principles, with customer focus and ongoing investment in research and development being key elements. We as a corporate entity believe that, not only is it possible to achieve our objectives through positive business practice, but we can equally take positive steps toward framing our future simultaneously.

Editor Danielle Petterson

Danielle.Petterson@3smedia.co.za

Managing editor Alastair Currie

Head of design Beren Bauermeister

Designer Jaclyn Dollenberg

Chief sub-editor Tristan Snijders

Contributors Lester Goldman, Dr Michele Kruger, Mike Smart, Chanelle Mulopo, Herman Smit, Peter Townshend, Peter van der Merwe, Achim Wurster

Operations & production manager Antois-Leigh Botma

Production coordinator Jacqueline Modise

Distribution manager Nomsa Masina

Distribution coordinator Asha Pursotham

Group sales manager Chilomia Van Wijk

Financial manager Andrew Lobban

Bookkeeper Tonya Hebenton

Printers Novus Print KZN

Advertising sales Hanlie Fintelman t +27 (0)11 467 6223 | c +27 (0)82 338 2266 Hanlie.Fintelman@3smedia.co.za

Publisher Jacques Breytenbach

Novus Print (Pty) Ltd t/a 3S Media

46 Milkyway Avenue, Frankenwald, 2090 PO Box 92026, Norwood 2117

Tel: +27 (0)11 233 2600 Fax: +27 (0)11 234 7274/5 www.3smedia.co.za

ISSN: 1990 - 8857

Annual subscription: R330 (SA rate) subs@3smedia.co.za

Copyright 2019. All rights reserved. All articles herein are copyright protected and may not be reproduced either in whole or in part without the prior written permission of the publishers. The views of contributors do not necessarily reflect those of the Water Institute of Southern Africa or the publishers.

WISA Contacts:

Head office

Tel: 086 111 9472(WISA) fax: +27 (0)11 315 1258

WISA’s Vision Inspiring passion for water

Physical address: 1st Floor, Building 5, Constantia Park, 546 16th Road, Randjiespark Ext 7, Midrand Website: www.wisa.org.za

BRANCHES

central Branch (Free State, Northern Cape, North West) chairperson: Dr Leana Esterhuizen company: Central University of Technology Tel: +27 (0)51 507 3850 email: lesterhu@cut.ac.za

eastern cape:

Branch contact: Dan Abrahams company: Aurecon Tel: +27 (0)41 503 3929 cell: +27 (0) 81 289 1624 email: Dan.Abraham@aurecongroup.com

Gauteng

Branch Lead: Zoe Gebhardt cell: +27 (0)82 3580876 email: zoe.gebhardt@gmail.com

KwaZulu-Natal chairperson: Lindelani Sibiya company: Umgeni Water cell: +27 (0)82 928 1081 email: lindelani.sibiya@umgeni.co.za

Limpopo chairperson: Mpho Chokolo company: Lepelle Northern Water cell: +27 (0)72 310 7576 email: mphoc@lepelle.co.za

Mpumalanga

Chairperson: Lihle Mbatha (Acting) Company: Inkomati-Usuthu Catchment Management Agency

Tel: +27 (0)13 753 9000

Email: mbathat@iucma.co.za

Western cape

chairperson: Natasia van Binsbergen company: AL Abbott & Associates

Tel: +27 (0)21 448 6340 cell: +27 (0)83 326 3887 email: natasia@alabbott.co.za

Namibia

Please contact the WISA Head Office on admin@wisa.org.za for more information

Are we flushing away our rivers? A

s we observe World Toilet Day on 19 November, it is worth giving some thought to the full sanitation value chain. While it is essential that we provide appropriate and dignified sanitation solutions for all members of society, it is equally important to ensure that our effluent is appropriately managed. Unfortunately, our rivers are paying the price for poor sanitation management. The recently released StateofRiversReport2017-2018 shows the ecological condition of our rivers based on data collected at 364 sites across the country. And the results are concerning.

State of rivers

The report categorises rivers into the following categories:

• A: unmodified/natural

• A/B: The system and its components are in a close to natural condition most of the time

• B: largely natural with few modifications

• B/C: close to largely natural most of the time

• C: moderately modified

• C/D: The system is in a close to moderately modified condition most of the time

• D: largely modified

• D/E: the system is in a close to largely modified condition most of the time

• E: seriously modified

• F: critically/extremely modified

Only 16% of sites, mostly located in the upper reaches of catchments, fell into the AB, B or BC categories. Approximately 50% are in a moderately modified (category C) condition and the Vaal River Water

Management Authority had no sites in a good condition (better than category C). Approximately 5% of the sites are in an unsustainable (DE to E) condition.

The report goes on to indicate that rivers in densely populated areas are in poor condition due to a lack of proper management and maintenance of wastewater treatment works and insufficient capacities of these works for the population served. Furthermore, many rural areas still lack proper sanitation, also leading to contamination of water resources.

Where to from here?

It is evident that a focus on sanitation should not only look at providing onsite solutions, but also at downstream management. Not only are we polluting our drinking water sources, but we are damaging the ecology of our rivers and dams.

Given the fact that drought conditions, high water use, and climate change are also impacting flow conditions, we must develop strategies to lessen our impacts, better manage land use and protect our water resources.

Poor sanitation, both urban and rural, is undoubtedly a threat to aquatic and human health, and is one of the largest contributors to the deterioration of our water resources.

This World Toilet Day, let’s focus on wellmanaged sanitation solutions from start to finish, ensuring we provide dignity while protecting our water resources.

Cover opportunity

In each issue, Water&Sanitation Africa offers companies the opportunity to get to the front of the line by placing a company, product or service on the front cover of the magazine. Buying this position will afford the advertiser the cover story and maximum exposure. For more information, contact Hanlie Fintelman on +27 (0)11 467 6223, or email Hanlie.Fintelman@3smedia.co.za

Sizabantu Piping Systems recently supplied the piping for the Driekoppies bulk water, Driekoppies reservoir and the Sibange bulk water pipeline projects for Ehlanzeni District Municipality and Nkomazi Local Municipality.

For all phases, a range of material options was assessed by Lubisi Consulting Engineers and GMH Tswelelo Consulting Engineers for the size and pressure classes required. Materials considered were steel, ductile iron and TOM 500 PVC-O. The design specification called for a pipeline at least 630 mm in diameter.

The decision was made to specify TOM 500 PVC-O as the most cost-effective option. TOM 500 PVC-O is supplied in

The advantages of PVC-O pipelines

Lightweight and requiring no specialised skills to install, TOM® 500 PVC-O is ideally suited for community projects in addition to providing longer-term savings for water utilities.

diameters up to 800 mm, so it comfortably met the varied scope requirements across the three projects.

“A key advantage of TOM 500 PVC-O piping systems is that they have between 15% and 40% greater hydraulic capacity compared to alternative material systems with the same external diameter,” explains Greg Loock, director, Sizabantu Piping Systems.

Sizabantu is the Southern African distributor for Spanish OEM Molecor, which is globally acknowledged as the pioneer of TOM 500 PVC-O, a major advancement on industry-standard PVC materials. This is because TOM 500 PVC-O’s molecular orientation reduces the thickness of the pipe wall, giving TOM 500 PVC-O pipes a greater internal diameter and flow section.

Additionally, the internal surface of TOM 500 PVO-O is extremely smooth, reducing load loss and making it more difficult for deposits to form on the inner walls.

Subsequently, TOM 500 PVC-O pipes carry more water which uses less energy than other material types, such as steel.

Thanks to their low density, TOM 500 PVC-O sections can be installed using a backhoe loader; smaller-diameter pipes can be installed by hand

“What’s more, they are arguably the most efficient in terms of the relationship between investment and available hydraulic capacity,” adds Loock.

A further advantage is that TOM 500 PVC-O is considerably lighter in weight than metallic options, measurably stronger and more flexible than standard PVC, and also does not require any special skills to install.

Materials lose their mechanical properties when they are subjected to strain over a long period of time. This characteristic, known as creep, appears to a far lesser extent in TOM 500 PVC-O than in conventional plastics, so providing better properties over the long term. TOM 500 PVC-O is also exceptionally resistant to fatigue and has a very good chemical resistance, much like conventional PVC.

Maintenance cost savings

Going the ductile iron or steel pipe route would have required the mandatory installation of cathodic protection. This prevents premature structural failure

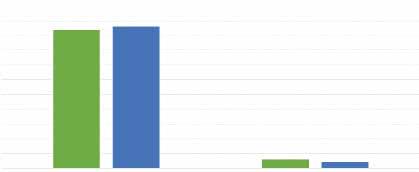

LEFT The extreme smoothness of the inner wall of the TOM pipe minimises pressure loss, so the energy required for transport is lower

Energy consumed by pumping (kWh)

“Only 43% of TOM 500 PVC-O’s composition depends on oil. Therefore, the required consumption of this resource is lower than in other plastic solutions.”

caused by stray electricity currents, especially where pipelines are located near railway tracks or overhead power lines.

Although essential, the downside to cathodic protection is that it typically costs around 12% to 27% of the overall price of the pipeline. It also requires regular maintenance to be effective. That poses additional challenges for today’s cash-strapped municipalities, which also continue to experience shortages of technically skilled personnel.

Either way, failure to protect or maintain the pipe will result in immediate corrosion. This is evident in the continuous leaking of metallic pipelines across South Africa, which contributes to increased nonrevenue water losses and places a severe strain

on an already water-scarce environment.

“TOM 500 PVC-O is clearly a highly viable alternative,” points out Loock. “Providing a design life of at least 100 years, TOM 500 PVC-O systems don’t require coating or linings and require minimal maintenance.

TOM 500 PVC-O allowed the engineers to design a pipeline within budget.”

The reservoir phase was the largest of the three pipeline projects and consisted

6 100 m of TOM 500 PVC-O was specified for the Driekoppies reservoir pipeline project

Charts figures for DN 200250 mm PN16 bar pipes

of 6 100 m of TOM 500 PVC-O. Sizabantu supplied TOM 500 PVC-O PN 16 and PN 20 sections for Sibange, and TOM 355 PVC-O PN 16 for the Driekoppies bulk water component. On all phases, ease of installation has enabled the contractor to use local labourers to complete the project in the shortest time possible.

TOM 500 PVC-O complies with SANS 16422 and is manufactured locally by Molecor South Africa at the company’s state-of-the-art manufacturing facility in Richards Bay, KwaZulu-Natal. To date, Sizabantu has sold more than 4 000 000 m throughout Southern Africa.

“TOM500 PVC-O is undoubtedly a world-class product and has enabled municipalities and water authorities to extend the life of their bulk water pipelines,” Loock concludes.

www.sizabantupipingsystems.com

ABOVE TOM 500 PVC-O pipes do not require any specialised skills to install

Bringing dignity

While we acknowledge the excellent work done in the sanitation sector, it is worth considering our commitment - as the entire water sector - towards this SDG sub-goal. Do our water professionals see the sanitation challenge only as a means of saving water, or do they see this as providing real dignity to communities?

Most of us have never been without a flushing toilet, which can sometimes make it difficult to keep the ongoing quest for dignified sanitation top of mind. However, seeing the appreciation and light in someone’s eyes when they are able to use a newly installed flush toilet should motivate us to enhance this endeavour while also seeking to save water.

Let us try to use the next 10 years to make a meaningful improvement in attaining SGD 6.2.1, by discussing this in our boardrooms, research labs, offices and work corridors. Maybe then, collectively, we can bring dignity where it is needed.

WISA volunteers who have supported and built upon a wonderful legacy left by the old WISA MoI. Now, more than ever, we are looking to members to provide us with feedback in terms of the direction and vision for the future.

In November, we observe World Toilet Day. And as we fast approach 2030, we must review our progress towards SDG 6.2.1 –“Proportion of population using (a) safely managed sanitation services and (b) a hand-washing facility with soap and water.”

By Dr Lester Goldman

You may have participated in our WISA Think Tanks, completed our survey, or attended information sessions at IFAT, the Young Water Professionals Conference, etc. For this participation, we are grateful. As the saying goes, ‘we cannot be everything for everyone’, but we do want to try to satisfy the majority. Your feedback allows us to take a focused approach to serving our members and water community.

After what has been a trying year in many respects, with much change and many challenges, I hope that you will have a much-deserved December break spent with loved ones. I hope you find peace and look forward to 2020 with renewed vigour.

We are very excited about our WISA 2020 Biennial Conference, with planning already more than a year under way

The year in review

I cannot believe that this is the last issue of 2019, as time seems to have found

I would like to express our gratitude to our

We are very excited about our WISA 2020 Biennial Conference, with planning already more than a year under way. And please always let us know your thoughts on the sector via our dedicated email channel: thinktank@wisa.org.za.

Wishing you and yours a happy holiday. Keep safe and many blessings!

Dr Lester Goldman, CEO, WISA

WPotty training, Version 2.0

The Sustainable Development Goals (SDGs) call for universal access to adequate and equitable sanitation and hygiene by 2030. While this is something we all want to achieve, it is clear that we must change our approach to sanitation.

By Achim Wurster

ell-off members of society often berate government over newspaper headlines such as ‘Sewage crisis’, ‘Vaal River pollution’ or ‘Sewage spill into Apies’, while the same headlines hardly elicit a thought as the toilet is flushed. Less well-off members of society often still rely on open defecation, bucket systems or pit latrines, while their cries for safe sanitation are not heard or are written off as unreasonable service delivery protests.

Achim Wurster, chair, WISA

The reality is that all sectors of society are a source of pollution if sanitation is not managed appropriately. Is this situation acceptable? If not, who are we holding accountable?

The easy way out is to blame local government or the Department of Water and Sanitation (DWS). They rightly have to shoulder responsibility, at least for those aspects under their direct control. However, it is our toilet flushing that is the root of the problem so let us investigate a little deeper.

The challenges

Potable water is getting more expensive and periods of physical supply constraints are increasing, making potable water less suitable for waste disposal. Many formal sewage disposal systems - consisting of gravity sewers, pump stations and wastewater treatment works - are buckling under many years of inadequate maintenance and lack of treatment capacity expansion while inflows increase. At the same time, many informal settlements are springing up, leaving local government or the DWS playing catch-up with infrastructure provision, without any means to effectively recover costs in these areas. While the DWS and local government are doing a lot, many projects and schemes implemented to

address these challenges suffer from a myriad of problems, including corruption, poor design, poor project management (both technical and financial) and, lately, also work stoppages due to threats from the ‘construction mafia’. The result is a lot of money being spent, with inadequate or only moderate results.

The financial constraints that government currently faces mean that funding may be even less for the foreseeable future. This does not bode well if we want to achieve the sanitation aspect of SDG 6: access to adequate and equitable sanitation and hygiene for all.

The solutions

Clearly more of the same will not solve our problems. We need to accept that. Ultimately, we must change our approach to sanitation and set a new course. But turning this ship around and steering it in the right direct is going to take time. In the meantime, we need the following:

• an effective and fair regulator

• adequate funding to maintain and upgrade infrastructure at both national and local government level

• excellence in project planning, design and execution for new infrastructure

• excellence in operations and maintenance of existing infrastructure

• effective protection to safeguard existing infrastructure against theft and allow new projects to proceed without interference.

The above will keep the ship afloat for now but we are still heading towards being beached on a sand bank in a dried-out lake. What I saw at the recent Water Research Commission Symposium gives me hope that a prosperous course exists. There were many examples of new sanitation systems that reduce water demand or don’t require any water, with many already available commercially. However, for large-scale acceptance by society, we need more of the following:

• robust research to verify the safety and technical efficacy of new sanitation systems

• improved resource recovery from the collected waste streams of new sanitation systems in order to improve the economics, ultimately making them financially self-sustaining

• financial models that show the advantages of implementing new sanitation systems, to motivate financial support from savings gained in other areas, until they become self-sustaining

• regulations and by-laws at national and local government level that support the implementation of new sanitation systems, including technical and business model aspects

• standards, technical documentation and guidelines to assist industry to certify new sanitation systems and to implement them appropriately

• widespread public campaigns to promote the benefits and educate the public regarding new sanitation systems so that these become the preferred choice.

We all want a clean environment and cost-effective reliable water and sanitation services. To achieve this, we have to ‘potty train’ our minds to the changes in reality that will necessitate new sanitation solutions. I, therefore, ask you to consider how you can contribute to this goal in your work and personal spheres of influence. Effectively sailing our ship and charting a sustainable and financially viable course to new sanitation

OPTIWAVE series –24 and 80 GHz FMCW radar level transmitters for liquids and solids

• Over 28 years of experience with FMCW radar technology

• Lens, Drop and Horn antenna styles with process connections starting from ¾“

• 3 year product warranty

World-class plastic solutions

HDPE pipe has a proven history of high performance in water transportation. It offers the lowest failure rates of all traditional materials used for water systems, superb chemical resistance and low water absorption, and is easily processed and machined. Leading Southern African polymer producer Safripol supplies versatile, quality plastic material that is ISO compliant.

The plastic pipes industry is still seen as fairly new in South Africa but plastic materials are evolving at a rapid rate, so allowing plastic pipes to be engineered to last a remarkable 50 to 100 years.

“Although there isn’t too much awareness of, or education around, plastic material science, it’s an exceptionally competitive industry and one that can positively contribute to the environment and the residents it supports,” says George Diliyannis, senior technical service and development engineer, Safripol.

Safripol was established in South Africa in 1972, currently employing over 500 people in Johannesburg, Sasolburg and Durban. The company is the only local producer of high density polyethylene (HDPE) with technology licensed by LyondellBasell, and is also the only local producer of polyethylene terephthalate (PET) with technology sourced from Invista and Polymetrix. It also produces polypropylene (PP) with LyondellBasell licenced technology. Safripol supplies the

African and global markets with PET, HDPE and PP from its manufacturing operations in Sasolburg and Durban. Safripol has leveraged the best technologies and operational processes through global partnerships to design and provide unique, fit-for-purpose solutions that local customers have come to expect from the market leader.

iMPacT100

Safripol’s flagship HDPE PE100 pipe resin, branded as iMPACT100®, provides a single solution to both the water and wastewater transfer markets that conforms to the latest ISO standards.

iMPACT100 is a premium material and its high molecular mass grade offers good impact strength, abrasion, chemical and UV resistance. Compliant with the latest PE100 material requirements of ISO/SANS 4427, iMPACT100 is the preferred product for use in large-bore pipes up to 1.2 m in diameter.

According to Diliyannis, iMPACT100’s intrinsic properties – including resistance to cracking and longevity – make it

suitable for potable water, stormwater and sewerage pipes. “This versatile material is recognised globally for use in all of these functions and is more durable and sustainable than traditional pipe material,” he says.

Built on strong foundations

iMPACT100 is the result of Safripol’s strong international partnerships, which encourage the use of the very best pipe technology and operational and safety standards.

“Not only have we harnessed the global expertise of our partnerships with LyondellBasell and Qenos to comply with the highest industry standards, but we’ve also cultivated these relationships to allow us to develop a better understanding of the possibilities within the local market, and implement best global practice solutions relatively quickly,” explains Diliyannis. Safripol’s iMPACT100 was developed in collaboration with Qenos under a licence agreement that allows for informationsharing and gives Safripol’s Sasolburg plant

George Diliyannis Senior Technical Service and Development Engineer, Safripol

Safripol’S five core valueS underpin itS miSSion to become Southern africa’S preferred polymer partner:

access to future product developments in the HDPE pressure pipe industry.

With many years of experience in developing high-performance PE100 pipe grades for water supply and waste management in line with the latest ISO standards, Safripol considered Australian company Qenos as the partner of choice for pipe technology.

Meeting the standards

As part of the technical support offered through their exclusive partnership, Qenos’ ISO 17025 accredited laboratory assists with process verification testing, ensuring that Safripol’s iMPACT100 product meets compliance standards.

Safripol is currently in the process of becoming SANS/ISO 4427 certified, with third-party verification under way by the SABS.

“We stay on top of innovative technology through our collaborations and partnerships in the plastics industry, and SABS certification will ensure that iMPACT100 meets the global standard so that we can meet the market’s need for cost-effective, leak-free piping systems,” says Diliyannis.

Safripol also works with machine manufacturers to ensure its materials work with their machines and processes to facilitate the creation of fit-for-purpose piping products.

The Safripol advantage

“We have deep roots in South Africa, and we pride ourselves on bringing the very best technologies and products to the local market. We go to great lengths to ensure that our products and technology are globally competitive and that we serve the market demand,” says Diliyannis.

As a local supplier of raw materials, Safripol offers many advantages to customers, including a quicker supply chain response time, decreased inventory requirements, and easy access to product and technical support, as well as supporting local communities through job creation and economic growth.

global research project to determine the effects of using recycled materials in plastic pipes. “This forms part of our focus to produce long-lasting plastics sustainably. We strive to add value to the environment while using global expertise to improve local understanding. In this way, we work to ensure that Safripol remains Southern Africa’s preferred polymer partner.”

By ensuring it has the best local technical knowledge, Safripol is working to improve the industry through knowledge-sharing.

Diliyannis, together with some of Safripol’s partners, is currently undertaking a

www.safripol.com Neo

+27 (0)11 575 1031

nmekgoe@safripol.com

impact100 SupportS award-winning project

Safripol’s iMPACT100 was used to produce the 800 mm PN16 HDPE pipe used in the award-winning Temba Water Purification Plant upgrade in Hammanskraal.

The project, which won the Joop van Wamelen SASTT Award of Excellence, employed horizontal directional drilling (HDD) to ream out the existing 800 mm asbestos cement pipeline and replace it with a new 800 mm PN16 HDPE pipe supplied by Marley Pipe Systems. Specialist contractor Trenchless Technologies achieved a world first with this project: undertaking the pipereaming process and installation of the 800 mm HDPE pipe in a single pass.

In order to reduce the number of butt-welds required, the 800 mm PN16 HDPE pipe was delivered to site in 18 m lengths. These 18 m lengths were buttwelded into long continuous sections of approximately 150 m to be pulled into position in the reamed-out bore. This is the largest-diameter host pipe known to have been replaced by pipereaming technology.

The implications of inadequate WASH services on health in poorly resourced settings

Thought piece by Chanelle Mulopo, Communications Lead YWP

Water and sanitation are critical drivers of health. Although there has been much focus on, and investments in, the improvement and development of water and sanitation technology, little effort has been invested in WASH-related health outcomes.

Chanelle Mulopo

WASH-related diseases are among the leading causes of death among children below the age of five. Approximately 700 000 children die annually because of diarrhoeal diseases resulting from inadequate WASH services. Additionally, WASH is reported to have an impact on stunting and wasting in early childhood.

Studies show that the most vulnerable group affected by WASH-related diseases are children below the age of five. Furthermore, WASH plays an important role in combating neglected tropical diseases (NTDs) which cause about 543 000 deaths in sub-Saharan Africa. However, to date the WASH component of the strategy to combat NDTs has

received little attention. Schistosomiasis alone affects approximately 500 million people of which more than 90% of the infected population is in subSaharan Africa.

WASH-related diseases are common in poorly resourced settings such as rural areas and informal settings within the urban areas. Communities in these settings are characterised by limited access to improved water sources and inadequate sanitation.

Everyone understands that there is a link between WASH and health, however, both researchers and communities have a poor understanding of some of the transmission pathways of WASH-related diseases. Therefore, it is imperative for researchers to work hand in hand

with communities in order to understand the behaviours, which exacerbate the transmission of pathogens, as well as to identify transmission pathways.

Communities with limited WASH services are more likely to engage in practices that make them susceptible to WASH-related diseases. For example, if the community has inadequate sanitation facilities, some individuals may resort to practising open defecation.

As a young water professional pursing a PhD in public health, I believe that - in order to effect change - there is a definite need for collaboration between the water and sanitation sector and the Department of Health. Currently, these entities work in isolation. This collaboration is crucial because it will pave a way for the development of WASH technology and/or interventions that consider health outcomes.

To give a practical example, schistosomiasis is prevalent in some parts of South Africa. Various factors are responsible for the transmission and persistence of the disease. These include climate change, global warming and proximity to water bodies. Most villages where schistosomiasis is prevalent have limited access to water. In addition,

the villages are in close proximity to the rivers and other freshwater bodies. The combination of inadequate access to water supply and the proximity to the river has resulted in majority of these communities relying on rivers and dams as their main source of water. This has tremendously predisposed these communities to schistosomiasis.

As a public health specialist pursuing a career in the water and sanitation sector, I recommend that public health specialists should be involved in all water and sanitation interventions to ensure that communities have tangible health benefits. Public health specialists in the water and sanitation sector will also ensure appropriate measures are taken to ensure community engagement of all WASH projects.

In conclusion, stakeholder engagement is critical for successful WASH interventions. Collaborations between the water and sanitation sector, the Department of Health and the community are the future. This will ensure accelerated uptake of WASH technology, sustainability and improved health outcomes at the community level.

ForalistofreferencescontactChanelleMulopoon cmulopo@gmail.com.

YWPZA WC chapter welcomes new Lead

Anya Eilers has been appointed as the new Lead for the YWPZA Western Cape Chapter.

Eilers is a young water professional with a masters degree in hydrogeology from Stellenbosch University. She has worked in a range of different sectors in the water space and believes that a strong scientific understanding of water resources is becoming increasingly important for Africa’s fight against climate change.

Eilers recently returned to her home city of Cape Town to take up the role of a hydrologist at Aurecon. Prior to this, she worked in Addis Ababa for two years as an associate at the Global Green Growth Institute, where she managed water and climate change-related projects with the government of Ethiopia.

She still plans to pursue another masters degree in environmental economics as she believes that tackling climate change and promoting sustainable economic growth must go hand in hand. However, in the meantime she is happy to be home and is excited to become involved once again with the South African Young Water Professionals and other platforms that promote inter-disciplinary collaboration in the sciences and water space. Anya Eilers

KENyA

Water and sanitation in Africa

Kimwarer Dam cancelled President Uhuru Kenyatta of Kenya has cancelled the construction of the KSh22.2 billion (R3.14 billion) Kimwarer Dam.

This follows an investigation, which revealed that the dam project was technically and financially unfeasible. It is reported that no reliable feasibility study was conducted on the Kimwarer project before its construction.

A statement from State House reads, “The KSh22.2 billion Kimwarer Dam was found to have been overpriced and the project is neither technically nor financially viable. The water

R3.14 bilion

supply mechanism would involve pumping, an aspect the technical committee found to be unsustainable in terms of operations and maintenance costs.”

Kenyatta has, however, greenlit the commencement of the Arror Dam project, which was deemed economically viable by a technical committee.

However, since it was also found to be overpriced, new design components and a cost rationalisation plan have been developed. The changes will see the dam scaled down to 60 m from the original design height of 96 m, which was found to be unviable.

Kenyatta has since come under fire for cancelling the Kimwarer project and some leaders continue to push for the building of the multipurpose dam. A petition by two residents from Elgeyo Marakwet County has led to the Senate Standing Committee on Lands and Natural Resources being tasked to investigate the circumstances that led to the president’s cancellation of Kimwarer Dam and the downscaling of Arror Dam. There are also reports of major financial losses, with KSh19 billion (R2.69 billion) said to have been paid in advance in connection with the Kimwarer and Arror dams.

ETHIoPIA

First sustainable water to Serdo

USAID, together with DuPont Water Solutions and the Afar Regional State Government, has unveiled a state-of-the-art reverse osmosis (RO) water system in the Ethiopian community of Serdo.

The RO water system features a stand-alone cooling tower – the first of its kind in Afar. The facility is designed to safely treat salinity, filter out impurities and harmful bacteria, and reduce the high temperature of the local groundwater, making it safe to drink.

The system will provide the first-ever sustainable source of safe drinking water for more than 2 000 people in the area.

AFRICA

Marshall Plan for water During World Water Week in Stockholm, Sweden, African water ministers and several NGOs launched a proposal for a ‘Marshall Plan for Water in Africa’ for the next decade, to guarantee that all Africans have clean water and safe sanitation in 2030.

In nearly all African countries, more than 50% of the population does not have access to at least basic water and sanitation services. “If countries invest in this sector, economies start growing quickly. Inadequate water and sanitation services create 780 000 deaths worldwide per year from diarrhoea and cholera – more than deaths from flooding, droughts,

epidemics, earthquakes and conflicts combined,” said Wambui Gichuri, director: Water and Sanitation, African Development Bank.

Total investments are US$40 billion (R587 billion) per year. African governments and consumers will finance 50% of this, while the other half will be funded by donors, banks and private companies, including climate adaptation funds. This water plan fits in the broader ‘Marshall Plan with Africa’, proposed by German Federal Minister of Economic Development Gerd Müller to create jobs, economic growth and rule of law.

“Current global water and sanitation finance is $16 billion (R235 billion) per

year, but investments needed to realise the UN SDG 6 water goals for 2030, signed by 190 countries in 2015, are $114 billion (R1.67 trillion) –six times more; a huge finance gap,” said Gustavo Saltiel, global lead: Water Supply and Sanitation, World Bank.

According to a World Bank report, of the $114 billion overall cost estimates, subSaharan Africa accounts for 31% of the global costs of reaching the goals (over R520 billion per year). For Northern Africa, $4.2 billion (R61.7 billion) is needed, adding up to $40 billion for the Marshall Plan with Africa.

The Marshall Plan for Water was applauded by the global water community in Stockholm and it was proposed that AMCOW and the AU take the lead in drafting the Marshall Plan for Water, and to publish sector finance plans for the next decade by African governments, utilities and consumers – capitalising up to $20 billion (R294 billion) how other actors can contribute to financing

President Uhuru Kenyatta of Kenya has cancelled the construction of the KSh22.2 billion (R3.14 billion) Kimwarer Dam.

Word from around Africa – including the latest industry, project and development news.

LESoTHo

LHWP tunnels shut down for maintenance

Water transfers from Lesotho to the Vaal River System have been shut down from 1 October to 30 November 2019 for routine maintenance on the Lesotho Highlands Water Project (LHWP) assets.

The Lesotho Highlands Development Authority (LHDA), together with the Trans Caledon Tunnel Authority (TCTA), is conducting routine inspection and maintenance works on the water transfer and delivery tunnels. The current inspection and maintenance follow up

on the works undertaken in 2012. The focus is to ensure continued sustainable operations and service of the tunnels and all electromechanical components from the Katse intake tower, through Muela power station to the Ash River outfall.

The LHDA will also install new, state-of-the-art water flow meters at Ngoajane flow measuring station and replace the valve at the Muela hydropower station bypass.

The TCTA is undertaking routine inspection and maintenance work on the South African side.

ZIMbAbWE

Assessing cholera and typhoid readiness

The Zimbabwean Ministry of Health and Child Care, in partnership with the World Health Organization, has embarked on an exercise to assess the preparedness of health institutions to fight cholera and typhoid in the event of an outbreak.

The assessment, which was undertaken in all 10 provinces in the country, seeks to determine readiness to effectively implement the national cholera emergency plan, and to pave the way for the implementation of corrective measures.

A cholera outbreak and emergency preparedness

and response plan was developed in February 2019. The plan identified key activities, materials and supplies that would ensure effective coordination for cholera prevention and response activities, timely detection and investigation of any suspected cholera or typhoid case.

The upcoming rainy season puts Zimbabwe at an increased risk for cholera and typhoid outbreaks. Although Zimbabwe last recorded a cholera case in March this year. Last year around 50 people died from cholera in Harare and parts of the Midlands as a result of water challenges.

Because water transfer had to be stopped to allow workers access to the tunnels, Lesotho will not be generating its own electricity during this period but will rely on supply from Eskom in South Africa and the EDM in Mozambique. The first part of the operation (the repair work on the Katse intake) commenced on 19 September 2019 while water delivery and hydropower generation stopped at midnight on 30 September 2019. The electricity generation for Lesotho and the water delivery to South Africa will resume at midnight on 30 November 2019.

MoZAMbIquE

Deadline set to end water crisis

Mozambican Minister of Public Works Joao Machatine has announced that the problem of water shortages in the Greater Maputo area will be solved by August 2020. Since 2015, drought has led to Maputo’s main water source, the Pequenos Libombos Dam on the Umbeluzi River, reaching dangerously low levels, resulting in water supply restrictions.

The government has since constructed a 95 km pipeline from Corumana to the water distribution centre in the Matola neighbourhood of Machava, as well as a new water treatment

station on the Sabie River. Boreholes have also been drilled in outlying Maputo neighbourhoods and smallscale water systems repaired. Construction on a larger treatment station on the Sabie is under way and expected to be completed in August next year. This will double supply from Corumana to Maputo to 60 000 m3 a day.

This, together with other sources, is expected to deliver 350 000 m3 of water a day to Maputo, which Machatine believes will result in constant water supply to the Greater Maputo area.

95 km pipeline

The government has since constructed a 95 km pipeline from Corumana to the water distribution centre in the Matola neighbourhood of Machava, as well as a new water treatment station on the

Sabie River.

HI801

Spectrophotometer

• With advanced split beam optical system, customizable methods and rechargeable battery

• Supplied with 85 factory methods

• 5 cuvette types with data storage for 14 000 measurements with ability to auto log results

• Create over 100 user methods

HI98703 Turbidity Meter

• Fast Tracker™ Technology

• Specially designed for water quality measurements

• Four-point calibration

• Log up to 200 records

• 25 mm round cuvettes

• Multiple reading modes - normal, continuous and signal averaging measurement

HI98198 Optical Dissolved Oxygen Meter

• Professional dissolved oxygen measurement with digital optical probe

• Percent saturation or concentration measurements (mg/L)

• Waterproof protection

• BOD, OUR and SOUR

• Built-in barometer

HI98199 pH • EC • DO

• Waterproof protection

• Quick connect digital probe and autosensor recognition

• Backlit graphic LCD display

• Long battery life

World Toilet Day 2019 Leaving no one behind

Atoilet is not just a toilet, but a life-saver, dignity-protector and opportunity-maker.

World Toilet Day 2019 draws attention to those people being left behind without sanitation and the social, economic and environmental consequences of inaction.

Alarmingly, children under the age of five living in countries affected by protracted conflict are, on average,

nearly 20 times more likely to die from diarrhoeal diseases caused by a lack of safe water, sanitation and hygiene as opposed to direct violence.

Inspiring action is needed to tackle the global sanitation crisis and achieve Sustainable Development Goal (SDG) 6, which promises sanitation for all and an end to open defecation by 2030.

Sanitation is a human right. We must expand access to safe toilets and leave no one behind.

4.2 billion people

4.2 billion people live without safely managed sanitation – more than half the global population

673 million people 673

2

people

Making school sanitation work

Between 2014 and 2016, Partners in Development (PID) conducted a study evaluating rural school sanitation in the South African provinces of the Eastern Cape, KwaZulu-Natal and Limpopo. One key finding: infrastructure without a management system will fail.

Rural school sanitation in Sa

The Department of Basic Education (DBE) is responsible for implementing school infrastructure, including toilets. But once installation is complete, it becomes entirely the school’s responsibility to manage sanitation infrastructure. “If the school cannot do that, the toilets will fail,” says Jeanette Neethling, engineer, PID.

“Once infrastructure has failed, the schools often deem it completely unusable and wait years for the DBE to come back and build new toilets.

Many schools in South Africa have ‘toilet graveyards’, which can include two to four toilet systems that have at some point failed,” she explains.

“We’re giving all of that management responsibility to schools that don’t have the capacity or the skills to manage it. This is vital when we look at projects like the SAFE initiative, which seeks to roll out toilets to schools with inadequate sanitation. We need to safeguard that investment by investing in

capacity-building for management at the school level,” Neethling stresses.

This management is important for both dry and wet sanitation systems. Although many schools are under the impression that you cannot clean ventilated improved pit latrines (VIPs), there are many disease hot spots that need to be cleaned regularly to maintain dignity and health.

Management also includes monitoring, which is very important for VIP systems to ensure there are no further tragedies that lead to the deaths of children. Moreover, Neethling points out that flush toilets with blockages and leakages are far worse than a VIP toilet because they quickly become unusable to learners.

School sanitation management model

The previous study resulted in the creation of the SchoolSanitationManagement Handbook . This provides schools with a breakdown of what is required for managing sanitation, particularly:

• WHY toilets should be made a priority

• WHAT needs to be done to ensure decent toilets

• WHO has a responsibility for managing school toilets

• HOW you can meet the requirements effectively and sustainably.

This model was piloted at seven schools around Pietermaritzburg for seven months. The pilot project included the training of cleaners and management personnel, supply of materials, ongoing monitoring and support, and closing workshops to get

Despite government’s focus on the roll-out of sanitation at schools, research shows that the infrastructure is doomed to fail without proper management.

By Danielle Petterson

feedback from participants.

Support mainly involved monthly visits to each school to help them problem-solve and collect information on the use of supplies, cleaning protocols and how people were beginning to work together and share responsibilities.

“There is often not a clear division of responsibilities, so it all lands on one person or no one at all,” explains Neethling. However, there are six important stakeholders involved in managing school sanitation infrastructure:

1. Health and safety officer (HSO), e.g. school cleaner

2. Health and safety manager (HSM), e.g. staff member that acts as a bridge between the HSO and principal

3. Principal

4. School governing body (SGB)

5. DBE

6. Learners.

A successful school sanitation model will have multiple links between all stakeholders so that everyone feels

example: School 1

School 1 had a major problem: no HSO. The school cleaner, who was employed by the DBE, claimed that it was not in her job description (which the school did not have a copy of) to clean the toilets. This was made worse by behavioural issues among the learners.

The school had managed to hire a dedicated cleaner for the toilets, but could only finance this for a few months. However, the school’s private security company got involved in monitoring the toilets, leading to a decrease in behavioural issues. The HSM also got very involved with educating learners and encouraging the principal to resolve the HSO issues.

“Although this was one of our less successful schools, there was an increase in linkages between the stakeholders, and I have hope for this school,” says Neethling.

example: School 2

Although School 2’s sanitation management was in a better state, the cleaner was only cleaning the toilets once to twice per week. The cleaner also reported that the school regularly did not have enough cleaning materials, partly due to a failure of the SGB to make funds available.

By the end of the programme, the SGB was making funds available for cleaning materials, and the HSO was reporting directly to the principal about what cleaning materials he needed. The HSO also adjusted his cleaning protocol so that he was deep cleaning the toilets twice a week and cleaning disease hot spots daily.

example: School 3

The big problem at School 3 was learner behaviour. The HSO was also very timid and therefore often not inclined to report problems to the principal. In this case, the HSM got very involved and bridged the gap between the HSO and the principal, resulting in the three stakeholders working very well as a team to address any issues. The HSM also got learners involved in monitoring the toilets, leading to better learner behaviour.

“This example shows how the programme really empowered the HSO who, in the end, felt better equipped to do his job with support that he had not had before,” says Neethling.

supported on multiple levels.

“What is really great is that this model raises the profile of the school cleaner and gives them additional responsibilities. They’re not just a cleaner, they are also responsible for educating learners, monitoring and many other skills,” says Neethling.

Key take-aways

The pilot project has led to a partnership with Unilever and the DBE, and the sanitation management model has been updated based on the outcomes. Following this, the model was

infrastructure after we engaged with them.

Just putting sanitation on people’s radar gets them to realise how important it is,” says Neethling.

PID has also created a sample budget for managing school sanitation (Table1), which comes to R20 per learner per year – only 2% of the budget for the

Following engagement with the schools, it became clear that there are a number of key factors for good sanitation management at schools, particularly:

• training and empowering school cleaners (HSOs)

• availability of the right materials to do the job

• staff support for the HSO, including monitoring of learners.

Neethling stresses: “Everyone in this chain needs to be more proactive than reactive.”

poorer schools that get the most funding from government, which is roughly R1 000 per learner per year. “When we present these figures, it is very empowering to schools because it is manageable,” says Neethling.

“We believe this programme should be adopted by the DBE, especially where it is employing cleaners, and should be providing annual training for school cleaners and health and safety committees. There are also a lot of opportunities for school franchising, and entrepreneurial approaches to school sanitation management should be encouraged.”

Changing perceptions

removal of microorganisms and emerging contaminants

• to optimise the treatment train and configuration

Umgeni Water is in the process of establishing a 2 MLD fullscale recovery plant at its Darvill Wastewater Treatment Works. By

Danielle Petterson

Given South Africa’s increasing water stress, wastewater reuse is becoming a necessity; however, it is

problematic to implement due to public perception. In fact, without public buy-in, direct reuse projects are unlikely to get off the ground.

With water sustainability in mind, Umgeni Water is establishing a 2 MLD reuse demonstration plant at the Darvill Wastewater Treatment Works (WWTW), which is currently undergoing an upgrade from 65 MLD to 150 MLD.

The reclaimed water plant will be fed from the WWTW’s normal activated sludge process. The final effluent will then go through a conventional water treatment process, followed by an advanced treatment process. The advanced treatment process has a flexible configuration that will allow interchangeability between ultrafiltration and activated carbon filters, while undergoing an advanced oxidisation process using ozone and peroxide.

The final product will initially be used as process water but will be treated to potable water standards and subsequently monitored in line with the appropriate international reclaimed water standards.

Umgeni Water has four technical aims it hopes to achieve with the demonstration plant:

• to investigate the effectiveness of the treatment train for the

• to assess life-cycle costs and apply findings on a full scale

• to develop plans for operation, maintenance, monitoring and public engagement.

Winning over the public

Key to the success of the project is achieving public buy-in to reclaimed water for potable purposes. According to Megan Schalkwyk, process engineer, Umgeni Water, this requires improving public trust in the entity delivering the water, together with an education and awareness programme. “Studies show that our municipalities need to increase the consistency and quality of our service delivery so that people can start trusting us to deliver clean reclaimed water,” she says.

A US study found that there are seven key areas to address to successfully implement reclamation projects, namely:

1. Changing normative associations –associate water reuse with positive applications, focusing on the use of the reclaiming water and not the source.

2. Constructing normative networks – look at water quality and infrastructure.

3. Mimicry – make the reclaimed water mimic ‘normal’ water, such as that from surface sources.

4. Educating – educate people on the terminology and be transparent about results.

5. Valorising and demonising – popularise reclaimed water with, for example, celebrity endorsements.

6. Mythologising – show historic good performance.

7. Imagery – associate reclaimed water with positive images. These points have informed Umgeni Water’s strategy to address public perception around reuse.

Umgeni’s approach

“Previously, reuse plants in South Africa have been implemented during severe drought and people had two choices: drink it or go thirsty. Now that the drought has eased up, we need to look at other ways of getting public buy-in. Unfortunately, people have had an aversion to reclaimed water for years and reuse plants in other parts of the world have been canned as a result,” says Schalkwyk.

Umgeni Water’s education and awareness strategy will target children, tertiary students, nurses, medical practitioners, as well as municipal and government leaders. “These are the people that have the most influence on our communities. A study in Beaufort West found that children change the mindsets of their parents and influence communities, as do political leaders,” she explains.

In a bid to increase public interaction, a learning centre has already been constructed on site at the Darvill WWTW, where Umgeni Water will invite the public

to learn more about water recovery, look at the treatment works in process, and interact with the units. External stakeholder engagements will be held in November 2019, followed by a water recovery masterclass initiative, which will be introduced in 2020.

“Our demonstration plant is an opportunity to establish a learning platform, which - besides educationwill aid in the research that is needed – we still have a long way to go before we fully understand all the different aspects related to reclaimed water,” says Schalkwyk.

Umgeni Water will lead this initiative over the next five years in the hopes of creating a national learning platform in South Africa. Annual national forum sessions will be utilised for engaging all stakeholders and slowly desensitising people to various issues and explaining strategies that are in place by Umgeni Water and the research team. These forums will also help to collate national information to prevent silos for forming.

SA municipal wastewater reuse can learn from international trends

A report by Herman Smit* on the 34th Annual WateReuse Symposium in San Diego, California

*Herman Smit is the managing director of Quality Filtration Systems, based in Cape Town, South Africa – herman@ qualityfilters.co.za.

“Water and air, the two essential fluids on which all life depends, have become global garbage cans.” - Jacques Cousteau

South Africa is in a water crisis and wastewater reuse, desalination and potable water quality are top of the agenda. Where will our future water be sourced?

Different water sources become viable solutions for the drought with advanced treatment technologies used for the augmentation of conventional water sources with reuse and desalination. We need to plan how to use our water to its maximum potential, and follow the international trends in water reuse and change the paradigm of water and wastewater management, which aims

and accelerating the natural process of cleaning the water to make it suitable for its intended purpose, from irrigation to industrial uses to drinking. While the science is clear that recycling water is safe, misinformation has contributed to community resistance for water reuse projects,” stated Paul Jones, president of the WateReuse Association.

The WateReuse Symposium creates the ideal platform to engage with municipalities, service providers and technology suppliers to promote the acceptance of recycled municipal wastewater. Acceptance starts with education, which is shared through the

‘Decentralised Reuse: The future of distributed infrastructure’. Commercial buildings can capture and treat water generated from within or around a building for beneficial use on site.

The US has many pilot facilities that are researching the quality of different process trains for the reuse of municipal wastewater. A developed economy like the US is spending a tremendous amount of money on research in universities as well as on large-scale pilot plants at municipalities. South Africa can use these results beneficially and design a system based on the findings of the US institutions. Unfortunately, South Africa cannot rival

process was chosen for the full-scale facility with similar capital values but a reduced operational cost on a year-to-year basis.

Andrew Salveson from Carollo Engineers presented the ‘Demonstration Facility: Innovative Potable Reuse Technologies for Pismo Beach’. The droughts in California highlighted the vulnerabilities of the region’s water supply portfolio. Recycled water was identified as the most effective augmentation supply option (see Figure 2).

The benefits of a demonstration plant include promoting engagement with the public, demonstrating the technology and optimising engineering. A thorough 12-month test regime will help drive the design and provide new research for the potable reuse industry.

The process was operated without chloramines to determine if this process can reduce the formation of NDMA and improve economics. Using no chloramines nearly eliminates NDMA formation but maintains post-RO UVT. UF membrane fouling must be considered without a disinfectant dose before the UF membranes. Chemical enhanced backwashes might be considered with biological fouling. Microbial reduction after the UF membrane is an essential test for the success of the downstream process and showed a positive result during the trial operational period (see Table 1).

Toilet-to-tap – Get over it!

Patricia Tennyson from Katz & Associates

challenged the notion that we are too sensitive for the ‘yuck’ factor associated with wastewater reuse. Properly treated wastewater is a valuable source of water to augment traditional surface water. Considering that the reuse of wastewater could mitigate water scarcity in drought

water, advanced purified water, purified potable water, highly purified water and water purification project (Sources: OCWD, Pure Water Monterey, PureWater Soquel, Padre Dam, Pure Water San Diego, PureWater Colorado).

A strategy is required to change the misconceptions associated with wastewater reuse, which includes:

• prioritising understanding the community that will be using the water, which will also determine the terminology used

• forging partnerships in the community to communicate your positive message and education around water

• using expert endorsement for the process and safety of the final water

• making the facility accessible for tours and public visits

• reaching out to the public with community days, bottled water and presentations

• using images to your advantage and engaging the media early

• using social media as a marketing tool.

areas, we should make sure the public is educated and informed about the facts related to wastewater reuse.

Tennyson advocated that everyone in the water industry should help to stop the media from using terms and headlines that create negative perceptions around wastewater reuse.

A 2014 water research study in the US investigated a model to communicate plans for increasing awareness and fostering acceptance of potable reuse. Recommended nomenclature, deemed more acceptable, was purified water, drinking water, pure new water, renewed water and pure water.

Phrases already being successfully used in the US for current projects and pilots are advanced water purification, purified

What is happening in South africa?

It was valuable for QFS to get exposure to leading technologies and the studies on wastewater reuse in the US. We must learn from their in-depth studies to make sure of the safe production of final potable quality water from wastewater, making use of tried and tested process trains with state-of-theart technologies.

The good news is that plants installed in South Africa using the same technology referenced in the presentations have successfully been used in Beaufort West, Ballito and De Doorns Valley. A process train of screening, UF, RO and UV AOP has proven to be the most reliable solution in South Africa, and is confirmed by the US studies.

South Africa needs a robust and proven solution to make sure we build a reputation for successful water reuse, which will be part of the solution of providing water security to a drought-ridden South Africa. We are on the right track to establish wastewater reuse as a safe and viable augmentation solution for every town and city in South Africa.

FIGurE 1 The two process trains tested by the City of Jacksonville, Florida

FIGurE 2 Water recycling process for Pismo Beach, California

TABLE 1 Microbial reduction after UF membrane treatment at Pismo Beach, California

The cycle of solutions –water technology by KSB

Water is crucial for our survival – for every one of us, for all nations and peoples. Clean water supplies and efficient sewage treatment have never been more important. Prosperity and well-being depend on it, worldwide. KSB’s know-how and extensive pumps and valves product range help you meet all water supply and treatment requirements, efficiently and affordably. We are one of the few suppliers worldwide with endto-end solutions addressing all stages of the water cycle – from water extraction to sewage treatment.

KSB Pumps and Valves (Pty) Ltd

www.ksbpumps.co.za

Tel: +27 11 876-5600

Powerful process technology

The mobile plant was equipped with an automatic self-cleaning TwistFlow Strainer as pre-filter, a 25 µm self-cleaning AutoFilt as main filter, with a 1 µm inline process depth filter as final polishing filter.

Upon receiving a request from the client, Hydac deployed this mobile plant on the Jukskei River near Lanseria, to test the suitability of its filtration technology for an upcoming project. Following a positive outcome after sampling, the client commenced with the feasibility study of a 250 m³/h water plant based

In 2014, Hydac Technology developed an 8 m³/h mobile water plant to demonstrate the effectiveness of the company’s OEM process technology equipment.

on the same set-up as the mobile plant for research and development (R&D) purposes.

Key performance indicators (KPIs) were a turbidity of 0.5 NTU and a filtrate throughput upwards of 96% of influent. In collaboration with the client, two dosing stations and a flocculation manifold were added to the design.

In 2018, Hydac was awarded the contract to design and build the R&D plant. Full operational wet FAT was conducted at Hydac’s Johannesburg works. The new R&D plant was installed adjacent to an operational traditional

multimedia filtration plant and the Hydac installation team followed through with successful commissioning on site. Water is now supplied to a disinfection station before distribution to the local community.

Features of the new R&D plant include automated system control and feedback via human-machine interface (HMI), monitoring of all parameters, trends and KPIs, real-time filter condition feedback, automated dosage control, bio-fouling indication, and auto bio-cleaning. The client monitors the plant via access from the HMI through off-site SCADA.

We focus on water, so you don’t have to.

Nafasi Water specialises in mine water treatment to aid in successful active mining, and mine closure requirements. formerly

Introducing Nafasi Water

Following its sale, established water treatment company Aveng Water will now be known as Nafasi Water.

Aveng Water was recently bought out of the Aveng Group by Infinity Partners, owned by Suzie Nkambule and E-Squared. Now in the process of rebranding to Nafasi Water, the company retains its expert capabilities and remains true to its goal of preserving sub-Saharan Africa’s water while ensuring access to alternative sources for potable and industrial use.

Building on strong foundations

With a focus on water reclamation and desalination technology for application in complex industrial and wastewater systems, Nafasi Water began a journey in 2003 to develop, implement and operate world-class industrial desalination projects.

As a 100% black-owned leading South African water technology and water utility service company, Nafasi Water partners with industry, government and local communities to provide sustainable solutions to broader water security challenges. Combining innovative technology with the funding and delivery of world-class water and wastewater treatment projects and services, the company aims to sustainably reclaim water affected by industrial and human activities. With considerable experience in the design, construction, commissioning and operation of complex water treatment plants, the company boasts three largescale water treatment plants under its O&M division. These include the eMalahleni and Middelburg Water Reclamation Plants, along with the flagship Erongo Sea Water

Desalination Plant in Namibia. Nafasi Water was also responsible for the construction and former operation of the Optimum Water Reclamation Plant.

expert capabilities

Nafasi Water provides consulting and contracting services for the mining, municipal and industrial water sectors, specialising in the design and engineering of treatment plants for:

• seawater desalination

• industrial effluent treatment and reuse

• municipal water and wastewater reuse

• water supply for power generation infrastructure.

For the treatment of mine water, Nafasi Water has developed a unique, internationally recognised product called HiPRO. With this, Nafasi has pioneered the application of reverse osmosis (RO) to treat mine water and achieve ultra-high water recoveries of 97% to 100%.

The HiPRO process achieves its high water recovery through the use of multiple stages of ultrafiltration and RO membrane systems, operating in series, and with interstage precipitation of low-solubility salts. This is applied without the expense of evaporators and crystallisers typically used in the final concentration step. The result is a very small brine stream that can be further treated or discharged into a lined evaporation dam.

Not only does HiPRO produce SANS-quality drinking water, it boasts lower capital and operating costs than other technologies and the recovery of potentially useful by-products.

operations and maintenance

Nafasi Water has the commercial experience and capability to offer project financing as build, own, operate (BOO) and build, own, operate, transfer (BOOT) contracts.

As leading providers of complete water treatment solutions, Nafasi Water offers a cost-effective water management service, which includes water analysis, utility management, audit and condition monitoring, routine maintenance and equipment renewal.

The company’s unique Sigma Ops monitoring and control system adds to its O&M capabilities, allowing Nafasi Water to extract the longest possible operational life from membranes, even with very difficult to treat feedwater.

Partner of choice

“Nafasi Water is a partner of choice for municipalities and organisations in search of full-scale water and wastewater treatment solutions,” says Suzie Nkambule, CEO, Nafasi Water.

“We partner closely with our clients to ensure we add value by developing local capacity through skills transfer. We are proud to be a business that contributes meaningfully to the sustainable development of the geographic markets in which we operate.”

info@nafasiwater.com

Nafasi Water has reclaimed over 160 billion litres of water affected by coal mining activities in Southern Africa

billion

AWater scarcity and pollution drive wastewater management

With global demand for quality water increasing at a rate inversely proportional to actual supply, the need for processes and systems that enable testing and purification becomes even more important.

world’s population will face severe water shortages, with ecosystems around the world under even greater strain.

lthough water makes up 70% of the planet, fresh water is incredibly rare. Only 3% of the world’s water is fresh water, and two-thirds of this are found in frozen glaciers or is unavailable for use or consumption by people.

Compounding this is inadequate sanitation. Some 2.4 billion people are exposed to waterborne diseases such as cholera and typhoid fever, with two million people (mostly children) dying each year from diarrhoeal diseases alone.

Many of the water systems that keep ecosystems thriving and feed a growing human population have become stressed. Rivers, lakes and aquifers are drying up or becoming too polluted to use. More than half the world’s wetlands have disappeared. Agriculture consumes more water than any other source and wastes much of that through inefficiencies. Climate change is altering weather and water patterns around the world, causing shortages and droughts in some areas and floods in others. By 2025, two-thirds of the

The widespread water quality degradation across the world is the most serious water problem, threatening human health and ecosystems’ integrity. It also represents a major concern for water resources sustainability. New water quality challenges, such as emerging pollutants and safe wastewater reuse, bring even greater concerns, calling for urgent attention.

Water quality, due to its serious human health and environmental impacts, represents a crucial but often neglected aspect of water resource management. Primary causes of water pollution are rapid urbanisation, increased agricultural activities, the use of fertilisers and pesticides, land degradation and

We look at the four biggest wastewater treatment problems and their solutions

deforestation, and the lack of adequate wastewater treatment and disposal. Poor water quality not only negatively affects

human health and ecosystems in multiple ways, but also makes water unfit for different uses and purposes so reducing the availability of water resources. As water treatment technologies are often expensive, wastewater management is inadequate or non-existent in most developing countries. Urgent action is needed to improve water quality and wastewater management.

We look at the four biggest wastewater treatment problems and their solutions below.

Problem 1: energy consumption

Energy consumption is one of the largest expenses in operating a wastewater treatment plant. Wastewater treatment consumes an estimated 2% to 3% of a developed nation’s electrical power, or approximately 60 terawatt hours (tWh) per year. In municipal wastewater treatment, the largest proportion of energy is used in biological treatment – generally 50% to 60% of plant usage.

Solution? Changes in biological treatment processes have the potential to significantly reduce a treatment plant’s energy demand, e.g. using fine screens in primary treatment, membrane technology for the aeration process, and the direct treatment of high-concentration return streams.

Problem 2: Staff requirements

Operators of wastewater treatment facilities must be adequately trained and certified. They are on call 24 hours a day and are responsible for overseeing everything from pipe leaks and valves to electrical and instrumentation equipment. This work becomes especially demanding during changes in influent and seasonal changes.

Solution? While there will always be a need for the physical presence of staff to be responsible for the overseeing of activities at treatment facilities, operator management can account for up to 30% of the operational costs of a wastewater treatment plant. Emerging technologies driven by reducing operational expenditure are utilising the benefits of automation, which reduces the requirement of operator engagement.

Problem 3: Sludge production

Sludge is the residue generated during physical, chemical and biological treatment. A major environmental challenge for wastewater treatment is disposing of the excess sludge that is

produced during the process.

Solution? Safe and long-term solutions for the destination of sludge produced by wastewater treatment plants are vital to a functional facility’s sustainability. The best solution for this is to recycle the sludge, which contains useful organic matter and nutrients, for use in agriculture. Some more modern treatment technologies are even able to reduce the burden of sludge, through lowering its production.

substantial land areas. Primary and secondary processes rely upon vast tracts of land for large and costly settling tanks and aeration basins. Due to continual population growth, municipal wastewater treatment plants also need to expand their capabilities.

Problem 4: footprint demand

Activated sludge treatment has many challenges, and one of the biggest is the footprint it demands. Activated sludge plants are costly to construct and occupy

Solution? Advanced technologies that use smaller process basins – by increasing the amount of biomass per unit volume via the addition of media for biofilm attachment or increasing the biomass concentration (such as MBR) – are leading the way in reducing site footprints. A smaller footprint means land cost savings, but also means reducing capex (less concrete, steel and equipment for construction).

How to perfect filter performance

Prompted by a baffling number of cases in which filter manufacturers are called upon to resolve filter problems that are easily prevented, industrial and municipal filtration specialist Superior Filtration conducted surveys among designers and end users of industrial plants.

Focusing on filtration system efficacy, the aim of the survey was to better understand the habits, needs and

The surprising results of a recent survey reveal the astonishing extent of easily prevented poor filter performance and filter failure.

frustrations of end users, as well as design engineers, project managers and consultants who provide industrial and municipal filtration solutions for water processing and industrial production environments.

Respondents used the full variety of filter types for inbound filtration to ensure clean

GrAPH 1 Have you ever found that a filter didn’t work as well as it might have – or even at all? What are the reasons?

2 Should design engineers or project managers consult widely with filtration experts or manufacturers to determine the correct filtration solution for each application before specifying a solution or provider?

water flowing into the plant, outbound filtration to ensure non-polluted water is returned to municipal systems or rivers, or for recycling and reuse inside the plant.

Shocking findings

The surveys revealed the astonishing extent of poor filter performance and the high level of filter failure across industries (see Graph 1).

These diagnostic or specification errors lead to excessive maintenance, unnecessary management oversight, and ultimately to more plant stoppages and higher costs.